Review of Recent Offshore Floating Photovoltaic Systems

Abstract

:1. Introduction

2. Overview of FPV Systems

2.1. The Composition of FPV Systems

2.2. Advantages and Disadvantages of FPV Systems

- Saving land resources.

- Enhancing power generation efficiency.

- Reducing evaporation of water.

- Improving water quality.

- Harsh working environment.

- Impact on the growth of aquatic organisms.

3. Research on Offshore Floating Photovoltaic Systems

3.1. Offshore FPV with Rigid Floating Structures

3.1.1. Research Status of Rigid Floating Structures

3.1.2. Properties and Application of Rigid Floating Structures

3.2. Offshore FPV Systems with Flexible Floating Structures

3.2.1. Research Status on Flexible Floating Structures

3.2.2. Properties and Application of Flexible Floating Structures

4. Application of Offshore FPV System

5. Challenges of Offshore FPV Systems

5.1. Stability of FPV Systems

5.2. Economic Performance of FPV Systems

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| PV | Photovoltaic |

| FPV | Floating photovoltaic |

| HDEP | High-density polyethylene |

| LCOE | Levelized cost of electricity |

| FRP | Fiberglass-reinforced plastic |

| PFRP | Pultruded fiberglass-reinforced plastic |

| ETFE | Ethylene tetrafluoroethylene |

| DNV | Det Norske Veritas |

| TNO | The Netherlands Organization for Applied Scientific Research |

| CIGS | Copper–Indium–Gallium–Selenide |

| MDPE | Medium-density polyethylene |

| GM-PV | Ground-mounted photovoltaic |

References

- Das, U.K.; Tey, K.S.; Seyedmahmoudian, M.; Mekhilef, S.; Idris, M.Y.I.; Van Deventer, W.; Horan, B.; Stojcevski, A. Forecasting of photovoltaic power generation and model optimization: A review. Renew. Sustain. Energy Rev. 2018, 81, 912–928. [Google Scholar] [CrossRef]

- Kumari, P.A.; Geethanjali, P. Parameter estimation for photovoltaic system under normal and partial shading conditions: A survey. Renew. Sustain. Energy Rev. 2018, 84, 1–11. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Sreenath, S.; Sudhakar, K.; Af, Y. 7E analysis of a conceptual utility-scale land-based solar photovoltaic power plant. Energy 2021, 219, 119610. [Google Scholar] [CrossRef]

- Liu, H.; Krishna, V.; Lun Leung, J.; Reindl, T.; Zhao, L. Field experience and performance analysis of floating PV technologies in the tropics. Prog. Photovolt. Res. Appl. 2018, 26, 957–967. [Google Scholar] [CrossRef]

- Teo, J.C.; Tan, R.H.G.; Mok, V.H.; Ramachandaramurthy, V.K.; Tan, C. Impact of Partial Shading on the P-V Characteristics and the Maximum Power of a Photovoltaic String. Energies 2018, 11, 1860. [Google Scholar] [CrossRef]

- Zitouni, H.; Azouzoute, A.; Hajjaj, C.; El Ydrissi, M.; Regragui, M.; Polo, J.; Oufadel, A.; Bouaichi, A.; Ghennioui, A. Experimental investigation and modeling of photovoltaic soiling loss as a function of environmental variables: A case study of semi-arid climate. Sol. Energy Mater. Sol. Cells 2021, 221, 110874. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M.; Ventura, C. Floating photovoltaic plants: Performance analysis and design solutions. Renew. Sustain. Energy Rev. 2018, 81, 1730–1741. [Google Scholar] [CrossRef]

- Taboada, M.E.; Cáceres, L.; Graber, T.A.; Galleguillos, H.R.; Cabeza, L.F.; Rojas, R. Solar water heating system and photovoltaic floating cover to reduce evaporation: Experimental results and modeling. Renew. Energy 2017, 105, 601–615. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M.; Nizetic, S. Floating photovoltaic plants and wastewater basins: An Australian project. Energy Procedia 2017, 134, 664–674. [Google Scholar] [CrossRef]

- Redón Santafé, M.; Torregrosa Soler, J.B.; Sánchez Romero, F.J.; Ferrer Gisbert, P.S.; Ferrán Gozálvez, J.J.; Ferrer Gisbert, C.M. Theoretical and experimental analysis of a floating photovoltaic cover for water irrigation reservoirs. Energy 2014, 67, 246–255. [Google Scholar] [CrossRef]

