Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction

Abstract

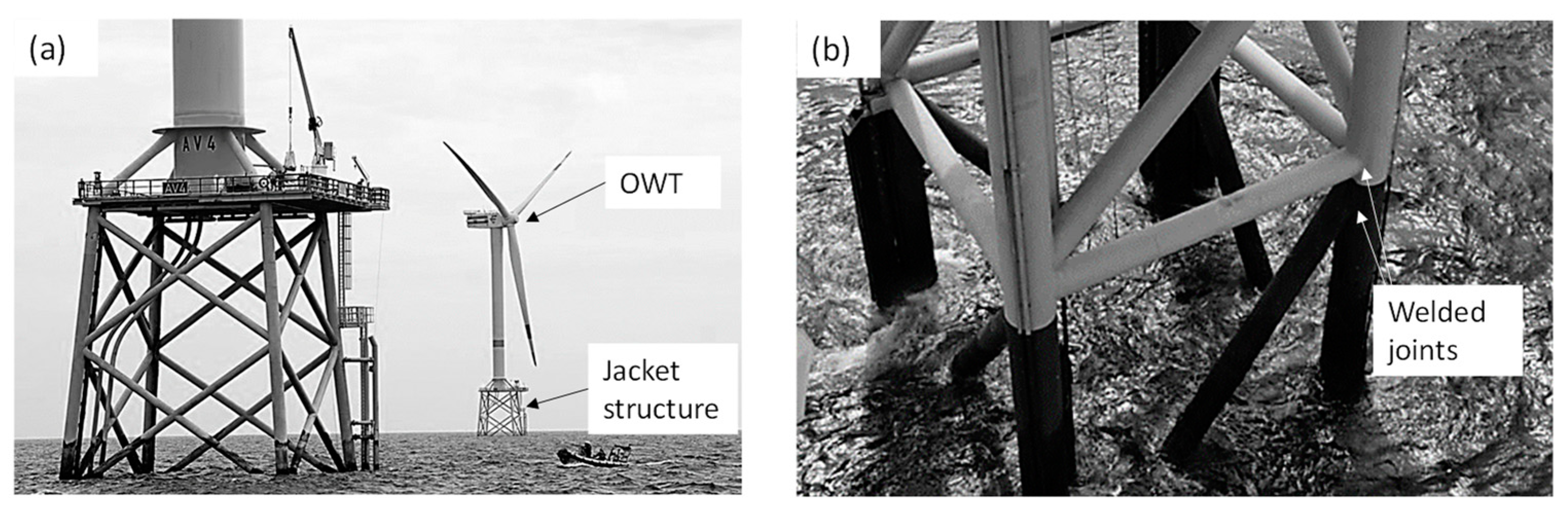

:1. Introduction

2. Material, Specimens, and the Welding Process

3. Fatigue Tests

4. Residual Stress Measurement

4.1. X-ray Diffraction

4.2. Cos -Method

4.3. Measurement Approach

5. Results

5.1. Structure in As-Welded (Unloaded) Conditions

5.2. Structure under Loading Conditions

6. Discussion

7. Conclusions

- High tensile residual stresses up to 250 MPa were determined in as welded (unloaded) conditions of the jacket structure. The highest tensile residual stresses at each measurement position are always located at the transition of the weld bead to the base material (weld toe);

- The measured loading stresses (difference of effective stress and residual stress) are between 1.4 and 4 times higher than the applied nominal stress. It is assumed that this is based on the local notch effect as well as the global misalignment of the structure;

- Local grinding for removing the start–stop position significantly changes the residual stress state and removes the tensile residual stresses.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leimeister, M.; Kolios, A. A review of reliability-based methods for risk analysis and their application in the offshore wind industry. Renew. Sustain. Energy Rev. 2018, 91, 1065–1076. [Google Scholar] [CrossRef]

- Shittu, A.A.; Kolios, A.; Mehmanparast, A. A Systematic Review of Structural Reliability Methods for Deformation and Fatigue Analysis of Offshore Jacket Structures. Metals 2021, 11, 50. [Google Scholar] [CrossRef]

- Hobbacher, A.F. Recommendations for Fatigue Design of Welded Joints and Components, 2nd ed.; Springer: New York, NY, USA, 2016. [Google Scholar]

