State-of-the-Art Review and Future Perspectives on Maneuvering Modeling for Automatic Ship Berthing

Abstract

1. Introduction

1.1. Background

1.2. Application of Automatic Berthing

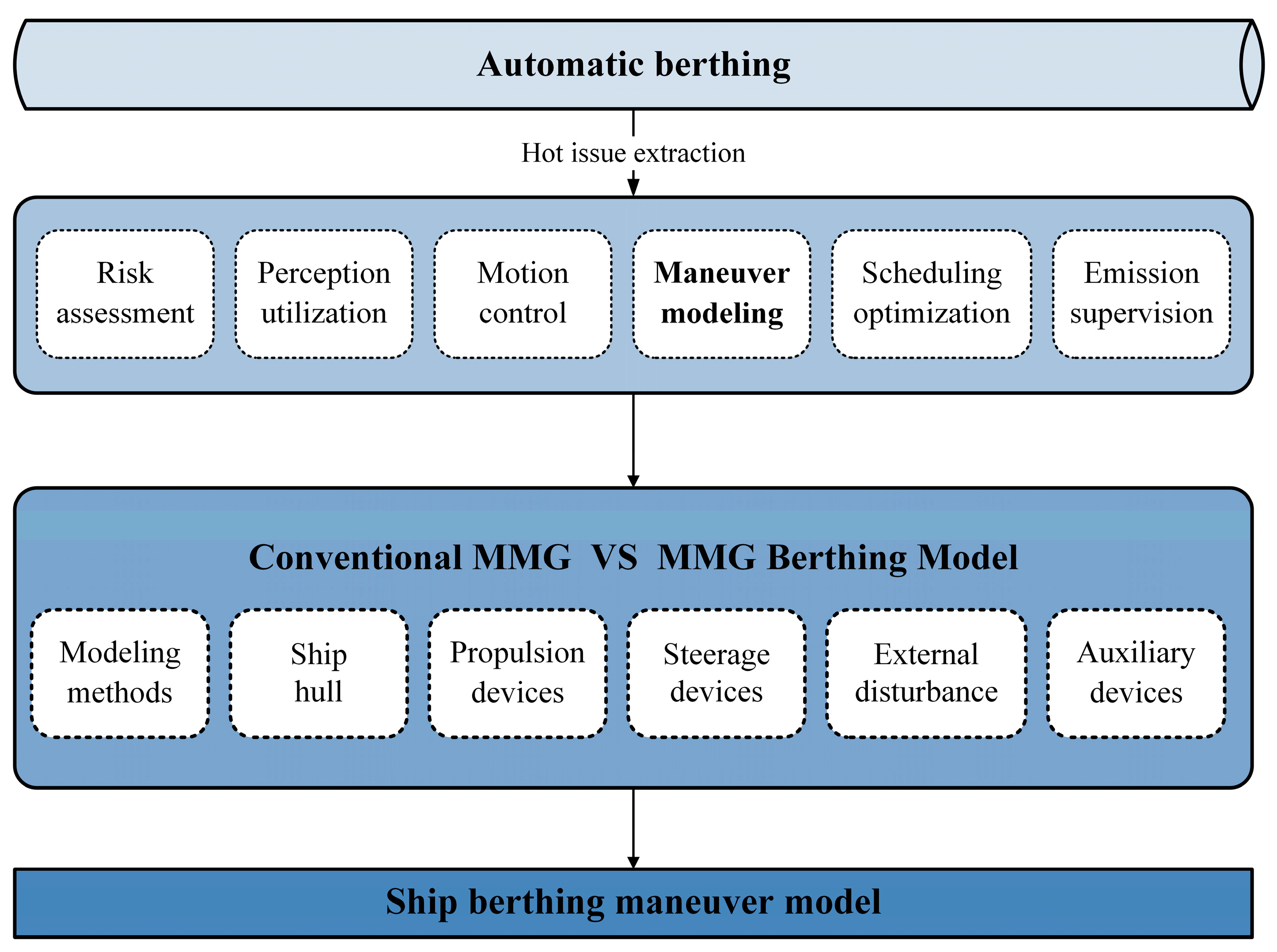

1.3. Contributions

- (1)

- Conducts bibliometric and statistical analysis on existing automatic berthing research, and extracts the hot issues of automatic berthing.

- (2)

- Demonstrates the similarities and differences between the conventional MMG model and berthing maneuver MMG model.

- (3)

- Summarizes the motion specifications and hydrodynamic performances of the berthing maneuver, and provides proper mathematical expressions.

1.4. Outline

2. Bibliometric Analysis

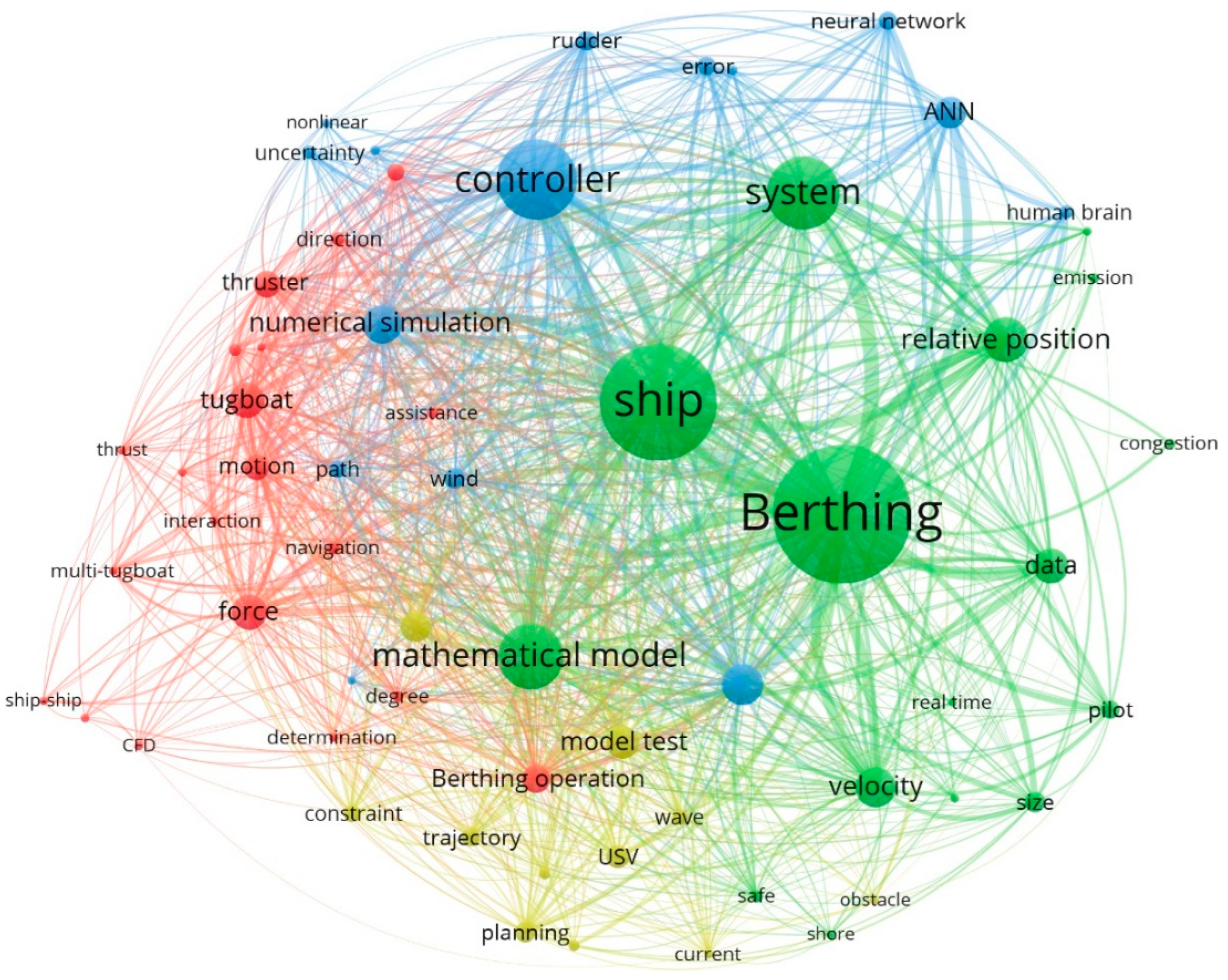

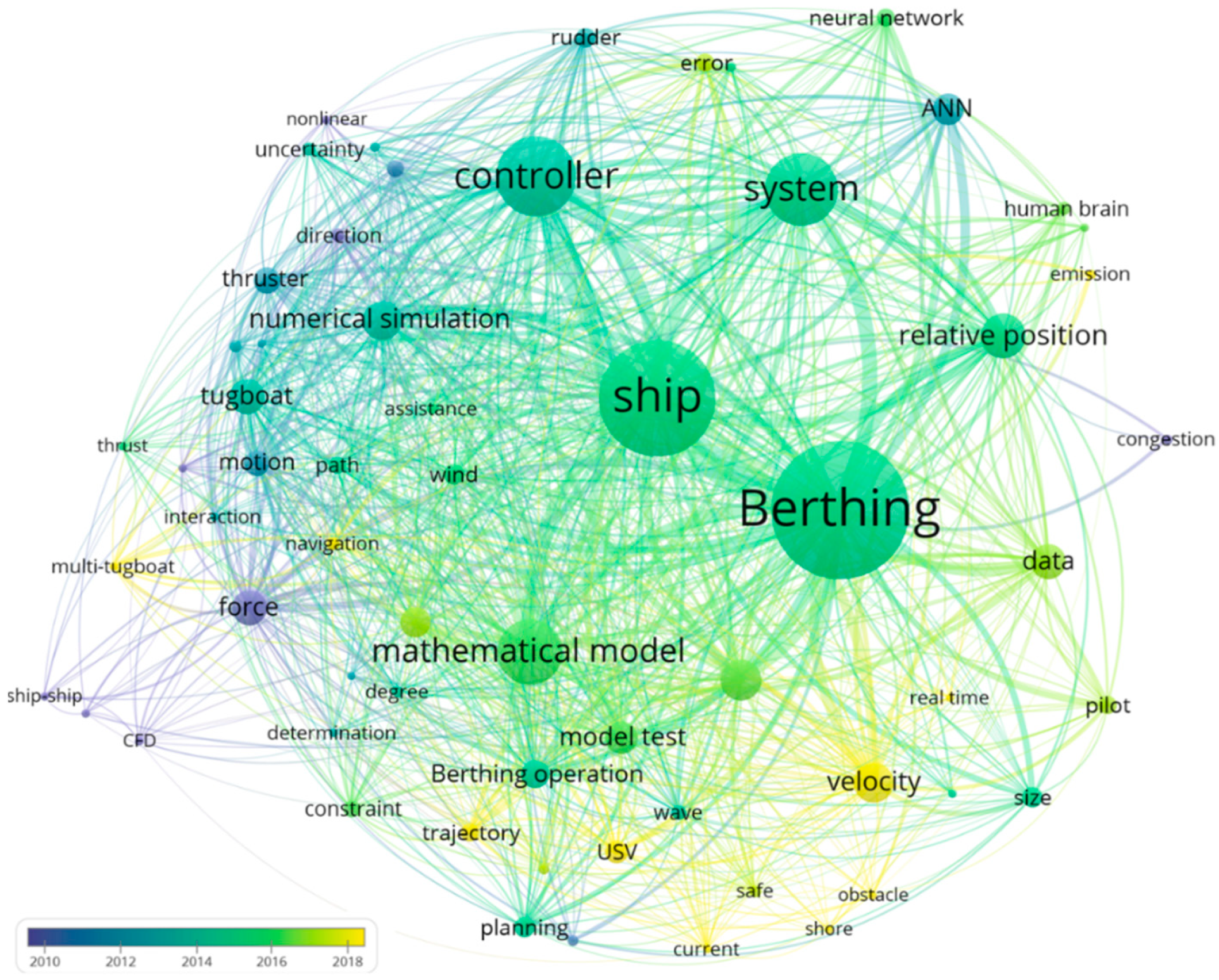

2.1. Literature Search and Visualization

- (1)

- The first step is to search the literature in the WoS database and the KCI-Korean journal database, with the following index keywords in the theme, abstract, and keywords: (“berthing*” OR “docking*”) AND (“ASV” OR “unmanned surface vessel” OR “unmanned surface vehicle” OR “autonomous surface vessel” OR “autonomous surface vehicle” OR “ship”) NOT (“underwater” OR “ROV” OR “UUV” OR “AUV” OR “aircraft” OR “drone” OR “car” OR “truck” OR “launch” OR “recovery” OR “cell” OR “actuator”);

- (2)

- The second step is to go through the collected literature and remove the research that is out of this work’s scope; 115 papers are retained;

- (3)

- The third step is to supplement studies and papers that are the source of certain research or cited in the selected papers but not included in the database; finally, 134 papers are added. With the literature collection and filter, a total of 249 articles consistent with the research scope are collected.

