3.2.1. Characterization of Changes in Water Content

Changes in water content were characterized by monitoring the remaining water content percentage ω1, drained water percentage ω2 and evaporated water percentage ω3. The remaining water percentage ω1 is the percentage of the initial weight of water added initially to all the samples. The drained water percentage ω2 is the percentage of the water released from all the samples and gathered into the support, from the beginning of the dewatering process until the time of measurement. Likewise, the evaporated water percentage ω3 is the water evaporated from all samples in the same conditions. So, the different water percentages give Equation (2).

The evolution of ω

1 is directly dependent on water content as one can deduce from Equation (3). The sediment water content ω at any given day during the dewatering process is then characterized through a normalized expression.

where ω/L

L is the water content to liquidity limit; w

w is the initial weight of water added to all samples and w

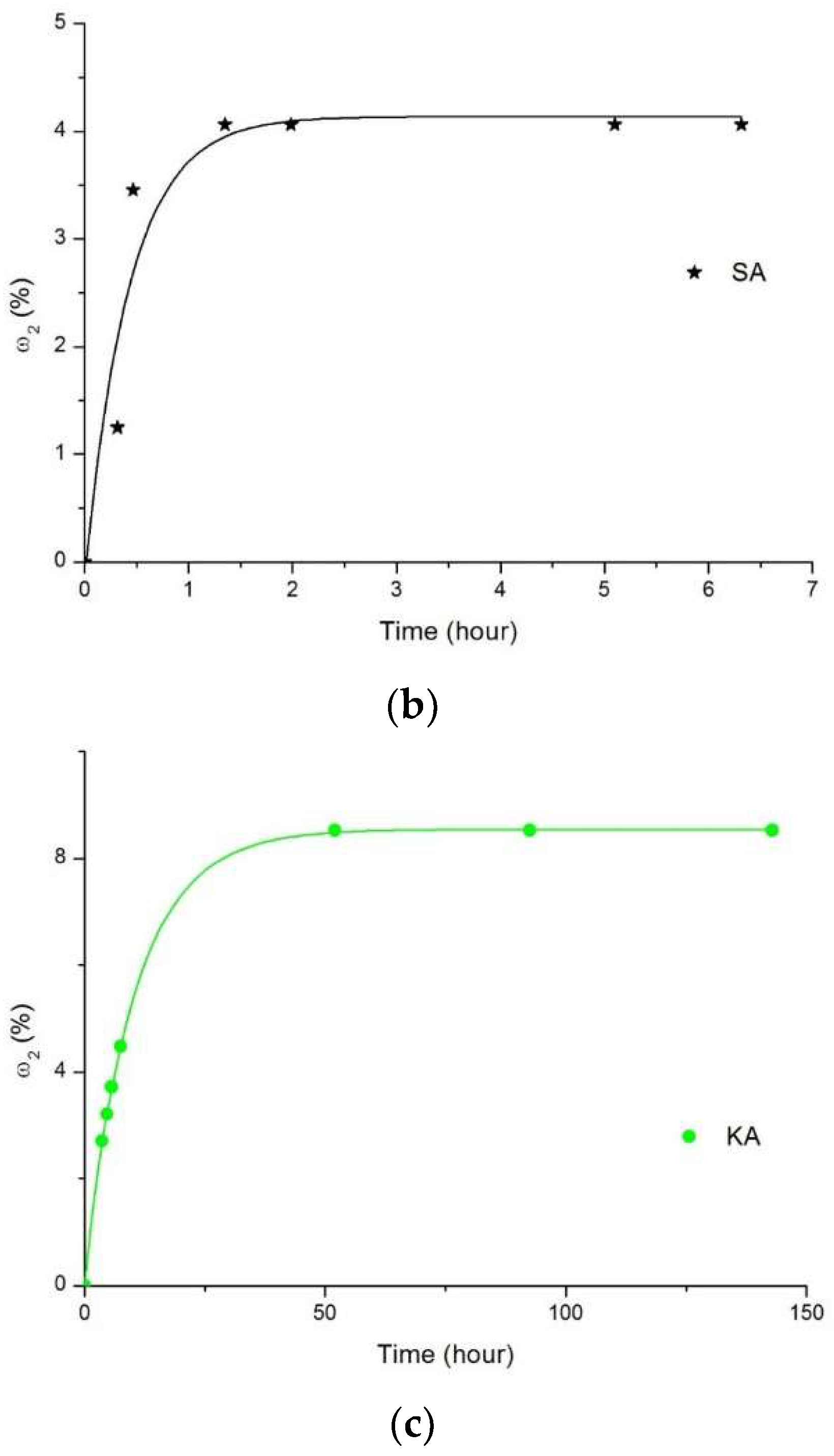

s is the corresponding dry weight. The change in drained water is plotted in

Figure 4. Quick drainage of the IS, RA and RH sediments is observed compared to the others; see

Figure 4a. In particular, these sediments have high drainage capacity where ω

2 has reached 32%, 28% and 46%, respectively, compared to 4% and 8.5% for the SA sediment and the kaolin (KA), respectively; see

Figure 4b,c.

A maximum amount of drained water is reached (

Figure 4a) for sediments with coarser soil texture, which is the case for the RA and RH sediments when compared to the IS sediment. Having the highest liquid limit—and therefore having the highest initial water content and consequently the highest void ratio—also explains the important quantity of drained water for the RH sediment. On the same figure, we observe, for the IS sediment, a finer soil texture than that of the RA sediment; the water drained was lesser for the RA sediment because of greater organic matter content; see

Table 2. Sediment SA, with a significant amount of organic matter content (6.61%), contributed also to shortening the drainage time, and a low quantity of water (4%) was drained despite its coarse soil texture and minimum CaCO

