Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber

Abstract

:1. Introduction

2. Materials and Methods

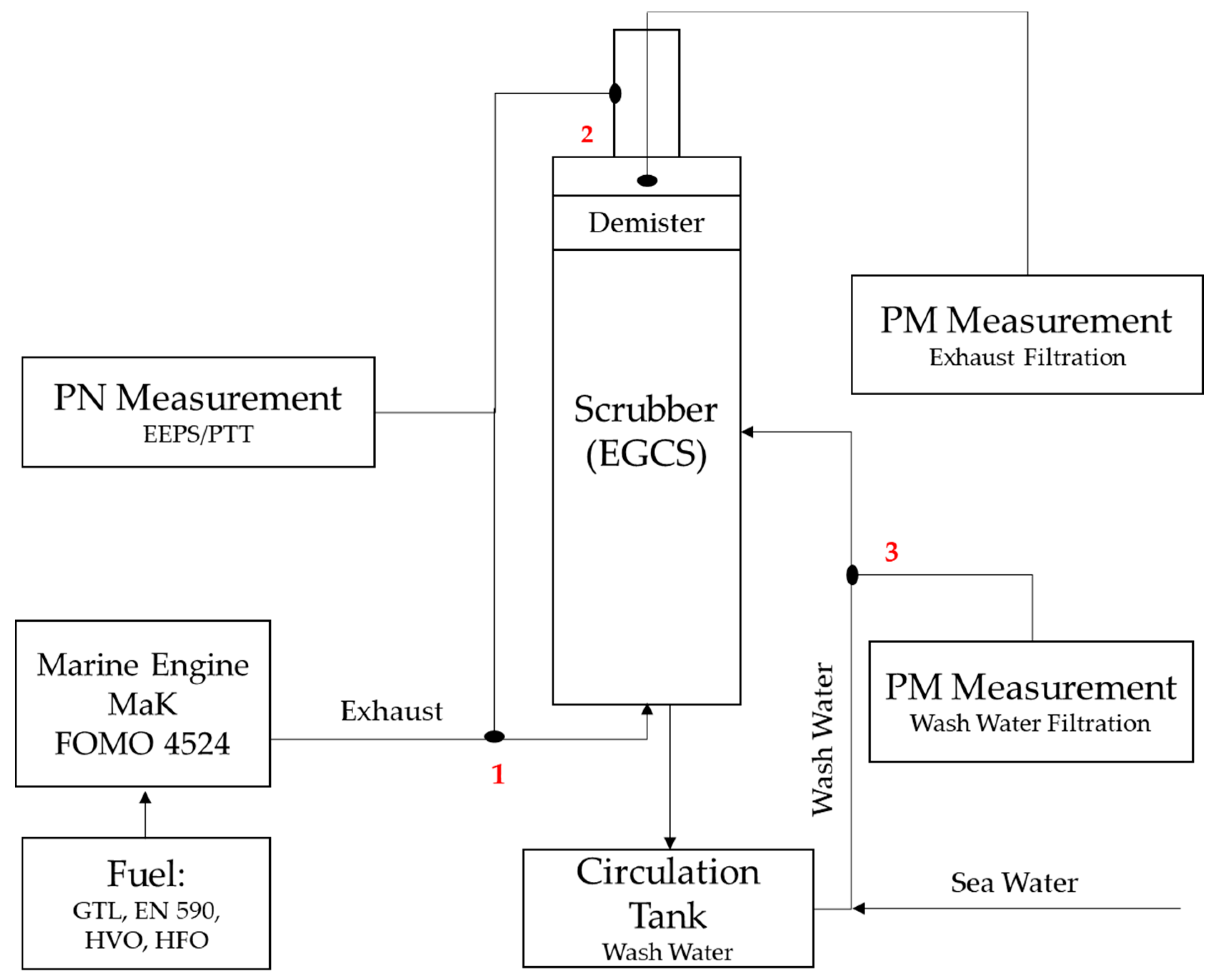

2.1. Engine and EGCS

2.2. Fuels

2.3. Measurement Setup

