Figure 1.

General Arrangement and Component of a single cage, showing the structure parameters.

Figure 1.

General Arrangement and Component of a single cage, showing the structure parameters.

Figure 2.

The aquaculture SPM system, side view.

Figure 2.

The aquaculture SPM system, side view.

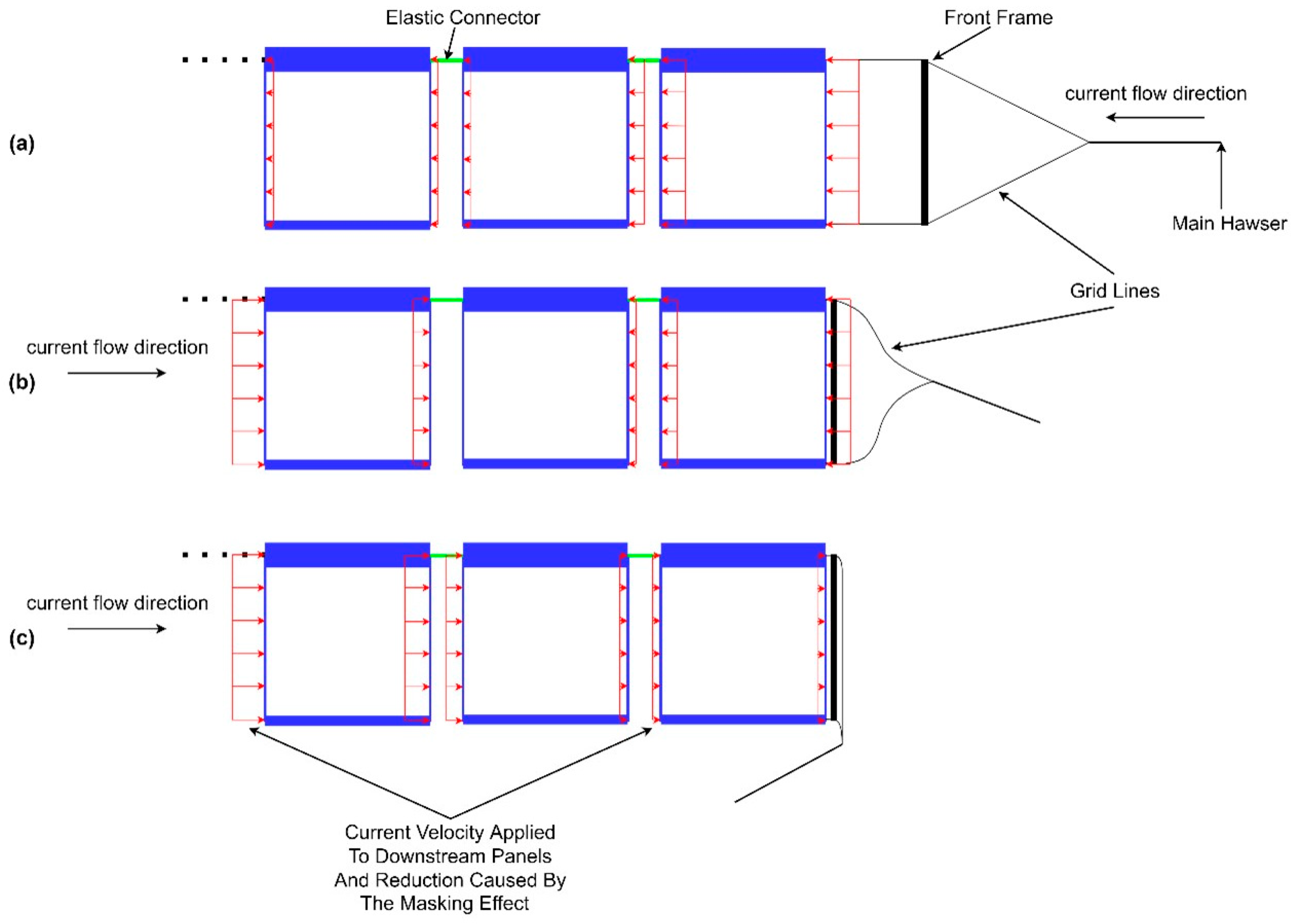

Figure 3.

