Safety Analysis of Initial Separation Phase for AUV Deployment of Mission Payloads

Abstract

:1. Introduction

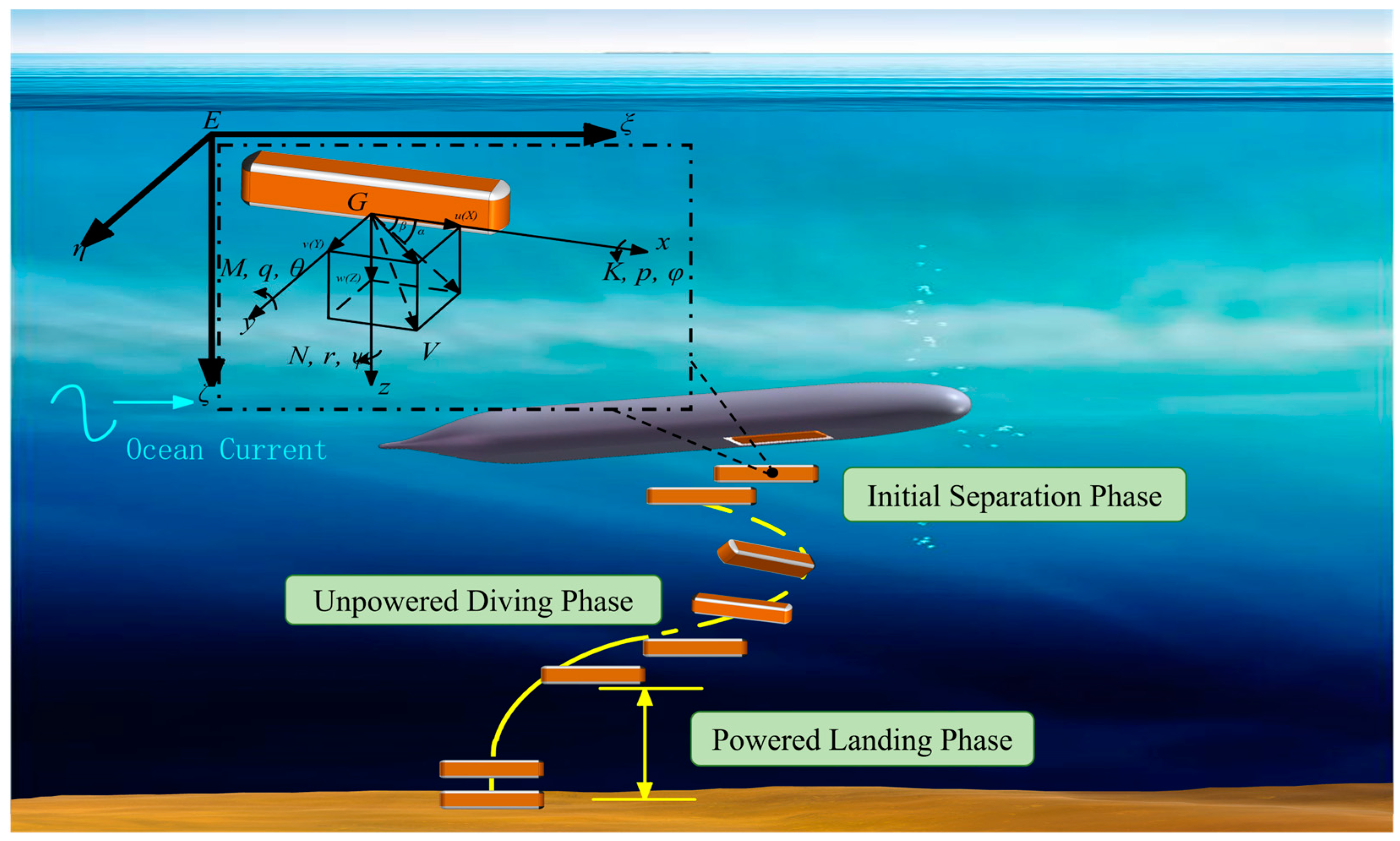

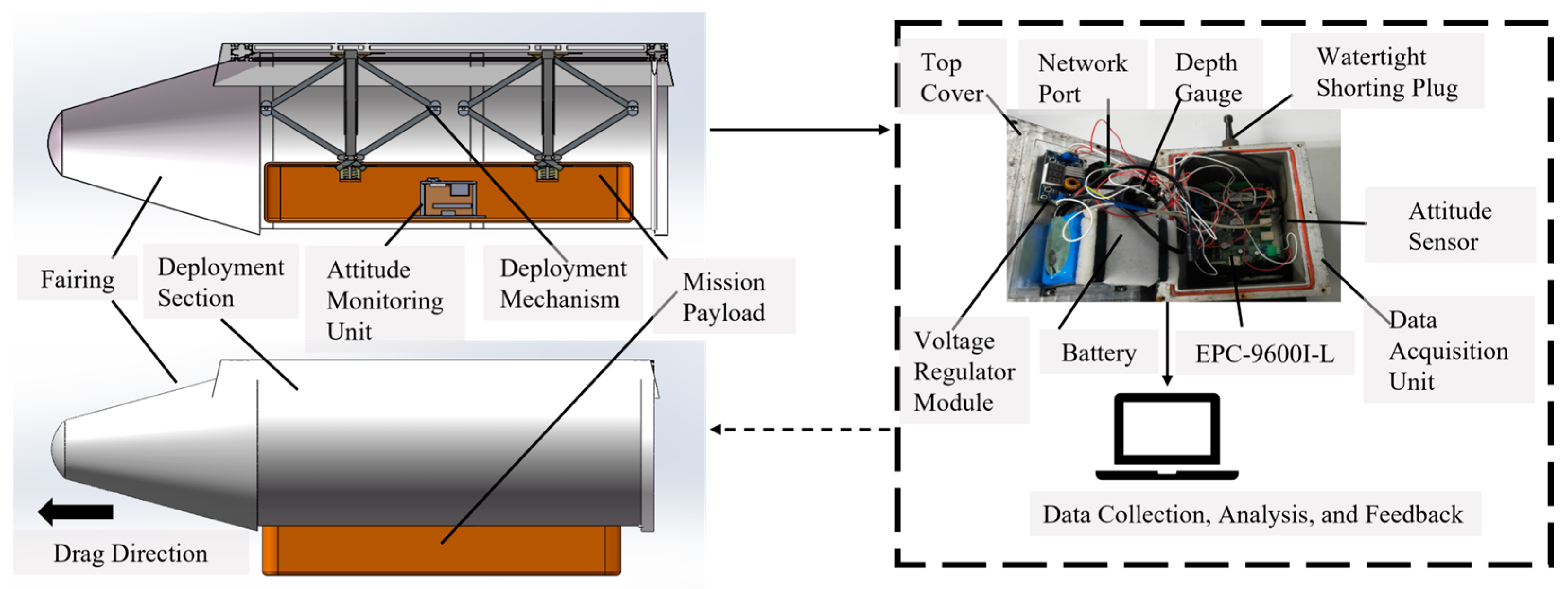

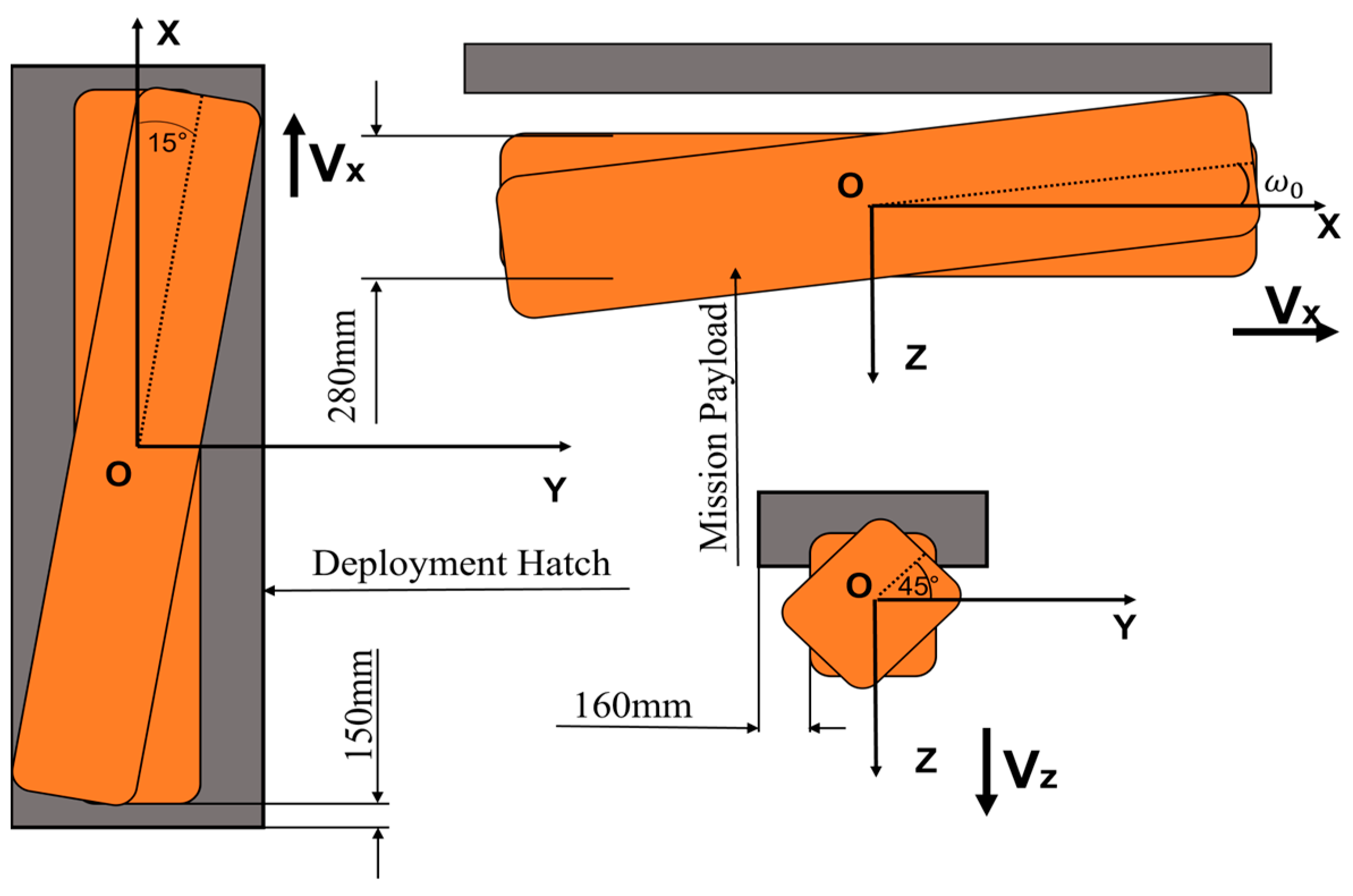

2. Materials and Methods

2.1. Separation Model and Parameters

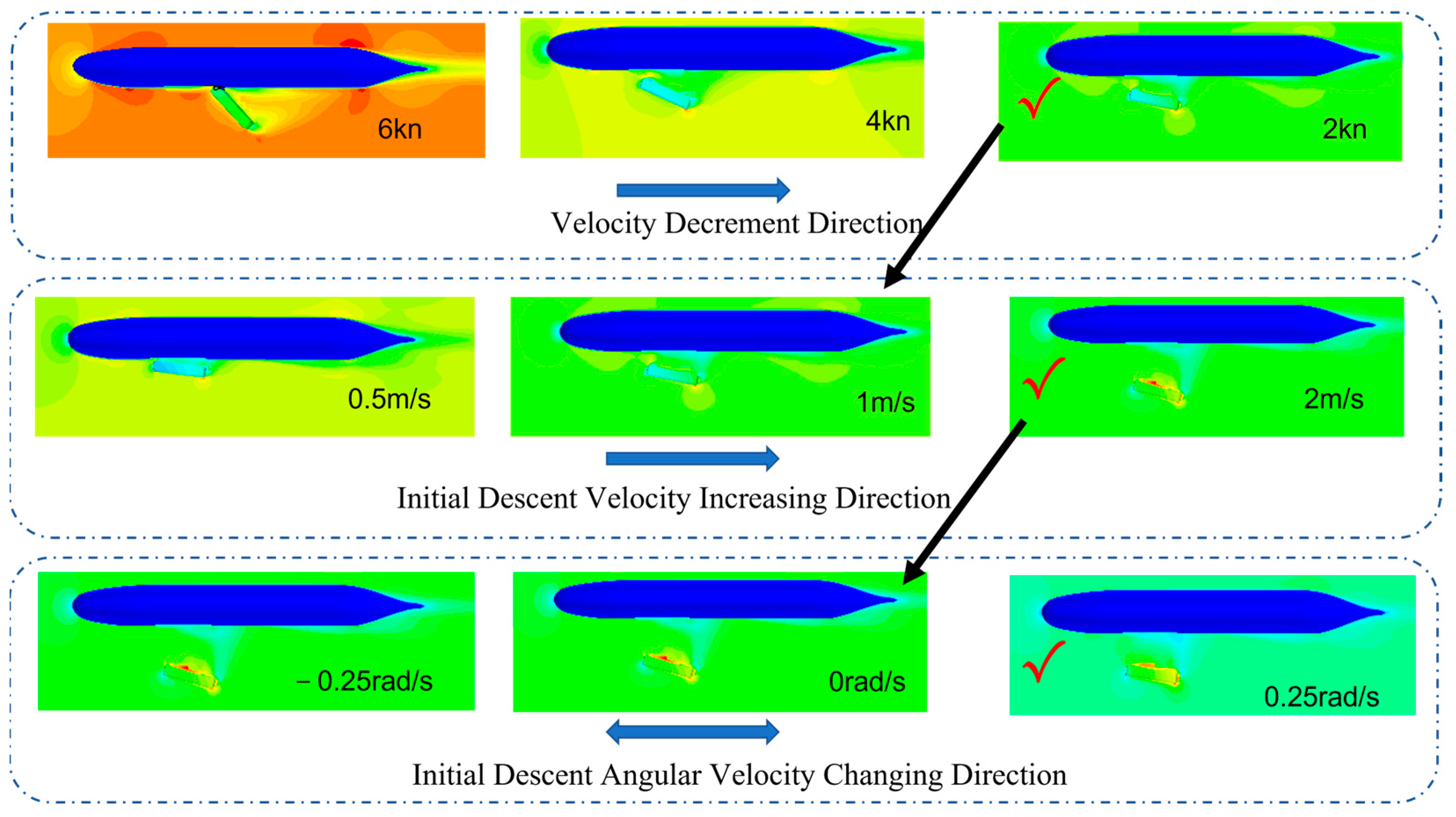

- AUV velocities Vx are set at 0 kn, 2 kn, 4 kn, and 6 kn;

- Initial separation velocities Vz are set at 0 m/s, 0.5 m/s, 1 m/s, and 2 m/s;

- Initial pitching angular velocities ω0 are chosen as 0.25 rad/s, 0 rad/s, −0.5 rad/s, and −1.0 rad/s;

- Ocean currents are varied at different navigation depths.

