Abstract

The new-type stainless steel–concrete–carbon steel double-skin tubular (SCCDST) members, characterized by their exceptional corrosion resistance and mechanical bearing capacity, have promising applications in ocean engineering, particularly in deep-water engineering. The external hydraulic pressure and interfacial action of various materials intensify the complexity of composite performance of SCCDST members. This paper describes an analytical investigation on the concentric compressive performance of SCCDST members under external hydraulic pressure. The full-range mechanism, including load–displacement response, bearing capacity contribution, and contact pressures, was investigated through the finite element (FE) model that was validated by the failure mode, bearing capacity, and response of axial load versus strain. Subsequently, influences of key geometric–physical parameters were analyzed, e.g., diameter-to-thickness ratios (Do/to, Di/ti), material strengths (fyo, fyi, and fc), hollow ratios (χ), and water depths (H). Typical results indicate that: the initial active confinement action derived from the hydraulic pressure can enhance the interfacial contact pressure and axial compression capacity of SCCDST members due to the tri-axial compression state; the enhancement of confinement effect is mainly from the interfacial interaction between outer stainless steel tube and concrete infill; influence of water depth on bearing capacity cannot be ignored, e.g., the bearing capacity of an SCCDST member with larger hollow ratio (χ = 0.849) is not enhanced under a higher hydraulic pressure (H = 900 m) because of the cross-sectional buckling failure risk. Finally, a modified method considering the effect of water depth was proposed and verified for SCCDST members under hydraulic pressure.

1. Introduction

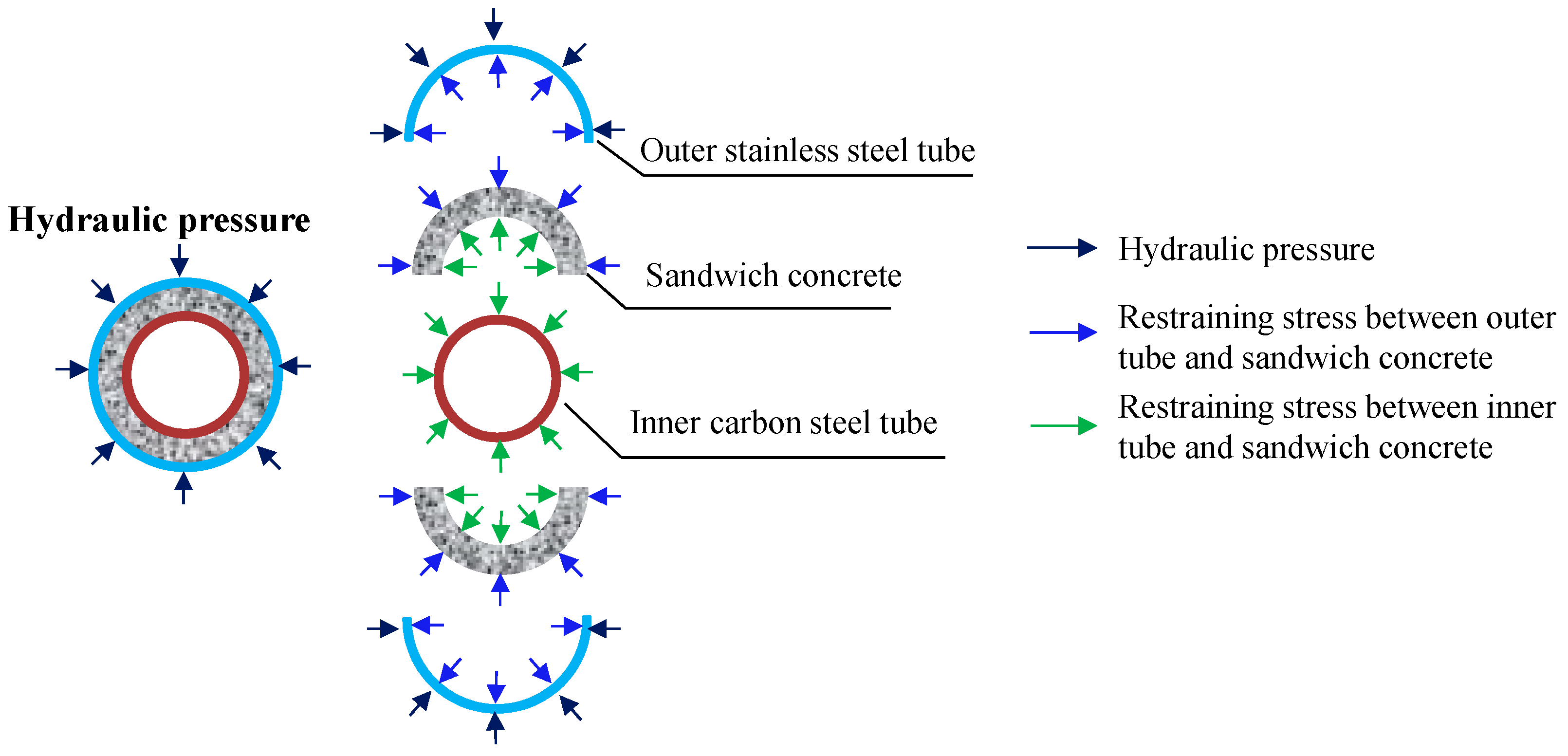

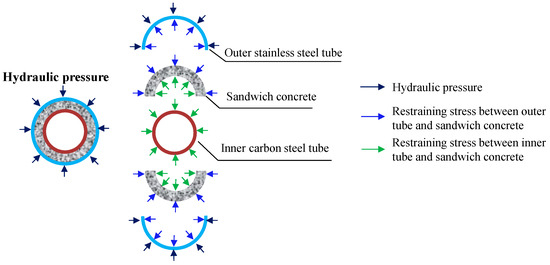

Corrosion damage in ocean environments has received significant attention for steel or steel–concrete structures, such as pile foundations and jacket platforms [1,2]. As a typical high-performance structure, concrete-filled double-skin steel tubular (CFDST) structures increasingly demonstrate a promising application in ocean engineering for bearing complex loads [3,4,5,6]. Nevertheless, the traditional CFDST structure typically comprises double-skin carbon steel tubes and sandwich concrete, referred to as the concrete-filled double-skin carbon steel tubular (CFDSCST) section, which is prone to corrosion [5,6,7]. Consequently, a new type of double-skin composite member, i.e., stainless steel–concrete–carbon steel double-skin tubular (SCCDST) members, has been proposed to enhance the corrosion resistance of CFDSCST members (Figure 1) [8,9]. The utilization of SCCDST members is expected to expand significantly in coastal and deep-sea engineering projects. Design methods suitable for land engineering are ever-improving for double-skin composite members with CFDSCST or SCCDST sections [6,7,8,9,10,11,12,13]. In contrast to land sites, the deep-water environment subjects SCCDST members to external hydraulic pressure, where the composite performance is influenced by the combination of passive and active confinement actions (Figure 2) [13]. The passive confinement action refers to the interactive behavior between the double-skin stainless or steel tubes and sandwich concrete, and the active action is derived from the external hydraulic pressure. The design method mentioned earlier, based on passive confinement action, is no longer applicable to deep-sea engineering [14,15]. Therefore, it is vital and necessary to conduct research on the mechanical performance and calculation theory of SCCDST members under hydraulic pressure in order to provide guidance for deep-water projects.

Figure 1.

Potential engineering utilization of SCCDST members for avoiding corrosion.

Figure 2.

Confinement action under external hydraulic pressure.

The CFDST members including the traditional CFDSCST members and new-type SCCDST members are usually used as the structural members that mainly undergo axial compression. Research on the axial compressive behavior can provide a fundamental reference for their design and construction. Extensive work has been carried out on the axial compressive behavior of conventional CFDSCST members [7,10,11,14,16,17,18,19,20,21,22,23,24]. Similarly, in order to enhance corrosion resistance, the performance of SCCDST members under concentric compression is gradually being examined [9,12,15,25,26,27,28,29,30,31]. It should be noted that those abovementioned studies about CFDSCST and SCCDST members are mainly limited to the application scenario of land engineering with passive confinement action. For example, Li et al. [25] experimentally researched the axial compression performance of circular-in-circular double-skin stainless steel tubular composite columns filled with seawater sea sand concrete, revealing that the cross-sectional hollow ratio has a slight impact on the concrete’s ultimate stress and member’s post-peak behavior. Wang et al. [26] investigated the mechanical property of axially compressed circular-in-circular CFDST stub members with outer stainless steel tubes through numerical and experimental methods, in which the investigation on applicability of current design codes points out that the methods in EC4 [32] and AS 5100 [33] tend to predict unsafe results and the methods in AISC 360 [34] and ACI 318 [35] can lead to a scattered and conservative prediction. Results of Castanheira et al. [29] demonstrate that SCCDST members with recycled aggregate concrete can perform a similar concentric compressive behavior compared to the SCCDST members using traditional concrete, and double-skin tubes can be easily locally buckled combined with apparently lower bearing capacity in the case of high void ratios.

Research on SCCDST members in ocean environments, especially for deep-water conditions, is still limited. Wang and Han [15] numerically analyzed the concentric compressive behavior and flexural behavior of submarine pipelines under external and inner hydraulic pressures, where the cross-section is composed of carbon steel outer pipe, sandwich concrete, and stainless steel inner pipe, and it reveals that the confinement action between double-skin pipes and sandwiched concrete is significantly affected by the hydraulic pressure. However, the influence of various external hydraulic pressures, specifically the variations in water depths, on the confinement action and composite mechanism of new-type SCCDST members remains undisclosed. The accuracy of existing design codes applicable to land engineering, such as T/CCES 7-2020 [36] and T/CECS 952-2021 [37], cannot be guaranteed when it comes to bearing capacity calculation, parameter matching, and structural measures for deep-water engineering. The application of SCCDST structures in ocean projects, such as deep-water jacket platforms and pile foundations, is hindered by a research deficiency in design methodology and mechanical mechanisms. Hence, it is essential to carry out analytical work on the aforementioned details of SCCDST members under external hydraulic pressure to address this issue.

This paper presents a numerical investigation on the analytical axial compressive behavior of SCCDST members subjected to external hydraulic pressure. A finite element (FE) model is constructed and validated based on failure mode, bearing capacity assessment, and complete load–displacement curves. The effects of key parameters (e.g., Do/to, Di/ti, fyo, fyi, fc, χ) are examined for various water depths ranging from 0 m to 900 m. Subsequently, a modified design approach is proposed to calculate the axial compressive strength for deep-water engineering applications. The findings of this study can provide valuable design references for the construction of ocean engineering projects.

2. Finite Element Modeling

2.1. Establishment of FE Model

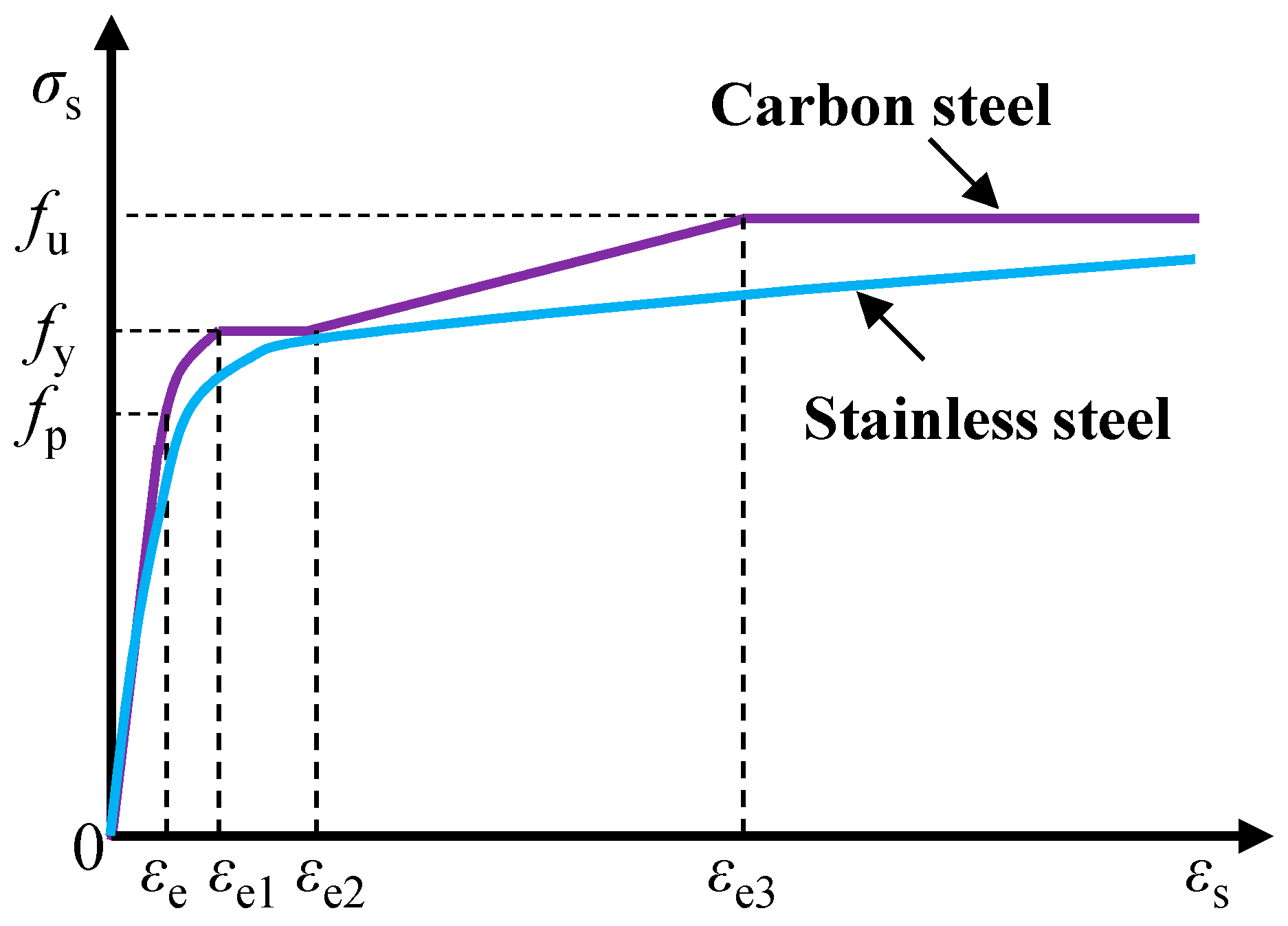

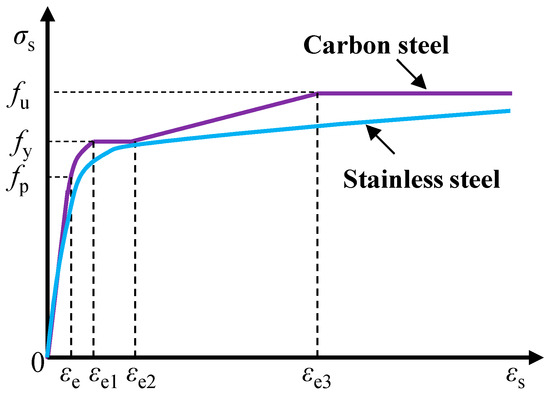

To analyze the nonlinear behavior of inner carbon steel tubes, a constitutive relationship consisting of five stages was adopted [38,39], as shown in Figure 3, including two horizontal plastic parts. The confined concrete model under compressive loading of Han was utilized to calculate the performance of sandwich concrete [40]:

where is the dimensionless strain; is the nondimensional stress. The peak strain ε0 and computing coefficient β0 are given as follows.

where ξ is the confinement coefficient [40]. Its tensile behavior was modeled by the fracture energy method:

Figure 3.

Constitutive relationships for carbon steel and stainless steel.

