Numerical Investigation into the Stability of Offshore Wind Power Piles Subjected to Lateral Loads in Extreme Environments

Abstract

:1. Introduction

2. Numerical Model

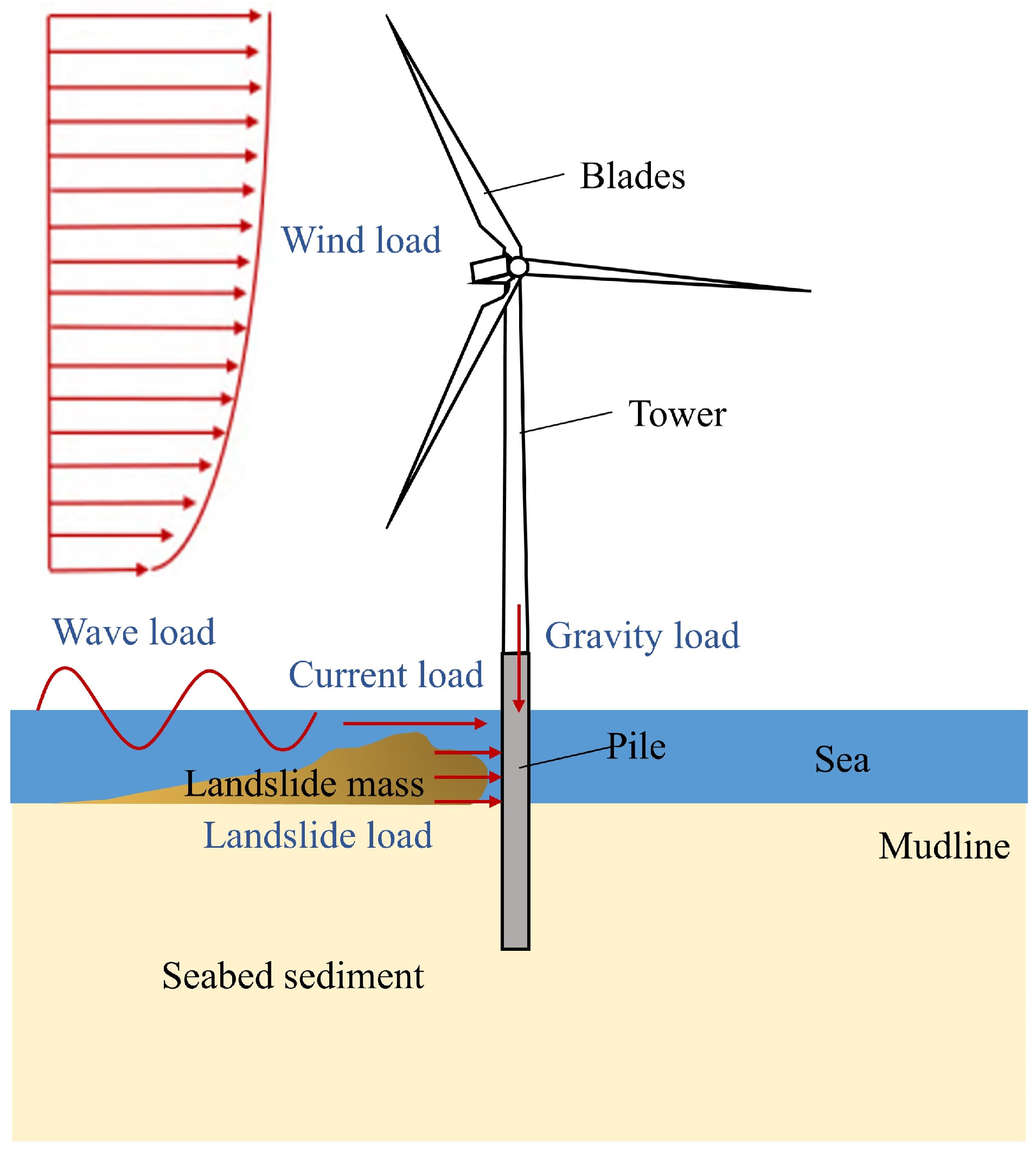

2.1. Generalization of Loads on Offshore Wind Turbine Structures in Complex Environments

2.1.1. Aerodynamic Loads

2.1.2. Hydrodynamic Loads

2.1.3. Submarine Landslide Impact Loads

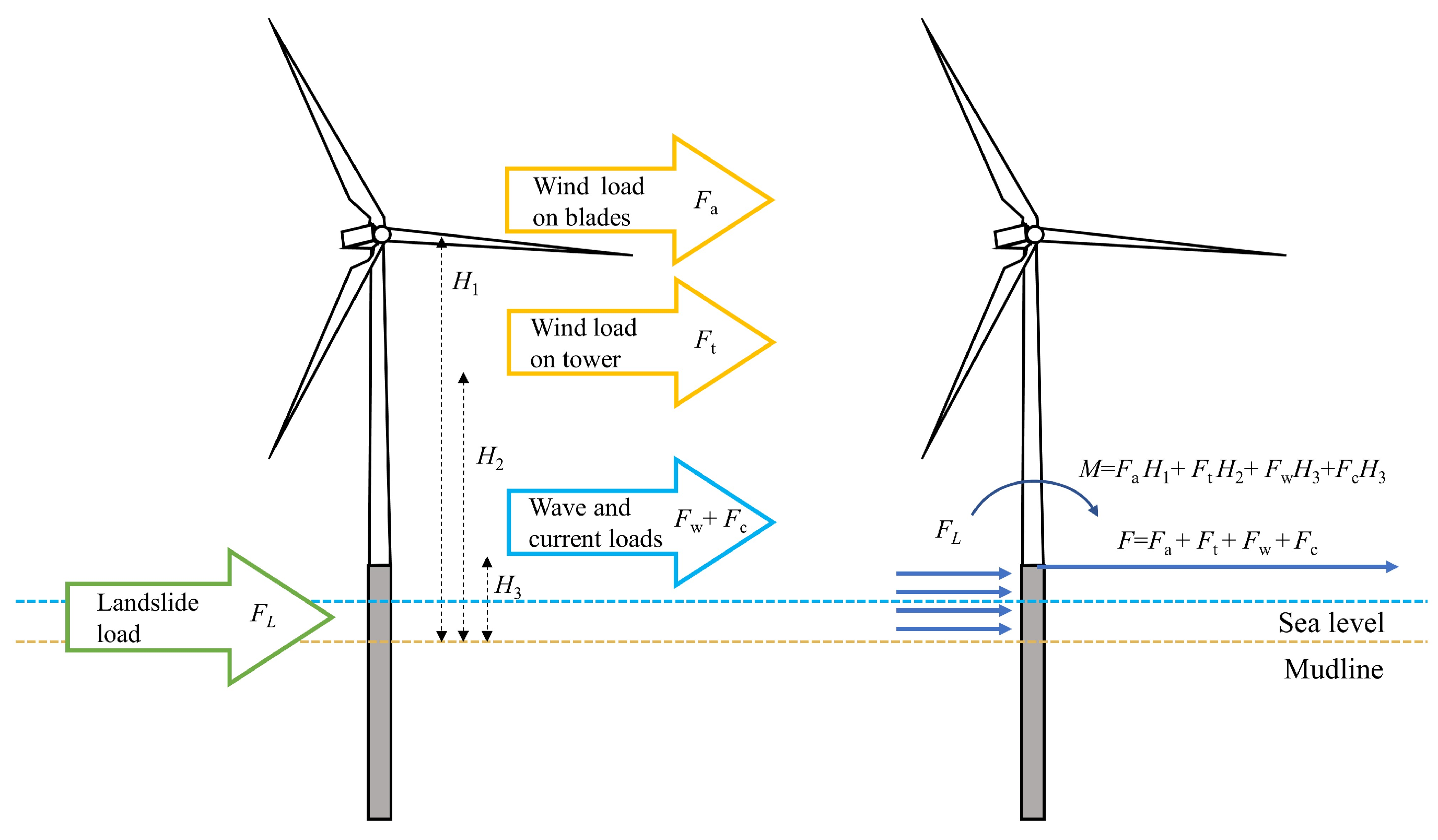

2.1.4. Superimposition of Environmental Loads

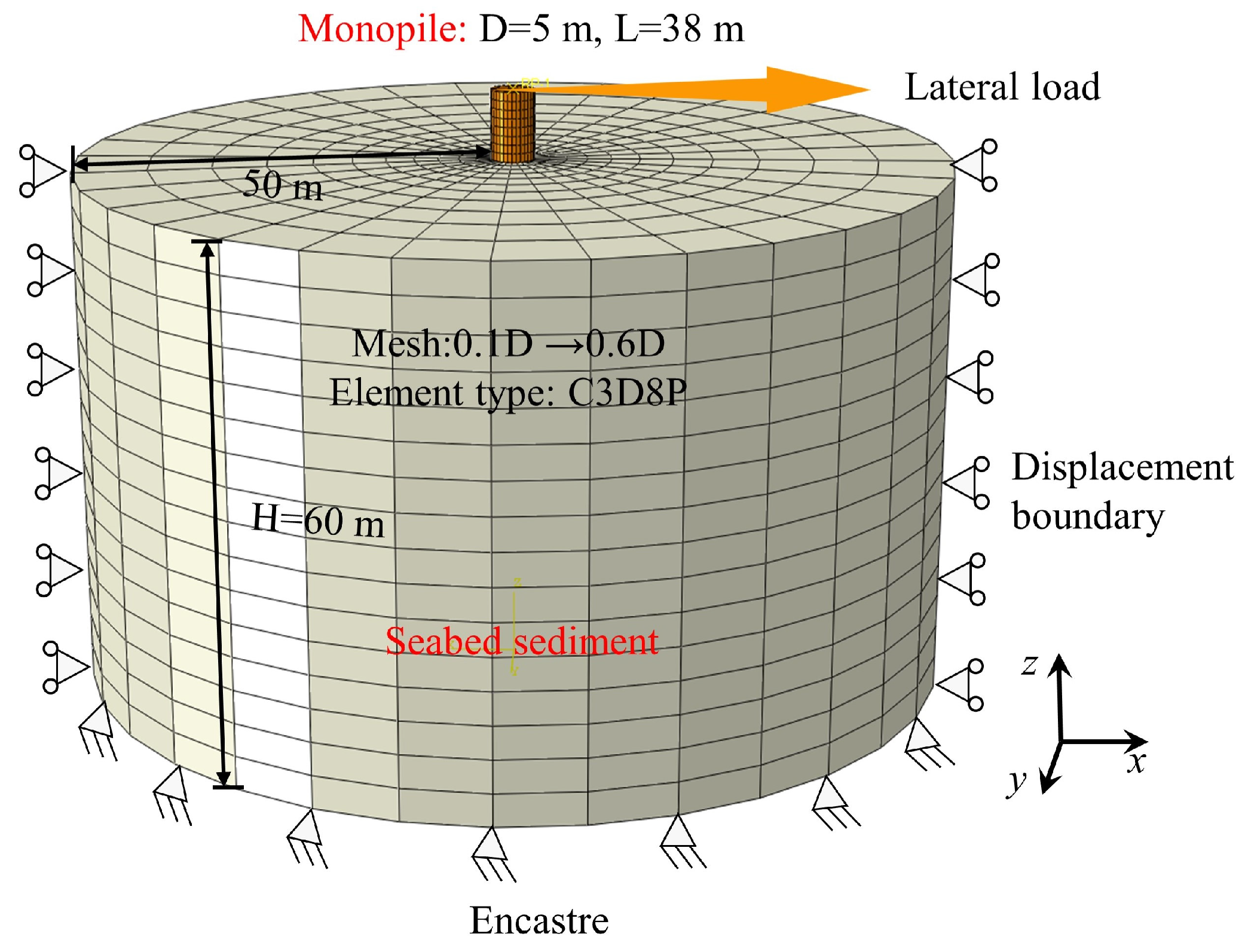

2.2. Pile–Soil Interaction Model under Complex Horizontal Loads

2.2.1. Monopile Model

2.2.2. Soil Model

2.2.3. Pile–Soil Contact Model

2.2.4. Finite Element Method for Solution

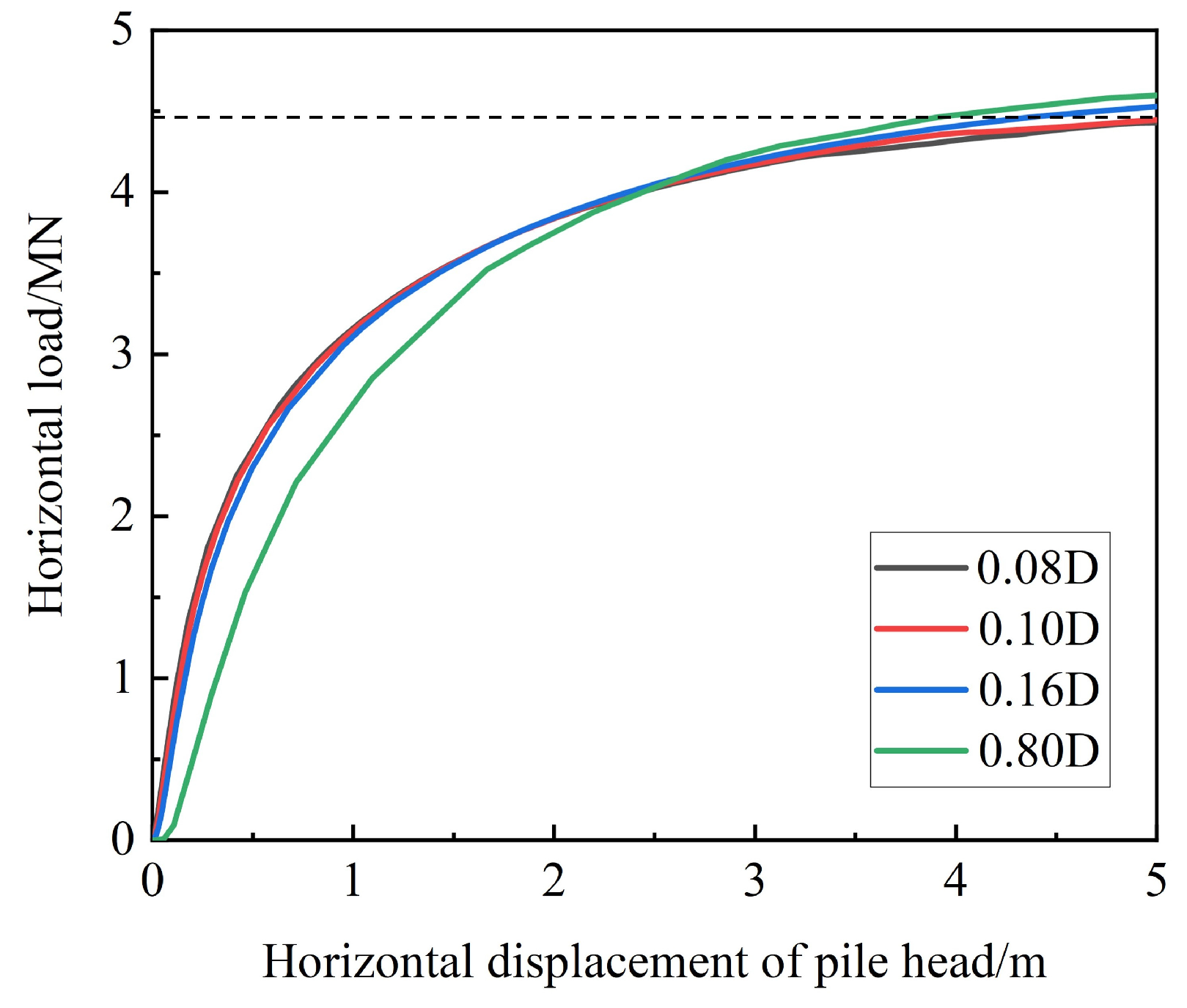

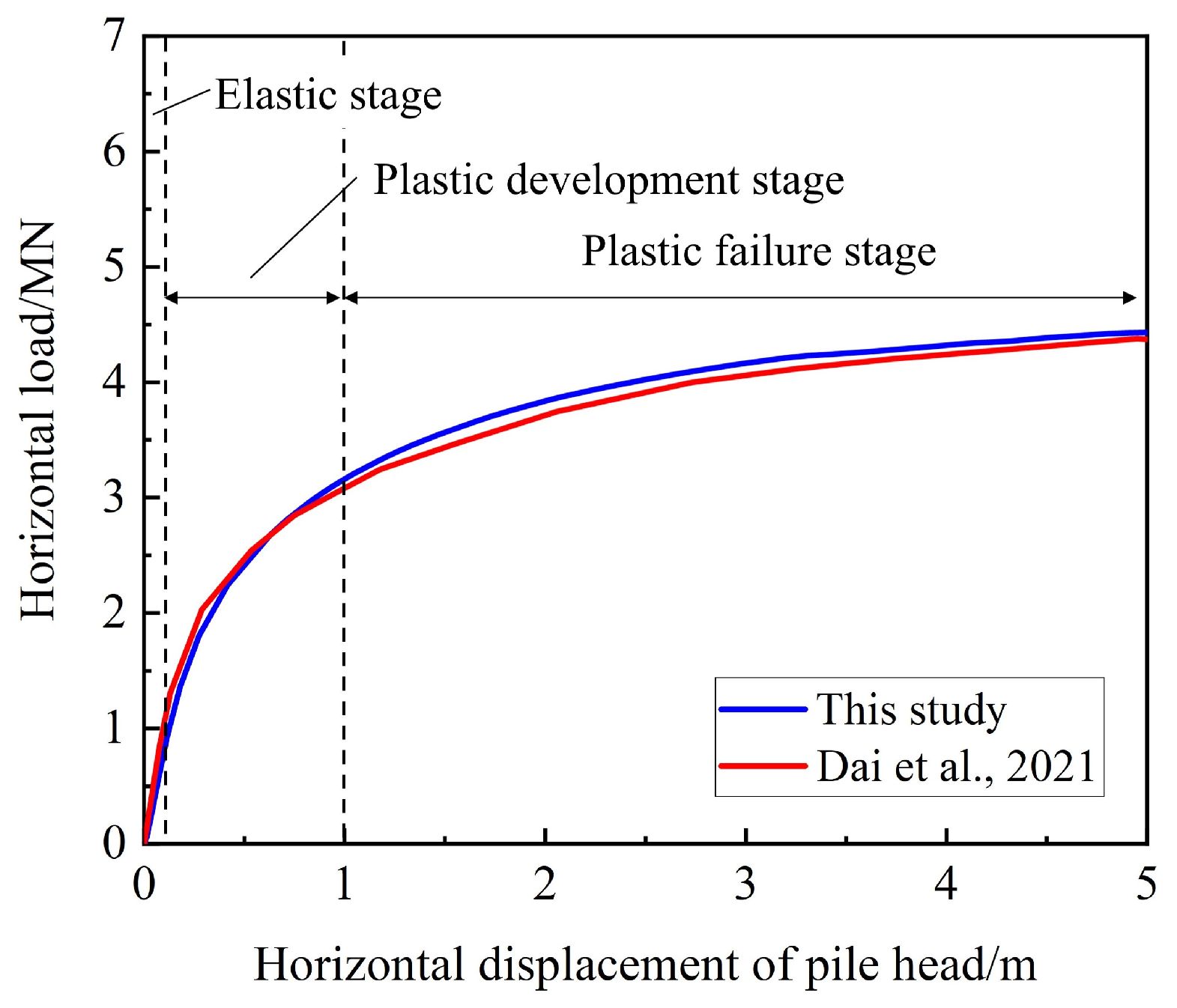

2.3. Numerical Model Verification

3. Results and Discussion

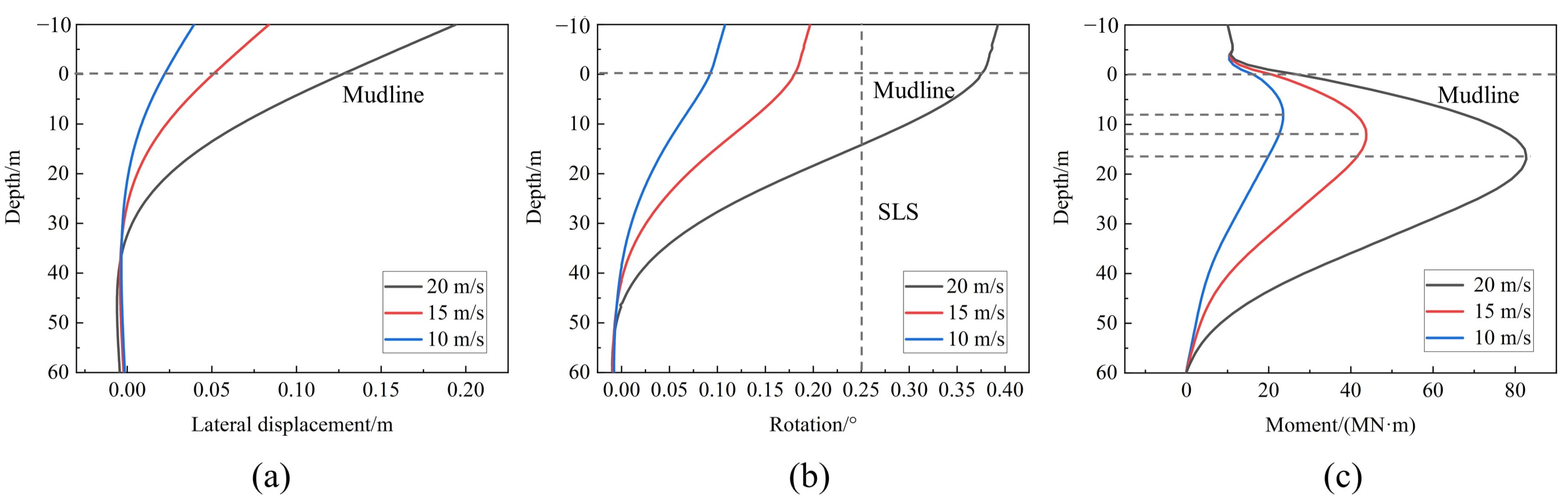

3.1. Case Study on Stability Analysis of Monopile under Complex Loads

3.2. The Influence of Different Types of Submarine Landslides on the Stability of Monopiles

3.2.1. Effect of Submarine Landslide Density

3.2.2. Effect of Submarine Landslide Velocity

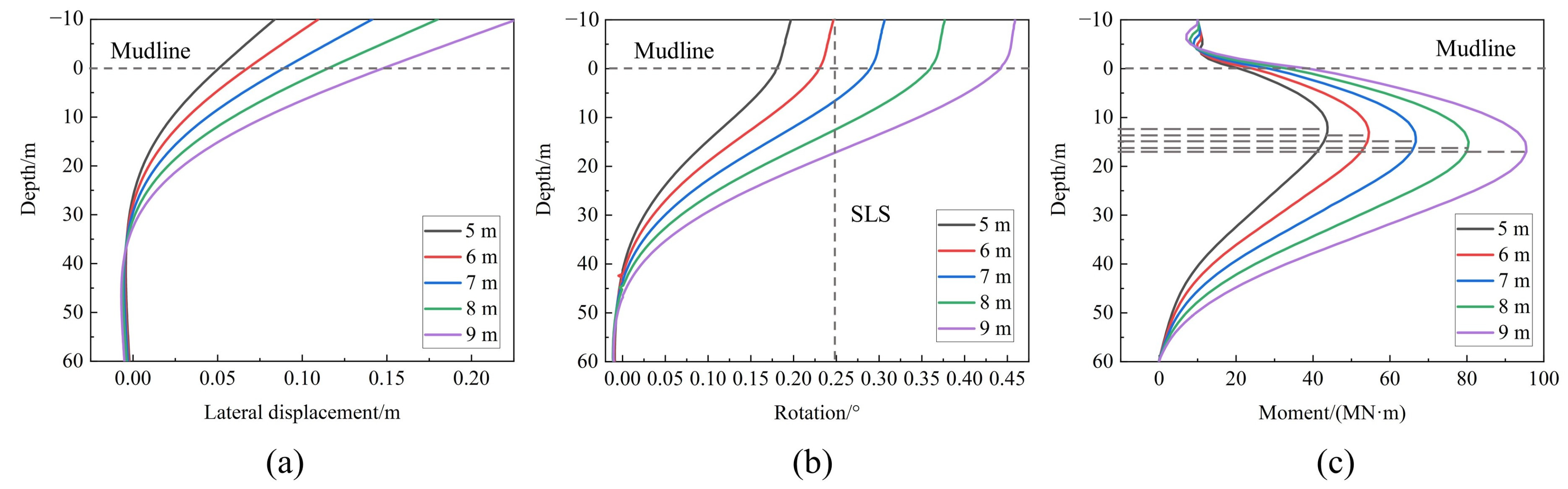

3.2.3. Effect of Submarine Landslide Impact Height

3.3. The Influence of Seabed Sediment Strength on the Stability of Monopiles

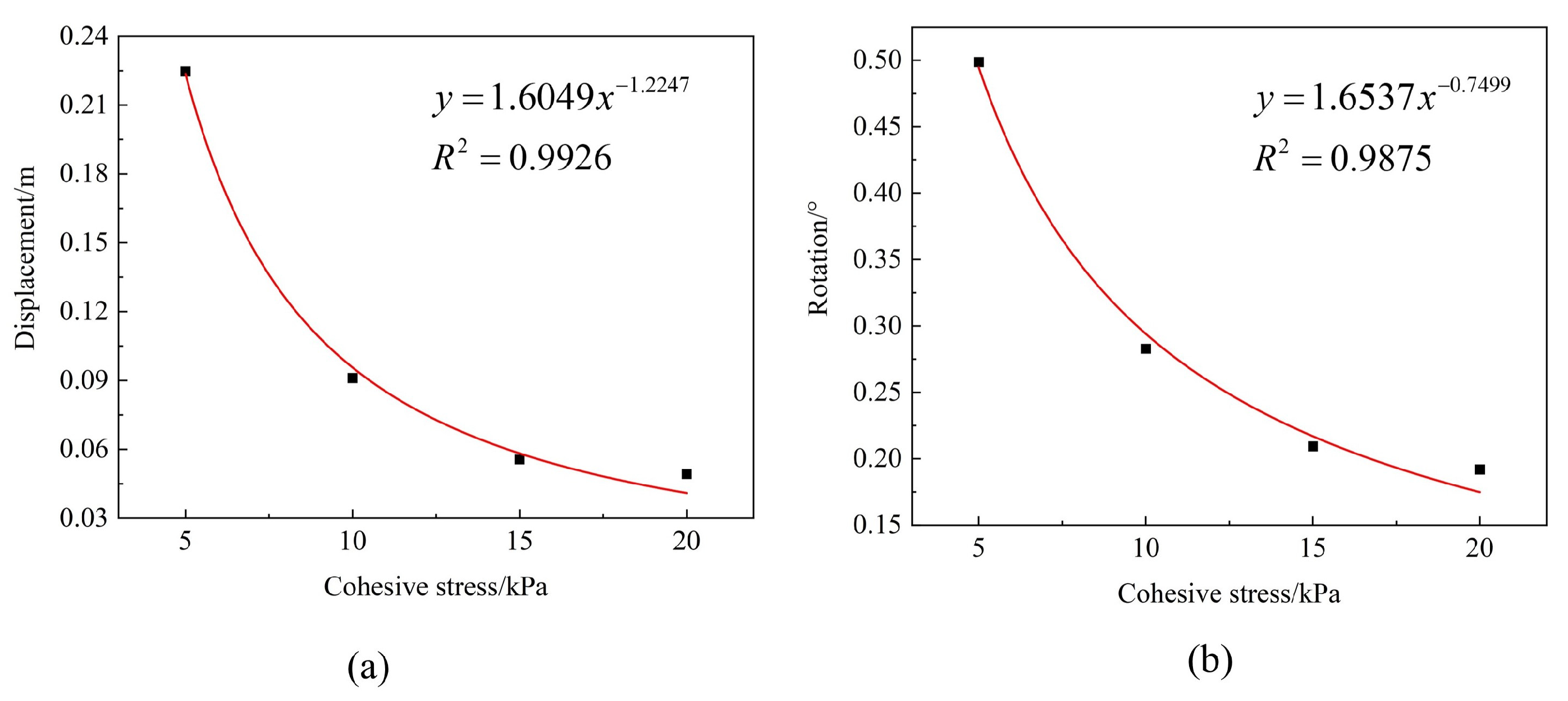

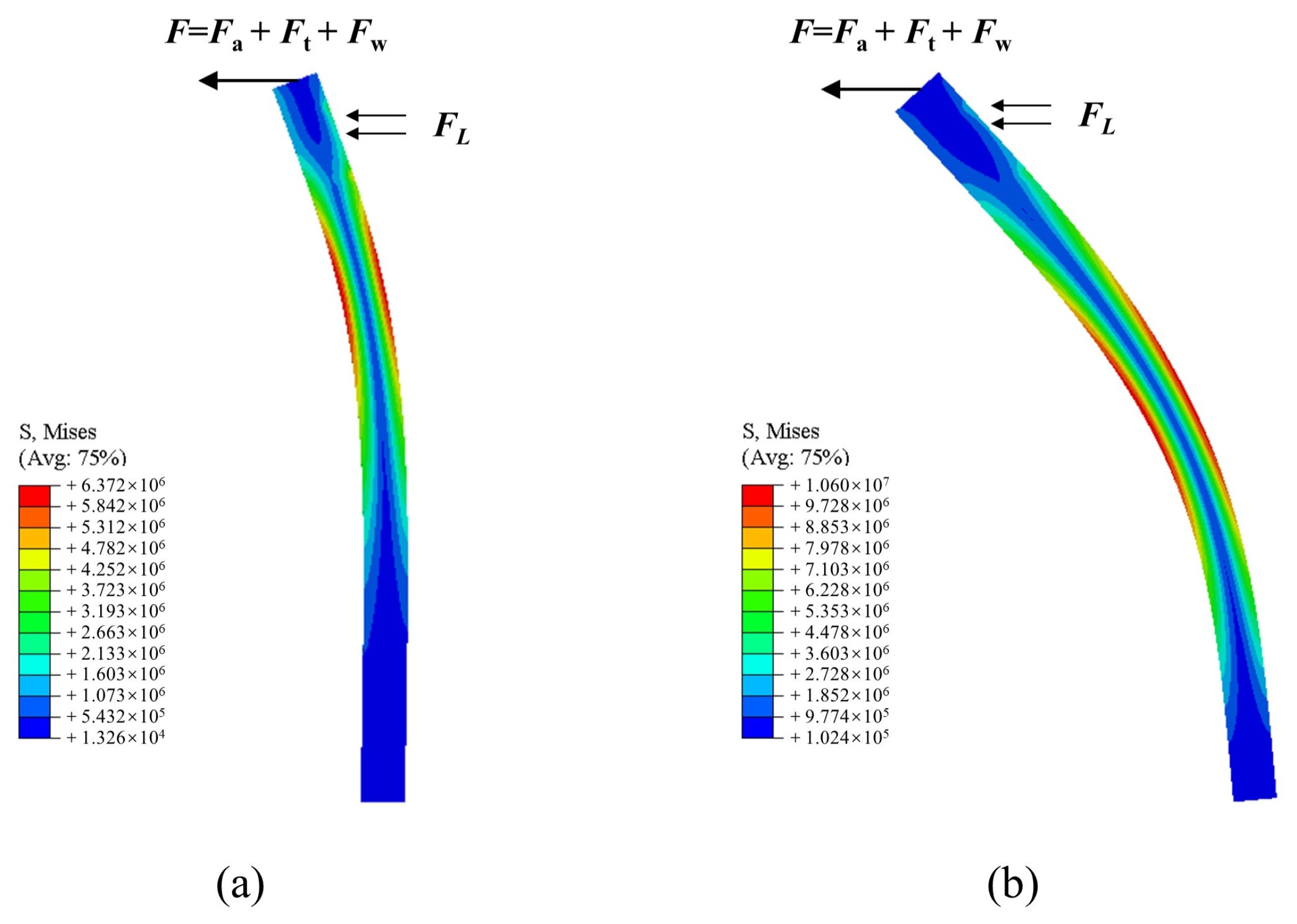

3.3.1. Effect of Cohesion

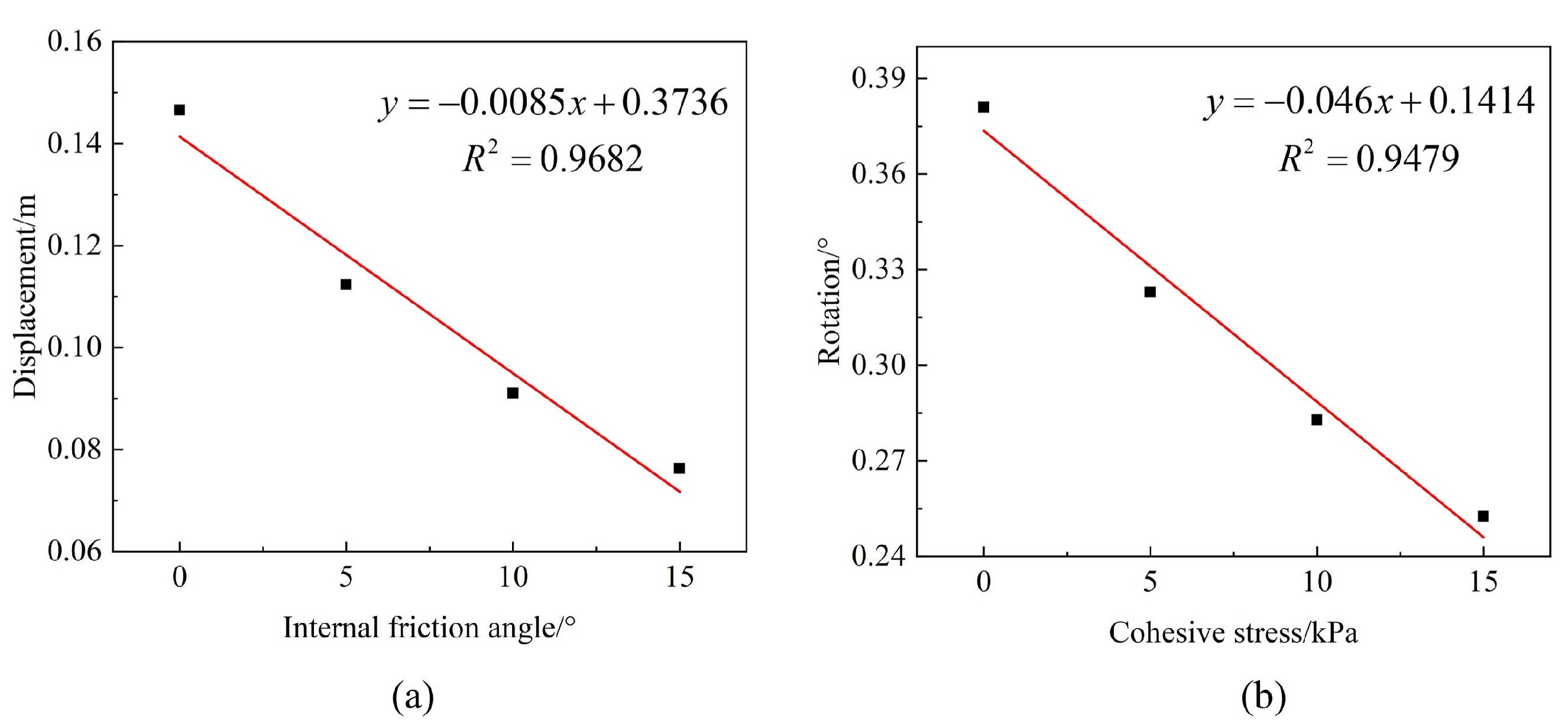

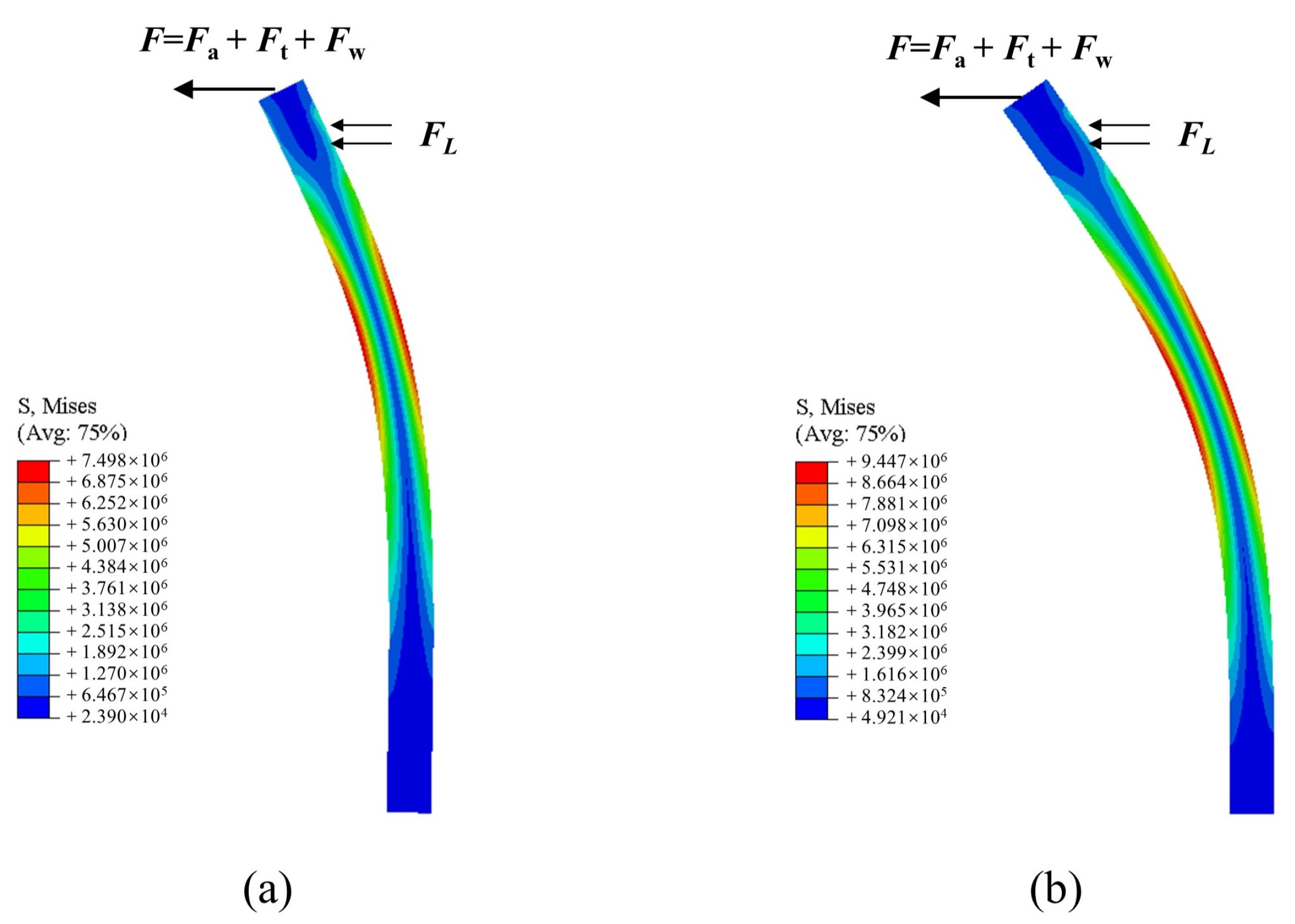

3.3.2. Effect of Internal Friction Angle

4. Conclusions