- Cromratie Clemons, S.K.; Salloum, C.R.; Herdegen, K.G.; Kamens, R.M.; Gheewala, S.H. Life cycle assessment of a floating photovoltaic system and feasibility for application in Thailand. Renew. Energy 2021, 168, 448–462. [Google Scholar] [CrossRef]

- Gorjian, S.; Sharon, H.; Ebadi, H.; Kant, K.; Scavo, F.B.; Tina, G.M. Recent technical advancements, economics and environmental impacts of floating photovoltaic solar energy conversion systems. J. Clean. Prod. 2021, 278, 124285. [Google Scholar] [CrossRef]

- Panda, S.; Panda, B.; Kumar, R.; Sharma, K.; Pradhan, R.; Ranjan Kabat, S. Analyzing and evaluating floating PV systems in relation to traditional PV systems. Mater. Today Proc. 2023, in press. [CrossRef]

- Ramanan, C.J.; Lim, K.H.; Kurnia, J.C.; Roy, S.; Bora, B.J.; Medhi, B.J. Towards sustainable power generation: Recent advancements in floating photovoltaic technologies. Renew. Sustain. Energy Rev. 2024, 194, 114322. [Google Scholar] [CrossRef]

- Ravichandran, N.; Ravichandran, N.; Panneerselvam, B. Comparative assessment of offshore floating photovoltaic systems using thin film modules for Maldives islands. Sustain. Energy Technol. Assess. 2022, 53, 102490. [Google Scholar] [CrossRef]

- Kumar, M.; Mohammed Niyaz, H.; Gupta, R. Challenges and opportunities towards the development of floating photovoltaic systems. Sol. Energy Mater. Sol. Cells 2021, 233, 111408. [Google Scholar] [CrossRef]

- Kim, S.-M.; Oh, M.; Park, H.-D. Analysis and Prioritization of the Floating Photovoltaic System Potential for Reservoirs in Korea. Appl. Sci. 2019, 9, 395. [Google Scholar] [CrossRef]

- Vidović, V.; Krajačić, G.; Matak, N.; Stunjek, G.; Mimica, M. Review of the potentials for implementation of floating solar panels on lakes and water reservoirs. Renew. Sustain. Energy Rev. 2023, 178, 113237. [Google Scholar] [CrossRef]

- Wang, J.; Lund, P.D. Review of Recent Offshore Photovoltaics Development. Energies 2022, 15, 7462. [Google Scholar] [CrossRef]

- López, M.; Soto, F.; Hernández, Z.A. Assessment of the potential of floating solar photovoltaic panels in bodies of water in mainland Spain. J. Clean. Prod. 2022, 340, 130752. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Rosa-Clot, M. The booming of floating PV. Sol. Energy 2021, 219, 3–10. [Google Scholar] [CrossRef]

- Aghahosseini, A.; Bogdanov, D.; Breyer, C. A Techno-Economic Study of an Entirely Renewable Energy-Based Power Supply for North America for 2030 Conditions. Energies 2017, 10, 1171. [Google Scholar] [CrossRef]

- Keiner, D.; Salcedo-Puerto, O.; Immonen, E.; van Sark, W.G.J.H.M.; Nizam, Y.; Shadiya, F.; Duval, J.; Delahaye, T.; Gulagi, A.; Breyer, C. Powering an island energy system by offshore floating technologies towards 100% renewables: A case for the Maldives. Appl. Energy 2022, 308, 118360. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Stokkermans, J. Marine floating solar plants: An overview of potential, challenges and feasibility. Proc. Inst. Civ. Eng. —Marit. Eng. 2020, 173, 120–135. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Stokkermans, J. Assessment of the potential of different floating solar technologies—Overview and analysis of different case studies. Energy Convers. Manag. 2020, 211, 112747. [Google Scholar] [CrossRef]

- Vo, T.T.; Ko, H.; Huh, J.; Park, N. Overview of Possibilities of Solar Floating Photovoltaic Systems in the OffShore Industry. Energies 2021, 14, 6988. [Google Scholar] [CrossRef]