- (4)

- The fourth step is to extract the research objects, methods, contents, and publication time from the titles, abstracts, and keyword section of the collected references, and establish a bibliometric database.

- (5)

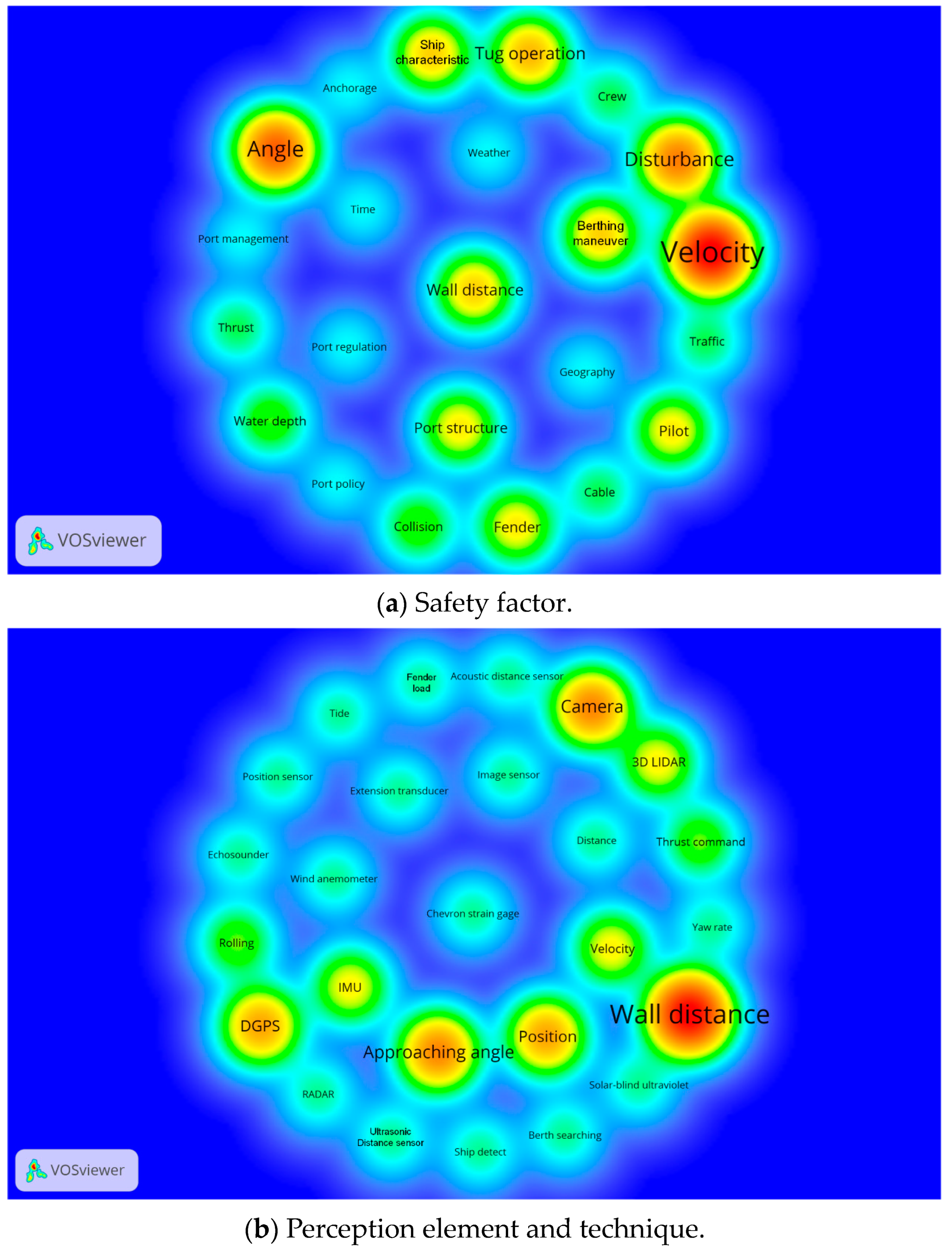

- The fifth step is to set up the threshold for the occurrence number in the extraction database, and then plot the network illustration on automatic berthing studies and density diagrams of the detailed research methods and techniques.

2.2. Global Analysis

2.3. Correlation Analysis

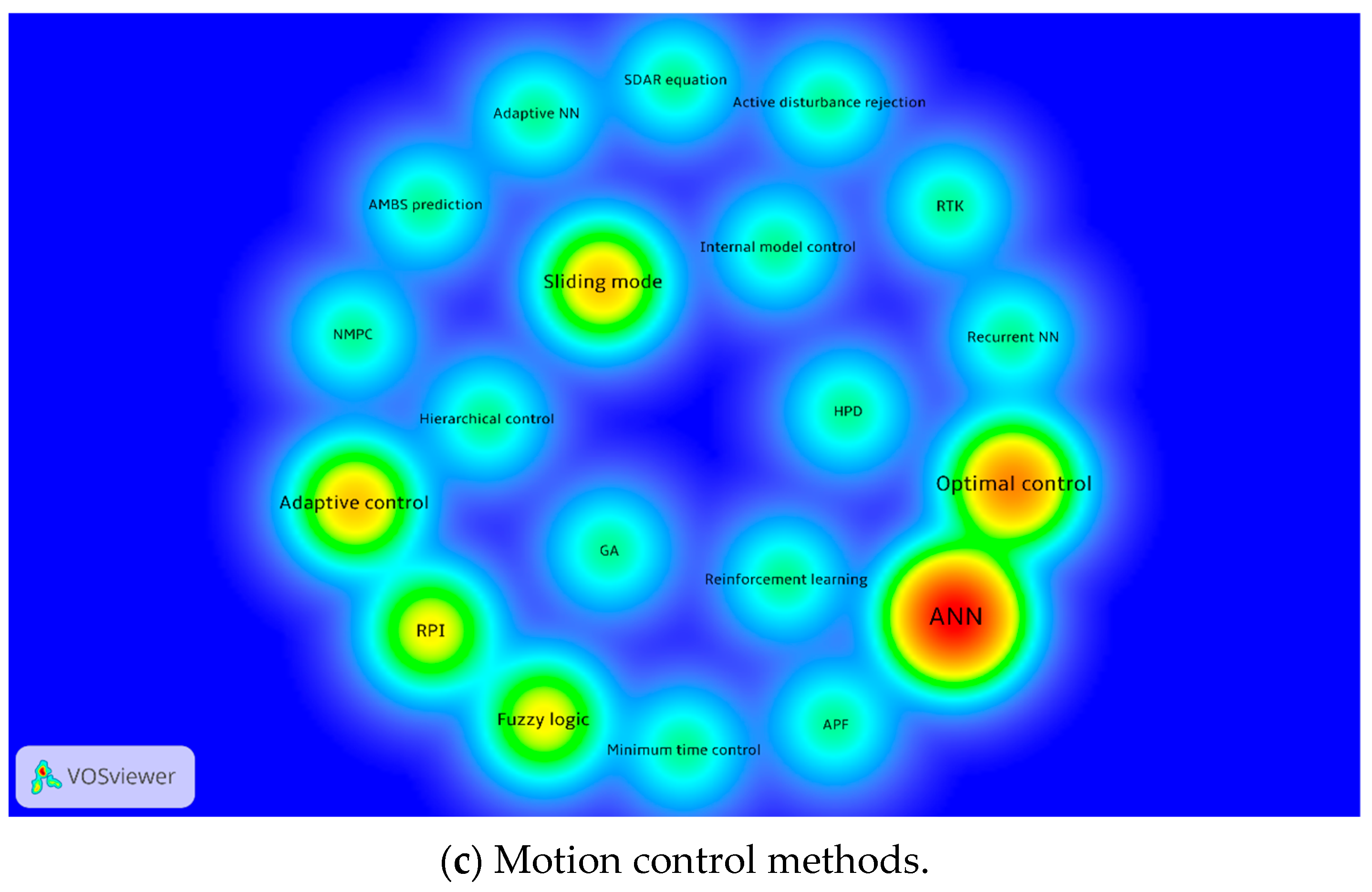

2.3.1. Risk Assessment, Perception Utilization and Motion Control

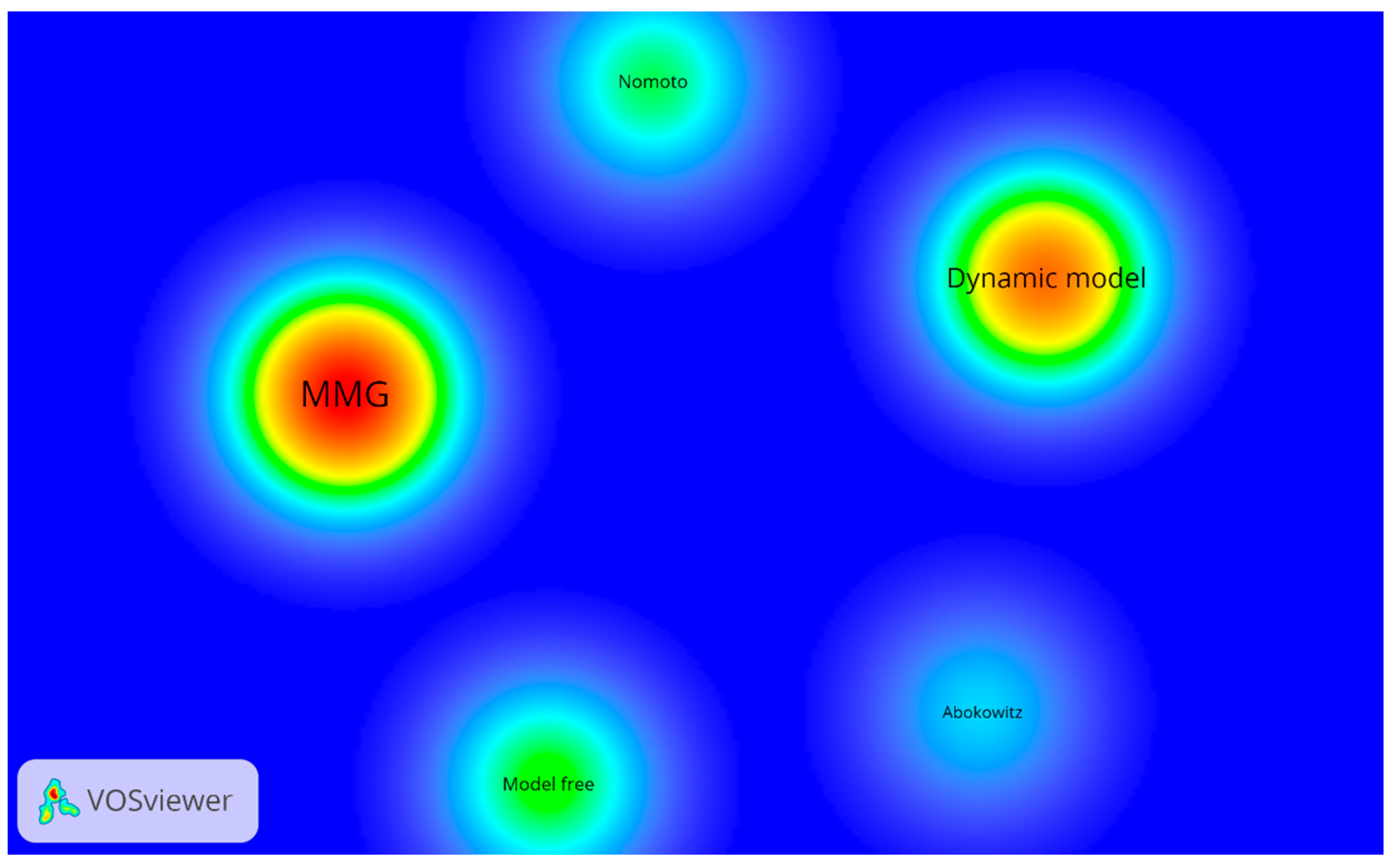

2.3.2. Maneuverability Modeling

2.4. Discussion of MMG Model

- ▪

- Hydrodynamic forces acting on the ship are treated quasi-steadily.

