Risk Identification and Safety Evaluation of Offshore Wind Power Submarine Cable Construction

Abstract

1. Introduction

2. Methods

2.1. Analytic Hierarchy Process (AHP)

- (1)

- Hierarchical analytical modeling

- (2)

- Constructing a judgment matrix

- (3)

- Hierarchical ordering and testing

- (4)

- Consistency check

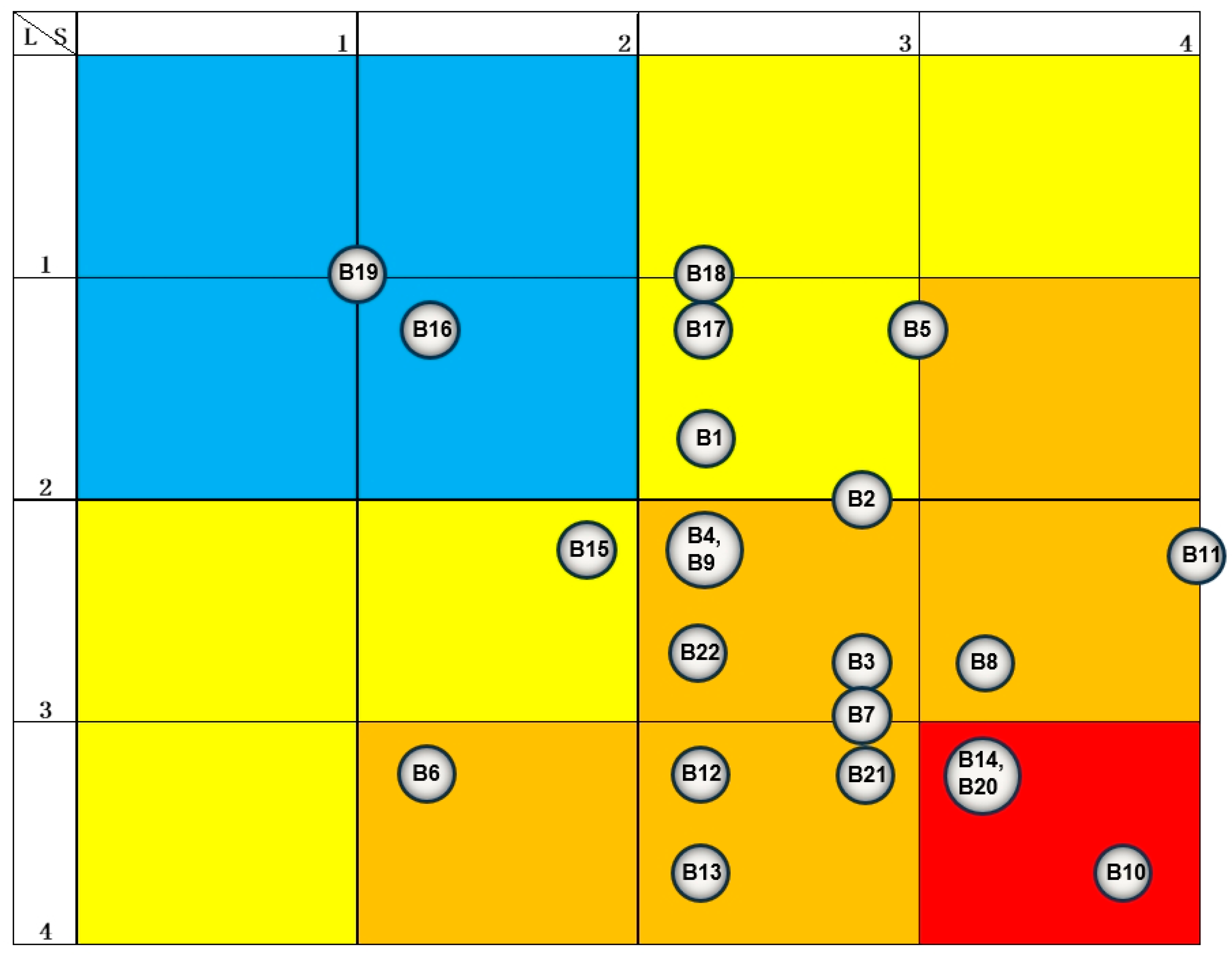

2.2. Risk Matrix Method (LS)

3. Risk Identification

3.1. Construction Workflow

3.2. Risk Identification

- (1)

