A Review of Recent Developments in Friction Stir Welding for Various Industrial Applications

Abstract

1. Introduction

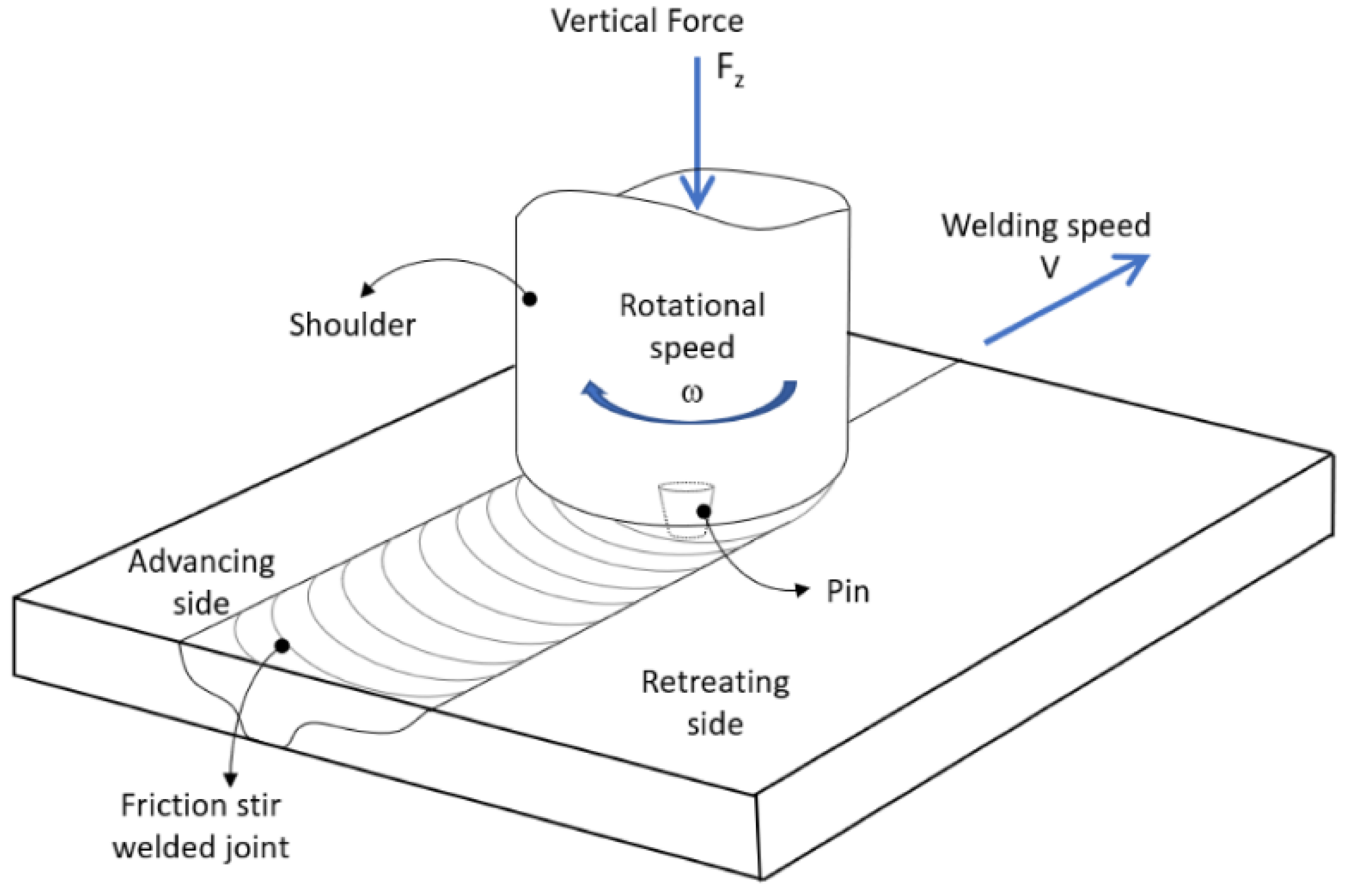

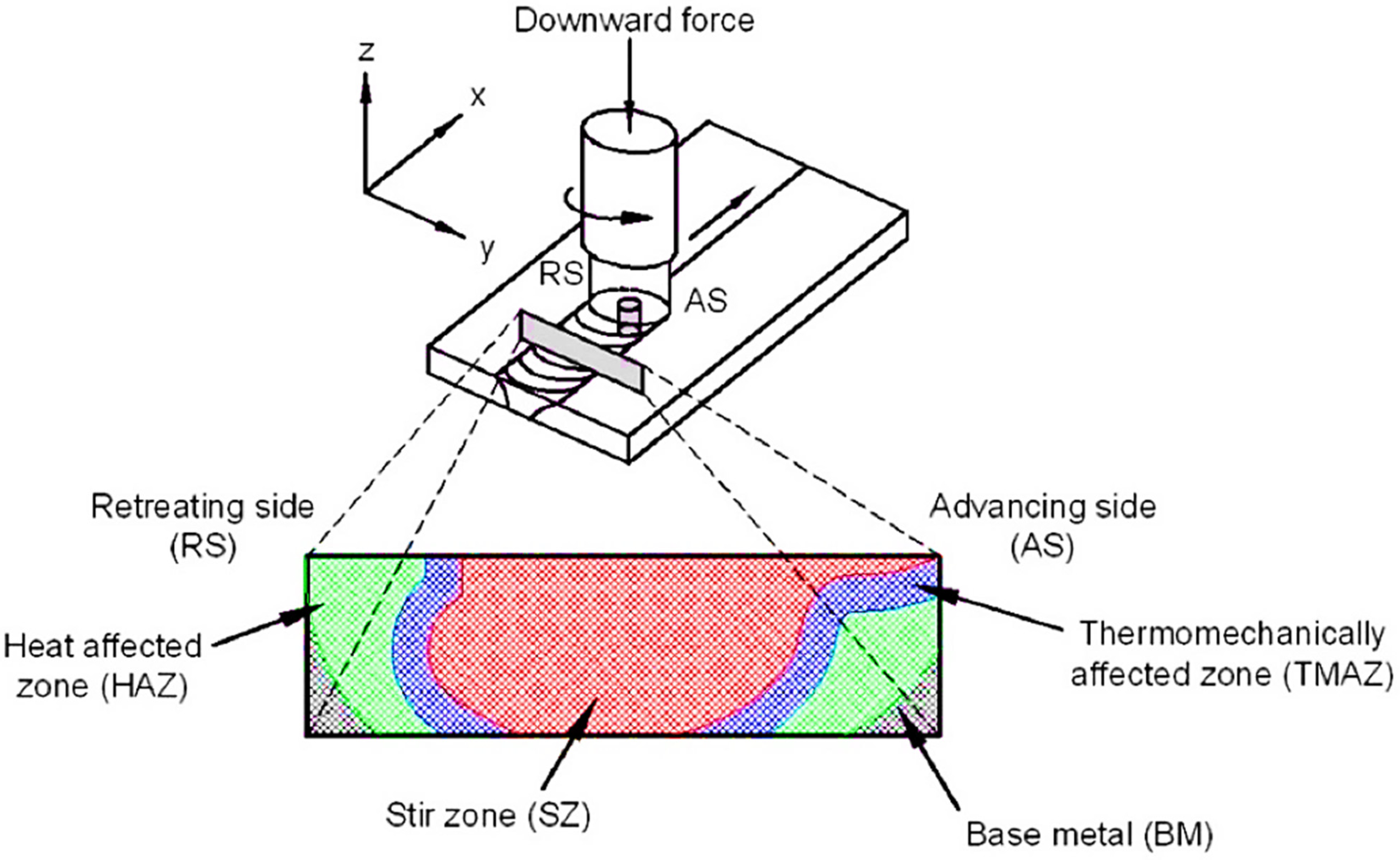

2. Fundamentals of Friction Stir Welding

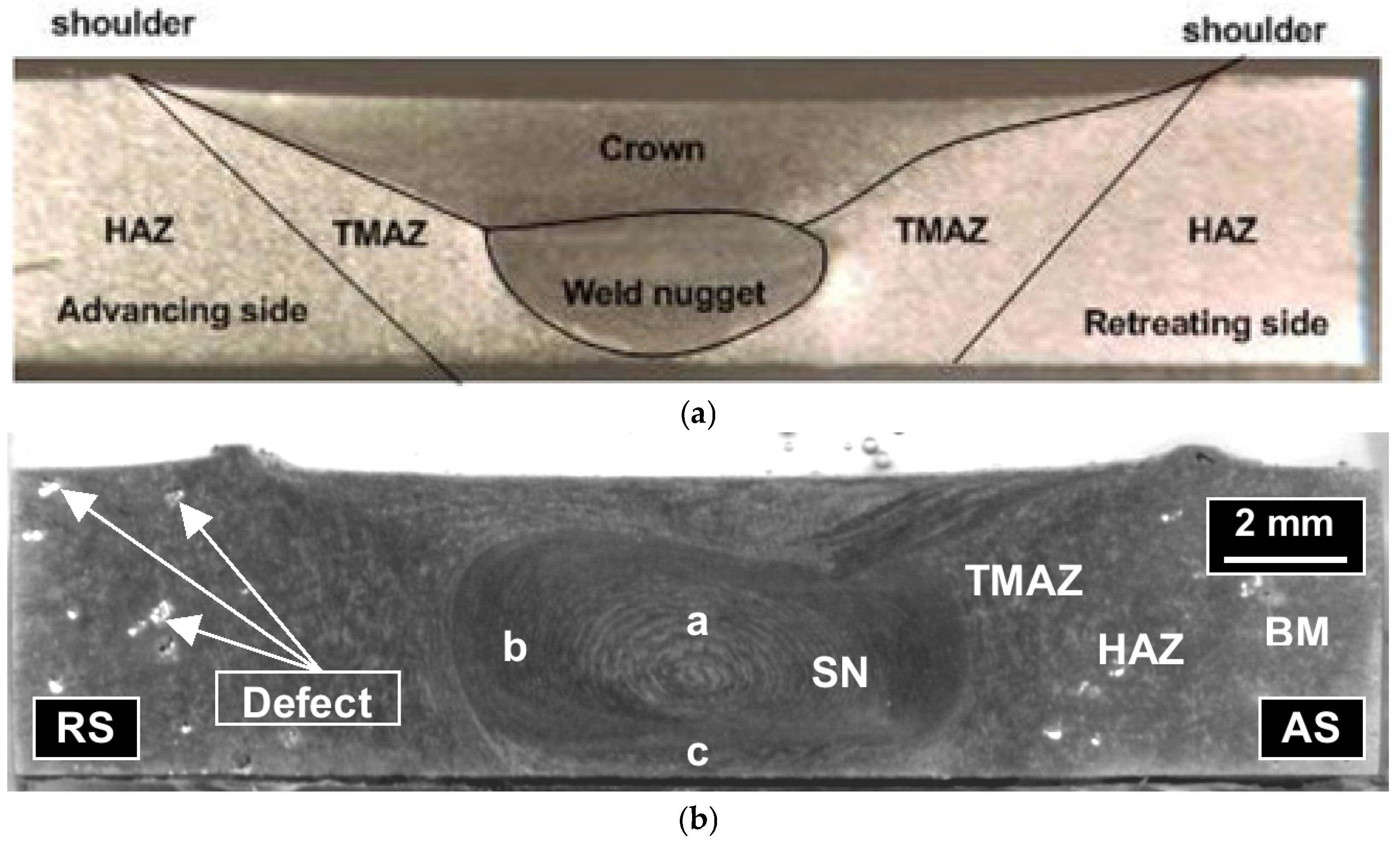

2.1. Tool Design and Material Flow in the FSW Process

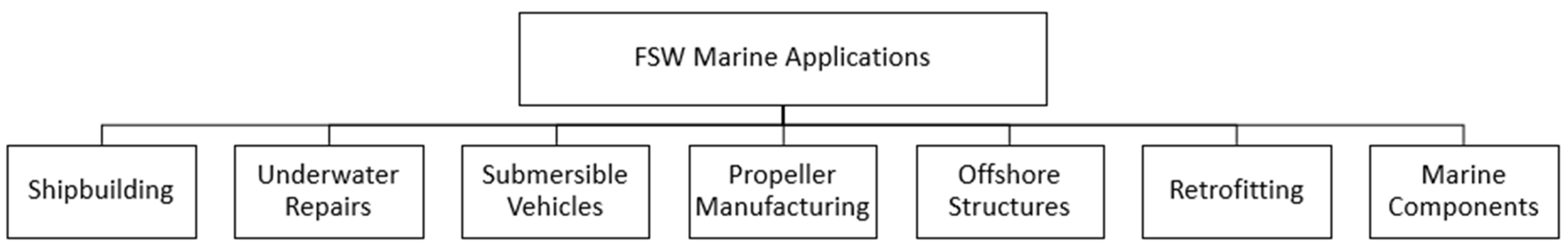

2.2. FSW in Marine Applications

2.3. Parameters Influencing the FSW Process

3. Friction Stir Welding for Marine Applications

4. Recent Technological Advancements in Friction Stir Welding

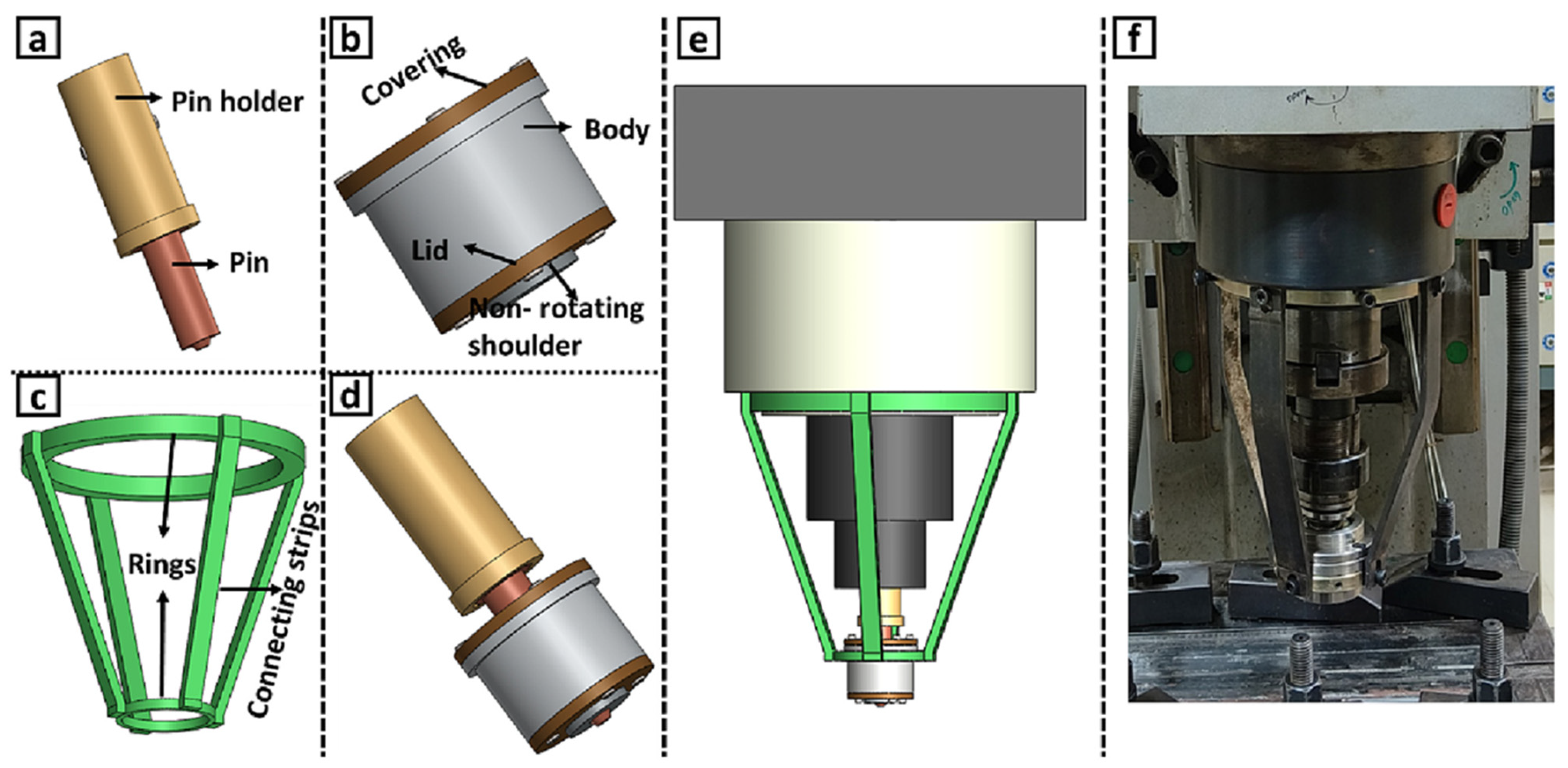

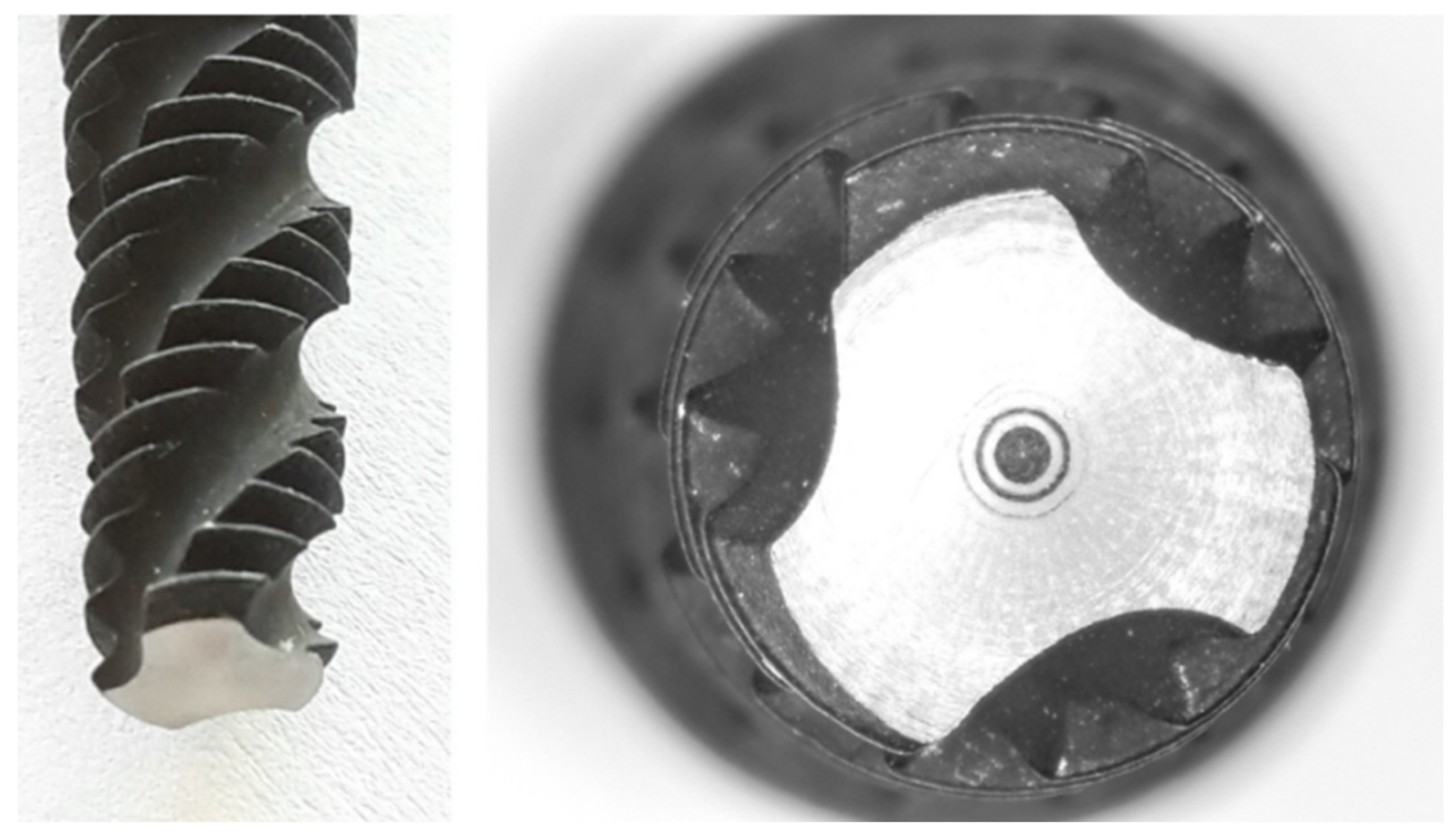

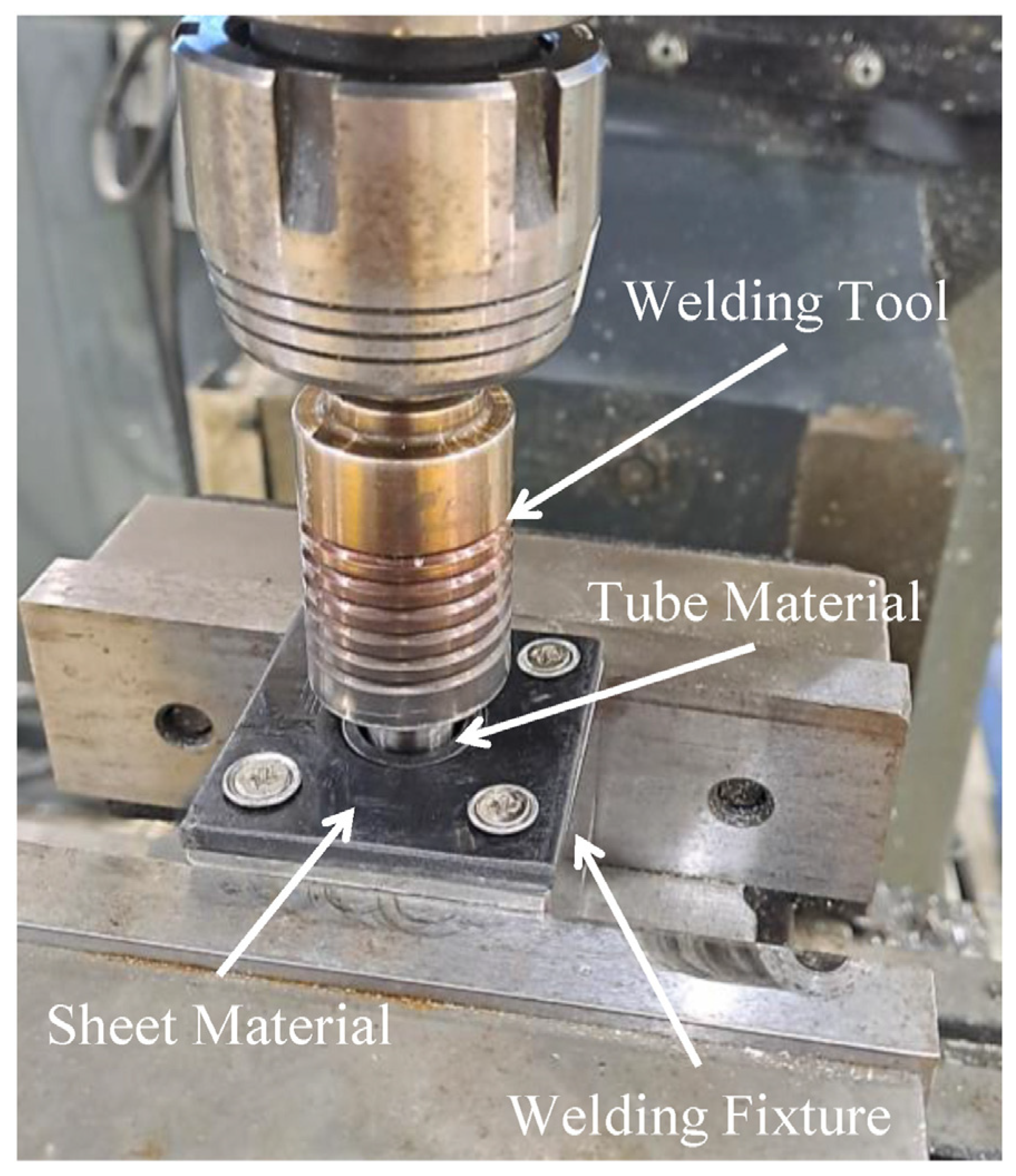

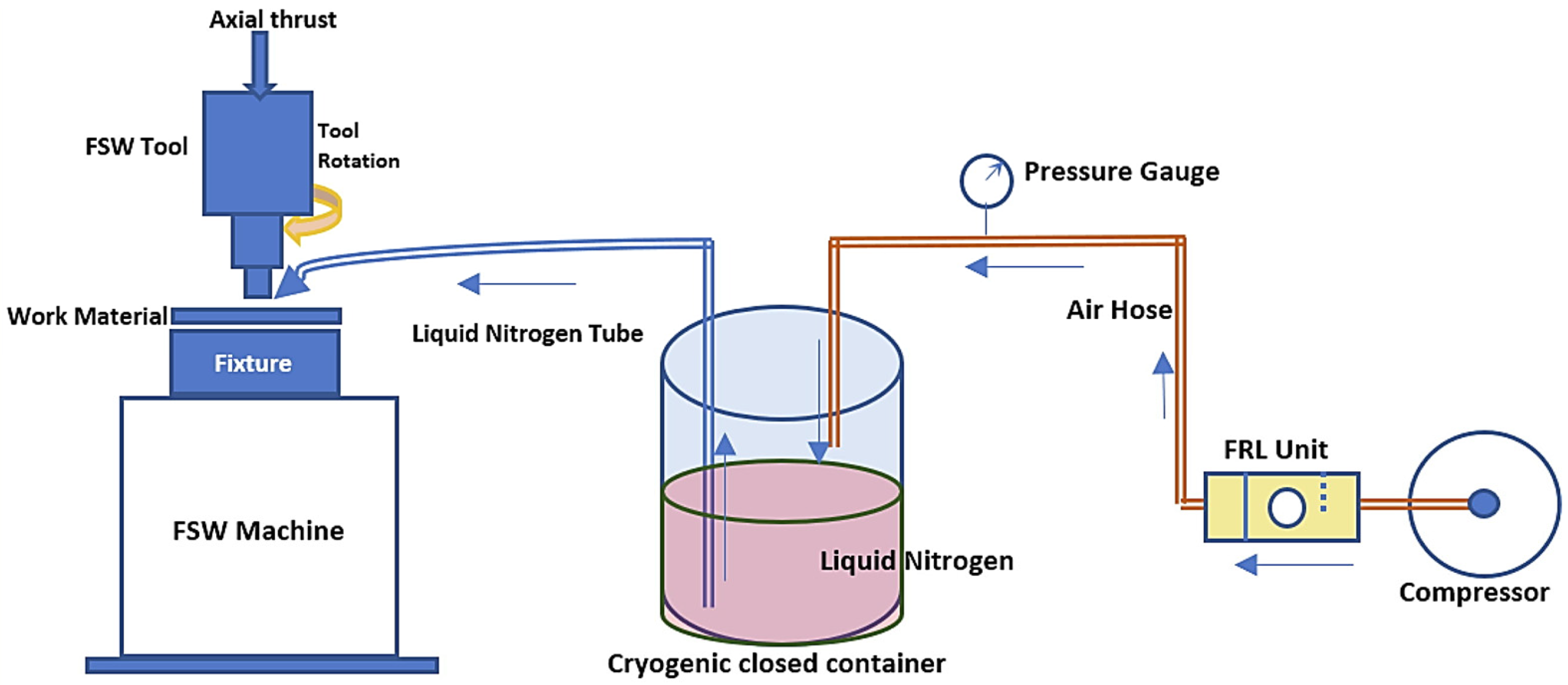

4.1. Developments in Friction Stir Welding Tools and their Design

4.2. Material Combination and Process Optimization Developments

4.3. Use of Machine Learning and Artificial Intelligence (AI) in Friction Stir Welding

5. Microstructural and Mechanical Characterization

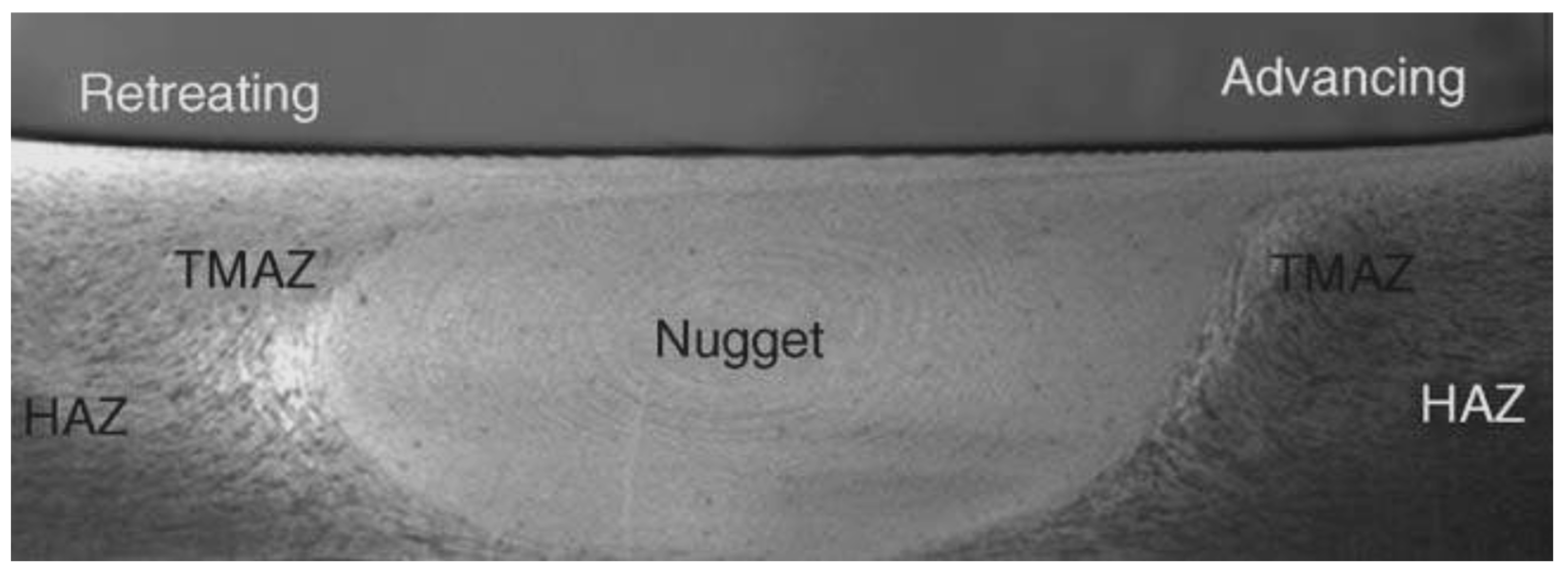

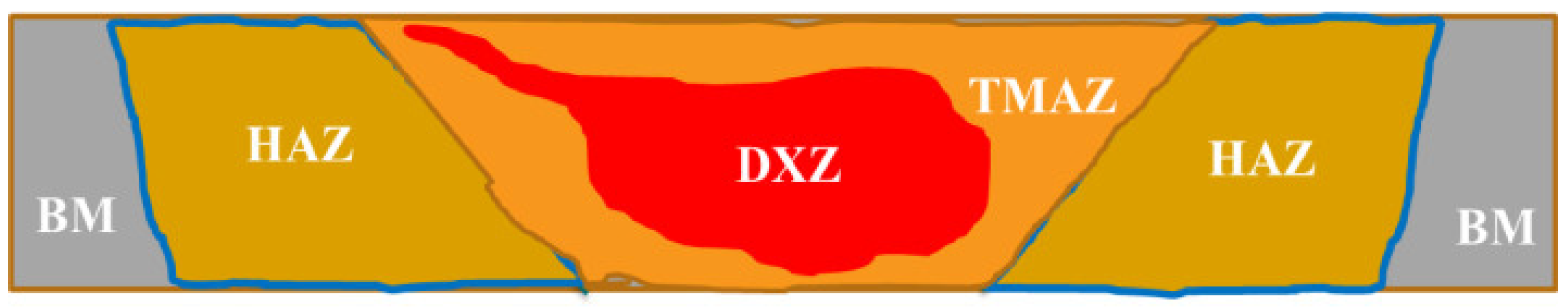

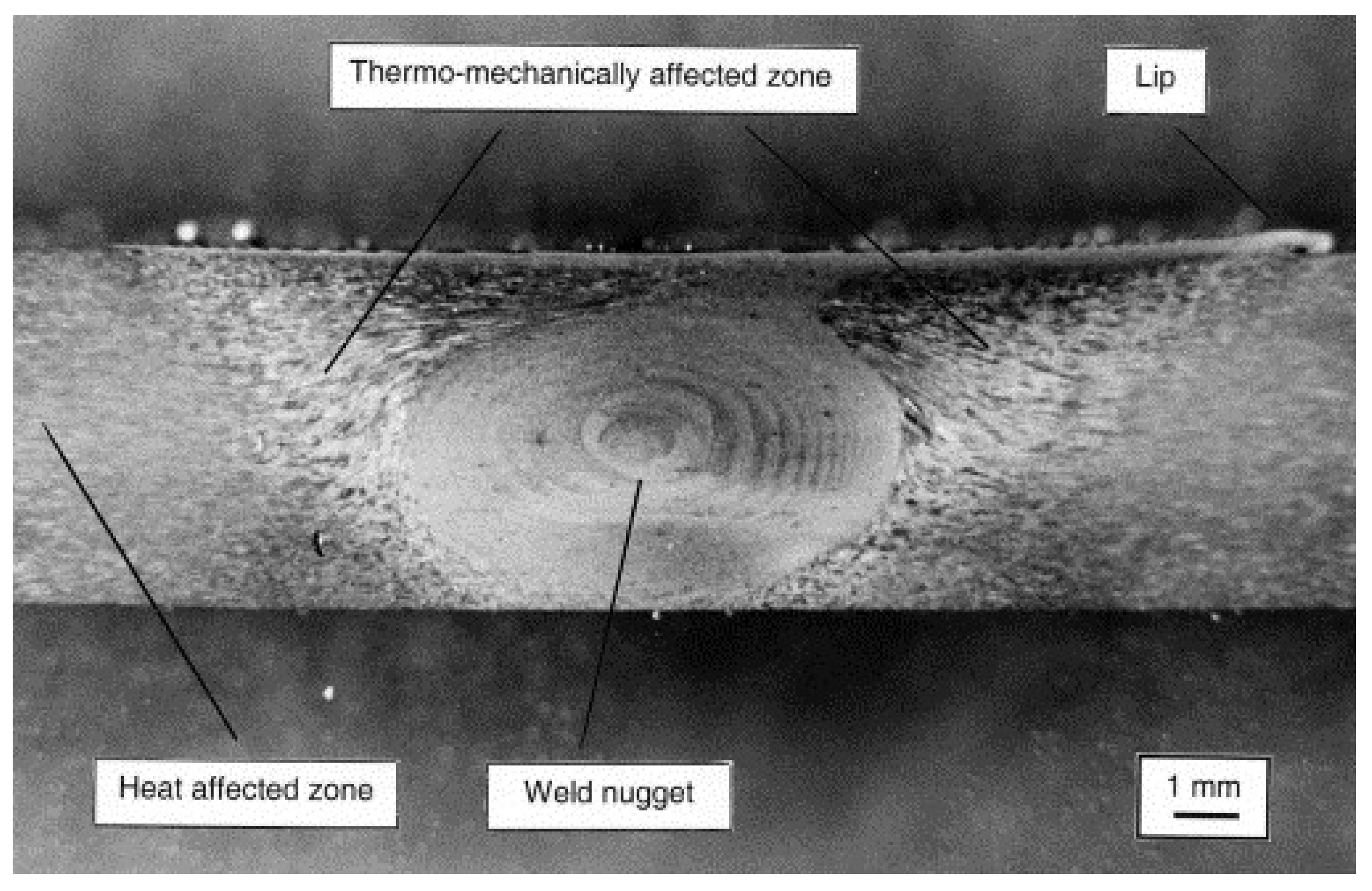

5.1. Microstructural Changes Occurring during FSW

5.2. Enhancement in the Mechanical Properties of FSW Joints

5.3. Inclusion of Studies on the Effect of Welding Parameters on the Microstructure and Mechanical Properties

6. Corrosion Mitigation and Surface Protection

7. Future Trends of FSW

8. Concluding Remarks and Future Studies

- →