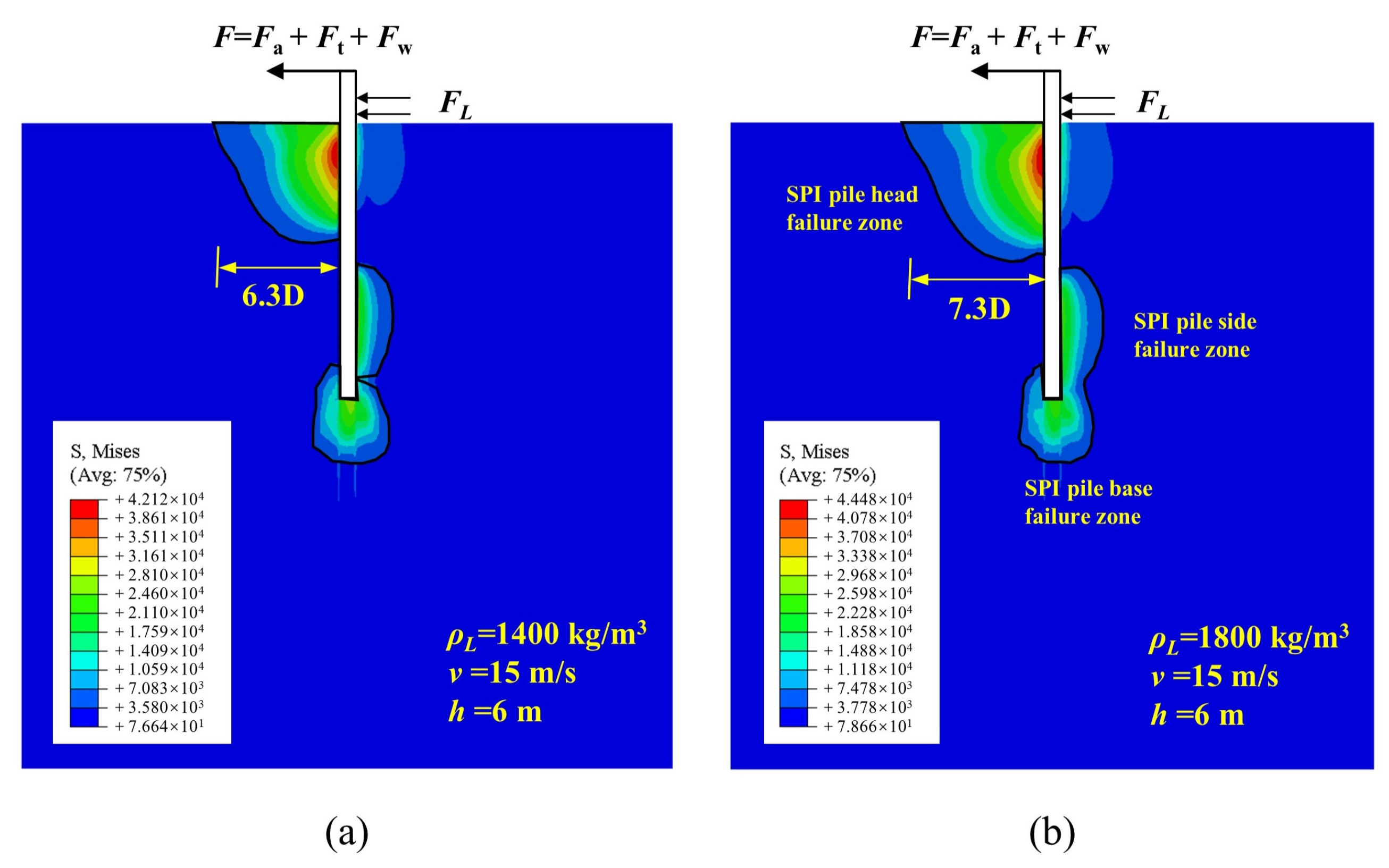

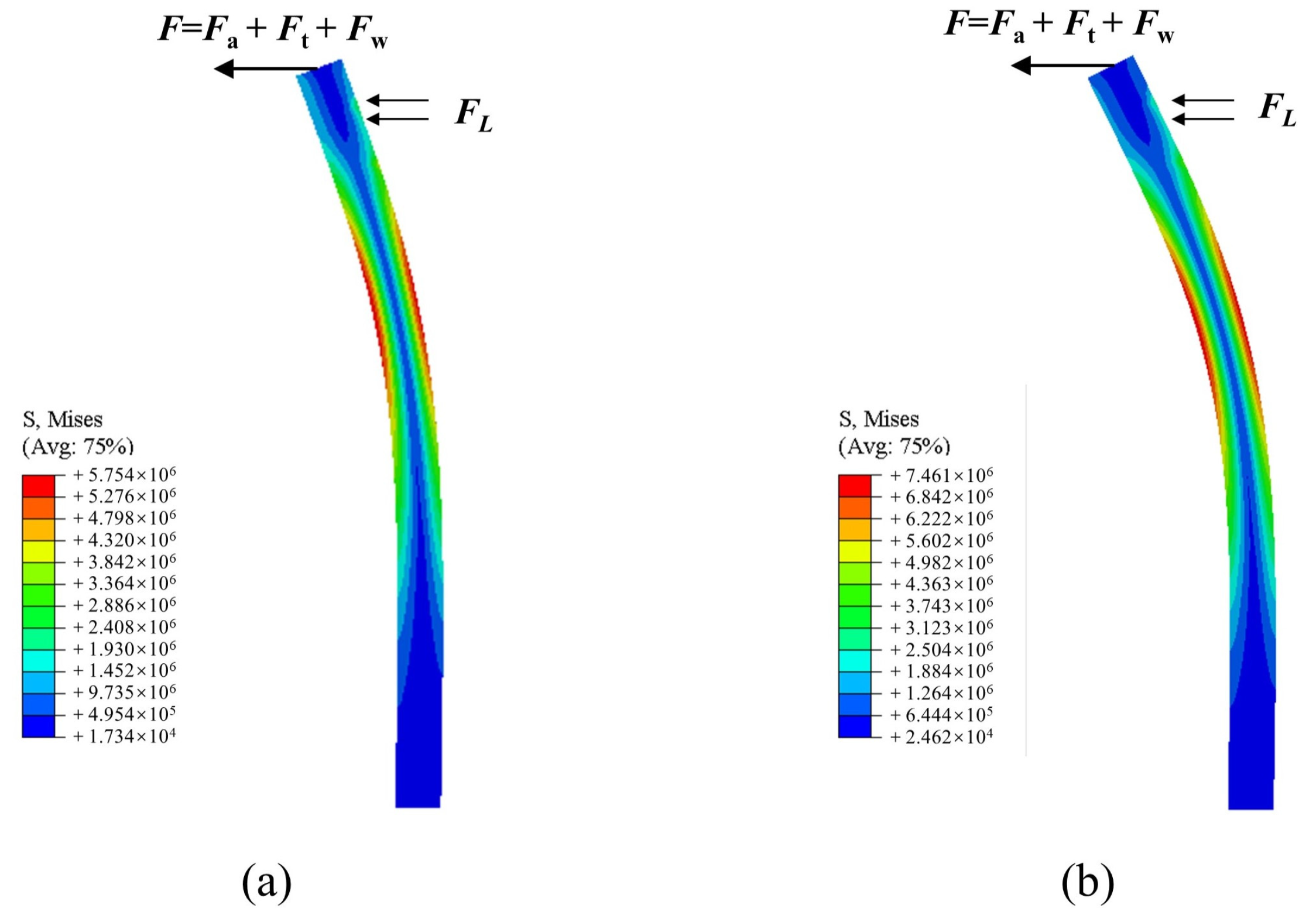

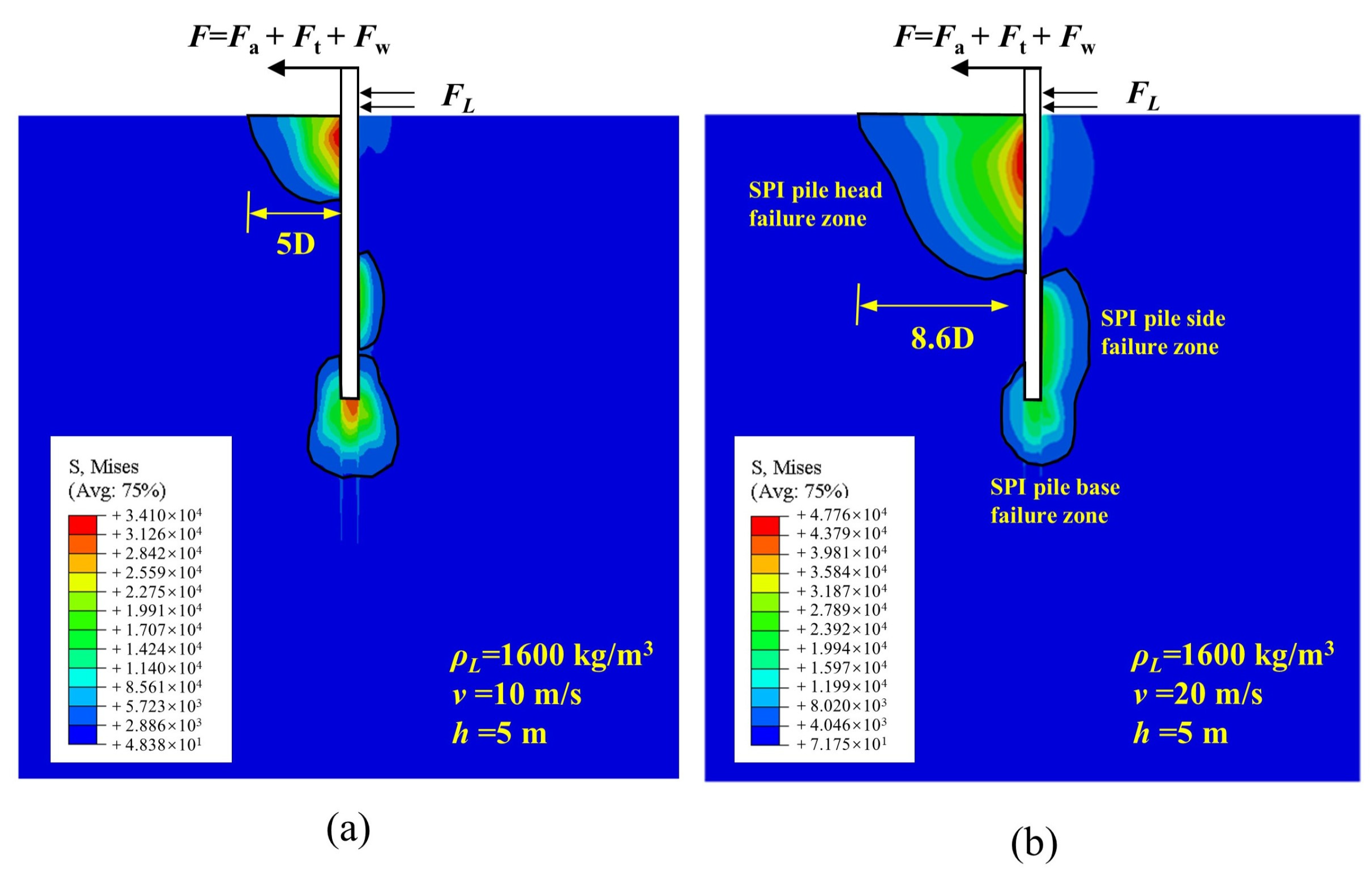

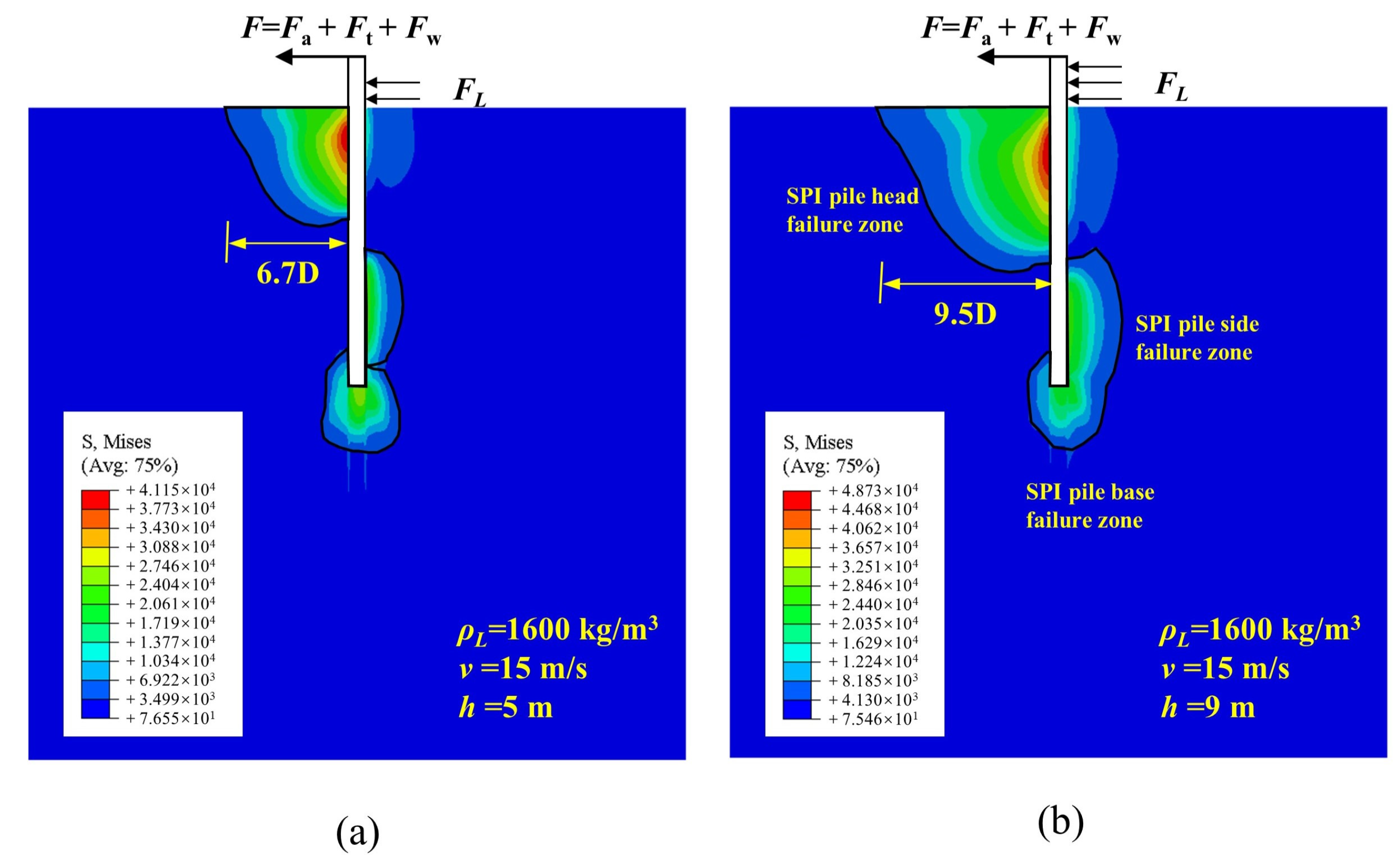

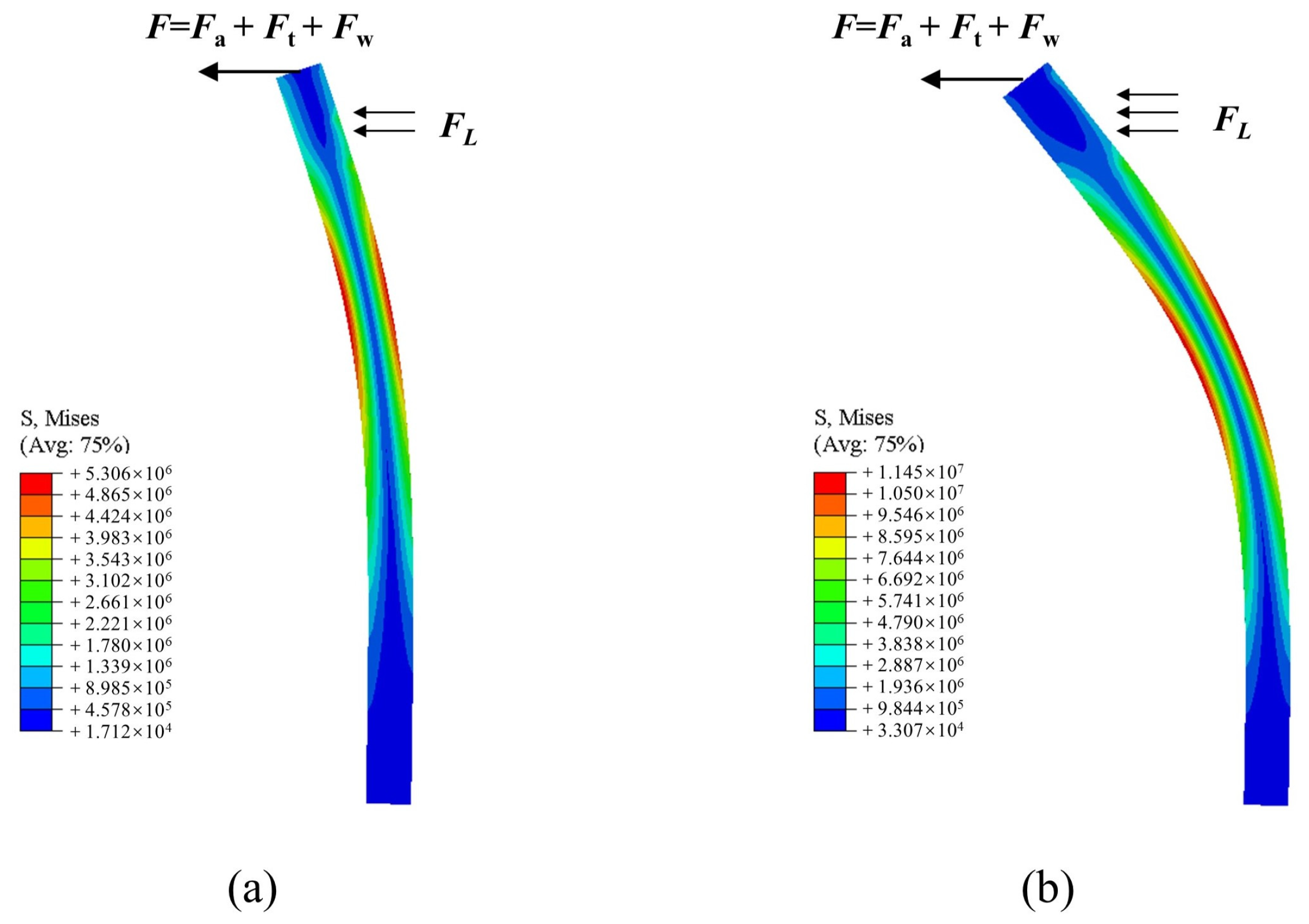

- As the density, velocity, and impact height of submarine landslides increase, the force on the monopile increases. Consequently, all the horizontal displacement, pile rotation angle, and maximum bending moment at the pile head increase. The escalation in submarine landslide density and impact height yields a proportional increase in the horizontal displacement, pile rotation angle, and maximum bending moment. Moreover, an increase in submarine landslide velocity leads to a hyperbolic surge in the horizontal displacement, pile rotation angle, and maximum bending moment. Once a specific lateral loading threshold is reached, three distinct SPI failure zones emerge within the seabed sediment, i.e., the compressive wedge failure zone at the pile head, the rotational shear failure zone at the pile base, and the failure zone along the pile side. Further increase in lateral loading prompts a gradual expansion of the sediment compression failure zone at the pile head, while the shear failure zone at the pile base progressively intertwines with the failure zone along the pile side. In the scenario of the designated case study, the cumulative rotation angle at the mudline of the monopile reaches 0.27° when the horizontal influence range at the pile head extends to 7.3 D, thereby triggering instability failure in accordance with DNV standards.