2.4. Particle Number Measurement in Exhaust Gas

2.5. Particle Matter Measurement in Exhaust Gas

2.6. Particle Matter Measurement in Wash Water

3. Results

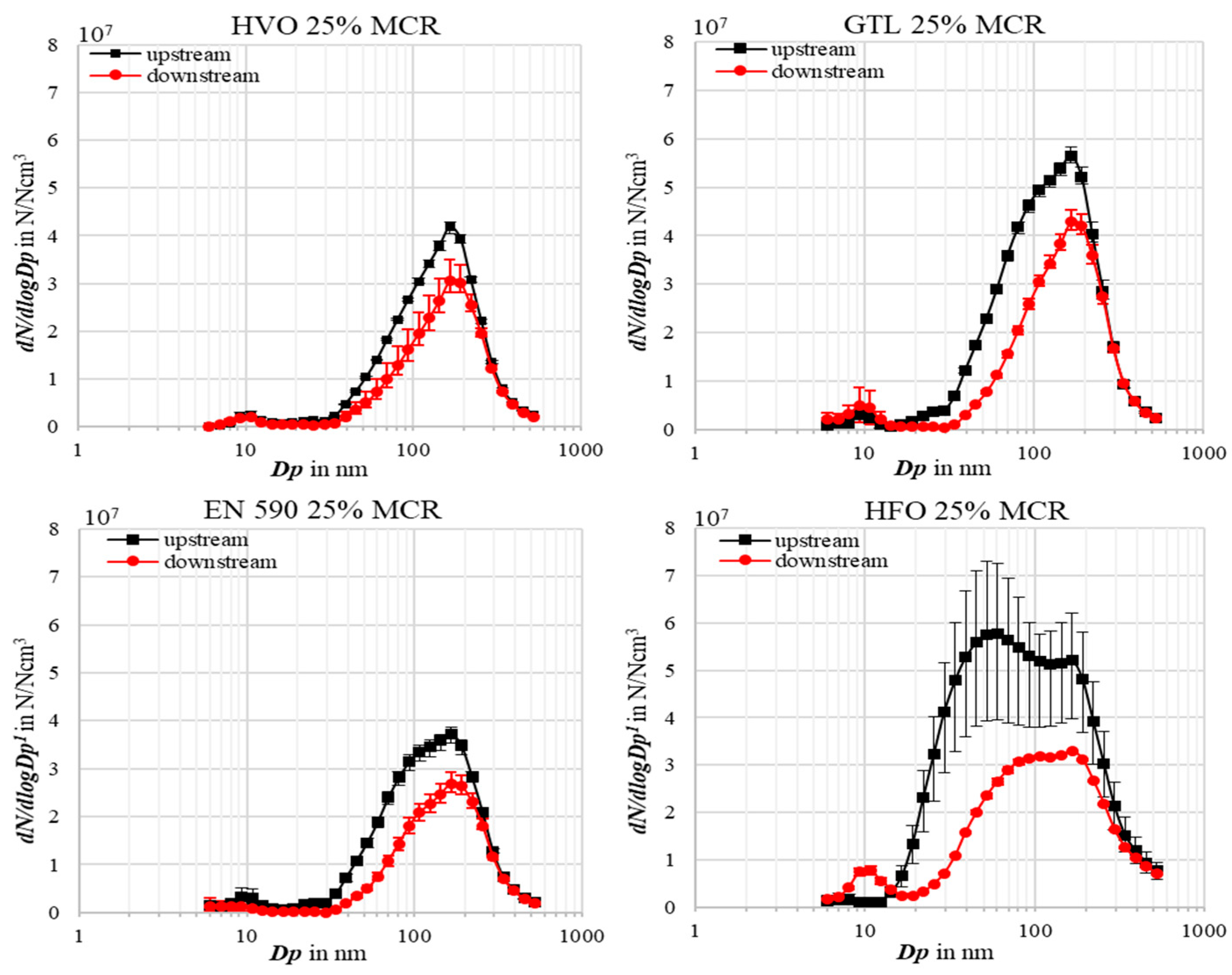

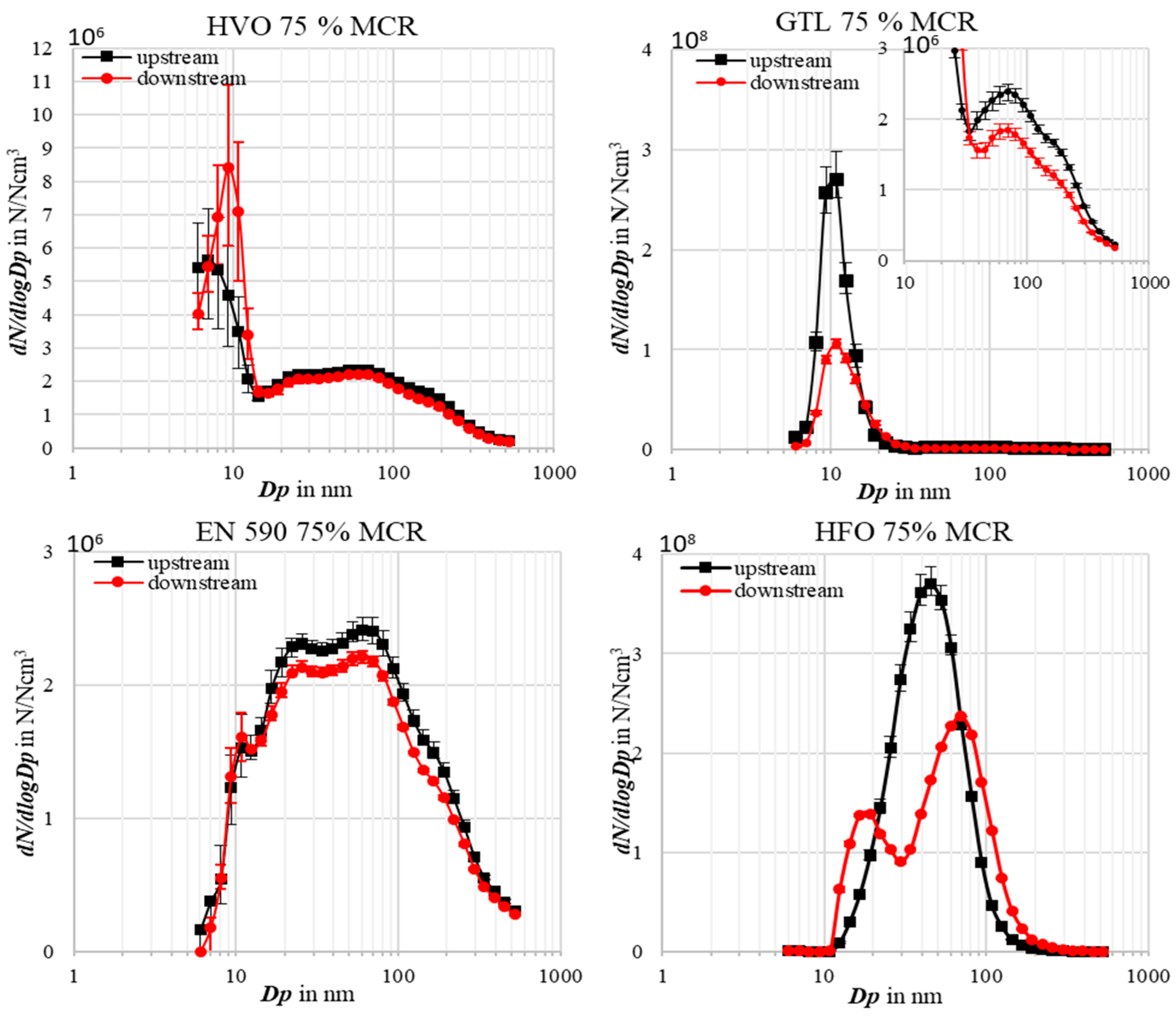