- ▪

- The lateral velocity component is small compared with the longitudinal velocity component.

- ▪

- Hydrodynamic forces acting on the ship have strong non-linearity; the ship longitudinal velocity is small, and is of the same order as the lateral velocity and yaw moment.

- ▪

- Thrust and steerage forces have four-quadrant characteristics.

- ▪

- The ship is vulnerable to external disturbances.

- ▪

- Ship motion is assisted by auxiliary devices like side thrusters, tugs, cables, and anchors.

- (1)

- What are the similarities and differences between the conventional MMG maneuvering model and the automatic berthing maneuvering model?

- (2)

- How can an accurate automatic berthing maneuvering model be established?

2.5. Remarks

3. Berthing Modeling Methods

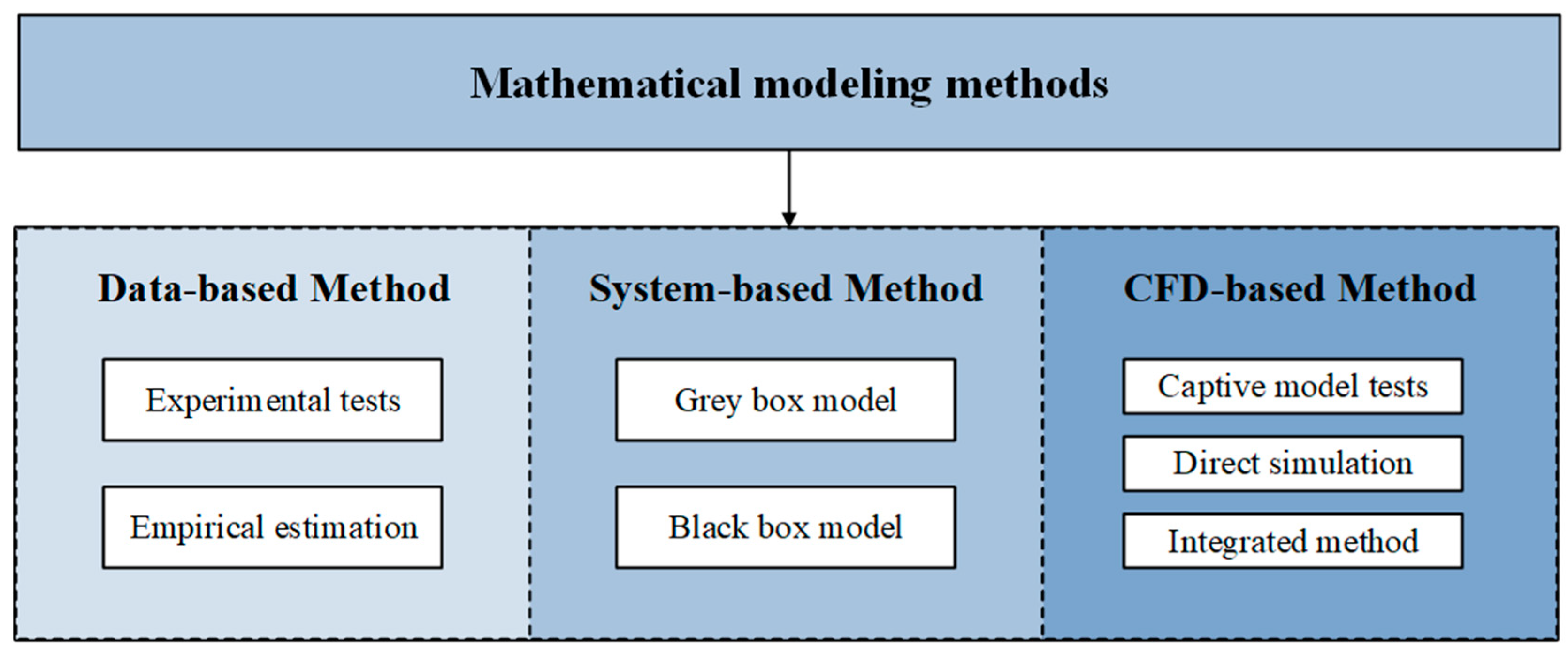

3.1. Mathematical Modeling Methods

3.2. Data-Based Methods

- (1)

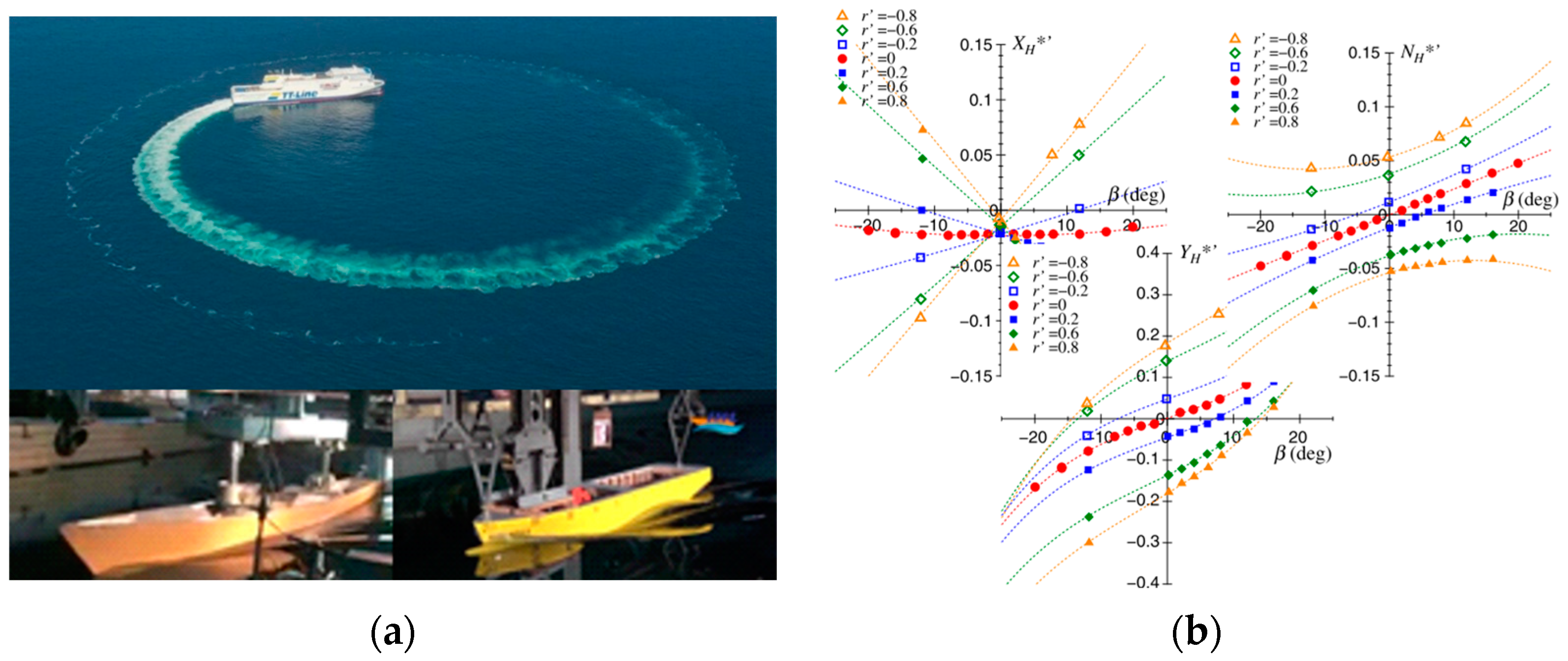

- The experimental method mainly contains full/model-scale free-running tests, and captive model tests. The former method establishes a database involving the ship maneuverability indices of advance, transfer, overshoot, track reach, etc., to characterize the turning, yaw-checking, and stopping abilities, and to evaluate the ship’s inherent dynamic and course-keeping stabilities (shown in Figure 9a). Meanwhile, the captive model tests measure the hydrodynamic performance of ships to indicate the ship response under various external conditions.

- (2)

- The empirical method makes a quick estimation of the resistance [70] and hydrodynamic derivatives [71,72] of a target ship. This method conducts regression analysis on massive captive model test results of ships within a hull-type set; the hydrodynamic derivatives are expressed as functions of the ship’s main dimensions, and form parameters (shown in Figure 9b).

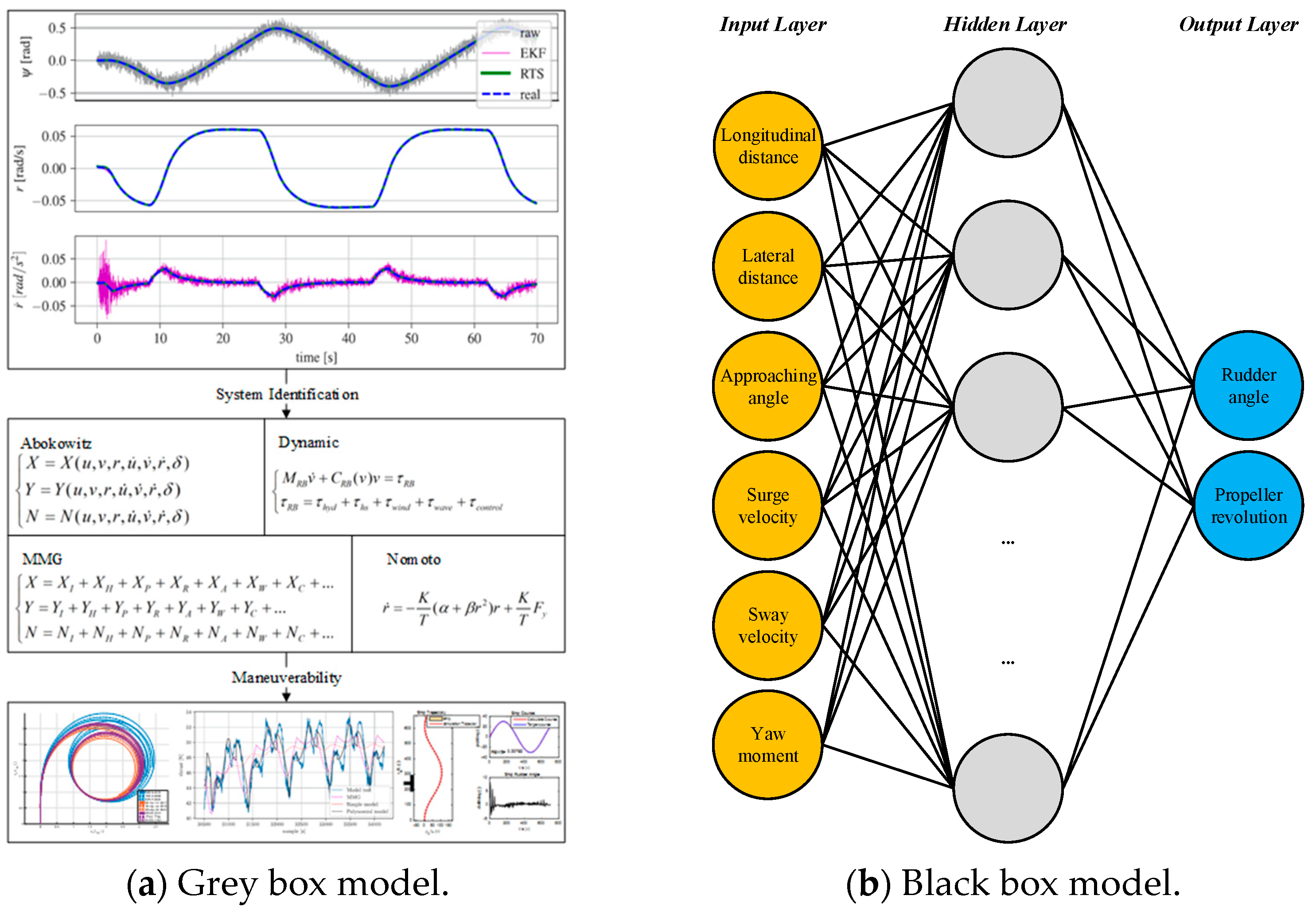

3.3. System-Based Methods

- (1)