- Identification of equipment failure risk sources

- (2)

- Identification of worker error risk sources

- (3)

- Identification of environmental impact risk sources

- (4)

- Identification of management defect risk sources

- (5)

- Identification of third-party destruction risk sources

4. Safety Evaluation

4.1. First-Level Risk Factor Evaluation

4.1.1. Severity Analysis

4.1.2. Probability Analysis

4.1.3. Detection Difficulty Analysis

4.1.4. Evaluate Results

4.2. Secondary-Level Risk Factor Evaluation

5. Discussion

- (1)

- Environmental monitoring

- (2)

- Third-party destruction protection

- (3)

- Worker training

- (4)

- Equipment improvements

- (5)

- Improvement of the level of management

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martinez, A.; Iglesias, G. Global wind energy resources decline under climate change. Energy 2024, 288, 129765. [Google Scholar] [CrossRef]

- Fang, S.-H.; Zhu, H.-Q.; Yang, D.-D.; Yu, J.-X.; Wang, J.; Hu, L.-T. Microscopic investigation of the effect of uniaxial stress on the structure of pore-fissure system and methane adsorption in lean coal. Energy 2024, 288, 129837. [Google Scholar] [CrossRef]

- Yang, D.-D.; Qin, Y.-J.; Xu, Y.-R.; Xing, K.-X.; Chen, Y.-J.; Jia, X.-P.; Aviso, K.-B.; Tan, R.-R.; Wang, B.-H. Sequestration of carbon dioxide from the atmosphere in coastal ecosystems: Quantification, analysis, and planning. Sustain. Prod. Consum. 2024, 47, 413–424. [Google Scholar] [CrossRef]

- Joyce, L.F.Z. Global Wind Report 2024; Global Wind Energy Council: Brussels, Belgium, 2024. [Google Scholar]

- Karayel, G.K.; Dincer, I. A study on green hydrogen production potential of Canada with onshore and offshore wind power. J. Clean. Prod. 2024, 437, 140660. [Google Scholar] [CrossRef]

- Wang, W.; Huang, H.; Peng, X.; Wang, Z.; Zeng, Y. Utilizing support vector machines to foster sustainable development and innovation in the clean energy sector via green finance. J. Environ. Manag. 2024, 360, 121225. [Google Scholar] [CrossRef]

- Zhao, Y.; Xue, Y.; Gao, S.; Wang, J.; Cao, Q.; Sun, T.; Liu, Y. Computation and Analysis of an Offshore Wind Power Forecast: Towards a Better Assessment of Offshore Wind Power Plant Aerodynamics. Energies 2022, 15, 4223. [Google Scholar] [CrossRef]

- Jia, Y.; Ren, B.; Li, Q.; Wang, C.; Wang, D.; Zou, X. An Integrated Scheme for Forecasting and Controlling Ramps in Offshore Wind Farms Considering Wind Power Uncertainties during Extreme Storms. Electronics 2023, 12, 4443. [Google Scholar] [CrossRef]

- Rebecca, W.F.Z. Global Offshore Wind Report 2024; Global Wind Energy Council: Brussels, Belgium, 2024. [Google Scholar]

- Wang, J.-Z.; Qin, S.-S.; Jin, S.-Q.; Wu, J. Estimation methods review and analysis of offshore extreme wind speeds and wind energy resources. Renew. Sustain. Energy Rev. 2015, 42, 26–42. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, L.-P.; Sun, H.; Guo, Q.; Bai, X. Floating offshore wind turbine reliability analysis based on system grading and dynamic FTA. J. Wind Eng. Ind. Aerodyn. 2016, 154, 21–33. [Google Scholar] [CrossRef]