As for the stainless steel in Figure 3, it usually has a strong nonlinear stress–strain relationship; therefore, the method proposed by Rasmussen was herein adopted to simulate the outer austenitic stainless steel tube [41]:

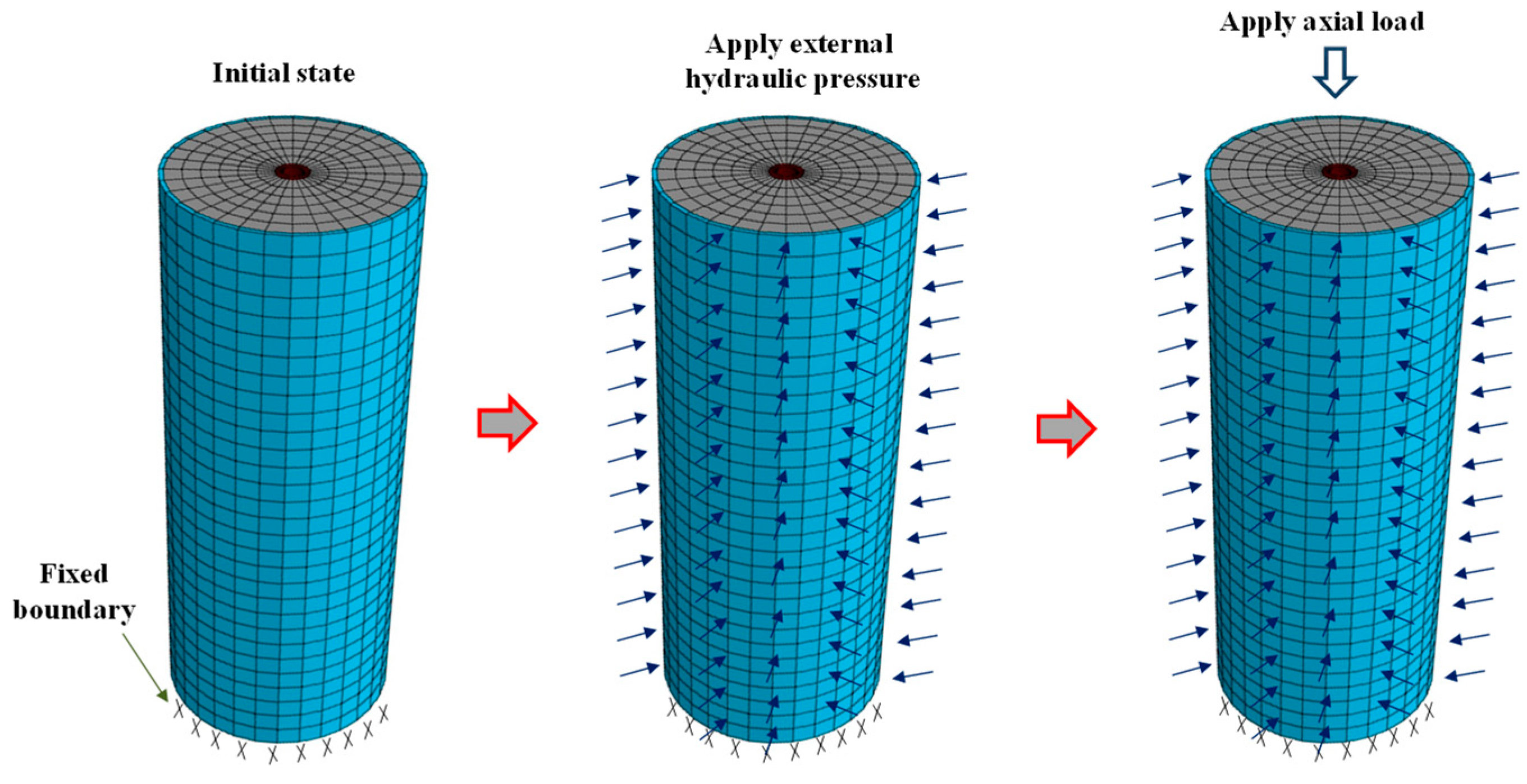

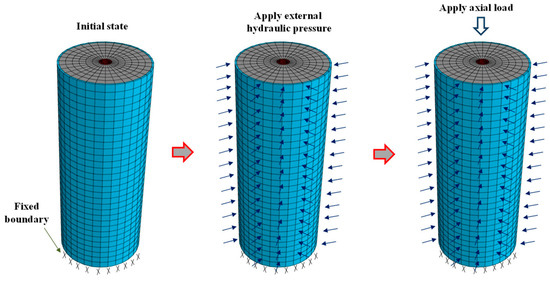

The sandwich concrete and double-skin tubes (stainless steel and carbon steel) were simulated using the C3D8R solid element and S4R shell element, respectively, where the mesh sizes in the circumferential direction and longitudinal direction were equally divided into thirty-two elements and thirty elements after the sensitivity analysis of mesh size, respectively. Moreover, the mesh size through the thickness direction of sandwich concrete was set as six layers. The normal and tangential interactions of the stainless steel–concrete–carbon steel interfaces were computed using the hard contact method and Coulomb friction method. The friction coefficient was set to 0.6 [38]. No experimental investigations have been conducted on the concentric compressive behavior of SCCDST members subjected to external hydraulic pressure. Therefore, the analytical finite element (FE) model was initially validated by performing tests without hydraulic pressure (0 MPa). Subsequently, the validated FE model was further enhanced to analyze the axial compressive behavior of SCCDST members under different external hydraulic pressures. In these aforementioned FE models, the axial load was applied using a displacement-controlled mode, where the FE models with hydraulic pressures were initially subjected to the target pressures before the application of axial load (Figure 4). Validation details and further analytical behavior are displayed in subsequent sections.

Figure 4.

Established FE model.

2.2. Validation of FE Model

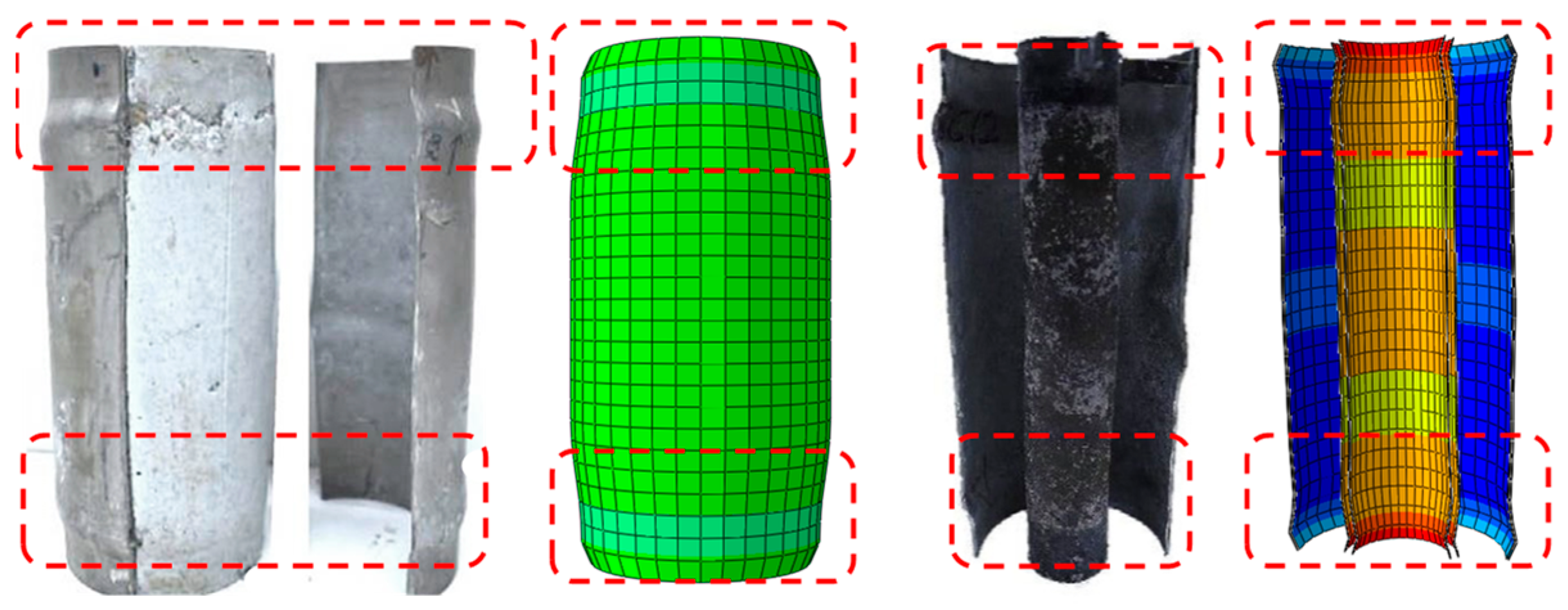

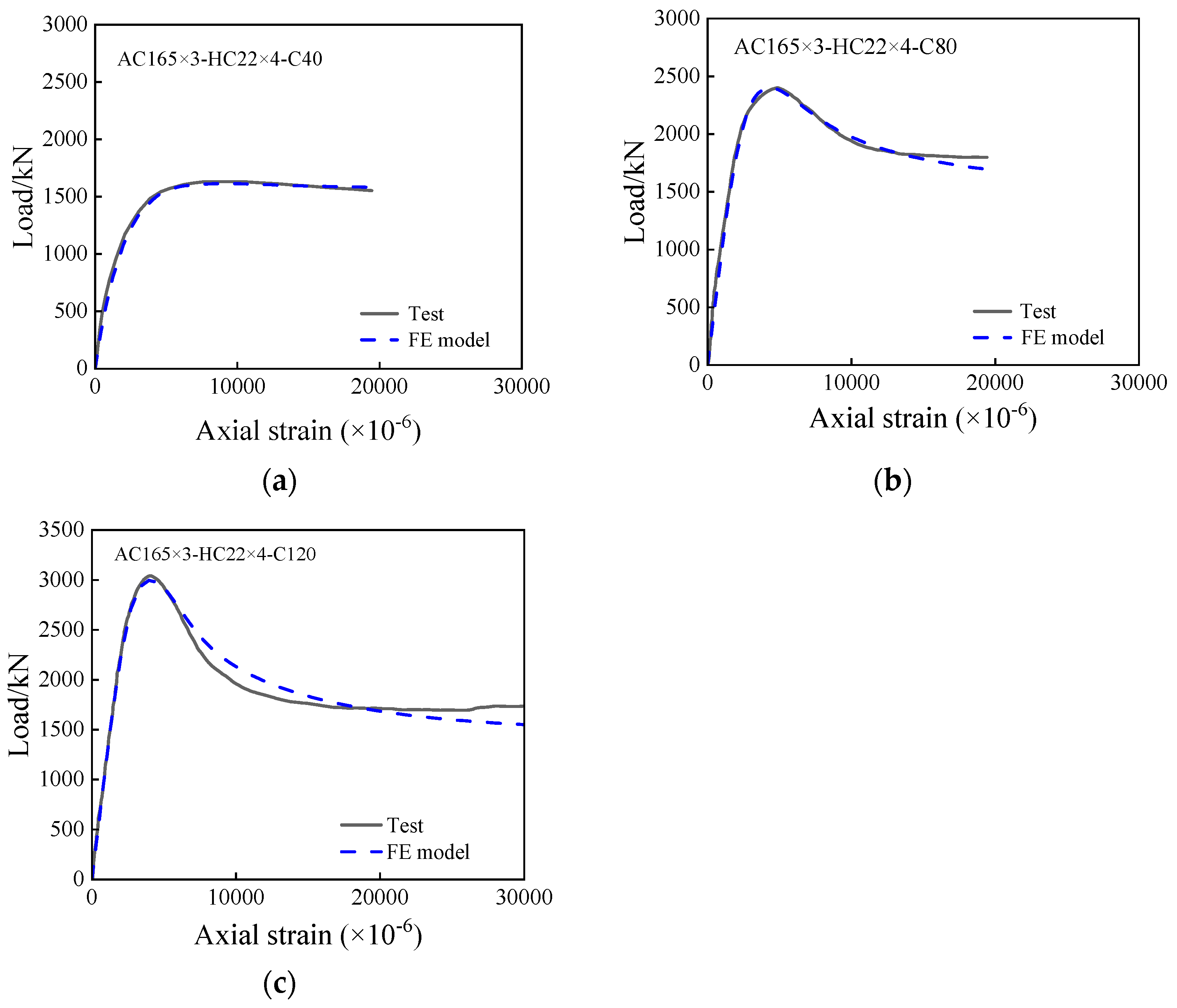

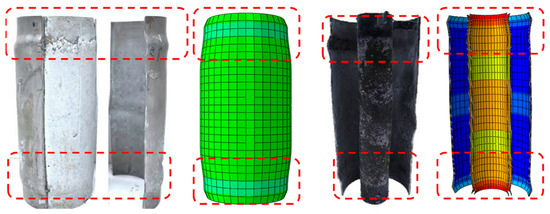

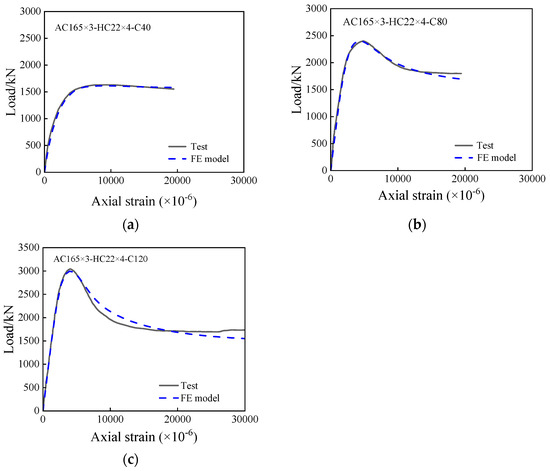

In order to validate the established FE model, the collected test results from a previous study [26] were compared against the failure mode, axial bearing capacity, and curve of load versus axial strain. The FE model implemented in Figure 5 demonstrates good agreement with the occurrence of local buckling in the double-skin tubes, as well as the crushing of concrete. The comparison between the anticipated axial compressive strengths (NFE) and the corresponding test strengths (NT) of SCCDST members in Table 1 demonstrates the accurate predictive capabilities of the FE model, with a mean value NFE/NT of 0.9985. In Figure 6, the typical full-range axial load versus strain curves of the tested SCCDST members are compared, considering the limitation of page space. It can be observed that the load–displacement curves of the FE models exhibit favorable agreement with the pre-peak stiffness, ultimate load-carrying capacity, and nonlinear behavior during the post-peak stage of the tested SCCDST members. Given the validation of the three aspects mentioned above, the established FE model can effectively simulate the compressive behavior of SCCDST specimens and can provide basic guidance for the analysis of axial compression performance under deep-water pressure.

Figure 5.

Verification of failure mode [26].

Table 1.

Verification of bearing capacity.

Figure 6.

Verification of load–displacement curves. (a) AC165×3-HC22×4-C40; (b) AC165×3-HC22×4-C80; (c) AC165×3-HC22×4-C120.

2.3. Analysis on Full-Range Performance with Hydraulic Pressure

Using the verified FE model, this section examines the concentric compressive performance of SCCDST members subjected to hydraulic pressure in deep-water conditions. A representative member at a water depth of 300 m is presented to enhance comprehension, and its geometric–physical characteristics are as follows: the outer stainless steel tube has a diameter of Do = 165 mm and a wall thickness of to = 3 mm; the inner carbon steel tube has a diameter of Di = 90 mm and a wall thickness of ti = 4 mm; steel yield strengths of outer and inner tubes are fyo = 280 MPa and fyi = 960 MPa, respectively; the concrete strength is fc = 80 MPa; the length of the member is 413 mm; the water pressure at a depth of 300 m is considered to be approximately 3 MPa.