- A decrease in the cohesion of the seabed sediment subjected to the same lateral load leads to a reduction of the horizontal bearing capacity of the sediment. Consequently, this triggers a hyperbolic increase in displacement and rotation angle at the mudline of the monopile. For instance, when the cohesion of the seabed sediment decreases from 20 kPa to 5 kPa, the area of sediment compression failure zone at the pile head enlarges and the horizontal influence range surges from 5.9 D to 13.8 D. It is noteworthy that the area of the full-flow failure zone on the pile side decreases, while the area of the shear failure zone at the pile base increases. The shear failure zone at the pile base extends upwards to cover the original failure zone on the pile side. In the context of the specified case study, the monopile experiences instability failure when the cohesion of the seabed sediment drops below 10 kPa.

- Under the same lateral load, a decrease in the internal friction angle of the seabed sediment leads to a linear increase in displacement and rotation angle at the mudline of the monopile. When the internal friction angle decreases from 15° to 0°, the area of the sediment compression failure zone at the pile head enlarges, and the horizontal influence range expands from 6.6 D to 13.6 D. The failure zone on the pile side merges with the shear failure zone on the pile base. Concurrently, the area of stress concentration zones on the compression side of the pile head and on the opposite side of the pile base, where seabed sediments are distributed, increases significantly. This stress concentration renders sediment more susceptible to failure. In the conditions of the chosen case study, the monopile experiences instability failure when the internal friction angle of the sediment is below 15°.

