Optimal Control Strategy for Ship Cabin’s Active Chilled Beam System Using Improved Multi-Objective Salp Swarm Algorithm

Abstract

:1. Introduction

- (1)

- A dynamic simulation environment considering changing weather conditions, the ship’s position, and its heading angle is developed for the optimal control of a cabin’s ACB system. The control of cabin air conditioning systems, considering the movement of ships and the changing weather conditions in different navigation areas, offers a more accurate and realistic scenario compared to controlling systems in fixed locations. However, due to its complexity, this particular aspect has received limited attention in the current literature.

- (2)

- We propose a modified tent chaotic map, which demonstrates high sensitivity to initial conditions and which can generate a more evenly distributed sequence. These characteristics can significantly enhance the diversity of the population and the efficiency of chaotic searches using optimization algorithms.

- (3)

- An adaptive weight update strategy and a refinement search mechanism based on the modified tent chaotic map are incorporated into the MSSA, forming the improved multi-objective salp swarm algorithm (IMSSA). The results show that, compared to the original algorithm, the IMSSA can achieve a more accurate and uniform Pareto front with a faster convergence speed and greatest energy savings while maintaining thermal comfort.

2. Nomenclature

3. Simulation Model and Conditions

3.1. Overview of the Simulation Model

3.2. Dynamic Simulation Conditions

3.3. Energy and Thermal Comfort Model

3.3.1. Energy Predictive ANN Model Development

3.3.2. Thermal Comfort Model

3.3.3. Optimization Model Formulation

4. Proposed Modified Multi-Objective Salp Swarm Algorithm

4.1. Salp Swarm Algorithm (SSA)

- (1)

- If the current solution dominates a solution in the repository, the two solutions are swapped. If the solution dominates a set of solutions in the repository, the solution is added to the repository, and the set of dominated solutions is removed from the repository.

- (2)

- If there exists a solution in the repository that dominates the current solution, the current solution should be discarded directly.

- (3)

- If the current solution is non-dominated in comparison with all solutions in the repository, the current solution is added to the repository.

4.2. A Modified Tent Chaotic Map and Chaos-Based Strategy

4.2.1. Proposed m-Tent

4.2.2. Adaptive Refinement Search Based on m-Tent

4.3. Adaptive Weight Update Strategy

4.4. Knee Point Solution Selecting

5. Co-Simulation Testbed

6. Results Analysis and Discussions

6.1. Comparison of MSSA and IMSSA

6.2. Comparison of Different Control Strategies

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Pseudocode of IMSSA

| Pseudo-code of IMSSA |

| Inputs: maximum number of iterations , boundary limits and , the dimension , repository size and the population Outputs: the pareto optimal solution Initialize the population within the solution space via using the m-tent while () calculate the fitness of each salp determine the non-dominated salps update the repository considering the obtained non-dominated salps if the repository becomes full call the repository maintenance procedure to remove one repository resident add the non-dominated salp to the repository end if while () do for p = 1: obtain a new individual by means of adaptive refinement search via Equations (15)–(17) if replace individual with end if end for end while choose a source of food from repository: F = SelectFood(repository) update c1 by Equation (10) for each salp () if update the position of the leading salps by Equation (9) else update the position of the following salps by Equations (18)–(21) end if end for amend the salps based on the upper and lower bounds of variables end while |

References

- Simonsen, M.; Walnum, H.J.; Gössling, S. Model for estimation of fuel consumption of cruise ships. Energies 2018, 11, 1059. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Yip, T.L.; Lau, Y.-Y. Location characteristics of cruise terminals in China: A lesson from Hong Kong and Shanghai. Sustainability 2019, 11, 5056. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Zheng, R.; Parmak, M. Factors Influencing the Willingness to Pay in Yachting Tourism in the Context of COVID-19 Regular Prevention and Control: The Case of Dalian, China. Sustainability 2022, 14, 13132. [Google Scholar] [CrossRef]

