A Study on Offshore Anchor Selection with a Focus on Torpedo Anchor Stability and Performance

Abstract

:1. Introduction

- Types of mooring systems: Types of mooring systems include catenary and taut leg systems. The catenary system is suitable for use when the water depth is shallow [12]. The primary concern with using a taut leg system in shallow water is that the mooring lines become overly stiff, leading to excessive tension and vertical loading on the anchors [7].

- Soil composition of the seabed: Another critical factor that should be considered in anchor selection is the soil properties. Soil is mainly divided into two properties: (a) cohesive and (b) cohesionless.

- Manufacturing, transport, and installation costs: Building an offshore wind energy facility entails significant financial investment [13], with substantial costs associated with anchors’ manufacturing, installation, and transportation. Byrne and Houlsby’s [14] estimates suggest that foundation costs could account for up to 35% of the total cost of installing offshore wind systems. Cost data for floating systems are limited due to the novelty, fast developments, and few actual deployments.

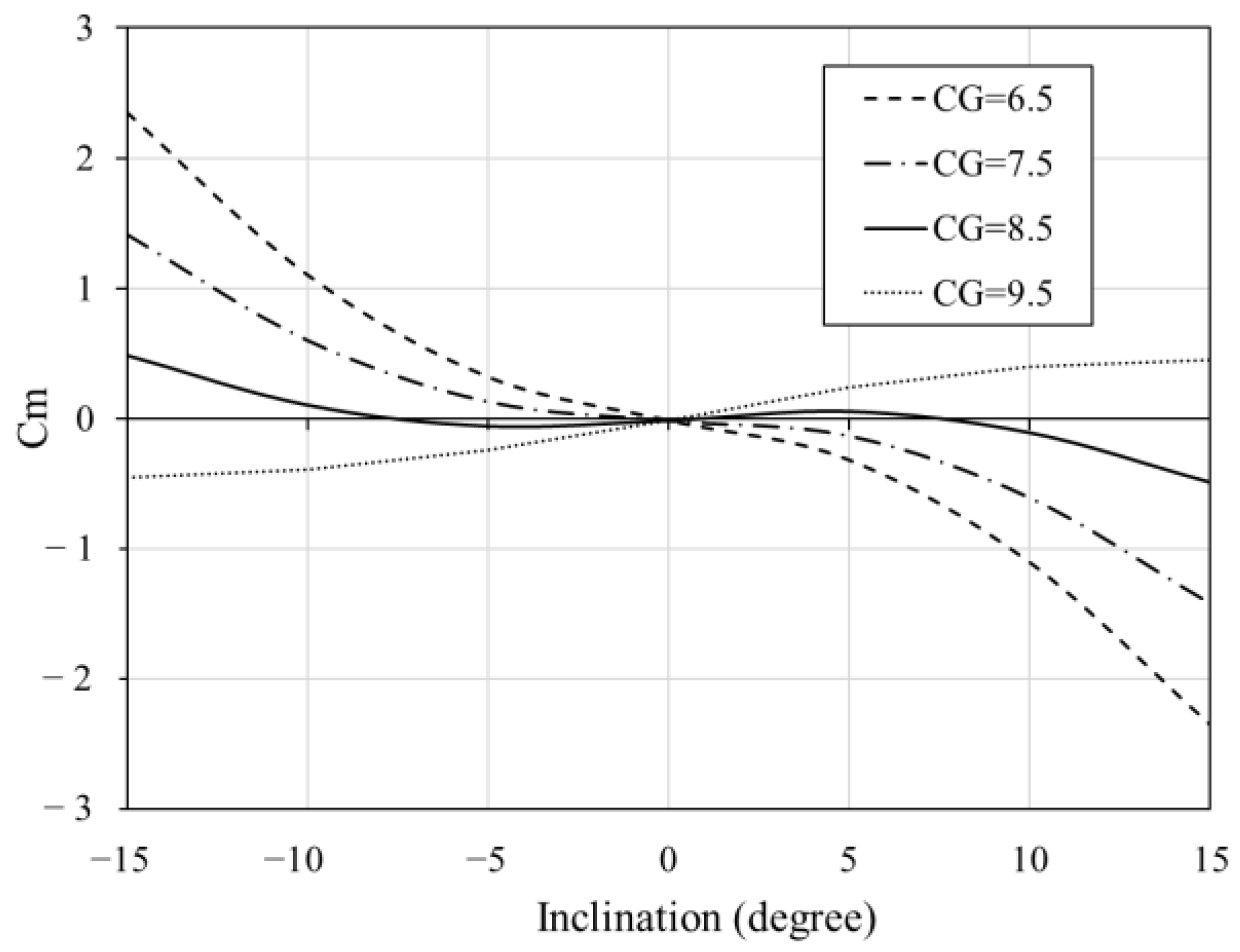

- To determine the optimal position of the center of gravity and investigate the stability;

- To enhance the stability of torpedo anchors with respect to the location of the gravity center;

- To evaluate the relationship between penetration velocity, penetration resistance, and penetration depth of torpedo anchors;

- To estimate the maximum holding capacity of a prototype torpedo anchor.

2. Types of Anchors for FOWTS

2.1. Driven Piles

- Installation and Functionality:

- Driven piles are installed using powerful pile-driving hammers that drive them deeply into the seabed, ensuring secure anchorage and sufficient holding capacity to support wind turbine structures. They can also anchor large floating structures and withstand both vertical and horizontal loads.

- The installation process requires large cranes and specialized equipment, making it technically demanding, especially in deep water. Figure 1a illustrates the slender, hollow steel pipes embedded into the seabed during installation.

- Design and Performance:

- Randolph and Murphy [22] discuss the design theory for driven piles, which helps determine pile dimensions and optimal chain bracket positions.

