Combining Lightness and Stiffness through Composite-Reinforced Additive Manufacturing in the Yacht Industry: Case Study Analysis and Application on Large Functional Components

Abstract

:1. Introduction

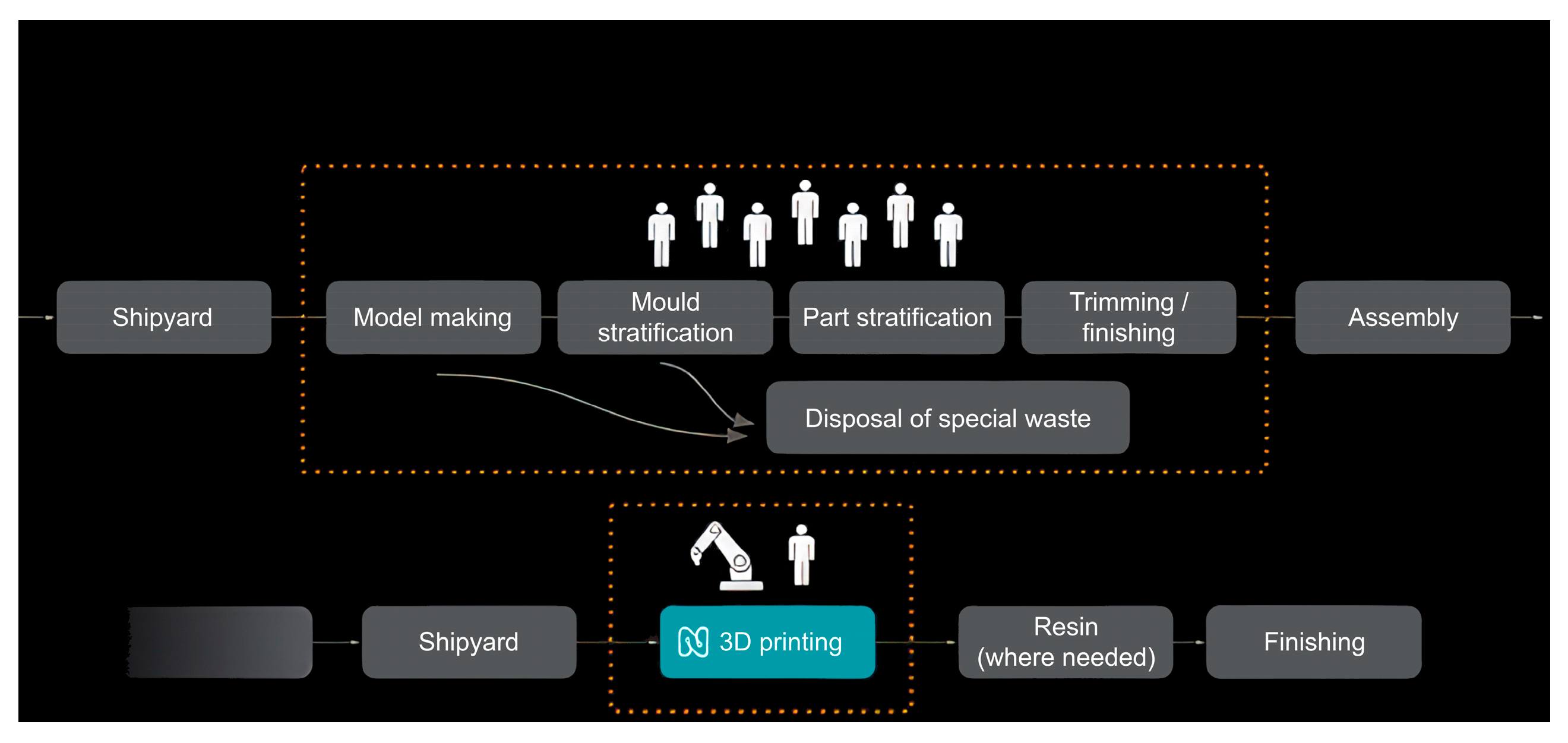

2. Materials and Methods: Description of the Technology Used

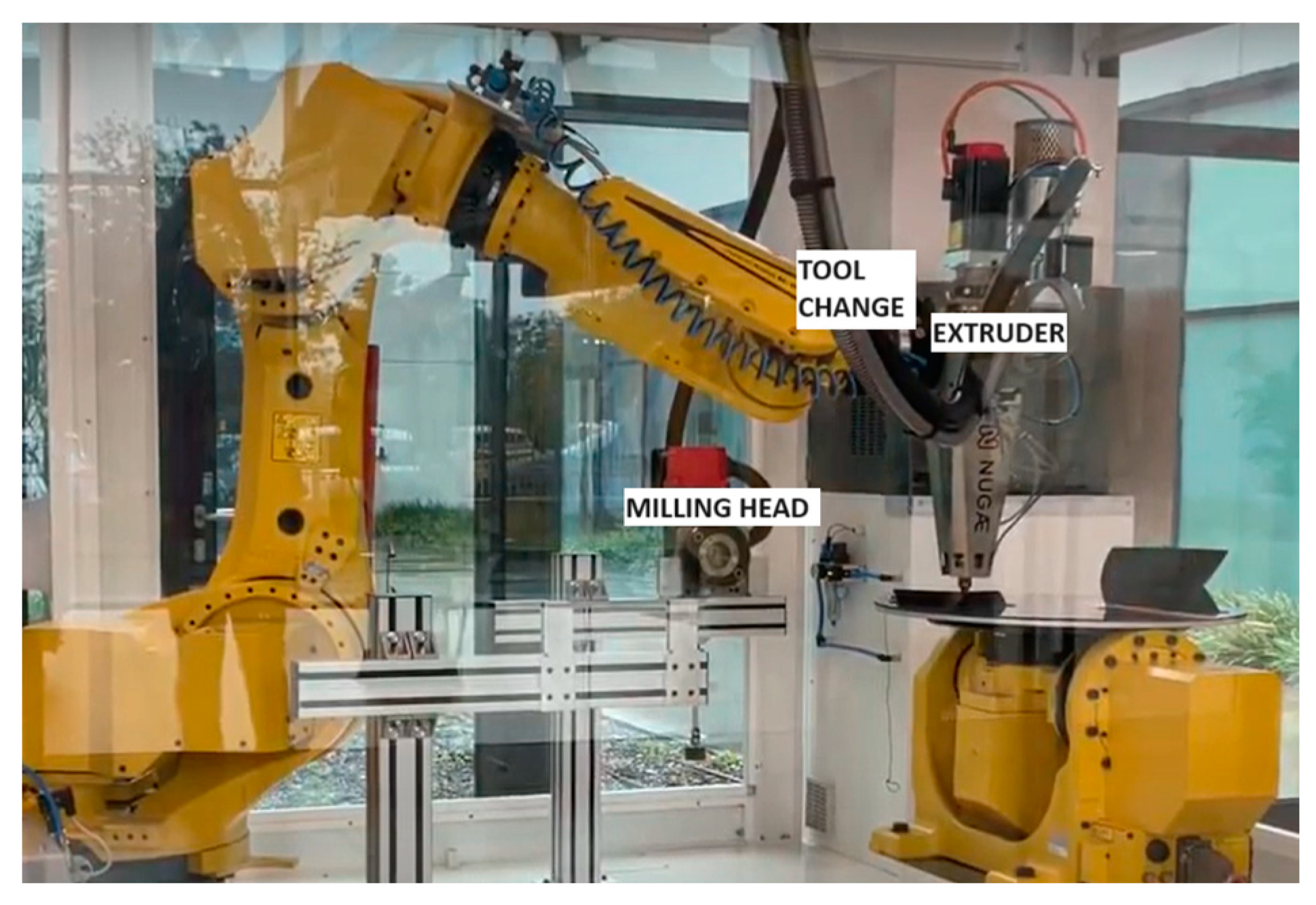

2.1. The Robot

2.2. The Strategic Approach

2.3. The Software

2.4. Materials

3. Results of Case Studies

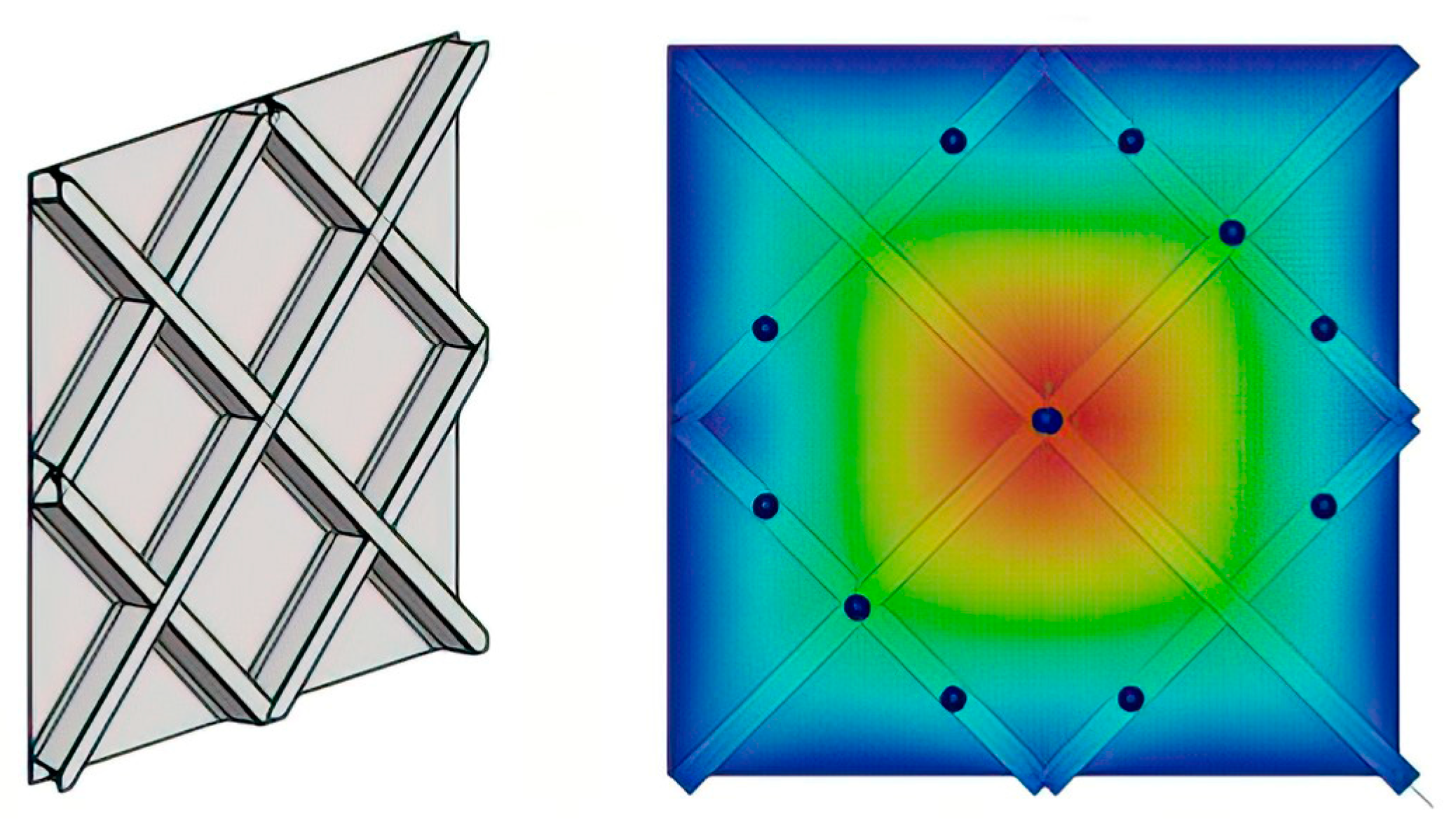

3.1. Case Study 1: 3D-Printed Fibreglass Structural Panels

3.1.1. Objective

3.1.2. Methodology

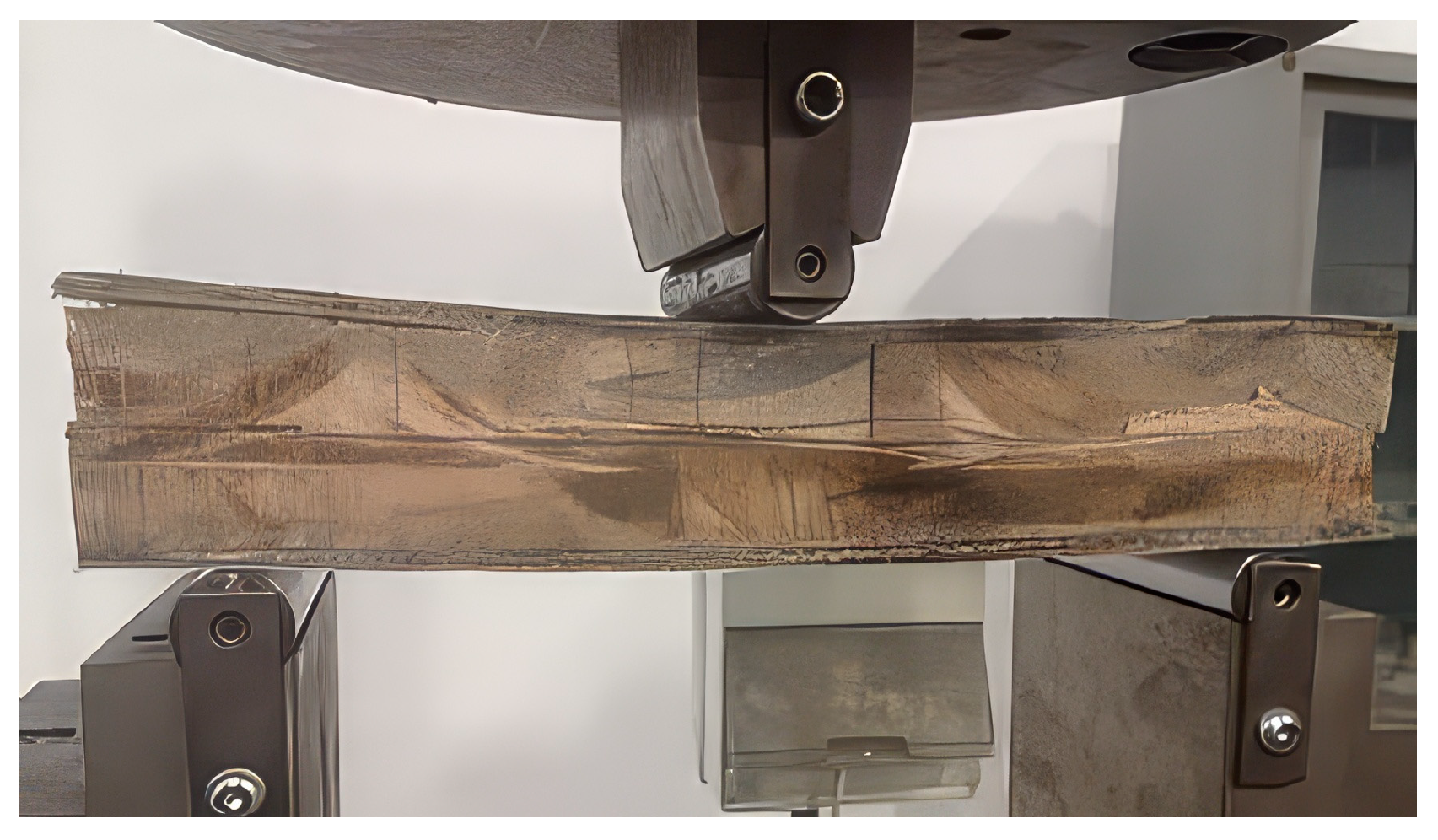

- Three-point bending tests were performed following ASTM C393 standards on scaled-down test specimens (250 × 100 mm), involving three sets of specimens: (a) two samples derived from the Type B balsa sandwich panel, (b) two 3D-printed ribs vacuum-bag-laminated with polyester resin and glass fibre, and (c) two 3D-printed ribs vacuum-bag-laminated with epoxy resin and glass fibre;

- Finite element method (FEM) models were calibrated based on the data obtained from the tests in step 1, establishing the engineering constants for both the balsa core of the balsa sandwich panels and the thermoplastic core of the prototype panels;