A simplified vertical side schematic view of the SPM system, showing current load symbols according to current flow direction and the state of the system: (a) the initial state, where the system is tensed by the prevailing current; (b) the Drift State, where sudden opposing current starts drifting the system toward the anchor (here the load symbols shows the sum of the current loads and reacting inertia loads); (c) the holding by the anchor state, after the system drifted with no yaw rotation, until being held by the anchor line at the most unfavorable situation to buckling.

Figure 3.

A simplified vertical side schematic view of the SPM system, showing current load symbols according to current flow direction and the state of the system: (a) the initial state, where the system is tensed by the prevailing current; (b) the Drift State, where sudden opposing current starts drifting the system toward the anchor (here the load symbols shows the sum of the current loads and reacting inertia loads); (c) the holding by the anchor state, after the system drifted with no yaw rotation, until being held by the anchor line at the most unfavorable situation to buckling.

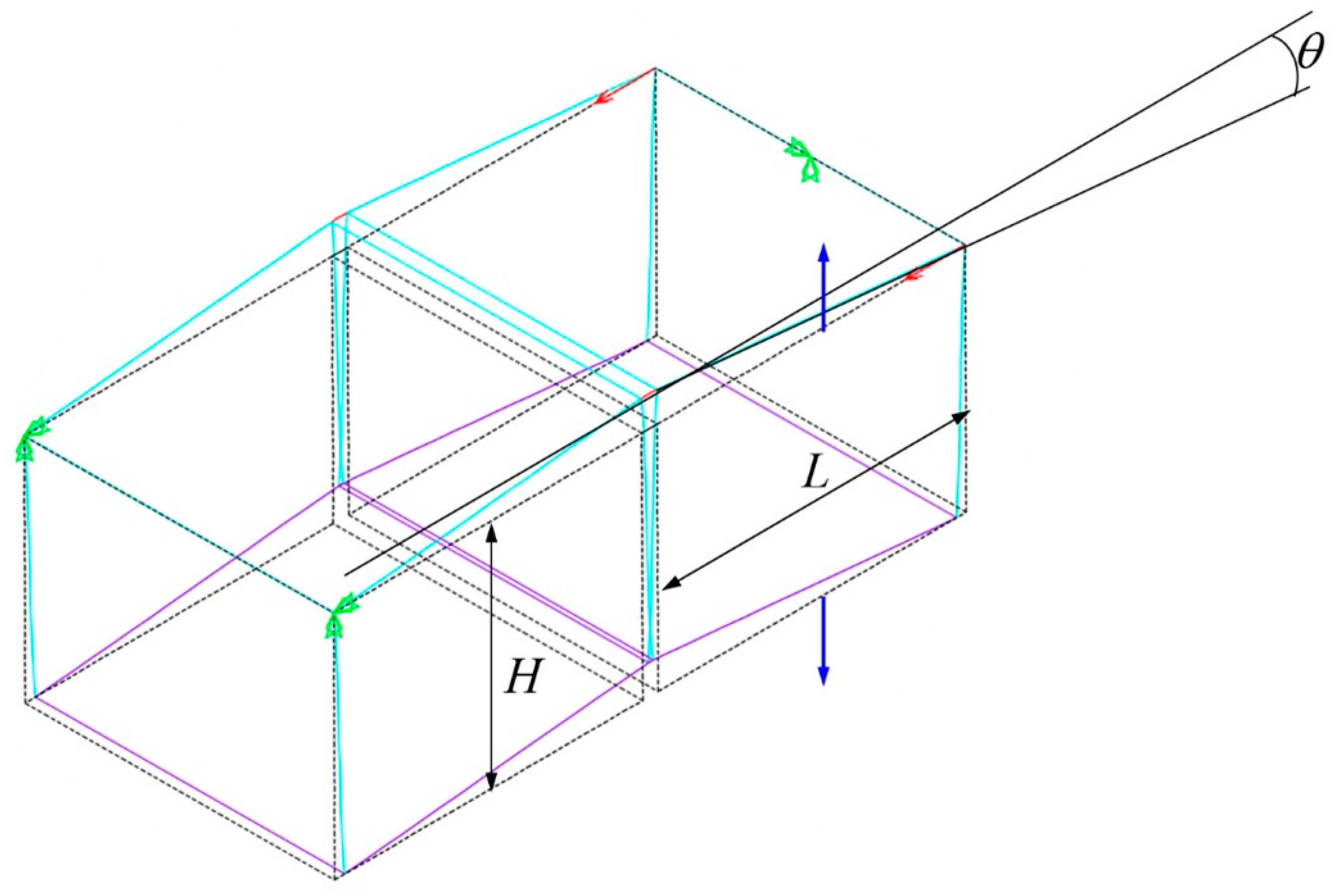

Figure 4.