- This study investigates the stability of wind turbine foundations during operation by simplifying submarine landslide, wind, wave, and current loads into horizontal loads, which offers insights into the design of such foundations. However, further research should consider the distribution and instantaneous dynamic characteristics of submarine landslide, wind, wave, and flow loads, and conduct more comprehensive calculations to enhance analytical precision. In addition, future studies can integrate analysis with field-measured environmental data to better quantify environmental loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Symbols

| Rotor swept area | |

| Coefficient of drag force perpendicular to the axis of the cylinder | |

| Coefficient of inertial force | |

| Coefficient of thrust | |

| Coefficient of drag force for current | |

| Coefficient of drag force for landslide | |

| Coefficient of drag force for wind | |

| Young’s modulus of pile | |

| Flexural rigidity of pile | |

| Current load | |

| Drag force | |

| Inertial force | |

| Landslide load | |

| Wave load | |

| Wind load on blades | |

| Wind load on tower | |

| Monopile buried depth | |

| Total load | |

| Vertical load | |

| Residual | |

| Wave speed | |

| Cut-in wind speed | |

| Cut-out wind speed | |

| Volume of drainage per unit of cylinder height | |

| Standard height | |

| Shear rate of the near-pile slurry | |

| Friction angle of the pile–soil interface in the critical state | |

| Component of strain | |

| Debris flow density of submarine landslides | |

| Density of air | |

| Density of pile | |

| Density of seawater | |

| Principal stress | |

| Medium principal stress | |

| Normal effective stress | |

| Component of stress | |

| Shear stress of the contact surface | |

| Poisson’s ratio of pile | |

| Impact height of submarine landslides | |

| Rated wind speed | |

| Projected area per unit beam height perpendicular to the wave propagation direction | |

| Diameter of a monopile | |

| Elastic modulus | |

| Internal force of the finite element node | |

| Pile length | |

| Moment | |

| External load on the finite element node | |

| Shear force | |

| Wind speed | |

| Average wind speed | |

| Cohesion intercept | |

| Iteration | |

| Earth reaction force | |

| Displacement correction | |

| Displacement of the node | |

| Flow velocity of the landslide | |

| Wind shear index | |

| Debris flow viscosity | |

| Shear stress | |

| Poisson’s ratio | |

| Internal friction angle | |

| Dilation angle |

References

- Esteban, M.D.; Diez, J.J.; López, J.S.; Negro, V. Why offshore wind energy? Renew. Energy 2011, 36, 444–450. [Google Scholar] [CrossRef]

- Zhang, J.H.; Hao, W. Development of offshore wind power and foundation technology for offshore wind turbines in China. Ocean Eng. 2022, 266, 113256. [Google Scholar] [CrossRef]