3 content (

Table 2). Once the plateau is observed on the graphs, the drainage phenomenon tends to stop. We also note that the drainage lasts from a few hours for sediments to several days for kaolin clay (between 2 and 3 days; see

Figure 4c) for a low water volume of around 8% of the initial water content. This is due to the fine colloidal texture of the kaolin that contributes to water retention, even with low percentages of CaCO

3 and organic matter content. Drained water graphs fit well with an exponential function over time that corresponds to Equations (4)–(6); see

Table 3.

Table 3.

Possible relationships of drained water vs. time for all samples.

Table 3.

Possible relationships of drained water vs. time for all samples.

| From Figure 4a ω2 [%] = f(t)[hour], for RA and RH sediments |

| Equation (4): ω2 = a(1 − bt), type: Exponential, BoxLucas 1 Mod |

| Sediment | a | b | r2 |

| RA | 27.61 | 0.11 | 0.99 |

| RH | 45.64 | 0.23 | 0.99 |

| From Figure 4a,c, for IS sediment and for kaolin clay (KA) |

| Equation (5): ω2 = a(1 − e−bt)c, type: Exponential, Chapman |

| Sediment | a | b | c | r2 |

| IS | 33.81 | 0.10 | 0.64 | 0.99 |

| Kaolin clay | 8.55 | 0.09 | 0.94 | 0.99 |

| From Figure 4b, ω2[%] = f(t)[hour], for SA sediment |

| Equation (6): ω2 = a − bct, type: Exponential, Asymptotic |

| Sediment | a | b | c | r2 |

| SA | 4.14 | 4.28 | 0.10 | 0.92 |

Figure 5 shows how the drained water ω

2 evolves versus the normalized water content ω/L

L. Drainage ends when the curve becomes constant. A similar trend is observed from the beginning of drainage till the end when the plateau appears. It is confirmed by all samples with normalized water content ω/L

L = 2. The level of the plateau depends on the factors previously mentioned and govern the drainage behavior. Since the dewatering of SA sediment began from normalized water content lesser than the other tested samples (ω/L

L = 1.56), it seems that the initial slope is not so different from the other samples as illustrated in

Figure 5. It is evident that the drainage depends on the initial water content of the sample as well as its consistency. The evolution of ω

2 versus normalized water content ω/(L

L) is well characterized by a sigmoidal-type function; see Equation (7) in

Table 4.