- The study investigates the influence of FSW parameters on material microstructural changes, revealing that tool stirring, grain refining, and super plasticity enhance the joint mechanical properties, enhancing the efficiency and economic feasibility in marine applications. It emphasizes the need for materials compatible with FSW to withstand harsh marine conditions and reduce corrosion.

- →

- This paper explores future research in FSW for maritime engineering, highlighting the need to integrate environmental and economic factors for sustainability and cost efficiency in large-scale marine endeavors. The maritime sector should develop methodologies that enhance efficiency and productivity while mitigating its ecological impact. The paper highlights the significant contribution of FSW to these objectives and encourages its full utilization.

- →

- The study highlights the significant impact of FSW in marine applications, highlighting its ability to improve joint strength, corrosion resistance, and fatigue performance. It emphasizes the importance of choosing materials compatible with FSW for project sustainability.

- →

- The study examines the welding processes’ microstructural and mechanical aspects, emphasizing parameter optimization. It contributes to marine structure preservation by minimizing corrosion and protecting surfaces. Future research should focus on advanced FSW apparatus, novel materials, and environmental impact mitigation strategies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S.; Kumar, V.; Kumar, S.; Kumar, A. Variant of MIG welding of similar and dissimilar metals: A review. Mater. Today Proc. 2022, 56, 3550–3555. [Google Scholar] [CrossRef]

- Fande, A.W.; Taiwade, R.V.; Raut, L. Development of activated tungsten inert gas welding and its current status: A review. Mater. Manuf. Process. 2022, 37, 841–876. [Google Scholar] [CrossRef]