- Johnston, A.; Cook, A.; Wright, L.; Humphreys, E.; Burton, N. Modelling flight heights of marine birds to more accurately assess collision risk with offshore wind turbines. J. Appl. Ecol. 2014, 51, 31–41. [Google Scholar] [CrossRef]

- Wu, Y.-N.; Zhang, T. Risk assessment of offshore wave-wind-solar-compressed air energy storage power plant through fuzzy compre-hensive evaluation model. Energy 2021, 223, 120057. [Google Scholar] [CrossRef]

- Lian, J.-J.; Hou, G.; Cai, O.; Xu, K. Assessing the life cycle risks of offshore wind turbines with suction bucket foundations. J. Clean. Prod. 2022, 362, 132366. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Wu, Y.-F. Investment Evaluation and Partnership Selection Model in the Offshore Wind Power Underwater Foundations Industry. J. Mar. Sci. Eng. 2021, 9, 1371. [Google Scholar] [CrossRef]

- Kazmi, S.; Laneryd, T.; Giannikas, K.; Ahrenfeldt, S.; Sørensen, T.; Olesen, T.; Holbøll, J. Cost optimized dynamic design of offshore windfarm transformers with reliability and contingency considerations. Int. J. Electr. Power Energy Syst. 2021, 128, 106684. [Google Scholar] [CrossRef]

- Soukissian, T.; Karathanasi, F.; Zaragkas, D. Exploiting offshore wind and solar resources in the Mediterranean using ERA5 reanalysis data. Energy Convers. Manag. 2021, 237, 114092. [Google Scholar] [CrossRef]

- Kuang, J.; Chen, G.; Yuan, Z.; Qi, X.; Yu, Q.; Liu, Z. Dynamic Interactions of a Cable-Laying Vessel with a Submarine Cable during Its Landing Process. J. Mar. Sci. Eng. 2022, 10, 774. [Google Scholar] [CrossRef]

- Dong, T.; Brakelmann, H.; Anders, G.J. Analysis method for the design of long submarine cables. Renew. Sustain. Energy Rev. 2023, 171, 113029. [Google Scholar] [CrossRef]

- Perveen, R.; Kishor, N.; Mohanty, S.R. Off-shore wind farm development: Present status and challenges. Renew. Sustain. Energy Rev. 2014, 29, 780–792. [Google Scholar] [CrossRef]

- Zhu, Z.; Liang, Y.; Chen, L.; Liu, Y.; Du, Y. Study on AC interference law of high voltage AC cable to submarine pipeline and safe distance. Mater. Corros. 2022, 74, 560–575. [Google Scholar] [CrossRef]

- Cazzaro, D.; Koza, D.F.; Pisinger, D. Combined layout and cable optimization of offshore wind farms. Eur. J. Oper. Res. 2023, 311, 301–315. [Google Scholar] [CrossRef]

- Choi, J.-K.; Yokobiki, T.; Kawaguchi, K. ROV-Based Automated Cable-Laying System: Application to DONET2 Installation. IEEE J. Ocean. Eng. 2018, 43, 665–676. [Google Scholar] [CrossRef]

- Lux, J.; Olschewski, M.; Schafer, P.; Hill, W. Real-Time Determination of Depth of Burial Profiles for Submarine Power Cables. IEEE Trans. Power Deliv. 2019, 34, 1079–1086. [Google Scholar] [CrossRef]

- Pérez-Rúa, J.A.; Lumbreras, S.; Ramos, A.; Cutululis, N.A. Reliability-based topology optimization for offshore wind farm collection system. Wind Energy 2021, 25, 52–70. [Google Scholar] [CrossRef]

