A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors

Abstract

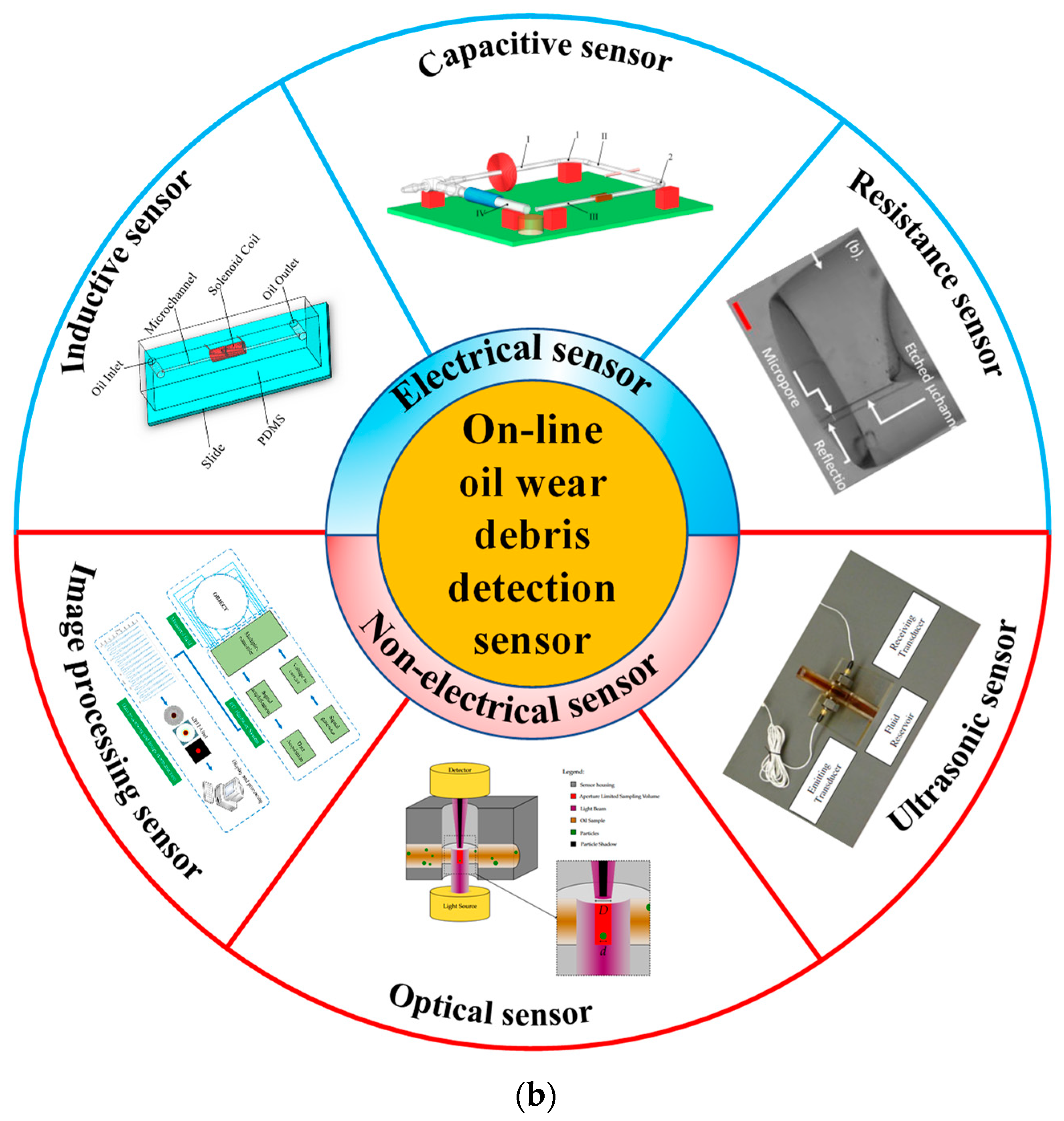

:1. Introduction

| Detection Type | Sensor Type | Distinguish Ferrous and Non-Ferrous Particles | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Electrical sensors | Inductive sensor | Yes | Simple structure, easy to implement on-line, distinguish ferromagnetic and non-ferromagnetic metal particles | Unable to differentiate between non-metallic particles | [39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66] |

| Capacitive sensor | No | Simple structure and high sensitivity | Unable to distinguish metal particle properties | [67,68,69,70,71,72,73,74,75,76,77,78] | |

| Resistance sensor | No | Detection of particle concentration and size distribution | Poor accuracy, high accuracy only for oil containing a large amount of metal particles | [79,80,81] | |

| Non-electrical sensors | Image processing sensor | No | The particle morphology can be directly observed to infer the particle composition with high sensitivity | Equipment is expensive and testing process is slow | [82,83,84,85,86,87,88,89,90,91] |

| Optical sensor | No | High sensitivity, fast detection speed, and particle morphology analysis | High cost, easily affected by oil discoloration and particle aggregation and unable to distinguish particle properties | [92,93,94,95,96] | |

| Ultrasonic sensor | No | Unaffected by oil discoloration, solid particles and bubbles can be distinguished | Lower sensitivity and greater vibration impact | [97,98,99,100] |