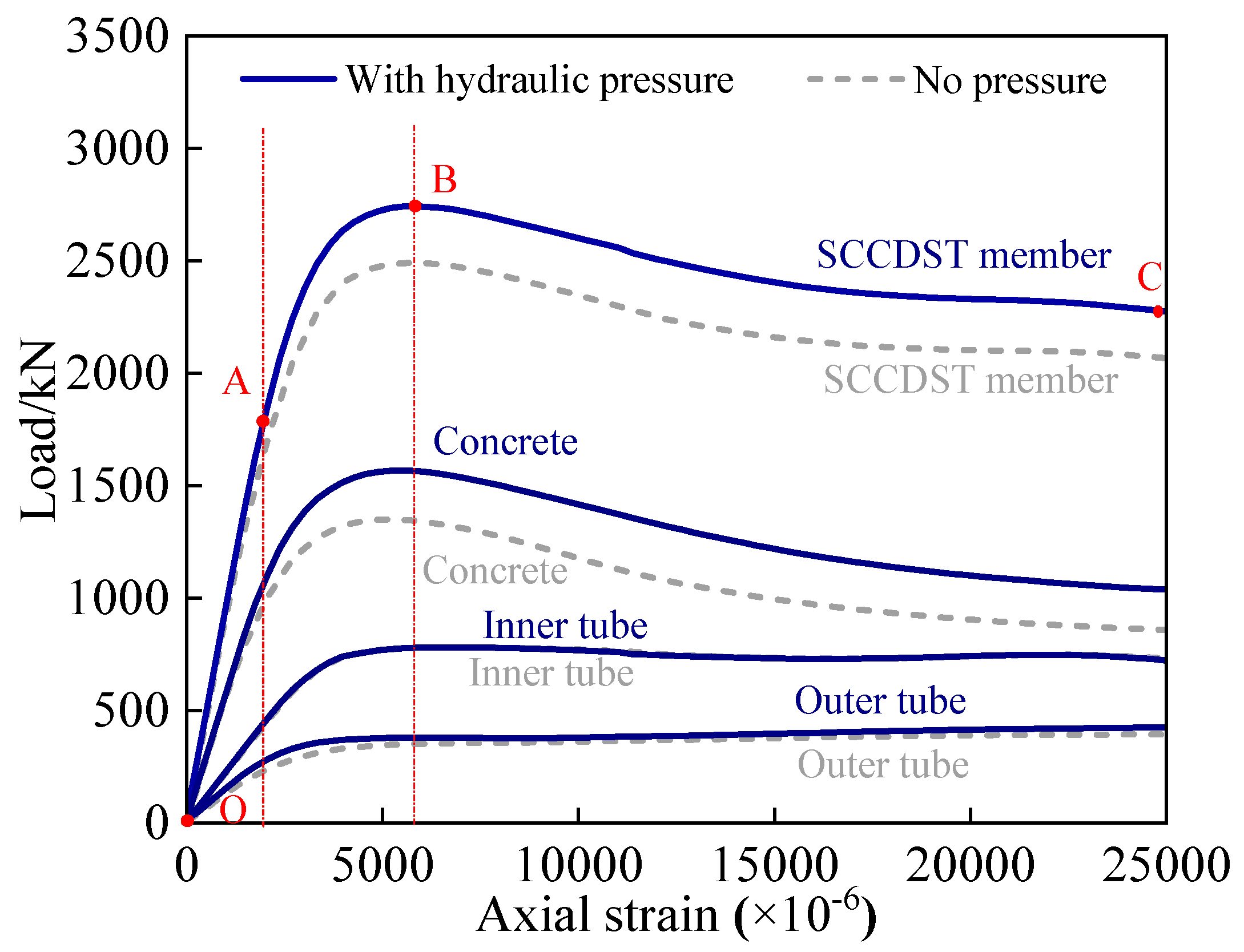

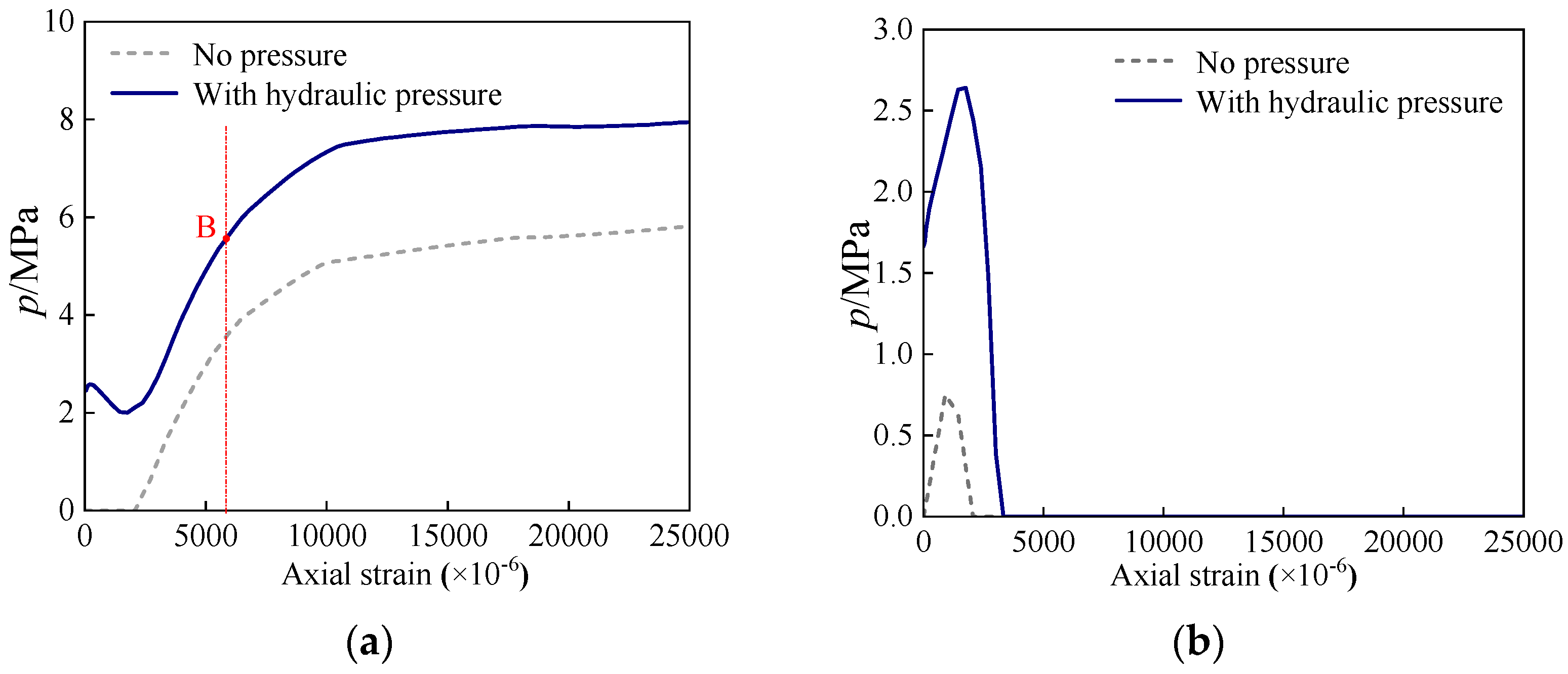

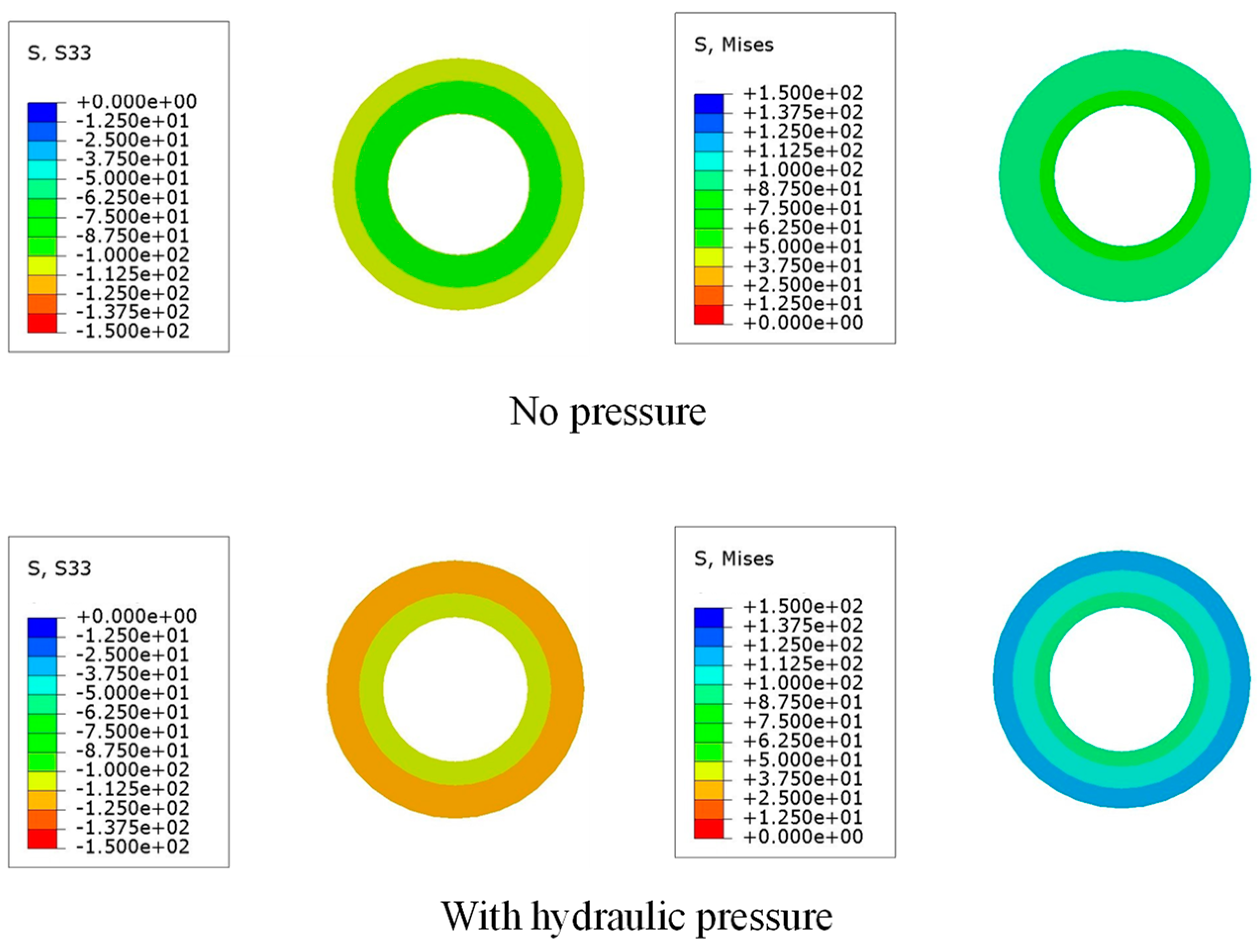

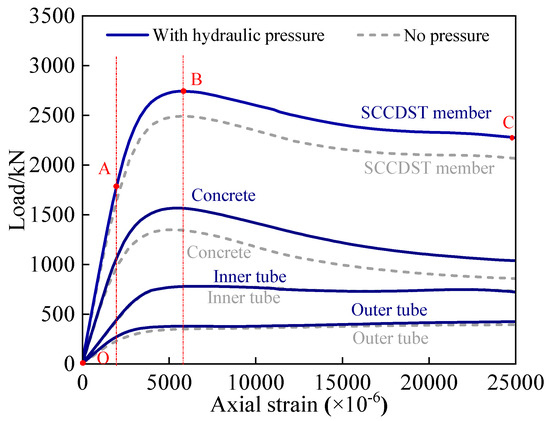

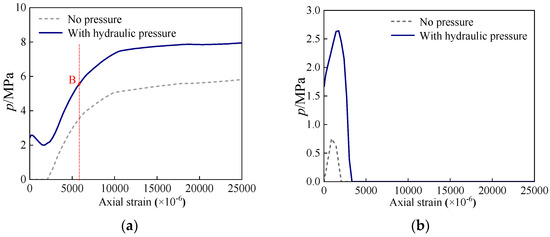

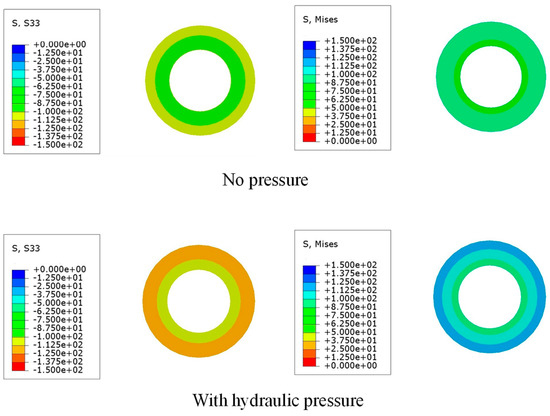

Analysis on the full-range behavior of an SCCDST member with deep-water hydraulic pressure is offered in Figure 7 and Figure 8, in which its performance response is compared to its counterpart without hydraulic pressure. Generally, the variation trend of SCCDST members with hydraulic pressure behaves analogously to that of the SCCDST member without hydraulic pressure, but the member exposed to deep-water hydraulic pressure displays a higher bearing capacity to resist axial load with an increased percentage of 10.04%, where the contributions of inner carbon steel tubes are nearly the same for both. In the condition of hydraulic pressure, the contribution of the outer stainless steel tube is slightly higher than that of the member without hydraulic pressure. The primary disparity that leads to the augmentation of load-bearing capacity can be attributed to the enhanced contribution of sandwich concrete when subjected to an elevated level of tri-axial compression in hydraulic pressure, therefore resulting in the higher axial strength or von Mises stress in Figure 9. Moreover, through the curve of axial load versus strain in Figure 7, three typical stages can be divided by four feature points for the SCCDST member with hydraulic pressure. During the stage OA, the SCCDST member is in an elastic working state. Subsequently, the outer stainless steel tube, sandwich concrete, and inner carbon steel tube gradually show elastic–plastic performance, in which the material strengths of cross-sectional materials are fully utilized. At point B, the sandwich concrete, inner tube, and outer tube contribute 57.08%, 28.45%, and 14.47% of the total axial bearing capacity of the SCCDST member, respectively. During the stage O-A-B, the confining stress between the outer stainless steel tube and sandwich concrete is increased quickly (Figure 8a), but the confining stress of the inner carbon steel tube and concrete gradually degrades to zero, as displayed in Figure 8b. Thereafter, the SCCDST member progresses to the failure phase accompanied by capacity degradation, while the concrete undergoes severe crushing and the outer or inner tubes reach a highly plastic state, resulting in the rapid increase in confining stress of the outer tube to concrete (Figure 8a). As illustrated in Figure 8, the existing hydraulic pressure promotes the composite performance between double-skin tubes and concrete infill, leading to an initial active confining stress and a heightened state of the full-range process, from which the confining stress between the inner tube and sandwich concrete is comparatively lower than that between the outer tube and concrete, and it rapidly decreases before reaching the maximum load point B.

Figure 7.

Analysis on full-range axial load–strain curves.

Figure 8.

Analysis on confinement effect. (a) Confining stress between outer stainless steel tube and sandwich concrete; (b) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 9.

Stress-field nephogram of sandwich concrete at peak load.

3. Parametric Study

This section displays the result of a parametric study, including the influences of diameter-to-thickness ratio of outer stainless steel tube (Do/to), diameter-to-thickness ratio of inner carbon steel tube (Di/ti), material strengths (fyo, fyi, and fc), hollow ratio (χ), and water depth (H). A summary of the studied parameters is given in Table 2. The benchmark specimen corresponds to the member described in Section 2.3.

Table 2.

Summary of studied parameters.