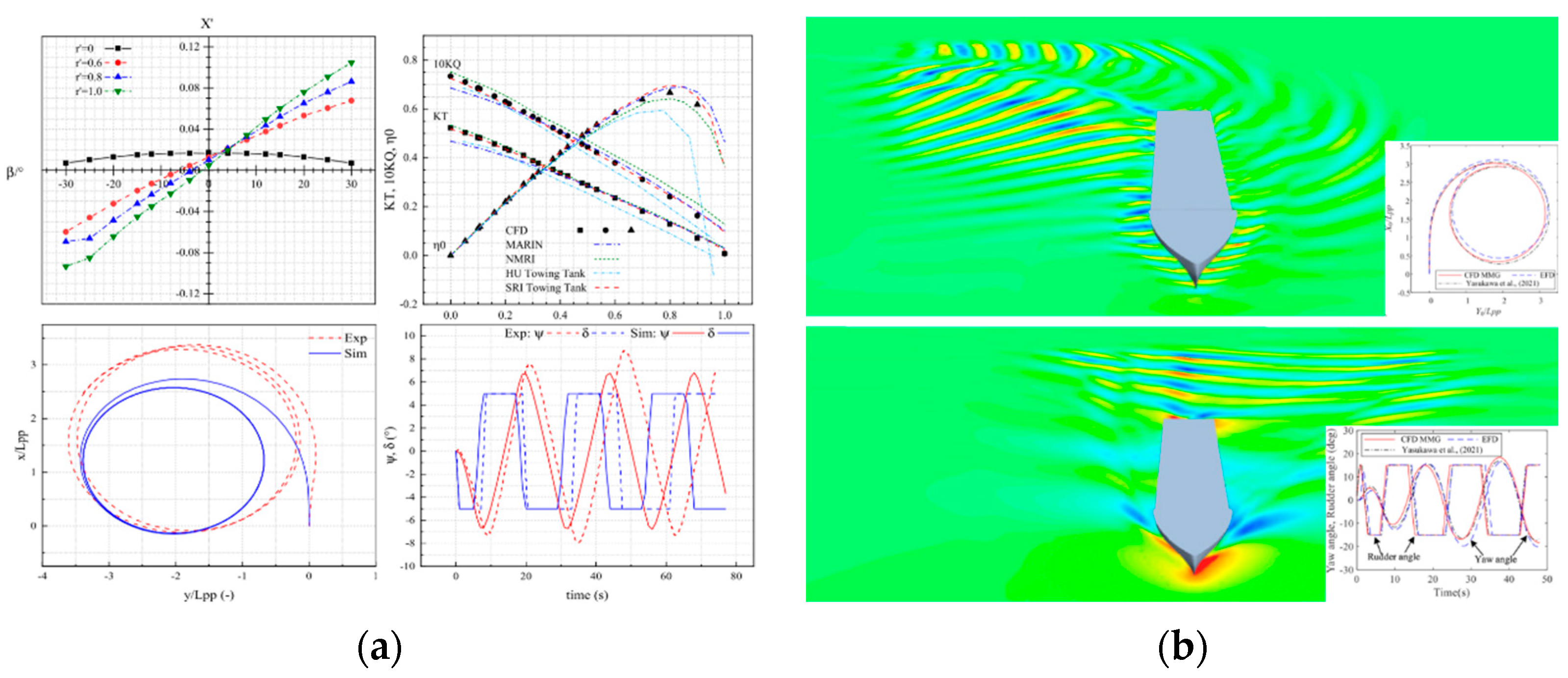

- The grey box model sets a prior model structure [75]; some identification algorithms, such as maximum likelihood (ML) [76], Kalman filtering (KF) [77], the least squares method (LS) [78] or the improved algorithm are used to identify the experiment/simulation parameters like ship speed, yaw rate, propeller revolution, rudder angle, and trajectories. The maneuverability of the target ship is then obtained (shown in Figure 10a). However, these methods have some inherent disadvantages: the accuracy is sensitive to signal noise and initial estimations, and simultaneous drift is another critical issue.

- (2)

- To cope with these defects, the black box model is proposed. No prior information is needed other than the datasets to gain the mapping relationship between system input variables and output variables [79] (shown in Figure 10b). Machine learning and deep learning techniques have been successfully applied as tools to establish the identified model, for example, the least-squares support-vector machine (LS-SVM) [80], the fully connected neural network [81], the deep neural network [55,82], etc.

3.4. CFD-Based Methods

- (1)

- The virtual captive model tests method conducts specific maneuvering test simulations based on the maneuvering model [83,84] of the target ship, the hydrodynamic characteristics of which are obtained via the CFD method (shown in Figure 11a, where upper left is the dimensionless longitudinal force X’, upper right the propeller thrust coefficient KT, torque coefficient KQ, and thrust efficiency η0, lower left the comparisons of the turning maneuver trajectory, and lower right the comparisons of the heading angle ψ and rudder angle δ time histories). Moreover, the propeller–rudder interaction, ship–ship interaction, ship–bank interaction, shallow-water effects, and detailed ship amplitudes and flow field development could also be obtained. This is the most effective, economical, and widely used method for studying the maneuverability of a ship.

- (2)

- The direct simulation method indicates that the maneuvering model tests are performed with the CFD method directly (shown in Figure 11b, where the upper part is the turning maneuver, and lower part the zig-zag maneuver). This method can assess the maneuverability of a ship under various external conditions and working conditions (calm water, regular and irregular waves, constraint water, wind, propeller reversal, etc.), and observe the response of the target ship to rudder/propeller operations. However, this method demands longer research periods and stronger computing power, and it is not the best option for the maneuverability study at present.

- (3)

- In consideration of the research requirements, efficiency, and rapidity, a hybrid method that integrates the empirical method and CFD method is constructed, based on the study experience and solid foundation [85,86,87]. The hydrodynamic performances of the ship hull, propeller, and rudder are obtained from the CFD method, and the hull–propeller–rudder interaction factors are solved by empirical methods. The accuracy of this method is affected by the ship-type diversity involved in the empirical formula.

3.5. Remarks

4. Berthing Maneuver Modeling

- (1)

- Low-speed effect, large drifting and yaw rate. Compared with the service speed, in the berthing process the longitudinal velocity is very low, the lateral speed and yaw rate are of the same magnitude, the hydrodynamic forces and moments acting on the ship hull present strong non-linearity, and the ship motion covers the full drifting conditions.

- (2)

- Four-quadrant propulsion and steerage. Ships in berthing operation need to operate the main engine frequently to adjust the ship amplitude and maintain the rudder steerage. Under such circumstances, the propeller and rudder work in four-quadrant conditions, and their performances are explicitly different from the designed capabilities.

- (3)

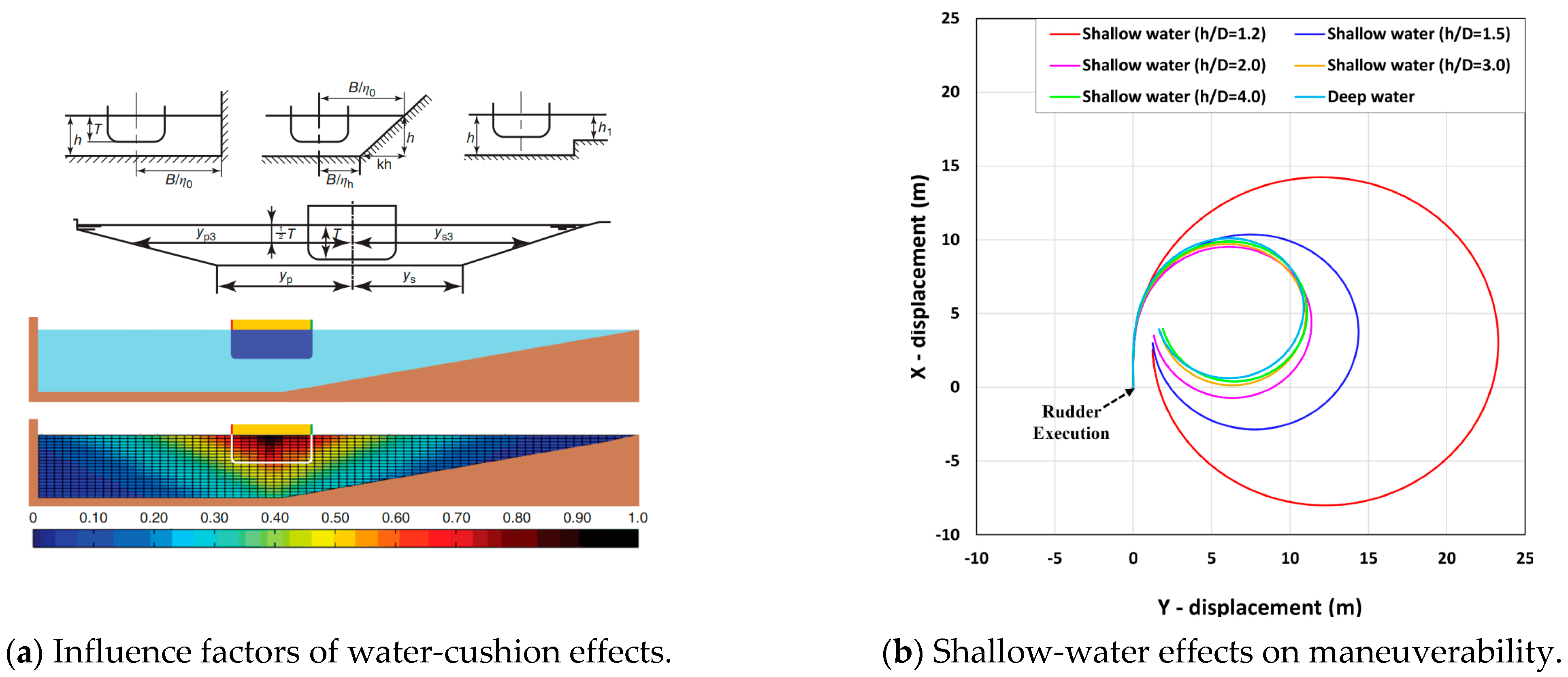

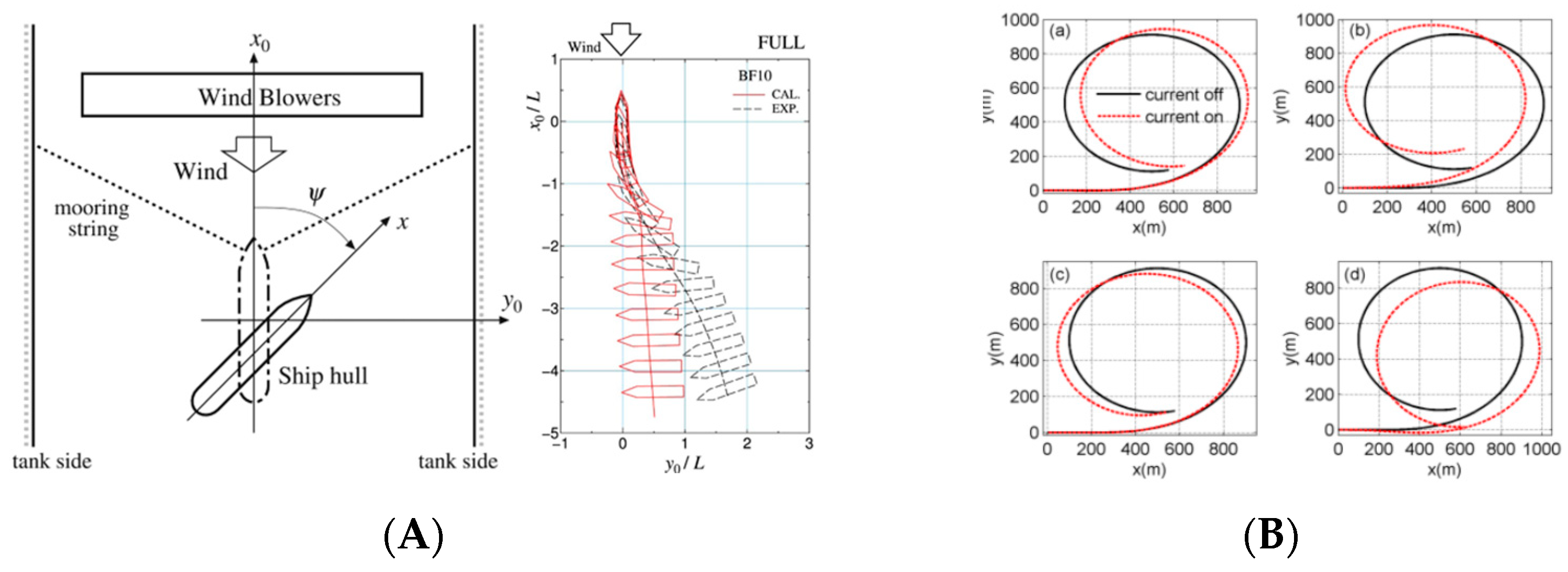

- External disturbances. Under berthing maneuver, thrust due to the propeller cannot counteract the disturbances induced by external environments. To maintain the steerage of the ship, the external disturbances, including the water-cushion effect (shallow-water effect, bank effect, ship–ship interaction), wind, and current, should be considered.