Applied current and buoyancy loads FC, FB accordingly, on a cage hinged at the end, indicating the angle of pitch θ, the cage height H, and the cage length L.

Figure 4.

Applied current and buoyancy loads FC, FB accordingly, on a cage hinged at the end, indicating the angle of pitch θ, the cage height H, and the cage length L.

Figure 5.

A schematic demonstration of the Hydrostatic Buckling and the principle of virtual work, for two connected cages. The dashed lines show the initial position of the cages while the colored solid lines present the displaced position due to Hydrostatic Buckling.

Figure 5.

A schematic demonstration of the Hydrostatic Buckling and the principle of virtual work, for two connected cages. The dashed lines show the initial position of the cages while the colored solid lines present the displaced position due to Hydrostatic Buckling.

Figure 6.

Longitudinal Hydrostatic Buckling mode of a two cages system applied to a distributed current load, in the Drift State. The distributed forces are represented in red and the constraints in light blue arrows.

Figure 6.

Longitudinal Hydrostatic Buckling mode of a two cages system applied to a distributed current load, in the Drift State. The distributed forces are represented in red and the constraints in light blue arrows.

Figure 7.

Longitudinal buckling mode of a two cages system applied to distributed current load, in the Holding State. The distributed forces are represented in red and the constraints in light blue arrows.

Figure 7.

Longitudinal buckling mode of a two cages system applied to distributed current load, in the Holding State. The distributed forces are represented in red and the constraints in light blue arrows.