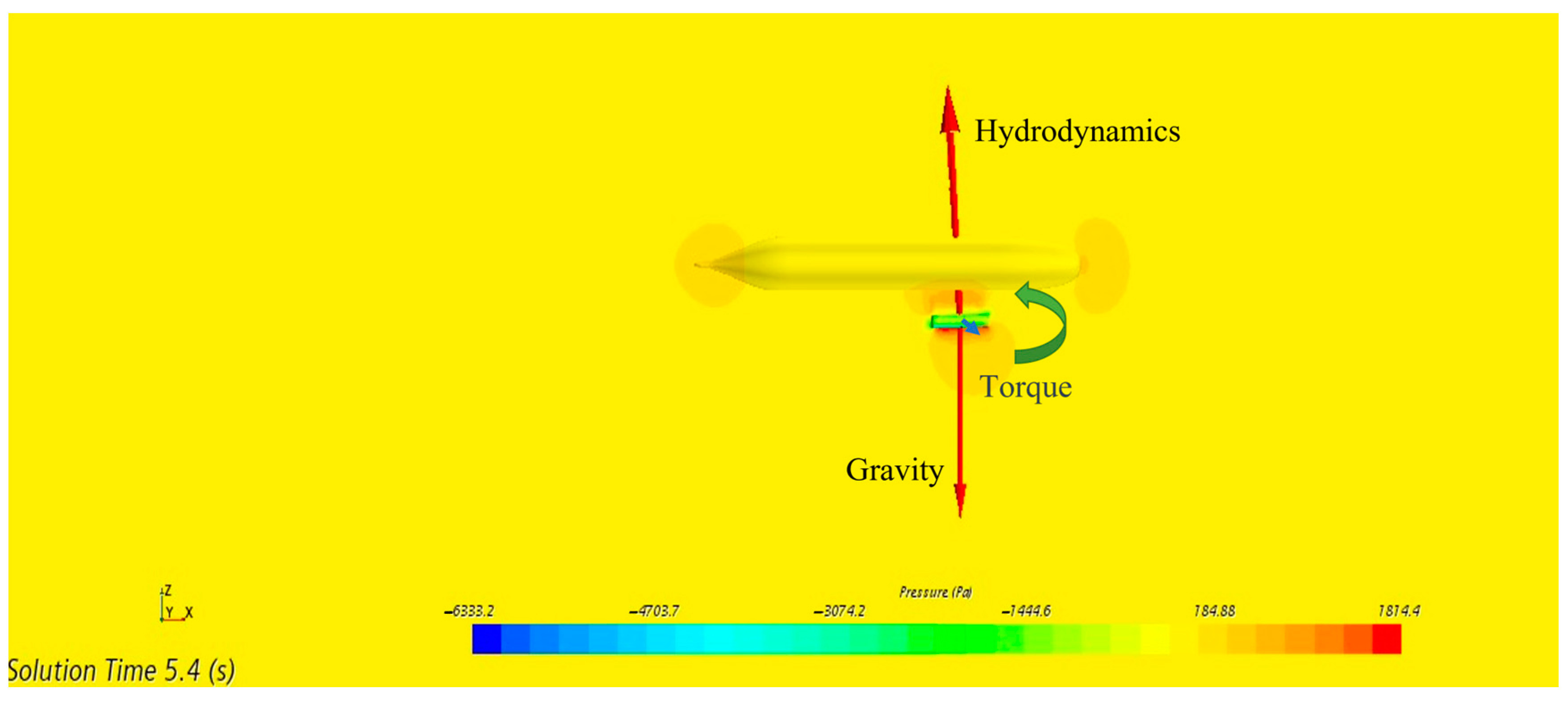

2.2. Governing Equation

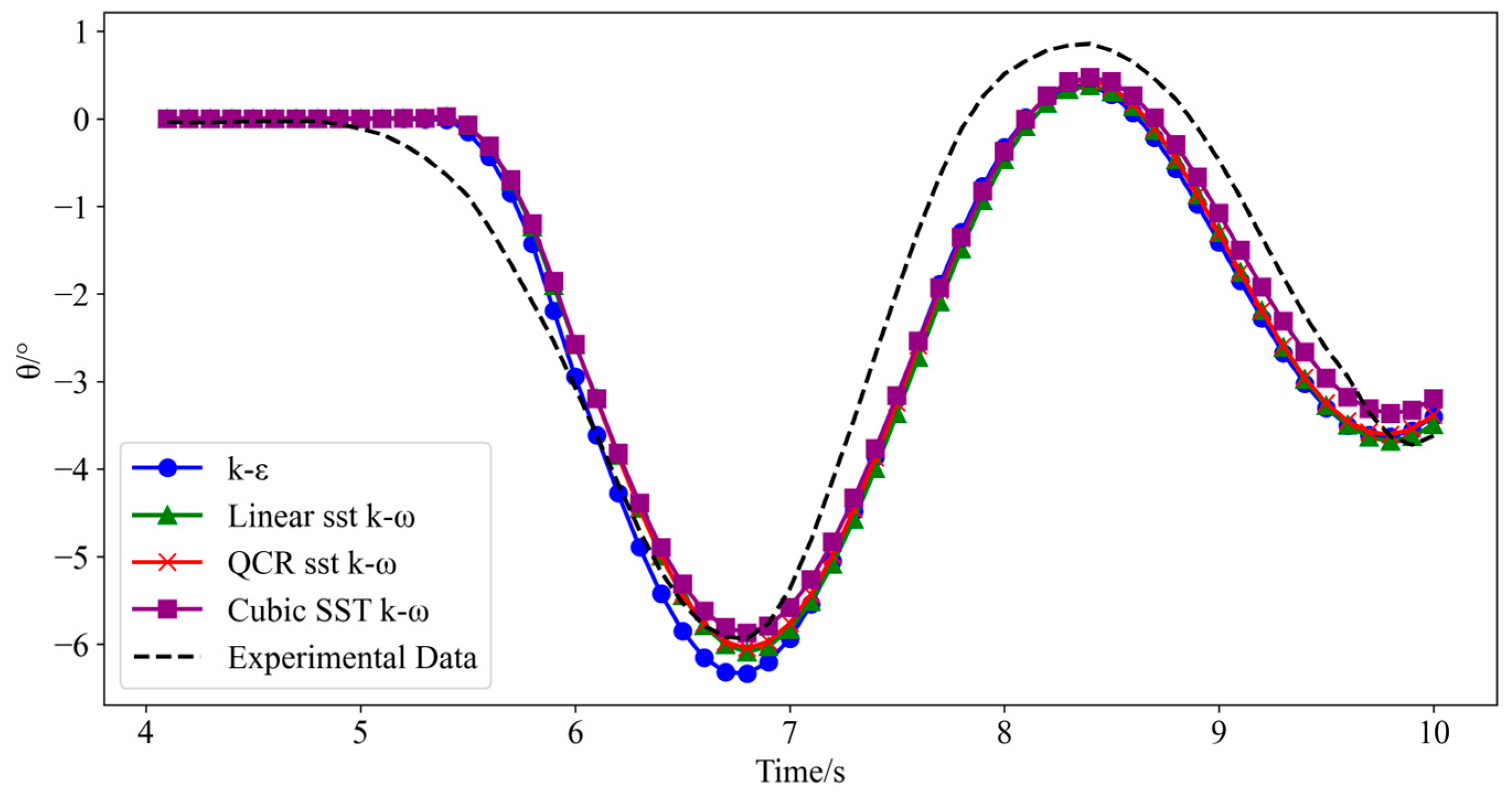

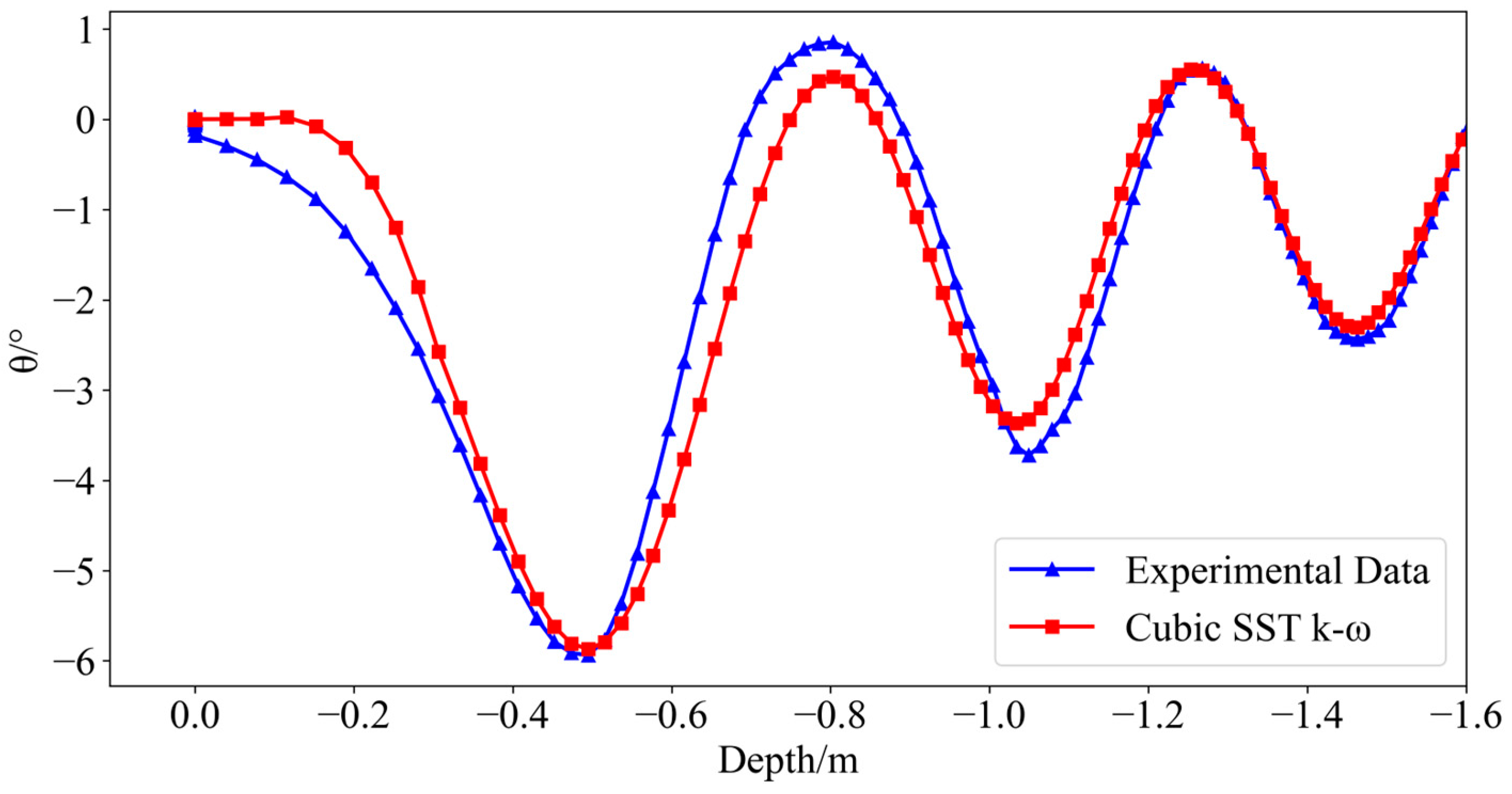

2.3. Selection of the Turbulence Model

2.4. DFBI and Overlapping Grid

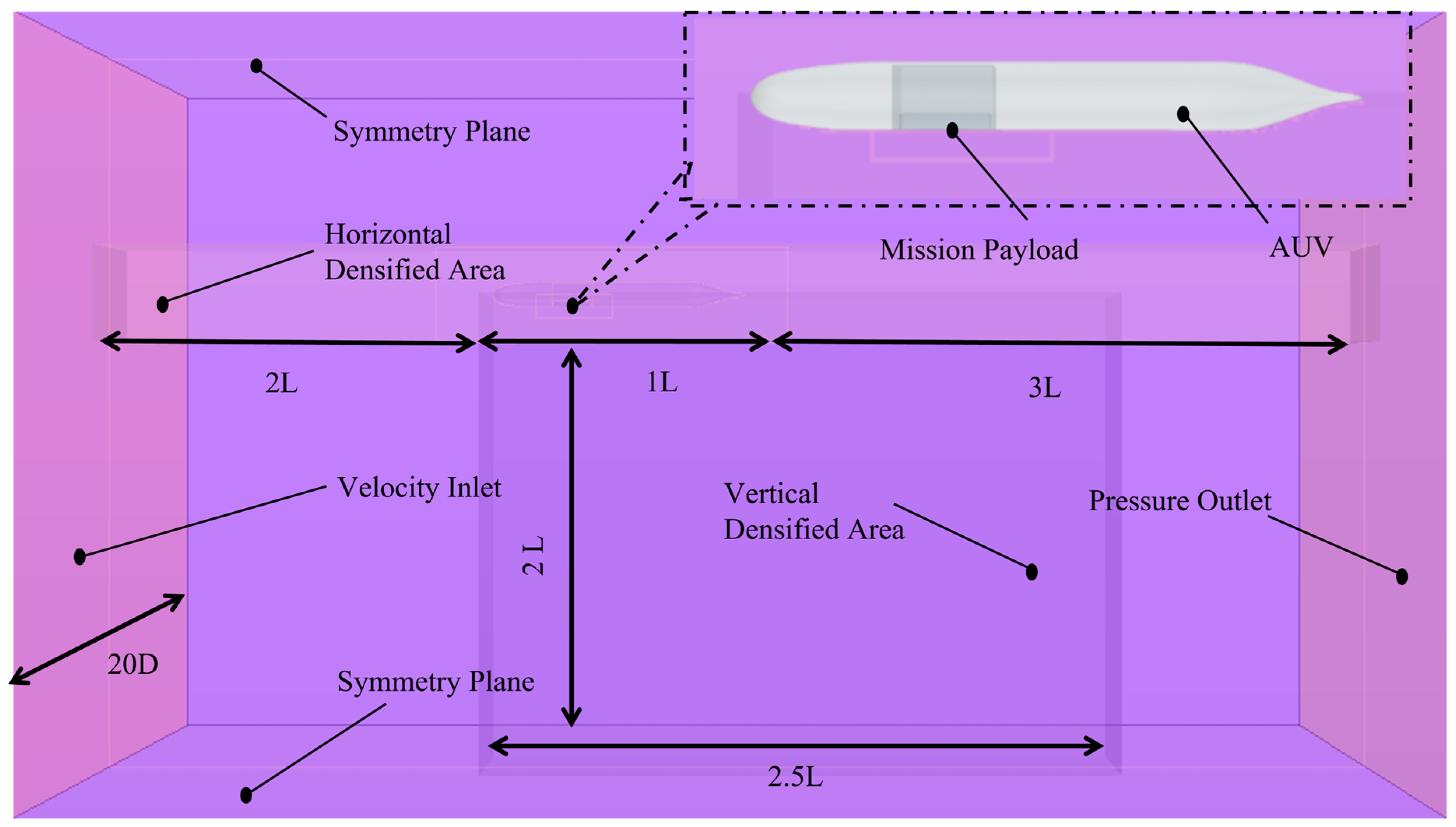

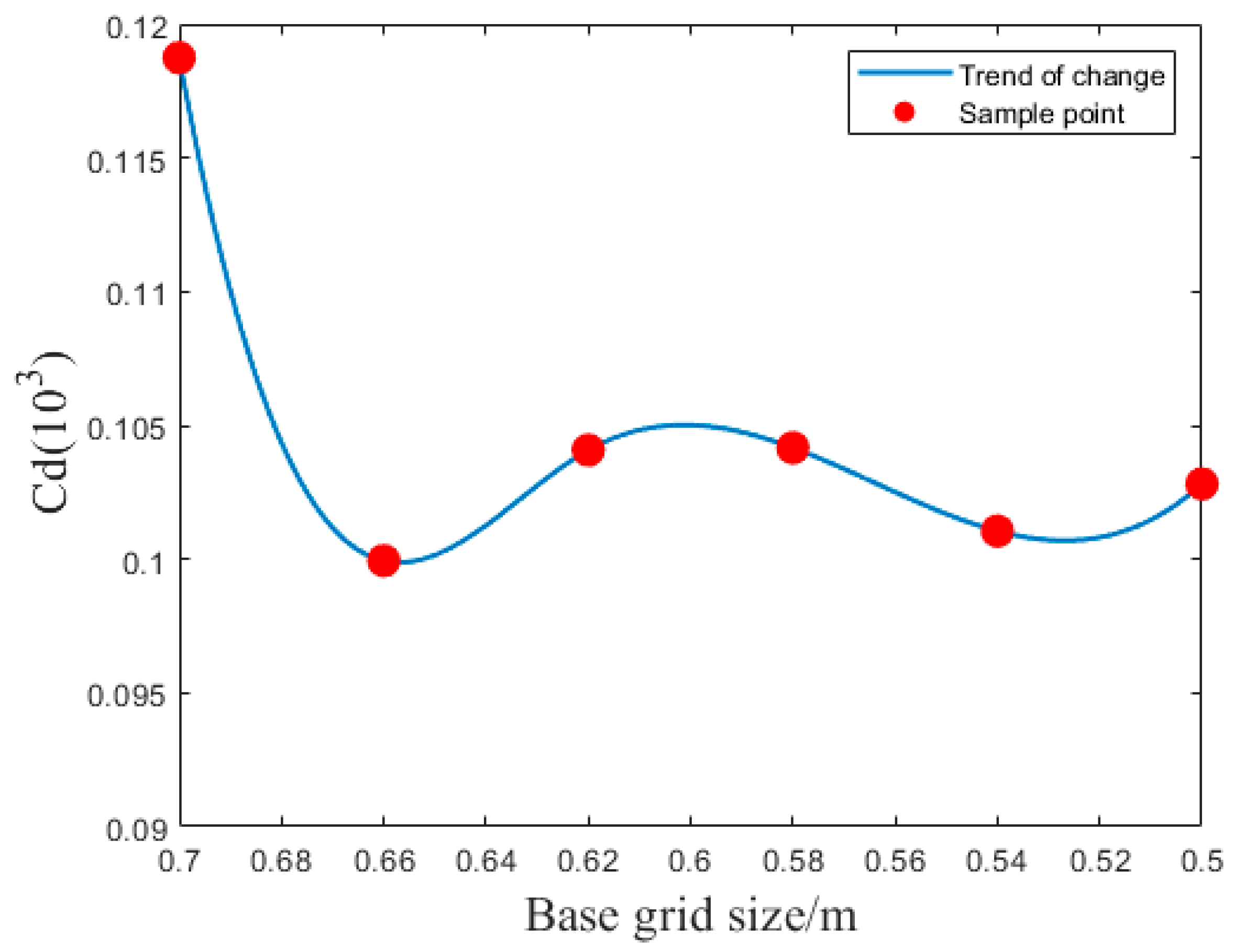

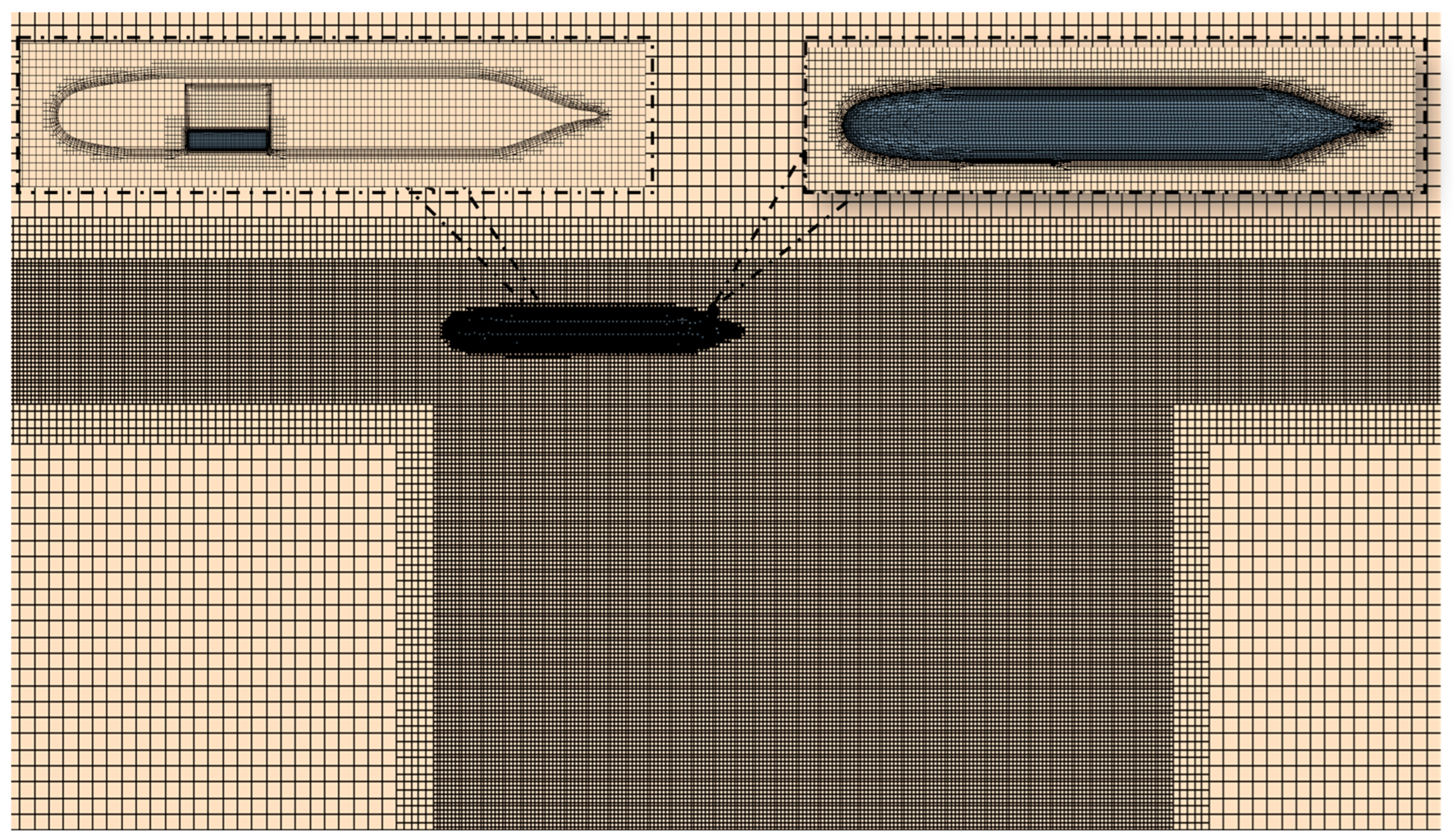

2.5. Simulation Settings and Grid Independence Analysis

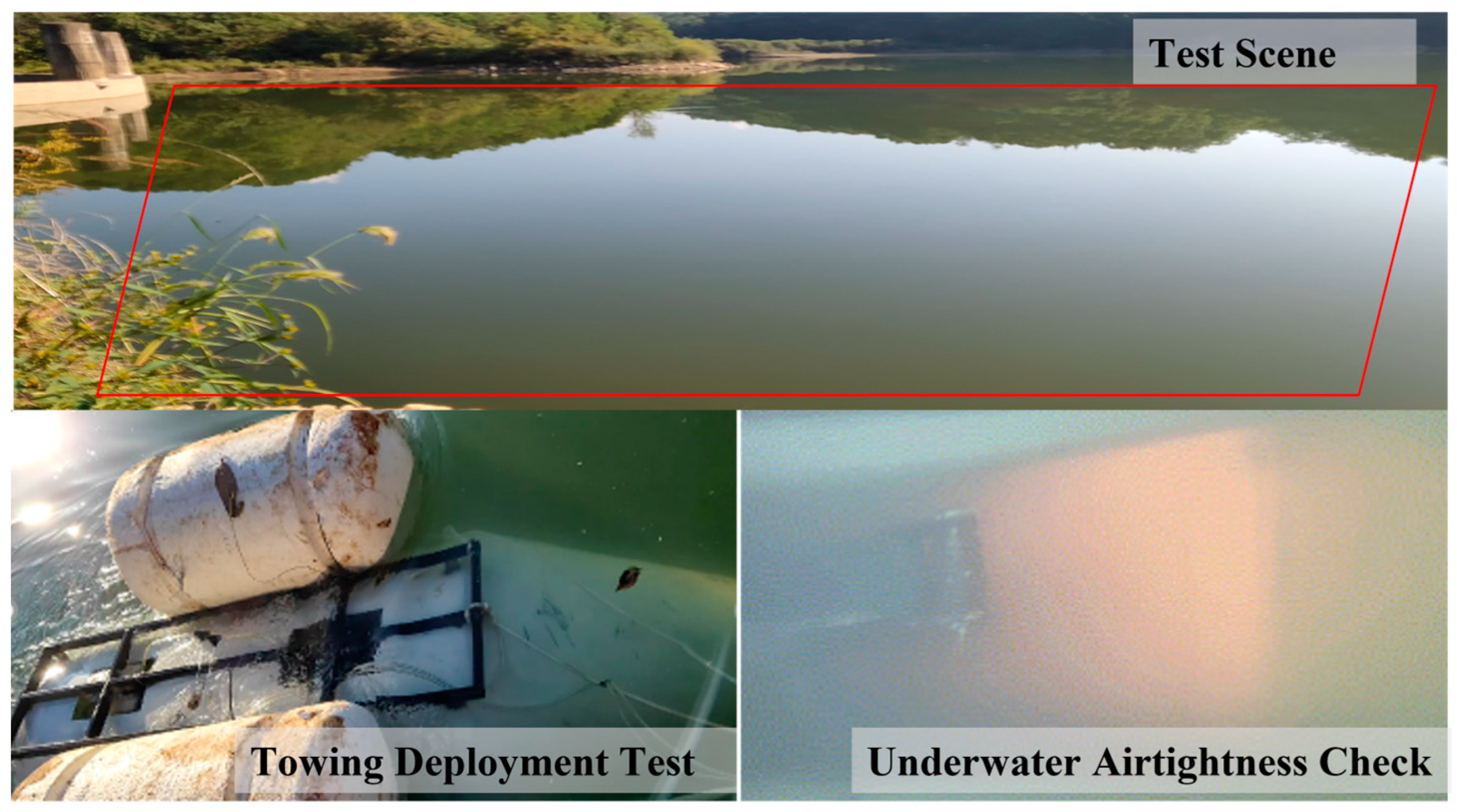

3. Test Platform and Verification

3.1. Experimental Process

- Pressure Maintenance: An air compressor was employed to pressurize the system. The switch was turned, and the cylinder’s reciprocating motion was checked. Synchronized push–pull movements of the two cylinders indicated normal conditions.

- Payload Loading: A rod fork was inserted into the payload’s mounting port. The switch was turned counterclockwise, and the release mechanism pulled the payload back to the center of the test platform to complete the installation.

- Water Entry: After entering the water, the buoy’s position was adjusted to maintain a horizontal state of the test platform for five minutes, and the airtightness of the deployment mechanism system (pressure gauge) was verified.

- Deployment: The towing mechanism was towed horizontally. Upon reaching the predetermined velocity, the switch was turned clockwise to deploy the payload into the water. Then, the timing was commenced.

- Recovery: A 25 m safety rope was reserved, where its ends were connected to a recovery ring on the payload and a fixed position near the deployment point. The payload was recovered 20 s after release.