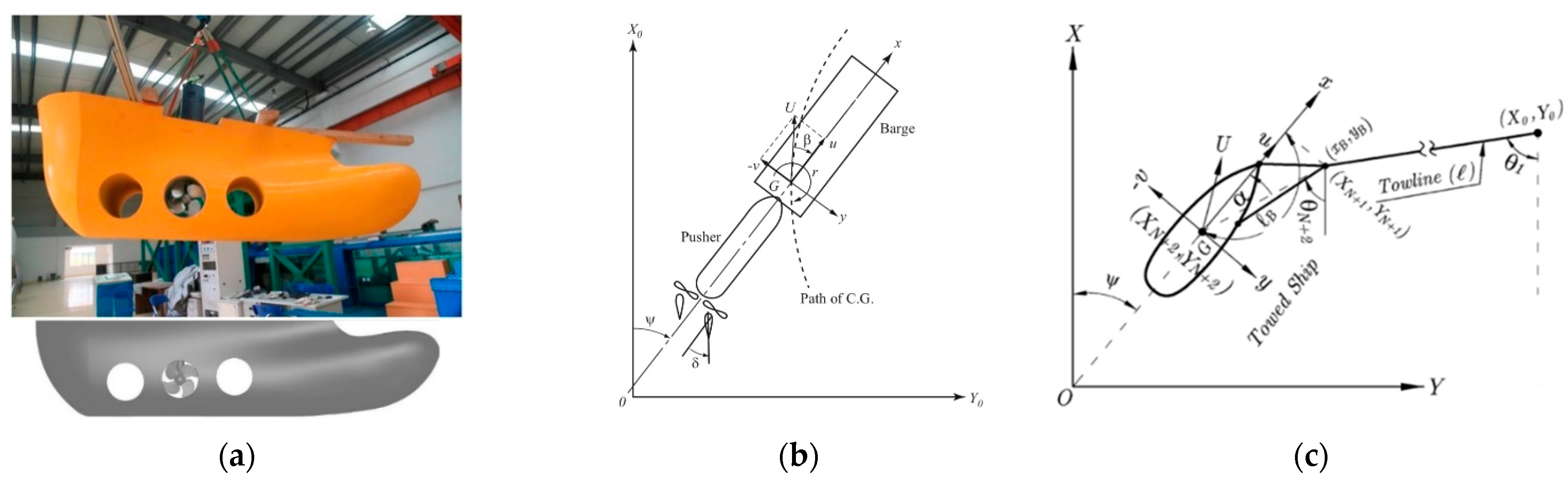

- (4)

- Auxiliary-device-induced forces. Due to the small velocity and low propeller revolution, the rudder is affected by the wake, and the crabbing motion and turning motion of the ship usually count on the assistance of auxiliary devices like side thrusters, tugs, and anchors.

4.1. Hydrodynamic Forces Acting on the Hull

4.1.1. Ship Speed

4.1.2. Drifting and Rotation Rate

- (1)

- The piecewise model [89] involving the small drifting model, moderate drifting model, and large drifting model. It should be noted that the moderate drifting model is the interpolation of the small drifting model and the large drifting model.

- (2)

- (3)

4.2. Propulsion and Steerage Devices

4.3. External Disturbance

4.3.1. Shallow-Water Effect

4.3.2. Bank Effect

4.3.3. Ship–Ship Interaction

4.3.4. Wind and Current

4.4. Auxiliary Devices

4.4.1. Side Thruster

4.4.2. Tug Assistance

4.5. Remarks

5. Conclusions

- (1)

- What are the similarities and differences between the conventional MMG maneuvering model and the automatic berthing maneuvering model?

- (2)

- How can an accurate automatic berthing maneuvering model be established?

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rothblum, A.M. Human error and marine safety. In Proceedings of the National Safety Council Congress and Expo, Orlando, FL, USA, 16–18 October 2000. [Google Scholar]

- Ahmed, Y.A.; Hasegawa, K. Implementation of automatic ship berthing using artificial neural network for free running experiment. IFAC Proc. Vol. 2013, 46, 25–30. [Google Scholar] [CrossRef]

- China Classification Society. Rules for Intelligent Ships; China Classification Society: Ningbo, China, 2015. [Google Scholar]

- China Classification Society. Rules for Intelligent Ships; China Classification Society: Ningbo, China, 2020. [Google Scholar]

- China Classification Society. Rules for Intelligent Ships; China Classification Society: Ningbo, China, 2023. [Google Scholar]

- Executive, T.M. Video: Japanese Demonstration of Autonomous Docking System. Available online: https://maritime-executive.com/article/video-japanese-demonstration-of-autonomous-docking-system (accessed on 24 May 2021).

- SAFETY4SEA. Watch: World’s First Successful Trail of Auto Berthing and un-Berthing System. Available online: https://safety4sea.com/watch-worlds-first-successful-trial-of-auto-berthing-and-un-berthing-system/ (accessed on 24 May 2021).

- Executive, T.M. First Autonomous Navigation and Berthing Test on a Containership. Available online: https://maritime-executive.com/article/first-autonomous-navigation-and-berthing-test-on-a-containership (accessed on 25 January 2022).

- Project, K.A.S.S. Detailed Task. Available online: https://kassproject.org/en/task/task.php (accessed on 24 May 2021).

- Qingdaonews. Water Test of the First Domestic Autonomous Navigation System Experimental Ship. Available online: https://news.qingdaonews.com/qingdao/2019-05/17/content_20362302.htm (accessed on 17 May 2019).

- Brilliance, N. The First Unmanned Container Ship in China Successfully Undocked. Available online: http://www.brinav.com/pages/News/NewsDetails.aspx?ID=2022 (accessed on 1 July 2021).

- Rolls-Royce. Rolls-Royce and Finferries Demonstrate World’s First Fully Autonomous Ferry. Available online: https://www.rolls-royce.com/media/press-releases/2018/03-12-2018-rr-and-finferries-demonstrate-worlds-first-fully-autonomous-ferry.aspx (accessed on 3 December 2018).

- Corporation, W. World’s first Autodocking Installation Successfully Tested by Wärtsilä. Available online: https://www.wartsila.com/media/news/26-04-2018-world-s-first-autodocking-installation-successfully-tested-by-wartsila-2169290 (accessed on 26 April 2018).

- MARITIME, K. Autonomous Ship Project, Key Facts About Yara Birkeland: The Zero Emission, Autonomous Container Feeder. Available online: https://www.kongsberg.com/zh-hans/maritime/support/themes/autonomous-ship-project-key-facts-about-yara-birkeland/ (accessed on 24 May 2021).

- PENTA, V. Launching the First Fully Integrated Assisted Docking System. Available online: https://www.volvopenta.com/about-us/news-page/2021/jan/launching-the-first-fully-integrated-assisted-docking-system/ (accessed on 24 May 2021).

- Yasukawa, H.; Yoshimura, Y. Introduction of MMG standard method for ship maneuvering predictions. J. Mar. Sci. Technol. 2015, 20, 37–52. [Google Scholar] [CrossRef]

- Li, J.; Goerlandt, F.; Reniers, G. Mapping process safety: A retrospective scientometric analysis of three process safety related journals (1999–2018). J. Loss Prev. Process Ind. 2020, 65, 104141. [Google Scholar] [CrossRef]

- Li, J.; Goerlandt, F.; Reniers, G. An overview of scientometric mapping for the safety science community: Methods, tools, and framework. Saf. Sci. 2021, 134, 105093. [Google Scholar] [CrossRef]

- He, Y.; Mou, J.; Chen, L.; Zeng, Q.; Chen, P.; Zhang, S. Survey on hydrodynamic effects on cooperative control of Maritime Autonomous Surface Ships. Ocean. Eng. 2021, 235, 109300. [Google Scholar] [CrossRef]

- Koyama, T.; Yan, J.; Huan, J.K. A systematic study on automatic berthing control (1st report). J. Soc. Nav. Archit. Jpn. 1987, 1987, 201–210. [Google Scholar] [CrossRef]

- Shouji, K.; Ohtsu, K.; Mizoguchi, S. An automatic berthing study by optimal control techniques. IFAC Proc. Vol. 1992, 25, 185–194. [Google Scholar] [CrossRef]

- Yamato, H.; Koyama, T.; Nakagawa, T. Automatic berthing system using expert system. J. Soc. Nav. Archit. Jpn. 1993, 1993, 327–337. [Google Scholar] [CrossRef]

- Meng, W.; Li, G.; Hua, L. A goal-programming based optimal port docking scheme under COVID-19. Ocean. Coast. Manag. 2022, 225, 106222. [Google Scholar]

- Han, S.; Wang, L.; Wang, Y. A potential field-based trajectory planning and tracking approach for automatic berthing and COLREGs-compliant collision avoidance. Ocean. Eng. 2022, 266, 112877. [Google Scholar] [CrossRef]

- Lee, H.-T.; Lee, J.-S.; Son, W.-J.; Cho, I.-S. Development of machine learning strategy for predicting the risk range of ship’s berthing velocity. J. Mar. Sci. Eng. 2020, 8, 376. [Google Scholar] [CrossRef]

- Liao, Y.; Jia, Z.; Zhang, W.; Jia, Q.; Li, Y. Layered berthing method and experiment of unmanned surface vehicle based on multiple constraints analysis. Appl. Ocean. Res. 2019, 86, 47–60. [Google Scholar] [CrossRef]

- Gravendeel, A.; Noorland, J.; Jacobs, S. Automatic Berthing; Mainport Rotterdam University: Rotterdam, Netherlands, 2017. [Google Scholar]

- Digerud, L.; Volden, Ø.; Christensen, K.A.; Kohtala, S.; Steinert, M. Vision-based positioning of Unmanned Surface Vehicles using Fiducial Markers for automatic docking. IFAC-Pap. Online 2022, 55, 78–84. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y. Estimation of ship berthing parameters based on Multi-LiDAR and MMW radar data fusion. Ocean. Eng. 2022, 266, 113155. [Google Scholar] [CrossRef]

- Hu, B.; Liu, X.; Jing, Q.; Lyu, H.; Yin, Y. Estimation of berthing state of maritime autonomous surface ships based on 3D LiDAR. Ocean. Eng. 2022, 251, 111131. [Google Scholar] [CrossRef]

- Chen, L.; Negenborn, R.; Huang, Y.; Hopman, H. Survey on cooperative control for waterborne transport. IEEE Intell. Transp. Syst. Mag. 2020, 13, 71–90. [Google Scholar] [CrossRef]

- Bitar, G.I. Towards the Development of Autonomous Ferries; NTNU: Trondheim, Norway, 2017. [Google Scholar]

- Zhang, Q.; Im, N.-K.; Ding, Z.; Zhang, M. Review on the research of ship automatic berthing control. In Offshore Robotics Volume I Issue 1, 2021; Springer: Singapore, 2022; pp. 87–109. [Google Scholar]

- de Kruif, B.J. Applied trajectory generation to dock a feeder vessel. IFAC-Pap. Online 2022, 55, 172–177. [Google Scholar] [CrossRef]

- Wang, X.; Deng, Z.; Peng, H.; Wang, L.; Wang, Y.; Tao, L.; Lu, C.; Peng, Z. Autonomous docking trajectory optimization for unmanned surface vehicle: A hierarchical method. Ocean. Eng. 2023, 279, 114156. [Google Scholar] [CrossRef]

- Bitar, G.; Martinsen, A.B.; Lekkas, A.M.; Breivik, M. Trajectory planning and control for automatic docking of ASVs with full-scale experiments. IFAC-Pap. Online 2020, 53, 14488–14494. [Google Scholar] [CrossRef]

- Rachman, D.M.; Maki, A.; Miyauchi, Y.; Umeda, N. Warm-started semionline trajectory planner for ship’s automatic docking (berthing). Ocean. Eng. 2022, 252, 111127. [Google Scholar] [CrossRef]

- Bidikli, B.; Tatlicioglu, E.; Zergeroglu, E. Robust dynamic positioning of surface vessels via multiple unidirectional tugboats. Ocean. Eng. 2016, 113, 237–245. [Google Scholar] [CrossRef]

- Du, Z.; Reppa, V.; Negenborn, R.R. Cooperative control of autonomous tugs for ship towing. IFAC-Pap. Online 2020, 53, 14470–14475. [Google Scholar] [CrossRef]