3.1. Effect of Engine Load and Fuel on Particle Number and Particle Size Distribution

3.2. Effects of Fuel and Engine Load on Particle Matter

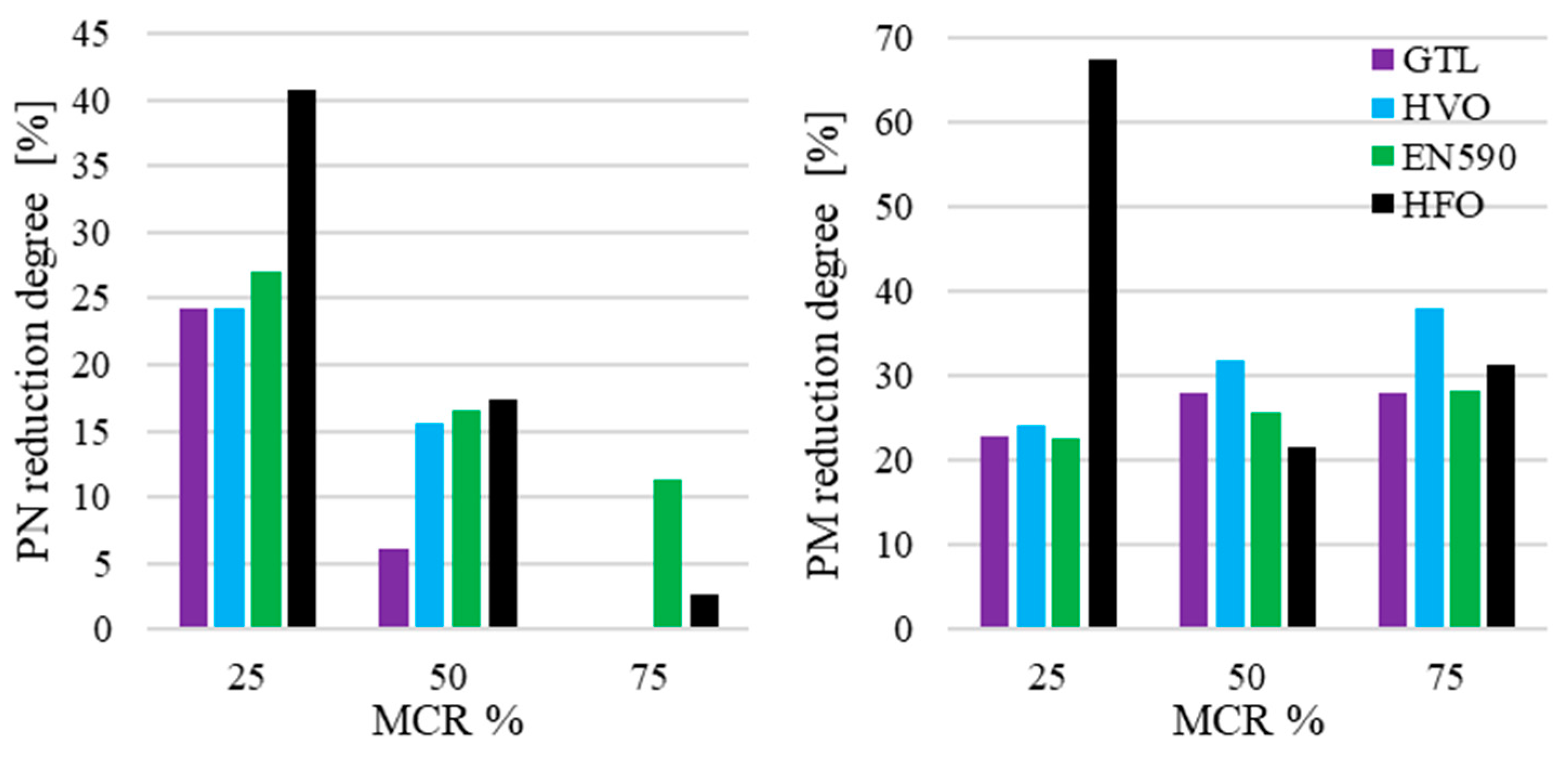

3.3. Impact of the EGCS on PN Emissions