- FEM simulations of a large-scale three-point bending test were conducted on the Type B balsa sandwich panel (1150 × 565 × 47 mm), and FEM simulations were performed to design a prototype panel of comparable size and stiffness (1150 × 565 × 85 mm);

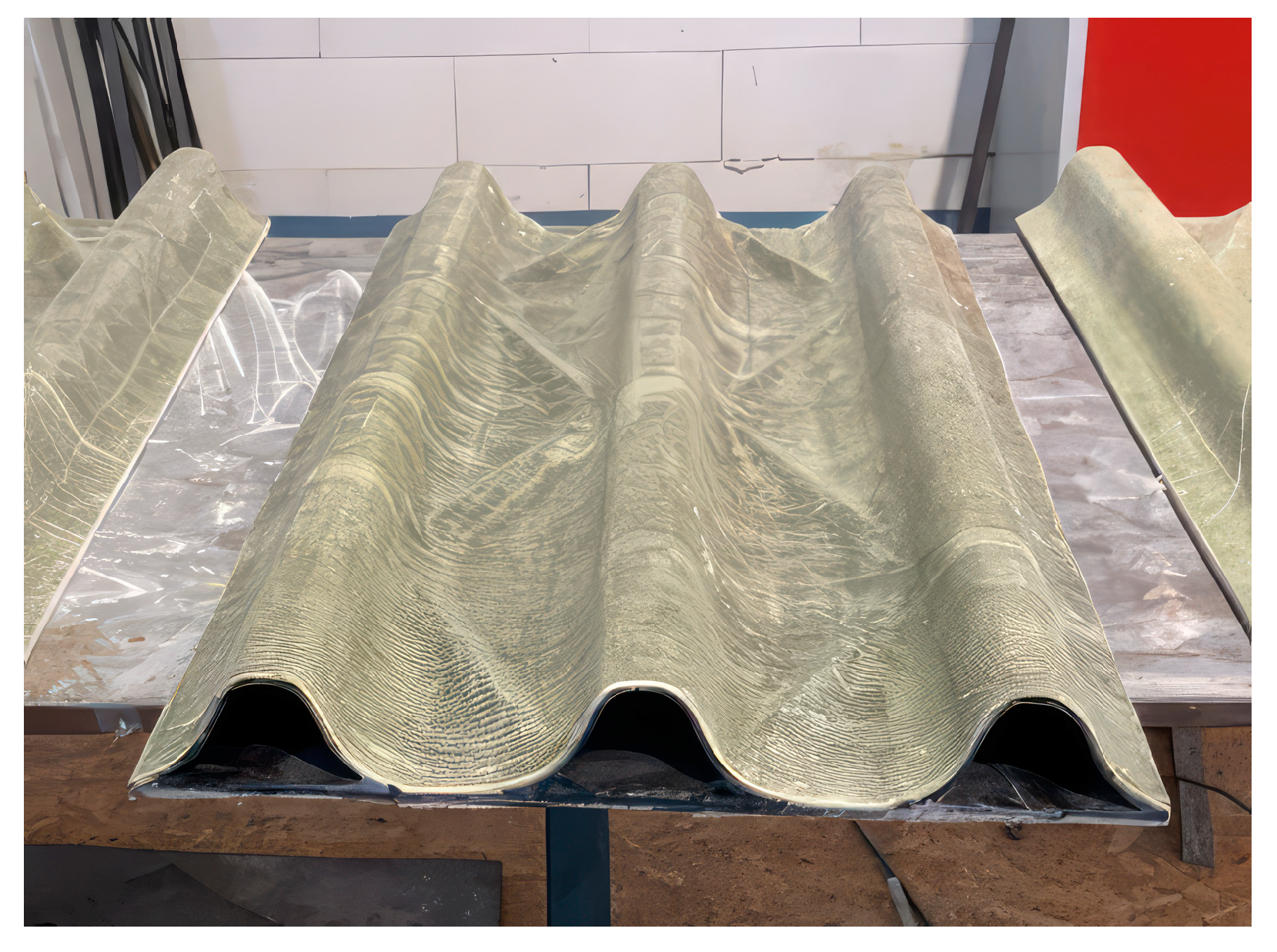

- Two composite panels with thermoplastic cores (1150 × 565 × 85 mm) were manufactured, vacuum-bag-laminated with polyester resin and glass fibre, and then dispatched to the balsa sandwich panel testing laboratory;