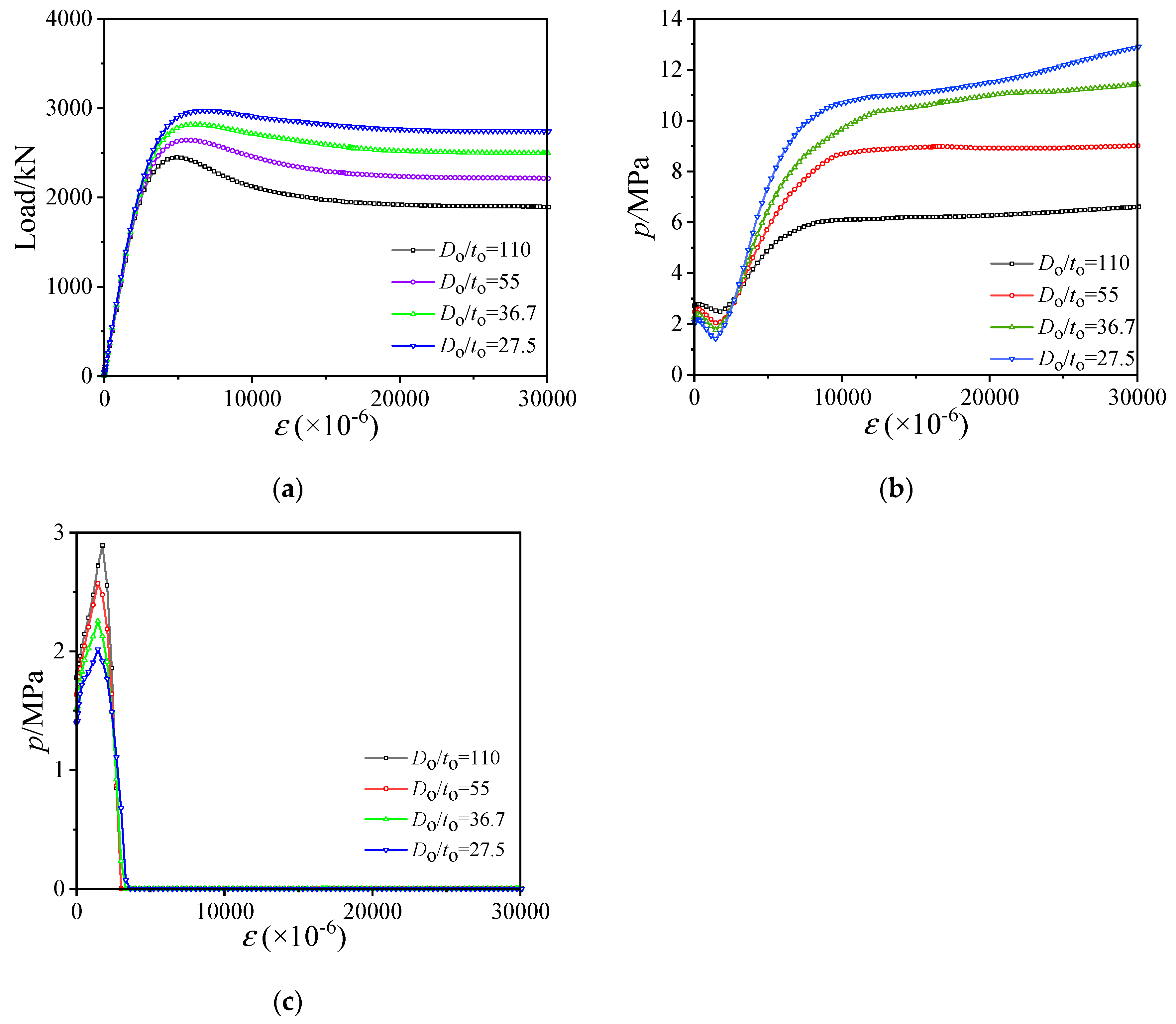

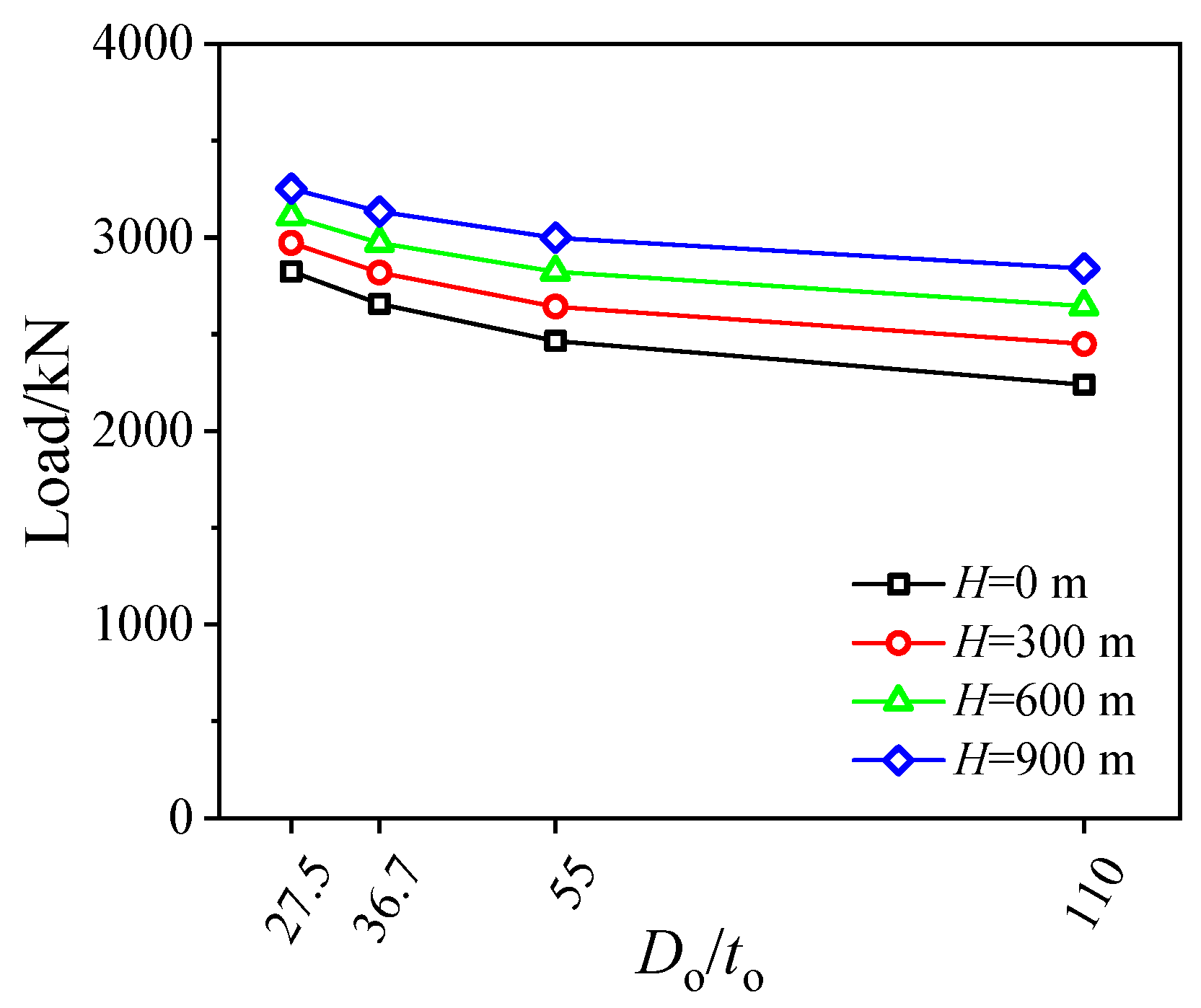

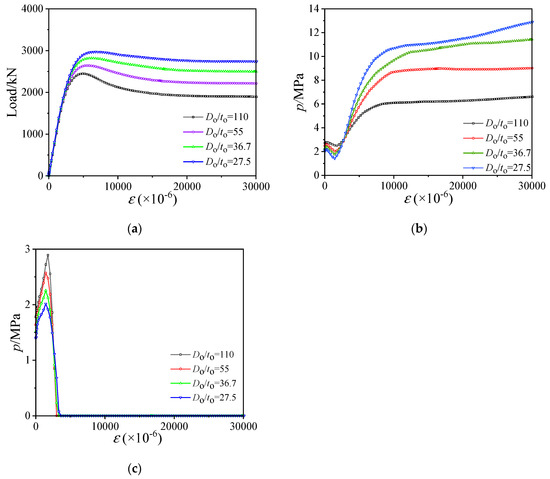

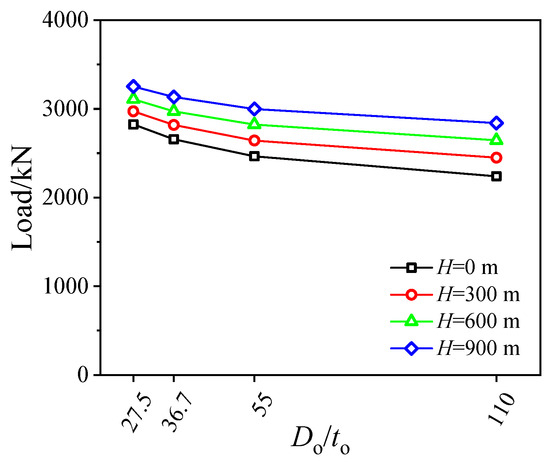

3.1. Influence of Do/to Ratio

Influences of the Do/to ratio on full-range responses are shown in Figure 10. Due to similar patterns, the analysis results at a depth of 300 m are used as an example for explanation. Altering values of Do/to ratios was achieved by keeping diameter Do consistent but changing values of thickness to. The axial bearing capacity is enhanced with a decrease in the Do/to ratios, while the post-peak behavior, such as ductility, is also improved (Figure 10a). When it comes to the impact on the contact pressure between double-skin tubes and sandwich concrete, reducing the Do/to ratios, i.e., increasing the area of the stainless steel tube, gradually enhances the confining stress of the outer stainless steel tube on the sandwich concrete due to the improvement in the confinement coefficient, but it has an opposite impact on the confining stress of the inner tube to sand concrete because of the amplified nonuniform confinement effect. Generally, amplifying the Do/to ratios causes a gradual decrease in axial bearing capacity at the same water depth (Figure 11), e.g., at the water depth H = 300 m, improving the Do/to ratio from 27.5 to 36.7, 55, and 110, respectively, reduces the axial compressive strength by 5.16%, 11.08%, and 17.57%. And at the same value of Do/to ratio, a greater water depth, namely due to higher hydraulic pressure, can enhance the axial bearing capacity for SCCDST members, e.g., for a member with Do/to = 55, its axial compression strength is gradually increased by 7.18%, 14.51%, and 21.62% with increasing water depth from 0 m to 300 m, 600 m, and 900 m, respectively.

Figure 10.

Influence of Do/to at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 11.

Influence of Do/to on bearing capacity at various water depths.

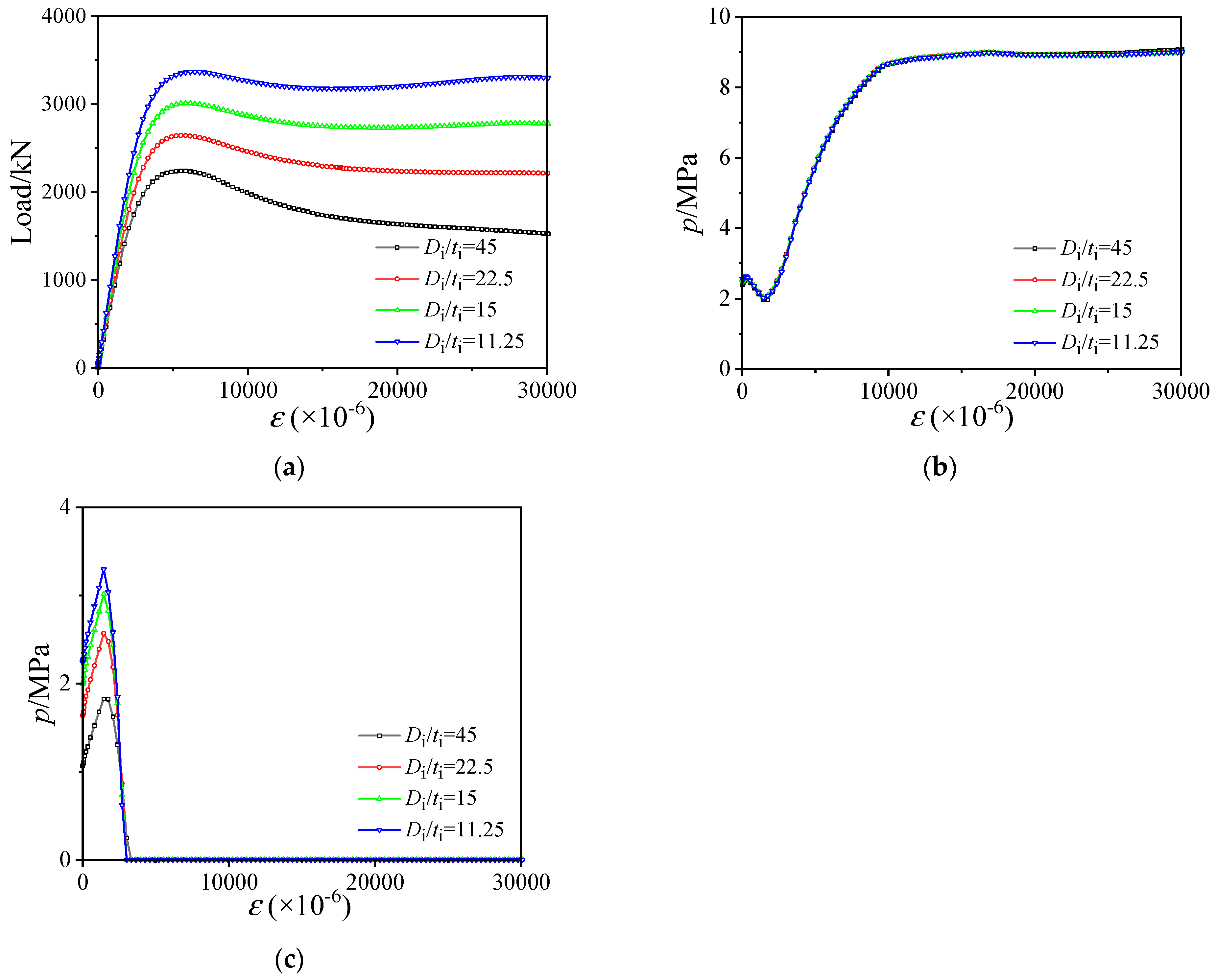

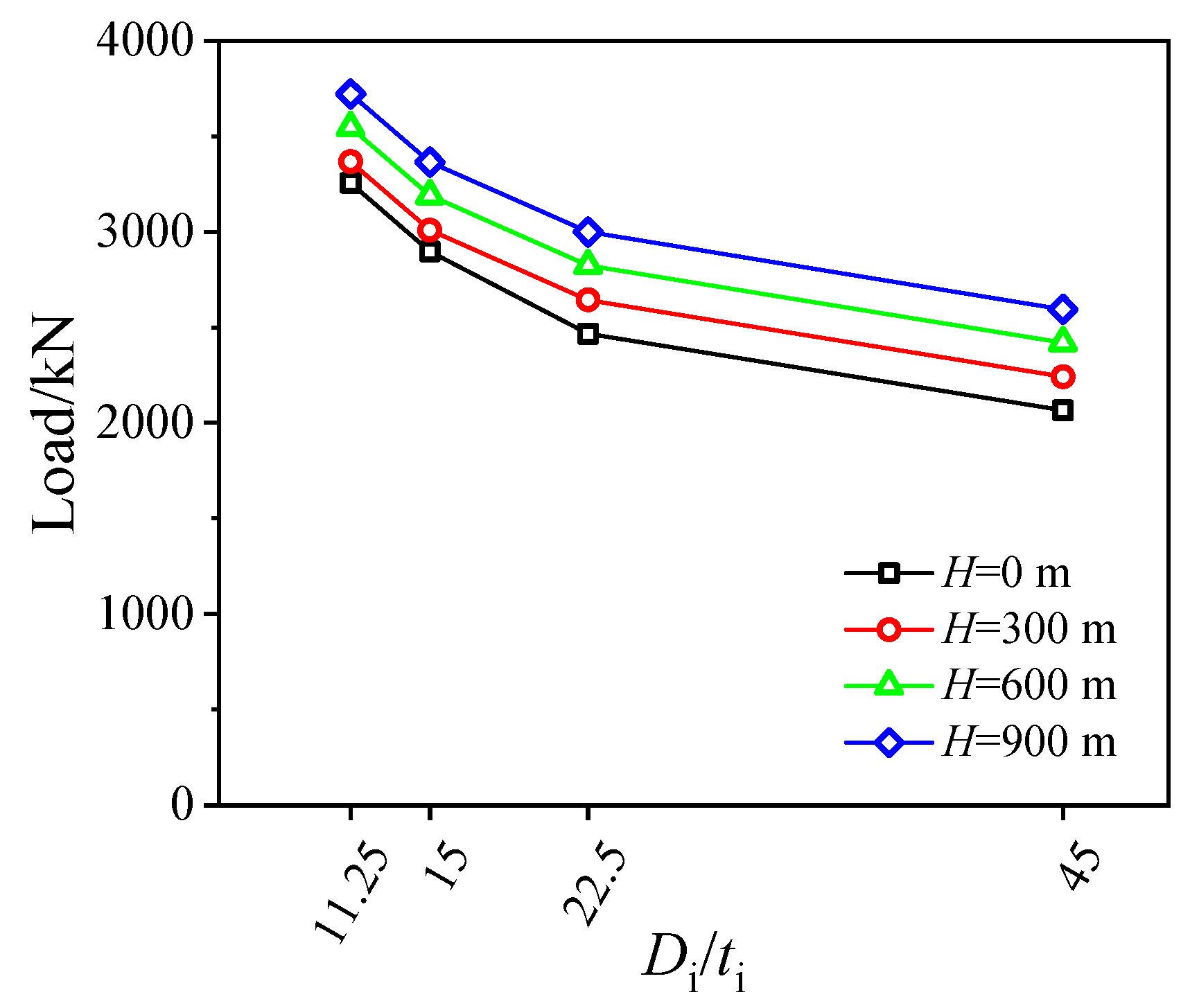

3.2. Influence of Di/ti Ratio

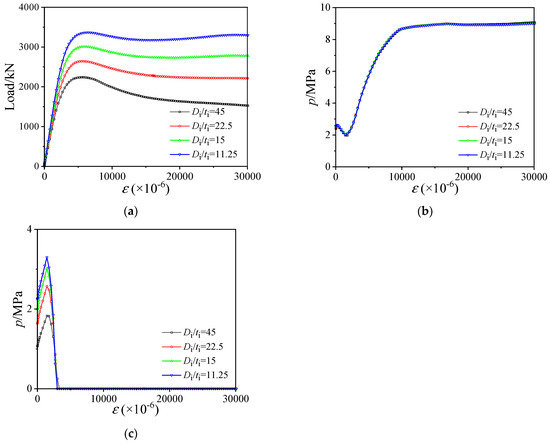

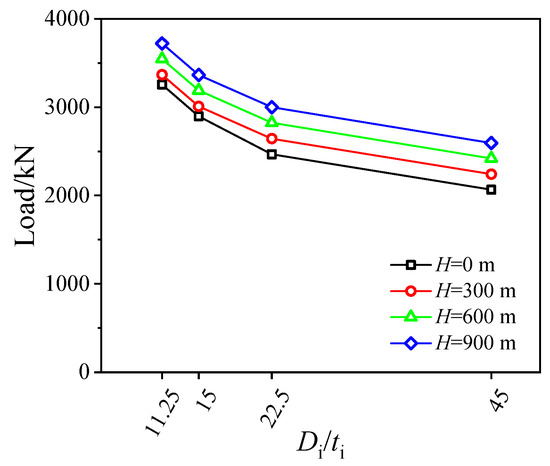

Influences of Di/ti ratio are offered in Figure 12 and Figure 13. Modifying the Di/ti ratios was accomplished by keeping the initial diameter Di consistent while altering the values of thickness ti. In Figure 12, increasing the Di/ti ratios causes a gradual decrease in the axial bearing capacity, but the Di/ti ratios do not significantly affect the confinement coefficient for restricting the lateral deformation of sandwich concrete. This minor influence is observed in the confining stress between the outer stainless steel tube and sandwich concrete (Figure 12b). On the contrary, a reduced Di/ti ratio, indicating an increased wall thickness, enhances the local buckling resistance of the inner tube, thereby reinforcing the confinement effect and contact pressure in limiting concrete expansion (Figure 12c). The changing trend in the influence of the Di/ti ratio on bearing capacity, as depicted in Figure 13, is similar to that of the Do/to ratio. For example, at the water depth H = 300 m, enhancing the Di/ti ratio from 11.25 to 15, 22.5, and 45, respectively, decreases the axial bearing capacity by 10.62%, 21.49%, and 33.41%; at Di/ti = 15, increasing water depth from 0 m to 300 m, 600 m, and 900 m gradually enhances the bearing capacity by 3.89%, 10.11%, and 16.17%, respectively.