2. Electrical Wear Debris Detection Sensors

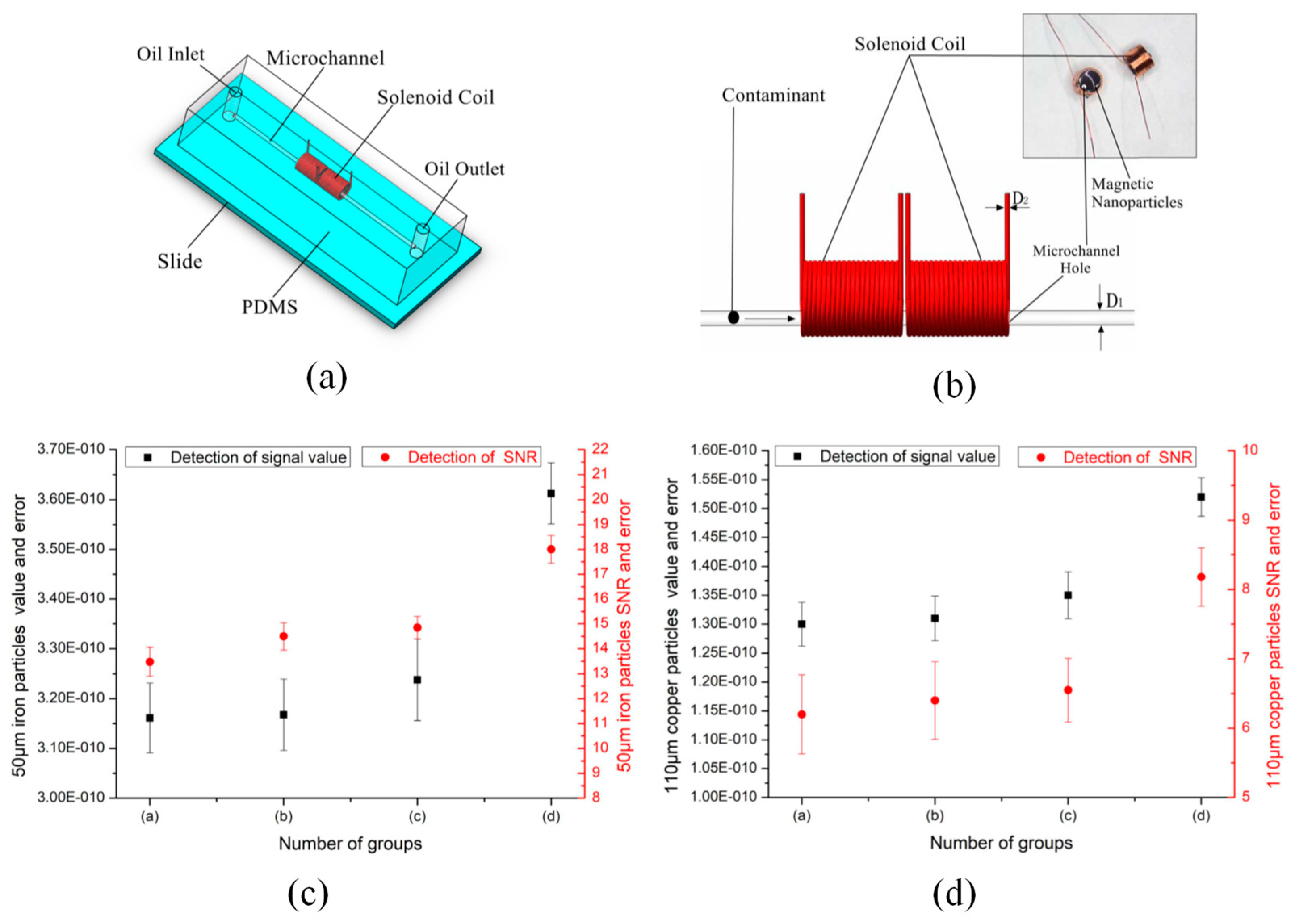

2.1. Inductive Sensor

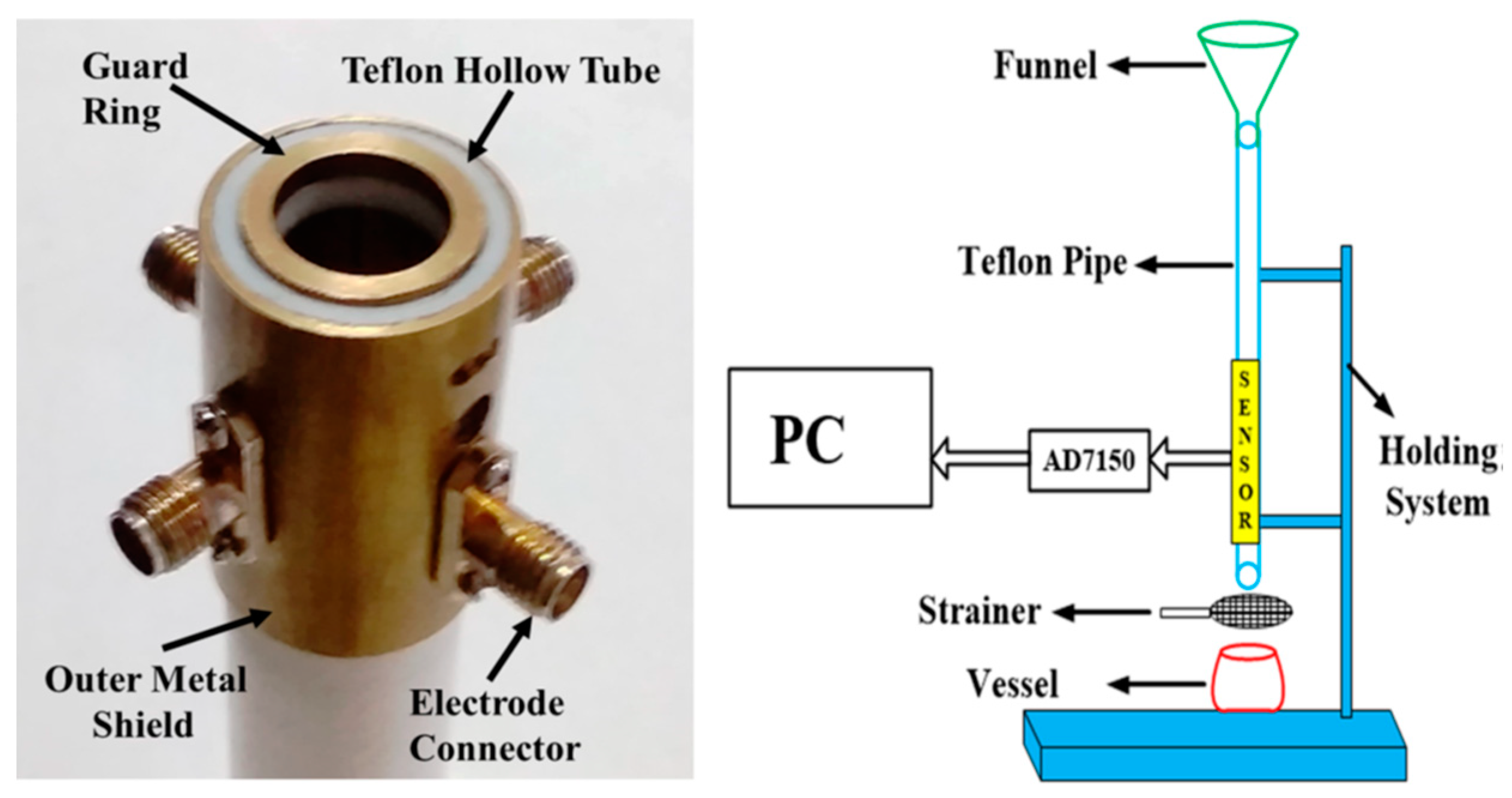

2.2. Capacitive Sensor

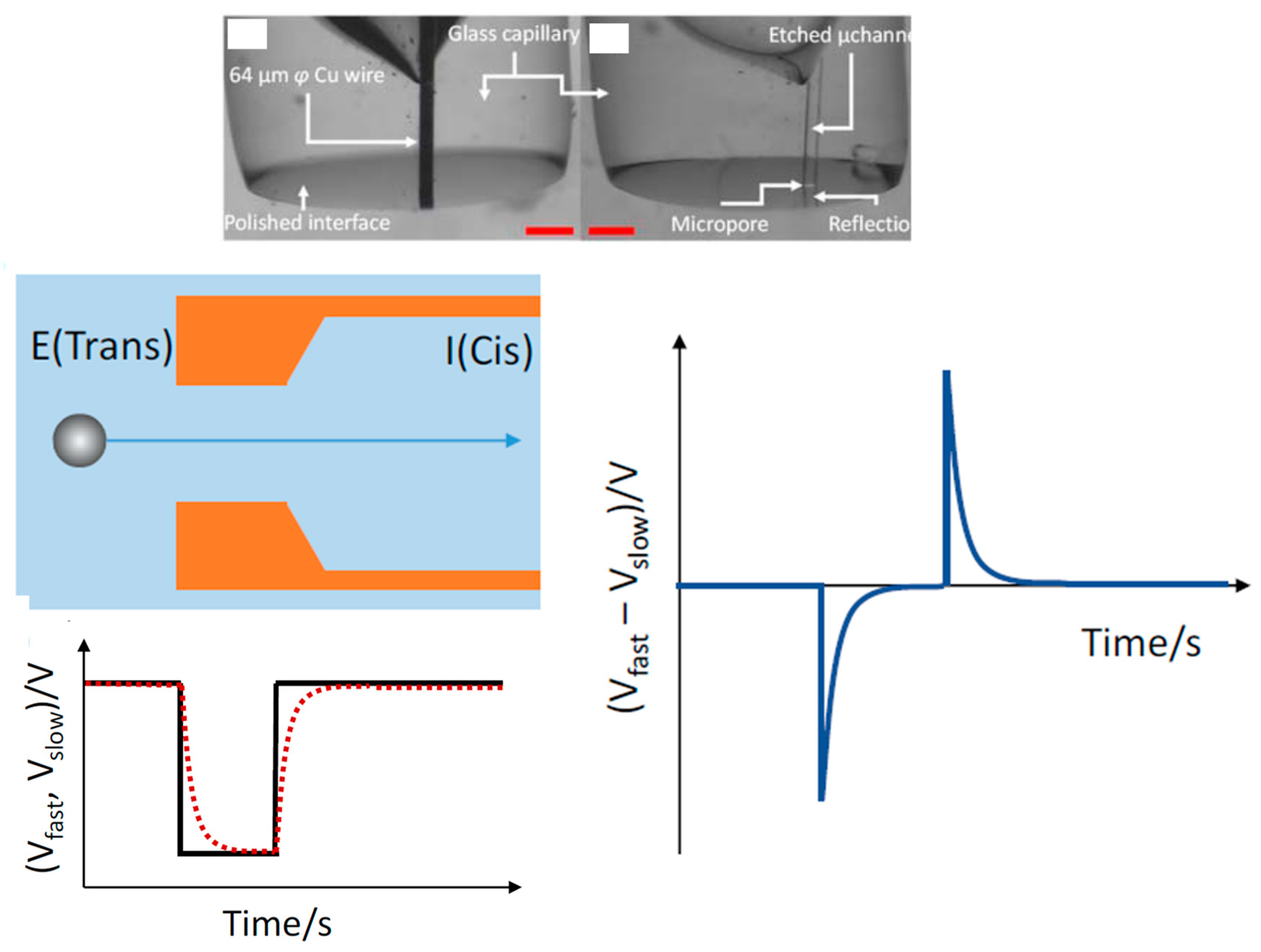

2.3. Resistance Sensor

3. Non-Electrical Wear Debris Detection Sensors

3.1. Image Processing Sensor

3.2. Optical Sensor

3.3. Ultrasonic Sensor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, H.; Huo, D.; Zhang, H.; Li, W.; Sun, Y.; Li, G.; Chen, H. An Impedance Sensor for Distinguishing Multi-Contaminants in Hydraulic Oil of Offshore Machinery. Micromachines 2021, 12, 1407. [Google Scholar] [CrossRef]

- Zhang, X.; Cao, Y.; Xue, B.; Hua, G.; Zhang, H. Method for Identifying Materials and Sizes of Particles Based on Neural Network. JMSE 2023, 11, 541. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Urban, A.; Zhe, J. A microsensor array for diesel engine lubricant monitoring using deep learning with stochastic global optimization. Sens. Actuators A 2022, 343, 113671. [Google Scholar] [CrossRef]

- Hong, W.; Cai, W.; Wang, S.; Tomovic, M.M. Mechanical wear debris feature, detection, and diagnosis: A review. Chin. J. Aeronaut. 2018, 31, 867–882. [Google Scholar] [CrossRef]