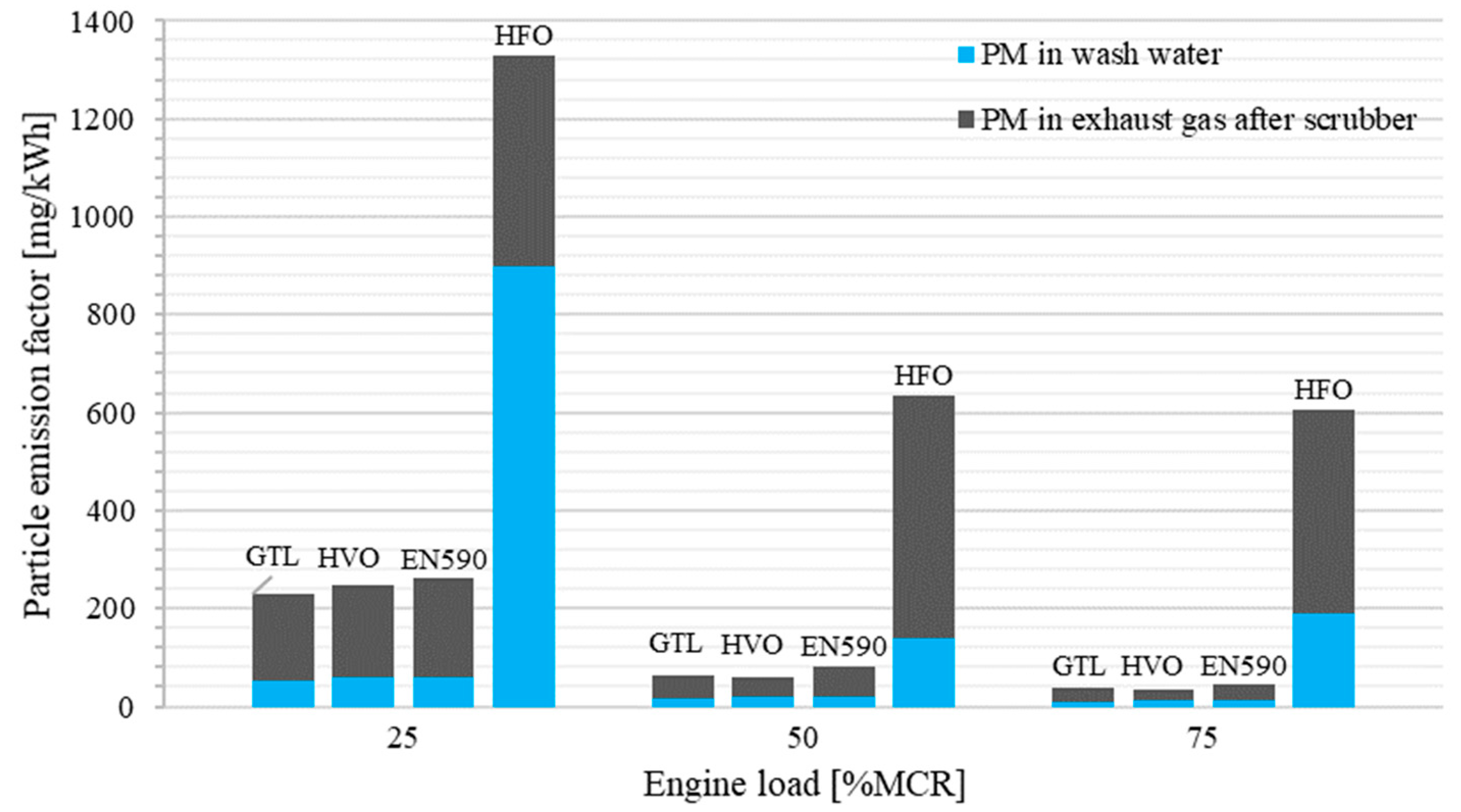

3.4. Impact of the EGCS on PM Emissions

4. Discussion

| Fuel | Load | Total PN us | Total PN ds | PN red. | PM ds | PM Wash Water | Total PM us | PM red. |