3.2. Validating Turbulence Models

4. Analysis of Simulation Results

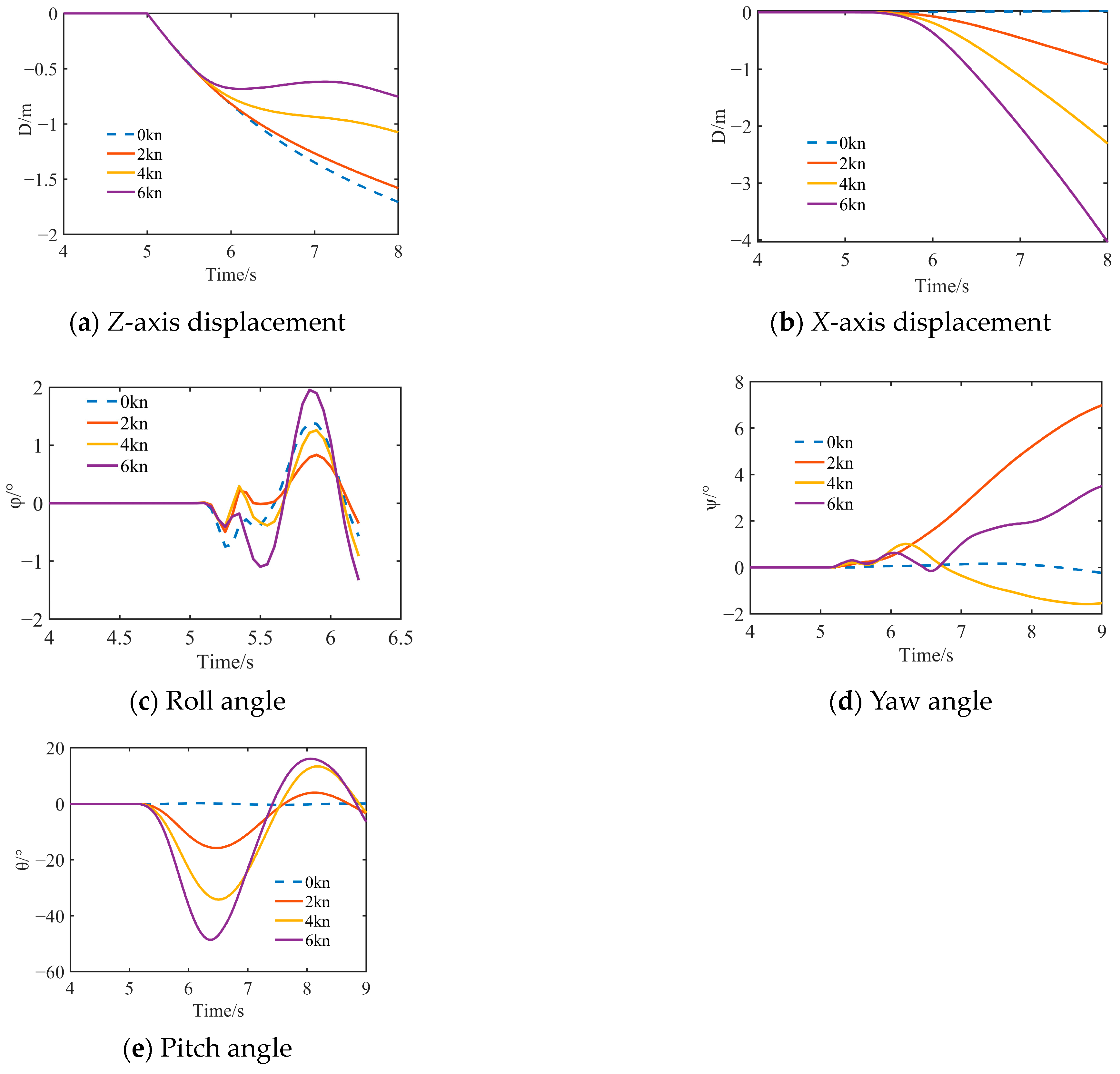

4.1. The Impact of Cruising Velocity on Initial Separation

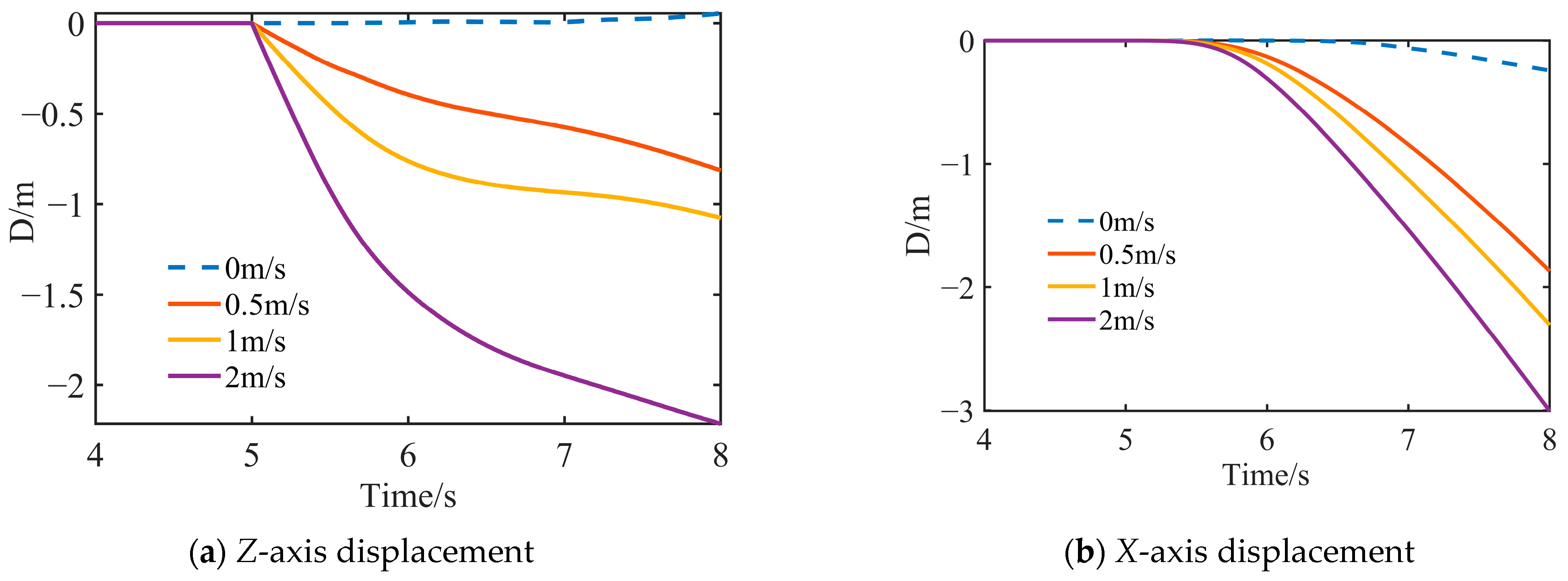

4.2. Impact of Initial Separation Velocity on Payload

4.3. The Impact of Initial Descent Angular Velocity on Payload

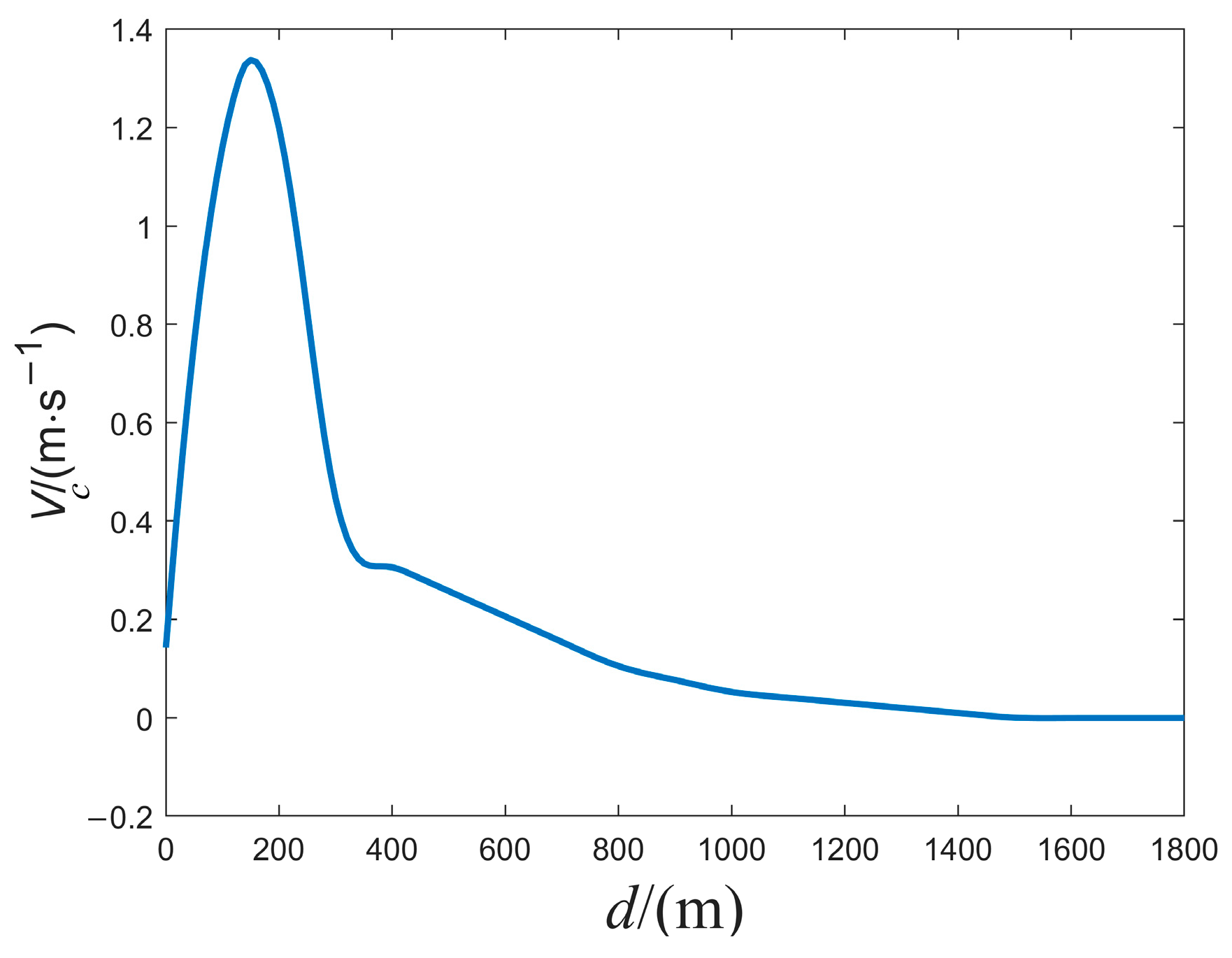

4.4. Impact of Payload Release Depth

5. Conclusions

- As cruising velocity increases, the disturbance from the flow field around the AUV during separation intensifies, degrading the payload’s separation and stability.

- Increasing the initial descent velocity allows the payload to pass through the complex flow field near the AUV quickly. Although it facilitates safe separation, it requires pitch angle control during the initial deployment phase.

- An appropriate initial pitch angular velocity can increase the time to reach the maximum pitch angle during initial separation. This makes the payload continuously move away from the AUV while slowing horizontal movement, thus enhancing separation safety.

- As the deployment depth of the payload increases, ocean current interference decreases, decreasing the effect of disturbances on the AUV during the separation process, thus enhancing the safety of payload separation.

- The payload should be deployed at low velocity and high depth as deep as possible while ensuring AUV dynamic stability.

- A release mechanism with guide rods and pushing devices should be designed.