- Fu, C.; Lu, K.; Li, Q.; Xu, Y.; Gu, F.; Ball, A.D.; Zheng, Z. Physics-Based Modelling for On-Line Condition Monitoring of a Marine Engine System. JMSE 2023, 11, 1241. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Roger, L.L.B.; De Oliveira, G.G.; Vaz, G.C. Novelty Sensor for Detection of Wear Particles in Oil Using Integrated Microwave Metamaterial Resonators With Neodymium Magnets. IEEE Sens. J. 2022, 22, 10508–10514. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Ren, X.; Wu, S.; Meng, M.; Wang, Y.; Pan, X. A Novel Method for Detecting Ferromagnetic Wear Debris with High Flow Velocity. Sensors 2022, 22, 4912. [Google Scholar] [CrossRef]

- Jiao, D.; Urban, A.; Zhu, X.; Zhe, J. Oil property sensing array based on a general regression neural network. Tribol. Int. 2021, 164, 107221. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. A review of online condition monitoring and maintenance strategy for cylinder liner-piston rings of diesel engines. Mech. Syst. Sig. Process. 2022, 165, 108385. [Google Scholar] [CrossRef]

- Wang, J.; Maw, M.M.; Yu, X.; Dai, B.; Wang, G.; Jiang, Z. Applications and perspectives on microfluidic technologies in ships and marine engineering: A review. Microfluid. Nanofluid. 2017, 21, 39. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, J.; Shi, H.; Xie, Y.; Zhang, H.; Zhang, S.; Li, W.; Chen, H. Magnetic Plug Sensor with Bridge Nonlinear Correction Circuit for Oil Condition Monitoring of Marine Machinery. JMSE 2022, 10, 1883. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Li, J.; Li, F.; Li, J.; Lu, H. Online oil debris monitoring of rotating machinery: A detailed review of more than three decades. Mech. Syst. Sig. Process. 2021, 149, 107341. [Google Scholar] [CrossRef]

- Li, W.; Bai, C.; Wang, C.; Zhang, H.; Ilerioluwa, L.; Wang, X.; Yu, S.; Li, G. Design and Research of Inductive Oil Pollutant Detection Sensor Based on High Gradient Magnetic Field Structure. Micromachines 2021, 12, 638. [Google Scholar] [CrossRef]

- Zamorano, M.; Avila, D.; Marichal, G.N.; Castejon, C. Data Preprocessing for Vibration Analysis: Application in Indirect Monitoring of ‘Ship Centrifuge Lube Oil Separation Systems’. JMSE 2022, 10, 1199. [Google Scholar] [CrossRef]

- Gebarin, S. On-line and In-line Wear Debris Detectors: What’s Out There? Available online: https://www.machinerylubrication.com/Read/521/in-line-wear-debris-detectors (accessed on 8 December 2023).

- Zeng, L.; Chen, X.; Zhang, R.; Hu, S.; Zhang, H.; Zhang, Y.; Yang, H. High-Resolution Separation of Nanoparticles Using a Negative Magnetophoretic Microfluidic System. Micromachines 2022, 13, 377. [Google Scholar] [CrossRef]

- Wu, X.; Liu, H.; Qian, Z.; Qian, Z.; Liu, D.; Li, K.; Wang, G. On the Investigation of Frequency Characteristics of a Novel Inductive Debris Sensor. Micromachines 2023, 14, 669. [Google Scholar] [CrossRef]

- Gupta, K.K.; Hirani, H.; Muzakkir, S.M. Online Gear Wear Particle Detection and Categorization Using a Convolutional Neural Network Algorithm Integrated with Cascade Classifier. Tribol. Ind. 2023, 45, 212–225. [Google Scholar] [CrossRef]

- Jia, R.; Ma, B.; Zheng, C.; Ba, X.; Wang, L.; Du, Q. Magnetic properties of micro-particles with different shapes and postures in the high precision particles detection. Powder Technol. 2019, 356, 628–639. [Google Scholar] [CrossRef]

- Zhang, H.; Chon, C.H.; Pan, X.; Li, D. Methods for counting particles in microfluidic applications. Microfluid Nanofluid 2009, 7, 739. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox condition monitoring in wind turbines: A review. Mech. Syst. Sig. Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, H.; Wang, W.; Zeng, L.; Sun, G.; Chen, H. An Integrated Inductive-Capacitive Microfluidic Sensor for Detection of Wear Debris in Hydraulic Oil. IEEE Sens. J. 2019, 19, 11583–11590. [Google Scholar] [CrossRef]

- Huang, H.; He, S.; Xie, X.; Feng, W.; Zhen, H.; Tao, H. Research on the influence of inductive wear particle sensor coils on debris detection. AIP Adv. 2022, 12, 075204. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Zuo, H.; Wang, H.; Wang, C. Oil debris and viscosity monitoring using optical measurement based on Response Surface Methodology. Measurement 2022, 195, 111152. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Zuo, H.; Wang, H.; Chen, Z. An Oil Wear Particles Inline Optical Sensor Based on Motion Characteristics for Rotating Machines Condition Monitoring. Machines 2022, 10, 727. [Google Scholar] [CrossRef]

- Abedini-Nassab, R.; Pouryosef Miandoab, M.; Şaşmaz, M. Microfluidic Synthesis, Control, and Sensing of Magnetic Nanoparticles: A Review. Micromachines 2021, 12, 768. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zuo, H.; Liu, Y.; Li, X.; Chen, Z. Research on Wear Particle Online Monitoring Using Machine Vision for Rotating Machinery. IEEE Trans. Instrum. Meas. 2023, 72, 3519311. [Google Scholar] [CrossRef]

- Wang, S.; Wu, T.; Wang, K. Automated 3D ferrograph image analysis for similar particle identification with the knowledge-embedded double-CNN model. Wear 2021, 476, 203696. [Google Scholar] [CrossRef]

- Cao, W.; Han, Z.; Yang, Z.Z.; Wang, N.; Qu, J.X.; Wang, D. Deterioration state diagnosis and wear evolution evaluation of planetary gearbox using vibration and wear debris analysis. Measurement 2022, 193, 110978. [Google Scholar] [CrossRef]