- Zhang, C.; Dai, J.; Ang, K.K.; Lim, H.V. Development of compliant modular floating photovoltaic farm for coastal conditions. Renew. Sustain. Energy Rev. 2024, 190, 114084. [Google Scholar] [CrossRef]

- Bugeja, R.; Mule’ Stagno, L.; Branche, N. The effect of wave response motion on the insolation on offshore photovoltaic installations. Sol. Energy Adv. 2021, 1, 100008. [Google Scholar] [CrossRef]

- Lee, N.; Grunwald, U.; Rosenlieb, E.; Mirletz, H.; Aznar, A.; Spencer, R.; Cox, S. Hybrid floating solar photovoltaics-hydropower systems: Benefits and global assessment of technical potential. Renew. Energy 2020, 162, 1415–1427. [Google Scholar] [CrossRef]

- Yan, C.; Shi, W.; Han, X.; Li, X.; Verma, A.S. Assessing the dynamic behavior of multiconnected offshore floating photovoltaic systems under combined wave-wind loads: A comprehensive numerical analysis. Sustain. Horiz. 2023, 8, 100072. [Google Scholar] [CrossRef]

- Dai, J.; Zhang, C.; Lim, H.V.; Ang, K.K.; Qian, X.D.; Wong, J.L.H.; Tan, S.T.; Wang, C.L. Design and construction of floating modular photovoltaic system for water reservoirs. Energy 2020, 191, 116549. [Google Scholar] [CrossRef]

- Yoon, S.J.; Joo, H.J.; Kim, S.H. Structural analysis and design for the development of floating photovoltaic energy generation system. IOP Conf. Ser. Mater. Sci. Eng. 2018, 372, 012021. [Google Scholar] [CrossRef]

- Shi, W.; Yan, C.; Ren, Z.; Yuan, Z.; Liu, Y.; Zheng, S.; Li, X.; Han, X. Review on the development of marine floating photovoltaic systems. Ocean. Eng. 2023, 286, 115560. [Google Scholar] [CrossRef]

- Trapani, K.; Redón Santafé, M. A review of floating photovoltaic installations: 2007–2013. Prog. Photovolt. Res. Appl. 2015, 23, 524–532. [Google Scholar] [CrossRef]

- Ma, C.; Wu, R.; Liu, Z.; Li, X. Performance assessment of different photovoltaic module technologies in floating photovoltaic power plants under waters environment. Renew. Energy 2024, 222, 119890. [Google Scholar] [CrossRef]

- Lee, Y.-G.; Joo, H.-J.; Yoon, S.-J. Design and installation of floating type photovoltaic energy generation system using FRP members. Sol. Energy 2014, 108, 13–27. [Google Scholar] [CrossRef]

- Ramanan, C.J.; Lim, K.H.; Kurnia, J.C.; Roy, S.; Bora, B.J.; Medhi, B.J. Design study on the parameters influencing the performance of floating solar PV. Renew. Energy 2024, 223, 120064. [Google Scholar] [CrossRef]

- Ziar, H.; Prudon, B.; Lin, F.; Roeffen, B.; Heijkoop, D.; Stark, T.; Teurlincx, S.; Senerpont Domis, L.N.; Goma, E.G.; Extebarria, J.G.; et al. Innovative floating bifacial photovoltaic solutions for inland water areas. Prog. Photovolt. Res. Appl. 2020, 29, 725–743. [Google Scholar] [CrossRef]

- Choi, Y.; Choi, W.; Lee, J.H. Empirical Research on the Efficiency of Floating PV Systems. Sci. Adv. Mater. 2016, 8, 681–685. [Google Scholar] [CrossRef]

- Mayville, P.; Patil, N.V.; Pearce, J.M. Distributed manufacturing of after market flexible floating photovoltaic modules. Sustain. Energy Technol. Assess. 2020, 42, 100830. [Google Scholar] [CrossRef]

- Trapani, K.; Millar, D.L. The thin film flexible floating PV (T3F-PV) array: The concept and development of the prototype. Renew. Energy 2014, 71, 43–50. [Google Scholar] [CrossRef]

- Ghigo, A.; Faraggiana, E.; Sirigu, M.; Mattiazzo, G.; Bracco, G. Design and Analysis of a Floating Photovoltaic System for Offshore Installation: The Case Study of Lampedusa. Energies 2022, 15, 8804. [Google Scholar] [CrossRef]