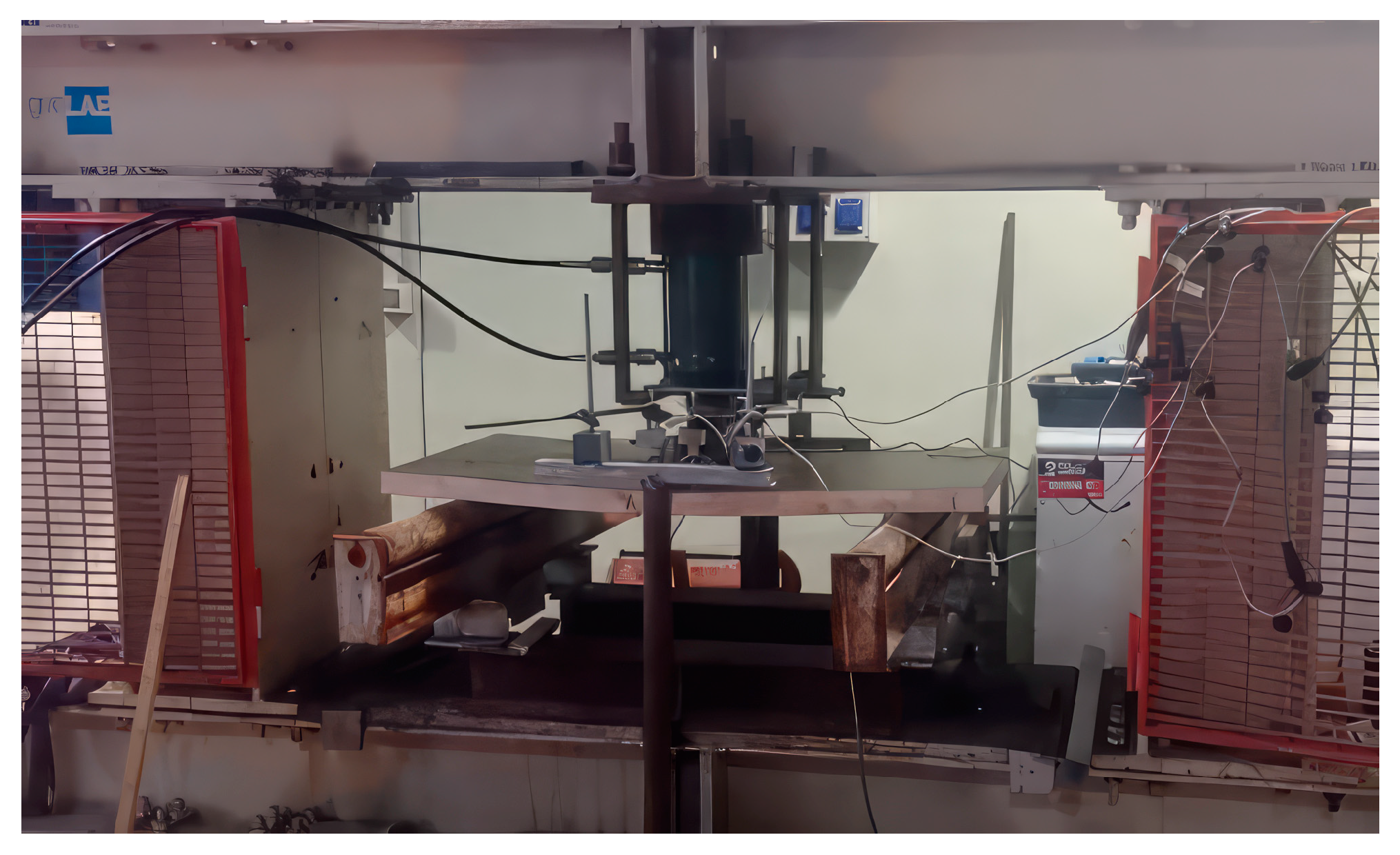

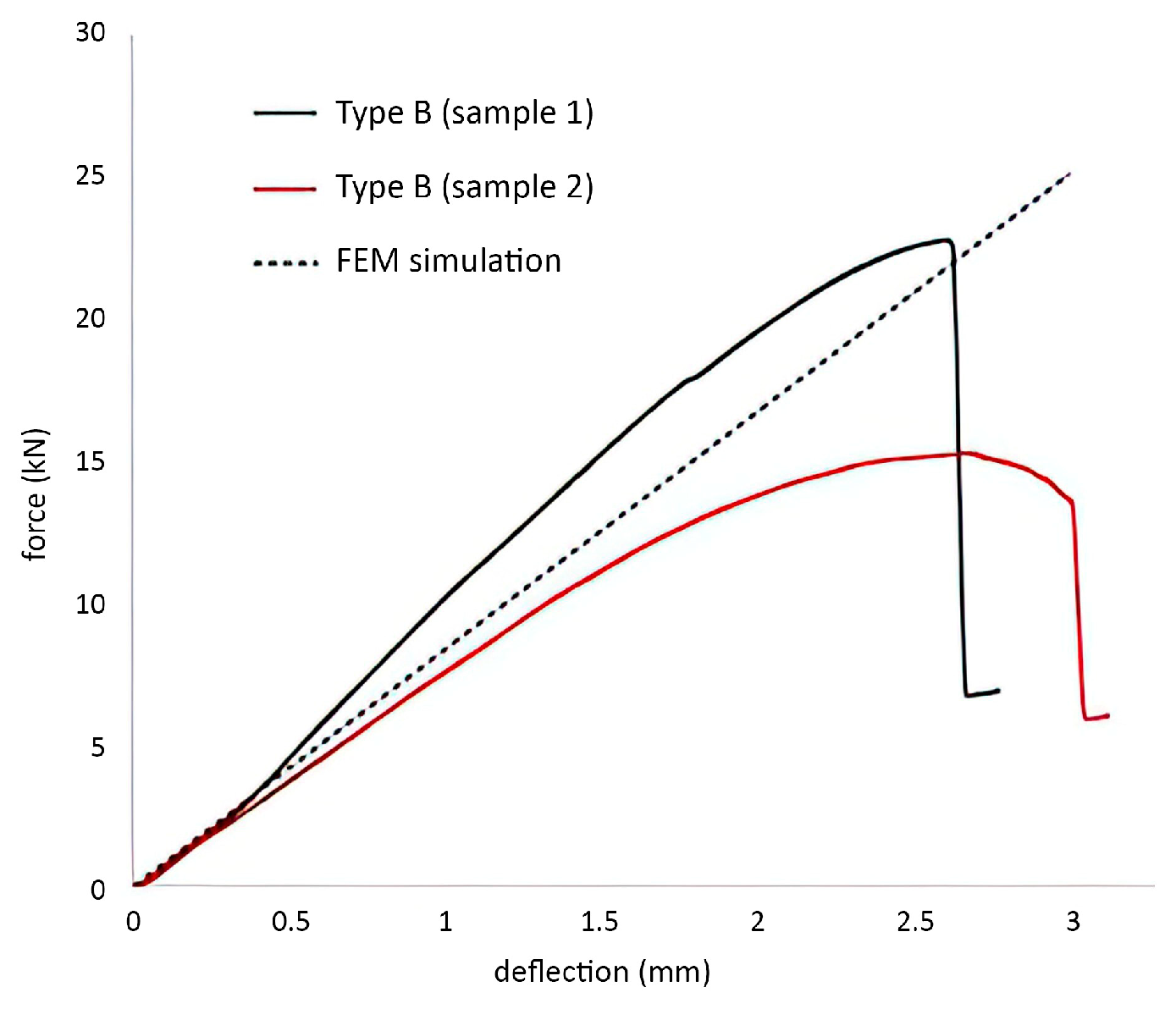

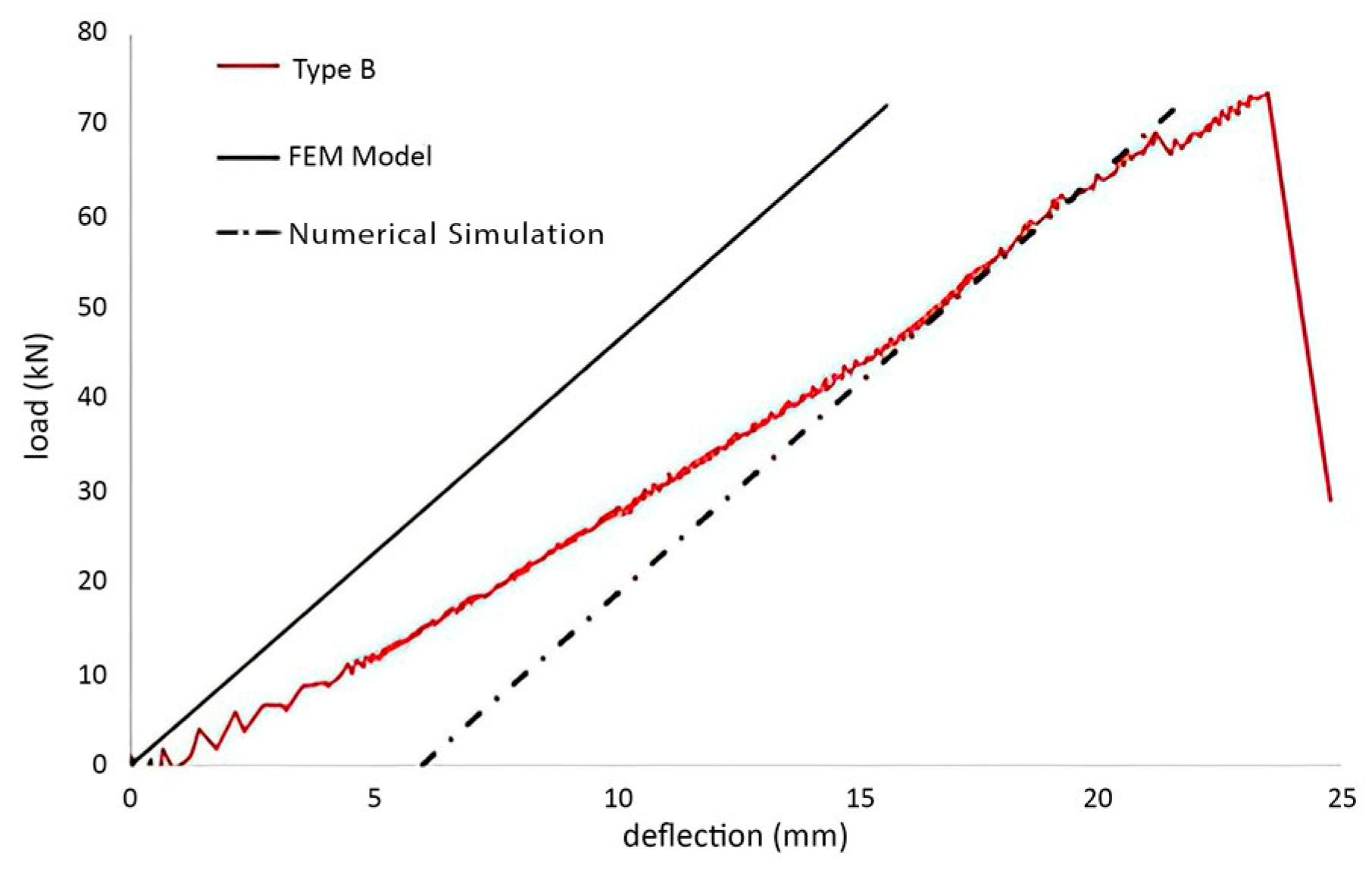

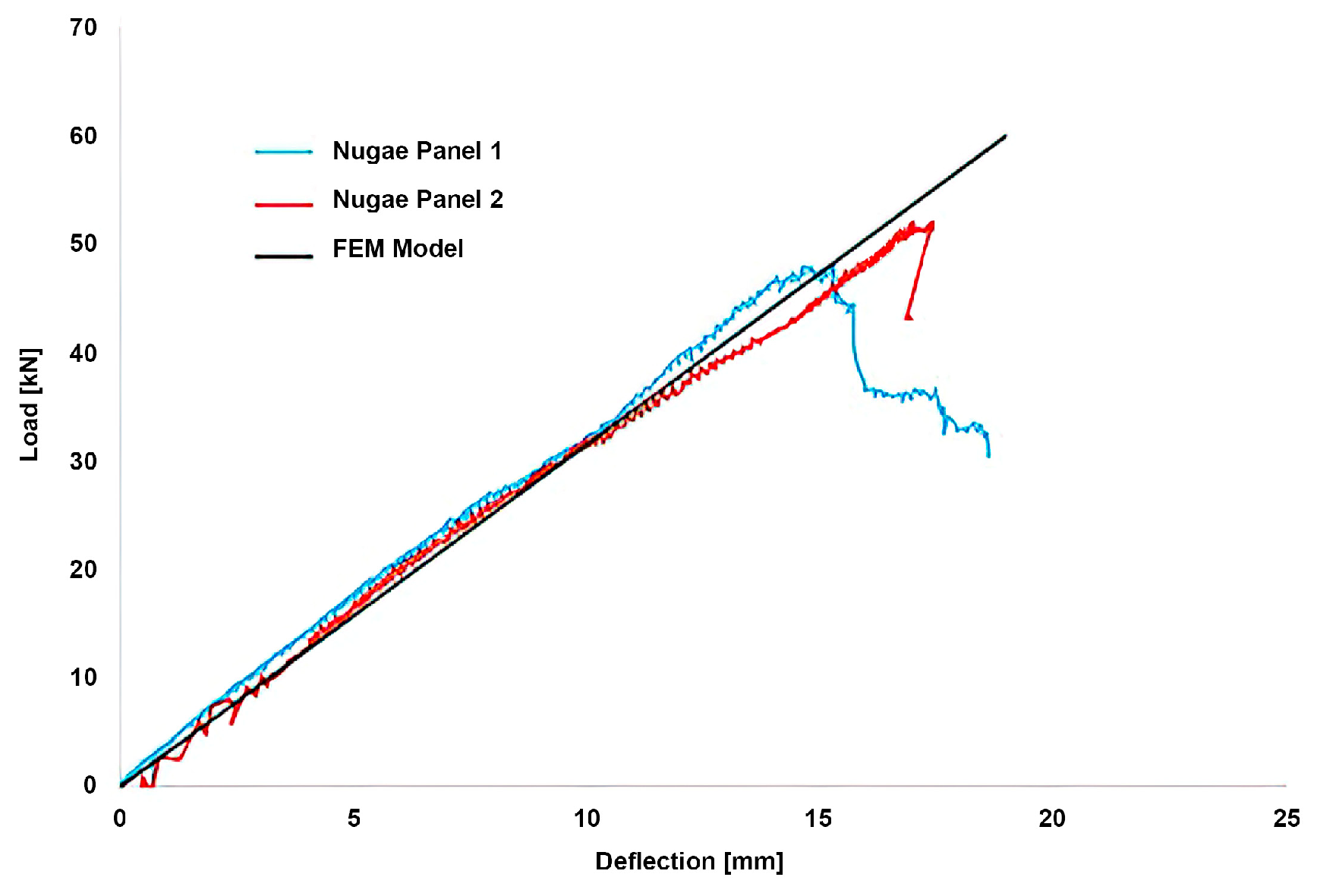

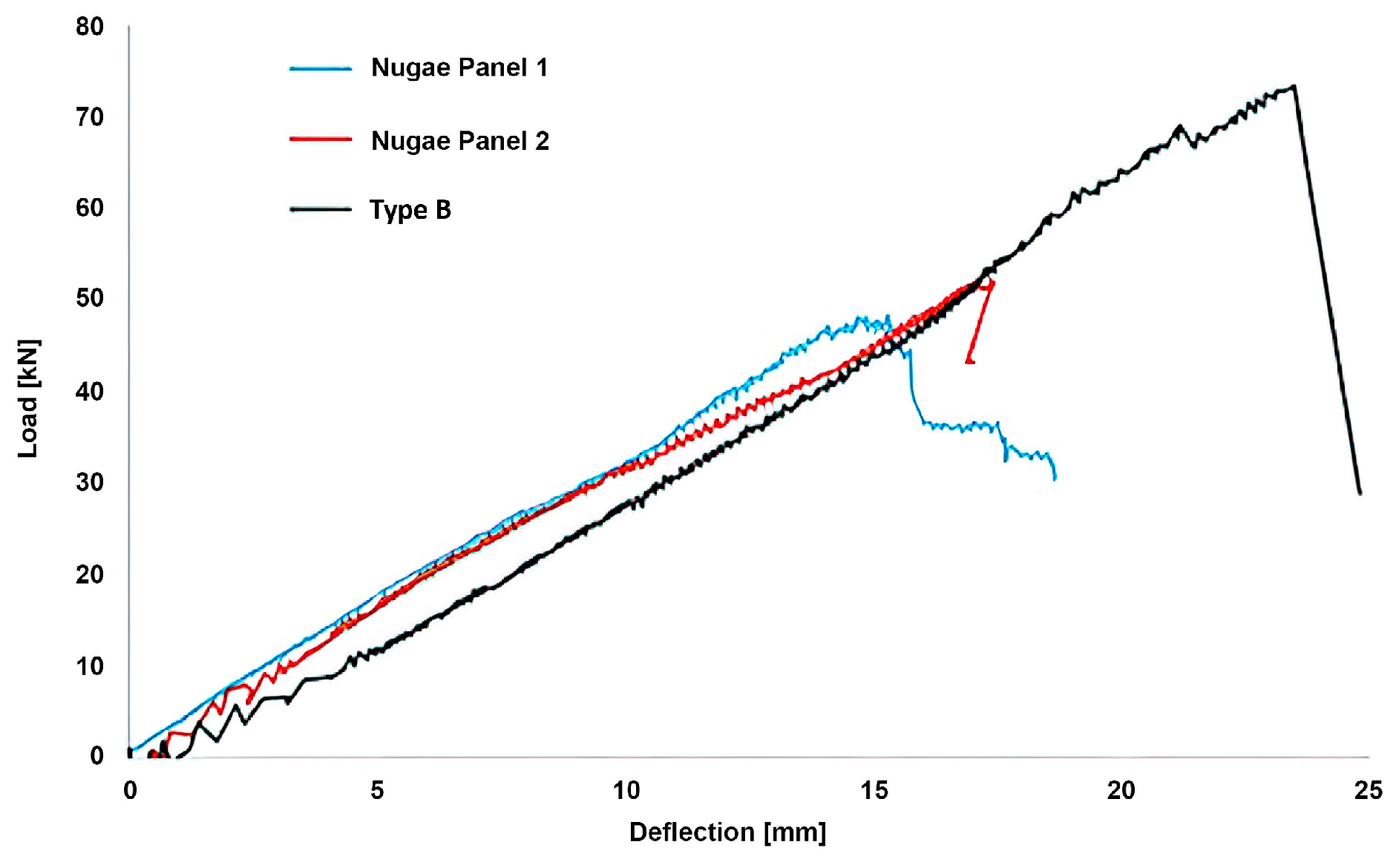

- A large-scale three-point bending test was carried out on the Type B balsa sandwich panel (1150 × 565 × 47 mm), the FEM simulation results from step 3 were validated, and the overall stiffness of the balsa sandwich panels was redefined based on the test’s outcomes;

- The thickness of the prototype panels was reduced to 78 mm to achieve the appropriate stiffness, two 1150 × 565 × 78 mm composite panels were produced (vacuum-bag-laminated with polyester resin and glass fibre), a large-scale three-point bending test was conducted on these newly optimised panels, and the accuracy of the FEM results from step 3 was confirmed.