- The anchorage force primarily comes from the frictional resistance between the pile’s outer surface and surrounding soil, which is crucial for maintaining stability and load-bearing capacity.

- Driven piles are versatile, supporting both catenary and tensioned mooring systems. However, high installation costs and environmental concerns, such as hammer noise [23], necessitate the use of bubble curtains to mitigate noise and protect aquatic life. These factors must be carefully assessed for each project.

- Case Study:

2.2. Suction Caissons

- Installation and Functionality:

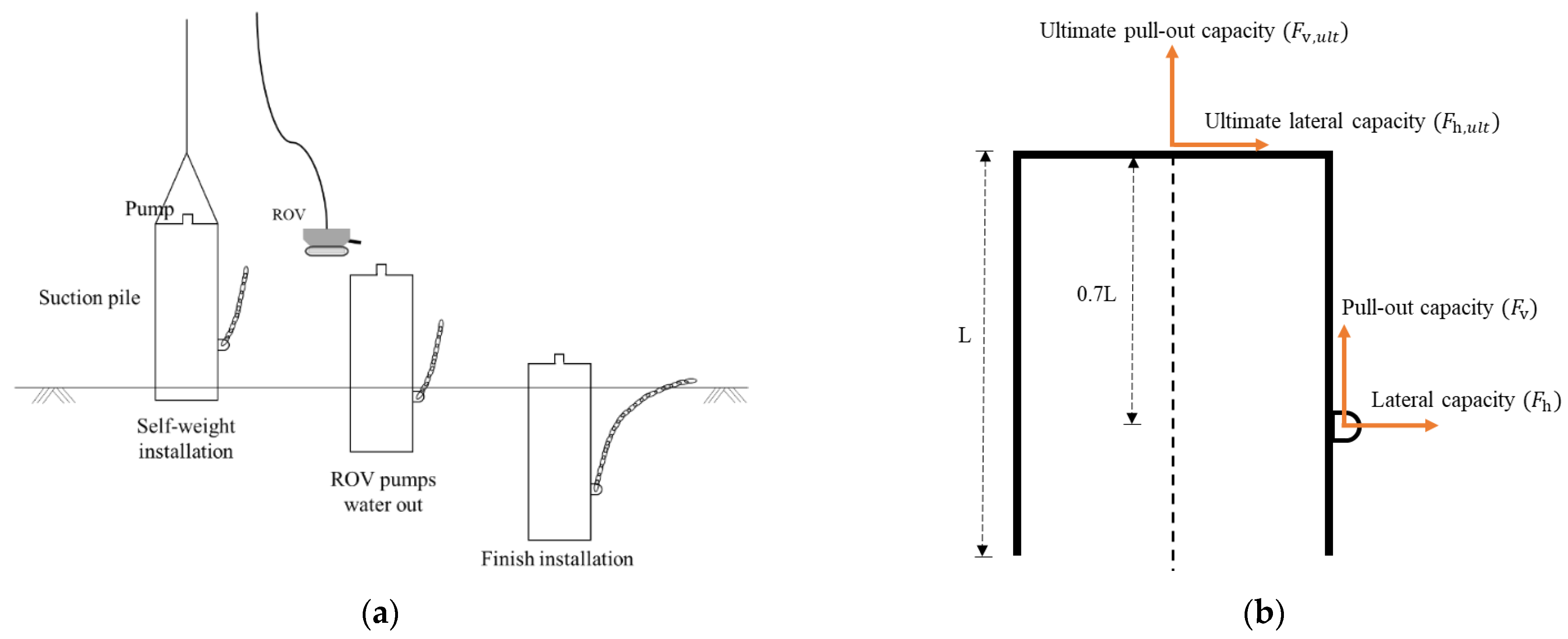

- Suction caissons are hollow steel pipes with closed tops and larger diameters compared to pile anchors, providing a robust anchoring solution [31].

- The design creates a pressure differential during installation, allowing secure embedding into the seabed. A pump, typically operated by a remotely operated underwater vehicle (ROV), removes seawater from inside the pile, drawing it into the seabed [30,32]. Figure 2a illustrates the installation process, which includes self-weight penetration and water being pumped out, controlled by the ROV.

- Performance and Applications:

- The holding capacity comes from friction between the soil and the anchor’s contact areas. Suction caissons are suitable for catenary and taut leg mooring systems, offering stability in various conditions.

- They can penetrate harder seabed, but care must be taken to avoid pipe wall deformation due to excessive negative pressure.

- Considerations:

- The need for substantial deck space during transport and crane installation vessels contribute to higher deployment costs. These factors should be considered in offshore project planning.

2.3. Drag Anchors

- Installation and Functionality:

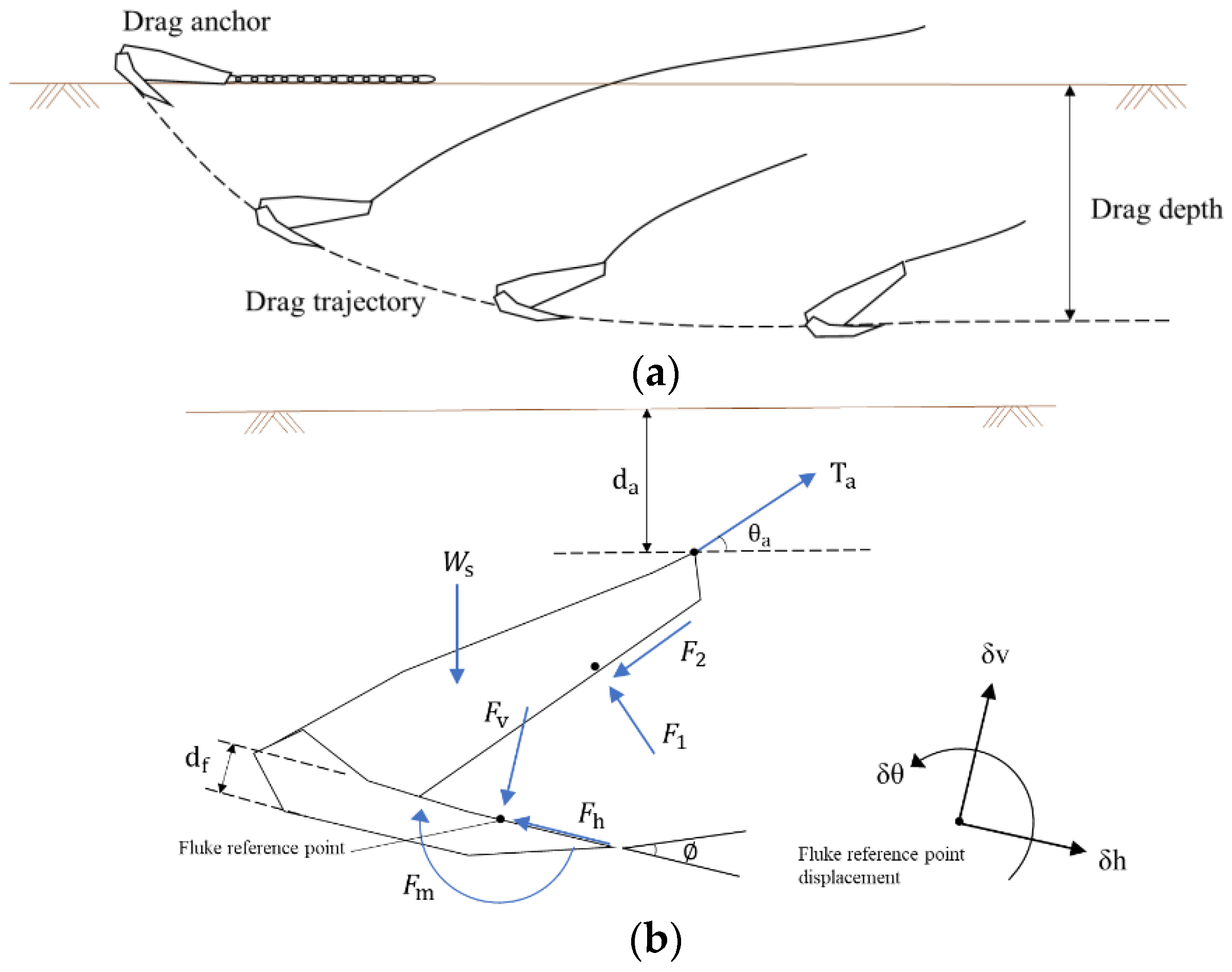

- Drag anchors cannot be precisely positioned, as their final location depends on how they embed during dragging. The holding capacity increases with deeper penetration. Figure 3a illustrates the installation process, where an Anchor Handling Vessel (AHV) drags the anchor into place.

- Drag anchors are unsuitable for vertical loads and cannot be used as shared anchors.

- Testing and Performance:

- Testing drag anchor resistance is crucial to ensure adequate holding capacity, typically using the AHV’s tensioning equipment to confirm proper embedment and stability.

- They are effective in catenary mooring systems, handling horizontal loads well. Predicting performance involves:

- Soil Considerations:

- Drag anchors struggle in hard soils due to limited penetration but are effective in softer soils like clay, which allow deeper embedding and better support, including some vertical loads. These factors are critical for determining their suitability in offshore mooring systems.