- Sharma, P.; Muni, B.; Sen, D. Design parameters of 10 KW floating solar power plant. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 12–34. [Google Scholar] [CrossRef]

- Zeng, F.; Bi, C.; Sree, D.; Huang, G.; Zhang, N.; Law, A.W.-K. An Adaptive Barrier-Mooring System for Coastal Floating Solar Farms. Appl. Energy 2023, 348, 121618. [Google Scholar] [CrossRef]

- Kanotra, R.; Shankar, R. Floating Solar Photovoltaic Mooring System Design and Analysis. In Proceedings of the OCEANS 2022—Chennai, Chennai, India, 21–24 February 2022; pp. 1–9. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Saboor, S.; Ghosh, A.; Sheikhnejad, Y. Floating PVs in Terms of Power Generation, Environmental Aspects, Market Potential, and Challenges. Sustainability 2022, 14, 2626. [Google Scholar] [CrossRef]

- Tina, G.M.; Bontempo Scavo, F.; Merlo, L.; Bizzarri, F. Analysis of water environment on the performances of floating photovoltaic plants. Renew. Energy 2021, 175, 281–295. [Google Scholar] [CrossRef]

- Abid, M.; Abid, Z.; Sagin, J.; Murtaza, R.; Sarbassov, D.; Shabbir, M. Prospects of floating photovoltaic technology and its implementation in Central and South Asian Countries. Int. J. Environ. Sci. Technol. 2019, 16, 1755–1762. [Google Scholar] [CrossRef]

- Refaai, M.R.A.; Dhanesh, L.; Ganthia, B.P.; Mohanty, M.; Subbiah, R.; Anbese, E.M. Design and Implementation of a Floating PV Model to Analyse the Power Generation. Int. J. Photoenergy 2022, 2022, 3891881. [Google Scholar] [CrossRef]

- Sutanto, B.; Iacovides, H.; Nasser, A.; Cioncolini, A.; Afgan, I.; Indartono, Y.S.; Prasetyo, T.; Wijayanta, A.T. Design and analysis of passively cooled floating photovoltaic systems. Appl. Therm. Eng. 2024, 236, 121801. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Q.; Lin, H.; Li, H.; Sun, Q.; wennersten, R. Power Generation Efficiency and Prospects of Floating Photovoltaic Systems. Energy Procedia 2017, 105, 1136–1142. [Google Scholar] [CrossRef]

- El Hammoumi, A.; Chalh, A.; Allouhi, A.; Motahhir, S.; El Ghzizal, A.; Derouich, A. Design and construction of a test bench to investigate the potential of floating PV systems. J. Clean. Prod. 2021, 278, 123917. [Google Scholar] [CrossRef]

- Nagananthini, R.; Nagavinothini, R. Investigation on floating photovoltaic covering system in rural Indian reservoir to minimize evaporation loss. Int. J. Sustain. Energy 2021, 40, 781–805. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M. Integration of PV floating with hydroelectric power plants. Heliyon 2019, 5, e01918. [Google Scholar] [CrossRef]

- Ravichandran, N.; Fayek, H.H.; Rusu, E. Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt. Processes 2021, 9, 1005. [Google Scholar] [CrossRef]

- Ravichandran, N.; Ravichandran, N.; Panneerselvam, B. Floating photovoltaic system for Indian artificial reservoirs—An effective approach to reduce evaporation and carbon emission. Int. J. Environ. Sci. Technol. 2022, 19, 7951–7968. [Google Scholar] [CrossRef]

- Moraes, C.A.; Valadão, G.F.; Renato, N.S.; Botelho, D.F.; Oliveira, A.C.L.d.; Aleman, C.C.; Cunha, F.F. Floating photovoltaic plants as an electricity supply option in the Tocantins-Araguaia basin. Renew. Energy 2022, 193, 264–277. [Google Scholar] [CrossRef]

- Jin, Y.; Hu, S.; Ziegler, A.D.; Gibson, L.; Campbell, J.E.; Xu, R.; Chen, D.; Zhu, K.; Zheng, Y.; Ye, B.; et al. Energy production and water savings from floating solar photovoltaics on global reservoirs. Nat. Sustain. 2023, 6, 865–874. [Google Scholar] [CrossRef]