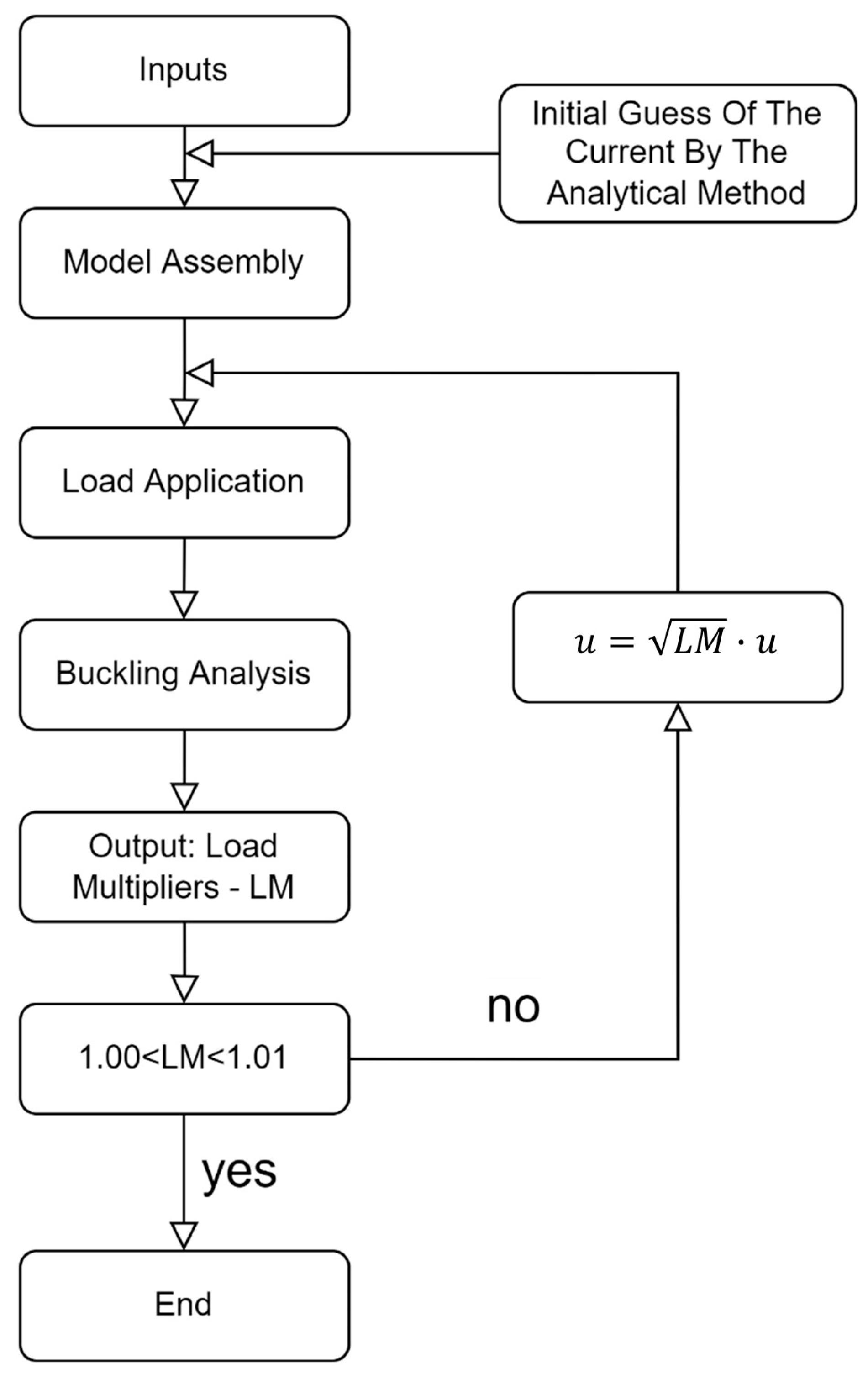

Figure 8.

Flow chart of the iterating procedure to solve the critical buckling velocity, by the APDL model.

Figure 8.

Flow chart of the iterating procedure to solve the critical buckling velocity, by the APDL model.

Figure 9.

First longitudinal Hydrostatic Buckling mode for the six–cages system, in the Drift State (upper sub figure) and the Holding State (lower sub figure). The initial geometry is shown in doted black, the system’s elements, in proportional size, are in dark blue, the constraints are in a lighter blue and the drag (and reacted inertia in the Drift State) loads are shown by red arrows.

Figure 9.

First longitudinal Hydrostatic Buckling mode for the six–cages system, in the Drift State (upper sub figure) and the Holding State (lower sub figure). The initial geometry is shown in doted black, the system’s elements, in proportional size, are in dark blue, the constraints are in a lighter blue and the drag (and reacted inertia in the Drift State) loads are shown by red arrows.