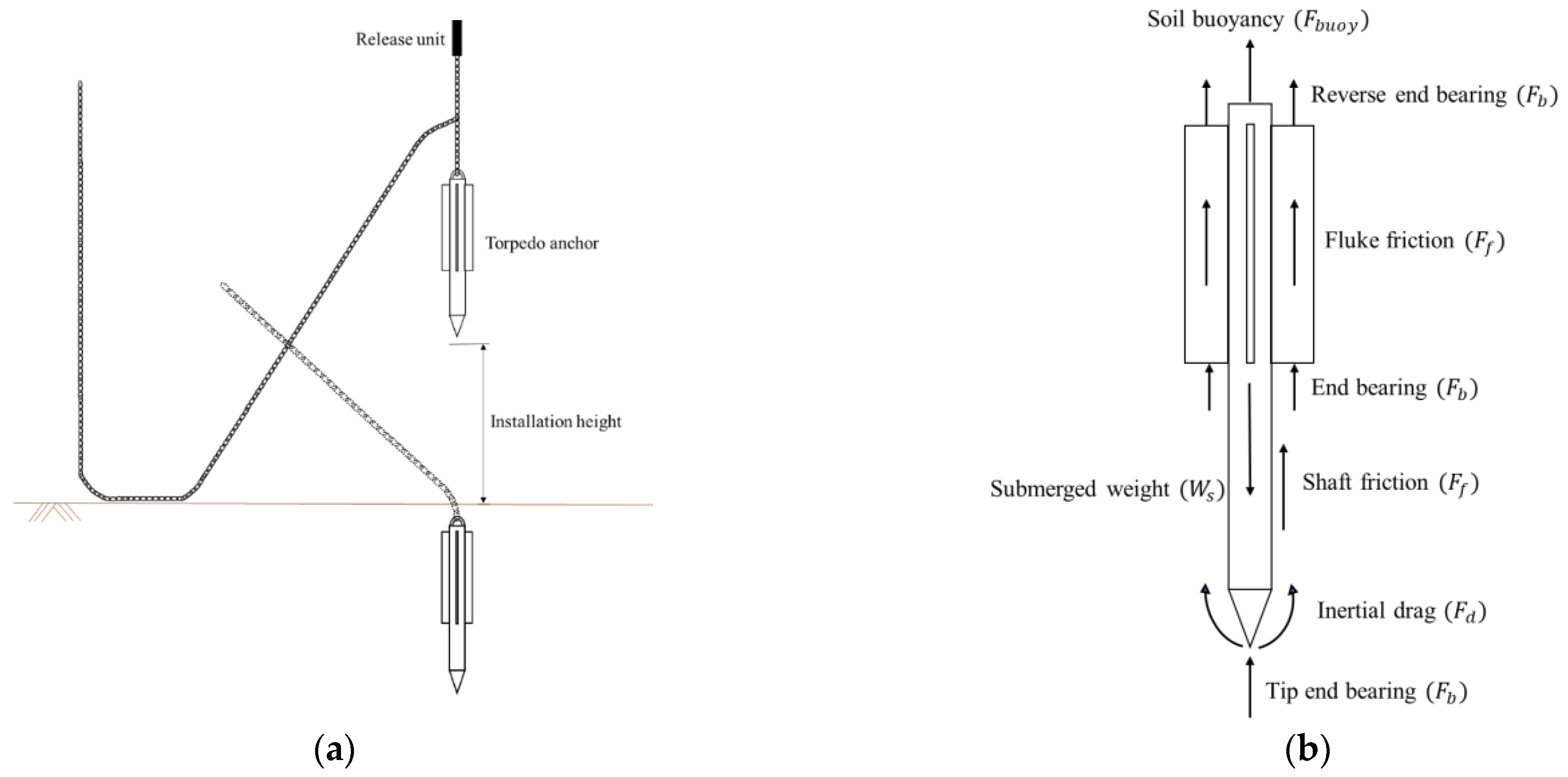

2.4. Torpedo Anchors

- Gravity-Based Installation: Torpedo anchors are released in water and allowed to free-fall, using the kinetic energy from their descent to penetrate the seabed (as illustrated in Figure 4a). This method simplifies installation and reduces costs by minimizing the need for complex equipment.

- Cost-Effectiveness: The gravity-based process reduces the need for specialized vessels and expensive equipment, leading to significant savings.

- Deployment Conditions: Successful deployment depends on:

- Seabed Compatibility: The seabed must be suitable for the anchor’s penetration dynamics.

- Release Height: The height from which the anchor is released must be sufficient to generate the necessary kinetic energy.

