Modeling and Analysis of Resistance-Sensing Characteristics for Two-Way Shape Memory Alloy-Based Deep-Sea Actuators

Abstract

:1. Introduction

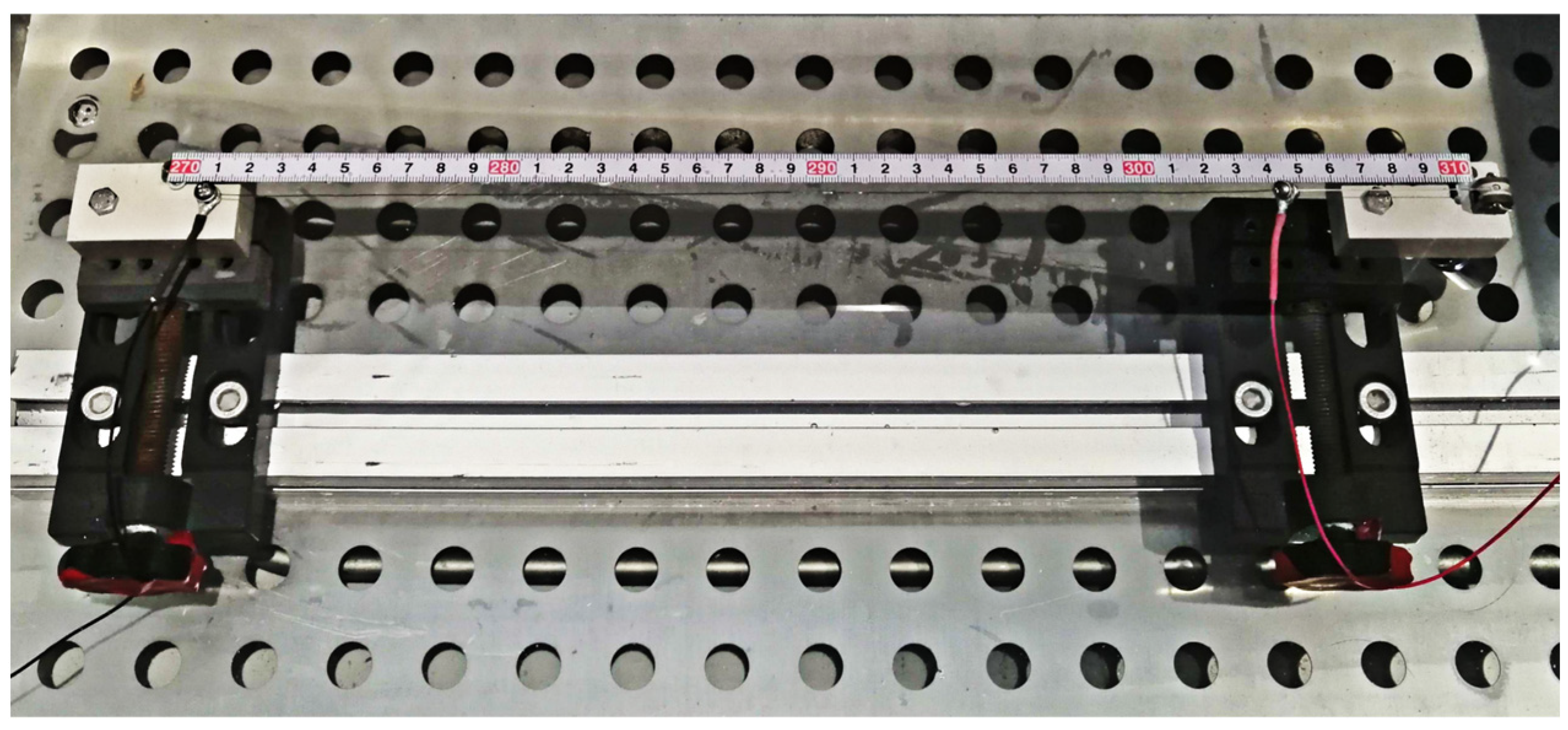

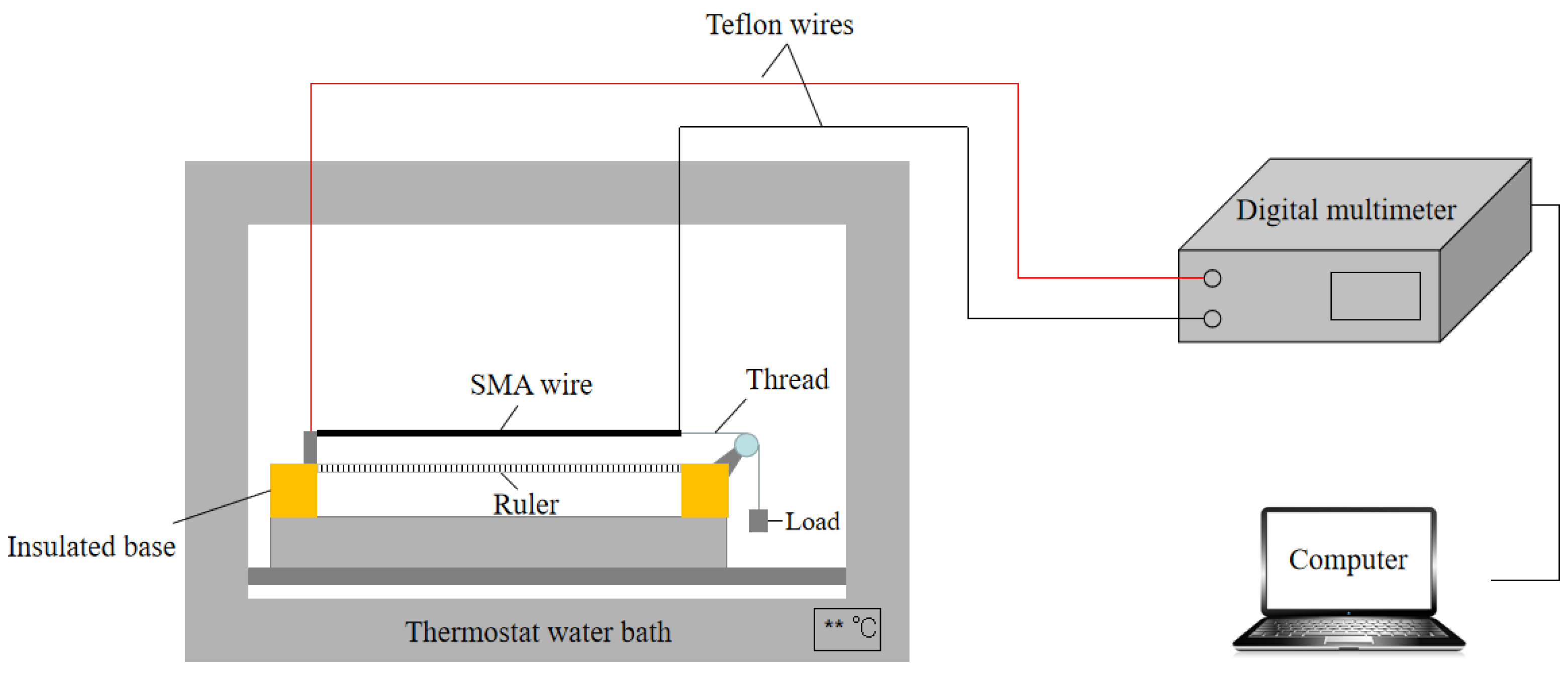

2. Experimental Setup

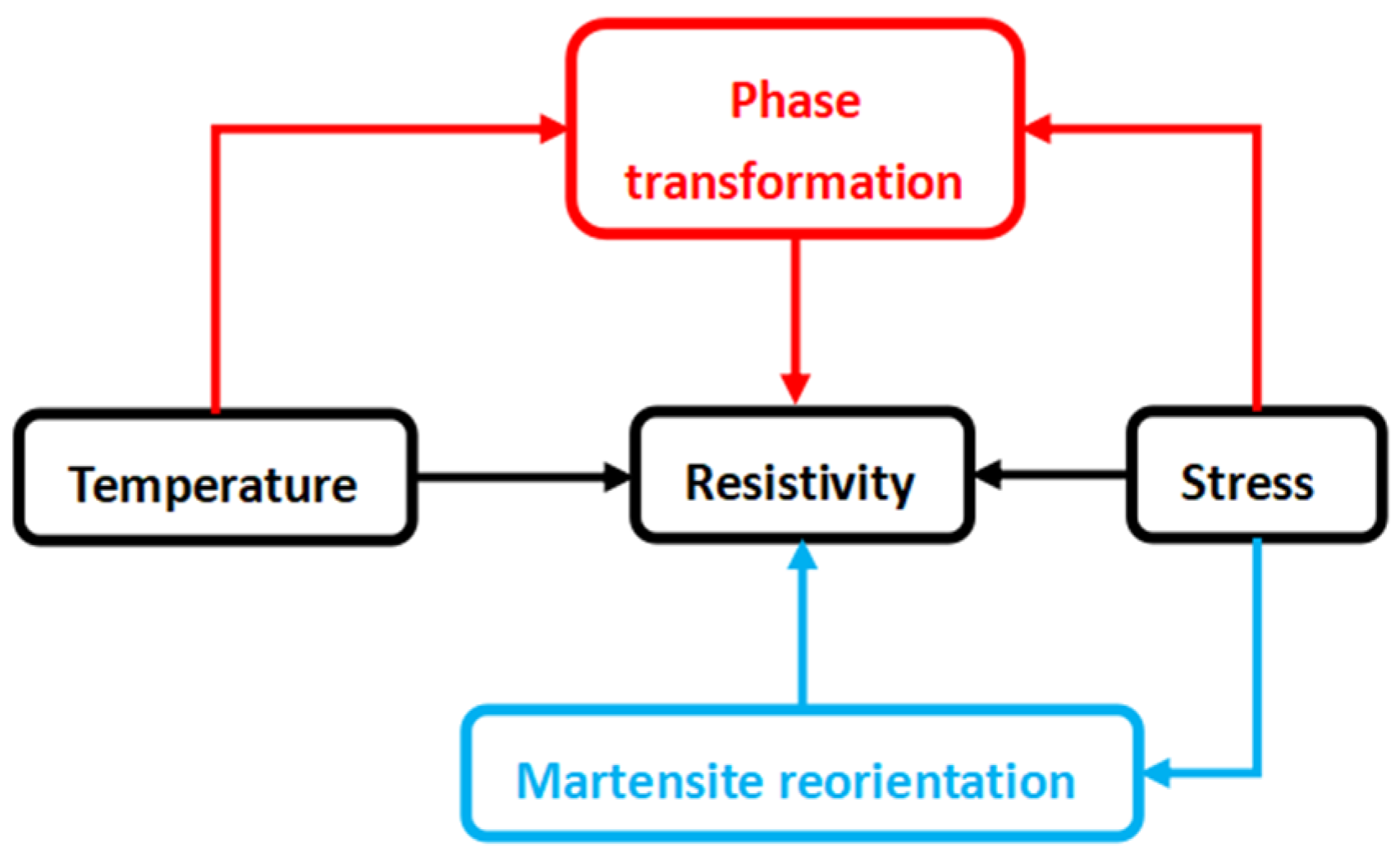

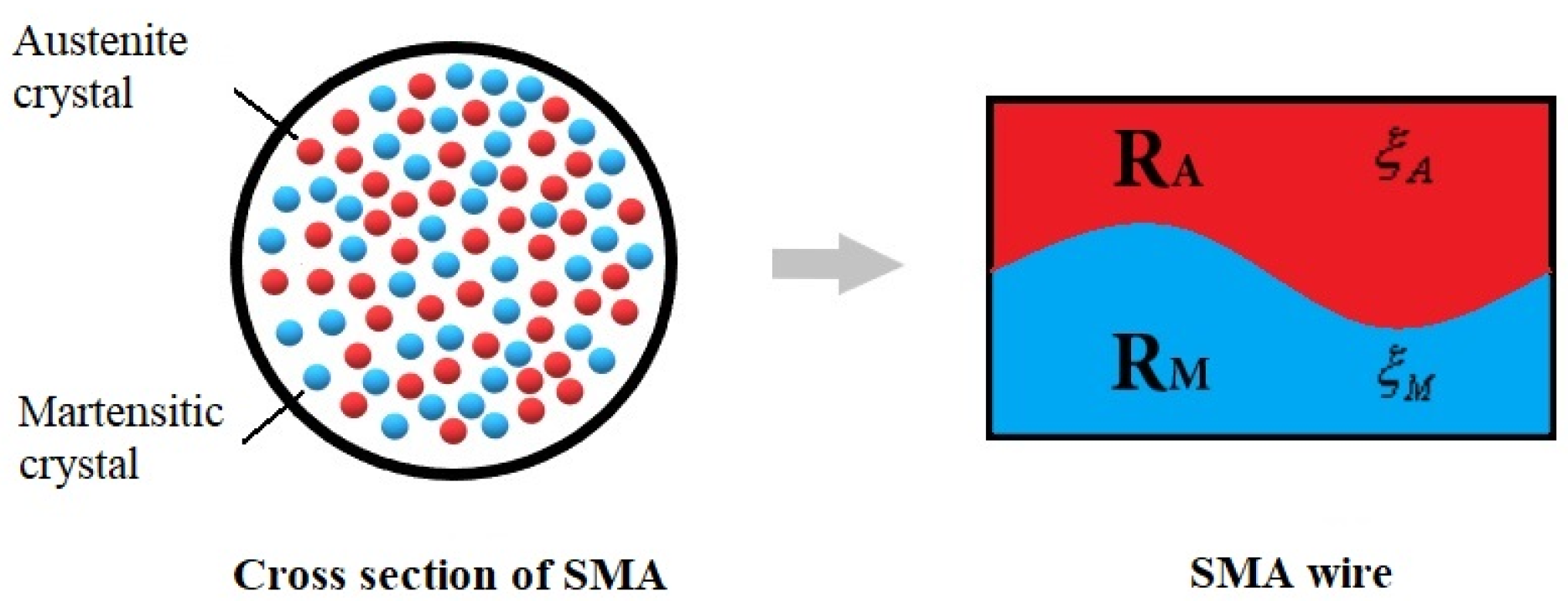

3. Resistance-Sensing Model of SMA