- Alhassan, M.O.; Opoku, R.; Uba, F.; Obeng, G.Y.; Sekyere, C.K.K.; Nyanor, P. Techno-economic and environmental estimation assessment of floating solar PV power generation on Akosombo dam reservoir in Ghana. Energy Rep. 2023, 10, 2740–2755. [Google Scholar] [CrossRef]

- Santos, F.R.d.; Wiecheteck, G.K.; Virgens Filho, J.S.d.; Carranza, G.A.; Chambers, T.L.; Fekih, A. Effects of a Floating Photovoltaic System on the Water Evaporation Rate in the Passaúna Reservoir, Brazil. Energies 2022, 15, 6274. [Google Scholar] [CrossRef]

- Farfan, J.; Breyer, C. Combining Floating Solar Photovoltaic Power Plants and Hydropower Reservoirs: A Virtual Battery of Great Global Potential. Energy Procedia 2018, 155, 403–411. [Google Scholar] [CrossRef]

- Pringle, A.M.; Handler, R.M.; Pearce, J.M. Aquavoltaics: Synergies for dual use of water area for solar photovoltaic electricity generation and aquaculture. Renew. Sustain. Energy Rev. 2017, 80, 572–584. [Google Scholar] [CrossRef]

- Al-Widyan, M.; Khasawneh, M.; Abu-Dalo, M. Potential of Floating Photovoltaic Technology and Their Effects on Energy Output, Water Quality and Supply in Jordan. Energies 2021, 14, 8417. [Google Scholar] [CrossRef]

- Poulek, V.; Ales, Z.; Finsterle, T.; Libra, M.; Beránek, V.; Severová, L.; Belza, R.; Mrázek, J.; Kozelka, M.; Svoboda, R. Reliability characteristics of first-tier photovoltaic panels for agrivoltaic systems—Practical consequences. Int. Agrophysics 2024, 38, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Ates, A.M. Unlocking the floating photovoltaic potential of Turkiye’s hydroelectric power plants. Renew. Energy 2022, 199, 1495–1509. [Google Scholar] [CrossRef]

- Goswami, A.; Sadhu, P.K. Degradation analysis and the impacts on feasibility study of floating solar photovoltaic systems. Sustain. Energy Grids Netw. 2021, 26, 100425. [Google Scholar] [CrossRef]

- Bax, V.; van de Lageweg, W.I.; Hoosemans, R.; van den Berg, B. Floating photovoltaic pilot project at the Oostvoornse lake: Assessment of the water quality effects of three different system designs. Energy Rep. 2023, 9, 1415–1425. [Google Scholar] [CrossRef]

- Exley, G.; Armstrong, A.; Page, T.; Jones, I.D. Floating photovoltaics could mitigate climate change impacts on water body temperature and stratification. Sol. Energy 2021, 219, 24–33. [Google Scholar] [CrossRef]

- Exley, G.; Hernandez, R.R.; Page, T.; Chipps, M.; Gambro, S.; Hersey, M.; Lake, R.; Zoannou, K.S.; Armstrong, A. Scientific and stakeholder evidence-based assessment: Ecosystem response to floating solar photovoltaics and implications for sustainability. Renew. Sustain. Energy Rev. 2021, 152, 111639. [Google Scholar] [CrossRef]

- Hooper, T.; Armstrong, A.; Vlaswinkel, B. Environmental impacts and benefits of marine floating solar. Sol. Energy 2021, 219, 11–14. [Google Scholar] [CrossRef]

- Claus, R.; López, M. Key issues in the design of floating photovoltaic structures for the marine environment. Renew. Sustain. Energy Rev. 2022, 164, 112502. [Google Scholar] [CrossRef]

- Trapani, K.; Millar, D.L.; Smith, H.C.M. Novel offshore application of photovoltaics in comparison to conventional marine renewable energy technologies. Renew. Energy 2013, 50, 879–888. [Google Scholar] [CrossRef]

- Jiang, Z.; Dai, J.; Saettone, S.; Tørå, G.; He, Z.; Bashir, M.; Souto-Iglesias, A. Design and model test of a soft-connected lattice-structured floating solar photovoltaic concept for harsh offshore conditions. Mar. Struct. 2023, 90, 103426. [Google Scholar] [CrossRef]

- Daroen, I. Risk Assessment of Offshore Floating Photovoltaic Systems. Master’s Thesis, Delft University of Technology, Delft, The Netherland, 2021. [Google Scholar]