Table 4.

Possible relationships of drained water vs. normalized water content for all samples.

Table 4.

Possible relationships of drained water vs. normalized water content for all samples.

| From Figure 5, ω2 = [%] = f(ω/LL) |

| Equation (7): ω2 = A2 + (A1 − A2)/(1 + ((ω/LL)/((ω/LL0.5) p))) type: Sigmoidal, Logistic |

| Sediment | A1 | A2 | ω/LL0.5 | p | r2 |

| IS | 32.65 | −8.32 | 1.75 | 9.36 | 0.99 |

| KA | 8.55 | −1.25 | 1.92 | 43.64 | 0.99 |

| RA | 27.52 | −0.10 | 1.66 | 30.47 | 0.99 |

| RH | 46.17 | −4.98 | 1.58 | 9.00 | 0.99 |

| SA | 4.08 | 0.00773 | 1.26 | 108.07 | 0.99 |

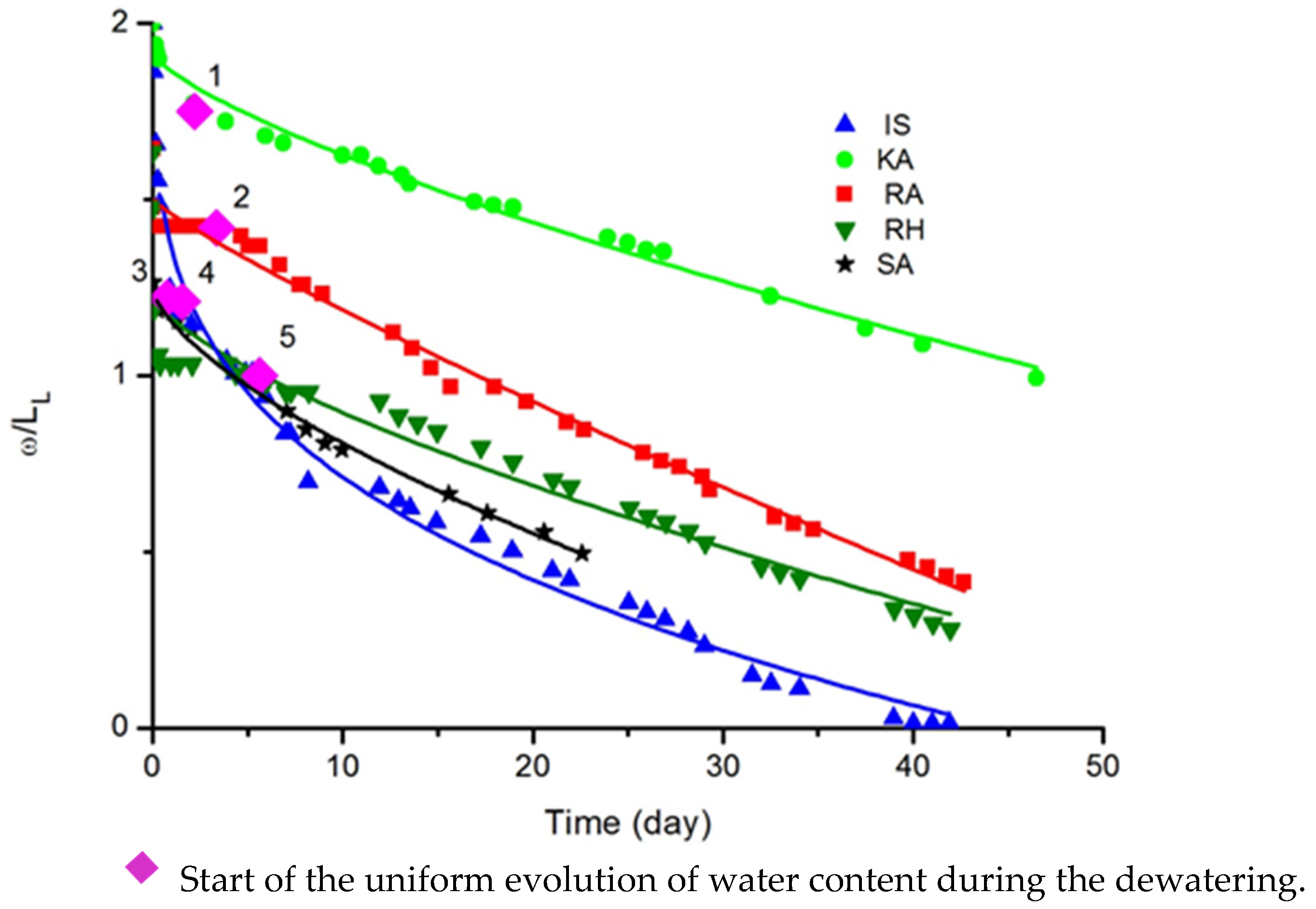

Figure 6 illustrates how the normalized water content evolves for all samples over time. When reaching a specific value in less than a week, indicated by pink diamonds, the normalized water content shows an approximately uniform rate of evolution. These specific values correspond to the end of drainage, which is observed in

Figure 4. Hence, in addition to the remaining water—see Equation (3)—the normalized-water-content-to-liquid-limit ratio ω/L

L depends also on the ω

2 percentage rather than the samples’ physical states.

The normalized-water-content-to-liquid-limit ratio ω/L

L seems to fit with a power type evolution with time for all the samples, as detailed in Equation (8); see

Table 5.

Table 5.

Possible relationships of water content to liquid limit vs. time for all samples.

Table 5.

Possible relationships of water content to liquid limit vs. time for all samples.