- Feng, S.; Tan, J.; Wen, Y.; Fan, B.; Luo, J.; Li, R. Sensing Model for Detecting Ferromagnetic Debris Based on a High-Gradient Magnetostatic Field. IEEE/Asme Trans. Mechatron. 2022, 27, 2440–2449. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, H.; Qiao, W.; Han, X.; Zeng, L.; Shi, H. Oil Metal Debris Detection Sensor Using Ferrite Core and Flat Channel for Sensitivity Improvement and High Throughput. IEEE Sens. J. 2020, 20, 7303–7309. [Google Scholar] [CrossRef]

- Gao, H.; Min, Y.; Chang, Q. Metal Particles Velocity Measurement Based on Capacitance Sensor With Double Triangular-Shaped Electrodes. IEEE Sens. J. 2022, 22, 11827–11834. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, S.; Raihan, M.K.; Zhu, D.; Yu, K.; Wang, F.; Pan, X. The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance. Energies 2022, 15, 7318. [Google Scholar] [CrossRef]

- Jia, R.; Wang, Z.; Song, Y.; Wang, L.; Chen, T.; Mi, Y.; Ding, Z. Magnetic coupling properties of multiple metal wear particles for high-precision electromagnetic debris detection applications. Adv. Powder Technol. 2023, 34, 103981. [Google Scholar] [CrossRef]

- Jia, R.; Wang, L.; Zheng, C.; Chen, T. Online Wear Particle Detection Sensors for Wear Monitoring of Mechanical Equipment—A Review. IEEE Sens. J. 2022, 22, 2930–2947. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, H.; Zheng, Y.; Zhang, Y.; Zhang, H.; Sun, Y.; Zhang, X.; Zhang, S. An Asymmetric Micro-Three-Coil Sensor Enabling Non-Ferrous Metals Distinguishment. IEEE Trans. Instrum. Meas. 2023, 72, 3508909. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Zhao, P.; Kong, D.; Gao, T.; Pan, X.; Wang, J. Tunable magnetophoretic method for distinguishing and separating wear debris particles in an Fe-PDMS based microfluidic chip. Electrophoresis 2023, 44, 1210–1219. [Google Scholar] [CrossRef]

- Sanga, R.; Srinivasan, V.S.; Sivaramakrishna, M.; Prabhakara Rao, G. Deployment of an inductance-based quasi-digital sensor to detect metallic wear debris in lubricant oil of rotating machinery. Meas. Sci. Technol. 2018, 29, 075102. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. Parallel sensing of metallic wear debris in lubricants using undersampling data processing. Tribol. Int. 2012, 53, 28–34. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. A high sensitivity wear debris sensor using ferrite cores for online oil condition monitoring. Meas. Sci. Technol. 2017, 28, 075102. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. A 3×3 wear debris sensor array for real time lubricant oil conditioning monitoring using synchronized sampling. Mech. Syst. Sig. Process. 2017, 83, 296–304. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, H.; Wang, W.; Zhao, X.; Chen, H.; Zeng, N. Inductive-Capacitive Dual-Mode Oil Detection Sensor Based on Magnetic Nanoparticle Material. IEEE Sens. J. 2020, 20, 12274–12281. [Google Scholar] [CrossRef]

- Hong, W.; Li, T.; Wang, S.; Zhou, Z. A General Framework for Aliasing Corrections of Inductive Oil Debris Detection Based on Artificial Neural Networks. IEEE Sens. J. 2020, 20, 10724–10732. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, X.; Li, H.; Luo, J.; Feng, S. An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field. Appl. Sci. 2019, 9, 1546. [Google Scholar] [CrossRef]

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive debris sensor using one energizing coil with multiple sensing coils for sensitivity improvement and high throughput. Tribol. Int. 2018, 128, 96–103. [Google Scholar] [CrossRef]

- Zeng, L.; Wang, W.; Rogers, F.; Zhang, H.; Zhang, X.; Yang, D. A High Sensitivity Micro Impedance Sensor Based on Magnetic Focusing for Oil Condition Monitoring. IEEE Sens. J. 2020, 20, 3813–3821. [Google Scholar] [CrossRef]

- Muthuvel, P.; George, B.; Ramadass, G.A. A Highly Sensitive In-Line Oil Wear Debris Sensor Based on Passive Wireless LC Sensing. IEEE Sens. J. 2021, 21, 6888–6896. [Google Scholar] [CrossRef]

- Wang, X.; Chen, P.; Luo, J.; Yang, L.; Feng, S. Characteristics and Superposition Regularity of Aliasing Signal of an Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2020, 20, 10071–10078. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Guo, Q. Electromagnetic Sensor for Detecting Wear Debris in Lubricating Oil. IEEE Trans. Instrum. Meas. 2020, 69, 2533–2541. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.; Zhao, G.; Feng, Z. Ultrasensitive Inductive Debris Sensor With a Two-Stage Autoasymmetrical Compensation Circuit. IEEE Trans. Ind. Electron. 2021, 68, 8885–8893. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Li, N.; Qian, Z.; Liu, D.; Qian, Z.; Zhang, C. A New Inductive Debris Sensor Based on Dual-Excitation Coils and Dual-Sensing Coils for Online Debris Monitoring. Sensors 2021, 21, 7556. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Fan, B.; Li, R.; Luo, J.; Mao, J. A Ferromagnetic Wear Particle Sensor Based on a Rotational Symmetry High-Gradient Magnetostatic Field. IEEE Trans. Instrum. Meas. 2021, 70, 9504709. [Google Scholar] [CrossRef]

- Park, J.; Yoo, S.-J.; Yoon, J.; Kim, Y.-J. Inductive particle detection system for real-time monitoring of metals in airborne particles. Sens. Actuators A 2021, 332, 113153. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, F.; Zhao, M.; Wang, B.; Yang, C. A Method for Measurement of Nonferrous Particles Sizes in Lubricant Oil Independent of Materials Using Inductive Sensor. IEEE Sens. J. 2021, 21, 17723–17731. [Google Scholar] [CrossRef]

- Li, Y.; Yu, C.; Xue, B.; Zhang, H.; Zhang, X. A Double Lock-in Amplifier Circuit for Complex Domain Signal Detection of Particles in Oil. IEEE Trans. Instrum. Meas. 2022, 71, 3503710. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, Y.; Yang, L.; Fan, B.; Zhang, P.; Feng, S. A Wear Particle Sensor Using Multiple Inductive Coils Under a Toroidal Magnetic Field. IEEE Access 2021, 9, 6250–6258. [Google Scholar] [CrossRef]