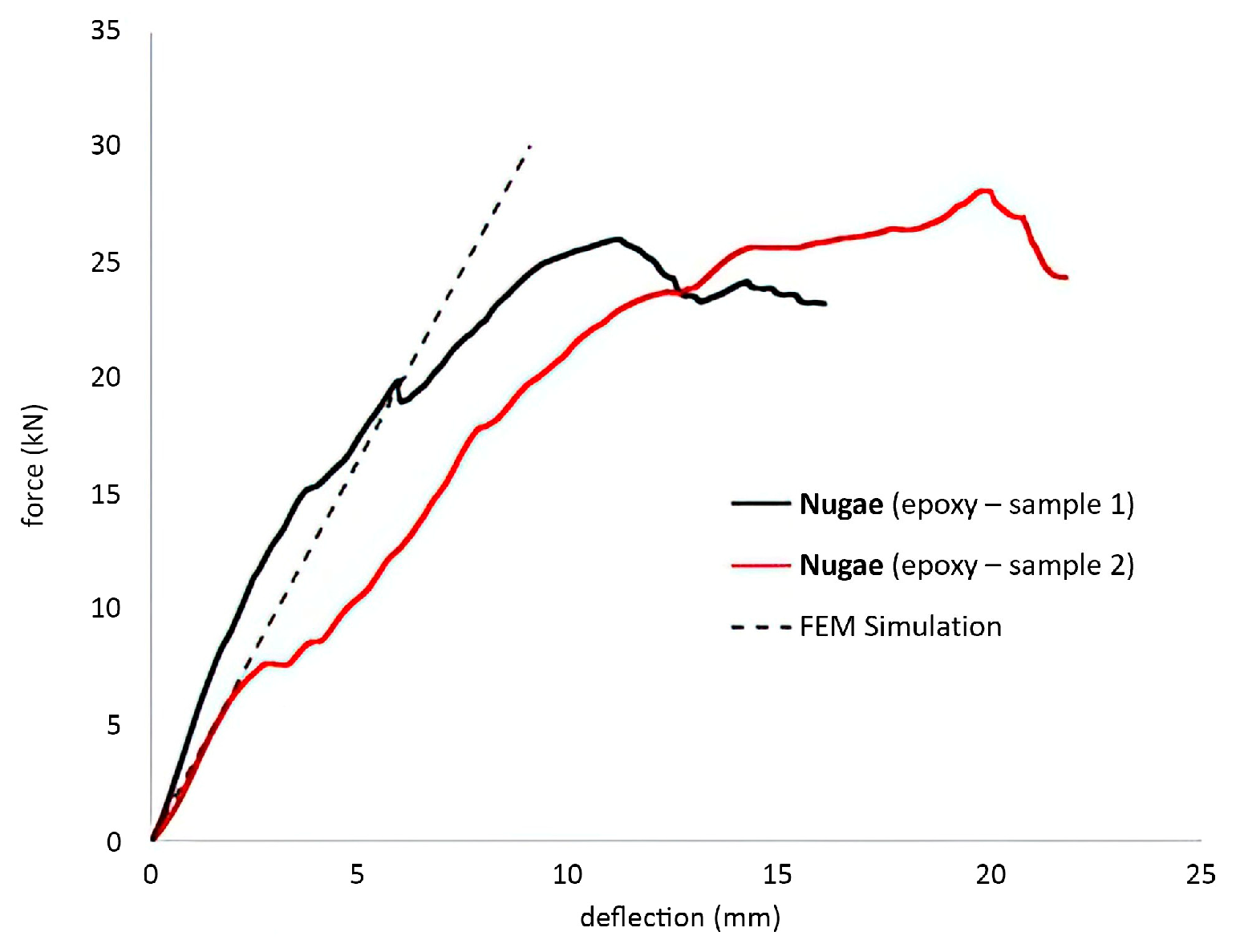

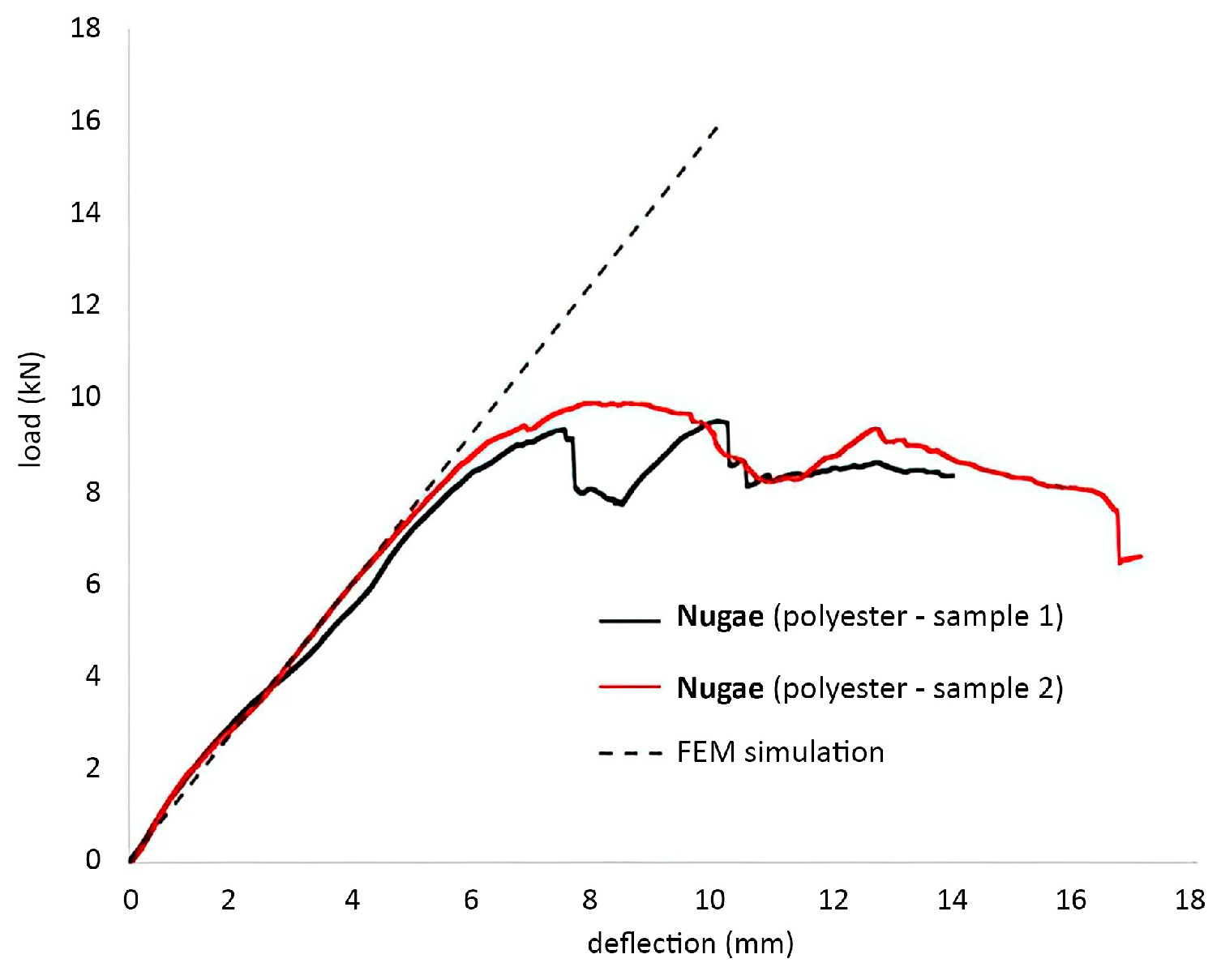

3.1.3. Test Findings and FEM Analysis for Small Specimens (Steps 1 and 2)

- Type 1. Polyester resin and glass fibre via a two-step vacuum-bag lamination process;

- Type 2. Epoxy resin and glass fibre via a single-step vacuum-bag lamination.

3.1.4. Test Results and FEM Modelling for Large Panels (Steps 5 and 6)

3.1.5. Final Product Outcome

- Stiffness comparable to that of conventional panels;

- Approximately 10% lighter than the reference panels (about 25 kg/m2 compared to 27.5 kg/m2);

- Ultimate strength about 30% lower than that of the reference panels.