|---|---|---|---|---|---|---|---|---|

| [%] | [1 N/cm3] | [1 N/cm3] | [%] | [mg/kWh] | [mg/kWh] | [mg/kWh] | [%] | |

| GTL | 25 | 1.20 × 1010 | 9.08 × 109 | 24.3 | 176.7 | 52.9 | 229.6 | 23.0 |

| HVO | 25 | 8.49 × 109 | 6.44 × 109 | 24.2 | 188.7 | 60.4 | 249.0 | 24.2 |

| EN 590 | 25 | 8.34 × 109 | 6.09 × 109 | 27 | 202.3 | 59.4 | 261.7 | 22.7 |

| HFO | 25 | 1.66 × 1010 | 9.87 × 109 | 40.7 | 431.9 | 898.2 | 1330.1 | 67.5 |

| GTL | 50 | 1.75 × 109 | 1.64 × 109 | 6.1 | 44.7 | 17.4 | 62.1 | 28.0 |

| HVO | 50 | 1.73 × 109 | 1.46 × 109 | 15.5 | 40.3 | 18.8 | 59.1 | 31.8 |

| EN 590 | 50 | 1.11 × 109 | 9.30 × 108 | 16.5 | 61.1 | 21.1 | 82.2 | 25.7 |

| HFO | 50 | 1.89 × 1010 | 1.56 × 1010 | 17.3 | 498.1 | 138.0 | 636.1 | 21.7 |

| GTL | 75 | 2.13 × 109 | 1.30 × 109 | - | 26.8 | 10.3 | 37.1 | 27.9 |

| HVO | 75 | 5.79 × 108 | 5.29 × 108 | - | 22.0 | 13.6 | 35.6 | 38.1 |

| EN 590 | 75 | 5.72 × 108 | 5.07 × 108 | 11.3 | 31.6 | 12.4 | 44.0 | 28.2 |

| HFO | 75 | 2.15 × 1010 | 2.10 × 1010 | 2.6 | 417.5 | 190.1 | 607.6 | 31.3 |

5. Conclusions

- The use of new fuels (GTL and HVO) results in the production of particulates, although their formation is on average 20% lower than that caused by the use of distillate fuel (diesel) and up to 90% lower than that caused by heavy fuel oil at any engine load tested. This is due to the lower aromatic content of the fuel, the absence of sulphur, a higher cetane number, as well as a better ratio of carbon to hydrogen.

- In the case of fossil fuels, switching from residual fuels (HFO) to distillates results in a reduction of more than 80% of particulates emitted at all engine loads, aligning with the objectives of the IMO as fixed in the MARPOL regulations.

- There is a clear trend showing the reduction in particulate emissions increases with engine load due to the more favourable fuel/air ratio for combustion. The highest values for measured PN and PM emission factors are observed at low engine loads, while medium loads achieve PM reductions of more than 50% for HFO and up to 70% for compliant fuels. High engine loads resulted in significant reductions in PM emissions, averaging 40% for new fuels and diesel. However, for HFO, only a 3% improvement in PM emissions was observed.

- According to current IMO regulations, the use of scrubbers in combination with compliant fuels is not an ideal option. The impact of scrubbers on the reduction of particulate matter was in the range between 20% and 40%. It is believed that the feasibility of scrubbing is downgraded by a higher presence of finer particle sizes and a decreasing residence time in the scrubber channel. The results suggest that the scrubber is more effective with coarse particles from HFO and to an even more limited extent with compliant fuels.

- In light of the high levels of PN and PM emissions—particularly respirable particles—during low engine loads typical of coastal ship operations, the use of an EGCS would, however, be advantageous for air quality and human health, especially considering the upcoming IMO regulations for further limiting particulate emissions such as soot. In this context, it is expected that EGCS equipment, such as scrubbers, will need to be optimized to reduce not only sulphur emissions but also particulate and soot emissions from marine engines.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gakidou, E.; Afshin, A.; Abajobir, A.A.; Abate, K.H.; Abbafati, C.; Abbas, K.M.; Abd-Allah, F.; Abdulle, A.M.; Abera, S.F.; Aboyans, V.; et al. Global, regional, and national comparative risk assessment of 84 behavioural, environmental and occupational, and metabolic risks or clusters of risks, 1990–2016: A systematic analysis for the Global Burden of Disease Study 2016. Lancet 2017, 390, 1345–1422. [Google Scholar] [CrossRef]

- Schraufnagel, D.E. The health effects of ultrafine particles. Exp. Mol. Med. 2020, 52, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Ohlwein, S.; Hoffmann, B.; Keppeler, R.; Joss, M.K.; Künzli, N. Health Effects of Ultrafine Particles—Systematic Literature Search and the Potential Transferability of the Results to the German Setting; No. UMWELT&GESUNDHEIT 05/2018; Umweltbundesamt: Dessau-Roßlau, Germany, 2008; p. 108. [Google Scholar]

- World Health Organization. Ambient (Outdoor) Air Pollution. 19 December 2022. Available online: https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health (accessed on 5 March 2024).