- Wu, G.; Zhao, X.; Sun, Y.; Wang, L. Cooperative maneuvering mathematical modeling for multi-tugs towing a ship in the port environment. J. Mar. Sci. Eng. 2021, 9, 384. [Google Scholar] [CrossRef]

- Wang, S.; Sun, Z.; Yuan, Q.; Sun, Z.; Wu, Z.; Hsieh, T.-H. Autonomous piloting and berthing based on Long Short Time Memory neural networks and nonlinear model predictive control algorithm. Ocean. Eng. 2022, 264, 112269. [Google Scholar] [CrossRef]

- Nguyen, V.S. Investigation on a novel support system for automatic ship berthing in marine practice. J. Mar. Sci. Eng. 2019, 7, 114. [Google Scholar] [CrossRef]

- Baek, S.; Woo, J. Model reference adaptive control-based autonomous berthing of an unmanned surface vehicle under environmental disturbance. Machines 2022, 10, 244. [Google Scholar] [CrossRef]

- Xu, Z.; Galeazzi, R. Guidance and Motion Control for Automated Berthing of Twin-waterjet Propelled Vessels. IFAC-Pap. Online 2022, 55, 58–63. [Google Scholar] [CrossRef]

- Martinsen, A.B.; Bitar, G.; Lekkas, A.M.; Gros, S. Optimization-based automatic docking and berthing of ASVs using exteroceptive sensors: Theory and experiments. IEEE Access 2020, 8, 204974–204986. [Google Scholar] [CrossRef]

- Mizuno, N.; Kuboshima, R. Implementation and evaluation of non-linear optimal feedback control for ship’s automatic berthing by recurrent neural network. IFAC-Pap. Online 2019, 52, 91–96. [Google Scholar] [CrossRef]

- Nguyen, V.S. Investigation of a multitasking system for automatic ship berthing in marine practice based on an integrated neural controller. Mathematics 2020, 8, 1167. [Google Scholar] [CrossRef]

- Mizuno, N.; Koide, T. Application of Reinforcement Learning to Generate Non-linear Optimal Feedback Controller for Ship’s Automatic Berthing System. IFAC-Pap. Online 2023, 56, 162–168. [Google Scholar] [CrossRef]

- Shimizu, S.; Nishihara, K.; Miyauchi, Y.; Wakita, K.; Suyama, R.; Maki, A.; Shirakawa, S. Automatic berthing using supervised learning and reinforcement learning. Ocean. Eng. 2022, 265, 112553. [Google Scholar] [CrossRef]

- Chopra, K. A Detailed Explanation of How a Ship Is Manoeuvered to a Port. Available online: https://www.marineinsight.com/guidelines/a-detailed-explanation-of-how-a-ship-is-manoeuvered-to-a-port/ (accessed on 4 March 2021).

- Wakita, K.; Akimoto, Y.; Rachman, D.M.; Miyauchi, Y.; Naoya, U.; Maki, A. Collision probability reduction method for tracking control in automatic docking/berthing using reinforcement learning. arXiv 2022, arXiv:2212.06415. [Google Scholar]

- Abkowitz, M.A. Lectures on Ship Hydrodynamics-Steering and Manoeuvrability; Hydro & Aerodynamic Laboratory: Lyngby, Denmark, 1964. [Google Scholar]

- Fossen, T.I. Handbook of Marine Craft Hydrodynamics and Motion Control; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Nomoto, K.; Taguchi, K.; Honda, K.; Hirano, S. On the steering qualities of ships. J. Zosen Kiokai 1956, 1956, 75–82. [Google Scholar] [CrossRef]

- Wang, Z.; Kim, J.; Im, N. Non-parameterized ship maneuvering model of Deep Neural Networks based on real voyage data-driven. Ocean. Eng. 2023, 284, 115162. [Google Scholar] [CrossRef]

- Ouyang, Z.; Liu, S.; Zou, Z. Nonparametric modeling of ship maneuvering motion in waves based on Gaussian process regression. Ocean. Eng. 2022, 264, 112100. [Google Scholar] [CrossRef]

- Im, N. A study on ship automatic berthing with assistance of auxiliary devices. Int. J. Nav. Archit. Ocean. Eng. 2012, 4, 199–210. [Google Scholar]

- Li, S.; Liu, J.; Negenborn, R.R.; Wu, Q. Automatic docking for underactuated ships based on multi-objective nonlinear model predictive control. IEEE Access 2020, 8, 70044–70057. [Google Scholar] [CrossRef]

- Piao, Z.; Guo, C.; Sun, S. Research into the automatic berthing of underactuated unmanned ships under wind loads based on experiment and numerical analysis. J. Mar. Sci. Eng. 2019, 7, 300. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, G.; Hu, X.; Yang, R. Adaptive neural network auto-berthing control of marine ships. Ocean. Eng. 2019, 177, 40–48. [Google Scholar] [CrossRef]

- Wu, G.; Zhao, X.; Wang, L. Modeling and Simulation of Automatic Berthing based on Bow and Stern Thruster Assist for Unmanned Surface Vehicle. J. Mar. Sci. Eng. 2021, 3, 16–21. [Google Scholar] [CrossRef]

- Ahmed, Y.A.; Hannan, M.A.; Siang, K.H. Artificial Neural Network controller for automatic ship berthing: Challenges and opportunities. Mar. Syst. Ocean. Technol. 2020, 15, 217–242. [Google Scholar] [CrossRef]

- Ahmed, Y.A.; Hasegawa, K. Automatic ship berthing using artificial neural network trained by consistent teaching data using nonlinear programming method. Eng. Appl. Artif. Intell. 2013, 26, 2287–2304. [Google Scholar] [CrossRef]

- Hasegawa, K.; Kitera, K. Mathematical model of manoeuvrability at low advance speed and its application to berthing control. In Proceedings of the 2nd Japan-Korea Joint Workshop of Ship and Marine Hydrodynamics, Osaka, Japan, 28–30 June 1993; pp. 144–153. [Google Scholar]

- Miyauchi, Y.; Maki, A.; Umeda, N.; Rachman, D.M.; Akimoto, Y. System parameter exploration of ship maneuvering model for automatic docking/berthing using CMA-ES. J. Mar. Sci. Technol. 2022, 27, 1065–1083. [Google Scholar] [CrossRef]

- Sawada, R.; Hirata, K.; Kitagawa, Y. Automatic berthing control under wind disturbances and its implementation in an embedded system. J. Mar. Sci. Technol. 2023, 452–470. [Google Scholar] [CrossRef]

- Okuda, R.; Yasukawa, H.; Yamashita, T.; Matsuda, A. Maneuvering simulations at large drift angles of a ship with a flapped rudder. Appl. Ocean. Res. 2023, 135, 103567. [Google Scholar] [CrossRef]

- Yoshimura, Y.; Nakao, I.; Ishibashi, A. Unified mathematical model for ocean and harbour manoeuvring. In Proceedings of the MARSIM2009, Panama City, FL, USA, 17–20 August 2009. [Google Scholar]

- ITTC. The Manoeuvring Committee Final Report and Recommendations. In Proceedings of the 25th International Towing Tank Conference (ITTC), Fukuoka, Japan, 14–20 September 2008. [Google Scholar]

- Holtrop, J.; Mennen, G. A statistical power prediction method. Int. Shipbuild. Prog. 1978, 25, 290. [Google Scholar] [CrossRef]

- Kijima, K.; Katsuno, T.; Nakiri, Y.; Furukawa, Y. On the manoeuvring performance of a ship with theparameter of loading condition. J. Soc. Nav. Archit. Jpn. 1990, 1990, 141–148. [Google Scholar] [CrossRef]

- Yoshimura, Y.; Masumoto, Y. Hydrodynamic database and manoeuvring prediction method with medium high-speed merchant ships and fishing vessels. In Proceedings of the International MARSIM Conference, Singapore, 23–27 April 2012; pp. 1–9. [Google Scholar]

- Pekic, S. TT-Line Starts Sea Trials of Its 1st Green Ship. Available online: https://www.offshore-energy.biz/tt-line-starts-sea-trials-of-their-1st-green-ship/ (accessed on 19 November 2021).

- Zhang, Z.; Zhang, Y.; Wang, J.; Wang, H. Parameter identification and application of ship maneuvering model based on TO-CSA. Ocean Eng. 2022, 266, 113128. [Google Scholar] [CrossRef]

- Liu, S.; Ouyang, Z.; Chen, G.; Zhou, X.; Zou, Z. Black-box modeling of ship maneuvering motion based on Gaussian process regression with wavelet threshold denoising. Ocean Eng. 2023, 271, 113765. [Google Scholar] [CrossRef]

- Astrom, K.J.; Kallstrom, C.; Norrbin, N.; Bystrom, L. The identification of linear ship steering dynamics using maximum likelihood parameter estimation. Medd. Från Statens Skeppsprovningsanst. 1975, 75, 105. [Google Scholar]

- Banazadeh, A.; Ghorbani, M. Frequency domain identification of the Nomoto model to facilitate Kalman filter estimation and PID heading control of a patrol vessel. Ocean Eng. 2013, 72, 344–355. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, X.; Pang, H. Multi-innovation auto-constructed least squares identification for 4 DOF ship manoeuvring modelling with full-scale trial data. ISA Trans. 2015, 58, 186–195. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, Z.; Zou, Z. Black-box modeling of ship maneuvering motion based on multi-output nu-support vector regression with random excitation signal. Ocean Eng. 2022, 257, 111279. [Google Scholar] [CrossRef]

- Xu, H.; Soares, C.G. Hydrodynamic coefficient estimation for ship manoeuvring in shallow water using an optimal truncated LS-SVM. Ocean Eng. 2019, 191, 106488. [Google Scholar] [CrossRef]

- He, H.; Wang, Z.; Zou, Z.; Liu, Y. Nonparametric modeling of ship maneuvering motion based on self-designed fully connected neural network. Ocean Eng. 2022, 251, 111113. [Google Scholar] [CrossRef]

- Jiang, Y.; Hou, X.; Wang, X.; Wang, Z.; Yang, Z.; Zou, Z. Identification modeling and prediction of ship maneuvering motion based on LSTM deep neural network. J. Mar. Sci. Technol. 2022, 27, 125–137. [Google Scholar] [CrossRef]

- Guo, H.; Zou, Z.; Liu, Y.; Wang, F. Investigation on hull-propeller-rudder interaction by RANS simulation of captive model tests for a twin-screw ship. Ocean Eng. 2018, 162, 259–273. [Google Scholar] [CrossRef]

- Liu, Y.; Zou, L.; Zou, Z.; Guo, H. Predictions of ship maneuverability based on virtual captive model tests. Eng. Appl. Comput. Fluid Mech. 2018, 12, 334–353. [Google Scholar] [CrossRef]

- Liu, J.; Hekkenberg, R.; Quadvlieg, F.; Hopman, H.; Zhao, B. An integrated empirical manoeuvring model for inland vessels. Ocean Eng. 2017, 137, 287–308. [Google Scholar] [CrossRef]

- Lu, S.; Cheng, X.; Liu, J.; Li, S.; Yasukawa, H. Maneuvering modeling of a twin-propeller twin-rudder inland container vessel based on integrated CFD and empirical methods. Appl. Ocean. Res. 2022, 126, 103261. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, Q.; Liu, J.; He, Y.; Li, S. Twin-screw ASD tug maneuvering prediction based on integrated CFD and empirical methods. Ocean Eng. 2023, 269, 113489. [Google Scholar] [CrossRef]

- Li, S.; Liu, C.; Chu, X.; Zheng, M.; Wang, Z.; Kan, J. Ship maneuverability modeling and numerical prediction using CFD with body force propeller. Ocean Eng. 2022, 264, 112454. [Google Scholar] [CrossRef]

- Jia, X.; Yang, Y. Ship motion mathematical model: Mechanism modeling and identification modeling; Dalian Maritime University Press: Dalian, China, 1999. [Google Scholar]

- Sutulo, S. Extension of polynomial ship mathematical models to arbitrary manoeuvres. In Proceedings of the The International Shipbuilding Conference in Commemoration of the Centenary of the Krylov Ship Research Institute (ISC), St. Petersburg, Russia, 8–12 October 1994; pp. 291–298. [Google Scholar]

- Sutulo, S.; Soares, C.G. Development of a core mathematical model for arbitrary manoeuvres of a shuttle tanker. Appl. Ocean. Res. 2015, 51, 293–308. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirata, N.; Nakayama, Y.; Matsuda, A. Drifting of a dead ship in wind. Ship Technol. Res. 2023, 70, 26–45. [Google Scholar] [CrossRef]