3.2. Case Study 2: RIB Windshield Design

3.2.1. Objective

3.2.2. Methodology

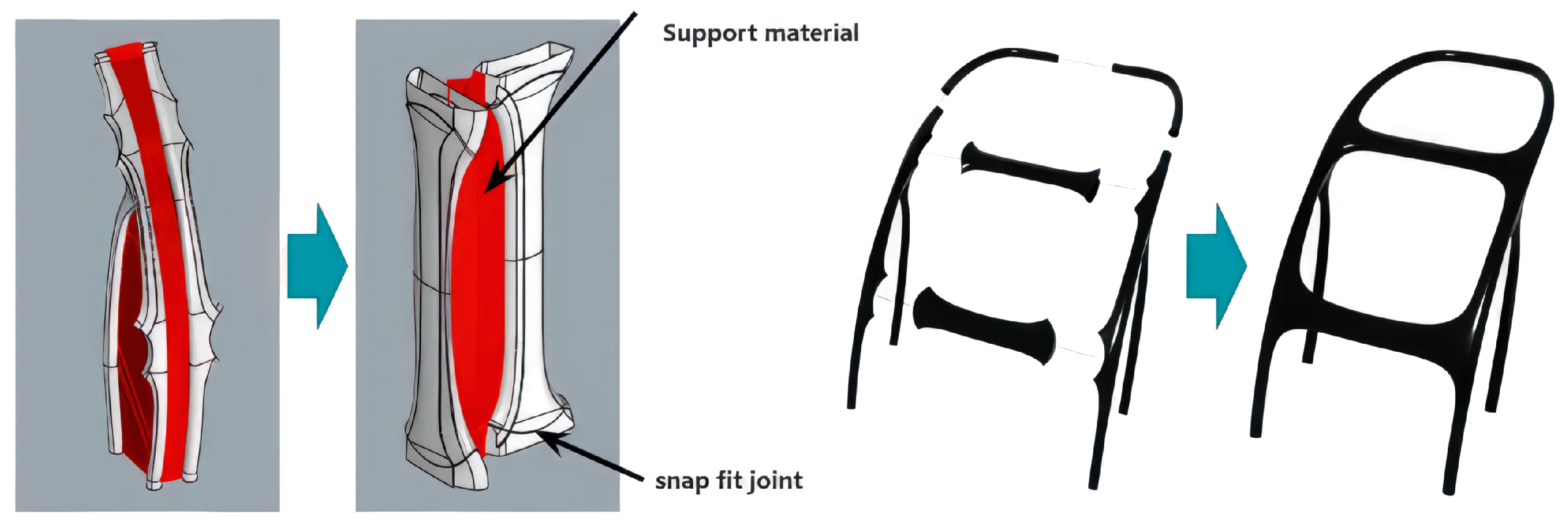

- Topological optimisation. The design of the organic structure included a division into three segments. This design focuses on topological optimisation, ensuring the structure is ergonomic and fits seamlessly with the boat’s existing console. The design incorporates irregular and interconnected tubular forms, integrating carbon fibre for strength and lightness.

- Milling of joints and eliminating support structures. The segments are designed with joints that allow them to fit together seamlessly (snap fit). These joints are milled for an optimal fit. The design process also eliminates the need for additional support flaps, which are standard in traditional AM methods.

- Application of additional fixation to base. At the end of the printing process, additional fixation to the base was applied using thermoplastic glue. Subsequently, the piece was milled with a 1 mm-deep carving at each stage while maintaining a 10 mm connection to preserve the stability and integrity of the part. These connections were manually removed in a subsequent phase.

- Preparation for single-element assembly (Figure 18). Although the structure is printed in three separate pieces, it is designed to be easily assembled into a single, cohesive unit. This modular approach allows for efficient printing and assembly.

- Focus on innovative geometries. The design involves innovative geometries that enhance the aesthetic appeal and contribute to the structure’s aerodynamic efficiency and lightness.

- Three-dimensional printing process. During printing, particular attention is given to support structures. These supports ensure stability during printing while being easy to remove afterwards, contributing to the final product’s overall lightness and clean finish.

3.2.3. Post-Printing Processes

- Lamination from the inside. As described above, the lamination step adds extra strength and weather resistance to the printed parts. The process involved inserting pre-impregnated carbon fibre sleeves around a tubular bag for internal laminating. Then, once inserted into the cavity using a probe, the sleeves were compacted against the 3D-printed part by inflating the sleeves to a pressure of 100 kPa.

- Painting. The structure was painted, likely with marine-grade paint, to match the boat’s aesthetics and provide additional protection.

- Assembly. The final step involved assembling the three printed parts into a single structure, achieving a seamless fit with the existing boat console.

- Integration with the boat. The newly printed windshield was then integrated with the boat, protecting the elements without compromising style or aerodynamics.

3.2.4. Final Product Outcome

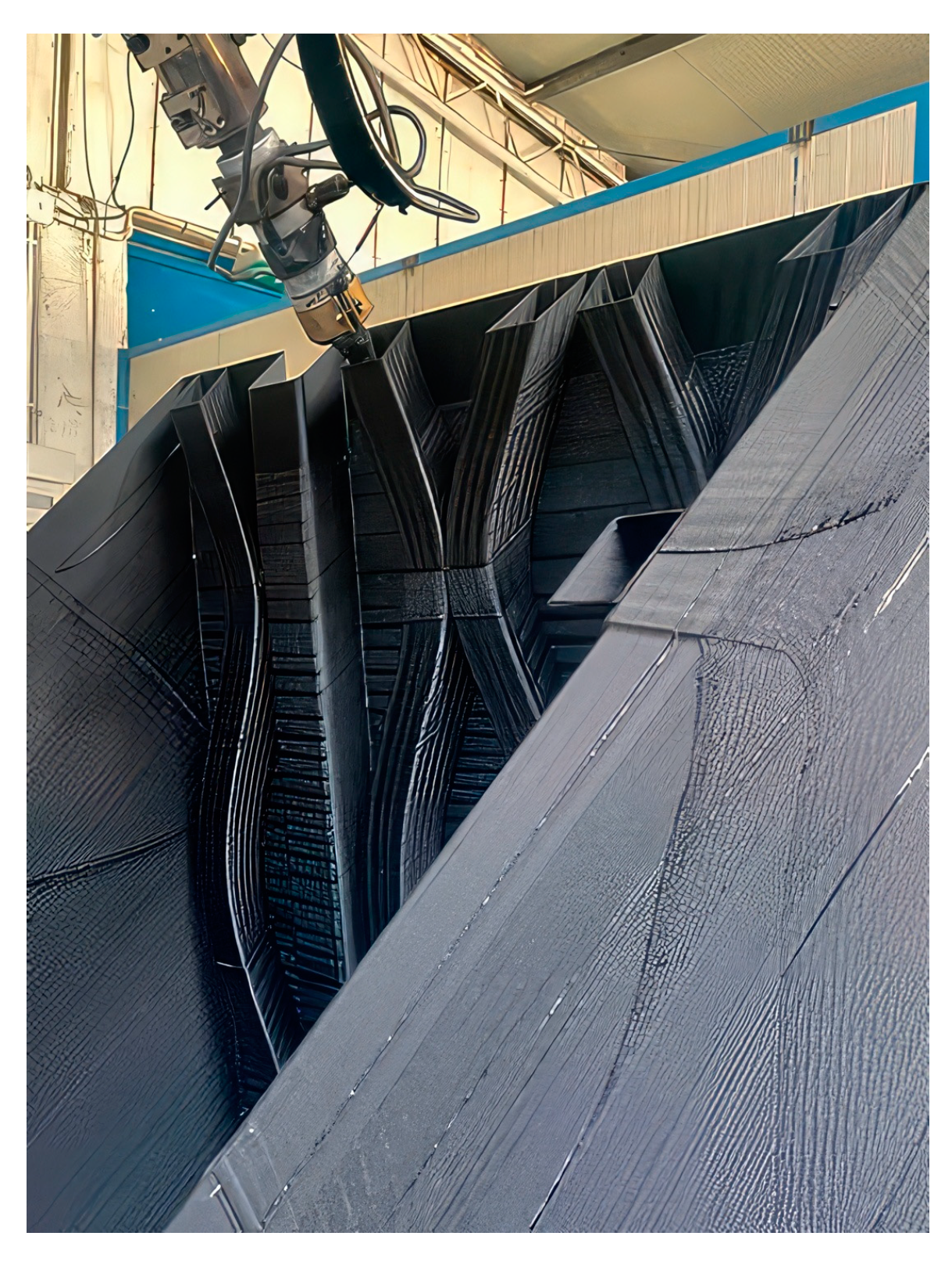

3.3. Case Study 3: Hardtop of 13 m RIB

3.3.1. Objective

3.3.2. Methodology

- Design optimisation. The hardtop was designed with careful consideration of the boat’s specifications, particularly its curved and sinuous shape, to achieve seamless integration.