| From Figure 6, ω/LL = [%] = f(t) |

| Equation (8): ω/LL = a + btc, type: Power, Allometric |

| Sediment | a | b | c | r2 |

| IS | 2.00 | −0.70 | 0.28 | 0.99 |

| RH | 1.23 | −0.07 | 0.69 | 0.90 |

| KA | 1.92 | −0.05 | 0.73 | 0.99 |

| RA | 1.50 | −0.04 | 0.87 | 0.99 |

| SA | 1.25 | −0.09 | 0.66 | 0.99 |

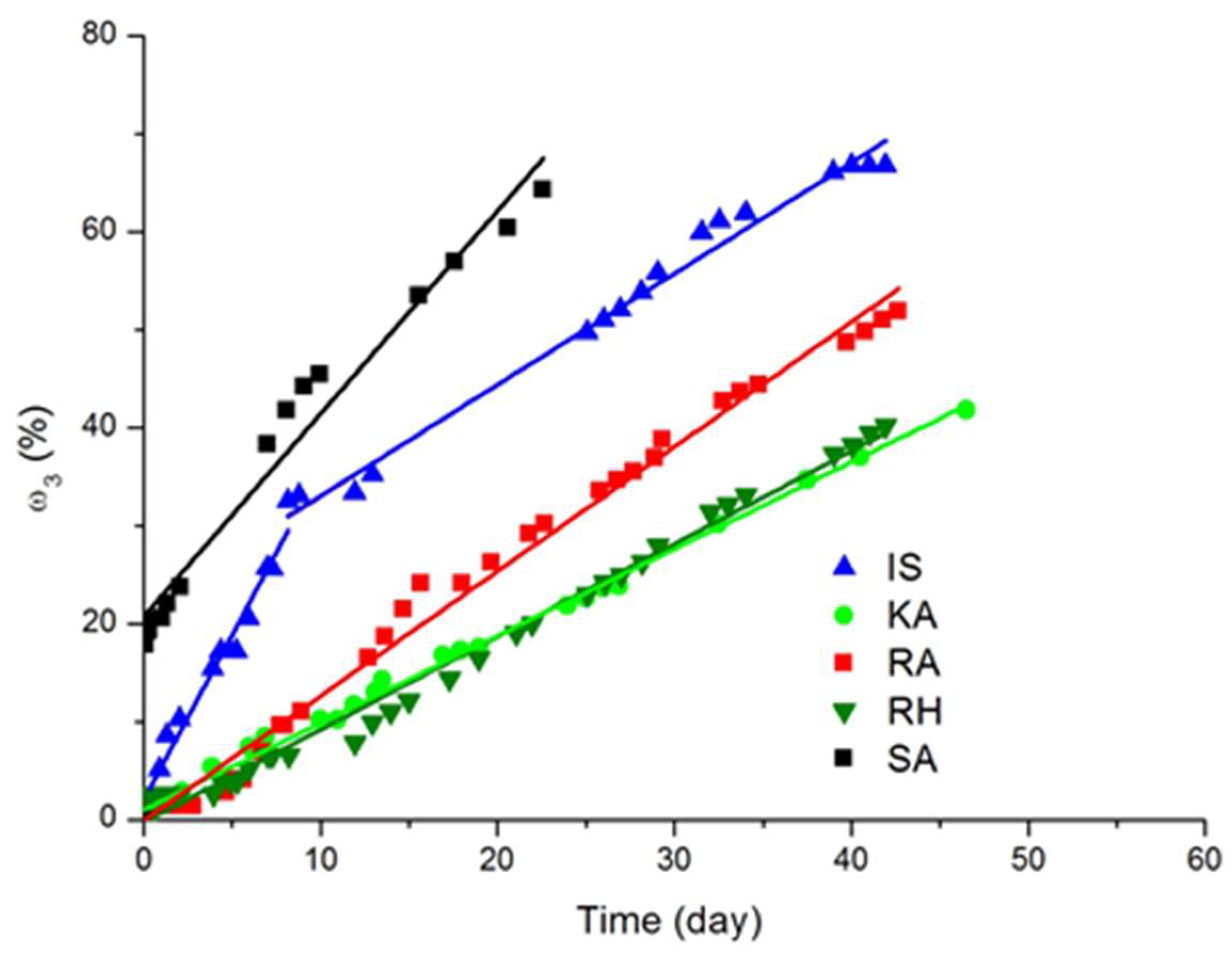

Considering the evaporated water in

Figure 7, a linear increase of ω

3 over time is observed fitted with Equation (9) in

Table 6.