- Li, H.; Jia, P.; Wang, X.; Yang, Z.; Wang, J.; Kuang, H. Ship carbon dioxide emission estimation in coastal domestic emission control areas using high spatial-temporal resolution data: A China case. Ocean Coast. Manag. 2023, 232, 106419. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, Q.; Xu, Z.; Chen, J.; Wang, Q. Impact of emission control areas on atmospheric pollutant emissions from major ocean-going ships entering the Shanghai Port, China. Mar. Pollut. Bull. 2019, 142, 525–532. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Palombo, A.; Vicidomini, M. Sustainable energy design of cruise ships through dynamic simulations: Multi-objective optimization for waste heat recovery. Energy Convers. Manag. 2020, 221, 113166. [Google Scholar] [CrossRef]

- Hüffmeier, J.; Johanson, M. State-of-the-art methods to improve energy efficiency of ships. J. Mar. Sci. Eng. 2021, 9, 447. [Google Scholar] [CrossRef]

- Nurmi, M. Improving the Energy Efficiency of a Cruise Ship Stateroom. Master’s Thesis, Aalto University, Espoo, Finland, 2017. [Google Scholar]

- Filipsson, P.; Trüschel, A.; Gräslund, J.; Dalenbäck, J.-O. Modelling of rooms with active chilled beams. J. Build. Perform. Simul. 2020, 13, 409–418. [Google Scholar] [CrossRef]

- Zhao, Z.C.; Cheng, H.; Feng, W.X.; Qin, B.J. Simulation analysis on dynamic load of air-conditioning system of ocean-going ship. Appl. Mech. Mater. 2014, 672, 1693–1699. [Google Scholar] [CrossRef]

- Gao, S. Dynamic Cooling Loads of Ship Air-Condition Analysis and Calculation. Master’s Thesis, Dalian University of Technology, Dalian, China, 2006. [Google Scholar]

- Huang, Z. Research on Comprehensive Energy Efficiency Evaluation Technology for Ship Air Conditioning System. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2019. [Google Scholar]

- Miao, W.; Yang, Z.; Junlong, X. Simulation analysis of dynamic cooling loads of ship air conditioning in summer. Chin. J. Ship Res. 2018, 13, 199–206. [Google Scholar]

- Kim, C.; Lee, J.; Lee, D.; Choi, S. Optimized operation method for an active chilled beam with VAV system. Sci. Technol. Built Environ. 2016, 22, 372–378. [Google Scholar] [CrossRef]

- Maccarini, A.; Hultmark, G.; Vorre, A.; Afshari, A.; Bergsøe, N.C. Modeling of active beam units with Modelica. Build. Simul. 2015, 8, 543–550. [Google Scholar] [CrossRef]

- Lee, J.M.; Hong, S.H.; Seo, B.M.; Lee, K.H. Application of artificial neural networks for optimized AHU discharge air temperature set-point and minimized cooling energy in VAV system. Appl. Therm. Eng. 2019, 153, 726–738. [Google Scholar] [CrossRef]

- Ye, G.; Yang, C.; Chen, Y.; Li, Y. A new approach for measuring predicted mean vote (PMV) and standard effective temperature (SET∗). Build. Environ. 2003, 38, 33–44. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, Z. Standard effective temperature based adaptive-rational thermal comfort model. Appl. Energy 2020, 264, 114723. [Google Scholar] [CrossRef]

- Jorge, F.; Carlos, P.; Ricardo, M.; Sandra, S.; Luís, B.a. Contribution of Portuguese Vernacular Building Strategies to Indoor Thermal Comfort and Occupants’ Perception. Buildings 2015, 5, 1242–1264. [Google Scholar]

- Azad, A.S.; Rakshit, D.; Wan, M.P.; Babu, S.; Sarvaiya, J.N.; Kumar, D.K.; Zhang, Z.; Lamano, A.S.; Krishnasayee, K.; Gao, C.P. Evaluation of thermal comfort criteria of an active chilled beam system in tropical climate: A comparative study. Build. Environ. 2018, 145, 196–212. [Google Scholar] [CrossRef]

- Yang, S.; Wan, M.P.; Ng, B.F.; Dubey, S.; Henze, G.P.; Chen, W.; Baskaran, K. Experimental study of model predictive control for an air-conditioning system with dedicated outdoor air system. Appl. Energy 2020, 257, 113920. [Google Scholar] [CrossRef]