- Henschel, S.; Gabrielle, C. Health Risks of Air Pollution in Europe—HRAPIE Project. October 2013. Available online: https://www.who.int/europe/publications/i/item/WHO-EURO-2013-6696-46462-67326 (accessed on 5 March 2024).

- Eyring, V.; Isaksen, I.S.A.; Berntsen, T.; Collins, W.J.; Corbett, J.J.; Endresen, O.; Grainger, R.G.; Moldanova, J.; Schlager, H.; Stevenson, D.S. Transport impacts on atmosphere and climate: Shipping. Atmos. Environ. 2010, 44, 4735–4771. [Google Scholar] [CrossRef]

- Toscano, D.; Murena, F. Atmospheric ship emissions in ports: A review. Correlation with data of ship traffic. Atmos. Environ. X 2019, 4, 100050. [Google Scholar] [CrossRef]

- United Nations Conference on Trade and Development. In Review of Maritime Transport 2021; S.l.: United Nations: New York, NY, USA, 2022; Available online: https://unctad.org/system/files/official-document/rmt2021_en_0.pdf (accessed on 5 March 2024).

- Corbett, J.J.; Winebrake, J.J.; Green, E.H.; Kasibhatla, P.; Eyring, V.; Lauer, A. Mortality from Ship Emissions: A Global Assessment. Environ. Sci. Technol. 2007, 41, 8512–8518. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zhang, Y.; Yang, Z.; Liu, Y.; Peng, S.; Hong, N.; Hu, J.; Wang, T.; Mao, H. A comprehensive study of particulate and gaseous emissions characterization from an ocean-going cargo vessel under different operating conditions. Atmos. Environ. 2020, 223, 117286. [Google Scholar] [CrossRef]

- Alanen, J.; Isotalo, M.; Kuittinen, N.; Simonen, P.; Martikainen, S.; Kuuluvainen, H.; Honkanen, M.; Lehtoranta, K.; Nyyssönen, S.; Vesala, H.; et al. Physical Characteristics of Particle Emissions from a Medium Speed Ship Engine Fueled with Natural Gas and Low-Sulfur Liquid Fuels. Environ. Sci. Technol. 2020, 54, 5376–5384. [Google Scholar] [CrossRef] [PubMed]

- Lehtoranta, K.; Aakko-Saksa, P.T.; Murtonen, T.; Vesala, H.; Ntziachristos, L.; Rönkkö, T.; Karjalainen, P.; Kuittinen, N.; Timonen, H. Particulate Mass and Nonvolatile Particle Number Emissions from Marine Engines Using Low-Sulfur Fuels, Natural Gas, or Scrubbers. Environ. Sci. Technol. 2019, 53, 3315–3322. [Google Scholar] [CrossRef] [PubMed]

- Di Natale, F.; Carotenuto, C.; Cajora, A.; Sippula, O.; Gregory, D. Short-sea shipping contributions to particle concentration in coastal areas: Impact and mitigation. Transp. Res. Part D Transp. Environ. 2022, 109, 103342. [Google Scholar] [CrossRef]

- Oeder, S.; Kanashova, T.; Sippula, O.; Sapcariu, S.C.; Streibel, T.; Arteaga-Salas, J.M.; Passig, J.; Dilger, M.; Paur, H.-R.; Schlager, C.; et al. Particulate Matter from Both Heavy Fuel Oil and Diesel Fuel Shipping Emissions Show Strong Biological Effects on Human Lung Cells at Realistic and Comparable In Vitro Exposure Conditions. PLoS ONE 2015, 10, e0126536. [Google Scholar] [CrossRef]

- IMO; MEPC. Effective Date of Implementation of The Fuel Oil Standard in Regulation 14.1.3 of Marpol Annex VI’. 28 October 2016. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.280(70).pdf (accessed on 10 March 2024).

- Zetterdahl, M.; Moldanová, J.; Pei, X.; Pathak, R.K.; Demirdjian, B. Impact of the 0.1% fuel sulfur content limit in SECA on particle and gaseous emissions from marine vessels. Atmos. Environ. 2016, 145, 338–345. [Google Scholar] [CrossRef]

- Winnes, H.; Fridell, E. Particle Emissions from Ships: Dependence on Fuel Type. J. Air Waste Manag. Assoc. 2009, 59, 1391–1398. [Google Scholar] [CrossRef] [PubMed]

- Rotterdam Bunker Prices HFO. Ship & Bunker. Available online: https://shipandbunker.com/prices/emea/nwe/nl-rtm-rotterdam#IFO380 (accessed on 9 February 2024).

- Rotterdam Bunker Prices LSFO. Ship & Bunker. Available online: https://shipandbunker.com/prices/emea/nwe/nl-rtm-rotterdam#LSFO (accessed on 9 February 2024).

- Rotterdam Bunker Prices MGO. Ship & Bunker. Available online: https://shipandbunker.com/prices/emea/nwe/nl-rtm-rotterdam#MGO (accessed on 9 February 2024).