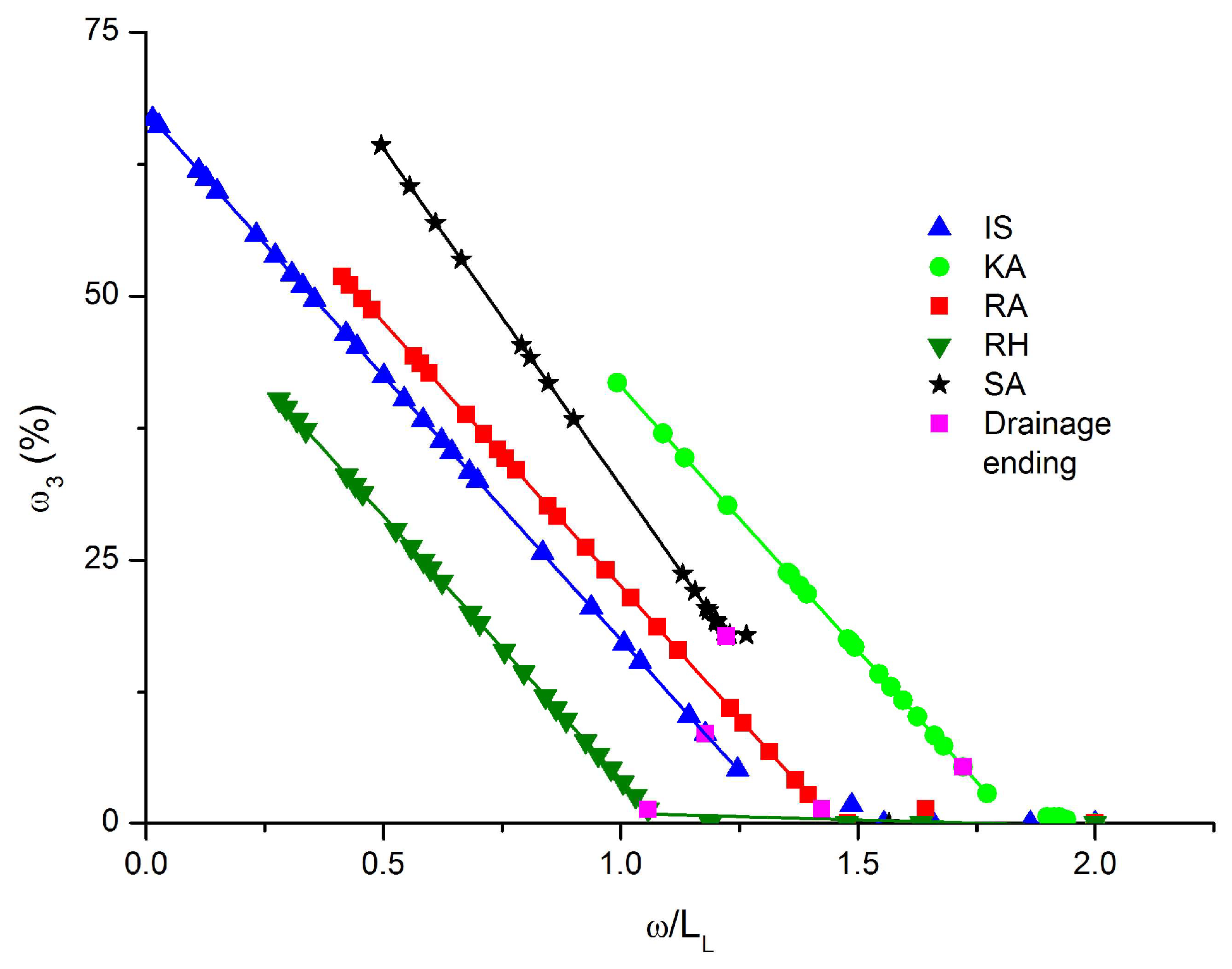

Beyond the end of drainage, if ω

3 is plotted as a function of ω/L

L, we also observe a linear variation. For the RH sediment, the linear increase starts when the sediment reaches the liquid limit; see

Figure 8.