- Soares-Ramos, E.P.P.; De Oliveira-Assis, L.; Sarrias-Mena, R.; Fernández-Ramírez, L.M. Current status and future trends of offshore wind power in Europe. Energy 2020, 202, 117787. [Google Scholar] [CrossRef]

- Simoncelli, M.; Zucca, M.; Ghilardi, M. Structural health monitoring of an onshore steel wind turbine. J. Civ. Struct. Health Monit. 2024, 1–15. [Google Scholar] [CrossRef]

- Global Wind Energy Council. Global offshore Wind Report 2023. Available online: https://gwec.net/gwecs-global-offshore-wind-report-2023/ (accessed on 28 August 2023).

- Xie, M.; Lopez-Querol, S. Numerical simulations of the monotonic and cyclic behaviour of offshore wind turbine monopile foundations in clayey soils. J. Mar. Sci. Eng. 2021, 9, 1036. [Google Scholar] [CrossRef]

- Chen, Y.; Gu, M.; Chen, R.; Kong, L.; Zhang, Z.; Bian, X. Behavior of pile group with elevated cap subjected to cyclic lateral loads. China Ocean Eng. 2015, 29, 565–578. [Google Scholar] [CrossRef]

- Zeng, X.; Shi, W.; Michailides, C.; Zhang, S.; Li, X. Numerical and experimental investigation of breaking wave forces on a monopile-type offshore wind turbine. Renew. Energy 2021, 175, 501–519. [Google Scholar] [CrossRef]

- Shi, Y.; Yao, W.; Jiang, M. Dynamic analysis on monopile supported offshore wind turbine under wave and wind load. Structures 2023, 47, 520–529. [Google Scholar] [CrossRef]

- Miles, J.; Martin, T.; Goddard, L. Current and wave effects around windfarm monopile foundations. Coast. Eng. 2017, 121, 167–178. [Google Scholar] [CrossRef]