- Mamatsopoulos, V.A.; Michailides, C.; Theotokoglou, E.E. An Analysis Tool for the Installation of Submarine Cables in an S-Lay Configuration Including “In and Out of Water” Cable Segments. J. Mar. Sci. Eng. 2020, 8, 48. [Google Scholar] [CrossRef]

- Cui, D.-h.; Zhang, X.-y. Application of gray analytic hierarchy process in project risk evaluation. In Proceedings of the 2009 International Conference on Artificial Intelligence and Computational Intelligence, Shanghai, China, 7–8 November 2009; pp. 592–594. [Google Scholar] [CrossRef]

- Díaz, H.; Teixeira, A.P.; Guedes Soares, C. Application of Monte Carlo and Fuzzy Analytic Hierarchy Processes for ranking floating wind farm locations. Ocean Eng. 2022, 245, 110453. [Google Scholar] [CrossRef]

- Jia, P.; Lv, J.; Sun, W.; Jin, H.; Meng, G.; Li, J. Modified analytic hierarchy process for risk assessment of fire and explosion accidents of external floating roof tanks. Process Saf. Prog. 2023, 43, 9–26. [Google Scholar] [CrossRef]

- Gass, S.I. Model World: The Great Debate—MAUT versus AHP. Interfaces 2005, 35, 308–312. [Google Scholar] [CrossRef]

- Wang, Y.-M.; Chin, K.-S.; Leung, J.P.-F. A note on the application of the data envelopment analytic hierarchy process for supplier selection. Int. J. Prod. Res. 2009, 47, 3121–3138. [Google Scholar] [CrossRef]

- Wang, F.; Lu, Y.; Li, J.; Ni, J. Evaluating Environmentally Sustainable Development Based on the PSR Framework and Variable Weigh Analytic Hierarchy Process. Int. J. Environ. Res. Public Health 2021, 18, 2836. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, H.; Qu, W.; Luan, P.; Sun, J. Research on Geological Safety Evaluation Index Systems and Methods for Assessing Underground Space in Coastal Bedrock Cities Based on a Back-Propagation Neural Network Comprehensive Evaluation–Analytic Hierarchy Process (BPCE-AHP). Sustainability 2023, 15, 8055. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Z.-R.; Song, Z.-Y.; Guo, P.-K.; Cao, X.-Y. Assessment of domino effects in the coal gasification process using Fuzzy Analytic Hierarchy Process and Bayesian Network. Saf. Sci. 2020, 130, 104888. [Google Scholar] [CrossRef]

| Scale | Meaning |

|---|---|

| 1 | Two factors are equally important |

| 2 | The former is slightly more important than the latter |

| 3 | The former is significantly more important than the latter |

| 4 | The former is strongly more important than the latter |

| 5 | The former is extremely more important than the latter |

| Reciprocal | The scale of factor Ai to factor Aj is aij, and vice versa, 1/aij |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| RI | 0 | 0 | 0.52 | 0.89 | 1.12 | 1.25 | 1.35 | 1.40 | 1.45 | 1.49 | 1.52 | 1.54 | 1.56 | 1.58 | 1.59 |

| Symbol | Value | Meaning |

|---|---|---|

| L | 1 | Almost never occurs |

| 2 | Rarely occurs | |

| 3 | Occasionally occurs | |

| 4 | Frequent occurrence | |

| S | 1 | Almost no loss |

| 2 | Minor loss | |

| 3 | Moderate loss | |

| 4 | Serious losses | |

| R | L < 2 and S < 2 | Low risk |

| L < 1 and 2 ≤ S; 1 ≤ L < 2 and 2 ≤ S < 3; 2 ≤ L < 3 and S < 2; 3 ≤ L and S < 1 | General risk | |

| 1 ≤ L < 2 and 3 ≤ S; 2 ≤ L <3 and 2 ≤ S; 3 ≤ L and 1 ≤ S < 3 | Significant risk | |