2.4.1. Holding Capacity of Torpedo Anchors

2.4.2. Hydrodynamic Directional Stability

3. Numerical Analysis of Torpedo Anchor

3.1. Governing Equations

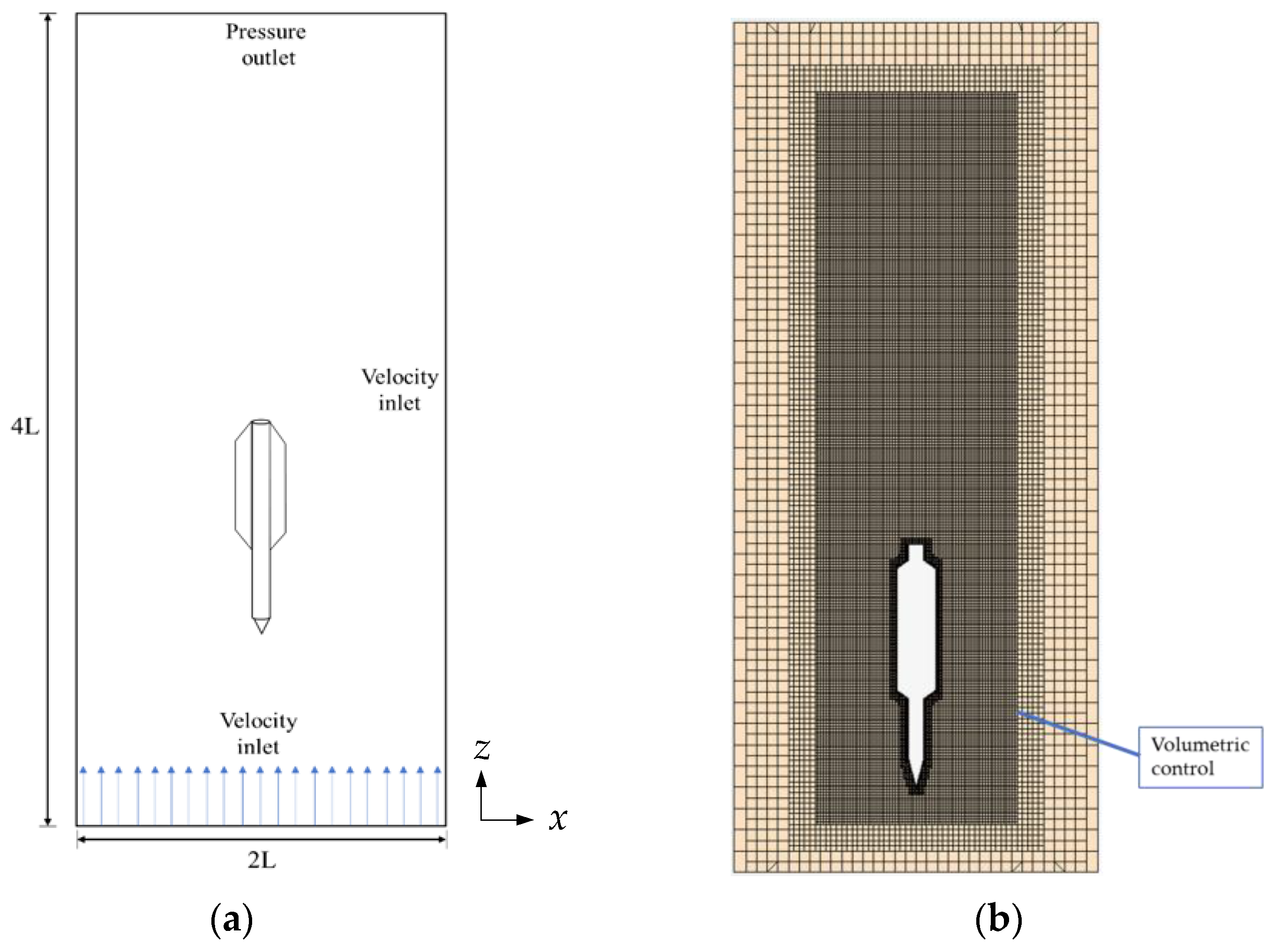

3.2. CFD Model Set-Up

- Inlet settings: To accurately account for the effect of fluid on the torpedo anchor when tilted, the water velocity in the inlet region can be expressed as:where , are the velocity of the fluid in the x direction and z direction, respectively, is fluid velocity (−), and denotes inclination angle.

- Outlet settings: The condition is set on the downstream surface, located at the top of the domain, where the relative pressure is assumed to be zero.

- Torpedo surface settings: The torpedo surface is treated as a smooth wall, ensuring no tangential or normal velocities are present.