Figure 12.

Influence of Di/ti at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 13.

Influence of Di/ti on bearing capacity at various water depths.

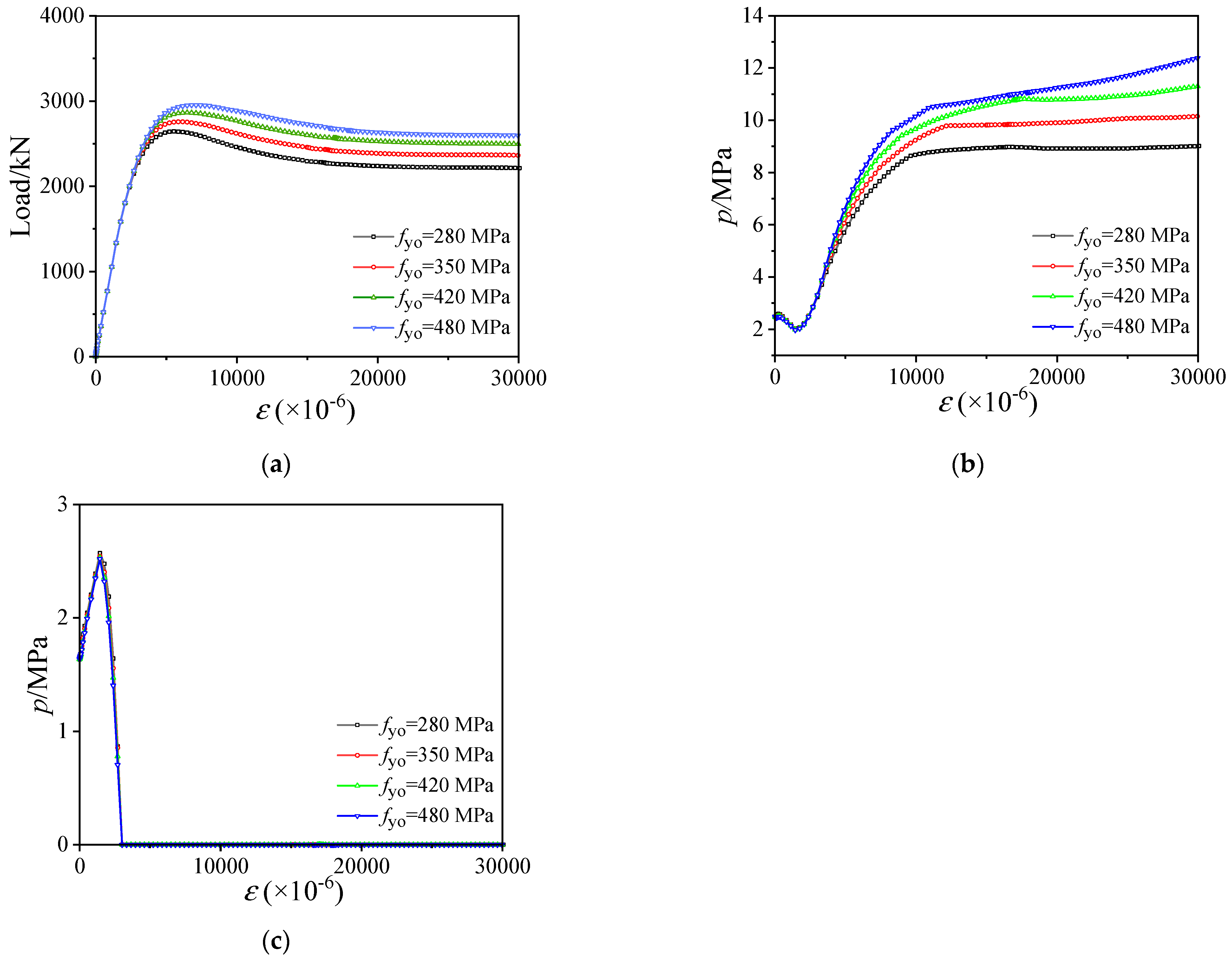

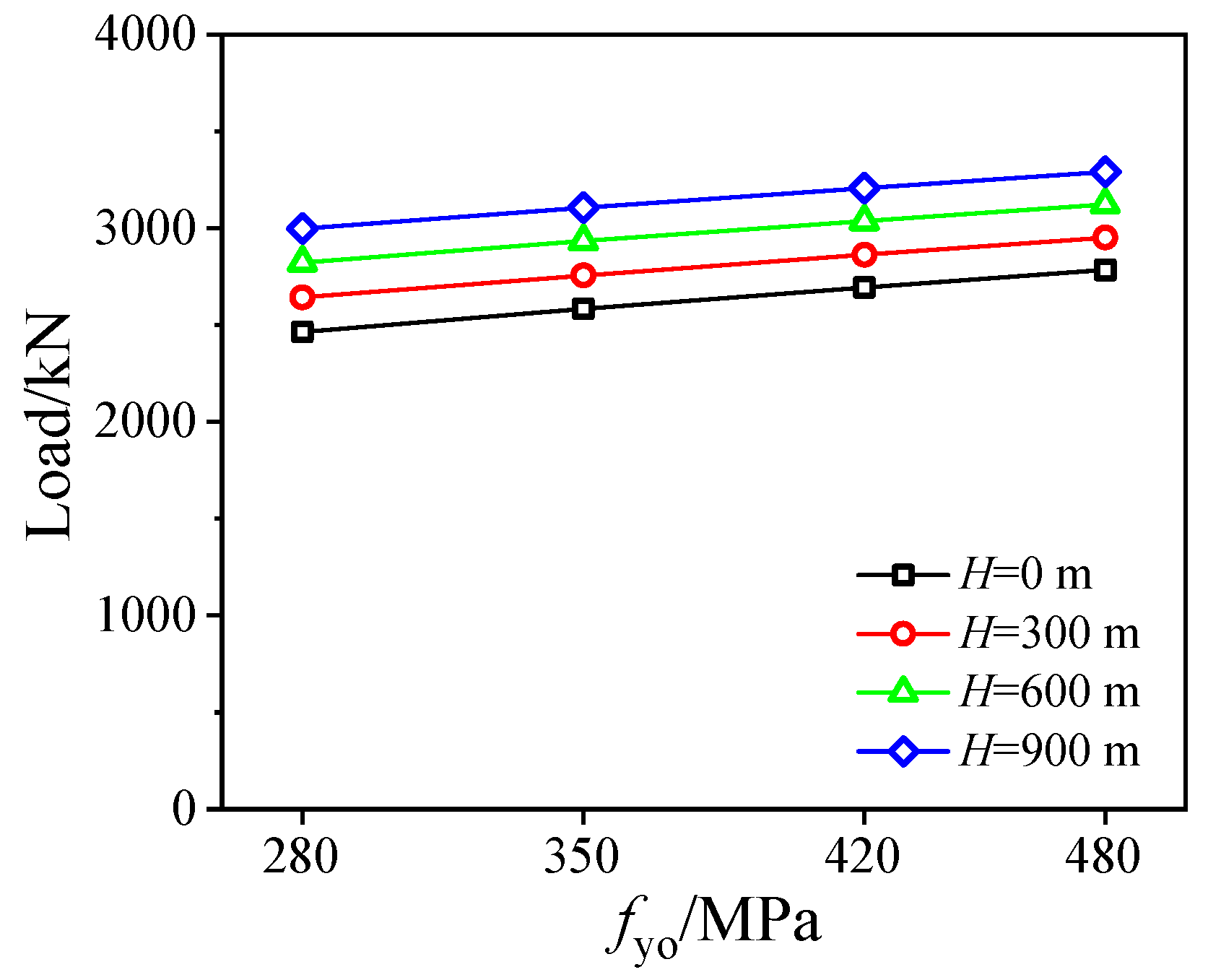

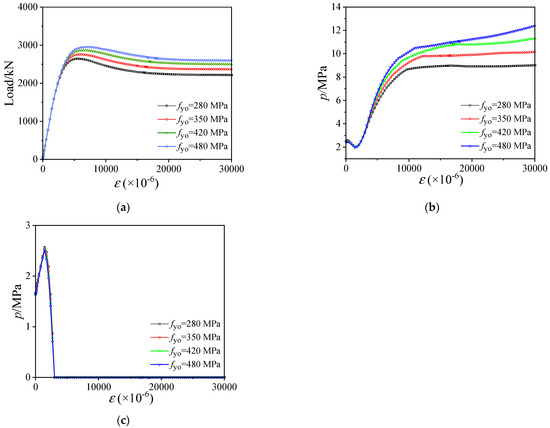

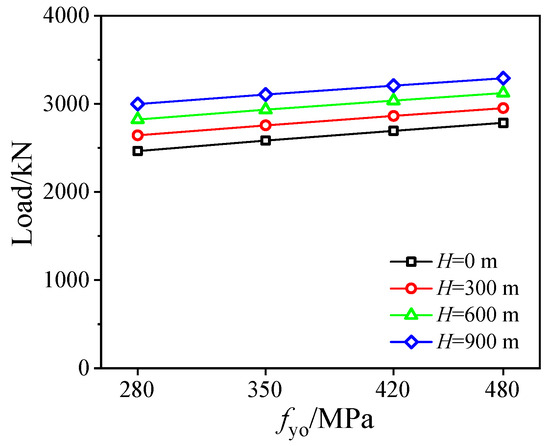

3.3. Influence of fyo

Influences of fyo are displayed in Figure 14 and Figure 15. Improving the yield strength of the outer stainless steel tube can directly increase the axial bearing capacity in a linear way, as shown in Figure 14a and Figure 15, where the capacity is respectively increased by 4.61%, 8.35%, and 11.71% by enhancing yield strength fyo from 280 MPa to 350 Mpa, 420 Mpa, and 480 Mpa at the water depth of 300 m. Moreover, increasing water depth also improves the axial compression strength of SCCDST members at a certain strength of fyo, e.g., at fyo = 350 Mpa, changing water depth from 0 m to 300 m, 600 m, and 900 m, respectively, enhances the bearing capacity by 6.64%, 13.53%, and 20.21%. Increasing yield strength fyo actually increases the confinement coefficient, thereby enhancing the confinement stress between the outer stainless steel tube and sandwich concrete (Figure 14b), but this has a minor impact on that between the inner tube and sandwich concrete (Figure 14c).

Figure 14.

Influence of fyo at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 15.

Influence of fyo on bearing capacity at various water depths.