| 3 ≤ L and 3 ≤ S | Major risks |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Matrix 1 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 2 | 2 | 4 | 4 | 0.3936 | λmax = 5.056 CI = 0.014 CR = 0.012 |

| A2 | 1/2 | 1 | 1 | 3 | 2 | 0.2135 | |

| A3 | 1/2 | 1 | 1 | 2 | 2 | 0.1968 | |

| A4 | 1/4 | 1/3 | 1/2 | 1 | 1/2 | 0.0810 | |

| A5 | 1/4 | 1/2 | 1/2 | 2 | 1 | 0.1151 | |

| (b) | |||||||

| Matrix 2 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 3 | 2 | 4 | 5 | 0.4146 | λmax = 5.139 CI = 0.035 CR = 0.031 |

| A2 | 1/3 | 1 | 1/2 | 3 | 3 | 0.1799 | |

| A3 | 1/2 | 2 | 1 | 2 | 4 | 0.2423 | |

| A4 | 1/4 | 1/3 | 1/2 | 1 | 2 | 0.1011 | |

| A5 | 1/5 | 1/3 | 1/4 | 1/2 | 1 | 0.0621 | |

| (c) | |||||||

| Matrix 3 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 2 | 1/3 | 1 | 2 | 0.1870 | λmax = 5.189 CI = 0.047 CR = 0.042 |

| A2 | 1/2 | 1 | 1/2 | 1/2 | 3 | 0.1526 | |

| A3 | 3 | 2 | 1 | 2 | 4 | 0.3786 | |

| A4 | 1 | 2 | 1/2 | 1 | 2 | 0.1999 | |

| A5 | 1/2 | 1/3 | 1/4 | 1/2 | 1 | 0.0818 | |

| (d) | |||||||

| Matrix 4 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 2 | 1/3 | 4 | 2 | 0.2335 | λmax = 5.160 CI = 0.040 CR = 0.036 |

| A2 | 1/2 | 1 | 1/3 | 2 | 2 | 0.1551 | |

| A3 | 3 | 3 | 1 | 4 | 3 | 0.4210 | |

| A4 | 1/4 | 1/2 | 1/4 | 1 | 1/2 | 0.0732 | |

| A5 | 1/2 | 1/2 | 1/3 | 2 | 1 | 0.1173 | |

| (e) | |||||||

| Matrix 5 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 5 | 2 | 4 | 3 | 0.4206 | λmax = 5.193 CI = 0.048 CR = 0.043 |

| A2 | 1/5 | 1 | 1/4 | 1/2 | 1/3 | 0.0619 | |

| A3 | 1/2 | 4 | 1 | 3 | 2 | 0.2654 | |

| A4 | 1/4 | 2 | 1/3 | 1 | 2 | 0.1296 | |

| A5 | 1/3 | 3 | 1/2 | 1/2 | 1 | 0.1224 | |

| Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Mean Value | Calculated Value | |

|---|---|---|---|---|---|---|---|

| A1 | 0.3936 | 0.4146 | 0.1870 | 0.2335 | 0.4206 | 0.3298 | 4.9479 |

| A3 | 0.1968 | 0.2423 | 0.3786 | 0.4210 | 0.2654 | 0.3008 | 4.5123 |

| A2 | 0.2135 | 0.1799 | 0.1526 | 0.1551 | 0.0619 | 0.1526 | 2.2890 |

| A4 | 0.0810 | 0.1011 | 0.1999 | 0.0732 | 0.1296 | 0.1170 | 1.7544 |

| A5 | 0.1151 | 0.0621 | 0.0818 | 0.1173 | 0.1224 | 0.0997 | 1.4961 |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Matrix 1 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/3 | 1/4 | 2 | 1/2 | 0.1001 | λmax = 5.065 CI = 0.016 CR = 0.015 |