- Fridell, E.; Salo, K. Measurements of abatement of particles and exhaust gases in a marine gas scrubber. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 230, 154–162. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, S.; Zhu, Y. Characterization of Particle and Gaseous Emissions from Marine Diesel Engines with Different Fuels and Impact of After-Treatment Technology. Energies 2017, 10, 1110. [Google Scholar] [CrossRef]

- Hansen, J.P. Exhaust Gas Scrubber Installed Onboard MV Ficaria Seaways; Miljøstyrelsen: Odense, Denmark, 2012. [Google Scholar]

- Aakko-Saksa, P.T.; Lehtoranta, K.; Kuittinen, N.; Järvinen, A.; Jalkanen, J.-P.; Johnson, K.; Jung, H.; Ntziachristos, L.; Gagné, S.; Takahashi, C.; et al. Reduction in greenhouse gas and other emissions from ship engines: Current trends and future options. Prog. Energy Combust. Sci. 2023, 94, 101055. [Google Scholar] [CrossRef]

- Ampah, J.D.; Yusuf, A.A.; Afrane, S.; Jin, C.; Liu, H. Reviewing two decades of cleaner alternative marine fuels: Towards IMO’s decarbonization of the maritime transport sector. J. Clean. Prod. 2021, 320, 128871. [Google Scholar] [CrossRef]

- IMO; MEPC. 2023 IMO Strategy on Reduction of GHG Emissions from Ships. 7 July 2023. Available online: https://www.imo.org/en/OurWork/Environment/Pages/2023-IMO-Strategy-on-Reduction-of-GHG-Emissions-from-Ships.aspx (accessed on 10 March 2024).

- Harahap, F.; Nurdiawati, A.; Conti, D.; Leduc, S.; Urban, F. Renewable marine fuel production for decarbonised maritime shipping: Pathways, policy measures and transition dynamics. J. Clean. Prod. 2023, 415, 137906. [Google Scholar] [CrossRef]

- Laursen, R.; Barcarolo, D.; Patel, H.; Dowling, M.; Penfold, M.; Faber, J.; Király, J.; van der Ven, R.; Pang, E.; van Grinsven, A. Update on Potential of Biofuels in Shipping. EMSA, 2021/2022-4837444. September 2023. Available online: https://www.emsa.europa.eu/newsroom/latest-news/item/4834-update-on-potential-of-biofuels-for-shipping.html (accessed on 9 February 2024).

- IMO; MEPC. 2021 Protecting the Arctic from Shipping Black Carbon Emissions. 26 November 2021. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Air%20pollution/MEPC.342%2877%29.pdf (accessed on 17 November 2023).

- Regulation (EU) 2016/1628 of the European Parliament and of the Council of 14 September 2016 on Requirements Relating to Gaseous and Particulate Pollutant Emission Limits and Type-Approval for Internal Combustion Engines for Non-Road Mobile Machinery, Amending Regulations (EU) No 1024/2012 and (EU) No 167/2013, and Amending and Repealing Directive 97/68/EC. 2020, p. 65. Available online: https://eur-lex.europa.eu/EN/legal-content/summary/emission-limits-and-type-approval-rules-for-non-road-mobile-machinery.html (accessed on 13 February 2024).

- EnergieDirect GmbH & Co. KG. ‘Shell GTL Fuel Marine|EnergieDirect’. Available online: https://www.energiedirect-bayern.de/firmenkunden/shell-gtl-fuel-marine (accessed on 15 February 2024).

- British Antarctic Survey. Trial of Lower Carbon Alternative Fuel Begins on RRS Sir David Attenborough. British Antarctic Survey. Available online: https://www.bas.ac.uk/media-post/trial-of-hvo-fuel-sda/ (accessed on 24 February 2024).

- Auf dem Grünen Weg. Available online: https://www.dbcargo.com/rail-de-de/logistik-news/auf-dem-gruenen-weg-db-cargo-testet-hvo-7327204 (accessed on 27 November 2023).

- Shell Supplies Hydrotreated Vegetable Oil for Rail Applications—Trade Release|Shell Global. Available online: https://www.shell.com/business-customers/catalysts-technologies/resources-library/hydrotreated-vegetable-oil-for-rail-applications.html (accessed on 27 November 2023).

- Lyyränen, J.; Jokiniemi, J.; Kauppinen, E.I.; Backman, U.; Vesala, H. Comparison of Different Dilution Methods for Measuring Diesel Particle Emissions. Aerosol Sci. Technol. 2004, 38, 12–23. [Google Scholar] [CrossRef]

- Ushakov, S.; Valland, H.; Nielsen, J.B.; Hennie, E. Effects of dilution conditions on diesel particle size distribution and filter mass measurements in case of marine fuels. Fuel Process. Technol. 2014, 118, 244–253. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.D.; Lähde, T.; Martini, G. Non-Volatile Particle Number Emission Measurements with Catalytic Strippers: A Review. Vehicles 2020, 2, 342–364. [Google Scholar] [CrossRef]

- Zetterdahl, M. Particle Emissions from Ships: Measurements on Exhausts from Different Marine Fuels; Doktorsavhandlingar vid Chalmers tekniska högskola, No. Ny serie nr. 4064; Chalmers University of Technology: Gothenburg, Sweden, 2016. [Google Scholar]