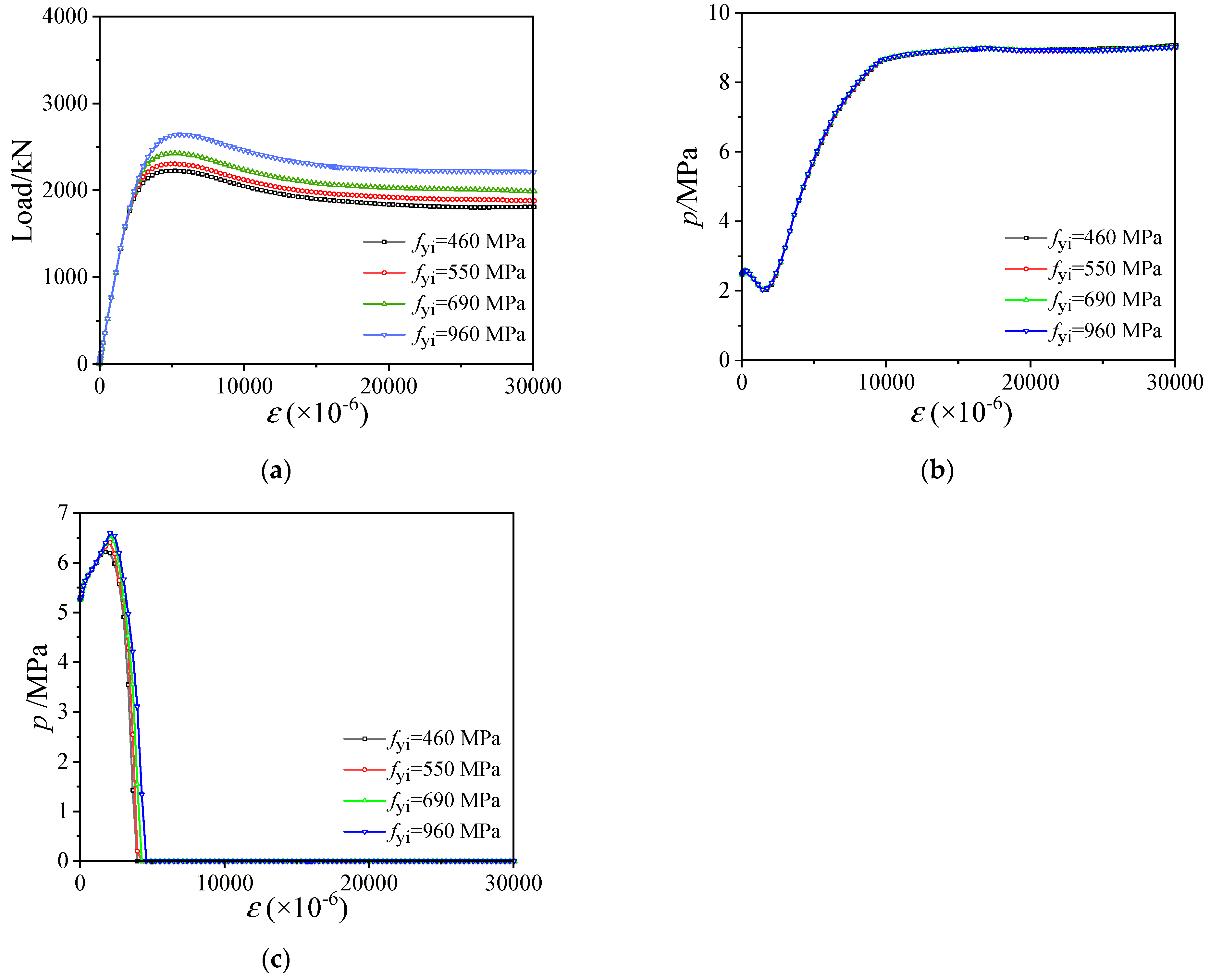

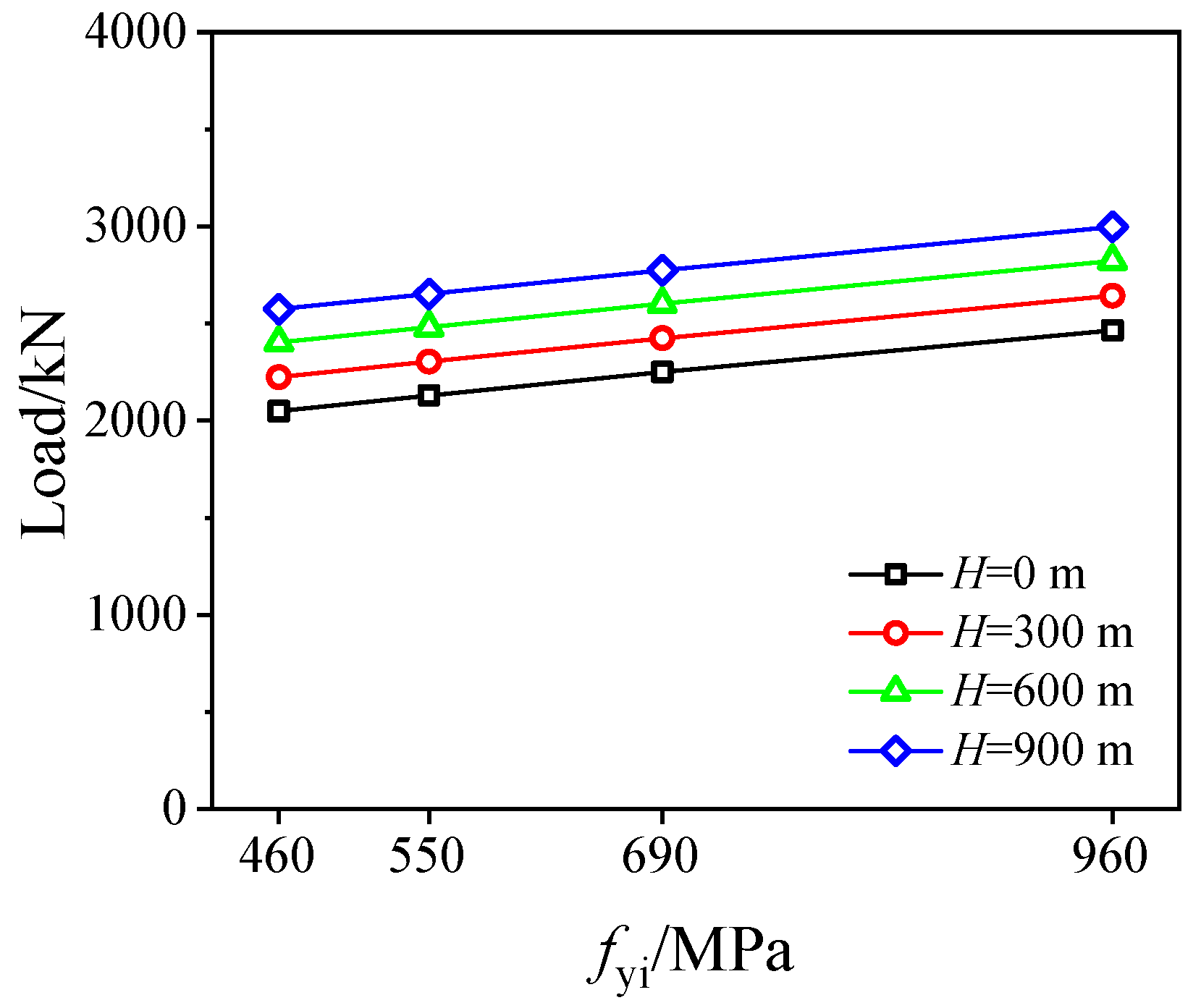

3.4. Influence of fyi

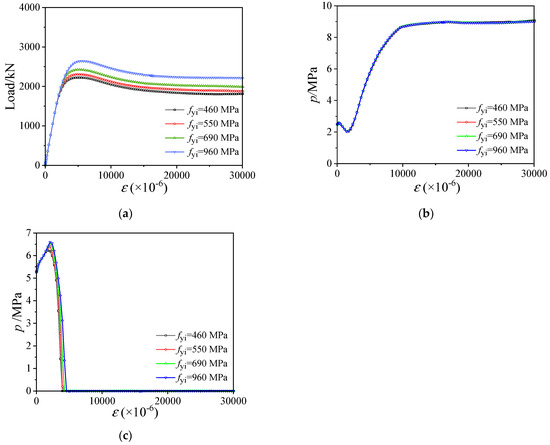

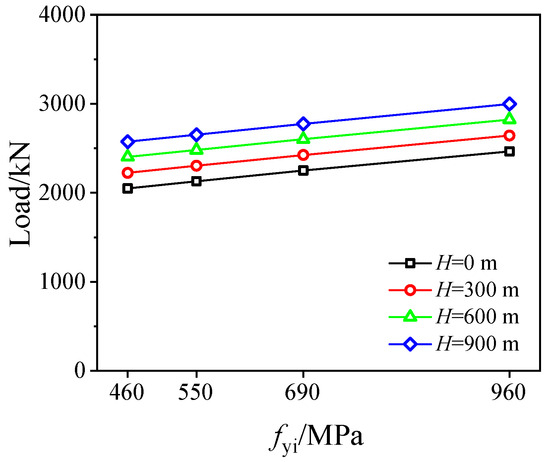

Influences of fyi are illustrated in Figure 16 and Figure 17. Similar to the effect of yield strength fyo, increasing yield strength fyi also has a positively correlated growth effect on axial compression strength. For example, the axial bearing capacity is respectively enhanced by 3.58%, 9.00%, and 18.82% when improving fyi from 460 MPa to 550 Mpa, 690 Mpa, and 960 Mpa at the water depth of 300 m; at fyi = 690 Mpa, increasing water depth from 0 m to 300 m, 600 m, and 900 m, respectively, improves the axial compression capacity by 7.73%, 15.63%, and 23.29%. As for the confining stress between the double-skin tubes and sandwich concrete in Figure 16b,c, altering yield strength fyi has a slight impact on it, revealing that the inner tube mainly contributes to axial compression strength by working as an independent part.

Figure 16.

Influence of fyi at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 17.

Influence of fyi on bearing capacity at various water depths.

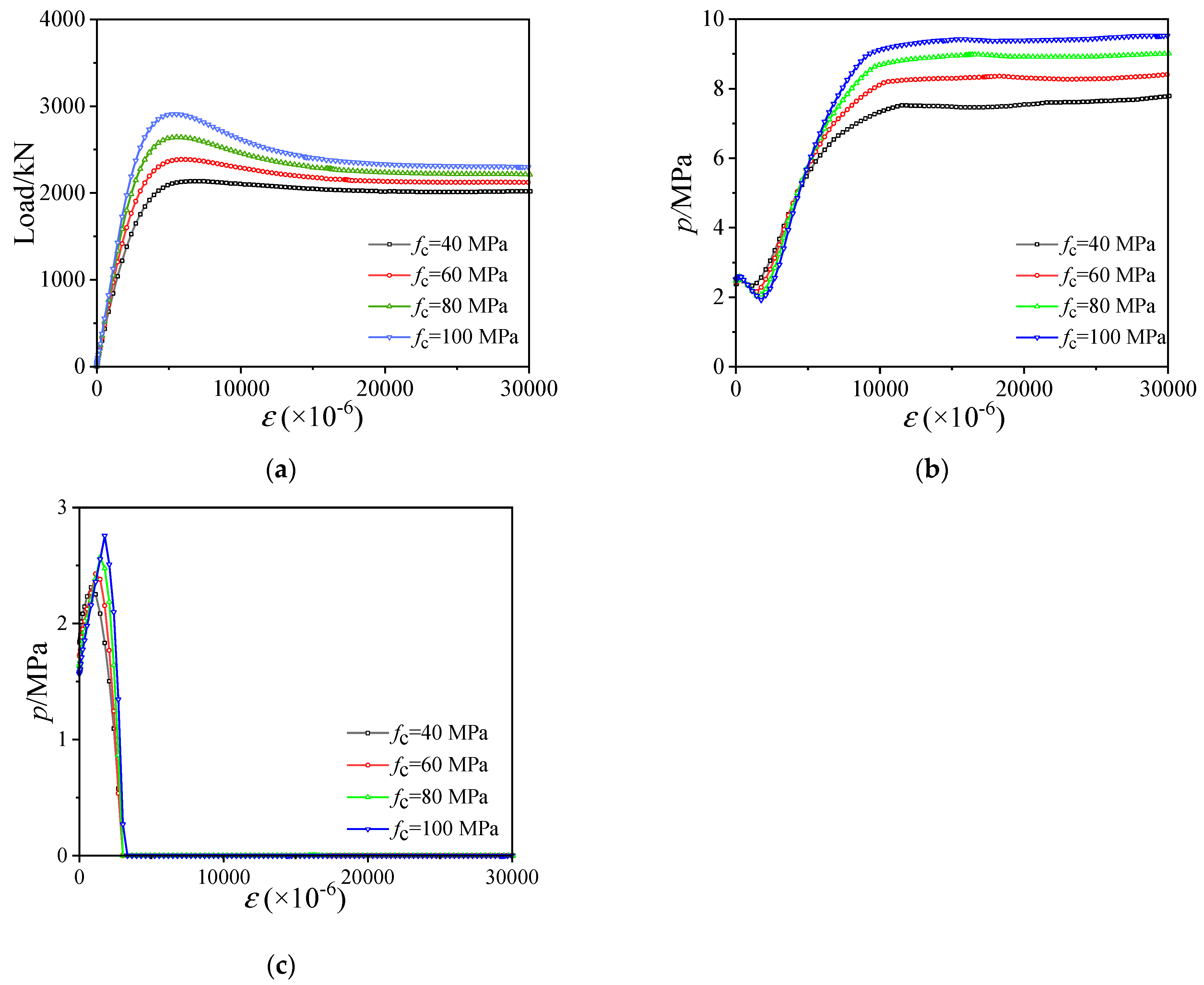

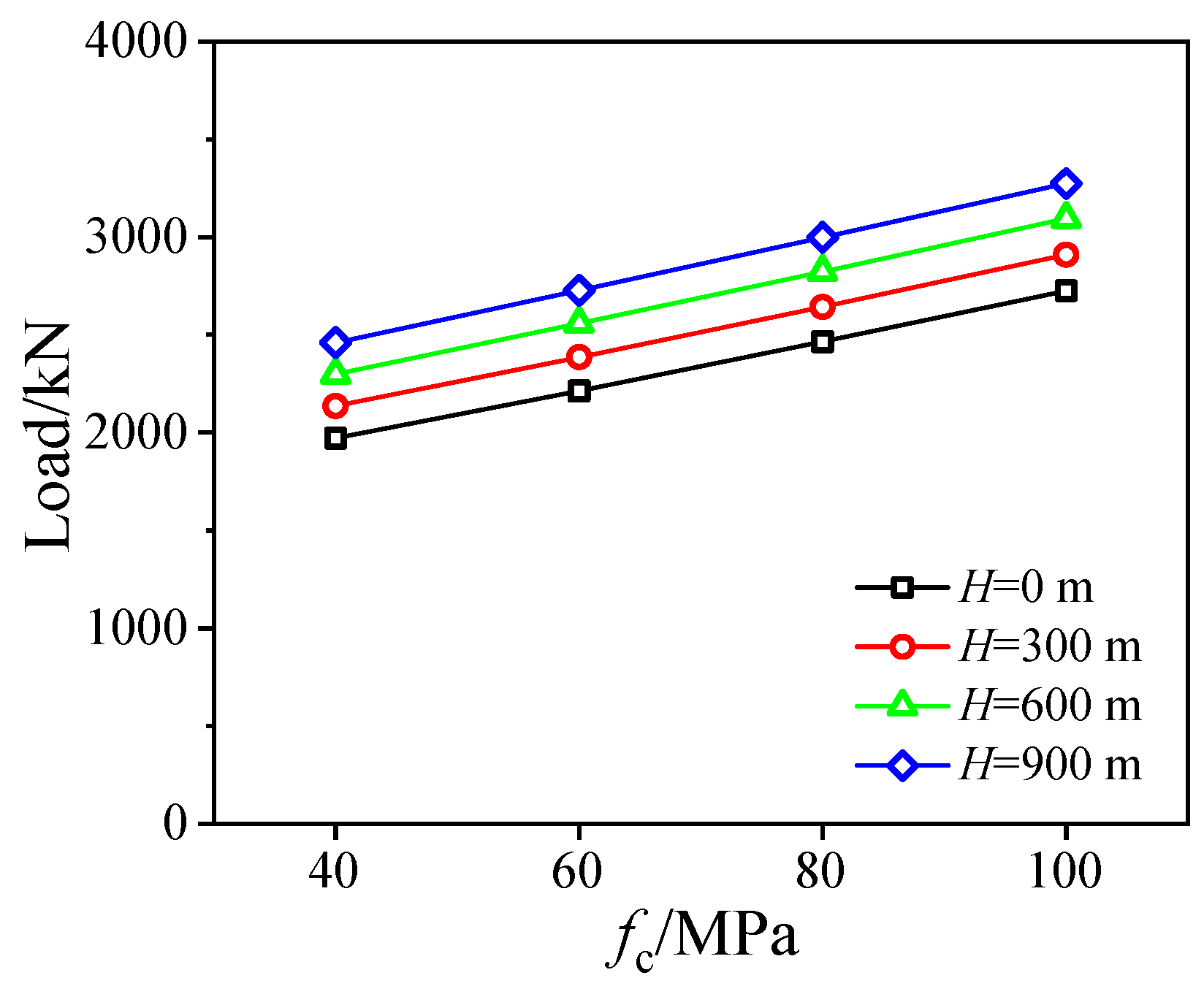

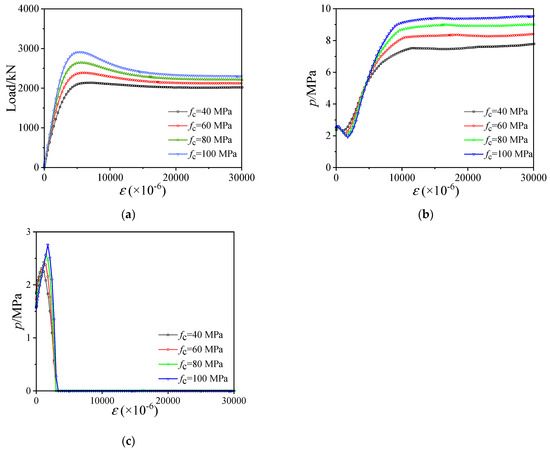

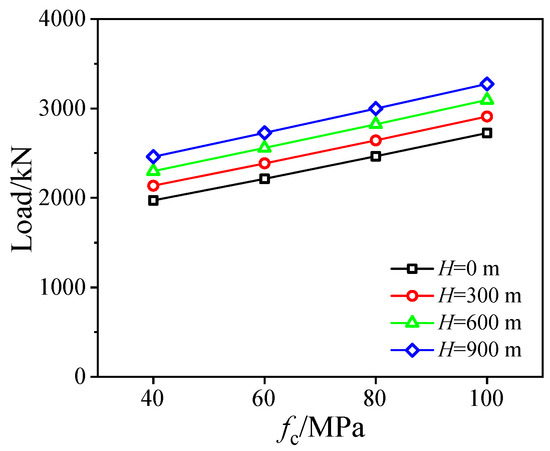

3.5. Influence of fc

Figure 18 and Figure 19 display the influences of concrete strength fc. As shown in Figure 18a, increasing the strength of fc greatly improves the axial compression capacity of SCCDST members. However, it also accelerates the degradation trend of the post-peak stage due to the brittleness of high-strength concrete. Regarding the effect on confining stress in Figure 18b, enhancing the concrete strength fc can slightly reduce interfacial interaction during the pre-peak stage (axial strain < 5000 με) owing to the decreased confinement coefficient; thereafter, the evolution trend is reversed, because the higher the strength of the concrete, the more prone it is to brittle failure, resulting in increased lateral deformation and increased contact pressure on the steel tube. The change in confining stress of the inner steel tube to sandwich concrete is also the same (Figure 18c). Increasing fc causes a linear increase in bearing capacity, as depicted in Figure 19, e.g., enhancing fc from 40 MPa to 60 Mpa, 80 Mpa, and 100 Mpa at the water depth of 300 m respectively increases the axial compression strength by 11.68%, 23.70%, and 36.21%. On the other hand, the axial bearing capacity is respectively improved by 6.75%, 13.53%, and 20.11% while gradually deepening water depth from 0 m to 900 m at the condition of fc = 100 Mpa. Influence of water depth (i.e., the hydraulic pressure) on the load-carrying capacity is significant and should be taken into consideration.

Figure 18.

Influence of fc at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 19.

Influence of fc on bearing capacity at various water depths.