- Mossolly, M.; Ghali, K.; Ghaddar, N. Optimal control strategy for a multi-zone air conditioning system using a genetic algorithm. Energy 2009, 34, 58–66. [Google Scholar] [CrossRef]

- Wu, B.; Cai, W.; Chen, H. A model-based multi-objective optimization of energy consumption and thermal comfort for active chilled beam systems. Appl. Energy 2021, 287, 116531. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, Y.; Fang, Z.; Huan, C.; Lin, Z. Optimization of room air temperature in stratum-ventilated rooms for both thermal comfort and energy saving. Appl. Energy 2017, 204, 420–431. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.d.S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Coello, C.C.; Lechuga, M.S. MOPSO: A proposal for multiple objective particle swarm optimization. In Proceedings of the 2002 Congress on Evolutionary Computation CEC’02 (Cat No 02TH8600), Honolulu, HI, USA, 12–17 May 2002. [Google Scholar]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Lan, L.; Pan, L.; Lian, Z.; Huang, H.; Lin, Y. Experimental study on thermal comfort of sleeping people at different air temperatures. Build. Environ. 2014, 73, 24–31. [Google Scholar] [CrossRef]

- Yamtraipat, N.; Khedari, J.; Hirunlabh, J. Thermal comfort standards for air conditioned buildings in hot and humid Thailand considering additional factors of acclimatization and education level. Sol. Energy 2005, 78, 504–517. [Google Scholar] [CrossRef]

- Cui, C.; Wu, T.; Hu, M.; Weir, J.D.; Li, X. Short-term building energy model recommendation system: A meta-learning approach. Appl. Energy 2016, 172, 251–263. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Li, F.; Wu, C. Research on intrusion detection method based on Pearson correlation coefficient feature selection algorithm. J. Phys. Conf. Ser. 2021, 1757, 012054. [Google Scholar] [CrossRef]

- Waseem, M.; Lin, Z.; Yang, L. Data-Driven Load Forecasting of Air Conditioners for Demand Response Using Levenberg–Marquardt Algorithm-Based ANN. Big Data Cogn. Comput. 2019, 3, 36. [Google Scholar] [CrossRef] [Green Version]

- Studer, D.; Barkyoumb, J.H.; Lee, E.; Ball, B.L.; Frank, S.; Holland, E.; Green, J.; Robinson, W.; Brown, J.; Golda, J. Leveraging Shore-Side, Building Energy Simulation Tools for Use in the Shipboard Environment. Nav. Eng. J. 2018, 130, 129–140. [Google Scholar]

- Monetti, V.; Davin, E.; Fabrizio, E.; André, P.; Filippi, M. Calibration of building energy simulation models based on optimization: A case study. Energy Procedia 2015, 78, 2971–2976. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.; Lee, T.; Kim, J.S. Increasing Neurons or Deepening Layers in Forecasting Maximum Temperature Time Series? Atmosphere 2020, 11, 1072. [Google Scholar] [CrossRef]

- Wang, G.G.; Shan, S. Review of metamodeling techniques in support of engineering design optimization. J. Mech. Des. 2007, 129, 370–380. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal comfort: Analysis and applications in environmental engineering. R. Soc. Health J. 1972, 92, 164. [Google Scholar]

- Liaison, S.; Cooper, K.W.; Turner, S.C.; Paliaga, G.; Lynch, B.M.; Arens, E.A.; Aynsley, R.M.; Brager, G.S.; Deringer, J.J.; Ferguson, J.M. ANSI/ASHRAE 55:2010; Thermal Environmental Conditions for Human Occupancy. American Society of Heating: Refrigerating, and Airconditioning Engineers, Inc.: Atlanta, GA, USA, 2010. [Google Scholar]

- Adrian, S.-C.; Sergiu, C.; Maria, M.; Anca, S.-C.; Monica, M. Models for the indices of thermal comfort. J. Med. Life 2008, 1, 148. [Google Scholar]

- Wu, B.; Cai, W.; Ji, K. Heat source effects on thermal comfort for active chilled beam systems. Build. Environ. 2018, 141, 91–102. [Google Scholar] [CrossRef]