| A2 | 3 | 1 | 1/2 | 4 | 2 | 0.2642 | |

| A3 | 4 | 2 | 1 | 5 | 3 | 0.4189 | |

| A4 | 1/2 | 1/4 | 1/5 | 1 | 1/2 | 0.0679 | |

| A5 | 2 | 1/2 | 1/3 | 2 | 1 | 0.1489 | |

| (b) | |||||||

| Matrix 2 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/2 | 1/3 | 1/2 | 1/2 | 0.0937 | λmax = 5.276 CI = 0.069 CR = 0.062 |

| A2 | 2 | 1 | 1/3 | 3 | 1/2 | 0.1654 | |

| A3 | 3 | 3 | 1 | 5 | 2 | 0.4005 | |

| A4 | 2 | 1/3 | 1/5 | 1 | 1/4 | 0.0932 | |

| A5 | 2 | 2 | 1/2 | 4 | 1 | 0.2471 | |

| (c) | |||||||

| Matrix 3 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/3 | 1/4 | 1/2 | 1/5 | 0.0627 | λmax = 5.072 CI = 0.018 CR = 0.016 |

| A2 | 3 | 1 | 1 | 2 | 1/3 | 0.1852 | |

| A3 | 4 | 1 | 1 | 3 | 1/2 | 0.2322 | |

| A4 | 2 | 1/2 | 1/3 | 1 | 1/4 | 0.0993 | |

| A5 | 5 | 3 | 2 | 4 | 1 | 0.4206 | |

| (d) | |||||||

| Matrix 4 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/2 | 1/3 | 1 | 1/2 | 0.1036 | λmax = 5.086 CI = 0.021 CR = 0.019 |

| A2 | 2 | 1 | 1/2 | 4 | 2 | 0.2524 | |

| A3 | 3 | 2 | 1 | 5 | 3 | 0.4079 | |

| A4 | 1 | 1/4 | 1/5 | 1 | 1/2 | 0.0806 | |

| A5 | 2 | 1/2 | 1/3 | 2 | 1 | 0.1555 | |

| (e) | |||||||

| Matrix 5 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/3 | 1/2 | 2 | 1/3 | 0.1071 | λmax = 5.262 CI = 0.065 CR = 0.058 |

| A2 | 3 | 1 | 1 | 4 | 2 | 0.3250 | |

| A3 | 2 | 1 | 1 | 2 | 1/3 | 0.1881 | |

| A4 | 1/2 | 1/4 | 1/2 | 1 | 1/4 | 0.0716 | |

| A5 | 3 | 1/2 | 3 | 4 | 1 | 0.3082 | |

| Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Mean Value | Calculated Value | |

|---|---|---|---|---|---|---|---|

| A3 | 0.4189 | 0.4005 | 0.2322 | 0.4079 | 0.1881 | 0.3295 | 4.9428 |

| A5 | 0.1489 | 0.2471 | 0.4206 | 0.1555 | 0.3082 | 0.2561 | 3.8409 |

| A2 | 0.2642 | 0.1654 | 0.1852 | 0.2524 | 0.3250 | 0.2384 | 3.5766 |

| A1 | 0.1001 | 0.0937 | 0.0627 | 0.1036 | 0.1071 | 0.0934 | 1.4016 |

| A4 | 0.0679 | 0.0932 | 0.0993 | 0.0806 | 0.0716 | 0.0825 | 1.2378 |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Matrix 1 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 2 | 1/3 | 1/2 | 1/2 | 0.1231 | λmax =5.194 CI = 0.049 CR = 0.043 |

| A2 | 1/2 | 1 | 1/3 | 1/2 | 1/3 | 0.0855 | |

| A3 | 3 | 3 | 1 | 3 | 2 | 0.3761 | |

| A4 | 2 | 2 | 1/3 | 1 | 1/3 | 0.1511 | |

| A5 | 2 | 3 | 1/2 | 3 | 1 | 0.2646 | |

| (b) | |||||||

| Matrix 2 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/2 | 1/2 | 1/4 | 1/5 | 0.0726 | λmax =5.180 CI = 0.045 CR = 0.040 |