- Nitschke-Pagel, T.; Dilger, K. Eigenspannungen in Schweißverbindungen—Teil 2: Bewertung von Eigenspannungen. Schweißen Und Schneid. 2007, 56, 23–33. [Google Scholar]

- Macherauch, E.; Wohlfahrt, H. Eigenspannungen und Ermüdung. Ermüdungsverhalten metallischer Werkstoffe, Residual stresses and fatigue. Fatigue behavior of metal components. In Ermüdungsverhalten Metallischer Werkstoffe, Fatigue of Metallic Materials; DGM Informationsgesellschaft Verlag GmbH: Oberursel, Germany, 1985; pp. 237–283. (In German) [Google Scholar]

- Gurney, T.R. Fatigue of Welded Structures, 2nd ed.; Cambridge Univercity Press: Cambridge, UK, 1979. [Google Scholar]

- Maddox, S.J. Fatigue Strength of Welded Structures; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Nitschke-Pagel, T. Eigenspannungen und Schwingfestigkeitsverhalten geschweißter Feinkornbaustähle [Residual Stresses and Fatigue Strength of Welded Fine Grained Steel]. Ph.D. Thesis, TU-Braunschweig, Brunswick, Germany, 1995. (In German). [Google Scholar]

- Farajian, M.; Nitschke-Pagel, T.; Dilger, K. Mechanisms of Residual Stress Relaxation and Redistribution in Welded High-Strength Steel Specimens under Mechanical Loading. Weld. World 2010, 54, R366–R374. [Google Scholar] [CrossRef]

- Farajian, M.; Nitschke-Pagel, T. Residual stress relaxation in welded large components. Mater. Test. 2015, 57, 750–754. [Google Scholar] [CrossRef]

- Hensel, J. Mean stress correction in fatigue design under consideration of welding residual stress. Weld. World 2020, 64, 535–544. [Google Scholar] [CrossRef] [Green Version]

- Hauk, V. (Ed.) Structural and Residual Stress Analysis by Nondestructive Methods; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Withers, P.J. Residual stress and its role in failure. Rep. Prog. Phys. 2007, 70, 2211–2264. [Google Scholar] [CrossRef] [Green Version]

- Schajer, G.S. Practical Residual Stress Measurement Methods; Wiley: Chichester, UK, 2013. [Google Scholar]

- Cullity, B.D. Elements of X-Ray Diffraction; IOP Publishing Ltd.: New York, NY, USA, 1956. [Google Scholar]

- Schubert, A.; Kämpfe, B.; Goldenbogen, S. X-Ray Stress Analysis by Use of an Area Detector. Textures Microstruct. 1997, 29, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Taira, S.; Tanaka, K.; Yamasaki, T. A Method of X-Ray Microbeam Measurement of Local Stress an Its Application to Fatigue Crack Growth Problems. J. Soc. Mater. Sci. 1978, 27, 251–256. [Google Scholar] [CrossRef]

- Müller, P.; Macherauch, E. Das sin 2 ψ-Verfahren der röntgenographischen Spannungsmessung. Z. Angew. Phys. 1961, 13, 305–312. [Google Scholar]

- Sasaki, T.; Sato, H. X-ray stress measurement of austenitic stainless steel with cosα method and two-dimensional X-ray detector. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Zurich, 2017; Volume 879, pp. 1679–1684. [Google Scholar] [CrossRef]

- Miyazaki, T.; Sasaki, T. X-ray residual stress measurement of austenitic stainless steel based on fourier analysis. Nucl. Technol. 2016, 194, 111–116. [Google Scholar] [CrossRef]

- Schubnell, J.; Sarmast, A.; Altenhöner, F.; Sheikhi, S.; Braun, M.; Ehlers, S. Residual stress analysis of butt welds made of additive an tradionally manufactured 316L stainless steel plates. In Proceedings of the 11th International Conference of Residual Stresses, Nancy, France, 27–30 March 2022. [Google Scholar]

- Delbergue, D.; Texier, D.; Levesque, M.; Bocher, P.; Texier, D.; Lévesque, M. Comparison of Two X-Ray Residual Stress Measurement Methods: Sin2 ψ and Cos α, Through the Determination of a Martensitic Steel X-Ray Elastic Constant. In Proceedings of the 10th International Conference on Residual Stresses (ICRS10), Sydney, Australia, 3–7 August 2016; Volume 2, pp. 55–60. [Google Scholar] [CrossRef] [Green Version]