- Favorable conditions should be established for the payload to exit the bay with the bow first and the stern following. Additionally, the pitch angle of the payload should be controlled.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xing, Y.; Santoso, T.A.D.; Ma, Y. Technical–economic feasibility analysis of subsea shuttle tanker. J. Mar. Sci. Eng. 2022, 10, 20. [Google Scholar] [CrossRef]

- Shu, Y.; Hu, A.; Zheng, Y.; Gan, L.; Xiao, G.; Zhou, C.; Song, L. Evaluation of ship emission intensity and the inaccuracy of exhaust emission estimation model. Ocean Eng. 2023, 287, 115723. [Google Scholar] [CrossRef]

- Chen, X.; Liu, S.; Liu, R.W.; Wu, H.; Han, B.; Zhao, J. Quantifying Arctic oil spilling event risk by integrating an analytic network process and a fuzzy comprehensive evaluation model. Ocean Coast. Manag. 2022, 228, 106326. [Google Scholar] [CrossRef]

- Brignone, L.; Opderbecke, J.; Bouhier, M.E.; Marfia, C.; Piasco, R.; Gobillot, N.; Magnier, C.; Arnaubec, A. Validation at sea for uly x, the latest deep diving AUV for oceanographic research. In Proceedings of the OCEANS 2023, Limerick, Ireland, 5–8 June 2023; pp. 1–6. [Google Scholar]

- Sun, K.; Cui, W.; Chen, C. Review of underwater sensing technologies and applications. Sensors 2021, 21, 7849. [Google Scholar] [CrossRef]

- Palmroos, N. Extra-Large Unmanned Underwater Vehicles (XLUUVs): Payload Benefits, Technological Advancements and Military Utility in the Baltic Sea. 2023. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2:1823200 (accessed on 5 December 2023).