- Yu, B.; Cao, N.; Zhang, T. A novel signature extracting approach for inductive oil debris sensors based on symplectic geometry mode decomposition. Measurement 2021, 185, 110056. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, H.; Zhang, H.; Yu, S.; Llerioluwa, L.; Zheng, Y.; Li, G.; Sun, Y.; Chen, H. A Bridge-Type Inductance Sensor With a Two-Stage Filter Circuit for High-Precision Detection of Metal Debris in the Oil. IEEE Sens. J. 2021, 21, 17738–17748. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, P.; Li, C.; Lei, X.; Yin, A. A Sensitive Large-Flow Debris Sensor Based on Dual-Excitation and Multi-Induction. IEEE Sens. J. 2022, 22, 3137–3146. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.; Feng, Z. Wear Debris Sensor Using Intermittent Excitation for High Sensitivity, Wide Detectable Size Range, and Low Heat Generation. IEEE Trans. Ind. Electron. 2022, 70, 6386–6394. [Google Scholar] [CrossRef]

- Shen, X.; Han, Q.; Wang, Y.; Wu, B.; Zhu, R. Research on Detection Performance of Four-coil Inductive Debris Sensor. IEEE Sens. J. 2023, 23, 6717–6727. [Google Scholar] [CrossRef]

- Luo, J.; Li, J.; Wang, X.; Feng, S. An Inductive Sensor Based Multi-Least-Mean-Square Adaptive Weighting Filtering for Debris Feature Extraction. IEEE Trans. Ind. Electron. 2023, 70, 3115–3125. [Google Scholar] [CrossRef]

- Chen, S.; Cao, N.; Zhang, W.; Yu, B. Separation of aliasing signals from inductive oil debris monitors based on fully convolutional neural networks. Meas. Sci. Technol. 2022, 33, 115016. [Google Scholar] [CrossRef]

- Li, K.; Bai, W.; Li, Y.; Zhou, S.; Wen, P. Online Symmetric Magnetic Excitation Monitoring Sensor for Metal Wear Debris. IEEE Sens. J. 2022, 22, 5571–5579. [Google Scholar] [CrossRef]

- Raadnui, S.; Kleesuwan, S. Low-cost condition monitoring sensor for used oil analysis. Wear 2005, 259, 1502–1506. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Y.; Qing, X. Characteristics Study of In-Situ Capacitive Sensor for Monitoring Lubrication Oil Debris. Sensors 2017, 17, 2851. [Google Scholar] [CrossRef] [PubMed]

- Bai, C.; Zhang, H.; Zeng, L.; Zhao, X.; Yu, Z. High-Throughput Sensor to Detect Hydraulic Oil Contamination Based on Microfluidics. IEEE Sens. J. 2019, 19, 8590–8596. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Xie, Y.; Yao, Z. Research on an on-line wear condition monitoring system for marine diesel engine. Tribol. Int. 2000, 33, 829–835. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, T.; Wu, D.; Zhu, L.; Qing, X.; Xue, W. A New In Situ Coaxial Capacitive Sensor Network for Debris Monitoring of Lubricating Oil. Sensors 2022, 22, 1777. [Google Scholar] [CrossRef]

- Islam, T.; Yousuf, M.; Nauman, M. A highly precise cross-capacitive sensor for metal debris detection in insulating oil. Rev. Sci. Instrum. 2020, 91, 025005. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Jia, L.; Zeng, Z. Hyper-Heuristic Capacitance Array Method for Multi-Metal Wear Debris Detection. Sensors 2019, 19, 515. [Google Scholar] [CrossRef] [PubMed]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive Coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Zhu, L.; Xiao, X.; Wu, D.; Wang, Y.; Qing, X.; Xue, W. Qualitative Classification of Lubricating Oil Wear Particle Morphology Based on Coaxial Capacitive Sensing Network and SVM. Sensors 2022, 22, 6653. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zheng, Y.; Zhang, H.; Li, W.; Zhang, S.; Hong, J.; Li, G.; Sun, Y. An Oil Multipollutant Detection Sensor With High Sensitivity and High Throughput. IEEE Trans. Instrum. Meas. 2022, 71, 6003611. [Google Scholar] [CrossRef]

- Muthuvel, P.; George, B.; Ramadass, G.A. Magnetic-Capacitive Wear Debris Sensor Plug for Condition Monitoring of Hydraulic Systems. IEEE Sens. J. 2018, 18, 9120–9127. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, H.; Huo, D.; Yu, S.; Su, J.; Xie, Y.; Li, W.; Ma, L.; Chen, H.; Sun, Y. An Ultrasensitive Microsensor Based on Impedance Analysis for Oil Condition Monitoring. IEEE Trans. Ind. Electron. 2022, 69, 7441–7450. [Google Scholar] [CrossRef]

- Birkin, P.R.; Linfield, S.; Denuault, G.; Jones, R.; Youngs, J.J.; Wain, E. An Analytical Differential Resistance Pulse System Relying on a Time Shift Signal Analysis–Applications in Coulter Counting. ACS Sens. 2019, 4, 2190–2195. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, H.; Chon, C.H.; Pan, X.; Li, D. Nanoparticle detection by microfluidic Resistive Pulse Sensor with a submicron sensing gate and dual detecting channels-two stage differential amplifier. Sens. Actuators B 2011, 155, 930–936. [Google Scholar] [CrossRef]

- Santilli, R. The Fulmer Method of Monitoring Fluid Abrasivity as an Indication of Fluid Condition and Machine Health. In COMADEM 89 International; Rao, R.B.K.N., Hope, A.D., Eds.; Springer: Boston, MA, USA, 1989; pp. 55–67. ISBN 978-1-4684-8907-1. [Google Scholar]

- Li, B.; Wu, W.; Zhou, M.; Xi, Y.; Wei, H.; Mao, J. A Full Field-of-View Online Visual Ferrograph Debris Detector Based on Reflected Light Microscopic Imaging. IEEE Sens. J. 2021, 21, 16584–16597. [Google Scholar] [CrossRef]