- Arora, H.; Singh, R.; Brar, G.S. Thermal and structural modelling of arc welding processes: A literature review. Meas. Control. 2019, 52, 955–969. [Google Scholar] [CrossRef]

- Singh, R.P.; Kumar, S.; Dubey, S.; Singh, A. A review on working and applications of oxy-acetylene gas welding. Mater. Today Proc. 2021, 38, 34–39. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Sambasivam, S.; Gupta, N.; Jassim, A.S.; Singh, D.P.; Kumar, S.; Giri, J.M.; Gupta, M. A review paper of FSW on dissimilar materials using aluminum. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Sadowski, T. A Review on Friction Stir Welding/Processing: Numerical Modeling. Materials 2023, 16, 5890. [Google Scholar] [CrossRef]

- ShivaKumar, G.N.; Rajamurugan, G. Friction stir welding of dissimilar alloy combinations—A Review. Proc. Inst. Mech. Engineers. Part C J. Mech. Eng. Sci. 2022, 236, 6688–6705. [Google Scholar] [CrossRef]

- Gebreamlak, G.; Palani, S.; Sirhabizu, B.; Atnaw, S.M.; Gebremichael, E. Dissimilar friction stir welding process—A review. Adv. Mater. Process. Technol. 2022, 8, 3900–3922. [Google Scholar] [CrossRef]

- Singh, V.; Kumar, R.; Kumar, A.; Dewangan, A.K. Automotive light weight multi-materials sheets joining through friction stir welding technique: An overview. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Thomas, W.; Nicholas, E.; Needham, J.; Murch, M. Improvements Relating to Friction Welding. WO1993010935A1, 8 November 1995. Available online: https://patents.google.com/patent/WO1993010935A1/enIt.pdf (accessed on 30 October 2023).