- Ong, M.C.; Li, H.; Leira, B.J.; Myrhaug, D. Dynamic analysis of offshore monopile wind turbine including the effects of wind-wave loading and soil properties. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Nantes, France, 9–14 June 2013; Volume 55423. [Google Scholar]

- Buljac, A.; Kozmar, H.; Yang, W.; Kareem, A. Concurrent wind, wave and current loads on a monopile-supported offshore wind turbine. Eng. Struct. 2022, 255, 113950. [Google Scholar] [CrossRef]

- Achmus, M.; Kuo, Y.S.; Abdel-Rahman, K. Behavior of monopile foundations under cyclic lateral load. Comput. Geotech. 2009, 36, 725–735. [Google Scholar] [CrossRef]

- Wu, T.; Lu, Z.; Dou, D. Model Tests and Finite Element Analysis of Behaviors of Ocean and Offshore Elevated Piles under Lateral Load. Sci. Technol. Eng. 2013, 13, 7697–7702. (In Chinese) [Google Scholar]

- Guo, X.; Liu, X.; Li, M.; Lu, Y. Lateral force on buried pipelines caused by seabed slides using a CFD method with a shear interface weakening model. Ocean. Eng. 2023, 280, 114663. [Google Scholar] [CrossRef]

- Rafiei, A.; Rahman, M.S.; Gabr, M.A.; Ghayoomi, M. Analysis of wave-induced submarine landslides in nearly saturated sediments at intermediate water depths. Mar. Georesources Geotechnol. 2022, 40, 1411–1423. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Zhang, H.; Guo, X. Susceptibility of typical marine geological disasters: An overview. Geoenvironmental. Disasters 2023, 10, 10. [Google Scholar] [CrossRef]

- Guo, X.; Fan, N.; Liu, Y.; Liu, X.; Wang, Z.; Xie, X.; Jia, Y. Deep seabed mining: Frontiers in engineering geology and environment. Int. J. Coal Sci. Technol. 2023, 10, 23. [Google Scholar] [CrossRef]