- Wang, R.-Q.; Zhang, C.-H.; Li, K. Multi-objective genetic algorithm based on improved chaotic optimization. Control Decis. 2011, 26, 1391–1397. [Google Scholar]

- Zou, J.; Li, Q.; Yang, S.; Bai, H.; Zheng, J. A prediction strategy based on center points and knee points for evolutionary dynamic multi-objective optimization. Appl. Soft Comput. 2017, 61, 806–818. [Google Scholar] [CrossRef]

- Erbe, D.; Sciarra, L.L.; Glazer, J.; Seeger, K.; Boldt, J.; Hart, R.; Rosenberg, M.I. A Conversation on Standard 90.1-2019. ASHRAE J. 2020, 62, 10–22. [Google Scholar]

| Type | Author | Features |

|---|---|---|

| calculation of dynamic cooling loads | Cheng Hua et al. [10] | They analyzed the effects of weather conditions on cooling loads in different navigational areas. |

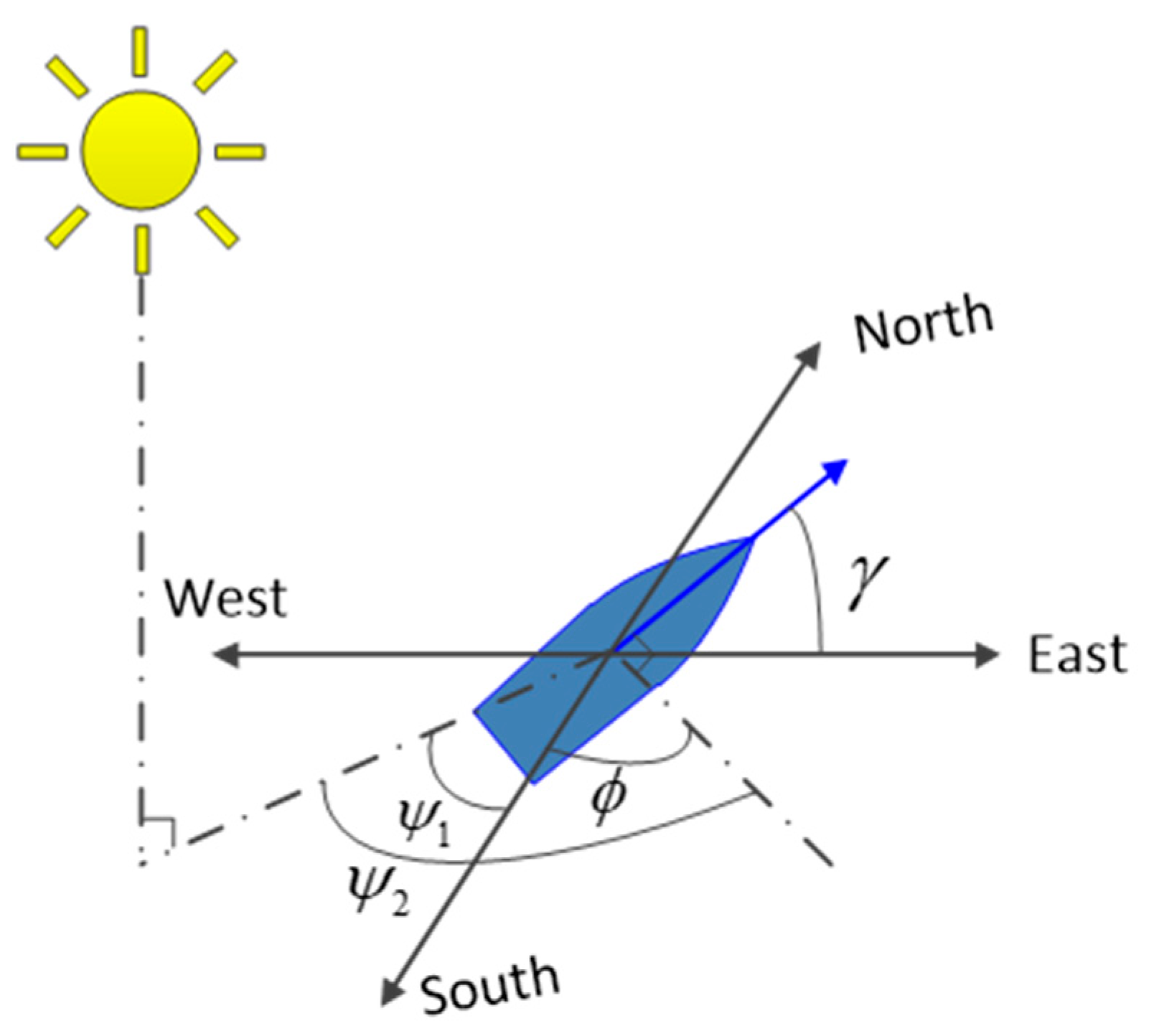

| Gao [11] | The advantage of the study is that changes in the solar azimuth angle are considered when calculating the cooling load of a cabin, but the solar radiation intensity was assumed to be fixed. | |

| Wang et al. [13] | They presented how a ship’s heading angle influences the cabin’s cooling load. | |

| optimal control strategies in HVAC systems | Kim et al. [14] | The study showed that, by optimizing the appropriate variables, controlling ACB systems can be more energy-efficient, but the study did not consider the constraints of the models. |

| Maccarini et al. [15] | The study introduced an empirical model for the heat transfer coefficient, which can be beneficial in variable selection. | |

| Lee et al. [16] | The study developed an energy consumption prediction model based on artificial neural networks to achieve the lowest energy consumption. One disadvantage is that thermal comfort was not considered. | |

| Yang et al. [21] | They implemented a model predictive control system for ACB systems considering thermal comfort. However, cooling power and thermal comfort were combined into a single function, with each being assigned a weighting factor, which is difficult to set. | |