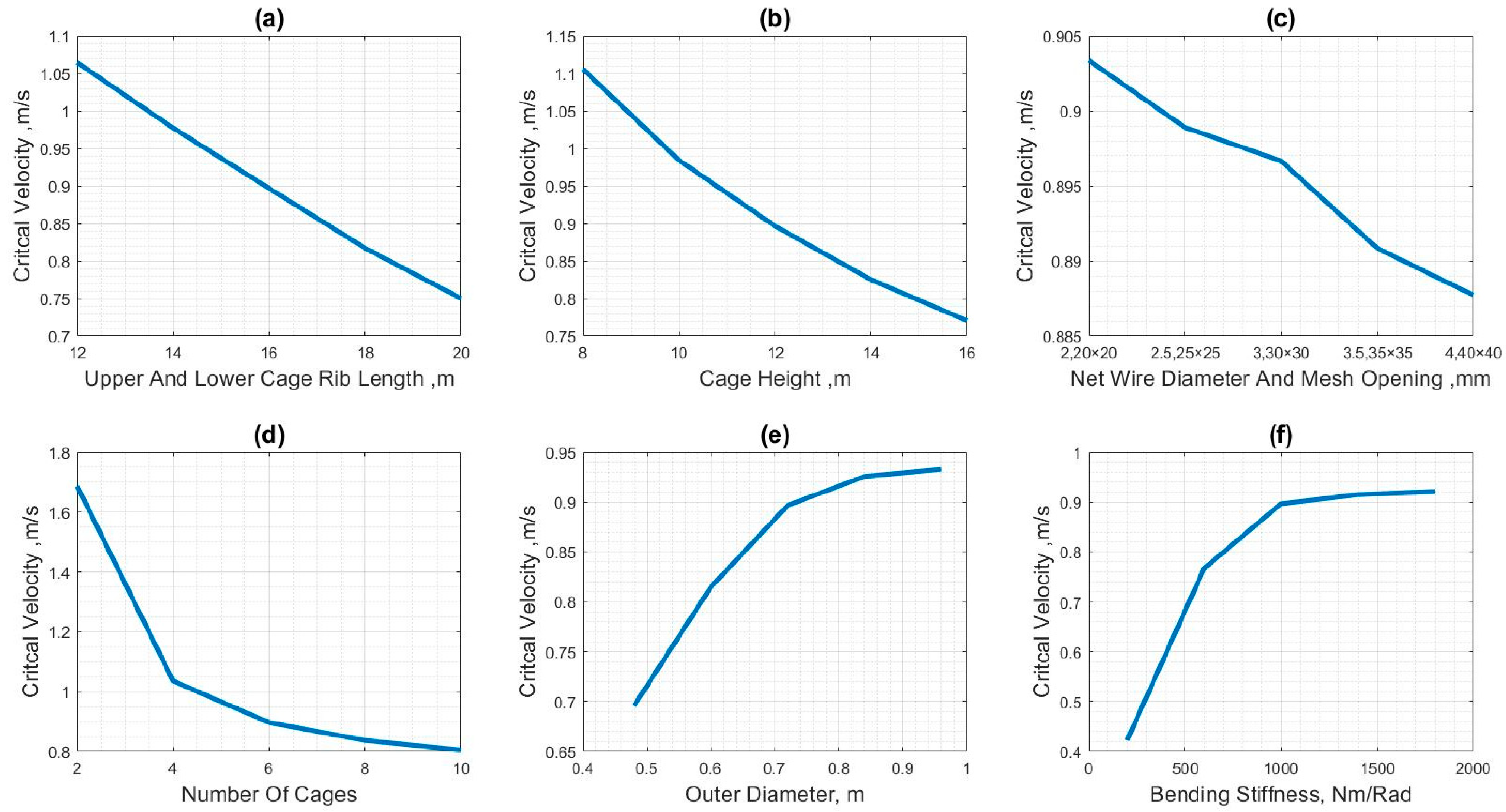

Figure 10.

The critical buckling velocity for the Drift State as a function of: (a) the cage length (and width), (b) the cage height, (c) the net mesh, (d) the number of cages, (e) the outer diameter of the upper floatation pipe and (f) the connector spring stiffness.

Figure 10.

The critical buckling velocity for the Drift State as a function of: (a) the cage length (and width), (b) the cage height, (c) the net mesh, (d) the number of cages, (e) the outer diameter of the upper floatation pipe and (f) the connector spring stiffness.

Figure 11.

The critical buckling velocity for the Holding State as a function of: (a) the cage length (and width), (b) the cage height, (c) the net mesh, (d) the number of cages, (e) the outer diameter of the upper floatation pipe and (f) the connector spring stiffness.

Figure 11.

The critical buckling velocity for the Holding State as a function of: (a) the cage length (and width), (b) the cage height, (c) the net mesh, (d) the number of cages, (e) the outer diameter of the upper floatation pipe and (f) the connector spring stiffness.

Figure 12.

The critical buckling velocity for the Drift State as a function of the cage dimension ratio H/L for combinations of and : (a) = 0.6, (b) = 0.6, (c) = 0.6, (d) = 0.72, (e) = 0.72, (f) = 0.72, (g) = 0.84, (h) = 0.84, (i) = 0.84.

Figure 12.

The critical buckling velocity for the Drift State as a function of the cage dimension ratio H/L for combinations of and : (a) = 0.6, (b) = 0.6, (c) = 0.6, (d) = 0.72, (e) = 0.72, (f) = 0.72, (g) = 0.84, (h) = 0.84, (i) = 0.84.

Figure 13.

The critical buckling velocity for the Holding State as a function of the cage dimension ratio H/L for nine combinations of and : (a) = 0.6, (b) = 0.6, (c) = 0.6, (d) = 0.72, (e) = 0.72, (f) = 0.72, (g) = 0.84, (h) = 0.84, (i) = 0.84.

Figure 13.

The critical buckling velocity for the Holding State as a function of the cage dimension ratio H/L for nine combinations of and : (a) = 0.6, (b) = 0.6, (c) = 0.6, (d) = 0.72, (e) = 0.72, (f) = 0.72, (g) = 0.84, (h) = 0.84, (i) = 0.84.

Table 1.

Structure parameters of the fish cage.

Table 1.