- Singh, V.P.; Patel, S.K.; Kumar, N.; Kuriachen, B. Parametric effect on dissimilar friction stir welded steel-magnesium alloys joints: A review. Science Technol. Weld. Join. 2019, 24, 653–684. [Google Scholar] [CrossRef]

- Threadgilll, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminum alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Ahmed, S.; Rahman, R.A.U.; Awan, A.; Ahmad, S.; Akram, W.; Amjad, M.; Yahya, M.Y.; Koloor, S.S.R. Optimization of Process Parameters in Friction Stir Welding of Aluminum 5451 in Marine Applications. J. Mar. Sci. Eng. 2022, 10, 1539. [Google Scholar] [CrossRef]

- Di Bella, G.; Alderucci, T.; Favaloro, F.; Borsellino, C. Effect of tool tilt angle on mechanical resistance of AA6082/AA5083 friction stir welded joints for marine applications. Procedia CIRP 2023, 118, 879–884. [Google Scholar] [CrossRef]

- Gibson, B.; Lammlein, D.; Prater, T.; Longhurst, W.; Cox, C.; Ballun, M.; Dharmaraj, K.; Cook, G.; Strauss, A. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Venugopal, V.; Singh, V.P.; Kuriachen, B. Underwater friction stir welding of marine grade aluminium alloys: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Di Bella, G.; Alderucci, T.; Salmeri, F.; Cucinotta, F. Integrating the sustainability aspects into the risk analysis for the manufacturing of dissimilar aluminium/steel friction stir welded single lap joints used in marine applications through a Life Cycle Assessment. Sustain. Futur. 2022, 4, 100101. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Akhavan-Safar, A.; Barbosa, A.; Beygi, R.; Cardoso, D.; Carbas, R.; Marques, E.; da Silva, L. A comprehensive review on structural joining techniques in the marine industry. Compos. Struct. 2022, 289, 115490. [Google Scholar] [CrossRef]

- Kavathia, K.; Badheka, V. Application of FSW in Automotive and Electric Vehicle. Lect. Notes Intell. Transp. Infrastruct. Part F 2022, 1361, 289–304. [Google Scholar]

- Chen, Y.; Nakata, K. Effect of tool geometry on microstructure and mechanical properties of friction stir lap welded magnesium alloy and steel. Mater. Des. 2009, 30, 3913–3919. [Google Scholar] [CrossRef]

- Qiu, R.; Iwamoto, C.; Satonaka, S. The influence of reaction layer on the strength of aluminum/steel joint welded by resistance spot welding. Mater. Charact. 2009, 60, 156–159. [Google Scholar] [CrossRef]

- Chadha, U.; Selvaraj, S.K.; Gunreddy, N.; Babu, S.S.; Mishra, S.; Padala, D.; Shashank, M.; Mathew, R.M.; Kishore, S.R.; Panigrahi, S.; et al. A Survey of Machine Learning in Friction Stir Welding, including Unresolved Issues and Future Research Directions. Mater. Des. Process. Commun. 2022, 2022, 1–28. [Google Scholar] [CrossRef]

- Balachandar, K.; Jegadeeshwaran, R. Friction stir welding tool condition monitoring using vibration signals and Random forest algorithm—A Machine learning approach. Mater. Today Proc. 2021, 46, 1174–1180. [Google Scholar] [CrossRef]

- Nguyen-Le, D.H.; Tao, Q.; Nguyen, V.-H.; Abdel-Wahab, M.; Nguyen-Xuan, H. A data-driven approach based on long short-term memory and hidden Markov model for crack propagation prediction. Eng. Fract. Mech. 2020, 235, 107085. [Google Scholar] [CrossRef]

- Ho, L.V.; Trinh, T.T.; De Roeck, G.; Bui-Tien, T.; Nguyen-Ngoc, L.; Wahab, M.A. An efficient stochastic-based coupled model for damage identification in plate structures. Eng. Fail. Anal. 2022, 131, 105866. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Najjar, I.; Sadoun, A.; Elaziz, M.A.; Abdallah, A.; Fathy, A.; Elsheikh, A.H. Predicting kerf quality characteristics in laser cutting of basalt fibers reinforced polymer composites using neural network and chimp optimization. Alex. Eng. J. 2022, 61, 11005–11018. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Zhou, Y.; Liu, J.; Dai, P.; Du, X.; Wahab, M.A. Automatic laser profile recognition and fast tracking for structured light measurement using deep learning and template matching. Measurement 2021, 169, 108362. [Google Scholar] [CrossRef]

- Elsheikh, A.H. Applications of machine learning in friction stir welding: Prediction of joint properties, real-time control and tool failure diagnosis. Eng. Appl. Artif. Intell. 2023, 121, 105961. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Shokri, V.; Sadeghi, A.; Sadeghi, M. Thermomechanical modeling of friction stir welding in a Cu-DSS dissimilar joint. J. Manuf. Process. 2018, 31, 46–55. [Google Scholar] [CrossRef]

- Çam, G.; Javaheri, V.; Heidarzadeh, A. Advances in FSW and FSSW of dissimilar Al-alloy plates. J. Adhes. Sci. Technol. 2023, 37, 162–194. [Google Scholar] [CrossRef]

- Singh, R.P.; Dubey, S.; Singh, A.; Kumar, S. A review paper on friction stir welding process. Mater. Today Proc. 2021, 38, 6–11. [Google Scholar] [CrossRef]

- Rudrapati, R. Effects of welding process conditions on friction stir welding of polymer composites: A review. Compos. Part C Open Access 2022, 8, 100269. [Google Scholar] [CrossRef]

- Uday, K.N.; Rajamurugan, G. Influence of process parameters and its effects on friction stir welding of dissimilar aluminium alloy and its composites—A review. J. Adhes. Sci. Technol. 2023, 37, 767–800. [Google Scholar] [CrossRef]

- Ambrosio, D.; Morisada, Y.; Ushioda, K.; Fujii, H. Material flow in friction stir welding: A review. J. Mater. Process. Technol. 2023, 320, 118116. [Google Scholar] [CrossRef]

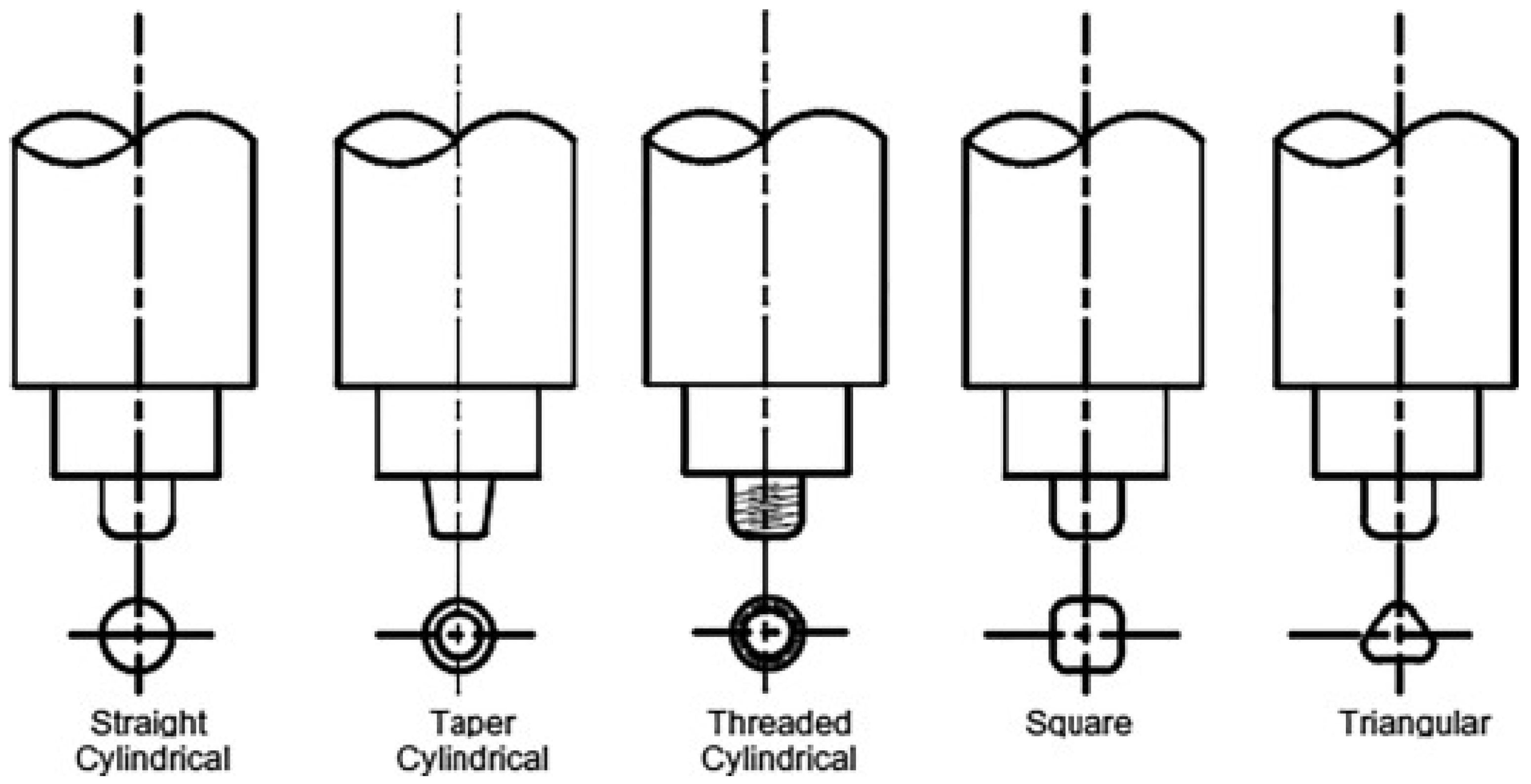

- Chandana, R.; Saraswathamma, K. Impact of tool pin profiles in friction stir welding process—A review. Mater. Today Proc. 2023, 76, 602–606. [Google Scholar] [CrossRef]

- Mohan, D.G.; Wu, C. A Review on Friction Stir Welding of Steels. Chin. J. Mech. Eng. 2021, 34, 137. [Google Scholar] [CrossRef]

- De Giorgi, M.; Scialpi, A.; Panella, F.W.; De Filippis, L.A.C. Effect of shoulder geometry on residual stress and fatigue properties of AA6082 fsw joints. J. Mech. Sci. Technol. 2009, 23, 26–35. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, P.; Pankaj, P.; Biswas, P.; Kore, S.D. FSW of low carbon steel using tungsten carbide (WC-10wt.%Co) based tool material. J. Mech. Sci. Technol. 2019, 33, 4931–4938. [Google Scholar] [CrossRef]

- Siddiquee, A.N.; Pandey, S. Experimental investigation on deformation and wear of WC tool during FSW of stainless steel. Int. J. Adv. Manuf. Technol. 2014, 73, 479–486. [Google Scholar] [CrossRef]

- Raj, S.; Pankaj, P.; Biswas, P. Friction Stir Welding of Inconel-718 Alloy Using a Tungsten Carbide Tool. J. Mater. Eng. Perform. 2022, 31, 2086–2101. [Google Scholar] [CrossRef]

- Mystica, A.; Sankavi, S.; Sakthi, V.S.; Ganesh, T.; Kumar, V.S. Heat Reduction in a Tool Holder during Friction Stir Welding of Aluminium Alloy. Appl. Mech. Mater. 2015, 766–767, 705–711. [Google Scholar] [CrossRef]

- Derazkola, H.A.; García, E.; Eyvazian, A.; Aberoumand, M. Effects of Rapid Cooling on Properties of Aluminum-Steel Friction Stir Welded Joint. Materials 2021, 14, 908. [Google Scholar] [CrossRef] [PubMed]

- Emamian, S.; Awang, M.; Yusof, F.; Hussain, P.; Mehrpouya, M.; Kakooei, S.; Moayedfar, M.; Zafar, A. A Review of Friction Stir Welding Pin Profile. In Proceedings of the 2nd International Conference on Mechanical, Manufacturing and Process Plant Engineering, Kuala Lumpur, Malaysia, 23–24 November 2016; pp. 1–18. [Google Scholar]

- Padmanaban, G.; Balasubramanian, V. Selection of FSW tool pin profile, shoulder diameter and material for joining AZ31B magnesium alloy—An experimental approach. Mater. Des. 2009, 30, 2647–2656. [Google Scholar] [CrossRef]

- Ding, R.J.; Oelgoetz, P.A. Mechanical Property Analysis in the Retracted Pin-Tool (RPT) Region of Friction Stir Welded (FSW) Aluminum Lithium 2195; NASA: Thousand Oaks, CA, USA, 1999. [Google Scholar]

- Chen, G.; Wang, G.; Shi, Q.; Zhao, Y.; Hao, Y.; Zhang, S. Three-dimensional thermal-mechanical analysis of retractable pin tool friction stir welding process. J. Manuf. Process. 2019, 41, 1–9. [Google Scholar] [CrossRef]