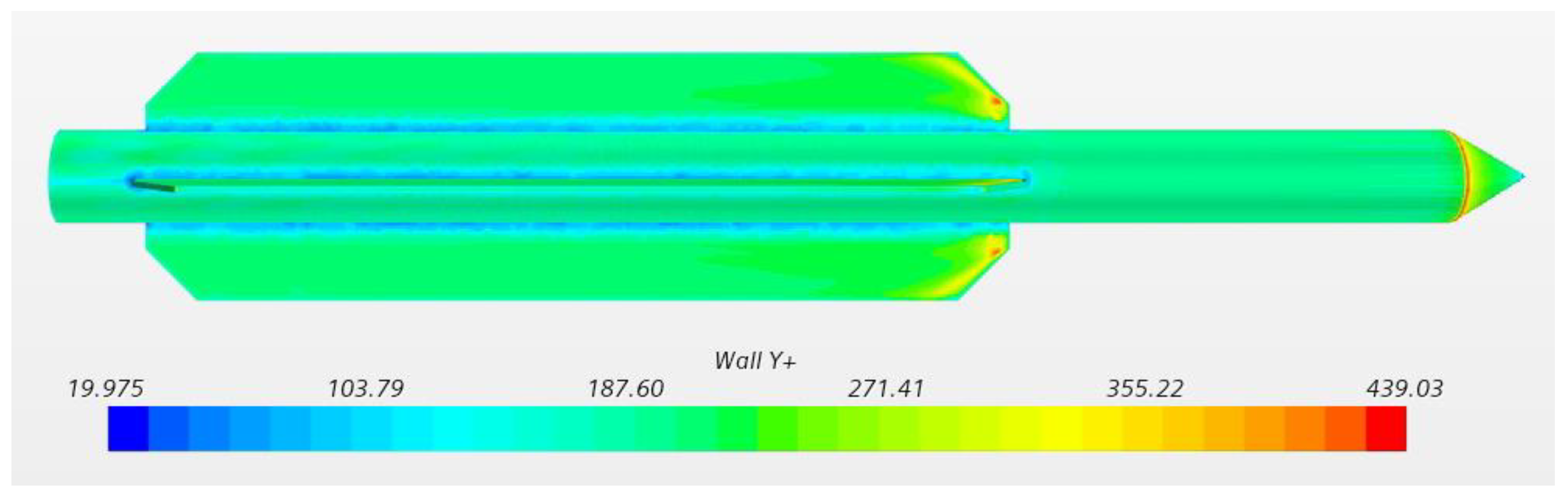

3.3. Convergence Study and Validation

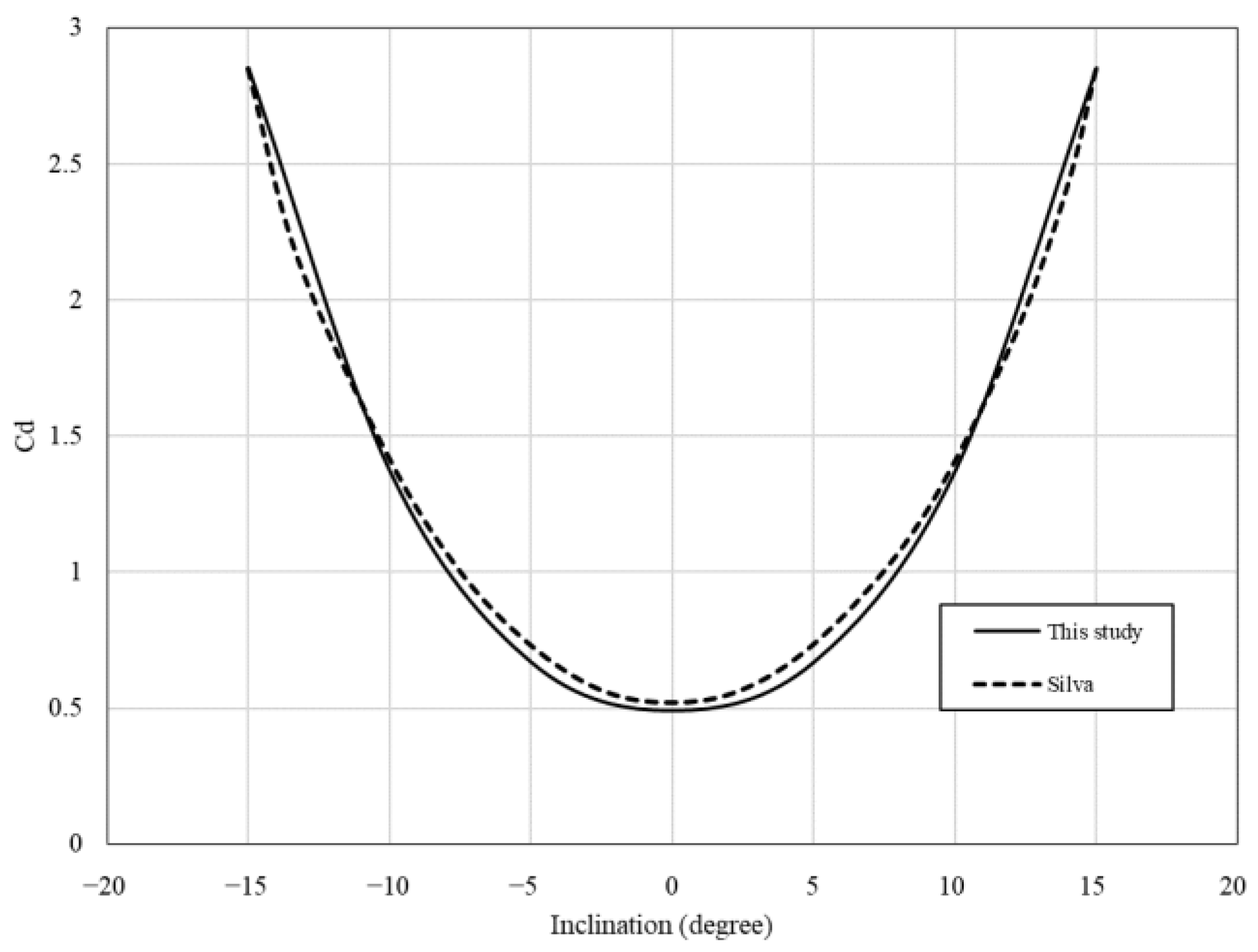

3.4. CFD Model Results

3.5. Theoretical Prediction of Pullout Capacity

4. Conclusions

- Seabed Conditions:

- ✓

- Driven piles and suction caissons offer the most predictable holding capacity. They can be reliably used in various types of soils.

- ✓

- Drag anchors and torpedo anchors are suitable mainly for silt or clay seabed. Torpedo anchors may not work at all in seabed with sand layers.

- Project Cost Perspective:

- ✓

- Driven piles and suction caissons provide sufficient holding capacity, but require auxiliary installation tools, such as hydraulic pile hammers and ROVs. With proper calculations during the engineering stage, proof loading in the field can be waived.

- ✓

- Drag anchors and torpedo anchors offer high anchoring efficiency and quick installation, and therefore cost less. However, they may not be able to provide the same high holding capacity as driven piles and suction caissons, which may be required by the mooring system of a very large floating structure. Additionally, the drag anchor must be proof loaded in the field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esteban, M.D.; Diez, J.J.; López, J.S.; Negro, V. Why offshore wind energy? Renew. Energy 2011, 36, 444–450. [Google Scholar] [CrossRef]

- Zheng, S.; Greaves, D.M.; Borthwick, A.G.L.; Meylan, M.H.; Zang, J.; Brocchini, M.; Liang, H. Recent advances in marine hydrodynamics. Phys. Fluids 2024, 36, 070402. [Google Scholar] [CrossRef]

- Possner, A.; Caldeira, K. Geophysical potential for wind energy over the open oceans. Proc. Natl. Acad. Sci. USA 2017, 114, 11338–11343. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Chen, J.; Liang, H.; Zhao, Y.; Shao, Y. Hydrodynamic responses of a 6 MW spar-type floating offshore wind turbine in regular waves and uniform current. Fluids 2020, 5, 187. [Google Scholar] [CrossRef]

- Katsouris, G.; Marina, A. Cost Modelling of Floating Wind Farms; ECN: Petten, The Netherlands, 2016. [Google Scholar]

- Henderson, A.R.; Witcher, D. Floating offshore wind energy—A review of the current status and an assessment of the prospects. Wind. Eng. 2010, 34, 1–16. [Google Scholar] [CrossRef]

- Ma, K.T.; Luo, Y.; Kwan, C.T.T.; Wu, Y. Mooring System Engineering for Offshore Structures; Gulf Professional Publishing: Houston, TX, USA, 2019. [Google Scholar]

- Martinez, R.; Arnau, S.; Scullion, C.; Collins, P.; Neilson, R.D.; Kapitaniak, M. Variable buoyancy anchor deployment analysis for floating wind applications using a Marine Simulator. Ocean Eng. 2023, 285, 115417. [Google Scholar] [CrossRef]

- Jostad, H.P.; Andersen, K.H. Design of suction piles for offshore applications. In Analysis of Pile Foundations Subject to Static and Dynamic Loading; CRC Press: Boca Raton, FL, USA, 2021; pp. 107–129. [Google Scholar]

- Lee, J.; Aubeny, C.P. Lateral undrained capacity of a multiline ring anchor in clay. Int. J. Geomech. 2021, 21, 04021047. [Google Scholar] [CrossRef]

- Fu, D.; Zhou, Z.; Yan, Y.; Pradhan, D.L.; Hennig, J. A method to predict the torsional resistance of suction caisson with anti-rotation fins in clay. Mar. Struct. 2021, 75, 102866. [Google Scholar] [CrossRef]

- Chen, C.A.; Chen, K.H.; Igarashi, Y.; Chen, D.; Ma, K.T.; Lai, Z.Y. Design of Mooring System for a 15MW Semi-Submersible, TaidaFloat, in Taiwan Strait. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Melbourne, Australia, 11–16 June 2023; American Society of Mechanical Engineers: New York, NY, USA. [Google Scholar]