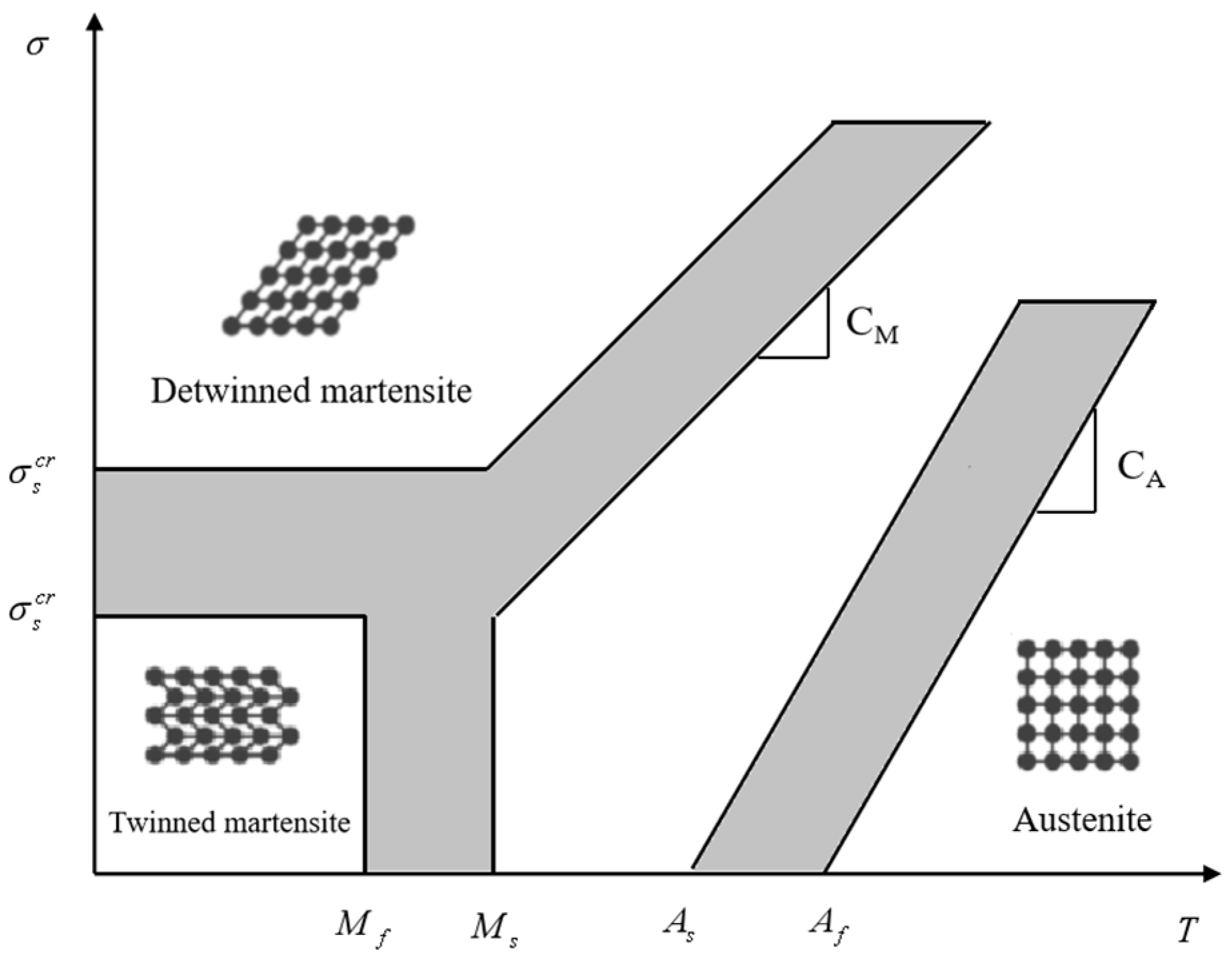

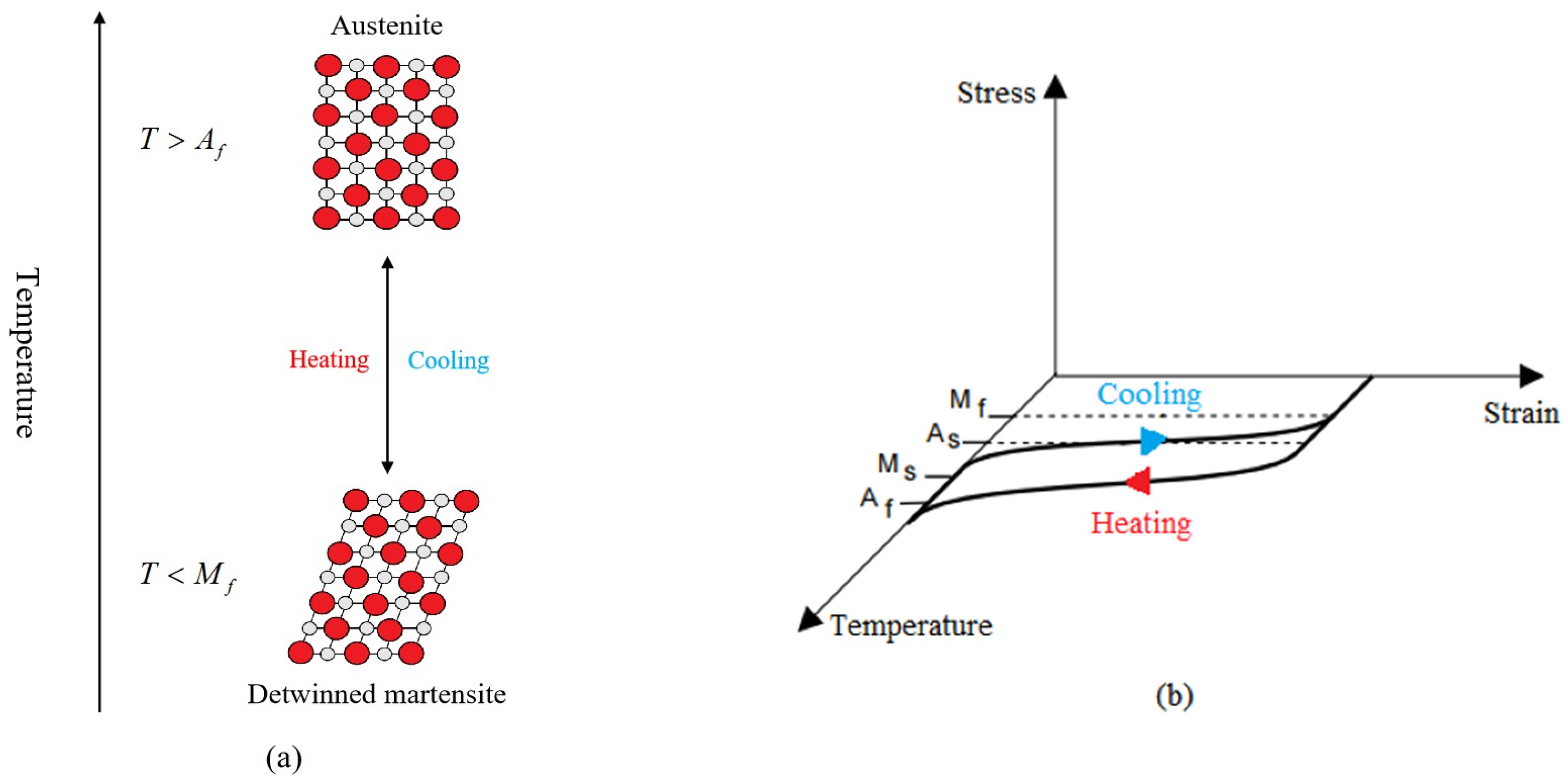

3.1. Macromechanical Characterization of SMAs in the Deep-Sea Environment

3.2. Temperature and Stress Dependence of Resistivity

3.3. Resistance-Sensing Characteristics of SMAs

4. Results

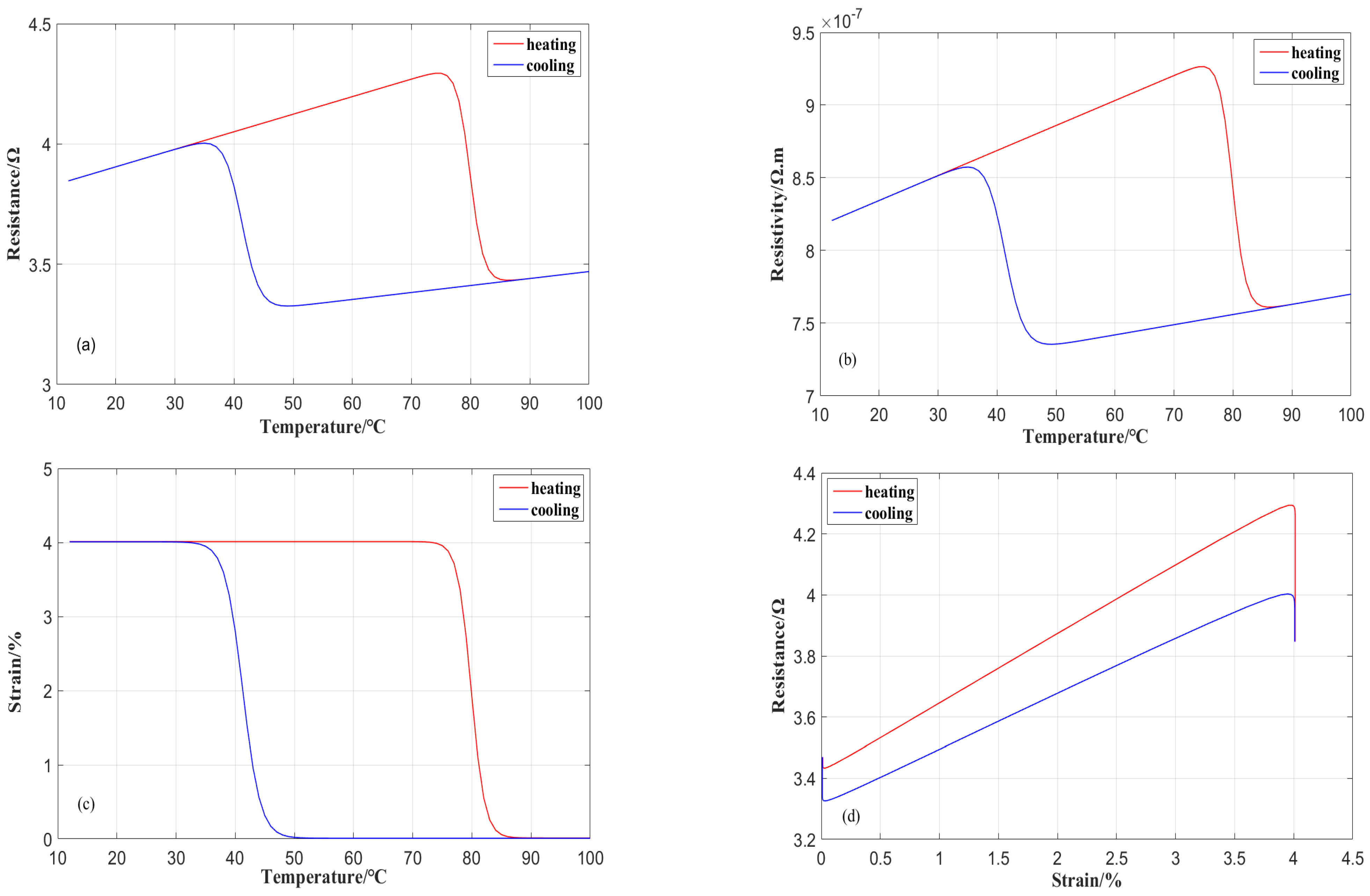

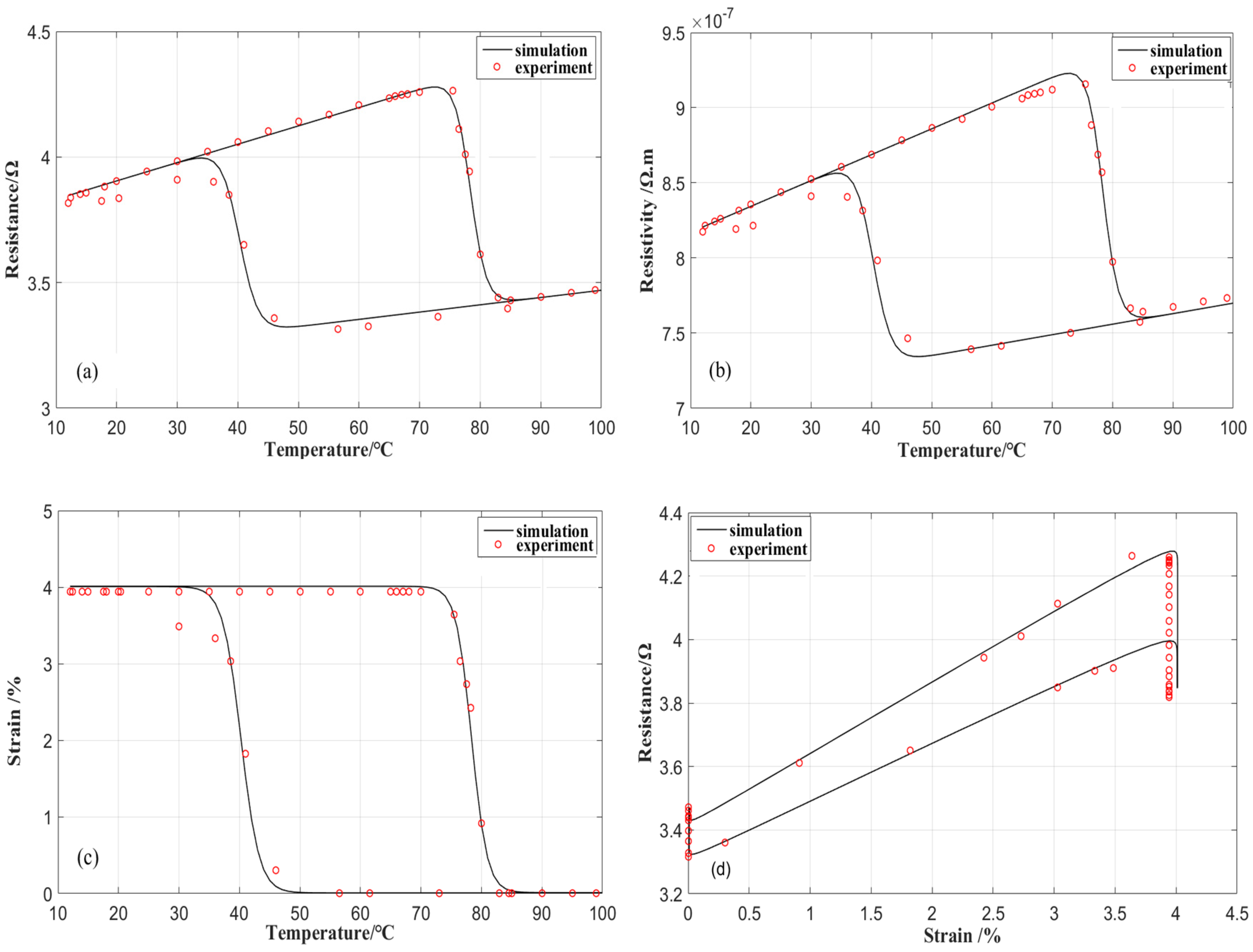

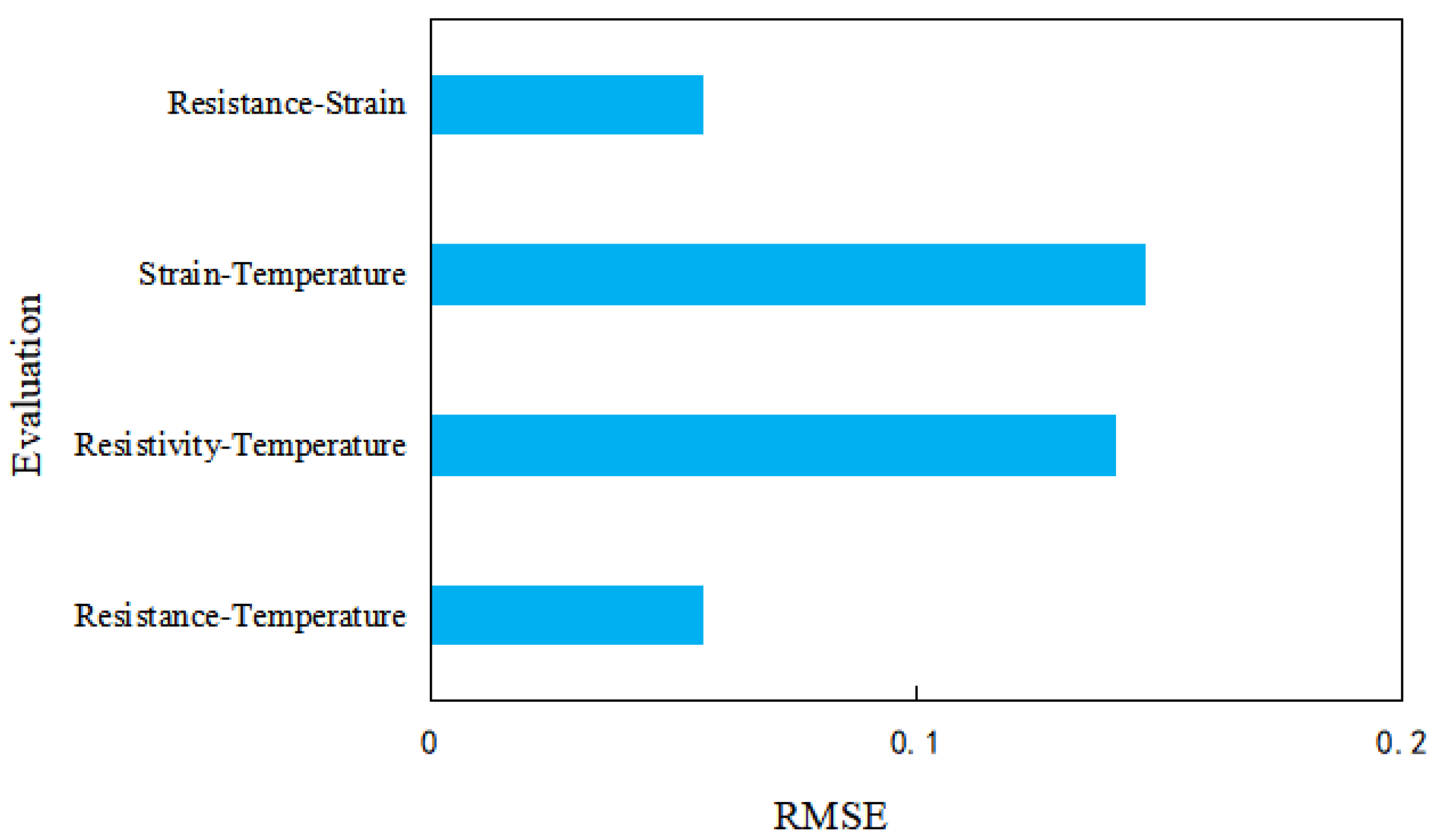