- Vlaswinkel, B.; Roos, P.; Nelissen, M. Environmental Observations at the First Offshore Solar Farm in the North Sea. Sustainability 2023, 15, 6533. [Google Scholar] [CrossRef]

- Nagananthini, R.; Nagavinothini, R.; Balamurugan, P. Floating Photovoltaic Thin Film Technology—A Review. In Intelligent Manufacturing and Energy Sustainability; Springer: Berlin/Heidelberg, Germany, 2020; pp. 329–338. [Google Scholar] [CrossRef]

- Trapani, K. Flexible Floating Thin Film Photovoltaic (PV) Array Concept for Marine and Lacustrine Environments. Ph.D. Thesis, Laurentian University of Sudbury, Sudbury, ON, Canada, 2014. [Google Scholar]

- Wijewardane, S.; Kazmerski, L.L. Inventions, innovations, and new technologies: Flexible and lightweight thin-film solar PV based on CIGS, CdTe, and a-Si:H. Sol. Compass 2023, 7, 100053. [Google Scholar] [CrossRef]

- Kumar, N.M.; Subramaniam, U.; Mathew, M.; Ajitha, A.; Almakhles, D.J. Exergy analysis of thin-film solar PV module in ground-mount, floating and submerged installation methods. Case Stud. Therm. Eng. 2020, 21, 100686. [Google Scholar] [CrossRef]

- Scully, J. Researchers Trial Thin-Film Floating Solar System for Offshore Applications. Available online: https://www.pv-tech.org/researchers-trial-thin-film-floating-solar-system-for-offshore-applications/ (accessed on 20 July 2024).

- Todorović, I. China Completes World’s First Hybrid Offshore Wind-Solar Power Plant. Available online: https://balkangreenenergynews.com/china-completes-worlds-first-hybrid-offshore-wind-solar-power-plant/ (accessed on 20 July 2024).

- Garanovic, A. Sunseap Installs One of World’s Largest Offshore Floating Solar Farms in Singapore. Available online: https://www.offshore-energy.biz/sunseap-installs-one-of-worlds-largest-offshore-floating-solar-farms-in-singapore/ (accessed on 18 August 2024).

- Garanovic, A. Watch: SolarDuck Debuts Its Floating Solar Platform. Available online: https://www.offshore-energy.biz/watch-solarduck-debuts-its-floating-solar-platform/ (accessed on 20 August 2024).

- Oceans of Energy. A World’s First: Offshore Floating Solar Farm Installed at the Dutch North Sea. Available online: https://oceansofenergy.blue/2019/12/11/a-worlds-first-offshore-floating-solar-farm-installed-at-the-dutch-north-sea/ (accessed on 20 August 2024).

- Oceans of Energy. Offshore Solar Project-North Sea 1. Available online: https://oceansofenergy.blue/north-sea-1/ (accessed on 26 August 2024).

- Swimsol. World’s First Offshore Floating Solar at Sea 2014 Maldives. Available online: https://swimsol.com/solar-projects/worlds-first-floating-solar-platform-at-sea/ (accessed on 23 August 2024).

- Swimsol. Offshore Floating Solar at a Fish Farm in Chile. Available online: https://swimsol.com/solar-projects/fishfarm-solarsea-chile-swimsol/ (accessed on 23 August 2024).

- Garanovic, A. China Launches Its First Semi-Submersible Offshore Solar Platform. Available online: https://www.offshore-energy.biz/china-launches-its-first-semi-submersible-offshore-solar-platform/ (accessed on 26 August 2024).

- Liu, X.; Gu, K.; Qian, Z.; Ding, S.; Wang, K.; Wang, H.; Sun, C. A Simplified Method for the Evaluation of Floating-Body Motion Responses over a Sloping Bottom. J. Mar. Sci. Eng. 2024, 12, 756. [Google Scholar] [CrossRef]

- Jin, Z.; Liu, Y.; Zhu, M.; Fang, H.; Li, A. A novel analytical model coupling hydrodynamic-structural-material scales for very large floating photovoltaic support structures. Ocean. Eng. 2023, 275, 114113. [Google Scholar] [CrossRef]

- Kaymak, M.K.; Şahin, A.D. Problems encountered with floating photovoltaic systems under real conditions: A new FPV concept and novel solutions. Sustain. Energy Technol. Assess. 2021, 47, 101504. [Google Scholar] [CrossRef]