- Sarker, B.R.; Faiz, T.I. Minimizing transportation and installation costs for turbines in offshore wind farms. Renew. Energy 2017, 101, 667–679. [Google Scholar] [CrossRef]

- Byrne, B.W.; Houlsby, G.T. Foundations for offshore wind turbines. Philosophical Transactions of the Royal Society of London. Ser. A Math. Phys. Eng. Sci. 2003, 361, 2909–2930. [Google Scholar] [CrossRef] [PubMed]

- de Araujo, J.B.; Machado, R.R.D.; de Medeiros, C.J., Jr. High holding power torpedo pile: Results for the first long term application. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–24 June 2004. [Google Scholar]

- Medeiros, C., Jr. Low cost anchor system for flexible risers in deep waters. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; OTC: Boca Raton, FL, USA. [Google Scholar]

- O’Loughlin, C.; White, D.; Stanier, S. Novel anchoring solutions for FLNG-opportunities driven by scale. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2015; OTC: Boca Raton, FL, USA. [Google Scholar]

- Triantafyllou, M.S.; Hover, F.S. Maneuvering and Control of Marine Vehicles; Massachusetts of Institute of Technology: Cambridge, MA, USA, 2003. [Google Scholar]

- Brandão, F.E.N.; Henriques, C.C.D.; Araújo, J.B.D.; Ferreira, O.C.G.; dos Santos Amaral, C. Albacora Leste field development-FPSO P-50 mooring system concept and installation. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006; OTC: Boca Raton, FL, USA. [Google Scholar]

- Cerfontaine, B.; White, D.; Kwa, K.; Gourvenec, S.; Knappett, J.; Brown, M. Anchor geotechnics for floating offshore wind: Current technologies and future innovations. Ocean Eng. 2023, 279, 114327. [Google Scholar] [CrossRef]

- Randolph, M.F.; Carter, J.; Wroth, C. Driven piles in clay—The effects of installation and subsequent consolidation. Geotechnique 1979, 29, 361–393. [Google Scholar] [CrossRef]

- Randolph, M.F.; Murphy, B. Shaft capacity of driven piles in clay. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1985; OTC: Boca Raton, FL, USA. [Google Scholar]

- Würsig, B.; Greene, C., Jr.; Jefferson, T. Development of an air bubble curtain to reduce underwater noise of percussive piling. Mar. Environ. Res. 2000, 49, 79–93. [Google Scholar] [CrossRef] [PubMed]

- Townsend, W. Ichthys: From Challenge to Reality. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2012; SPE: Richardson, TX, USA. [Google Scholar]

- Kumar, B.R. Case 29: Ichthys LNG Project. In Project Finance: Structuring, Valuation and Risk Management for Major Projects; Springer: Berlin/Heidelberg, Germany, 2022; pp. 237–240. [Google Scholar]

- Erbrich, C.; Lam, S.Y.; Zhu, H.; Derache, A.; Sato, A.; Al-Showaiter, A. Geotechnical design of anchor piles for Ichthys CPF and FPSO. In Proceedings of the Offshore Site Investigation Geotechnics 8th International Conference Proceeding, London, UK, 12–14 September 2017; Society for Underwater Technology: Houston, TX, USA, 2017. [Google Scholar]

- Institute, A.P. Recommended Practice for Planning, Designing, and Constructing Fixed Offshore Platforms-Working Stress Design: Upstream Segment. In API Recommended Practice 2A-WSD (RP 2A-WSD): Errata and Supplement 1, December 2002; American Petroleum Institute: New York, NY, USA, 2000. [Google Scholar]

- Reese, L.C.; Van Impe, W.F. Single Piles and Pile Groups under Lateral Loading; CRC press: Boca Raton, FL, USA, 2000. [Google Scholar]

- American Bureau of Shipping. Guidance Notes on Design and Installation of Dynamically Installed Piles; American Bureau of Shipping: Houston, TX, USA, 2018. [Google Scholar]

- Sparrevik, P. Suction pile technology and installation in deep waters. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; OTC: Boca Raton, FL, USA. [Google Scholar]

- Hogervorst, J. Field trails with large diameter suction piles. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1980; OTC: Boca Raton, FL, USA. [Google Scholar]

- Tjelta, T.I. Suction piles: Their position and application today. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2001; ISOPE: Bristol, UK. [Google Scholar]

- Randolph, M.; House, A. Analysis of suction caisson capacity in clay. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; OTC: Boca Raton, FL, USA. [Google Scholar]

- Senders, M.; Randolph, M.F. CPT-based method for the installation of suction caissons in sand. J. Geotech. Geoenvironmental Eng. 2009, 135, 14–25. [Google Scholar] [CrossRef]

- Steensen-Bach, J. Recent model tests with suction piles in clay and sand. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992; OTC: Boca Raton, FL, USA. [Google Scholar]

- Supachawarote, C. Inclined Load Capacity of Suction Caisson in Clay; University of Western Australia: Perth, Australia, 2006. [Google Scholar]

- Allersma, H.G.B.; Kirstein, A.A.; Brinkgreve RB, J.; Simon, T. Centrifuge and numerical modelling of horizontally loaded suction piles. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Brest, France, 30 May–5 June 1999; ISOPE: Bristol, UK. [Google Scholar]

- Randolph, M.; Gourvenec, S. Offshore Geotechnical Engineering; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- O’Neill, M.; Bransby, M.; Randolph, M. Drag anchor fluke soil interaction in clays. Can. Geotech. J. 2003, 40, 78–94. [Google Scholar] [CrossRef]

- Stewart, W. Drag embedment anchor performance prediction in soft soils. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1992; OTC: Boca Raton, FL, USA. [Google Scholar]

- Aubeny, C.; Chi, C. Mechanics of drag embedment anchors in a soft seabed. J. Geotech. Geoenvironmental Eng. 2010, 136, 57–68. [Google Scholar] [CrossRef]

- Ozmutlu, S. Harnessing Offshore Mooring Experience and Anchoring Technology for the Floating Renewable Energy Systems. VRYHOF. 2018. Available online: https://www.kivi.nl/uploads/media/5ae711f5178c0/SOZ-KIVI%20lecture%20-%20Anchoring%20Technologies%20for%20FOWT%20by%20Vryhof%20Anchors.pdf (accessed on 25 September 2024).