- Guo, X.; Liu, X.; Zheng, T.; Zhang, H.; Lu, Y.; Li, T. A mass transfer-based LES modelling methodology for analyzing the movement of submarine sediment flows with extensive shear behavior. Coast. Eng. 2024, 191, 104531. [Google Scholar] [CrossRef]

- Guo, X.; Fan, N.; Zheng, D.; Fu, C.; Wu, H.; Zhang, Y.; Song, X.; Nian, T. Predicting impact forces on pipelines from deep-sea fluidized slides: A comprehensive review of key factors. Int. J. Min. Sci. Technol. 2024, 34, 211–225. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, D.; Guo, X.; Gu, Z.; Shen, Y.; Nian, T. Investigation of offshore landslides impact on bucket foundations using a coupled SPH–FEM method. Geoenvironmental. Disasters 2024, 11, 2. [Google Scholar] [CrossRef]

- Guo, X.; Stoesser, T.; Zheng, D.; Luo, Q.; Liu, X.; Nian, T. A methodology to predict the run-out distance of submarine landslides. Comput. Geotech. 2023, 153, 105073. [Google Scholar] [CrossRef]

- Mohrig, D.; Ellis, C.; Parker, G.; Kelin, X.; Midhat, H. Hydroplaning of subaqueous debris flows. Geol. Soc. Am. Bull. 1998, 110, 387–394. [Google Scholar] [CrossRef]

- Guo, X.; Nian, T.; Stoesser, T. Using dimpled-pipe surface to reduce submarine landslide impact forces on pipelines at different span heights. Ocean. Eng. 2022, 244, 110343. [Google Scholar] [CrossRef]

- De Blasio, F.V.; Elverhøi, A.; Issler, D.; Harbitz, C.B.; Bryn, P.; Lien, R. Flow models of natural debris flows originating from overconsolidated clay materials. Mar. Geol. 2004, 213, 439–455. [Google Scholar] [CrossRef]

- Hsu, S.K.; Kuo, J.; Chung-Liang, L.; Ching-Hui, T.; Doo, W.B.; Ku, C.Y.; Sibuet, J.C. Turbidity currents, submarine landslides and the 2006 Pingtung earthquake off SW Taiwan. TAO Terr. Atmos. Ocean. Sci. 2008, 19, 7. [Google Scholar] [CrossRef]

- Li, D.L.; Yan, E.C.; Feng, B. Impact of submarine debris flow on offshore piles. J. Zhejiang Univ. Eng. Sci. 2019, 53, 2342–2347. (In Chinese) [Google Scholar]

- Li, R.Y.; Chen, J.J.; Liao, C.C. Numerical study on interaction between submarine landslides and a monopile using CFD techniques. J. Mar. Sci. Eng. 2021, 9, 736. [Google Scholar] [CrossRef]

- Xi, R.; Du, X.; Wang, P.; Xu, C.; Zhai, E.; Wang, S. Dynamic analysis of 10 MW monopile supported offshore wind turbine based on fully coupled model. Ocean. Eng. 2021, 234, 109346. [Google Scholar] [CrossRef]

- Bisoi, S.; Haldar, S. Dynamic analysis of offshore wind turbine in clay considering soil–monopile–tower interaction. Soil Dyn. Earthq. Eng. 2014, 63, 19–35. [Google Scholar] [CrossRef]

- Arany, L.; Bhattacharya, S.; Macdonald, J.; Hogan, S.J. Design of monopiles for offshore wind turbines in 10 steps. Soil Dyn. Earthq. Eng. 2017, 92, 126–152. [Google Scholar] [CrossRef]

- Frohboese, P.; Schmuck, C.; Hassan, G.G. Thrust coefficients used for estimation of wake effects for fatigue load calculation. In Proceedings of the European Wind Energy Conference, Berlin, Germany, 23–24 November 2010; pp. 1–10. [Google Scholar]

- Charlton, T.S.; Rouainia, M. Geotechnical fragility analysis of monopile foundations for offshore wind turbines in extreme storms. Renew. Energy 2022, 182, 1126–1140. [Google Scholar] [CrossRef]

- JTG/T 3360-01—2018; Recommend Profession Standard of the People’s Republic of China, Code for Wind Resistance Design of Highway Bridges. People’s Communications Press: Beijing, China, 2016. Available online: https://xxgk.mot.gov.cn/2020/jigou/glj/202006/t20200623_3313096.html (accessed on 1 March 2019).

- NB/T 10105-2018; Energy Industry Recommended Standard of the People’s Republic of China, Code for Basic Design of Wind Turbines for Offshore Wind Farm Projects. China Water Power Press: Beijing, China, 2018. Available online: https://www.chinesestandard.net/PDF/English.aspx/NBT10105-2018 (accessed on 25 December 2018).

- Morison, J.R.; Johnson, J.W.; Schaaf, S.A. The force exerted by surface waves on piles. J. Pet. Technol. 1950, 2, 149–154. [Google Scholar] [CrossRef]

- JTS 145-2015; Profession Standard of the People’s Republic of China, Code of Hydrology for Harbour. China Communications Press: Beijing, China, 1998; pp. 77–78. Available online: https://xxgk.mot.gov.cn/2020/jigou/syj/202006/t20200623_3313586.html (accessed on 31 August 2015).

- Zhang, C.; Tang, G.; Lu, L.; Jin, Y.; An, H.; Cheng, L. Flow-induced vibration of two tandem square cylinders at low Reynolds number: Transitions among vortex-induced vibration, biased oscillation and galloping. J. Fluid Mech. 2024, 986, A10. [Google Scholar] [CrossRef]

- Feng, B.; Sun, H.L.; Cai, Y.Q. Experimental study of submarine landslide impact on offshore wind power piles. Ocean. Eng. 2019, 37, 114–121. (In Chinese) [Google Scholar]

- Herschel, W.H.; Bulkley, R. Konsistenzmessungen von gummi-benzollösungen. Kolloid-Zeitschrift 1926, 39, 291–300. [Google Scholar] [CrossRef]

- Reese, L.C.; van Impe, W. Derivation of equations and methods of solution. In Book Single Piles and Pile Groups under Lateral Loading, 2nd ed.; Taylor and Francis: Abingdon, UK, 2001; pp. 23–24. [Google Scholar]

- Abbas, J.M.; Chik, Z.H.; Taha, M.R. Single pile simulation and analysis subjected to lateral load. Electron. J. Geotech. Eng. 2008, 13, 1–15. [Google Scholar]

- Johnson, K.; Lemcke, P.; Karunasena, W.; Sivakugan, N. Modelling the load–deformation response of deep foundation under oblique loading. Environ. Model. Softw. 2006, 21, 1375–1380. [Google Scholar] [CrossRef]

- Hu, Q.; Han, F.; Prezzi, M.; Salgado, R.; Zhao, M. Lateral load response of large-diameter monopiles in sand. Géotechnique 2022, 72, 1035–1050. [Google Scholar] [CrossRef]

- Liu, H.J.; Sun, P.P.; Geng, H.R.; Hao, R. Horizontal bearing capacity of offshore wind power pile foundation under different sea conditions and geological conditions. Period. Ocean. Univ. China 2019, 8, 51–58. (In Chinese) [Google Scholar]

- Dai, S.; Han, B.; Wang, B.; Luo, J.; He, B. Influence of soil scour on lateral behavior of large-diameter offshore wind-turbine monopile and corresponding scour monitoring method. Ocean. Eng. 2021, 239, 109809. [Google Scholar] [CrossRef]

- Zhang, X.L.; Liu, J.X.; Han, Y.; Du, X.L. A framework for evaluating the bearing capacity of offshore wind power foundation under complex loadings. Appl. Ocean Res. 2018, 80, 66–78. [Google Scholar] [CrossRef]

- DNV GL, DNVGL-ST-0126 Support Structures for Wind Turbines, 2018. Edition July 2018. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-st-0126-support-structures-for-wind-turbines (accessed on 1 December 2021).

- Takahashi, T. Mechanical characteristics of debris flow. J. Hydraul. Div. 1978, 104, 1153–1169. [Google Scholar] [CrossRef]

- Laberg, J.S.; Vorren, T.O. A late Pleistocene submarine slide on the Bear Island trough mouth fan. Geo-Mar. Lett. 1993, 13, 227–234. [Google Scholar] [CrossRef]

- Wang, X.F.; Yu, H.G. The experience relationship between the state and the direct shear test index about marine facies clayed soil. In Proceedings of the National Engineering Geology Academic Conference and “Engineering Geology and West Coast Construction” Academic Conference, Fujian, China, 17 November 2013; Volume 5. (In Chinese). [Google Scholar]

| Load Type | Force/N | Distance between the Action Point and the Pile Head/m |

|---|---|---|

| 205,319 | 52.3 | |

| 16,080 | 27.7 | |

| 54,557 | −2.5 | |

| 31,145 | −5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Shan, Z.; Wang, W.; Xu, S.; Liu, X.; Zhang, H.; Guo, X. Numerical Investigation into the Stability of Offshore Wind Power Piles Subjected to Lateral Loads in Extreme Environments. J. Mar. Sci. Eng. 2024, 12, 915. https://doi.org/10.3390/jmse12060915

Sun M, Shan Z, Wang W, Xu S, Liu X, Zhang H, Guo X. Numerical Investigation into the Stability of Offshore Wind Power Piles Subjected to Lateral Loads in Extreme Environments. Journal of Marine Science and Engineering. 2024; 12(6):915. https://doi.org/10.3390/jmse12060915

Chicago/Turabian StyleSun, Miaojun, Zhigang Shan, Wei Wang, Simin Xu, Xiaolei Liu, Hong Zhang, and Xingsen Guo. 2024. "Numerical Investigation into the Stability of Offshore Wind Power Piles Subjected to Lateral Loads in Extreme Environments" Journal of Marine Science and Engineering 12, no. 6: 915. https://doi.org/10.3390/jmse12060915