- Jiang, D.; Tan, K.H.; Wang, C.M.; Dai, J. Research and development in connector systems for Very Large Floating Structures. Ocean. Eng. 2021, 232, 109150. [Google Scholar] [CrossRef]

- Sree, D.K.K.; Law, A.W.-K.; Pang, D.S.C.; Tan, S.T.; Wang, C.L.; Kew, J.H.; Seow, W.K.; Lim, V.H. Fluid-structural analysis of modular floating solar farms under wave motion. Sol. Energy 2022, 233, 161–181. [Google Scholar] [CrossRef]

- Choi, S.M.; Park, C.-D.; Cho, S.-H.; Lim, B.-J. Effects of various inlet angle of wind and wave loads on floating photovoltaic system considering stress distributions. J. Clean. Prod. 2023, 387, 135876. [Google Scholar] [CrossRef]

- Aksnes, V.; Alsos, H.; Bachynski-Polić, E.; Berthelsen, P.A.; Delhaye, V.; Furevik, B.R.; Jostad, H.P.; Kristiansen, T.; Ommani, B. On Common Research Needs for the Next Generation of Floating Support Structures. In Proceedings of the ASME 2022 41st International Conference on Ocean, Offshore and Arctic Engineering, Hamburg, Germany, 5–10 June 2022; Volume 4. [Google Scholar] [CrossRef]

- Li, Z.; Chen, D.; Feng, X. Hydroelastic and expansibility analysis of a modular floating photovoltaic system with multi-directional hinge connections. Ocean. Eng. 2023, 289, 116218. [Google Scholar] [CrossRef]

- Munshi, A.H.; Sasidharan, N.; Pinkayan, S.; Barth, K.L.; Sampath, W.S.; Ongsakul, W. Thin-film CdTe photovoltaics—The technology for utility scale sustainable energy generation. Sol. Energy 2018, 173, 511–516. [Google Scholar] [CrossRef]

- Demirtaş, M.; Tamyürek, B.; Kurt, E.; Çetinbaş, İ.; Öztürk, M.K. Effects of Aging and Environmental Factors on Performance of CdTe and CIS Thin-Film Photovoltaic Modules. J. Electron. Mater. 2019, 48, 6890–6900. [Google Scholar] [CrossRef]

- López, M.; Rodríguez, N.; Iglesias, G. Combined Floating Offshore Wind and Solar PV. J. Mar. Sci. Eng. 2020, 8, 576. [Google Scholar] [CrossRef]

- Solomin, E.; Sirotkin, E.; Cuce, E.; Selvanathan, S.P.; Kumarasamy, S. Hybrid Floating Solar Plant Designs: A Review. Energies 2021, 14, 2751. [Google Scholar] [CrossRef]

- Jin, Y.; Zeng, Z.; Chen, Y.; Xu, R.; Ziegler, A.D.; Chen, W.; Ye, B.; Zhang, D. Geographically constrained resource potential of integrating floating photovoltaics in global existing offshore wind farms. Adv. Appl. Energy 2024, 13, 100163. [Google Scholar] [CrossRef]

- Costoya, X.; deCastro, M.; Carvalho, D.; Arguilé-Pérez, B.; Gómez-Gesteira, M. Combining offshore wind and solar photovoltaic energy to stabilize energy supply under climate change scenarios: A case study on the western Iberian Peninsula. Renew. Sustain. Energy Rev. 2022, 157, 112037. [Google Scholar] [CrossRef]

- Golroodbari, S.Z.M.; Vaartjes, D.F.; Meit, J.B.L.; van Hoeken, A.P.; Eberveld, M.; Jonker, H.; van Sark, W.G.J.H.M. Pooling the cable: A techno-economic feasibility study of integrating offshore floating photovoltaic solar technology within an offshore wind park. Sol. Energy 2021, 219, 65–74. [Google Scholar] [CrossRef]

| Producer | Float Structure | Capacity (KWp) | Features | Date | Location | The Physical Picture |

|---|---|---|---|---|---|---|

| Swimsol | Rigid floating structures | 15 | The inaugural offshore FPV system globally, along with the first floating solar platform at sea. This platform is robust enough to guarantee the safety of the photovoltaic modules. Every component in the system is designed to resist corrosion and has a lifespan of up to three decades. | 2014 | Maldives |  |

| Swimsol | Rigid floating structures | 24 | This project serves as a preliminary effort for the offshore floating solar platform, with the goal of acquiring experience that will facilitate the future installation of a more extensive offshore floating solar system. | 2017 | Maldives |  |