| Mossolly et al. [22] | A genetic algorithm is introduced to optimize both the thermal comfort and energy savings of HVAC systems simultaneously, but the solution can result in suboptimal outcomes. | |

| Wu et al. [23] | They developed the energy consumption model of ACB systems and a thermal comfort model for a room. The non-dominated sorting genetic algorithm II is utilized to balance the two objectives. However, the process of building the model requires extensive parameter settings. | |

| optimization methods | MPSO, Coello et al. [27] | Fast convergence and easy implementation, but it lacks diversity and is prone to converging to local optima. |

| MGWA, S Mirjalili et al. [26] | Capable of generating a Pareto solution set with uniform distribution, but its performance depends on the settings of algorithm parameters. | |

| NSGA-II, Deb et al. [25] | Able to ensure that excellent solutions are not lost; however, it is prone to becoming stuck in local optima. | |

| MSSA, Mirjalili in [28] | Simpler computational form but easily trapped in local optima. |

| Configuration | Materials or Parameters |

|---|---|

| bulkhead materials | 8 mm steel plate + 50 mm Rockwool + 100 mm air layer + 30 mm interior panel |

| cabin area | 4 m × 8.5 m |

| window-to-wall ratio | 0.4 |

| cabin height | 2.75 m |

| cabin occupancy | 2 |

| cabin set temperature | 26 °C |

| relative humidity of the cabin | 50% |

| R | 0.76 | 0.42 | 0.44 | 0.47 | 0.85 |

| Number of Hidden Neurons | |||||

|---|---|---|---|---|---|

| 6 | 35.22 | 32.79 | 31.79 | 30.58 | 31.04 |

| 7 | 31.25 | 29.12 | 29.01 | 29.11 | 29.77 |

| 8 | 27.33 | 26.01 | 26.11 | 27.01 | 27.12 |

| 9 | 27.21 | 24.46 | 25.12 | 26.72 | 26.55 |

| 10 | 28.13 | 26.21 | 25.87 | 26.61 | 27.12 |

| 11 | 26.45 | 26.62 | 25.66 | 27.12 | 26.69 |

| 12 | 27.76 | 25.77 | 24.72 | 25.01 | 28.12 |

| 13 | 27.82 | 26.11 | 26.23 | 27.79 | 29.01 |

| 14 | 29.01 | 27.58 | 27.13 | 27.91 | 29.87 |

| Models | ANN | SVR | MLR | RSM | |||

|---|---|---|---|---|---|---|---|

| Performance | Polynomial Kernel | Radial Basis Function Kernel | Sigmoid Kernel | ||||