- Quintana, K.J.; Silveira, J.L.L. Threaded pin effects analysis on forces in FSW. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 491. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.B.; Emamian, S.S.; Nor, M.K.B.M.; Pedapati, S.R. A Comparison of Different Finite Element Methods in the Thermal Analysis of FSW. Metals 2017, 7, 450. [Google Scholar] [CrossRef]

- Sillapasa, K.; Mutoh, Y.; Miyashita, Y.; Seo, N. Fatigue Strength Estimation Based on Local Mechanical Properties for Aluminum Alloy FSW Joints. Materials 2017, 10, 186. [Google Scholar] [CrossRef]

- Dudzik, K.; Jurczak, W. Influence of Friction Stir Welding on Corrosion Properties of Aw-7020M Alloy in Sea Water. Adv. Mater. Sci. 2015, 15, 7–13. [Google Scholar] [CrossRef]

- Ramesh, N.; Kumar, V.S. Experimental erosion-corrosion analysis of friction stir welding of AA 5083 and AA 6061 for sub-sea applications. Appl. Ocean Res. 2020, 98, 102121. [Google Scholar] [CrossRef]

- Golubev, I.A.; Chernikov, E.V.; Naumov, A.A.; Michailov, V.G. Temperature distribution and welding distortion measurements after FSW of Al 6082-T6 sheets. In Friction Stir Welding and Processing VIII; Springer International Publishing: Cham, Switzerland, 2015; pp. 289–295. [Google Scholar]

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

- Murr, L.E. A Review of FSW Research on Dissimilar Metal and Alloy Systems. J. Mater. Eng. Perform. 2010, 19, 1071–1089. [Google Scholar] [CrossRef]

- Morishige, T.; Kawaguchi, A.; Tsujikawa, M.; Hino, M.; Hirata, T.; Higashi, K. Dissimilar Welding of Al and Mg Alloys by FSW. Mater. Trans. 2008, 49, 1129–1131. [Google Scholar] [CrossRef]

- Karlsson, L.; Berqvist, E.-L.; Larsson, H. Application of Friction Stir Welding to Dissimilar Welding. Weld. World 2002, 46, 10–14. [Google Scholar] [CrossRef]

- DebRoy, T.; Bhadeshia, H.K.D.H. Friction stir welding of dissimilar alloys—A perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270. [Google Scholar] [CrossRef]

- Chien, C.-H.; Lin, W.-B.; Chen, T. Optimal FSW process parameters for aluminum alloys AA5083. J. Chinese Inst. Eng. 2011, 34, 99–105. [Google Scholar] [CrossRef]

- Eslami, N.; Hischer, Y.; Harms, A.; Lauterbach, D.; Böhm, S. Optimization of Process Parameters for Friction Stir Welding of Aluminum and Copper Using the Taguchi Method. Metals 2019, 9, 63. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of tool pin profile and tool rotational speed on mechanical properties of friction stir welded AA6061 aluminium alloy. Mater. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Prabha, K.A.; Putha, P.K.; Prasad, B.S. Effect of Tool Rotational Speed on Mechanical Properties of Aluminium Alloy 5083 Weldments in Friction Stir Welding. Mater. Today Proc. 2018, 5, 18535–18543. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H. Numerical studies on the effect of transverse speed in friction stir welding. Mater. Des. 2009, 30, 900–907. [Google Scholar] [CrossRef]

- Liu, F.C.; Hovanski, Y.; Miles, M.P.; Sorensen, C.D.; Nelson, T.W. A review of friction stir welding of steels: Tool, material flow, microstructure, and properties. J. Mater. Sci. Technol. 2018, 34, 39–57. [Google Scholar] [CrossRef]

- Kumar, K.; Kailas, S.V.; Srivatsan, T.S. Influence of Tool Geometry in Friction Stir Welding. Mater. Manuf. Process. 2008, 23, 188–194. [Google Scholar] [CrossRef]

- Arici, A.; Selale, S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2007, 12, 536–539. [Google Scholar] [CrossRef]

- Bhukya, S.N.; Wu, Z.; Maniscalco, J.; Elmustafa, A. Effect of copper donor material-assisted friction stir welding of AA6061-T6 alloy on downward force, microstructure, and mechanical properties. Int. J. Adv. Manuf. Technol. 2022, 119, 2847–2862. [Google Scholar] [CrossRef]

- Papahn, H.; Bahemmat, P.; Haghpanahi, M. Effect of cooling media on residual stresses induced by a solid-state welding: Underwater FSW. Int. J. Adv. Manuf. Technol. 2016, 83, 1003–1012. [Google Scholar] [CrossRef]

- Scutelnicu, E.; Birsan, D.; Cojocaru, R. Research on Friction Stir Welding and Tungsten Inert Gas assisted Friction Stir Welding of Copper. Available online: http://www.cmrs.ugal.ro (accessed on 31 October 2023).

- Bo, L.N.; Cojocaru, R. ISIM Achievements Regarding Friction Stir Welding in Inert Gas Environment. Adv. Mater. Res. 2022, 1172, 15–24. [Google Scholar] [CrossRef]

- Martin, J.; Wei, S. Friction stir welding technology for marine applications. In Friction Stir Welding and Processing VIII; Springer International Publishing: Cham, Switzerland, 2015; pp. 219–226. [Google Scholar]

- Feistauer, E.; Bergmann, L.; Barreto, L.; dos Santos, J. Mechanical behaviour of dissimilar friction stir welded tailor welded blanks in Al–Mg alloys for Marine applications. Mater. Des. 2014, 59, 323–332. [Google Scholar] [CrossRef]

- Wahid, M.A.; Siddiquee, A.N.; Khan, Z.A. Aluminum alloys in marine construction: Characteristics, application, and problems from a fabrication viewpoint. Mar. Syst. Ocean Technol. 2020, 15, 70–80. [Google Scholar] [CrossRef]

- Shanavas, S.; Dhas, J.E.R. Parametric optimization of friction stir welding parameters of marine grade aluminium alloy using response surface methodology. Trans. Nonferrous Met. Soc. China 2017, 27, 2334–2344. [Google Scholar] [CrossRef]

- Konkol, P.J.; Mathers, J.A.; Johnson, R.; Pickens, J.R. Friction Stir Welding of HSLA-65 Steel for Shipbuilding. J. Sh. Prod. 2003, 19, 159–164. [Google Scholar] [CrossRef]

- Sekban, D.M.; Aktarer, S.M.; Purcek, G. Friction Stir Welding of Low-Carbon Shipbuilding Steel Plates: Microstructure, Mechanical Properties, and Corrosion Behavior. Metall. Mater. Trans. A 2019, 50, 4127–4140. [Google Scholar] [CrossRef]

- Sabry, I.; Mourad, A.-H.I.; Thekkuden, D.T. Comparison of Mechanical Characteristics of Conventional and Underwater Friction Stir Welding of AA 6063 Pipe Joints. Int. Rev. Mech. Eng. 2020, 14, 64. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Rajasekaran, T.; Pandey, C.; Menaka, M. Mechanical and Microstructural Characteristics of Underwater Friction Stir Welded AA5083 Armor-Grade Aluminum Alloy Joints. J. Mater. Eng. Perform. 2022, 31, 8459–8472. [Google Scholar] [CrossRef]

- Sabry, I.; Allah, N.G.; Nour, M.A.; Ghafaar, M.A. Mechanical Characteristic of Al 6063 Pipe Joined by Underwater Friction Stir Welding. In Proceedings of Fourth International Conference on Inventive Material Science Applications; Springer: Singapore, 2022; pp. 689–699. [Google Scholar]

- Sebok, K.F. Design, Fabrication and Operation of A3000 FSW Submersible Work System. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 8–10 May 1978. [Google Scholar] [CrossRef]

- Polezhayeva, H.; Toumpis, A.I.; Galloway, A.M.; Molter, L.; Ahmad, B.; Fitzpatrick, M.E. Fatigue performance of friction stir welded marine grade steel. Int. J. Fatigue 2015, 81, 162–170. [Google Scholar] [CrossRef][Green Version]

- Delaune, P.T. On-Site Welded Repairs To Offshore Structures Using Dry Underwater Habitats. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 8–10 May 1978. [Google Scholar] [CrossRef]

- Lader, S.K.; Baruah, M.; Ballav, R. Significance of underwater friction stir welding on the weld integrity of thin sheets of aluminum (AA1050-O) and brass (CuZn34) joints. Mater. Sci. Eng. A 2023, 865, 144627. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.-S.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef] [PubMed]

- Kilic, S.; Ozturk, F.; Demirdogen, M.F. A comprehensive literature review on friction stir welding: Process parameters, joint integrity, and mechanical properties. J. Eng. Res. 2023. [Google Scholar] [CrossRef]

- Nathan, S.R.; Balasubramanian, V.; Rao, A.G.; Sonar, T.; Ivanov, M.; Rajendran, C. Influence of tool plunging rate on mechanical properties and microstructure of friction stir welded DMR249A high strength low alloy (HSLA) steel butt joints. Mater. Test. 2023, 65, 1528–1538. [Google Scholar] [CrossRef]

- Osman, M.; Tamin, N. Influence of tool pin profile on the mechanical strength and surface roughness of AA6061-T6 overlap joint friction stir welding. J. Mech. Eng. Sci. 2023, 17, 9576–9585. [Google Scholar] [CrossRef]

- Sundar, A.S.; Kar, A.; Mugada, K.K.; Kumar, A. Enhancement of microstructure, micro-texture, and mechanical properties of Al6061 friction stir welds using the developed static shoulder welding tool. Mater. Charact. 2023, 203, 113148. [Google Scholar] [CrossRef]

- Akbari, M.; Aliha, M.; Berto, F. Investigating the role of different components of friction stir welding tools on the generated heat and strain. Forces Mech. 2023, 10, 100166. [Google Scholar] [CrossRef]

- Arif, M.; Kumar, D.; Siddiquee, A.N. Morphological and Mechanical Characterization of Friction Stir Welded Zones in Acrylonitrile Butadiene Styrene (ABS) Polymer. J. Mater. Eng. Perform. 2023, 1–11. [Google Scholar] [CrossRef]

- Hossfeld, M. On Friction, Heat Input, and Material Flow Initiation during Friction Stir Welding: Tool and Process Optimization. J. Manuf. Mater. Process. 2023, 7, 34. [Google Scholar] [CrossRef]

- Mironov, S.Y. Temperature Distribution within the Friction Stir Welding Tool. Phys. Mesomech. 2023, 26, 33–38. [Google Scholar] [CrossRef]

- Shi, L.; Chen, J.; Yang, C.; Chen, G.; Wu, C. Thermal-fluid-structure coupling analysis of void defect in friction stir welding. Int. J. Mech. Sci. 2023, 241, 107969. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Essa, A.R.S.; Ataya, S.; Seleman, M.M.E.-S.; El-Aty, A.A.; Alzahrani, B.; Touileb, K.; Bakkar, A.; Ponnore, J.J.; Mohamed, A.Y.A. Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials 2023, 16, 2031. [Google Scholar] [CrossRef]

- Iftikhar, S.H.; Mourad, A.-H.I.; Thekkuden, D.T.; Cherupurakal, N.; Krishnapriya, R. Friction stir welding of carbon black reinforced high-density polyethylene tube-to-tubesheet joints. Int. J. Lightweight Mater. Manuf. 2023, 6, 589–605. [Google Scholar] [CrossRef]

- Trojovský, P.; Dhasarathan, V.; Boopathi, S. Experimental investigations on cryogenic friction-stir welding of similar ZE42 magnesium alloys. Alex. Eng. J. 2023, 66, 1–4. [Google Scholar] [CrossRef]