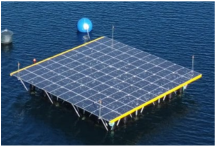

| Ocean Sun | Flexible floating structures | 100 | The individual float of the system is 50 m in diameter, and the system employs flexible thin film to support the rigid crystalline silicon PV panels, with the inverters placed on a nearby barge. The floats, thin film and PV panels of the system remained in good condition after surviving several winter storms. | 2018 | West Coast of Norway |  |

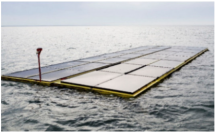

| Oceans of energy | Rigid floating structures | 50 | The system was installed 15 km offshore from the coast and successfully withstood severe sea conditions, including wave heights up to 9–10 m and hurricane winds in excess of 110 km/h. It is designed and tested to withstand waves up to 13 m high. | 2020 | The North Sea |  |

| Sunseap | Rigid floating structures | 5000 | The FPV system comprises 13,312 photovoltaic panels, 40 inverters, and over 30,000 floats. Based on Sunseap’s estimates, the system will generate 6,022,500 kWh of energy per year, leading to a reduction of around 4258 tons of CO2 emissions. | 2021 | Straits of Johor, Singapore |  |

| Solarduck | Rigid floating structures | 65 | The system’s individual float is triangular in shape, measuring 16 × 16 × 16 m, and it can be connected in a flexible configuration to form a large floating solar platform. It is lightweight, highly stable, and can withstand wind, waves, and currents, including sea breezes of up to 30 m/s. | 2021 | Rhine inshore waters |  |

| Swimsol | Rigid floating structures | 35 | The system is a PV-LPG hybrid power system installed near fish farms in the coastal waters of Chile, which provides power to the fish farms. | 2022 | Chile |  |

| Ocean Sun | Flexible floating structures | 500 | This project represents the inaugural offshore FPV undertaking to be operational within the “double 30” marine environment. This environment is defined by an offshore distance of 30 km, a water depth of 30 m, and an extreme wave height of 10 m. The project combines wind and PV power generation in the same field to reduce engineering, operating and maintaining costs. It explores technical routes for future offshore FPV systems to achieve scale, commercialization and standardization, and aims to realize value symbiosis with the industrial chain. | 2022 | Yantai, China |  |

| CIMC Raffles | Rigid floating structures | 400 | The offshore FPV power generation platform is semisubmersible and equipped with four single floating arrays. Its overall net deck area spans approximately 1900 square meters and includes eight systems, such as floating structural support system, buoyant material system, multi-body connection and mooring system, fender collision avoidance system, photovoltaic power generation and inverter system, intelligent monitoring system, dynamic cable transmission system and power consumption system. This platform is engineered to function safely in open ocean environments, capable of withstanding wave heights of up to 6.5 m, wind speeds reaching 34 m/s, and tidal ranges of as much as 4.6 m. | 2023 | Yantai, China |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Guo, J.; Peng, H.; Ping, H.; Ma, Q. Review of Recent Offshore Floating Photovoltaic Systems. J. Mar. Sci. Eng. 2024, 12, 1942. https://doi.org/10.3390/jmse12111942

Liu G, Guo J, Peng H, Ping H, Ma Q. Review of Recent Offshore Floating Photovoltaic Systems. Journal of Marine Science and Engineering. 2024; 12(11):1942. https://doi.org/10.3390/jmse12111942

Chicago/Turabian StyleLiu, Gang, Jiamin Guo, Huanghua Peng, Huan Ping, and Qiang Ma. 2024. "Review of Recent Offshore Floating Photovoltaic Systems" Journal of Marine Science and Engineering 12, no. 11: 1942. https://doi.org/10.3390/jmse12111942

APA StyleLiu, G., Guo, J., Peng, H., Ping, H., & Ma, Q. (2024). Review of Recent Offshore Floating Photovoltaic Systems. Journal of Marine Science and Engineering, 12(11), 1942. https://doi.org/10.3390/jmse12111942