- Jeong, S.; Bendl, J.; Saraji-Bozorgzad, M.; Käfer, U.; Etzien, U.; Schade, J.; Bauer, M.; Jakobi, G.; Orasche, J.; Fisch, K.; et al. Aerosol emissions from a marine diesel engine running on different fuels and effects of exhaust gas cleaning measures. Environ. Pollut. 2023, 316, 12052. [Google Scholar] [CrossRef] [PubMed]

- Järvinen, A.; Lehtoranta, K.; Aakko-Saksa, P.; Karppanen, M.; Murtonen, T.; Martikainen, J.; Kuusisto, J.; Nyyssönen, S.; Koponen, P.; Piimäkorpi, P.; et al. Performance of a Wet Electrostatic Precipitator in Marine Applications. J. Mar. Sci. Eng. 2023, 11, 393. [Google Scholar] [CrossRef]

- Lyyränen, J.; Jokiniemi, J.; Kauppinen, E.I.; Joutsensaari, J. Aerosol characterisation in medium-speed diesel engines operating with heavy fuel oils. J. Aerosol Sci. 1999, 30, 771–784. [Google Scholar] [CrossRef]

- Wu, G.; Ma, Q.; Wei, L.; Jiang, G.; Wang, T.; Li, T. Characteristics of Particulate Matter Emissions for Low-Sulfur Heavy Oil Used in Low-Speed Two-Stroke Diesel Engines of Ocean-Going Ships. J. Therm. Sci. 2024, 33, 739–750. [Google Scholar] [CrossRef]

- Ushakov, S.; Halvorsen, N.G.; Valland, H.; Williksen, D.H.; Æsøy, V. Emission characteristics of GTL fuel as an alternative to conventional marine gas oil. Transp. Res. Part D Transp. Environ. 2013, 18, 31–38. [Google Scholar] [CrossRef]

- Ushakov, S.; Lefebvre, N. Norway Assessment of Hydrotreated Vegetable Oil (HVO) Applicability as an Alternative Marine Fuel Based on Its Performance and Emissions Characteristics. SAE Int. J. Fuels Lubr. 2019, 12, 109–120. [Google Scholar] [CrossRef]

- Westerlund, J.; Hallquist, M.; Hallquist, M. Characterization of fleet emissions from ships through multi-individual determination of size-resolved particle emissions in a coastal area. Atmos. Environ. 2015, 112, 159–166. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Guo, J.; Hao, C.; Feng, Y. Particle emissions from a marine diesel engine burning two kinds of sulphur diesel oils with an EGR & scrubber system: Size, number & mass. Process. Saf. Environ. Prot. 2022, 163, 94–104. [Google Scholar] [CrossRef]

| Engine | EGCS | ||

|---|---|---|---|

| Item | Specification | Item | Specification |

| Manufacturer | MaK | Manufacturer | PureteQ A/S |

| Model | FOMO 4524 | Model | Inline Turbo Scrubber |

| Operation | Four-stroke diesel | Max. sulphur content [m/m] | 3.5% |

| Rated Power [kW] | 722 | Max. engine Power [MW] | 0.8 |

| Speed [rpm] | 600 | Alkalization medium | NaOH, 50% |

| Cylinder | 3 | Loop wash water flow [m3/h] | 21–36 |

| Bore [mm] | 240 | Sections and nozzles | 1 quench section, 16 pcs |

| Stroke [mm] | 450 | 3 washing sections, 27 pcs | |

| Air intake mode | Turbo charged | 1 demister cleaning, 3 pcs | |

| Height [mm] | 6800 | ||

| Diameter [mm] | 750 | ||

| GTL | HVO | EN 590 | HFO | |

|---|---|---|---|---|

| Net calorific value (MJ kg−1) | 44.06 | 44.04 | 42.78 | 40.4 |

| Density (kg m−3) at 15 °C | 781.0 | 783.0 | 840.0 | 990.3 |

| Sulphur (m/m%) | 0.0 | 0.0 | 0.009 | 2.4 |

| Carbon (m/m%) | 85.3 | 85.4 | 86.4 | 84.7 |

| Hydrogen (m/m%) | 14.7 | 14.6 | 13.2 | 9.9 |

| ∑16 EPA PAH (mg kg−1) | 9.6 | 190.7 | 1494.9 | 2970 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, D.; Vith, W.; Unger, J.L. Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber. J. Mar. Sci. Eng. 2024, 12, 1144. https://doi.org/10.3390/jmse12071144

Fischer D, Vith W, Unger JL. Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber. Journal of Marine Science and Engineering. 2024; 12(7):1144. https://doi.org/10.3390/jmse12071144

Chicago/Turabian StyleFischer, Dennis, Wiktoria Vith, and Jonas Lloyd Unger. 2024. "Assessing Particulate Emissions of Novel Synthetic Fuels and Fossil Fuels under Different Operating Conditions of a Marine Engine and the Impact of a Closed-Loop Scrubber" Journal of Marine Science and Engineering 12, no. 7: 1144. https://doi.org/10.3390/jmse12071144