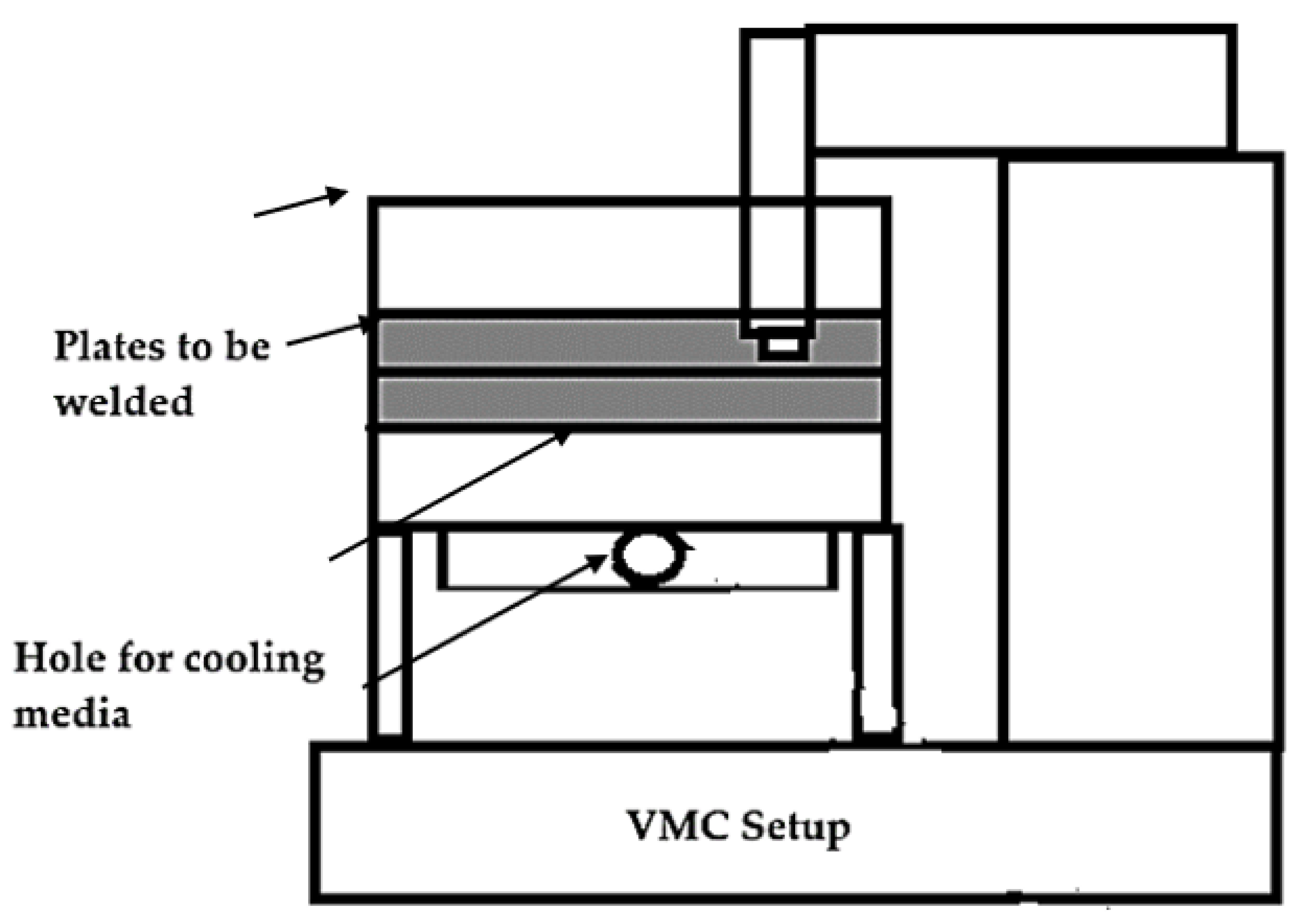

- Singh, R.; Kumar, Y. Effect of cooling tank embedded fixture design on the thermal analysis of friction stir welded aluminum alloy. J. Mater. Eng. Perform. 2023, 32, 7215–7224. [Google Scholar] [CrossRef]

- Al-Sabur, R.; Serier, M.; Siddiquee, A.N. Analysis and construction of a pneumatic-powered portable friction stir welding tool for polymer joining. Adv. Mater. Process. Technol. 2023, 1–5. [Google Scholar] [CrossRef]

- Senff, M.; Volk, W. Hybrid joining of cast aluminum and steel by compound casting and friction stir welding. Prod. Eng. 2023, 17, 521–534. [Google Scholar] [CrossRef]

- Akbari, M.; Asiabaraki, H.R. Modeling and optimization of tool parameters in friction stir lap joining of aluminum using RSM and NSGA II. Weld. Int. 2023, 37, 21–33. [Google Scholar] [CrossRef]

- Liu, T.S.; Qiu, F.; Yang, H.Y.; Liu, S.; Jiang, Q.C.; Zhang, L.C. Exploring the potential of FSW-ed Al–Zn–Mg–Cu-based composite reinforced by trace in-situ nanoparticles in manufacturing workpiece with customizable size and high mechanical performances. Compos. Part B Eng. 2023, 250, 110425. [Google Scholar] [CrossRef]

- Noga, P.; Skrzekut, T.; Wędrychowicz, M.; Węglowski, M.S.; Węglowska, A. Research of FSW and Electron Beam Welding (EBW) Process for 6082-T6 Aluminum Alloy. Materials 2023, 16, 4937. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ye, T.; Li, Y.; Pei, X.; Sun, Z. Quasi-in-situ characterization of microstructure evolution in friction stir welding of aluminum alloy. J. Mater. Res. Technol. 2023, 25, 6380–6394. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, Y. Microstructural analysis of cooling tank-assisted hybrid friction stir welded aluminium alloys: A novel approach. Weld. Int. 2023, 37, 445–456. [Google Scholar] [CrossRef]

- Kumar, R.; Bhadauria, S.S.; Sharma, V.; Kumar, M. Effect on microstructure and mechanical properties of single pass friction stir welded aluminium alloy AA-7075-T651 joint. Mater. Today Proc. 2023, 80, 40–47. [Google Scholar] [CrossRef]

- Wang, Q.; Zhai, H.; Chen, S.; Wang, L.; Huang, L.; Zhao, J.; Xia, H.; Ma, Y. Simultaneous enhancement of strength and ductility in friction stir welded AZ31 alloy via multi-pass hot-rolling and subsequent annealing. J. Mater. Res. Technol. 2023, 23, 5181–5192. [Google Scholar] [CrossRef]

- Baharudin, B.A.; Mustapha, M.; Ismail, A.; Zulkipli, F.N.; Ayob, F.; Ahmad, A. Microhardness and process parameter optimization of friction stir welding on an AA5052 thin plate. In Advancements in Materials Science and Technology Led by Women; Springer: Cham, Switzerland, 2023; pp. 133–141. [Google Scholar]

- Kumar, G.V.; Ravishankar, S.S.; Subrahmanyam, M.R.S.; Babu, P.K. An Analysis of Friction Stir Welding of Marine Grade 5083 Aluminium Alloy Using Weld Parameters. Ind. Eng. J. 2022, 51, 1–7. [Google Scholar]

- Vallavi, M.A.; Madhavan, K. Analysing the Influence of Tool Pin on Mechanical Properties of Friction Stir Welded Dissimilar Aluminium Alloys AA6082 & AA5052. Int. J. Progress. Res. Eng. Manag. Sci. 2023. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Pawłowski, Ł.; Gajowiec, G. Corrosion Properties of Dissimilar AA6082/AA6060 Friction Stir Welded Butt Joints in Different NaCl Concentrations. Int. J. Precis. Eng. Manuf. Green Technol. 2023, 10, 457–477. [Google Scholar] [CrossRef]

- Karumuri, S.; Haldar, B.; Pradeep, A.; Karanam, S.A.K.; Sri, M.N.S.; Anusha, P.; Sateesh, N.; Subbiah, R.; Vijayakumar, S. Multi-objective optimization using Taguchi based grey relational analysis in friction stir welding for dissimilar aluminium alloy. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Datta, R.; Gupta, S.K.; Bhargava, M. Comparison of underwater friction stir welded and conventional friction stir welded AA 5052 alloys based on the mechanical, formability and microstructure behaviour. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jain, S.; Mishra, R.; Mehdi, H.; Gupta, R.; Dubey, A.K. Optimization of processing variables of friction stir welded dissimilar composite joints of AA6061 and AA7075 using response surface methodology. J. Adhes. Sci. Technol. 2023. [Google Scholar] [CrossRef]

- Kandasamy, J.; Prakasham, G.; Chaitanya, P.; Eshwar, N. Experimental investigations on the position of plates in friction stir welding of dissimilar alloys. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V. The effect of friction stir processing on the friction stir welded AA1050-H14 and AA6082-T6 joints. Mater. Today Proc. 2019, 26, 193–199. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y. Effect of a novel intermediate heat treatment process on abnormal grain growth in 2219 aluminum alloy friction stir welds. Mater. Sci. Eng. A 2023, 885, 145604. [Google Scholar] [CrossRef]

- Sen, D.; Pal, S.K.; Panda, S.K. Effect of tool concavity on flash formation during fabrication of tubes through friction stir welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023. [Google Scholar] [CrossRef]

- Jain, S.; Mishra, R.S. Multi-response Optimization of Friction Stir Welded Reinforced Joints of Dissimilar Aluminum Alloys. Trans. Indian Inst. Met. 2023. [Google Scholar] [CrossRef]

- Singh, V.P.; Kumar, D.; Mahto, R.P.; Kuriachen, B. Microstructural and Mechanical Behavior of Friction-Stir-Welded AA6061-T6 and AZ31 Alloys with Improved Electrochemical Corrosion. J. Mater. Eng. Perform. 2023, 32, 4185–4204. [Google Scholar] [CrossRef]

- Battina, N.M.; Chirala, H.K.; Vanthala, V.S.P.; Javvadi, E.M.; Nukathoti, R.S.; Mohammed, A. Experimental and finite element investigations on formability of friction stir welded tailor welded blanks of AA6061 and AA2017. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Qu, L.; Ma, N.; Xiao, X.; Zhang, K.; Li, H. Microstructure and Properties of Nonlinear Lap Joint of 6061 Aluminum Alloy by Friction Stir Welding. Metals 2023, 13, 1494. [Google Scholar] [CrossRef]

- Yogaraj, P.; Kasirajan, L.; Senthamaraikannan, B. Effect of Tool Pin Positioning Factors on the Strength Behavior of Dissimilar Joints of AA5754-H111 and AA6101-T6 by Using Friction Stir Welding. Trans. Indian Inst. Met. 2023, 76, 3021–3030. [Google Scholar] [CrossRef]

- Matitopanum, S.; Pitakaso, R.; Sethanan, K.; Srichok, T.; Chokanat, P. Prediction of the Ultimate Tensile Strength (UTS) of Asymmetric Friction Stir Welding Using Ensemble Machine Learning Methods. Processes 2023, 11, 391. [Google Scholar] [CrossRef]

- Kumar, A.K.; Surya, M.S.; Venkataramaiah, P. Performance evaluation of machine learning based-classifiers in friction stir welding of Aa6061-T6 alloy. Int. J. Interact. Des. Manuf. 2023, 17, 469–472. [Google Scholar] [CrossRef]

- Khaliq, U.A.; Muhamad, M.R.; Yusof, F.; Ibrahim, S.; Isa, M.S.; Chen, Z.; Çam, G. A Review on Friction Stir Butt Welding of Aluminum with Magnesium: A New Insight on Joining Mechanisms by Interfacial Enhancement. J. Mater. Res. Technol. 2023, 27, 4595–4624. [Google Scholar] [CrossRef]

- Ye, X.; Su, Z.; Dahari, M.; Su, Y.; Alsulami, S.H.; Aldhabani, M.S.; Abed, A.M.; Ali, H.E.; Bouzgarrou, S.M. Hybrid modeling of mechanical properties and hardness of aluminum alloy 5083 and C100 Copper with various machine learning algorithms in friction stir welding. Structures 2023, 55, 1250–1261. [Google Scholar] [CrossRef]

- Balachandar, K.; Arockiaraj, K.S.; Sriraman, G.; Jegadeeshwaran, R.; Sakthivel, G.; Lakshmipathi, J. Development of a machine learning model to predict the friction stir welding tool condition. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Baruah, A.; Borkar, H. Optimised machine learning classification model to detect void formations in friction stir welding. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Anandan, B.; Manikandan, M. Machine learning approach with various regression models for predicting the ultimate tensile strength of the friction stir welded AA 2050-T8 joints by the K-Fold cross-validation method. Mater. Today Commun. 2023, 34, 105286. [Google Scholar] [CrossRef]

- Insua, P.; Nakkiew, W.; Wisittipanich, W. Post Weld Heat Treatment Optimization of Dissimilar Friction Stir Welded AA2024-T3 and AA7075-T651 Using Machine Learning and Metaheuristics. Materials 2023, 16, 2081. [Google Scholar] [CrossRef] [PubMed]

- Dorbane, A.; Harrou, F.; Sun, Y. Exploring Deep Learning Methods to Forecast Mechanical Behavior of FSW Aluminum Sheets. J. Mater. Eng. Perform. 2023, 32, 4047–4063. [Google Scholar] [CrossRef]

- Chiaranai, S.; Pitakaso, R.; Sethanan, K.; Kosacka-Olejnik, M.; Srichok, T.; Chokanat, P. Ensemble Deep Learning Ultimate Tensile Strength Classification Model for Weld Seam of Asymmetric Friction Stir Welding. Processes 2023, 11, 434. [Google Scholar] [CrossRef]

- Modi, U.; Ahmed, S.; Rai, A. Prediction of ultimate tensile strength of friction stir welding joint using deep learning-based-multilayer perceptron and long short term memory networks. Weld. Int. 2023, 37, 387–399. [Google Scholar] [CrossRef]

- Mandal, A.; Banik, A.; Barma, J.D.; Majumdar, G. Friction Stir Welding of Two Dissimilar Metals: Weld Quality Characterization Using the Wavelet Transform Approach. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Rabe, P.; Reisgen, U.; Schiebahn, A. Non-destructive evaluation of the friction stir welding process, generalizing a deep neural defect detection network to identify internal weld defects across different aluminum alloys. Weld. World 2023, 67, 549–560. [Google Scholar] [CrossRef]

- Yu, F.; Zhao, Y.; Lin, Z.; Miao, Y.; Zhao, F.; Xie, Y. Prediction of Mechanical Properties and Optimization of Friction Stir Welded 2195 Aluminum Alloy Based on BP Neural Network. Metals 2023, 13, 267. [Google Scholar] [CrossRef]

- Mishra, A. Artificial intelligence algorithms for prediction of the ultimate tensile strength of the friction stir welded magnesium alloys. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction Stir Welding and Processing; ASM International: Almere, The Netherlands, 2007. [Google Scholar]