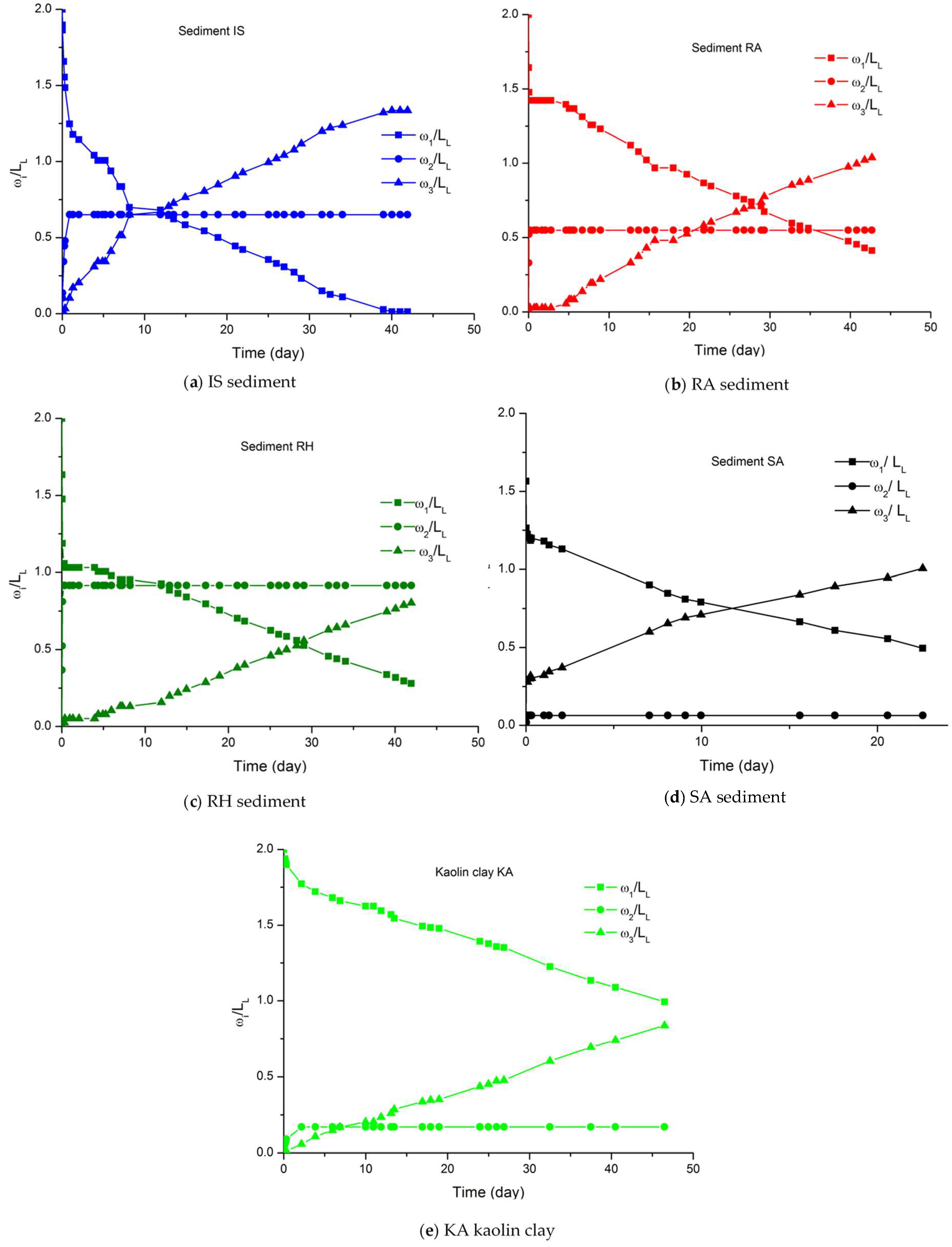

If we observe all the quantities of water, ω

1, ω

2 and ω

3, during the dewatering process in

Figure 9, it is confirmed that (1) the evaporated water increases linearly when drainage stops, and (2) the approximate slope change in water content in sediments is roughly noted. This is more perceptible for the sediments in

Figure 9a–d than it is for kaolin, as illustrated in

Figure 9e.