- Slocombe, G. Uninhabited systems: Autonomous unmanned vehicles could mean fewer large submarines. Asia-Pac. Def. Report. 2020, 46, 23–25. [Google Scholar]

- Greve, M.; Kurowski, M.; Ritz, S.; Golz, M.; Vijayasarathi, L.N.; Bayazit, N.; Rentzow, E. Design of the Propulsion System for the Autonomous XLUUV MUM. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 5–10 June 2022; p. V05AT06A035. [Google Scholar]

- McCarragher, S.T. The Marine Corps Future Prepositioned Network: Beneath the Oceans and Beyond. 2021. Available online: https://apps.dtic.mil/sti/citations/AD1178101 (accessed on 1 December 2023).

- Wei, G.; Tian, C.L.; Hai, T.G.; Zhi, B.S.; Yuan, S. Unpowered diving motion characteristics of deep-sea autonomous underwater vehicle. Robot 2021, 43, 674–683. (In Chinese) [Google Scholar]

- Xiang, G.; Soares, C.G. Improved dynamical modelling of freely falling underwater cylinder based on CFD. Ocean Eng. 2020, 211, 107538. [Google Scholar] [CrossRef]

- Yao, J.; Zhen, X.; Huang, Y.; Wang, W. Numerical investigation on hydrodynamic characteristics of immersed buoyant platform. J. Mar. Sci. Eng. 2021, 9, 168. [Google Scholar] [CrossRef]

- Pena, B.; Huang, L. A review on the turbulence modelling strategy for ship hydrodynamic simulations. Ocean Eng. 2021, 241, 110082. [Google Scholar] [CrossRef]

- Yan, Z.; Gong, P.; Zhang, W. Dynamic Docking Technology between AUV and Mobile Mothership. In Proceedings of the 2020 Chinese Control and Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 3045–3049. [Google Scholar]

- Ghoreyshi, M.; Bergeron, K.; Jirasek, A.; Seidel, J.; Noetscher, G. High-Fidelity Simulations of Flight Dynamics and Trajectory of a Parachute-Payload System Leaving the C-17 Aircraft. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 0419. [Google Scholar]

- Bogomolov, N.; Anfalov, A.; Borzykh, S.; Bakulin, V. Simulation of process of small satellites separation from deployer installed on cargo spacecraft. J. Phys. Conf. Ser. 2019, 1392, 012003. [Google Scholar] [CrossRef]

- Olejnik, A.; Dziubiński, A.; Kiszkowiak, Ł. Separation safety analysis using CFD simulation and remeshing. Aerosp. Sci. Technol. 2020, 106, 106190. [Google Scholar] [CrossRef]

- Xue, F.; Wang, Y.; Qin, H. Derivation and validation of wind tunnel free-flight similarity law for store separation from aircraft. Aerosp. Sci. Technol. 2020, 97, 105614. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Li, X.-C. The investigation of a sliding mesh model for hydrodynamic analysis of a SUBOFF model in turbulent flow fields. J. Mar. Sci. Eng. 2020, 8, 744. [Google Scholar] [CrossRef]

- Fun Sang Cepeda, M.; Freitas Machado, M.D.S.; Sousa Barbosa, F.H.; Santana Souza Moreira, D.; Legaz Almansa, M.J.; Lourenço de Souza, M.I.; Caprace, J.-D. Exploring Autonomous and Remotely Operated Vehicles in Offshore Structure Inspections. J. Mar. Sci. Eng. 2023, 11, 2172. [Google Scholar] [CrossRef]

- Liu, B.; Xu, X.; Pan, D. Resistance reduction optimization of an amphibious transport vehicle. Ocean Eng. 2023, 280, 114854. [Google Scholar] [CrossRef]

- Dey, S.; Mahato, R.K.; Ali, S.Z. Turbulent Shear Flow over a Downstream-Skewed Wavy Bed: Analytical Model Based on the RANS Equations with Boussinesq approximation Boussinesq Approximation. J. Hydraul. Eng. 2023, 149, 04023028. [Google Scholar] [CrossRef]

- Wei, S. Assessment of advanced rans turbulence models for prediction of complex flows in compressors. Chin. J. Aeronaut. 2023, 36, 162–177. [Google Scholar]

- Xu, Y.; Tan, L.; Yuan, Y.; Zhang, M. Numerical simulation on flow field and design optimization of a generator unit based on computational fluid dynamics analysis. Math. Probl. Eng. 2021, 2021, 3350867. [Google Scholar] [CrossRef]

- Wilcox, D.C. Formulation of the kw turbulence model revisited. AIAA J. 2008, 46, 2823–2838. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Eça, L.; Kerkvliet, M.; Toxopeus, S. Attaining the Asymptotic Range in Rans Simulations. Verif. Valid. 2023, 86748, V001T002A002. [Google Scholar]

- Hellsten, A. New advanced kw turbulence model for high-lift aerodynamics. AIAA J. 2005, 43, 1857–1869. [Google Scholar] [CrossRef]

- Wallin, S.; Johansson, A.V. An explicit algebraic Reynolds stress model for incompressible and compressible turbulent flows. J. Fluid Mech. 2000, 403, 89–132. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Z.; He, X. Numerical simulation of the complex flow field in a new recycling cyclone separator. J. Phys. Conf. Ser. 2024, 2707, 012085. [Google Scholar] [CrossRef]

- Pacheco, J.; Marta, A.C.; Eça, L. Wind tunnel testing of a Formula Student vehicle for checking CFD simulation trends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, R.; Huang, S.; Zha, L.; Gu, M. A study on hydrodynamic characteristics of a planing hull by CFD simulation and modified MS method. Ships Offshore Struct. 2023, 18, 157–174. [Google Scholar] [CrossRef]

- Wang, N. CAS Thesis & Disserta. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2021. Available online: http://dpaper.las.ac.cn/Dpaper/homeNew (accessed on 15 November 2023). (In Chinese).

| Parameter | Value | |

|---|---|---|

| SUBOFF Dimensions | Scale radio | 2.3 |

| Forebody/m | 2.337 | |

| Midbody/m | 5.127 | |

| Afterbody/m | 2.555 | |

| Middle swing diameter/m | 1.17 | |

| Hatch dimensions L/D | 1.8/0.5 | |

| Mission Payloads | Weight/kg | 100 |

| Negative buoyancy/N | 10 | |

| X-axis moment of inertia Lxx/kg·m2 | 1.17 | |

| Y-axis moment of inertia Lyy/kg·m2 | 19.16 | |

| Z-axis moment of inertia Lzz/kg·m2 | 19.02 | |

| HUGIN Endurance | Length/m | 10 |

| Diameter/m | 1.2 | |

| Navigational velocity/kn | 2–6 | |

| Operating depth/m | 6000 | |

| Detection area/km2 | 1100 | |

| Endurance/day | 15 |

| Base Grid Size/(m) | Grid Quantity | Cd/(103) | Relative Error |

|---|---|---|---|

| 0.70 | 1,825,351 | 0.118743 | 15.8321% |

| 0.66 | 2,213,153 | 0.099944 | 18.8101% |

| 0.62 | 2,533,876 | 0.104077 | −3.9717% |

| 0.58 | 3,077,055 | 0.104162 | −0.0809% |

| 0.54 | 3,790,317 | 0.101052 | 3.0772% |

| 0.50 | 4,981,844 | 0.102813 | −1.7131% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Gu, H.; Lang, J.; Xing, L. Safety Analysis of Initial Separation Phase for AUV Deployment of Mission Payloads. J. Mar. Sci. Eng. 2024, 12, 608. https://doi.org/10.3390/jmse12040608

Wang Z, Gu H, Lang J, Xing L. Safety Analysis of Initial Separation Phase for AUV Deployment of Mission Payloads. Journal of Marine Science and Engineering. 2024; 12(4):608. https://doi.org/10.3390/jmse12040608

Chicago/Turabian StyleWang, Zhengwei, Haitao Gu, Jichao Lang, and Lin Xing. 2024. "Safety Analysis of Initial Separation Phase for AUV Deployment of Mission Payloads" Journal of Marine Science and Engineering 12, no. 4: 608. https://doi.org/10.3390/jmse12040608

APA StyleWang, Z., Gu, H., Lang, J., & Xing, L. (2024). Safety Analysis of Initial Separation Phase for AUV Deployment of Mission Payloads. Journal of Marine Science and Engineering, 12(4), 608. https://doi.org/10.3390/jmse12040608