| A2 | 2 | 1 | 1/2 | 1/2 | 1/3 | 0.1173 | |

| A3 | 2 | 2 | 1 | 2 | 1/2 | 0.2216 | |

| A4 | 4 | 2 | 1/2 | 1 | 1/3 | 0.1842 | |

| A5 | 5 | 3 | 2 | 3 | 1 | 0.4043 | |

| (c) | |||||||

| Matrix 3 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/4 | 1/2 | 1/2 | 1/5 | 0.0707 | λmax = 5.138 CI = 0.034 CR = 0.031 |

| A2 | 4 | 1 | 1 | 2 | 1/3 | 0.2006 | |

| A3 | 2 | 1 | 1 | 3 | 1/2 | 0.2057 | |

| A4 | 2 | 1/2 | 1/3 | 1 | 1/4 | 0.1007 | |

| A5 | 5 | 3 | 2 | 4 | 1 | 0.4223 | |

| (d) | |||||||

| Matrix 4 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 1/3 | 1/2 | 1/2 | 1/4 | 0.0792 | λmax = 5.101 CI = 0.025 CR = 0.023 |

| A2 | 3 | 1 | 3 | 2 | 1/2 | 0.2665 | |

| A3 | 2 | 1/3 | 1 | 1/2 | 1/3 | 0.1129 | |

| A4 | 2 | 1/2 | 2 | 1 | 1/2 | 0.1715 | |

| A5 | 4 | 2 | 3 | 2 | 1 | 0.3699 | |

| (e) | |||||||

| Matrix 5 | A1 | A2 | A3 | A4 | A5 | Weight | Index |

| A1 | 1 | 2 | 3 | 1/2 | 2 | 0.2449 | λmax = 5.131 CI = 0.033 CR = 0.029 |

| A2 | 1/2 | 1 | 1/2 | 1/3 | 2 | 0.1617 | |

| A3 | 1/3 | 1/2 | 1 | 1/3 | 1/2 | 0.0863 | |

| A4 | 2 | 3 | 3 | 1 | 3 | 0.3832 | |

| A5 | 1/2 | 1/2 | 2 | 1/3 | 1 | 0.1239 | |

| Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Mean Value | Calculated Value | |

|---|---|---|---|---|---|---|---|

| A5 | 0.2646 | 0.4043 | 0.4223 | 0.3699 | 0.1239 | 0.3170 | 4.7550 |

| A3 | 0.3761 | 0.2216 | 0.2057 | 0.1129 | 0.0863 | 0.2005 | 3.0078 |

| A4 | 0.1511 | 0.1842 | 0.1007 | 0.1715 | 0.3832 | 0.1981 | 2.9721 |

| A2 | 0.0855 | 0.1173 | 0.2006 | 0.2665 | 0.1617 | 0.1663 | 2.4948 |

| A1 | 0.1231 | 0.0726 | 0.0707 | 0.0792 | 0.2449 | 0.1181 | 1.7715 |

| Severity | Probability | Detection Difficulty | Evaluation Risk Value | |

|---|---|---|---|---|

| A3 | 4.5123 | 4.9428 | 3.0078 | 67.0842 |

| A5 | 1.4961 | 3.8409 | 4.7550 | 27.3239 |

| A2 | 2.2890 | 3.5766 | 2.4948 | 20.4245 |

| A1 | 4.9479 | 1.4016 | 1.7715 | 12.2853 |

| A4 | 1.7544 | 1.2378 | 2.9721 | 6.4543 |

| First-Level Risk Factor | Secondary-Level Risk Factor | L | S | R | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L | S1 | S2 | S3 | S | |||