4.1. Numerical Simulation and Analysis of SMA Resistance-Sensing Model

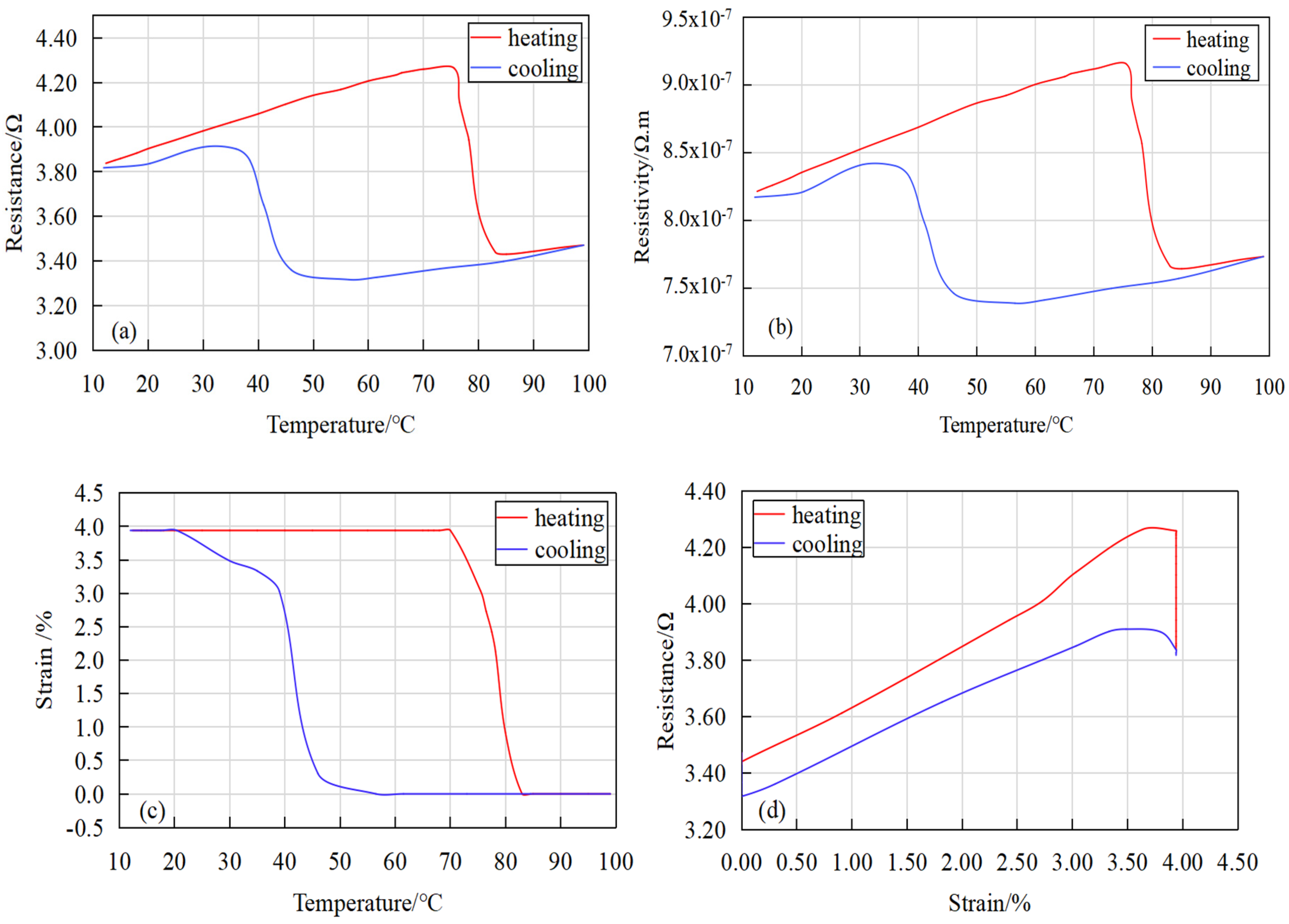

4.2. Thermomechanical Response in the Water Bath Environment

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, C. The potential and challenges of China’s marine science and technology development. People’s Forum·Acad. Front. 2017, 37–43. [Google Scholar] [CrossRef]