- Sarmast, A.; Schubnell, J.; Carl, E.; Hinterstein, J.-M.; Preußner, J. Residual stress analysis in industrial parts: A comprehensive comparison of XRD methods. J. Mater. Sci. 2023, Submitted. [Google Scholar]

- Tanaka, K. The cosα method for X-ray residual stress measurement using two-dimensional detector. Mech. Eng. Rev. 2019, 6, 18-00378. [Google Scholar] [CrossRef] [Green Version]

- Nitschke-Pagel, T. Recommendations for the measurement of residual stresses in welded joints by means of X-ray diffraction—Results of the WG6-RR test. Weld. World 2021, 65, 589–600. [Google Scholar] [CrossRef]

- Mattes, S. Röntgendiffraktometrie mit dem Pulstec µ-x360 Gerät-Vergleichende Untersuchungen; Technical University of Ilmenau: Ilmenau, Germany, 2019. [Google Scholar]

- Tanaka, K. X-ray stress measurement by the cos α method using two-dimensional detector, Part 2, Measurement procedure and applications. J. Soc. Mater. Sci. Jpn. 2017, 66, 479–487. [Google Scholar] [CrossRef] [Green Version]

- Hensel, J.; Nitschke-Pagel, T.; Dilger, K. Effects of residual stresses and compressive mean stresses on the fatigue strength of longitudinal fillet-welded gussets. Weld. World 2016, 60, 267–281. [Google Scholar] [CrossRef]

- Spieß, L.; Teichert, G.; Schwarzer, R.; Behnken, H.; Genzel, C. Röntgenographische Spannungsanalyse. In Moderne Röntgenbeugung: Röntgendiffraktometrie für Materialwissenschaftler, Physiker und Chemiker; Springer: New York, NY, USA, 2019; pp. 325–406. [Google Scholar] [CrossRef]

- Vashista, M.; Paul, S. Correlation between full width at half maximum (FWHM) of XRD peak with residual stress on ground surfaces. Mater. Sci. 2012, 92, 4194–4204. [Google Scholar] [CrossRef]

- Vashista, M.; Yusufzai, M.Z.K. Correlation between full width at half maximum (FWHM) of XRD peak with mechanical properties. Int. J. Metall. Alloy. 2015, 1, 15–23. [Google Scholar]

- Hensel, J.; Eslami, H.; Nitschke-Pagel, T.; Dilger, K. Fatigue Strength Enhancement of Butt Welds by Means of Shot Peening and Clean Blasting. Metals 2019, 9, 744. [Google Scholar] [CrossRef] [Green Version]

| Yield Strength [MPa] | Tensile Strength [MPa] | Elongation [%] |

|---|---|---|

| 431–466 | 502–542 | 22 |

| Radiation | Lattice Plane | Kollimator | Exposure Time | Distance | Tilt Angle | Measurement | Indentation |

|---|---|---|---|---|---|---|---|

| [-] | [-] | [mm] | [s] | [mm] | [°] | [mm] | [µm] |

| CrK | {211} | 1 | 14 | 60–71 | 20–30 | 2.25 * | 4–5 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schubnell, J.; Carl, E.; Widerspan, V.; Collmann, M. Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction. J. Mar. Sci. Eng. 2023, 11, 1304. https://doi.org/10.3390/jmse11071304

Schubnell J, Carl E, Widerspan V, Collmann M. Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction. Journal of Marine Science and Engineering. 2023; 11(7):1304. https://doi.org/10.3390/jmse11071304

Chicago/Turabian StyleSchubnell, Jan, Eva Carl, Viktor Widerspan, and Mareike Collmann. 2023. "Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction" Journal of Marine Science and Engineering 11, no. 7: 1304. https://doi.org/10.3390/jmse11071304

APA StyleSchubnell, J., Carl, E., Widerspan, V., & Collmann, M. (2023). Determination of Loading and Residual Stresses on Offshore Jacket Structures by X-ray Diffraction. Journal of Marine Science and Engineering, 11(7), 1304. https://doi.org/10.3390/jmse11071304