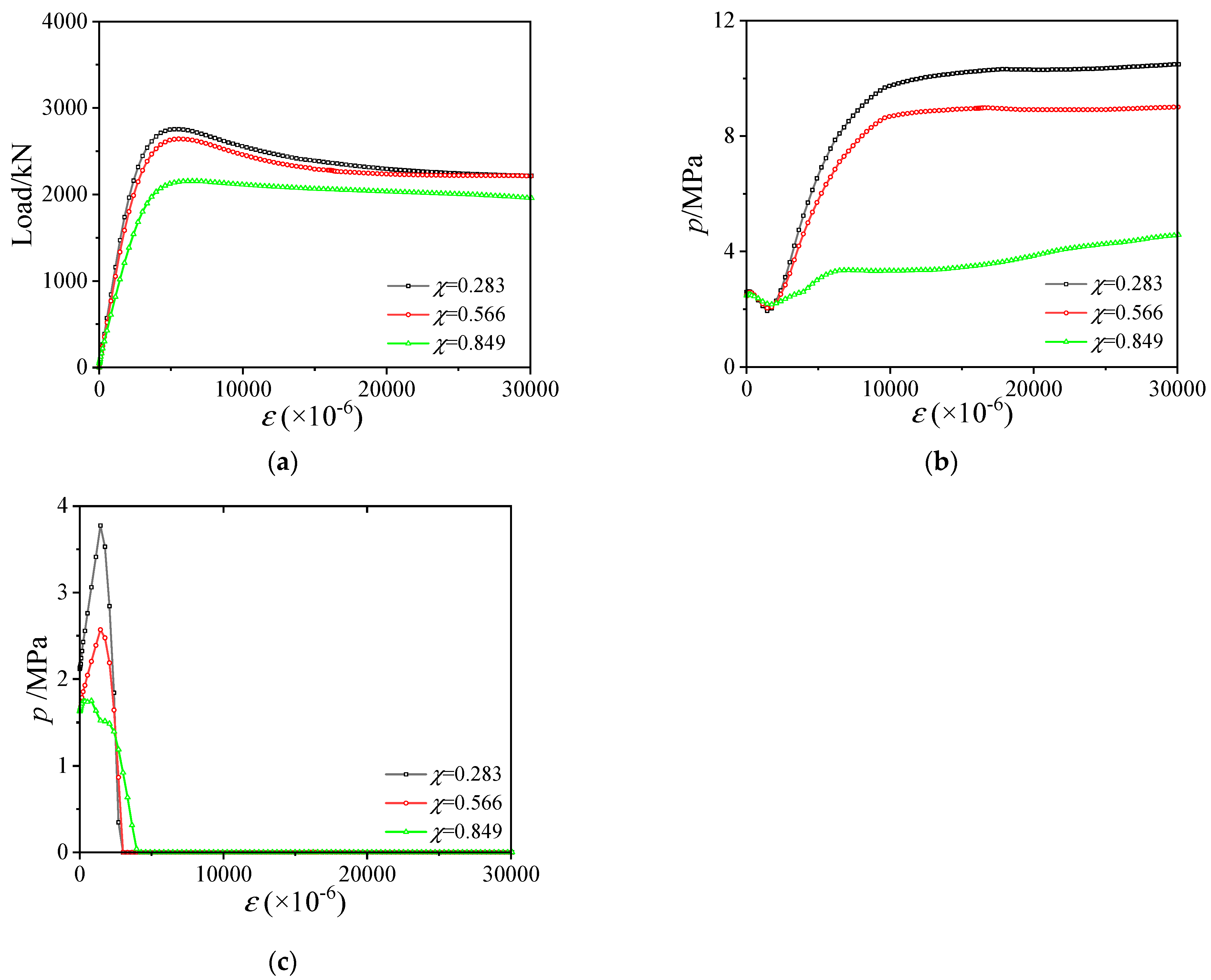

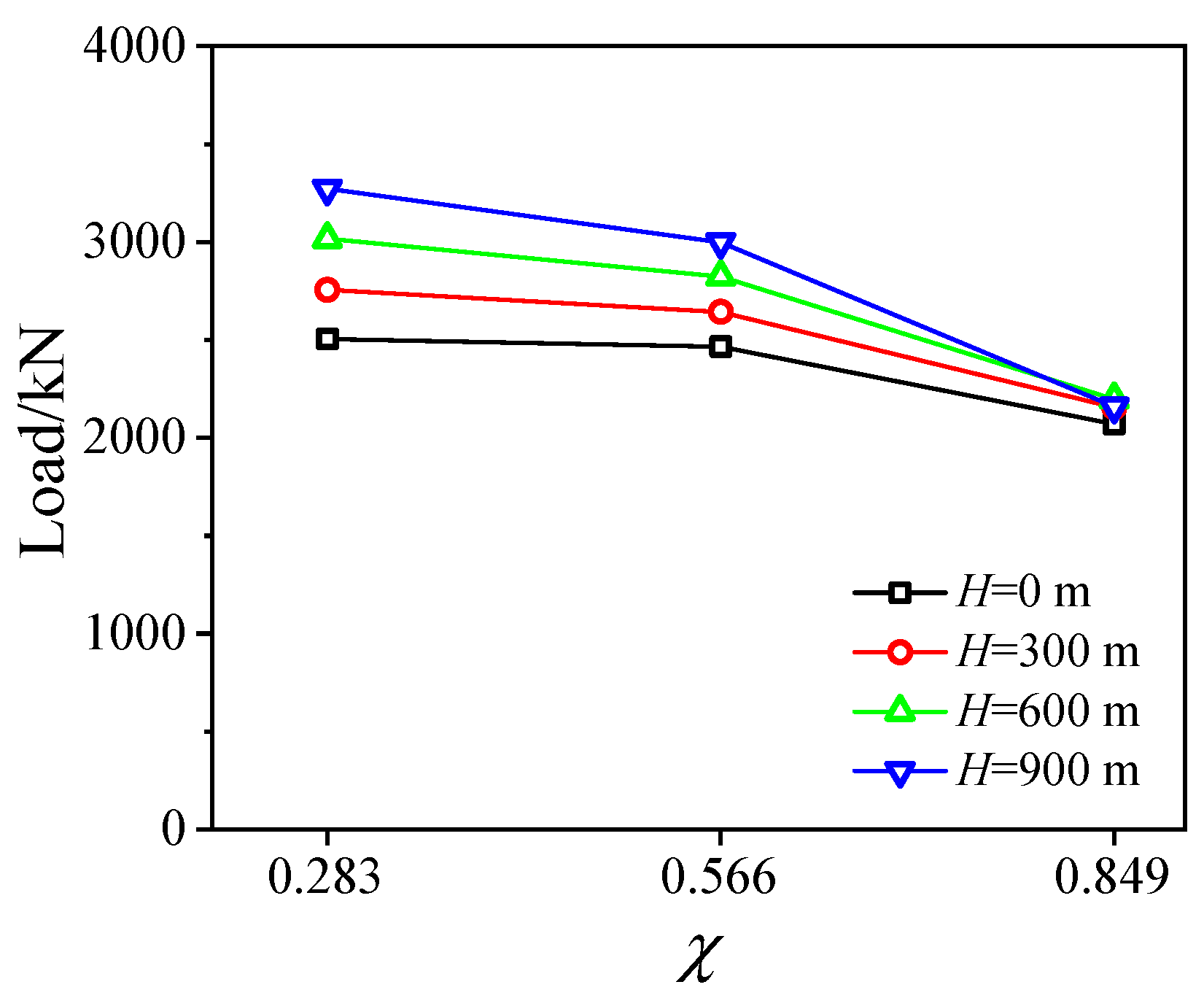

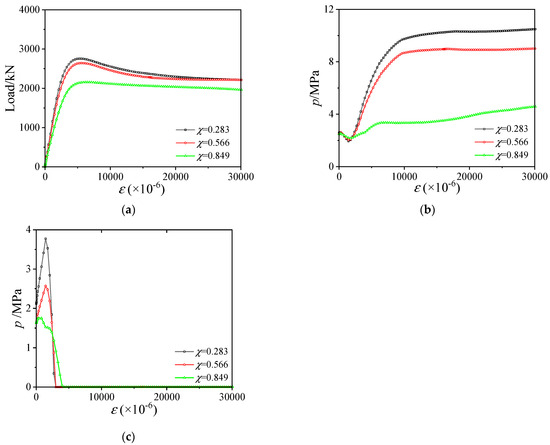

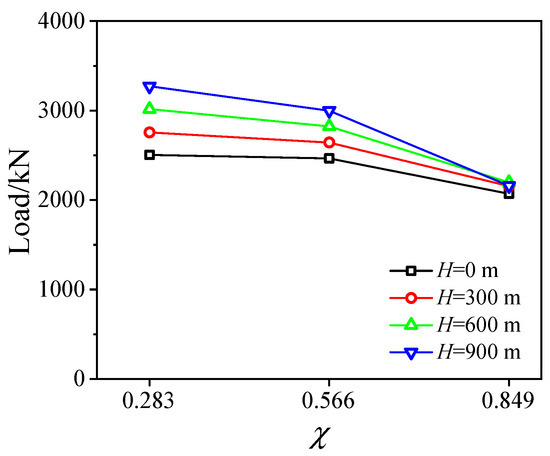

3.6. Influence of χ

Influences of hollow ratio χ are displayed in Figure 20 and Figure 21, where altering the hollow ratio is conducted by changing the diameter of the inner tube while keeping the diameter of the outer tube consistent. The results in Figure 20b,c indicate that a higher hollow ratio (e.g., χ = 0.849) obviously reduces the composite behavior between double-skin tubes and sandwich concrete due to the decreased cross-sectional stiffness, thereby resulting in a decline of bearing capacity (Figure 20a), e.g., the capacity is reduced by 4.06% and 21.75% when increasing the hollow ratio from 0.283 to 0.566 and 0.849 in the case of water depth of 300 m. Moreover, regarding the influence of water depth, a marginal variation exists in the case of the greater water depth (e.g., H = 900 m) for the SCCDST members with larger hollow ratios (e.g., χ = 0.849), reflecting that necessary measures should be conducted to control the hollow ratio in the deep-water environment where the maximum allowable hollow ratio should be stricter than that of land engineering.

Figure 20.

Influence of χ at the water depth of 300 m. (a) Load–displacement curves; (b) Confining stress between outer stainless steel tube and sandwich concrete; (c) Confining stress between inner carbon steel tube and sandwich concrete.

Figure 21.

Influence of χ on bearing capacity at various water depths.

4. Design Method on Bearing Capacity

In the current design system, the typical design codes, e.g., T/CCES 7-2020 [36] and T/CECS 952-2021 [37], mainly focus on land engineering using traditional CFDST members with carbon steel tubes and solid concrete-filled stainless steel tubular members, therefore, no available design method is suitable for new-type SCCDST members, especially for the deep-water service environment. In this section, a modified method for SCCDST members is proposed based on the existing design method. Details of the modification procedures are as follows.

In the design code T/CCES 7-2020 [36], the axial compression capacity of traditional CFDST members using carbon steel can be divided into two parts, i.e., the inner tube and the composite part of sandwich concrete and the outer tube:

where NCFDST is the axial compression capacity for the whole traditional CFDST member; Nosc denotes the contribution of the outer tube and sandwich concrete; Ni represents the contribution of the inner tube. By conducting a mechanism analysis and parametric study, it has been observed that the interfacial pressure between the inner tube and sandwich concrete generally leads to a subtle composite action on the SCCDST members. Therefore, for the new type, the calculation hypothesis in Equation (12) is still adopted for SCCDST members, where the contribution of the inner tube can be calculated by the following equation:

The capacity contribution Nosc can be derived from the composite strength method:

Regarding the composite strength fosc, there is no available equation to determine its accurate value in the case of the stainless steel tube–sandwich concrete composite part under the hollow section, in which the sandwich concrete suffers from nonuniform confining stress. The design code T/CECS 952-2021 [37] offers an equation for solid concrete-filled stainless steel tubular members, and the composite strength (fsc) for the outer stainless steel tube and solid core concrete is given as:

In this paper, the composite strength fosc can be approximately equal to fsc because the confinement effect is mainly induced by the restraint of the outer stainless tube:

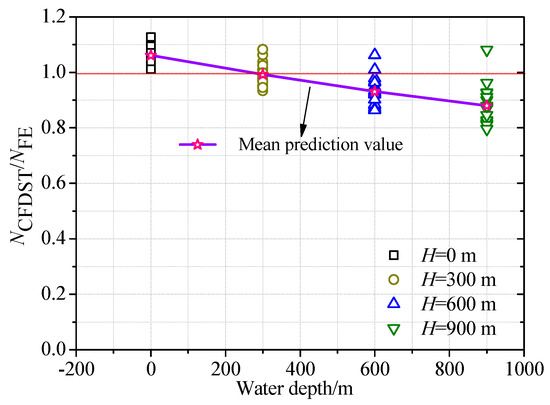

In Equations (15) and (16), the prismatic compressive strength fck can be derived from the following method [42]:

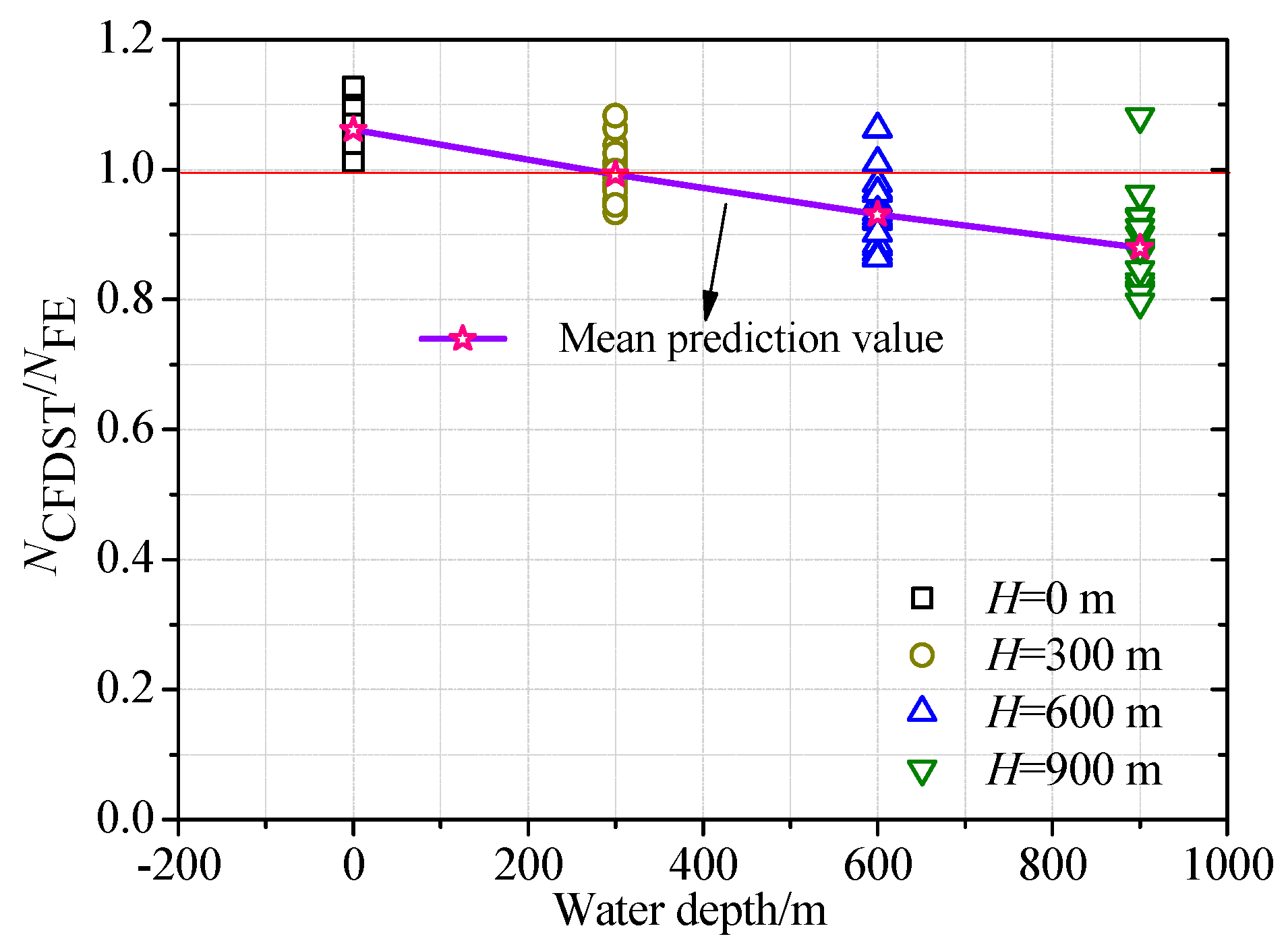

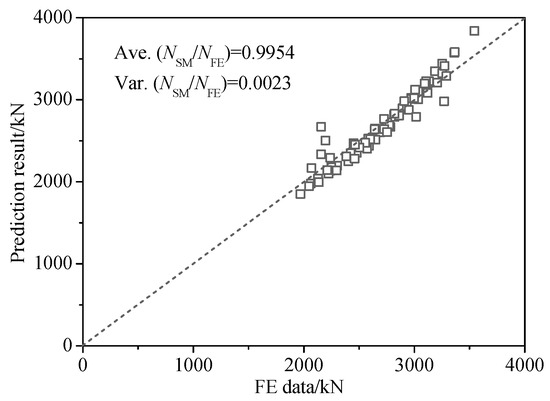

Based on the calculated results (NFE) of the FE model, a verification and comparison study on SCCDST members with external hydraulic pressure was conducted to validate the applicability of the aforementioned method for composite strength fosc and axial bearing capacity NCFDST. The validation results are shown in Figure 22, from which it can be observed that the accuracy of the existing design method predicts a gradual decline trend with increasing water depth, reflecting that the current design methods based on terrestrial engineering specifications have become difficult to apply in evaluating the safety of deep-sea engineering bearing capacity. Hence, to evaluate the axial compression capacity of SCCDST members under deep-water hydraulic pressure, a modified method was established by nonlinear regression analysis for reflecting the influence of various depths (i.e., pressures):