- Guo, J.; Pan, B.; Cui, W.; Hu, S.; Han, Z. Review of deep-sea actuators and marine bionic robots based on intelligent materials. Ship Mech. 2022, 26, 13. [Google Scholar]

- Bai, Z. Summary of research progress and application of smart materials. Mil. Civ. Dual-Use Technol. Prod. 2020, 3, 15–20. [Google Scholar] [CrossRef]

- Hao, L. Research on Mechanical Properties of Shape Memory Alloy Bulge. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Costanza, G.; Paoloni, S.; Tata, M.E. IR Thermography and Resistivity Investigations on Ni-Ti Shape Memory Alloy. Key Eng. Mater. 2014, 605, 23–26. [Google Scholar] [CrossRef]

- Naganuma, T.; Kyo, M.; Ueki, T.; Takeda, K.; Ishibashi, J.I. A new, automatic hydrothermal fluid sampler using a shape-memory alloy. J. Oceanogr. 1998, 54, 241–246. [Google Scholar] [CrossRef]

- Angilella, A.J.; Gandhi, F.S.; Miller, T.F. Design and testing of a shape memory alloy buoyancy engine for unmanned underwater vehicles. Smart Mater. Struct. 2015, 24, 115018. [Google Scholar] [CrossRef]

- Cui, D.; Song, G.; Li, H. Modeling of the electrical resistance of shape memory alloy wires. Smart Mater. Struct. 2010, 19, 055019. [Google Scholar] [CrossRef]

- Zhang, J.J.; Yin, Y.H.; Zhu, J.Y. Electrical resistivity-based study of self-sensing properties for shape memory alloy-actuated artificial muscle. Sensors 2013, 13, 12958–12974. [Google Scholar] [CrossRef] [PubMed]

- Dhanalakshmi, K. Shape memory alloy wire for self-sensing servo actuation. Mech. Syst. Signal Process. 2017, 83, 36–52. [Google Scholar]