Structure parameters of the fish cage.

| Component | Parameter | Model |

|---|

Upper Flotation Pipe

(Filled with air) | Length, L1 | 16.00 m |

| Diameter, DO1 | 0.720 m |

| Wall–Thickness, wt1 | 0.040 m |

| Vertical Connecting Pipes (filled with sea water) | Height, H | 12.00 m |

| Diameter, DO3 | 0.200 m |

| Wall–Thickness, wt3 | 0.040 m |

Lower Ballasting Pipes

(filled with sea water and ballast chain) | Length, L2 | 16.00 m |

| Diameter, DO2 | 0.300 m |

| Wall–Thickness, wt2 | 0.030 m |

| Ballast chain | Weight per meter | 290.262 Kg/m |

| Copper Netting | Twine Length, ltwine | 0.030 m |

| Twine Diameter, dtwine | 0.003 m |

| Elastic Connector | Length, LC | 1.000 m |

| Diameter, DC | 0.100 m |

Table 2.

The effect of the upper and lower cage pipe length (and width) on the critical velocity, for the Drift State.

Table 2.

The effect of the upper and lower cage pipe length (and width) on the critical velocity, for the Drift State.

| Length, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 12 | 1.0168 | 1.0644 |

1.0068

|

|

14

| 0.9390 | 0.9772 |

1.0080

|

|

16

| 0.8760 | 0.8967 |

1.0031

|

|

18

| 0.8237 | 0.8171 |

1.0081

|

|

20

| 0.7793 | 0.7500 |

1.0099

|

Table 3.

The effect of cage height on the critical velocity, for the Drift State.

Table 3.

The effect of cage height on the critical velocity, for the Drift State.

| Height, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 8 | 0.8947 | 1.1055 | 1.0073 |

| 10 | 0.8854 | 0.9843 | 1.0087 |

| 12 | 0.8760 | 0.8967 | 1.0031 |

| 14 | 0.8665 | 0.8251 | 1.0091 |

| 16 | 0.8568 | 0.7705 | 1.0020 |

Table 4.

The effect of net mesh and yarn diameter on the critical velocity, for the Drift State.

Table 4.

The effect of net mesh and yarn diameter on the critical velocity, for the Drift State.

| Net Mesh, mm | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 2.0, 20 × 20 | 0.9016 | 0.9034 | 1.0057 |

| 2.5, 25 × 25 | 0.8889 | 0.8989 | 1.0084 |

| 3.0, 30 × 30 | 0.8760 | 0.8967 | 1.0031 |

| 3.5, 35 × 35 | 0.8629 | 0.8908 | 1.0083 |

| 4.0, 40 × 40 | 0.8497 | 0.8877 | 1.0036 |

Table 5.

The effect of the number of cages on the critical velocity, for the Drift State.

Table 5.

The effect of the number of cages on the critical velocity, for the Drift State.

| Number of Cages | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 2 | 1.7202 | 1.6860 | 1.0035 |

| 4 | 0.9705 | 1.0353 | 1.0084 |

| 6 | 0.8760 | 0.8967 | 1.0031 |

|

8

| 0.8381 | 0.8372 | 1.0070 |

| 10 | 0.8176 | 0.8050 | 1.0042 |

Table 6.

The effect of the floatation pipe diameter on the critical velocity, for the Drift State.

Table 6.

The effect of the floatation pipe diameter on the critical velocity, for the Drift State.

Upper Pipe

Diameter, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 0.480 | 0.4721 | 0.6959 | 1.0082 |

| 0.600 | 0.6813 | 0.8148 | 1.0024 |

| 0.720 | 0.8760 | 0.8967 | 1.0031 |

| 0.840 | 1.0643 | 0.9257 | 1.0014 |

| 0.960 | 1.2490 | 0.9329 | 1.0000 |

Table 7.

The effect of the connector’s bending stiffness on the critical velocity, for the Drift State.

Table 7.

The effect of the connector’s bending stiffness on the critical velocity, for the Drift State.

| Connector Bending Stiffness, Nm/Rad | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 200 | 0.8760 | 0.4226 | 1.0063 |

| 600 | 0.8760 | 0.7670 | 1.0094 |

| 1000 | 0.8760 | 0.8967 | 1.0031 |

| 1400 | 0.8760 | 0.9150 | 1.0013 |

| 1800 | 0.8760 | 0.9213 | 1.0011 |

Table 8.

The effect of pipe length (and width) on the critical velocity, for the Holding State.

Table 8.

The effect of pipe length (and width) on the critical velocity, for the Holding State.

| Length, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

|

12

| 0.7616 | 0.4539 | 1.0026 |

|

14

| 0.6494 | 0.4132 | 1.0078 |

|

16

| 0.5652 | 0.3770 | 1.0051 |

|

18

| 0.4998 | 0.3439 | 1.0035 |

|

20

| 0.4473 | 0.3157 | 1.0014 |

Table 9.