| A1 | B1 | 1 | 2 | 2 | 1.7 | 2 | 3 | 2 | 2.3 | 3.9 |

| B2 | 2 | 2 | 2 | 2.0 | 3 | 2 | 3 | 2.7 | 5.3 | |

| B3 | 3 | 2 | 3 | 2.7 | 3 | 3 | 2 | 2.7 | 7.1 | |

| B4 | 2 | 3 | 2 | 2.3 | 2 | 2 | 3 | 2.3 | 5.4 | |

| B5 | 1 | 2 | 1 | 1.3 | 4 | 2 | 3 | 3.0 | 4.0 | |

| A2 | B6 | 4 | 3 | 3 | 3.3 | 2 | 1 | 1 | 1.3 | 4.4 |

| B7 | 3 | 2 | 4 | 3.0 | 2 | 3 | 3 | 2.7 | 8.0 | |

| B8 | 2 | 3 | 3 | 2.7 | 4 | 3 | 3 | 3.3 | 8.9 | |

| B9 | 3 | 2 | 2 | 2.3 | 2 | 3 | 2 | 2.3 | 5.4 | |

| A3 | B10 | 4 | 4 | 3 | 3.7 | 4 | 3 | 4 | 3.7 | 13.4 |

| B11 | 3 | 2 | 2 | 2.3 | 4 | 4 | 4 | 4.0 | 9.3 | |

| B12 | 3 | 4 | 3 | 3.3 | 2 | 3 | 2 | 2.3 | 7.8 | |

| B13 | 3 | 4 | 4 | 3.7 | 3 | 2 | 2 | 2.3 | 8.6 | |

| B14 | 3 | 3 | 4 | 3.3 | 3 | 4 | 3 | 3.3 | 11.1 | |

| A4 | B15 | 3 | 2 | 2 | 2.3 | 2 | 1 | 2 | 1.7 | 3.9 |

| B16 | 1 | 2 | 1 | 1.3 | 1 | 2 | 1 | 1.3 | 1.8 | |

| B17 | 1 | 1 | 2 | 1.3 | 2 | 4 | 1 | 2.3 | 3.1 | |

| B18 | 1 | 1 | 1 | 1.0 | 2 | 3 | 2 | 2.3 | 2.3 | |

| B19 | 1 | 1 | 1 | 1.0 | 1 | 1 | 1 | 1.0 | 1.0 | |

| A5 | B20 | 3 | 3 | 4 | 3.3 | 4 | 3 | 3 | 3.3 | 11.1 |

| B21 | 3 | 4 | 3 | 3.3 | 3 | 3 | 2 | 2.7 | 8.9 | |

| B22 | 3 | 2 | 3 | 2.7 | 3 | 2 | 2 | 2.3 | 6.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Zhang, Q.; Xu, H.; Li, Z.; Tian, X.; Fang, S.; Zheng, J.; Zhang, E.; Yang, D. Risk Identification and Safety Evaluation of Offshore Wind Power Submarine Cable Construction. J. Mar. Sci. Eng. 2024, 12, 1718. https://doi.org/10.3390/jmse12101718

Huang H, Zhang Q, Xu H, Li Z, Tian X, Fang S, Zheng J, Zhang E, Yang D. Risk Identification and Safety Evaluation of Offshore Wind Power Submarine Cable Construction. Journal of Marine Science and Engineering. 2024; 12(10):1718. https://doi.org/10.3390/jmse12101718

Chicago/Turabian StyleHuang, Hui, Qiang Zhang, Hao Xu, Zhenming Li, Xinjiao Tian, Shuhao Fang, Juan Zheng, Enna Zhang, and Dingding Yang. 2024. "Risk Identification and Safety Evaluation of Offshore Wind Power Submarine Cable Construction" Journal of Marine Science and Engineering 12, no. 10: 1718. https://doi.org/10.3390/jmse12101718

APA StyleHuang, H., Zhang, Q., Xu, H., Li, Z., Tian, X., Fang, S., Zheng, J., Zhang, E., & Yang, D. (2024). Risk Identification and Safety Evaluation of Offshore Wind Power Submarine Cable Construction. Journal of Marine Science and Engineering, 12(10), 1718. https://doi.org/10.3390/jmse12101718