- Segmentation and custom element printing. The complex design was segmented into manageable parts for efficient 3D printing and assembly. The segmentation of parts is visible in Figure 20.

- Incorporating an iso-grid system. A patented iso-grid system was utilised to enhance structural integrity and stiffness, ensuring that the final product was lightweight yet robust.

- Assembly system integration. These segments were assembled into one cohesive unit, wrapped with fibreglass, and then sanded and faired.

3.3.3. Final Product Outcome

4. Discussion

- Durability assessment. The windshield demonstrated its structural integrity under stress, such as strong waves and wind pressure.

- Performance analysis. Since the windshield was not compromised despite the rough testing conditions, qualities such as aerodynamics and stability at high speeds of the design were validated.

- Shielding verification. The windshield provided a secure boating experience since it effectively protected the boat owner from elements such as splashing water and direct sunlight.

- Longevity testing. The fact that the part was tested for an entire summer season demonstrated its ability to withstand prolonged exposure to various environmental factors, such as salt water, UV radiation, and temperature fluctuations.

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Musio-Sale, M.; Nazzaro, P.L.; Peterson, E. Visions, concepts, and applications in additive manufacturing for yacht design. Adv. Intell. Syst. Comput. 2020, 975, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Peterson, E. Technical challenges to adopting large-scale additive manufacturing for the production of yacht hulls. In Proceedings of the 3rd International Conference on Human Systems Engineering and Design (IHSED2020): Future Trends and Applications, Pula, Croatia, 22–24 September 2020. [Google Scholar] [CrossRef]

- Taş, Ş.O.; Şener, B. The use of additive manufacturing in maritime industry. Int. J. Eng. Trends Technol. 2019, 67, 47–51. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D Printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D Printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- De la Peña Zarzuelo, I.; Freire Soeane, M.J.; López Bermúdez, B. Industry 4.0 in the port and maritime industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar] [CrossRef]

- Hao, L.; Raymond, D.; Strano, G.; Dadbakhsh, S. Enhancing the Sustainability of Additive Manufacturing. In Proceedings of the 5th International Conference on Responsive Manufacturing-Green Manufacturing, ICRM 2010, Ningbo, China, 11–13 January 2010. [Google Scholar] [CrossRef]

- Ziółkowski, M.; Dyl, T. Possible applications of additive manufacturing technologies in shipbuilding: A review. Machines 2020, 8, 84. [Google Scholar] [CrossRef]

- Superfici Prints Smart Wheel. Available online: https://www.proboat.com/2020/09/superfici-prints-smart-wheel/ (accessed on 1 October 2023).

- Navigating the Best Examples of 3D Printed Boats. Available online: https://www.3dnatives.com/en/3d-printed-boats-300320214/ (accessed on 21 September 2023).

- Can 3D Printing Transform the Way Boats Are Designed and Built? Available online: https://www.boatinternational.com/yachts/yacht-design/is-3d-printing-the-future-of-yacht-design (accessed on 4 October 2023).

- Peterson, E. Recent innovations in additive manufacturing for marine vessels. Marit. Technol. Res. 2022, 4, 257491. [Google Scholar] [CrossRef]

- World’s First 3D Printed Water Taxi Is Also Largest 3D Printed Boat. Available online: https://www.3dnatives.com/en/3d-printed-water-taxi-is-worlds-largest-3d-printed-boat-201120234/ (accessed on 20 February 2024).

- Brun, A.; Karaosman, H. Customer influence on supply chain management strategies: An exploratory investigation in the yacht Industry. Bus. Process Manag. J. 2019, 25, 288–306. [Google Scholar] [CrossRef]

- Ponche, R.; Hascoet, J.Y.; Kerbrat, O.; Mognol, P. A new global approach to design for additive manufacturing. In Additive Manufacturing Handbook: Product Development for the Defense Industry; Badiru, A.B., Valencia, V.V., Liu, D., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 169–186. [Google Scholar] [CrossRef]

- Kostidi, E.; Nikitakos, N. Exploring the potential of 3D Printing of the spare parts supply chain in the maritime industry. In Proceedings of the 12th International Conference on Marine Navigation and Safety of Sea Transportation (TransNav 2017), Gdynia, Poland, 21–23 June 2017. [Google Scholar]

- Ford, P.; Dean, L. Additive manufacturing in product design education: Out with the old in and in with the new? In Proceedings of the E&PDE 2013, the 15th International Conference on Engineering and Product Design Education, Dublin, Ireland, 5–6 September 2013. [Google Scholar]

- 3D Printing in Boat Manufacturing. Available online: https://ceadgroup.com/3d-printing-in-boat-manufacturing/ (accessed on 23 April 2024).

- Post, B.K.; Chesser, P.C.; Lind, R.F.; Roschli, A.; Love, L.J.; Gaul, K.T.; Sallas, M.; Blue, F.; Wu, S. Using big area additive manufacturing to directly manufacture a boat hull mould. Virtual Phys. Prototyp. 2019, 14, 123–129. [Google Scholar] [CrossRef]

| Material | Tensile Strength [MPa] | Flexural Strength [MPa] | Flexural Strength [kJ/m2] | Heat Deflection Temperature [°C] | Max Water Absorption [%] | Ultraviolet (UV) Resistance |

|---|---|---|---|---|---|---|

| PLA | 60 | 95 | 2.5 | 57.5 | 0.25 | Low |

| ASA-PC | 100 | 115 | 25 | 105 | 0.35 | High |

| ABS | 42 | 80 | 16 | 98 | 0.6 | Moderate |

| PA 66 | 90 | 135 | 40 | 255 | 1.3 | Moderate |

| PA 12 | 52.5 | 60 | 70 | 165 | 0.25 | High |

| PC | 65 | 90 | 80 | 140 | 0.15 | High |

| Specimen Type | Quantity | Length [mm] | Width [mm] | Thickness [mm] |

|---|---|---|---|---|

| Type B | 2 | 250 | 100 | 47 |

| Type 1 | 2 | 250 | 100 | 78 |

| Type 2 | 2 | 250 | 100 | 78 |

| Number | Length [mm] | Width [mm] | Thickness [mm] | Weight [kg/m2] |

|---|---|---|---|---|

| 1 | 1150 | 565 | 47 | 27.5 |

| Quantity | Length [mm] | Width [mm] | Ribs Thickness [mm] | Ribs Width [mm] | Weight [kg/m2] |

|---|---|---|---|---|---|

| 2 | 1150 | 565 | 78 | 108 | 24–26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belvisi, F.; Piccioni, M.; Ratti, A. Combining Lightness and Stiffness through Composite-Reinforced Additive Manufacturing in the Yacht Industry: Case Study Analysis and Application on Large Functional Components. J. Mar. Sci. Eng. 2024, 12, 918. https://doi.org/10.3390/jmse12060918

Belvisi F, Piccioni M, Ratti A. Combining Lightness and Stiffness through Composite-Reinforced Additive Manufacturing in the Yacht Industry: Case Study Analysis and Application on Large Functional Components. Journal of Marine Science and Engineering. 2024; 12(6):918. https://doi.org/10.3390/jmse12060918

Chicago/Turabian StyleBelvisi, Francesco, Massimo Piccioni, and Andrea Ratti. 2024. "Combining Lightness and Stiffness through Composite-Reinforced Additive Manufacturing in the Yacht Industry: Case Study Analysis and Application on Large Functional Components" Journal of Marine Science and Engineering 12, no. 6: 918. https://doi.org/10.3390/jmse12060918

APA StyleBelvisi, F., Piccioni, M., & Ratti, A. (2024). Combining Lightness and Stiffness through Composite-Reinforced Additive Manufacturing in the Yacht Industry: Case Study Analysis and Application on Large Functional Components. Journal of Marine Science and Engineering, 12(6), 918. https://doi.org/10.3390/jmse12060918