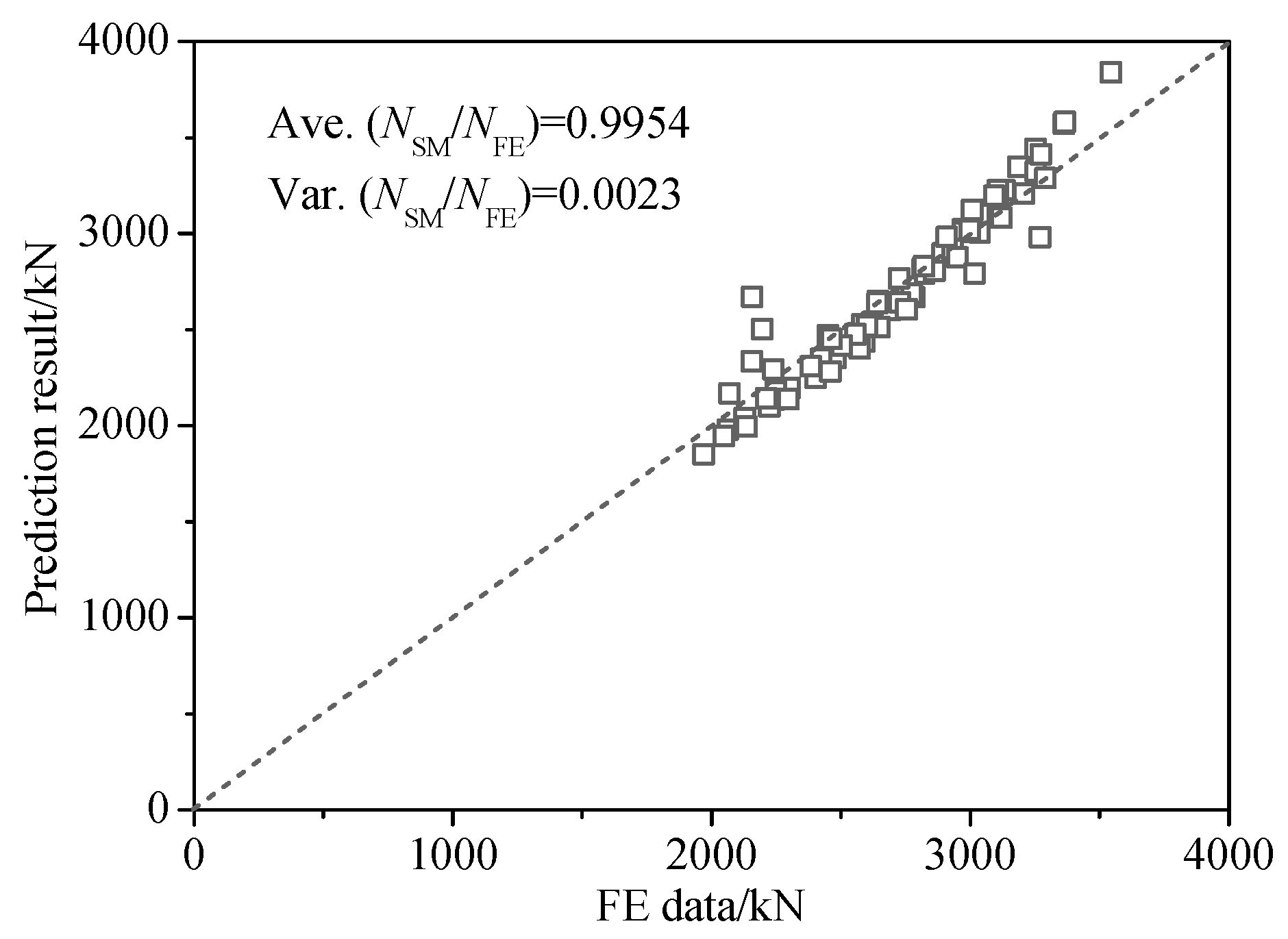

where NSM is the modified load-carrying capacity for SCCDST members with hydraulic pressures. To further verify the accuracy of the modified method in Equation (19), it was also compared to the finite element results, as shown in Figure 23. Results indicate that the modified method predicts well with the capacities of SCCDST members under hydraulic pressures by obtaining an average value (NSM/NFE) of 0.9954. Considering the current lack of research on the SCCDST structure in deep-water environments, the above modified method can be used as a preliminary reference for engineering design and safety evaluation.

Figure 22.

Prediction results of current method.

Figure 23.

Verification of the modified method.

5. Conclusions

This paper demonstrates the analytical compressive behavior and design method for stainless steel–concrete–carbon steel double-skin tubular (SCCDST) members under hydraulic pressures. It can be concluded through the current research that:

(1) The developed FE models for SCCDST members are verified by the failure mode, axial bearing capacity, and curve of load versus axial strain. A reasonable agreement is well achieved.

(2) The full-range mechanism incorporating the compressive load–strain response, composite actions, and bearing capacity contribution is analyzed for SCCDST members exposed to external hydraulic pressure. The result indicates that the external hydraulic pressure subjects the SCCDST member to an elevated level of tri-axial compression, therefore resulting in the enhancement of composite action and load-bearing capacity.

(3) Influences of key parameters are examined, including the influences of Do/to ratio, Di/ti ratio, material strengths (fyo, fyi, and fc), hollow ratio (χ), and water depth (H). The geometric–physical parameters of the inner tube (e.g., Di/ti and fyi) mainly contribute to axial compression capacity by working as an independent part due to the slight impact the interfacial contact pressure. The increased hydraulic pressure can increase the failure risk for SCCDST members with large hollow ratios (e.g., in the case of H = 900 m and χ = 0.849), therefore the maximum allowable hollow ratio in the deep-water environment should be stricter than that of land engineering.

(4) Accuracy of the existing method in design code predicts a gradual decline tendency with increasing water depth. A modified method incorporating the influence of water depth is proposed and verified for SCCDST members under hydraulic pressure, which can be accepted as a preliminary reference for safety evaluation of deep-water engineering.

Author Contributions

Conceptualization, J.-T.W.; methodology, J.-T.W. and K.-L.Y.; validation, J.-T.W., K.-L.Y. and J.-Y.S.; formal analysis, J.-T.W. and K.-L.Y.; investigation, J.-T.W., K.-L.Y. and J.-Y.S.; resources, J.-T.W.; writing—original draft preparation, J.-T.W., K.-L.Y. and J.-Y.S.; writing—review and editing, J.-T.W. and K.-L.Y.; visualization, J.-T.W. and K.-L.Y.; supervision, J.-T.W.; project administration, J.-T.W.; funding acquisition, J.-T.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by High-level Talent Research Startup Fund (No. 1608722024) of Xi’an University of Architecture and Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors acknowledge the numerical assistance from the team members of Xi’an Jiaotong University and Xi’an University of Architecture and Technology.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclatures

| fc | compression strength of concrete cylinder |

| fck | prismatic compressive strength of concrete |

| ft0 | tensile strength of concrete |

| fyo | yielding strength of outer steel tube |

| fyi | yielding strength of inner steel tube |

| ti or to | inner/outer tube’s thickness |

| fosc | composite strength of stainless steel tube–sandwich concrete composite part under the double-skin hollow section |

| fsc | composite strength of outer tube and core concrete under solid section |

| fcu | cubic concrete strength under compression |

| Ac | cross-sectional area of sandwich concrete |

| Asi | cross-sectional area of inner steel tube |

| Aso | cross-sectional area of outer steel tube |

| Acc | area of core concrete in solid section |

| Do | diameter of outer steel tube |

| Di | diameter of inner steel tube |

| E0 | elasticity modulus |

| GF | fracture energy |

| H | water depth |

| NCFDST | axial compression capacity for whole traditional CFDST members |

| Nosc | axial strength contribution of outer tube and sandwich concrete |

| Ni | axial strength contribution of inner tube |

| NSM | the modified load-carrying capacity for SCCDST members with hydraulic pressures |

| ξ | confinement coefficient |

| ε0 | peak strain |

| β0 | computing coefficient |

| εs | strain of stainless steel |

| σs | corresponding stress at strain εs |

| σ0.2 | 0.2% proof stress for stainless steel |

| ε0.2 | strain at σ0.2 for stainless steel |

| εssu | ultimate strain for stainless steel |

| σssu | tensile strength for stainless steel |

| n and m | calculation factors |

| σ0.01 | 0.01% proof stress for stainless steel |

| χ | hollow ratio |

References

- Qian, R.; Li, Q.; Fu, C.; Zhang, Y.; Wang, Y.; Jin, X. Atmospheric chloride-induced corrosion of steel-reinforced concrete beam exposed to real marine-environment for 7 years. Ocean Eng. 2023, 286, 115675. [Google Scholar] [CrossRef]

- Xiao, L.; Peng, J.; Cai, C.S.; Chen, H. Experimental and numerical investigations on the mechanical behavior of coastal high performance steel beams with local corrosion within the shear-span. Appl. Ocean Res. 2023, 136, 103581. [Google Scholar] [CrossRef]

- Peng, W.; Duan, T.; Hou, J.; Guo, W.; Ding, K.; Cheng, W.; Xu, L. Long-term corrosion behaviour of 1060 aluminium in deep-sea environment of South China Sea. Corros. Eng. Sci. Technol. 2021, 56, 327–340. [Google Scholar] [CrossRef]

- Katsoudas, A.S.; Silionis, N.E.; Anyfantis, K.N. Structural health monitoring for corrosion induced thickness loss in marine plates subjected to random loads. Ocean Eng. 2023, 273, 114037. [Google Scholar] [CrossRef]

- Li, G.; Hou, C.; Shen, L. Combined compression-bending performance and design of CFST with localised pitting corrosion. J. Constr. Steel Res. 2022, 192, 107247. [Google Scholar] [CrossRef]

- Li, W.; Han, L.H.; Zhao, X.L. Behavior of CFDST stub columns under preload, sustained load and chloride corrosion. J. Constr. Steel Res. 2015, 107, 12–23. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Y.; Hou, C.; Lu, B. CFDST stub columns with galvanized corrugated steel tubes: Concept and axial behaviour. Thin-Walled Struct. 2020, 157, 107116. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, R.; Lam, D.; Hou, C.C.; Zhang, R. Behaviours of circular CFDST with stainless steel external tube: Slender columns and beams. Thin-Walled Struct. 2021, 158, 107172. [Google Scholar] [CrossRef]

- Han, L.H.; Ren, Q.X.; Li, W. Tests on stub stainless steel–concrete–carbon steel double-skin tubular (DST) columns. J. Constr. Steel Res. 2011, 67, 437–452. [Google Scholar] [CrossRef]

- Li, W.; Han, L.H.; Zhao, X.L. Axial strength of concrete-filled double skin steel tubular (CFDST) columns with preload on steel tubes. Thin-Walled Struct. 2012, 56, 9–20. [Google Scholar] [CrossRef]

- Vernardos, S.; Gantes, C. Experimental behavior of concrete-filled double-skin steel tubular (CFDST) stub members under axial compression: A comparative review. Structures 2019, 22, 383–404. [Google Scholar] [CrossRef]

- Wang, F.; Young, B.; Gardner, L. CFDST sections with square stainless steel outer tubes under axial compression: Experimental investigation, numerical modelling and design. Eng. Struct. 2020, 207, 110189. [Google Scholar] [CrossRef]

- Aghamaleki, S.T.N.; Naghipour, M.; Amiri, J.V.; Nematzadeh, M. Compression behavior of the concrete-filled double skin steel tube columns under hydrostatic pressure: Experimental and modeling study. Structures 2023, 58, 105505. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, F.; Zhang, D. Analytical model for axially compressed circular concrete-filled double skin steel tubes (CFDSTs): Insights from concrete non-uniformly confined states. Thin-Walled Struct. 2023, 192, 111106. [Google Scholar] [CrossRef]

- Wang, F.C.; Han, L.H. Analytical behavior of carbon steel-concrete-stainless steel double-skin tube (DST) used in submarine pipeline structure. Mar. Struct. 2019, 63, 99–116. [Google Scholar] [CrossRef]

- Zhao, X.L.; Tong, L.W.; Wang, X.Y. CFDST stub columns subjected to large deformation axial loading. Eng. Struct. 2010, 32, 692–703. [Google Scholar] [CrossRef]

- Pagoulatou, M.; Sheehan, T.; Dai, X.H.; Lam, D. Finite element analysis on the capacity of circular concrete-filled double-skin steel tubular (CFDST) stub columns. Eng. Struct. 2014, 72, 102–112. [Google Scholar] [CrossRef]

- Ekmekyapar, T.; Hasan, H.G. The influence of the inner steel tube on the compression behaviour of the concrete filled double skin steel tube (CFDST) columns. Mar. Struct. 2019, 66, 197–212. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, R.; Ning, F.; Liang, Y. Compression behaviour and bearing capacity calculation of concrete filled double skin square steel columns. J. Build. Eng. 2021, 42, 103022. [Google Scholar] [CrossRef]

- Ci, J.; Ahmed, M.; Tran, V.L.; Jia, H.; Chen, S. Axial compressive behavior of circular concrete-filled double steel tubular short columns. Adv. Struct. Eng. 2022, 25, 259–276. [Google Scholar] [CrossRef]

- Abadel, A.A.; Khan, M.I.; Masmoudi, R. Experimental and numerical study of compressive behavior of axially loaded circular ultra-high-performance concrete-filled tube columns. Case Stud. Constr. Mater. 2022, 17, e01376. [Google Scholar] [CrossRef]

- Li, J.; Deng, Z. Axial compressive behavior of ultra-high performance concrete-filled double skin high-strength steel tubular short columns. Struct. Concr. 2023, 24, 3857–3876. [Google Scholar] [CrossRef]

- Yilmaz, B.C.C.; Binbir, E.; Guzelbulut, C.; Yildirim, H.; Celik, O.C. Circular concrete-filled double skin steel tubes under concentric compression: Tests and FEA parametric study. Compos. Struct. 2023, 309, 116765. [Google Scholar] [CrossRef]

- Hassanein, M.F.; Kharoob, O.F.; Liang, Q.Q. Circular concrete-filled double skin tubular short columns with external stainless steel tubes under axial compression. Thin-Walled Struct. 2013, 73, 252–263. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhao, X.L.; Raman, R.S.; Yu, X. Axial compression tests on seawater and sea sand concrete-filled double-skin stainless steel circular tubes. Eng. Struct. 2018, 176, 426–438. [Google Scholar] [CrossRef]

- Wang, F.; Young, B.; Gardner, L. Compressive testing and numerical modelling of concrete-filled double skin CHS with austenitic stainless steel outer tubes. Thin-Walled Struct. 2019, 141, 345–359. [Google Scholar] [CrossRef]

- Le, T.T.; Patel, V.I.; Liang, Q.Q.; Huynh, P. Numerical modeling of rectangular concrete-filled double-skin steel tubular columns with outer stainless-steel skin. J. Constr. Steel Res. 2021, 179, 106504. [Google Scholar] [CrossRef]

- Le, T.T.; Patel, V.I.; Liang, Q.Q.; Huynh, P. Axisymmetric simulation of circular concrete-filled double-skin steel tubular short columns incorporating outer stainless-steel tube. Eng. Struct. 2021, 227, 111416. [Google Scholar] [CrossRef]

- Castanheira, D.S.; De Lima, L.R.O.; Vellasco, P.D.S.; Cashell, K.A.; Gardner, L. Compressive behaviour of double skin sections with stainless steel outer tubes and recycled aggregate concrete. Structures 2022, 41, 750–763. [Google Scholar] [CrossRef]

- Le, T.T.; Patel, V.I.; Liang, Q.Q.; Huynh, P. Simulation modeling and design of circular concrete-filled double-skin tubular slender beam-columns with outer stainless-steel tube. Eng. Struct. 2023, 285, 116014. [Google Scholar] [CrossRef]

- Zhou, F.; Lama, L.; Zhao, K. Design of stainless steel CHS-concrete infill-carbon steel CHS double-skin stub columns. Eng. Struct. 2023, 278, 115479. [Google Scholar] [CrossRef]

- EN 1994-1-1; Eurcode 4, Design of Composite Steel and Concrete Structures, Part 1.1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- AS 5100.6-2004; Bridge Design Part 6: Steel and Composite Construction. Standards Australia: Sydney, Australia, 2004.

- ANSI/AISC 360-16; Specification for Structural Steel Buildings. American Institute of Steel Construction: Chicago, IL, USA, 2016.

- ACI 318-14; Building Code Requirements for Structural Concrete and Commentary. ACI: Farmington Hills, MI, USA, 2014.

- T/CCES 7-2020; Technical Specification for Concrete-Filled Double Skin Steel Tubular Structures. China Architecture & Building Press: Beijing, China, 2020. (In Chinese)

- T/CECS 952-2021; China Association for Engineering Construction Standardization. Technical Specification for Concrete-Filled Stainless Steel Tubular Structures. China Architecture & Building Press: Beijing, China, 2022. (In Chinese)

- Wang, J.T.; Liu, X.H.; Sun, Q.; Li, Y.W. Compressive–flexural failure mechanism and bearing capacity calculation of over-ranging tapered CFDST members for support structures of offshore wind turbines. J. Mar. Sci. Eng. 2023, 11, 1621. [Google Scholar] [CrossRef]

- Wang, J.T.; Liu, X.H.; Sun, Q.; Li, Y.W. Analytical behavior and bearing capacity research on out-of-code tapered CFDST members under pure torsion and compression-torsion combination. Ocean Eng. 2023, 284, 115324. [Google Scholar] [CrossRef]

- Han, L.H. Concrete Filled Steel Tubular Structures—Theory and Practice; Science Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Patel, V.I.; Hassanein, M.F.; Thai, H.T.; Al Abadi, H.; Paton-Cole, V. Behaviour of axially loaded circular concrete-filled bimetallic stainless-carbon steel tubular short columns. Eng. Struct. 2017, 147, 583–597. [Google Scholar] [CrossRef]

- Tang, G.Q.; Xiao, Y.; Zhang, Y.T. Study of bearing capacity and complete stress-strain curves for concrete filled square steel tube columns. Eng. Mech. 2015, 32, 103–111. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).