- Lu, Y.; Zhang, R.; Xu, Y.; Wang, L.; Yue, H. Resistance characteristics of SMA actuator based on the variable speed phase transformation constitutive model. Materials 2020, 13, 1479. [Google Scholar] [CrossRef] [PubMed]

- Liu, B. Study on the Phase Transformation Mechanism and Mechanical Properties of Porous Shape Memory Alloys. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2013. [Google Scholar]

- Zhu, X.; Dui, G. Modeling of superelastic–plastic behavior of porous shape memory alloys incorporating void shape effects. Acta Mech. Solida Sin. 2021, 34, 632–644. [Google Scholar] [CrossRef]

- Yang, J.; Huang, B.; Gu, X.; Wang, J.; Zhang, Y.; Zhu, J.; Zhang, W. Review of Mechanical Behavior and Application of Shape Memory Alloys. J. Solid Mech. 2021, 42, 345–375. [Google Scholar]

- Cisse, C.; Zaki, W.; Zineb, T.B. A review of constitutive models and modeling techniques for shape memory alloys. Int. J. Plast. 2016, 76, 244–284. [Google Scholar] [CrossRef]

- Wan, J.L.; Chen, Z.B.; Qin, S.J.; Shang, J.X. Effect of hydrostatic pressure on thermally induced phase transformation in NiTi alloy: A molecular dynamics study. Comput. Mater. Sci. 2018, 153, 119–125. [Google Scholar] [CrossRef]

- Ikuta, K.; Tsukamoto, M.; Hirose, S. Mathematical model and experimental verification of shape memory alloy for designing micro actuator. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, Nara, Japan, 30 December 1990–2 January 1991; pp. 103–108. [Google Scholar]

- Guo, J.; Pan, B.; Cui, W.; Hu, S. A nonlinear phase transition dynamic model for shape memory alloys based Deep Sea actuators. J. Mar. Sci. Eng. 2022, 10, 1951. [Google Scholar] [CrossRef]

- Guan, J.H.; Pei, Y.C.; Wu, J.T. A driving strategy of shape memory alloy wires with electric resistance modeled by logistic function for power consumption reduction. Mech. Syst. Signal Process. 2021, 160, 107839. [Google Scholar] [CrossRef]

- Lynch, B.; Jiang, X.X.; Ellery, A.; Nitzsche, F. Characterization, modeling, and control of Ni-Ti shape memory alloy based on electrical resistance feedback. J. Intell. Mater. Syst. Struct. 2016, 27, 2489–2507. [Google Scholar] [CrossRef]

- Brinson, L.C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J. Intell. Mater. Syst. Struct. 1993, 4, 229–242. [Google Scholar] [CrossRef]

- Novák, V.; Šittner, P.; Dayananda, G.N.; Braz-Fernandes, F.M.; Mahesh, K.K. Electric resistance variation of NiTi shape memory alloy wires in thermomechanical tests: Experiments and simulation. Mater. Sci. Eng. A 2008, 481, 127–133. [Google Scholar] [CrossRef]

- Brammajyosula, R.; Buravalla, V.; Khandelwal, A. Model for resistance evolution in shape memory alloys including R-phase. Smart Mater. Struct. 2011, 20, 035015. [Google Scholar] [CrossRef]

- Sakagami, T.; Seki, K.; Iwasaki, M. Sensorless position control based on resistance and heat transfer models in shape memory alloy actuators. In Proceedings of the 2019 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Hong Kong, China, 8–12 July 2019; pp. 217–222. [Google Scholar]

- Dutta, S.M.; Ghorbel, F.H. Differential hysteresis modeling of a shape memory alloy wire actuator. IEEE/ASME Trans. Mechatron. 2005, 10, 189–197. [Google Scholar] [CrossRef]

- Wu, Y. Research on Mechanical Properties and Constitutive Model of Shape Memory Alloys. Master’s Thesis, South China University of Technology, Guangzhou, China, 2012. [Google Scholar]

- Hu, Y. Precise Driving Method and Experimental Research of Wire-Type Shape Memory Alloy Vehicle-Mounted Actuator. Master’s Thesis, Jilin University, Jilin, China, 2021. [Google Scholar]

| Phase Transformation Temperature | Resistance Parameters | Young’s Modulus | Phase Transformation Parameters | Maximum Residual Strain |

|---|---|---|---|---|

| Mf = 34.5 °C | = 0.007 Ω/°C | DM = 67,000 MPa | CM = 8 MPa/°C | = 0.04 |

| Ms = 45 °C | = 0.003 Ω/°C | DA = 26,300 MPa | CA = 13.8 MPa/°C | |

| As = 73 °C | R0M = 3.84 Ω | Θ = 0.55 MPa/°C | = 7 | |

| Af = 82 °C | R0A = 3.47 Ω | |||

| T0M = 12 °C | ||||

| T0A = 99 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Pan, B.; Cui, W.; Xiang, H. Modeling and Analysis of Resistance-Sensing Characteristics for Two-Way Shape Memory Alloy-Based Deep-Sea Actuators. J. Mar. Sci. Eng. 2024, 12, 1703. https://doi.org/10.3390/jmse12101703

Guo J, Pan B, Cui W, Xiang H. Modeling and Analysis of Resistance-Sensing Characteristics for Two-Way Shape Memory Alloy-Based Deep-Sea Actuators. Journal of Marine Science and Engineering. 2024; 12(10):1703. https://doi.org/10.3390/jmse12101703

Chicago/Turabian StyleGuo, Jian, Binbin Pan, Weicheng Cui, and Huiming Xiang. 2024. "Modeling and Analysis of Resistance-Sensing Characteristics for Two-Way Shape Memory Alloy-Based Deep-Sea Actuators" Journal of Marine Science and Engineering 12, no. 10: 1703. https://doi.org/10.3390/jmse12101703