The effect of cage height on the critical velocity, for the Holding State.

Table 9.

The effect of cage height on the critical velocity, for the Holding State.

| Height, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 8 | 0.5895 | 0.4664 | 1.0014 |

| 10 | 0.5774 | 0.4146 | 1.0066 |

| 12 | 0.5652 | 0.3770 | 1.0051 |

| 14 | 0.5530 | 0.3475 | 1.0058 |

| 16 | 0.5407 | 0.3242 | 1.0007 |

Table 10.

The effect of the net mesh and yarn diameter on the critical velocity, for the Holding State.

Table 10.

The effect of the net mesh and yarn diameter on the critical velocity, for the Holding State.

| Net Mesh, mm | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 2.0, 20 × 20 | 0.5987 | 0.3801 | 1.0071 |

| 2.5, 25 × 25 | 0.5820 | 0.3783 | 1.0083 |

| 3.0, 30 × 30 | 0.5652 | 0.3770 | 1.0051 |

| 3.5, 35 × 35 | 0.5485 | 0.3752 | 1.0045 |

| 4.0, 40 × 40 | 0.5317 | 0.3734 | 1.0031 |

Table 11.

The effect of the number of cages on the critical velocity, for the Holding State.

Table 11.

The effect of the number of cages on the critical velocity, for the Holding State.

| Number of Cages | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 2 | 1.1396 | 0.6592 | 1.0092 |

| 4 | 0.7557 | 0.4512 | 1.0048 |

| 6 | 0.5652 | 0.3770 | 1.0051 |

|

8

| 0.4515 | 0.3300 | 1.0019 |

| 10 | 0.3758 | 0.2956 | 1.0048 |

Table 12.

The effect of the floatation pipe diameter on the critical velocity, Holding State.

Table 12.

The effect of the floatation pipe diameter on the critical velocity, Holding State.

Upper Pipe

Diameter, m | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 0.480 | 0.1642 | 0.2916 | 1.0044 |

| 0.600 | 0.3419 | 0.3421 | 1.0016 |

| 0.720 | 0.5652 | 0.3770 | 1.0051 |

| 0.840 | 0.8343 | 0.3940 | 1.0040 |

| 0.960 | 1.1491 | 0.3989 | 1.0057 |

Table 13.

The effect of the connector’s bending stiffness on the critical velocity, for the Holding State.

Table 13.

The effect of the connector’s bending stiffness on the critical velocity, for the Holding State.

| Connector Bending Stiffness, Nm/Rad | Initial Velocity by the Analytical Method, m/s | Critical Velocity Assessment, m/s | Load Multiplier Factor |

|---|

| 200 | 0.5652 | 0.1825 | 1.0051 |

| 600 | 0.5652 | 0.3122 | 1.0008 |

| 1000 | 0.5652 | 0.3770 | 1.0051 |

| 1400 | 0.5652 | 0.3833 | 1.0052 |

| 1800 | 0.5652 | 0.3846 | 1.0085 |

Table 14.

Dimensions of the cages for studying the effect of cave dimensions ratio at constant cage volume 4096 m3.

Table 14.

Dimensions of the cages for studying the effect of cave dimensions ratio at constant cage volume 4096 m3.

| Parameter | Values Shape 1 | Values Shape 2 | Values Shape 3 | Values Shape 4 | Values Shape 5 |

|---|

| H/L | 0.500 | 0.750 | 1.000 | 1.250 | 1.500 |

| L [m] | 20.159 | 17.610 | 16.000 | 14.853 | 13.977 |

| H [m] | 10.079 | 13.208 | 16.000 | 18.566 | 20.966 |

Table 15.

Assessment of the critical opposing current for two systems with operational experiance.

Table 15.

Assessment of the critical opposing current for two systems with operational experiance.

| Parameter | Symbol | Value Case A | Value Case B |

|---|

| Cage Height | | 12.0 [m] | 16.0 [m] |

| Cage Length | | 16.0 [m] | 24.0 [m] |

| Floatation of Cage Upper Collar | FB | 4936 [N] | 17,917 [N] |

| Critical Current Load by Equation (4) | FC | 3702 [N] | 11,944 [N] |

| Critical current velocity | | 0.17 [m/s] | 0.23 [m/s] |