- Xu, N.; Ueji, R.; Fujii, H. Dynamic and static change of grain size and texture of copper during friction stir welding. J. Mater. Process. Technol. 2016, 232, 90–99. [Google Scholar] [CrossRef]

- Xu, N.; Chen, L.; Feng, R.; Song, Q.; Bao, Y. Recrystallization of Cu-30Zn brass during friction stir welding. J. Mater. Res. Technol. 2020, 9, 3746–3758. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Vairis, A.; Badheka, V. Recent Development in Friction Stir Processing as a Solid-State Grain Refinement Technique: Microstructural Evolution and Property Enhancement. Crit. Rev. Solid State Mater. Sci. 2019, 44, 378–426. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W. Heat generation, plastic deformation and residual stresses in friction stir welding of aluminium alloy. Int. J. Mech. Sci. 2023, 238, 107827. [Google Scholar] [CrossRef]

- Morozova, I.; Królicka, A.; Obrosov, A.; Yang, Y.; Doynov, N.; Weiß, S.; Michailov, V. Precipitation phenomena in impulse friction stir welded 2024 aluminium alloy. Mater. Sci. Eng. A 2022, 852, 143617. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Kumar, K.; Kailas, S.V. The role of friction stir welding tool on material flow and weld formation. Mater. Sci. Eng. A 2008, 485, 367–374. [Google Scholar] [CrossRef]

- Zhang, H.; Khoshnaw, F. Friction stir welding. In Welding of Metallic Materials. Methods, Metallurgy, and Performance; Elsevier: Amsterdam, The Netherlands, 2023; pp. 197–228. [Google Scholar] [CrossRef]

- Dutta, V.; Kumara, R.; Kumar, V.; Sapkal, V. Influence of FSP on Microstructure and Mechanical Properties of Al Metal Composites (AMCS)—A Review. J. East China Univ. Sci. Technol. 2022, 65, 555–561. Available online: http://hdlgdxxb.info/index.php/JE_CUST/article/view/131 (accessed on 15 November 2023).

- Qin, X.; Xu, Y.; Sun, Y.; Fujii, H.; Zhu, Z.; Shek, C.H. Effect of process parameters on microstructure and mechanical properties of friction stir welded CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2020, 782, 139277. [Google Scholar] [CrossRef]

- Zolghadr, P.; Akbari, M.; Asadi, P. Formation of thermo-mechanically affected zone in friction stir welding. Mater. Res. Express 2019, 6, 086558. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Hong, S.I.; Pavese, M. Grain boundary transition associated intergranular failure analysis at TMAZ/SZ interface of dissimilar AA7475-AA2198 joints by friction stir welding. Mater. Lett. 2020, 280, 128557. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, G.; Cao, Y.; Zhu, Y.; Huang, X.; Zhou, Y.; Li, Q.; Zeng, Q.; Liu, Q. Microstructure evolution of thermo-mechanically affected zone in dissimilar AA2024/7075 joint produced by friction stir welding. Vacuum 2020, 179, 109515. [Google Scholar] [CrossRef]

- Sato, Y.; Arkom, P.; Kokawa, H.; Nelson, T.; Steel, R. Effect of microstructure on properties of friction stir welded Inconel Alloy 600. Mater. Sci. Eng. A 2008, 477, 250–258. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Bussu, G.; Irving, P. The role of residual stress and heat affected zone properties on fatigue crack propagation in friction stir welded 2024-T351 aluminium joints. Int. J. Fatigue 2003, 25, 77–88. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, Z.; Yu, B.; Xue, P.; Ni, D.; Xiao, B.; Ma, Z. Friction stir welding of 2060–T8 AlLi alloy. Part I: Microstructure evolution mechanism and mechanical properties. Mater. Charact. 2020, 168, 110524. [Google Scholar] [CrossRef]

- Ghosh, B.; Das, H.; Samanta, A.; Majumdar, J.D.; Ghosh, M. Majumdar, and M. Ghosh, Influence of tool rotational speed on the evolution of microstructure and mechanical properties of precipitation-hardened Aluminium 6061 butt joint during friction stir welding. Eng. Res. Express 2022, 4, 015009. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xue, P.; Wang, D.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Realising equal strength welding to parent metal in precipitation-hardened Al–Mg–Si alloy via low heat input friction stir welding. Sci. Technol. Weld. Join. 2018, 23, 478–486. [Google Scholar] [CrossRef]

- Ni, Y.; Fu, L.; Shen, Z.; Liu, X. Role of tool design on thermal cycling and mechanical properties of a high-speed micro friction stir welded 7075-T6 aluminum alloy. J. Manuf. Process. 2019, 48, 145–153. [Google Scholar] [CrossRef]

- Kalinenko, A.; Vysotskiy, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Influence of the weld thermal cycle on the grain structure of friction-stir joined 6061 aluminum alloy. Mater. Charact. 2021, 178, 111202. [Google Scholar] [CrossRef]

- Wahid, M.A.; Khan, Z.A.; Siddiquee, A.N. Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties. Trans. Nonferrous Met. Soc. China 2018, 28, 193–219. [Google Scholar] [CrossRef]

- Svensson, L.-E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Eren, B.; Guvenc, M.A.; Mistikoglu, S. Artificial Intelligence Applications for Friction Stir Welding: A Review. Met. Mater. Int. 2021, 27, 193–219. [Google Scholar] [CrossRef]

- Shinde, G.; Gajghate, S.; Dabeer, P.; Seemikeri, C. Low Cost Friction Stir Welding: A Review. Mater. Today Proc. 2017, 4, 8901–8910. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Y.; Hao, Y. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J. Mater. Sci. Technol. 2018, 34, 73–91. [Google Scholar] [CrossRef]

- Kalinenko, A.; Kim, K.; Vysotskiy, I.; Zuiko, I.; Malopheyev, S.; Mironov, S.; Kaibyshev, R. Microstructure-strength relationship in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2020, 793, 139858. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, Y.; Ng, F.; Goh, M.; Liaw, P.; Fujii, H.; Nguyen, Q.; Xu, Y.; Shek, C.; Nai, S.; et al. Friction-stir welding of a ductile high entropy alloy: Microstructural evolution and weld strength. Mater. Sci. Eng. A 2018, 711, 524–532. [Google Scholar] [CrossRef]

- Lin, P.-T.; Liu, H.-C.; Hsieh, P.-Y.; Wei, C.-Y.; Tsai, C.-W.; Sato, Y.S.; Chen, S.-C.; Yen, H.-W.; Lu, N.-H.; Chen, C.-H. Heterogeneous structure-induced strength-ductility synergy by partial recrystallization during friction stir welding of a high-entropy alloy. Mater. Des. 2021, 197, 109238. [Google Scholar] [CrossRef]

- Wang, Y.; Duan, R.; Hu, J.; Luo, Z.; Ma, Z.; Xie, G. Improvement in toughness and ductility of friction stir welded medium-Mn steel joint via post-welding annealing. J. Mater. Process. Technol. 2022, 306, 117621. [Google Scholar] [CrossRef]

- Khajeh, R.; Jafarian, H.R.; Jabraeili, R.; Eivani, A.R.; Seyedein, S.H.; Park, N.; Heidarzadeh, A. Strength-ductility synergic enhancement in friction stir welded AA2024 alloy and copper joints: Unravelling the role of Zn interlayer’s thickness. J. Mater. Res. Technol. 2022, 16, 251–262. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of tool geometry in dissimilar Al-Steel Friction Stir Welding. J. Manuf. Process. 2021, 68, 198–208. [Google Scholar] [CrossRef]

- Khan, N.; Rathee, S.; Srivastava, M. Friction stir welding: An overview on effect of tool variables. Mater. Today Proc. 2021, 47, 7196–7202. [Google Scholar] [CrossRef]

- Wen, Q.; Li, W.; Patel, V.; Gao, Y.; Vairis, A. Investigation on the Effects of Welding Speed on Bobbin Tool Friction Stir Welding of 2219 Aluminum Alloy. Met. Mater. Int. 2020, 26, 1830–1840. [Google Scholar] [CrossRef]

- Amatullah, M.; Jan, M.; Farooq, M.; Zargar, A.S.; Maqbool, A.; Khan, N.Z. Effect of tool rotational speed on the friction stir welded aluminum alloys: A review. Mater. Today Proc. 2022, 62, 245–250. [Google Scholar] [CrossRef]

- Li, Y.; Sun, D.; Gong, W. Effect of Tool Rotational Speed on the Microstructure and Mechanical Properties of Bobbin Tool Friction Stir Welded 6082-T6 Aluminum Alloy. Metals 2019, 9, 894. [Google Scholar] [CrossRef]

- Zhai, M.; Wu, C.; Su, H. Influence of tool tilt angle on heat transfer and material flow in friction stir welding. J. Manuf. Process. 2020, 59, 98–112. [Google Scholar] [CrossRef]

- Rajendran, C.; Srinivasan, K.; Balasubramanian, V.; Balaji, H.; Selvaraj, P. Effect of tool tilt angle on strength and microstructural characteristics of friction stir welded lap joints of AA2014-T6 aluminum alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1824–1835. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Wang, F.; Jiang, Y.; Ma, X.; Wan, L.; Huang, Y. Insight on corrosion behavior of friction stir welded AA2219/AA2195 joints in astronautical engineering. Corros. Sci. 2021, 192, 109800. [Google Scholar] [CrossRef]

- Corral, J.; Trillo, E.A.; Li, Y.; Murr, L.E. Corrosion of friction-stir welded aluminum alloys 2024 and 2195. J. Mater. Sci. Lett. 2000, 19, 2117–2122. [Google Scholar] [CrossRef]

- Zucchi, F.; Trabanelli, G.; Grassi, V. Pitting and stress corrosion cracking resistance of friction stir welded AA 5083. Mater. Corros. 2001, 52, 853–859. [Google Scholar] [CrossRef]

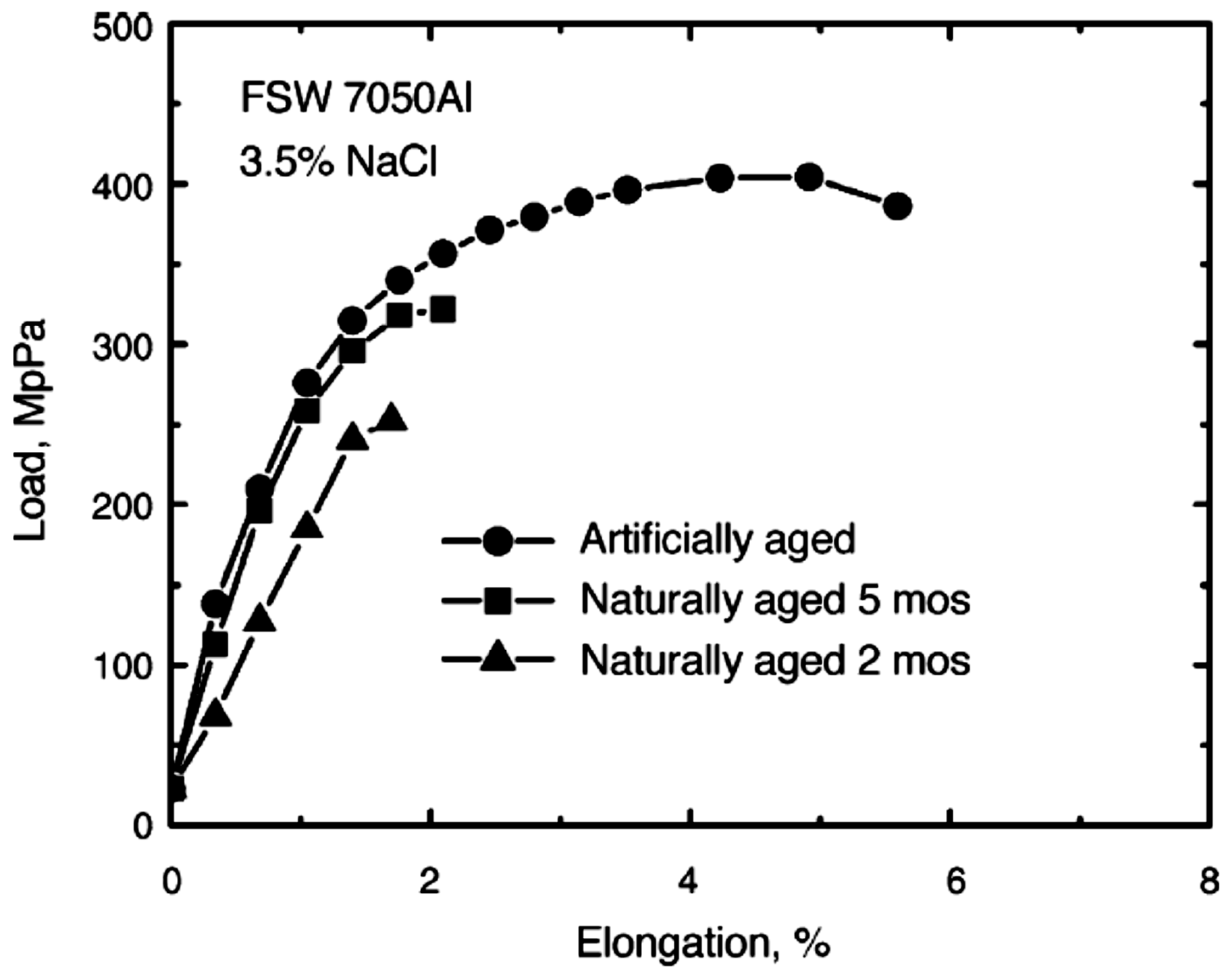

- Paglia, C.; Carroll, M.; Pitts, B.; Reynolds, T.; Buchheit, R. Strength, Corrosion and Environmentally Assisted Cracking of a 7075-T6 Friction Stir Weld. Mater. Sci. Forum 2002, 396–402, 1677–1684. [Google Scholar] [CrossRef]