- More, P.P.; Jaybhaye, M.D. Wear Pattern and Debris Analysis in Gearbox System. J. Fail. Anal. Prev. 2021, 21, 1697–1703. [Google Scholar] [CrossRef]

- Yuan, W.; Chin, K.S.; Hua, M.; Dong, G.; Wang, C. Shape classification of wear particles by image boundary analysis using machine learning algorithms. Mech. Syst. Sig. Process. 2016, 72–73, 346–358. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, Y.; Zhang, W.; Xiao, X.; Liu, Y.; Xue, W. tdEIT and Unet-based rapid imaging of redistributed wear particles in lubricating oil. Tribol. Int. 2023, 177, 107981. [Google Scholar] [CrossRef]

- Peng, Y.; Cai, J.; Wu, T.; Cao, G.; Kwok, N.; Peng, Z. WP-DRnet: A novel wear particle detection and recognition network for automatic ferrograph image analysis. Tribol. Int. 2020, 151, 106379. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Wu, M.; Wang, X. Direct detection of wear conditions by classification of ferrograph images. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 152. [Google Scholar] [CrossRef]

- Wu, T.H.; Wang, J.Q.; Wu, J.Y.; Xie, Y.B.; Mao, J.H. Wear Characterization by an On-Line Ferrograph Image. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 23–34. [Google Scholar] [CrossRef]

- Mohanty, S.; Hazra, S.; Paul, S. Intelligent prediction of engine failure through computational image analysis of wear particle. Eng. Fail. Anal. 2020, 116, 104731. [Google Scholar] [CrossRef]

- Feng, S.; Qiu, G.; Luo, J.; Han, L.; Mao, J.; Zhang, Y. A Wear Debris Segmentation Method for Direct Reflection Online Visual Ferrography. Sensors 2019, 19, 723. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Zhang, H.; Wang, S.; Yang, Z.; Fu, J.; Sun, Y. Marine-Hydraulic-Oil-Particle Contaminant Identification Study Based on OpenCV. JMSE 2022, 10, 1789. [Google Scholar] [CrossRef]

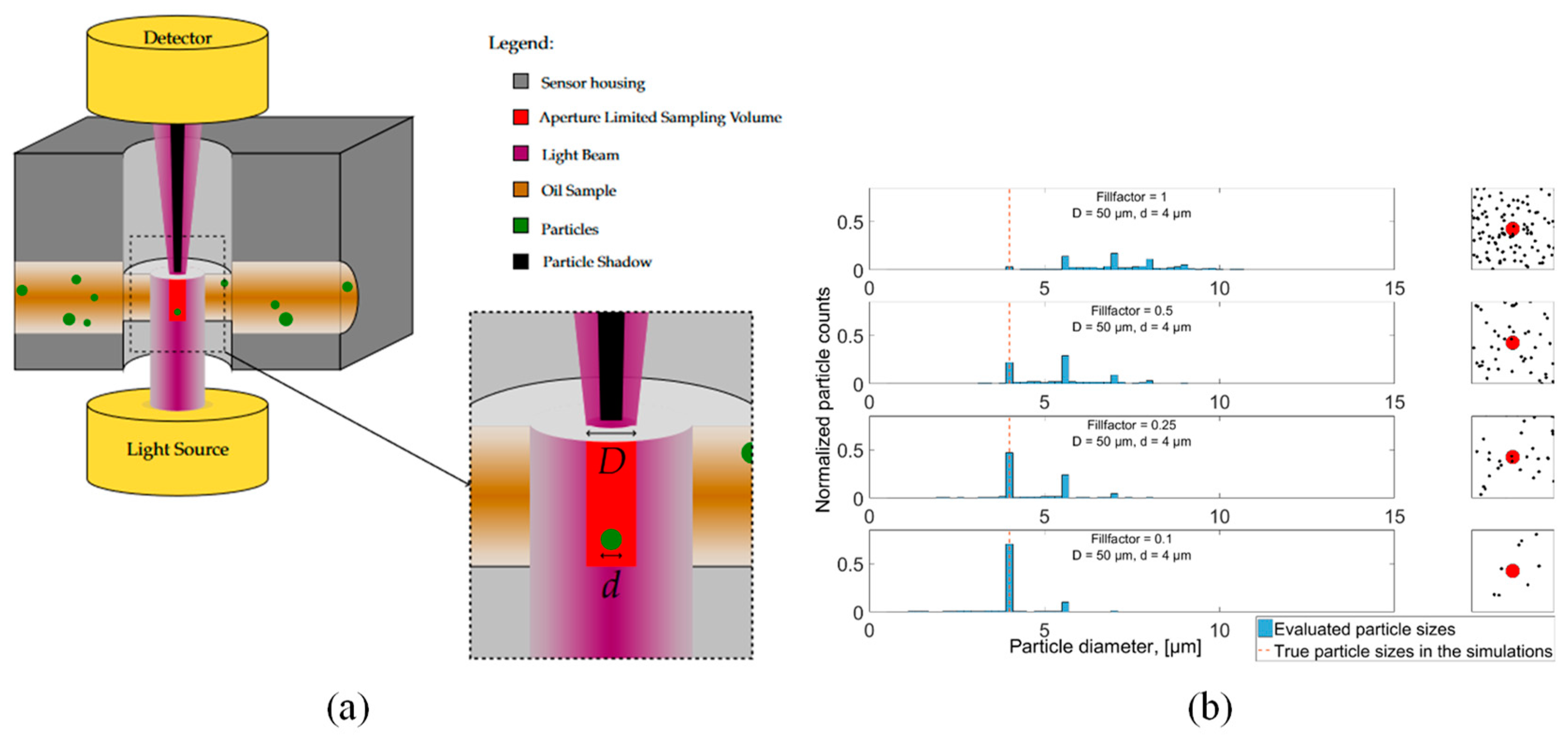

- Krogsøe, K.; Henneberg, M.; Eriksen, R. Model of a Light Extinction Sensor for Assessing Wear Particle Distribution in a Lubricated Oil System. Sensors 2018, 18, 4091. [Google Scholar] [CrossRef]