- Inoue, S.; Hirano, M.; Kijima, K. Hydrodynamic derivatives on ship manoeuvring. Int. Shipbuild. Prog. 1981, 28, 112–125. [Google Scholar] [CrossRef]

- Yoshimura, Y. Mathematical model for the manoeuvring ship motion in shallow water (2nd Report)-Mathematical model at slow forward speed. J. Kansai Soc. Nav. Archit. Jpn. 1988, 210, 77–84. [Google Scholar]

- Oltmann, P.; Sharma, S. Simulation of Combined Engine and Rudder Maneuvers Using an Improved Model of Hull-Propeller-Rudder Interactions; Hamburg University of Technology: Hamburg, Germany, 1984. [Google Scholar]

- Yasukawa, H.; Ishikawa, T.; Yoshimura, Y. Investigation on the rudder force of a ship in large drifting conditions with the MMG model. J. Mar. Sci. Technol. 2021, 26, 1078–1095. [Google Scholar] [CrossRef]

- Van Lammeren, W.; van Manen, J.v.; Oosterveld, M. The Wageningen B-Screw Series; National Academy of Sciences: Washington, DC, USA, 1969; Volume 77, p. 43. [Google Scholar]

- Yoshimura, Y.; Sasaki, N.; Takekawa, M. Prediction of ship manoeuvrability with a flapped rudder. J. Soc. Nav. Archit. Jpn. 1997, 1997, 191–196. [Google Scholar] [CrossRef]

- Huang, G.; Li, X.; Zhu, Y.; Nie, S. Experimental Study on Reaction Thrust Characteristics of Water Jet for Conical Nozzle. China Ocean Eng. 2009, 23, 669–678. [Google Scholar]

- Jiang, F.; Li, Y.; Gong, J. Study on the manoeuvre characteristics of a trimaran under different layouts by water-jet self-propulsion model test. Appl. Ocean. Res. 2021, 108, 102550. [Google Scholar] [CrossRef]

- Reichel, M. Prediction of manoeuvring abilities of 10000 DWT pod-driven coastal tanker. Ocean Eng. 2017, 136, 201–208. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirata, N.; Tanaka, S.; Kose, K. Study on Maneuverability of a Ship with Azimuthing Propellers. J. Jpn. Soc. Nav. Archit. Ocean. Eng. 2009, 9, 155–165. [Google Scholar]

- ITTC. ITTC Recommended Procedures and Guidelines. In Free Running Model Tests; No. 7.5-02-06-01; ITTC: Lawrence, KS, USA, 2008. [Google Scholar]

- Vantorre, M.; Eloot, K.; Delefortrie, G.; Lataire, E.; Candries, M.; Verwilligen, J. Maneuvering in shallow and confined water. In The Encyclopedia of Marine Offshore Engineering; Wiley Online Library: Hoboken, NJ, USA, 2017; pp. 1–17. [Google Scholar]

- Pianc. Capability of ship manoeuvring simulation models for approach channels and fairways in harbours. In Report of Working Group no. 20 of Permanent Technical Committee II. Supplement to Bulletin no. 77; Pianc: Brussels, Belgium, 1992. [Google Scholar]

- Havelock, T.H. The propagation of groups of waves in dispersive media, with application to waves on water produced by a travelling disturbance. Proc. R. Soc. London. Ser. A Contain. Pap. A Math. Phys. Character 1908, 81, 398–430. [Google Scholar]

- Delefortrie, G.; Eloot, K.; Lataire, E.; Van Hoydonk, W.; Vantorre, M. Captive model tests based 6 DOF shallow water manoeuvring model. In Proceedings of the 4th MASHCON-International Conference on Ship Manoeuvring in Shallow and Confined Water with Special Focus on Ship Bottom Interaction, Hamburg, Germany, 23–25 May 2016; pp. 273–286. [Google Scholar]

- Eloot, K. Selection, Experimental Determination and Evaluation of a Mathematical Model for Ship Manoeuvring in Shallow Water; Ghent University: Ghent, Belgium, 2006. [Google Scholar]

- Liu, Y.; Zou, Z.; Zou, L.; Fan, S. CFD-based numerical simulation of pure sway tests in shallow water towing tank. Ocean Eng. 2019, 189, 106311. [Google Scholar] [CrossRef]

- Zeng, Q.; Hekkenberg, R.; Thill, C. On the viscous resistance of ships sailing in shallow water. Ocean Eng. 2019, 190, 106434. [Google Scholar] [CrossRef]

- Yoshimura, Y.; Sakurai, H. Mathematical Model for the Manoeuvring Ship Motion in Shallow Water (3rd Report: Manoeuvrability of a Twin-propeller Twinrudder ship). J. Kansai Soc. Nav. Archit. Jpn. 1989, 211, 115–126. [Google Scholar]

- Yoshimura, Y. Mathematical model for the manoeuvring ship motion in shallow water-Application of MMG mathematical model to shallow water. J. Kansai Soc. Nav. Archit. Jpn. 1986, 200, 42–51. [Google Scholar]

- Kijima, K.; Yoshimura, Y.; Takashina, J. Report of MSS. 2: Mathematical model for ship maneuverability in shallow water. Bull. Soc. Nav. Archit. Jpn. 1989, 718, 207–220. [Google Scholar]

- ITTC. The Manoeuvring Committee–Final Report and Recommendations to the 23rd ITTC. In Proceedings of the Proceedings of the 23rd ITTC, Venice, Italy, 8–14 September 2002; pp. 153–234.

- Liu, H.; Ma, N.; Gu, X. Ship–bank interaction of a VLCC ship model and related course-keeping control. Ships Offshore Struct. 2017, 12, S305–S316. [Google Scholar] [CrossRef]

- Duan, W.; Liu, J.; Chen, J.; Wang, L. Comparison research of ship-to-ship hydrodynamic interaction in restricted water between TEBEM and other computational method. Ocean Eng. 2020, 202, 107168. [Google Scholar] [CrossRef]

- Lataire, E.; Vantorre, M.; Laforce, E.; Eloot, K.; Delefortrie, G. Navigation in confined waters: Influence of bank characteristics on ship-bank interaction. In Proceedings of the International Conference on Marine Research and Transportation, ICMRT, Naples, Italy, 19–21 September 2007; pp. 1–9. [Google Scholar]

- Norrbin, N.H. Bank clearance and optimal section shape for ship canals. In Proceedings of the 26th PIANC international navigation congress, Brussels, Belgium, 16–28 June 1985; pp. 167–178. [Google Scholar]

- Kijima, K. Calculation of the Derivatives on Ship Manoeuvring in Narrow Waterways by Rectangular Plate. J. Soc. Nav. Archit. Jpn. 1972, 1972, 155–163. [Google Scholar] [CrossRef]

- Yasukawa, H. Bank effect on ship maneuverability in a channel with varying width. Proc. Trans. West-Jpn. Soc. Nav. Archit. 1991, 81, 85–100. [Google Scholar]

- DeMarco Muscat-Fenech, C.; Sant, T.; Zheku, V.V.; Villa, D.; Martelli, M. A Review of Ship-to-Ship Interactions in Calm Waters. J. Mar. Sci. Eng. 2022, 10, 1856. [Google Scholar] [CrossRef]

- Vantorre, M.; Verzhbitskaya, E.; Laforce, E. Model test based formulations of ship-ship interaction forces. Ship Technol. Res. 2002, 49, 124–141. [Google Scholar]

- Fujiwara, T.; Ueno, M.; Nimura, T. Estimation of Wind Forces and Moments acting on Ships. J. Soc. Nav. Archit. Jpn. 1998, 1998, 77–90. [Google Scholar] [CrossRef]

- Isherwood, R.M. Wind resistance of merchant ships. Trans. RINA 1973, 115, 327–338. [Google Scholar]

- Yoshimura, Y.; Nagashima, J. Estimation of the Manoeuvring Behaviour of Ship in Uniform Wind. J. Soc. Nav. Archit. Jpn. 1985, 1985, 125–136. [Google Scholar] [CrossRef]

- Fitriadhy, A.; Yasukawa, H. Course stability of a ship towing system. Ship Technol. Res. 2011, 58, 4–23. [Google Scholar] [CrossRef]

- Kijima, K.; Varyani, K. Wind effect on course stability of two towed vessels. J. Soc. Nav. Archit. Jpn. 1985, 1985, 137–148. [Google Scholar] [CrossRef]

- Kijima, K.; Wada, Y. Course stability of towed vessel with wind effect. J. Soc. Nav. Archit. Jpn. 1983, 1983, 117–126. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirono, T.; Nakayama, Y.; Koh, K.K. Course stability and yaw motion of a ship in steady wind. J. Mar. Sci. Technol. 2012, 17, 291–304. [Google Scholar] [CrossRef]

- Wang, Y.; Du, W.; Li, G.; Li, Z.; Hou, J.; Hu, H. Efficient Ship Maneuvering Prediction with Wind, Wave and Current Effects; IOS Press: Clifton, VA, USA, 2022. [Google Scholar]

- Chislett, M.S.; Wied, S. A note on the mathematical modelling of ship manoeuvring in relation to a nautical environment with particular reference to currents. In Proceedings of the International Conference on Numerical and Hydraulic Modelling of Ports and Harbours, Birmingham, UK, 23–25 April 1985; pp. 1–11. [Google Scholar]

- Zhou, Y.; Daamen, W.; Vellinga, T.; Hoogendoorn, S.P. Impacts of wind and current on ship behavior in ports and waterways: A quantitative analysis based on AIS data. Ocean Eng. 2020, 213, 107774. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, Z.; Dai, Y.; Zhang, Z.; Wang, P. An experimental and numerical investigation on hydrodynamic characteristics of the bow thruster. Ocean Eng. 2020, 209, 107348. [Google Scholar] [CrossRef]

- Koh, K.K.; Yasukawa, H.; Hirata, N.; Kose, K. Maneuvering simulations of pusher-barge systems. J. Mar. Sci. Technol. 2008, 13, 117–126. [Google Scholar]

- Fitriadhy, A.; Yasukawa, H.; Maimun, A. Theoretical and experimental analysis of a slack towline motion on tug-towed ship during turning. Ocean. Eng. 2015, 99, 95–106. [Google Scholar] [CrossRef]

- Fujino, M.; Saruta, T.; IDA, T. Experimental studies on the effectiveness of the side thruster. J. Kansai Soc. Nav. Archit. 1978, 168, 35–44. [Google Scholar]

- Kijima, K. The Effect of Drift Angle on Side Thruster Performance. Trans. West-Jpn. Soc. Nav. Archit. 1977, 54, 179–192. [Google Scholar]

- Zhang, S.; Liu, J.; Li, S.; Ye, J. System design and key technology of ship automatic berthing and unberthing. China Ship Surv. 2022, 10, 42–47. [Google Scholar]

- Yang, Y. Study on ship manoeuvring mathematical model in shiphandling simulator. In Marine Simulation and Ship Manoeuvrability; Routledge: London, UK, 1996; pp. 607–615. [Google Scholar]

- Yang, Y. Study on mathematical model for simulating ship berthing or unberthing (in Chinese). J. Dalian Marit. Univ. 1996, 22, 11–15. [Google Scholar]

- Yang, Y.; Fang, X. Study on Ship Maneuvering Mathematical Model with Assistance of Tugs in the Harbor. Navig. China 1997, 2, 19–24. (In Chinese) [Google Scholar]

- Koh, K.K.; Yasukawa, H. Comparison study of a pusher–barge system in shallow water, medium shallow water and deep water conditions. Ocean Eng. 2012, 46, 9–17. [Google Scholar] [CrossRef]

- Koh, K.K.; Yasukawa, H.; Hirata, N. Hydrodynamic derivatives investigation of unconventionally arranged pusher-barge systems. J. Mar. Sci. Technol. 2008, 13, 256–268. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirata, N.; Koh, K.K.; Krisana, P.; Kose, K. Hydrodynamic Force Chracteristics on Maneuvering of Pusher-Barge Systems. J. Jpn. Soc. Nav. Archit. Ocean. Eng. 2007, 5, 133–142. [Google Scholar] [CrossRef][Green Version]

- Fitriadhy, A.; Yasukawa, H. Turning ability of a ship towing system. Ship Technol. Res. 2011, 58, 112–124. [Google Scholar] [CrossRef]