- Neubecker, S.; Randolph, M. Profile and frictional capacity of embedded anchor chains. J. Geotech. Eng. 1995, 121, 797–803. [Google Scholar] [CrossRef]

- de Medeiros, C.J.; Hassui, L.H.; Machado, R.D. Pile for Anchoring Floating Structures and Process for Installing the Same. U.S. Patent No 6,106,199, 22 August 2000. [Google Scholar]

- O’Loughlin, C.; Randolph, M.; Richardson, M. Experimental and theoretical studies of deep penetrating anchors. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2004; OTC: Boca Raton, FL, USA. [Google Scholar]

- O’Loughlin, C.; Richardson; Randolph, M.; Gaudin, C. Penetration of dynamically installed anchors in clay. Géotechnique 2013, 63, 909–919. [Google Scholar] [CrossRef]

- de Carvalho e Silva, D.F. CFD hydrodynamic analysis of a torpedo anchor directional stability. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, HI, USA, 16 February 2010. [Google Scholar]

- Simcenter STAR-CCM+, version 202X.Y; Siemens Industries Digital Software: Plano, TX, USA, 2024.

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. In Numerical Prediction of Flow, Heat Transfer, Turbulence and Combustion; Elsevier: Amsterdam, The Netherlands, 1983; pp. 96–116. [Google Scholar]

- Schlichting, H.; Gersten, K. Boundary-Layer Theory; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Fluent, A. Lecture 7: Turbulence Modeling; ANSYS: Canonsburg, PA, USA, 2014. [Google Scholar]

- Kim, Y.; Hossain, M.; Wang, D.; Randolph, M. Numerical investigation of dynamic installation of torpedo anchors in clay. Ocean Eng. 2015, 108, 820–832. [Google Scholar] [CrossRef]

- O’Loughlin, C.D.; Richardson, M.D.; Randolph, M.F. Centrifuge tests on dynamically installed anchors. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, Hawaii, USA, 31 May–6 June 2009. [Google Scholar]

- Viggiani, C.; Mandolini, A.; Russo, G. Piles and Pile Foundations; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Reese, L.C.; Beard, R.M. A design method for an anchor pile in a mooring system. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 27 April–1 May 1973; OTC: Boca Raton, FL, USA. [Google Scholar]

- Randolph, M.F.; Oneill, M.P.; Stewart, D.P.; Erbrich, C. Performance of suction anchors in fine-grained calcareous soils. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998; OTC: Boca Raton, FL, USA. [Google Scholar]

- Neubecker, S.; Randolph, M. The performance of drag anchor and chain systems in cohesive soil. Mar. Georesources Geotechnol. 1996, 14, 77–96. [Google Scholar] [CrossRef]

| Type | Mass , Tonne) | Diameter (m) | Length (m) | Fins (m) |

|---|---|---|---|---|

| T-98 | 98 | 1.07 | 17 | 10 × 0.9 |

| Parameter | Value |

|---|---|

| (kPa) | |

| Effective unit weight | |

| Strain-rate parameters ) | 0.1, 0.05 |

| ) | 0.33 |

| Anchor Types | Ref. | Example Projects and Locations | Suitable Soil Types | Suitable Mooring System | As Shared Anchor | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| Drive pile | [54,55] | Ichthys LNG in Australia | Sand, Silt, Clay | Catenary, Taut leg | Suitable |

|

|

| Suction caisson | [30,56] | FPU P-19 and P-26 in Brazil | Sand, Silt, Clay | Catenary, Taut leg | Suitable |

|

|

| Drag anchor | [42,57] | Hywind in Norway, WindFloat in Portugal, and Fukushima in Japan | Silt, Clay, (Sand in some cases) | Catenary only | Not suitable |

|

|

| Torpedo anchor | [16,19] | FPSO P-50 and many other FPSOs in Brazil | Silt, Clay | Catenary, Taut leg | Not suitable, possible in certain cases |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.-C.; Noorizadegan, A.; Liu, Y.-H.; Ma, K.-T. A Study on Offshore Anchor Selection with a Focus on Torpedo Anchor Stability and Performance. J. Mar. Sci. Eng. 2024, 12, 1721. https://doi.org/10.3390/jmse12101721

Chang H-C, Noorizadegan A, Liu Y-H, Ma K-T. A Study on Offshore Anchor Selection with a Focus on Torpedo Anchor Stability and Performance. Journal of Marine Science and Engineering. 2024; 12(10):1721. https://doi.org/10.3390/jmse12101721

Chicago/Turabian StyleChang, Hung-Chun, Amir Noorizadegan, Yi-Hsiu Liu, and Kai-Tung Ma. 2024. "A Study on Offshore Anchor Selection with a Focus on Torpedo Anchor Stability and Performance" Journal of Marine Science and Engineering 12, no. 10: 1721. https://doi.org/10.3390/jmse12101721

APA StyleChang, H.-C., Noorizadegan, A., Liu, Y.-H., & Ma, K.-T. (2024). A Study on Offshore Anchor Selection with a Focus on Torpedo Anchor Stability and Performance. Journal of Marine Science and Engineering, 12(10), 1721. https://doi.org/10.3390/jmse12101721