| RMSE | 0.11 | 0.22 | 0.13 | 0.17 | 0.24 | 0.25 | |

| CV-RMSE (%) | 24.46 | 46.71 | 27.46 | 36.90 | 52.23 | 54.61 | |

| MAE | 0.10 | 0.19 | 0.12 | 0.17 | 0.22 | 0.23 | |

| MRE (%) | 26.92 | 53.11 | 30.97 | 42.05 | 59.81 | 62.82 | |

| Initial value | 0.100000 | 0.200000 | 0.300000 | 0.400000 | 0.500000 | 0.600000 |

| The changed initial value | 0.100001 | 0.200001 | 0.300001 | 0.400001 | 0.500001 | 0.600001 |

| m-tent | 0.5077 | 0.5029 | 0.5031 | 0.5022 | 0.5028 | 0.5033 |

| Logistic | 0.5034 | 0.5021 | 0.4983 | 0.4997 | 0.4973 | 0.5016 |

| Improved tent | 0.4963 | 0.4979 | 0.4987 | 0.4963 | 0.5011 | 0.4986 |

| % of Time Cabin Absolute PMV Is Within the Range | |||

|---|---|---|---|

| Range of Deviation | Less than 0.2 | 0.2 < PMV ≤ 0.3 | PMV > 0.5 |

| Strategy 1 | 100% | 0% | 0% |

| Strategy 2 | 100% | 0% | 0% |

| Strategy 3 | 86.4% | 13.6% | 0% |

| Strategy 4 | 92.7% | 7.3% | 0% |

| Symbol | Definition | Unit |

|---|---|---|

| HVAC | heating, ventilation, and air conditioning | |

| ACB | active chilled beam | |

| ANN | artificial neural network | |

| PPD | predicted percentage dissatisfied | |

| MSSA | multi-objective salp swarm algorithm | |

| IMSSA | improved multi-objective salp swarm algorithm | |

| NSGA-II | non-dominated sorting genetic algorithm II | |

| MPSO | multi-objective particle swarm optimization algorithm | |

| MGWA | multi-objective grey wolf algorithm | |

| PMV | predicted mean vote | |

| AHU | air handling unit | |

| COP | coefficient of performance | |

| PLR | part load ratio | |

| VAV | variable air volume | |

| outdoor air dry bulb temperature | °C | |

| outdoor air relative humidity | ||

| diffuse solar radiation rate per area | ||

| direct solar radiation rate per area | ||

| indoor cooling load demand | W | |

| supply air temperature | °C | |

| primary air flow rate | ||

| chilled water flow rate | ||

| RMSE | root mean squared error | |

| CV | coefficient of variation | |

| CV(RMSE) | coefficient of variation of the root mean squared error | |

| prediction value | ||

| actual measurement value | ||

| number of measurement values | ||

| average of measurement values | ||

| indoor air temperature | °C | |

| mean radiant temperature | °C | |

| indoor relative humidity | ||

| relative air velocity | ||

| metabolic rate | met | |

| effective mechanical power | W | |

| clothing insulation | clo | |

| maximum air velocity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Su, Y.; Zhang, D. Optimal Control Strategy for Ship Cabin’s Active Chilled Beam System Using Improved Multi-Objective Salp Swarm Algorithm. J. Mar. Sci. Eng. 2023, 11, 1396. https://doi.org/10.3390/jmse11071396

Liu C, Su Y, Zhang D. Optimal Control Strategy for Ship Cabin’s Active Chilled Beam System Using Improved Multi-Objective Salp Swarm Algorithm. Journal of Marine Science and Engineering. 2023; 11(7):1396. https://doi.org/10.3390/jmse11071396

Chicago/Turabian StyleLiu, Chenyu, Yixin Su, and Danhong Zhang. 2023. "Optimal Control Strategy for Ship Cabin’s Active Chilled Beam System Using Improved Multi-Objective Salp Swarm Algorithm" Journal of Marine Science and Engineering 11, no. 7: 1396. https://doi.org/10.3390/jmse11071396