- Kishimoto, T.; Kijima, K. The manoeuvring characteristics on tug-towed ship systems. IFAC Proc. Vol. 2001, 34, 173–178. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirata, N.; Nakamura, N.; Matsumoto, Y. Simulations of Slewing Motion of a Towed Ship. J. Jpn. Soc. Nav. Archit. Ocean. Eng. 2006, 4, 137–146. [Google Scholar] [CrossRef]

- Yasukawa, H.; Hirata, N.; Yokoo, R.; Fitriadhy, A. Slack Towline of Tow and Towed Ships during Turning. J. Jpn. Soc. Nav. Archit. Ocean. Eng. 2012, 16, 41–48. [Google Scholar]

| Name | Type | Date | Affiliations | Overview for Development | |

|---|---|---|---|---|---|

| Asia | Shioji Maru | Training ship (49 m) | 2018 | MES-S, MOL, TUMST, etc. |

|

| Sunflower Shiretoko | Car ferry (190 m) | 2022 | MOL Ferry |

| |

| Mikage | Container ship (95.4 m, 194TEU) | 2022 | MOL Ferry |

| |

| / | System | 2020 | KASS |

| |

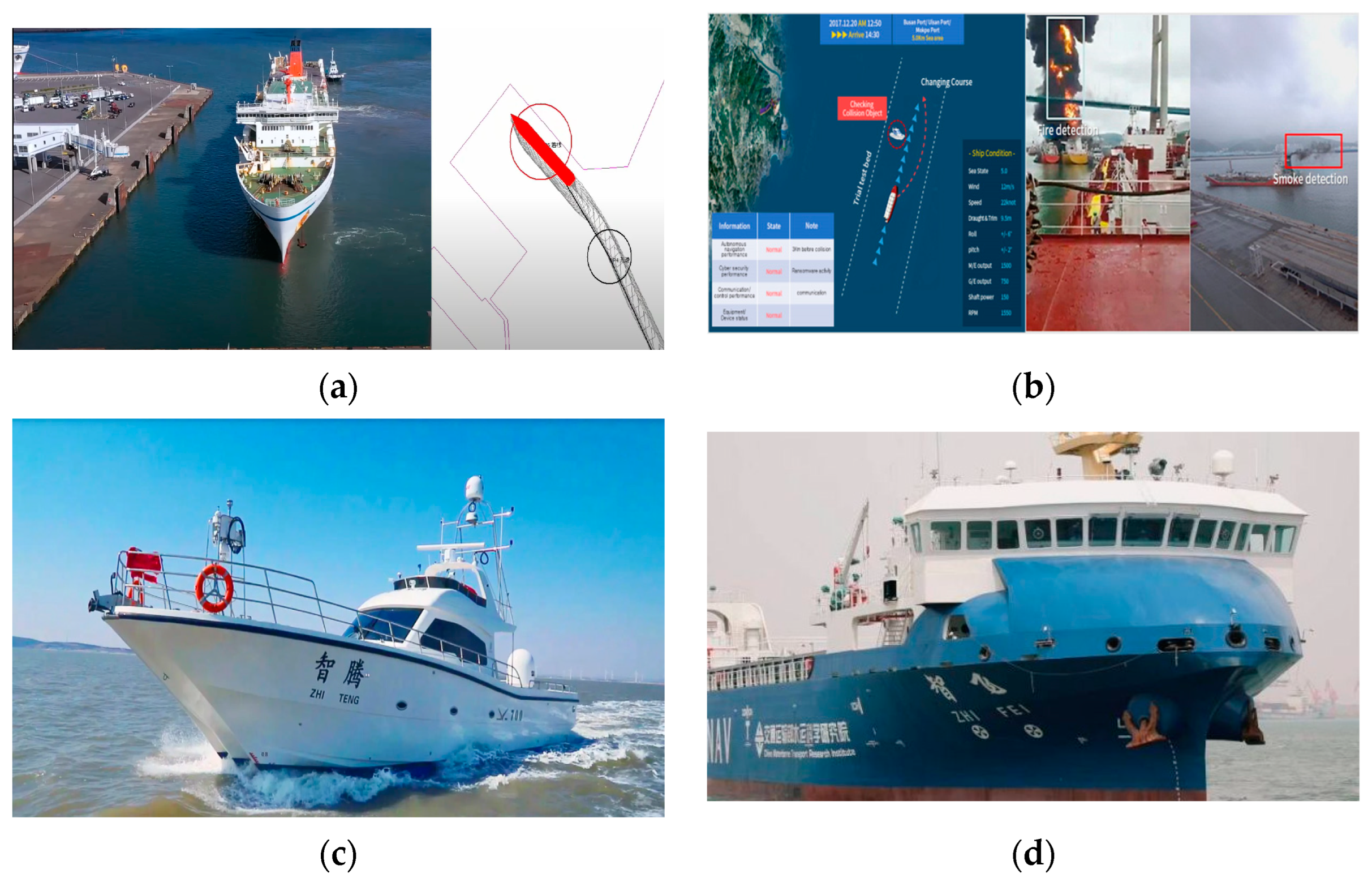

| ZhiTeng | Training ship (21 m) | 2019 | China waterborne transport research institute, etc. |

| |

| ZhiFei | Container ship (117 m, 300TEU) | 2021 | China waterborne transport research institute, etc. |

| |

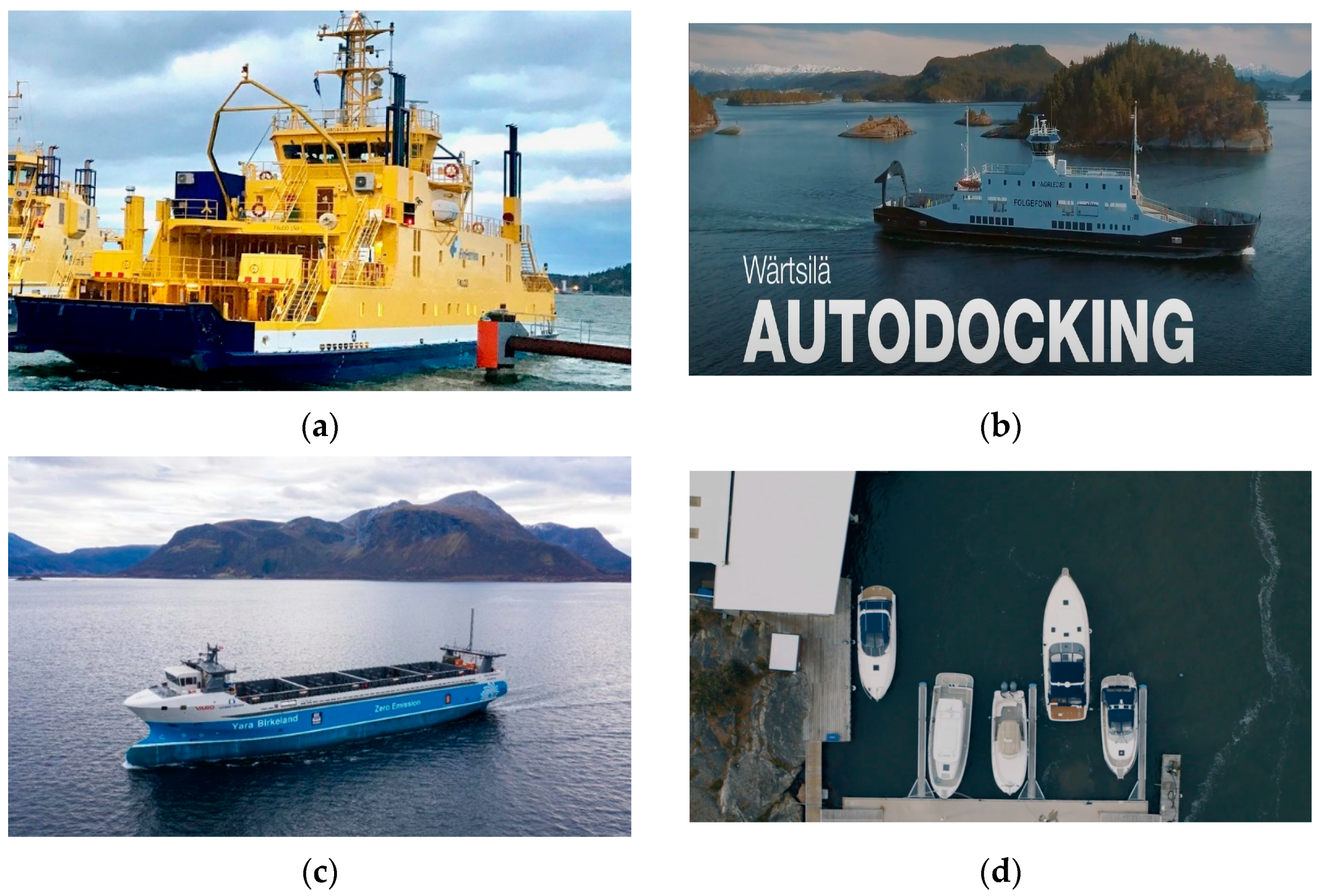

| Europe | Falco | Car ferry (53.8 m) | 2018 | Rolls-Royce |

|

| Folgefonn | Ferry (83 m) | 2018 | Wartsilia |

| |

| YARA Birkeland | Container ship (117 m, 300TEU) | 2021 | Kongsberg and Yara |

| |

| PENTA | Fully integrated assisted docking system | 2021 | Volvo Penta |

|

| Indices | Conventional MMG Model | MMG Berthing Maneuver Model | ||

|---|---|---|---|---|

| Similarities | Modeling methods | Data-based System-based CFD-based | Data-based System-based CFD-based | |

| Differences | Hull | Ship speed | 0.1 < Fr < 0.3 | Fr < 0.1 |

| Drifting | |β| = [0, 20°] |r’| = [0, 0.6] | |β| = [0, 180°] |r’| > 0.6 | ||

| Rotation rate | ||||

| Propulsion, Steerage devices | Thruster | First-quadrant inflow angle | Four-quadrant inflow angle | |

| Rudder | Small resultant inflow angle High rudder effect | Large resultant inflow angle Low rudder effect | ||

| External disturbance | Insensitive | Vulnerable and sensitive | ||

| Auxiliary devices | None | Side thruster, tug, and cable | ||

| Prediction Methods | Advantages | Disadvantages | |

|---|---|---|---|

| Data-based | Full/model-scale free-running tests |

|

|

| Captive model tests |

|

| |

| Empirical methods |

|

| |

| System-based | Grey box |

|

|

| Black box |

| ||

| CFD-based | Virtual captive model tests |

|

|

| Direct simulation | |||

| Integrated method |

|

|

| Motion | Quadrant | θp | U | np |

|---|---|---|---|---|

| ahead ship ahead telegraph | Ⅰ | 0–90° | ahead | normal |

| ahead ship astern telegraph | Ⅱ | 90°–180° | ahead | reverse |

| astern ship astern telegraph | Ⅲ | −180°–−90° | astern | reverse |

| astern ship ahead telegraph | Ⅳ | −90°–0 | astern | normal |

| Propulsion | Advantages | Disadvantages |

|---|---|---|

| Conventional propulsion |

|

|

| Azimuth electric diesel |

|

|

| Mechanically azimuth thruster |

|

|

| Stern-bow thrusters |

|

|

| Water-jet propulsion |

|

|

| Water-jet thrusters |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Wu, Q.; Liu, J.; He, Y.; Li, S. State-of-the-Art Review and Future Perspectives on Maneuvering Modeling for Automatic Ship Berthing. J. Mar. Sci. Eng. 2023, 11, 1824. https://doi.org/10.3390/jmse11091824

Zhang S, Wu Q, Liu J, He Y, Li S. State-of-the-Art Review and Future Perspectives on Maneuvering Modeling for Automatic Ship Berthing. Journal of Marine Science and Engineering. 2023; 11(9):1824. https://doi.org/10.3390/jmse11091824

Chicago/Turabian StyleZhang, Song, Qing Wu, Jialun Liu, Yangying He, and Shijie Li. 2023. "State-of-the-Art Review and Future Perspectives on Maneuvering Modeling for Automatic Ship Berthing" Journal of Marine Science and Engineering 11, no. 9: 1824. https://doi.org/10.3390/jmse11091824

APA StyleZhang, S., Wu, Q., Liu, J., He, Y., & Li, S. (2023). State-of-the-Art Review and Future Perspectives on Maneuvering Modeling for Automatic Ship Berthing. Journal of Marine Science and Engineering, 11(9), 1824. https://doi.org/10.3390/jmse11091824