- Bastidas, S.; Allmaier, H. Application of a Wear Debris Detection System to Investigate Wear Phenomena during Running-In of a Gasoline Engine. Lubricants 2023, 11, 237. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, T.; Wang, S.; Du, Y.; Kwok, N.; Peng, Z. A microfluidic device for three-dimensional wear debris imaging in online condition monitoring. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 965–974. [Google Scholar] [CrossRef]

- Wu, T.H.; Mao, J.H.; Wang, J.T.; Wu, J.Y.; Xie, Y.B. A New On-Line Visual Ferrograph. Tribol. Trans. 2009, 52, 623–631. [Google Scholar] [CrossRef]

- Iwai, Y.; Honda, T.; Miyajima, T.; Yoshinaga, S.; Higashi, M.; Fuwa, Y. Quantitative estimation of wear amounts by real time measurement of wear debris in lubricating oil. Tribol. Int. 2010, 43, 388–394. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, P.; Wang, H.; Li, Y.; Lv, C. Ultrasonic echo waveshape features extraction based on QPSO-matching pursuit for online wear debris discrimination. Mech. Syst. Sig. Process. 2015, 60–61, 301–315. [Google Scholar] [CrossRef]

- Weser, R.; Wöckel, S.; Hempel, U.; Wessely, B.; Auge, J. Particle characterization in highly concentrated suspensions by ultrasound scattering method. Sens. Actuators A 2013, 202, 30–36. [Google Scholar] [CrossRef]

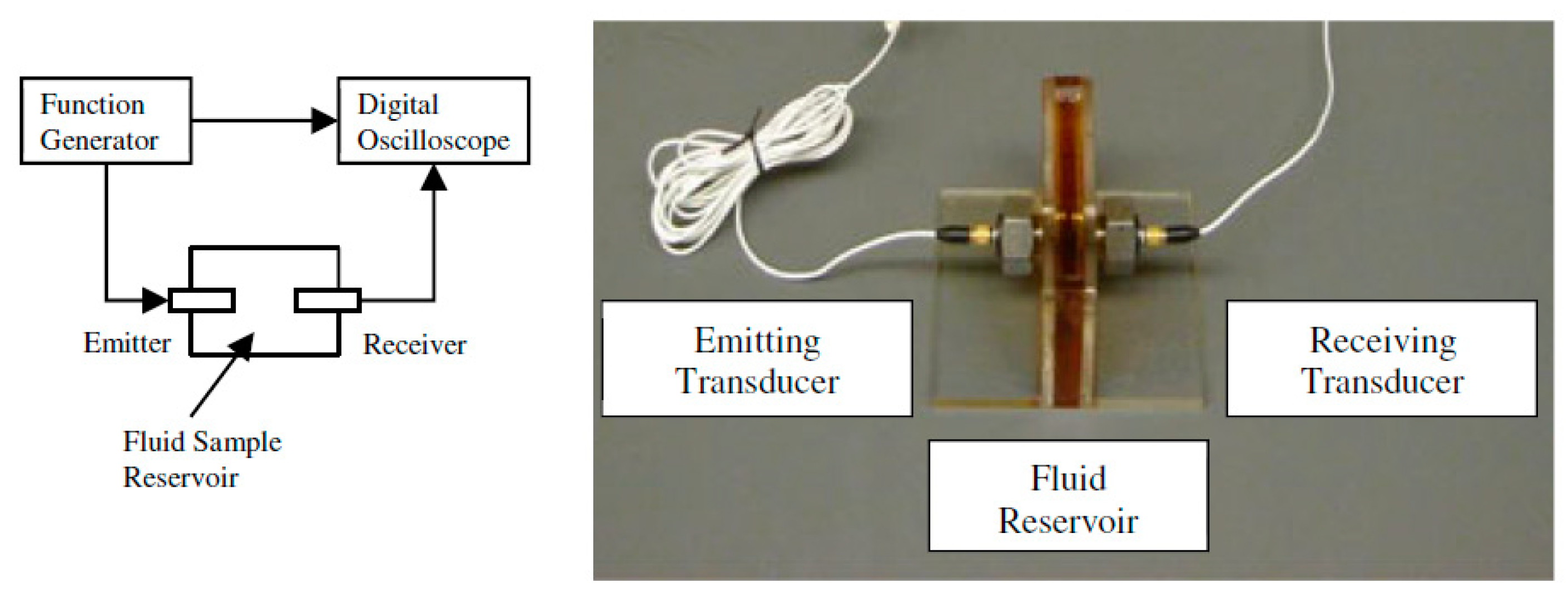

- Du, L.; Zhe, J. An integrated ultrasonic–inductive pulse sensor for wear debris detection. Smart Mater. Struct. 2013, 22, 025003. [Google Scholar] [CrossRef]

- Appleby, M.; Choy, F.K.; Du, L.; Zhe, J. Oil debris and viscosity monitoring using ultrasonic and capacitance/inductance measurements: Oil Debris and Viscosity Monitoring Using Ultrasonic and Capacitance. Lubr. Sci. 2013, 25, 507–524. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, W.; Mu, X.; Liu, Y.; Wang, X.; Li, W.; Bai, C.; Zhang, H. A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors. J. Mar. Sci. Eng. 2023, 11, 2363. https://doi.org/10.3390/jmse11122363

Han W, Mu X, Liu Y, Wang X, Li W, Bai C, Zhang H. A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors. Journal of Marine Science and Engineering. 2023; 11(12):2363. https://doi.org/10.3390/jmse11122363

Chicago/Turabian StyleHan, Wenbo, Xiaotong Mu, Yu Liu, Xin Wang, Wei Li, Chenzhao Bai, and Hongpeng Zhang. 2023. "A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors" Journal of Marine Science and Engineering 11, no. 12: 2363. https://doi.org/10.3390/jmse11122363

APA StyleHan, W., Mu, X., Liu, Y., Wang, X., Li, W., Bai, C., & Zhang, H. (2023). A Critical Review of On-Line Oil Wear Debris Particle Detection Sensors. Journal of Marine Science and Engineering, 11(12), 2363. https://doi.org/10.3390/jmse11122363