- Frankel, G.S.; Xia, Z. Localized corrosion and stress corrosion cracking resistance of friction stir welded aluminum alloy 5454. Corrosion 1999, 55, 139–150. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Chandra, B.R.; Manna, I. Friction and wear behavior of laser composite surfaced aluminium with silicon carbide. Wear 2007, 262, 641–648. [Google Scholar] [CrossRef]

- Lumsden, J.B.; Mahoney, M.W.; Pollock, G.; Rhodes, C.G. Intergranular corrosion following friction stir welding of aluminum alloy 7075-T651. Corrosion 1999, 55. [Google Scholar] [CrossRef]

- Muller, I.L.; Galvele, J.R. Pitting potential of high purity binary aluminium alloys—II. AlMg and AlZn alloys. Corros. Sci. 1977, 17, 995–1007. [Google Scholar] [CrossRef]

- Wong, K.J.; Johar, M.; Koloor, S.S.R.; Petrů, M.; Tamin, M.N. Moisture absorption effects on mode II delamination of carbon/epoxy composites. Polymers 2020, 12, 2162. [Google Scholar] [CrossRef]

- Williams, S.W.; Ambat, R.; Price, D.; Jariyaboon, M.; Davenport, A.J.; Wescott, A. Laser treatment method for improvement of the corrosion resistance of friction stir welds. Mater. Sci. Forum 2003, 426, 2855–2860. [Google Scholar] [CrossRef]

- Omidi Bidgoli, M.; Reza Kashyzadeh, K.; Rahimian Koloor, S.S.; Petru, M. Estimation of critical dimensions for the crack and pitting corrosion defects in the oil storage tank using finite element method and taguchi approach. Metals 2020, 10, 1372. [Google Scholar] [CrossRef]

- Kim, H.T.; Kil, S.C.; Hwang, W.S.; Cho, W.-S. Investigation on the corrosion behaviour of weld structure. Corros. Sci. Technol. 2007, 6, 33–35. [Google Scholar]

- Khan, M.S.; Abdul-Latif, A.; Koloor, S.S.R.; Petrů, M.; Tamin, M.N. Representative cell analysis for damage-based failure model of polymer hexagonal honeycomb structure under the out-of-plane loadings. Polymers 2020, 13, 52. [Google Scholar] [CrossRef] [PubMed]

- Jacquin, D.; Guillemot, G. A review of microstructural changes occurring during FSW in aluminium alloys and their modelling. J. Mater. Process. Technol. 2021, 288, 116706. [Google Scholar] [CrossRef]

- Sorger, G.; Sarikka, T.; Vilaça, P.; Santos, T.G. Effect of processing temperatures on the properties of a high-strength steel welded by FSW. Weld. World 2018, 62, 1173–1185. [Google Scholar] [CrossRef]

- Gangwar, K.; Ramulu, M. Friction stir welding of titanium alloys: A review. Mater. Des. 2018, 141, 230–255. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.; Nagamadhu, M.; Malyadri, T. A critical review on microstructure and hardness of aluminum alloy 6061 joints obtained by friction stir welding-past, present, and its prospects. Mater. Today Proc. 2023, 82, 75–78. [Google Scholar] [CrossRef]

- Mishra, D.; Gupta, A.; Raj, P.; Kumar, A.; Anwer, S.; Pal, S.K.; Chakravarty, D.; Pal, S.; Chakravarty, T.; Pal, A.; et al. Real time monitoring and control of friction stir welding process using multiple sensors. CIRP J. Manuf. Sci. Technol. 2020, 30, 1–11. [Google Scholar] [CrossRef]

- Vishwakarma, R.P.; Singh, U.K.; Dubey, A.K. Thermal Analysis of Laser-assisted Friction Stir Welding (LAFSW) for Different Geometrical Parameters. Int. J. Laser Sci. Fundam. Theory Anal. Methods 2022, 3, 65–87. [Google Scholar]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Awang, M. A review on numerical modelling techniques in friction stir processing: Current and future perspective. Arch. Civ. Mech. Eng. 2023, 23, 154. [Google Scholar] [CrossRef]

- Mishra, R.S.; Haridas, R.S.; Agrawal, P. Friction stir-based additive manufacturing. Sci. Technol. Weld. Join. 2022, 27, 141–165. [Google Scholar] [CrossRef]

- Longhurst, W.R.; Strauss, A.M.; E Cook, G.; Cox, C.D.; E Hendricks, C.; Gibson, B.T.; Dawant, Y.S. Investigation of force-controlled friction stir welding for manufacturing and automation. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 937–949. [Google Scholar] [CrossRef]

| S. No. | Research Focus | Key Findings | Author and Reference |

|---|---|---|---|

| 1 | Joining EN AW6082 T6 alloy using EBM and FSW. | EBM resulted in high mechanical strength but brittle nature. FSW had better peak elongation. | [104] |

| 2 | Microstructural evolution of the FSW of AA1050 Al alloy. | The temperature profile stabilized during the acceleration stage. Balance stage for grain recrystallization and deformation. | [105] |

| 3 | Development of a novel FSW technique with cooling tank. | Novel setup improved uniform heating and cooling. Maximum strength was observed at 153.16 MPa for the ICFSW process. | [106] |

| 4 | Optimization of FSW conditions for AA-7075-T651 Al alloys. | Optimal conditions: 800 rpm tool rotation and 50 mm/min feed rate. Maximum strength of 278 MPa. | [107] |

| 5 | Effect of multi-pass rolling and annealing on FSW of AZ31 alloy. | Improved ultimate strength from 308 MPa to 383 MPa with increased elongation. | [108] |

| 6 | Optimization of FSW conditions for AA5052 thin plate. | Standard optimum conditions: 350 rpm rotation, 900 Kg axial load, and 550 mm/min welding speed. | [109] |

| 7 | Effect of increased traverse speed on the mechanical strength of FSW joints. | Increased traverse speed negatively affected mechanical strength. | [110] |

| 8 | FSW of dissimilar alloys (AA6082 and AA5052) with different pin profiles. | The square pin profile yielded maximum strength (185 MPa) with 96.35% joint efficiency. | [111] |

| 9 | Corrosion behavior of dissimilar material weld (AA6082 and AA6060). | Increased linear feed rate (200 mm/min) reduced residual stresses. | [112] |

| 10 | Evaluation of dissimilar FSW weld for AA6082 and AA5456 plates. | Optimized conditions: traverse speed 200 mm/min, tool rotation 1000 rpm, tool tilt angle 1°, and depth of pin 4 mm. A straight pin profile was the best. | [113] |

| 11 | Comparison of underwater FSW and conventional FSW with varying welding speeds. | Conventional FSW at 60 mm/min had maximum strength. Underwater FSW at 45 mm/min yielded the best results. | [114] |

| 12 | Dissimilar FSW for A6061 and AA7075 Al alloys with optimized process parameters. | Optimal parameters: 1164 rpm tool rotation, 32 mm/min traverse speed, 8.7% SiC particles. Max tensile strength of 252 MPa and a microhardness of 178 HV. | [115] |

| 13 | Effect of plate position on FSW weld characteristics for AA6061 and AA6082. | Better strength with AA6082 on the advancing side. Max tensile strength of 218 MPa along the weldment sample. | [116] |

| 14 | Positioning effect on mechanical properties of AA1050-H14 and AA6082-T6 Al alloys. | AA1050-H14 on the advancing side resulted in better mechanical strength. (Tool rotation: 1200 rpm, traverse speed: 40 mm/min, tool tilt: 2°). | [117] |

| 15 | Novel heat treatment process effect on grain coarsening for Al2219 alloy. | The intermediate heat treatment process improved weld strength by 20% and reduced crack propagation along the grain boundary. | [118] |

| 16 | Welding tubular components using the FSW technique with a novel tool design. | 3° concave tool design yielded maximum strength with minimum pores, while higher concavities improved surface roughness. | [119] |

| 17 | Joining of AA6061 and AA7075 using FSW with Al2O3 reinforcement. | Optimal conditions: 971 rpm tool speed, 40 mm/min traverse speed, and 10% Al2O3 volume percentage, resulting in a maximum joint strength of 226.2 MPa and a microhardness of 144.3 HV. | [120] |

| 18 | Corrosion behavior of FSW-welded Al6061-T6/AZ31 dissimilar alloy. | Maximum corrosion for sample A1 with the lowest pH value of 2. Increasing welding speed led to a decreased corrosion rate. Impact strength is reduced with decreasing temperature. | [121] |

| 19 | Formability for FSW for a dissimilar material of AA6061 and AA2017. | Optimized conditions: 1300 rpm tool rotation, 20 mm/min traverse speed, and 1° tool tilt angle. These conditions provided the best joint in comparison with other conditions. | [122] |

| 20 | Impact of the curvature radius of the tool on weld performance. | A curvature radius of less than 7 mm resulted in an accumulation of welding material. A 7 mm curvature radius was critical, with values below it leading to poor joint performance and values above it improving strength. | [123] |

| 21 | Effect of pin eccentricity on weld joint for AA5754-H111 and AA6101-T6 alloy. | Optimized conditions: 900 rpm tool rotational speed, 40 mm/min traverse speed, and 0.35 mm pin eccentricity for the FSW of dissimilar alloys. | [124] |

| S. No. | Research Focus | Key Findings | Reference |

|---|---|---|---|

| 1 | Mechanical strength prediction for AA5083 and AA5061 dissimilar alloys in FSW weld joints | The model used in the study was more accurate than other suggested models. | [125] |

| 2 | Mechanical properties prediction for AA6061-T6 alloy | XGBoost model gave an accuracy greater than 95%. | [126] |

| 3 | Various applications of machine learning in FSW | The hybrid approach using least square SVM-RVM provided the highest accuracy in predicting mechanical strength and hardness. | [128] |

| 4 | Relationship model for FSW weld characteristics and tool condition monitoring (TCM) | LGBMC worked better than other tested ML models. | [129] |

| 5 | Prediction of void formation in the FSW process | The hybrid model gave 90% accuracy in predicting voids in the FSW process. | [130] |

| 6 | Prediction of ultimate tensile strength for AA2050 alloy | K-Fold cross-validation provided the highest accuracy. | [131] |

| 7 | Prediction of ultimate tensile strength and elongation of FS-welded samples | SVR-PSO gave the fastest convergence. | [132] |

| 8 | Deep learning for predicting mechanical behavior in AA6061-T6 alloys | GRU deep learning model predicted properties with high accuracy and a fast response. | [133] |

| 9 | Prediction of weld quality based on images | The model achieved 96% accuracy for dissimilar alloy welding. | [134] |

| 10 | Deep learning for prediction of optimized working conditions for mechanical strength | DMLP model outperformed other deep learning techniques. | [135] |

| 11 | Wavelet transformation for dissimilar welding characteristics prediction | Relationship between signal types and output. | [136] |

| 12 | Deep learning for predicting weld defects | Bi-directional LSTM achieved accuracy greater than 95% for specific conditions. | [137] |

| 13 | Prediction of strength and FSW processing condition for Al 2195 alloy | Established a 92% accurate model for FSW processing conditions. | [138] |

| 14 | AI-based models for predicting mechanical strength in FSW welds | Various AI and deep learning models are used for relationship modeling between process variables and output signals. | [139] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bharti, S.; Kumar, S.; Singh, I.; Kumar, D.; Bhurat, S.S.; Abdullah, M.R.; Rahimian Koloor, S.S. A Review of Recent Developments in Friction Stir Welding for Various Industrial Applications. J. Mar. Sci. Eng. 2024, 12, 71. https://doi.org/10.3390/jmse12010071

Bharti S, Kumar S, Singh I, Kumar D, Bhurat SS, Abdullah MR, Rahimian Koloor SS. A Review of Recent Developments in Friction Stir Welding for Various Industrial Applications. Journal of Marine Science and Engineering. 2024; 12(1):71. https://doi.org/10.3390/jmse12010071

Chicago/Turabian StyleBharti, Shalok, Sudhir Kumar, Inderjeet Singh, Dinesh Kumar, Swapnil Sureshchandra Bhurat, Mohamed Ruslan Abdullah, and Seyed Saeid Rahimian Koloor. 2024. "A Review of Recent Developments in Friction Stir Welding for Various Industrial Applications" Journal of Marine Science and Engineering 12, no. 1: 71. https://doi.org/10.3390/jmse12010071

APA StyleBharti, S., Kumar, S., Singh, I., Kumar, D., Bhurat, S. S., Abdullah, M. R., & Rahimian Koloor, S. S. (2024). A Review of Recent Developments in Friction Stir Welding for Various Industrial Applications. Journal of Marine Science and Engineering, 12(1), 71. https://doi.org/10.3390/jmse12010071