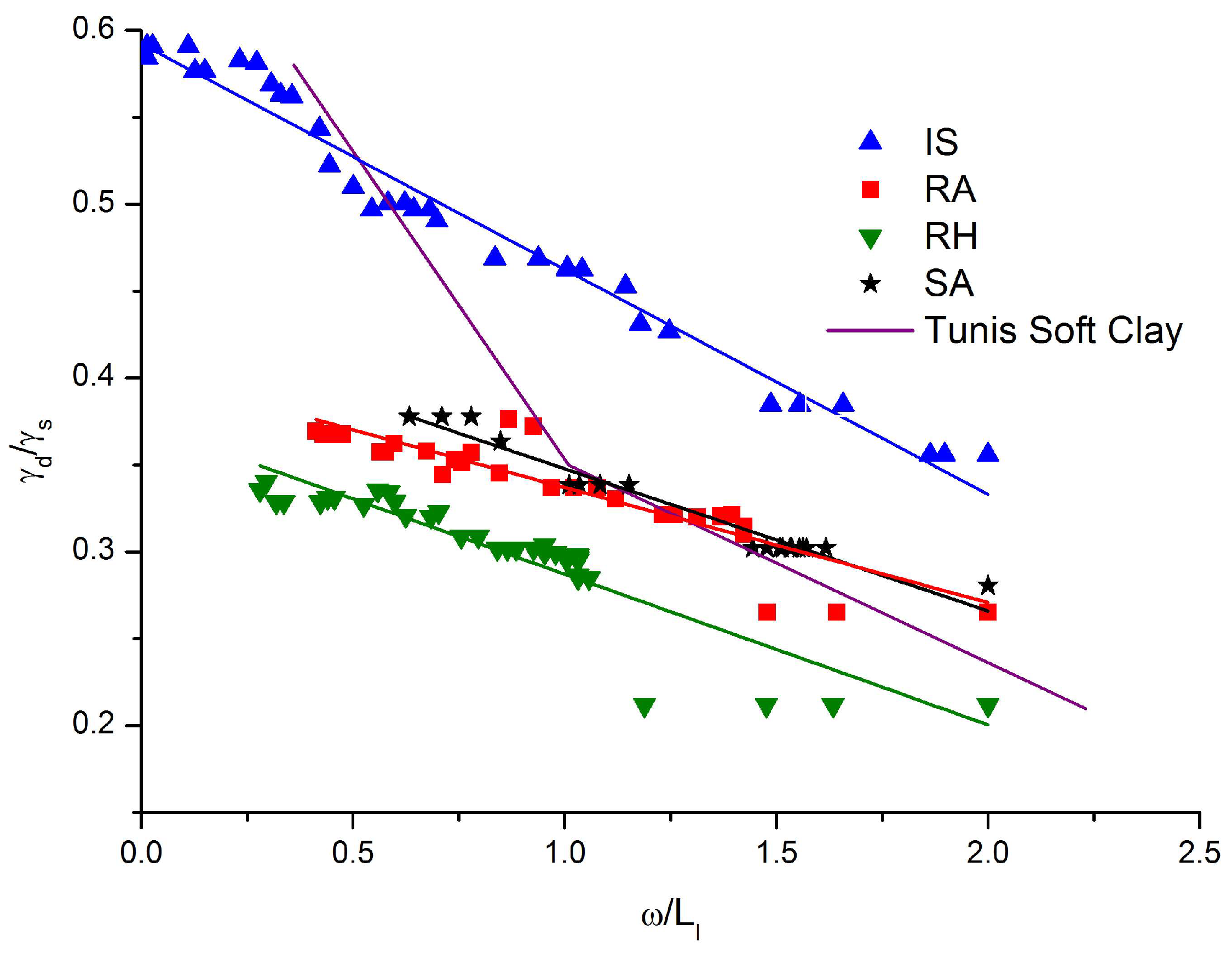

3.2.2. Void Ratio Evolution

The void ratio e is usually calculated from Equation (10):

where ɤ

s = 26.5 kN/m

3; g = 9.81 m/s

2; ɤ

d is the dry unit weight; Ms is the mass of dry solid particles; and V

T is the total volume. The dewatering phenomenon resulted in sediment shrinkage. Shrinkage characterization requires the determination of the void ratio by finding out the initial weight of the sample and its initial volume as given in

Table 1. The variation in the diameter and height of the sample versus time is assessed as explained in

Section 2.2.1; it allows one to determine the void ratio. Considering

Figure 10, the RH sediment underwent significant shrinkage over 5 hours; its void ratio decreased from 3.7 to 2.5. This is explained by the high sand fraction of about 41.7% which enhances water drainage and then subsequent grain rearrangement. The same shrinkage behavior is also observed for the RA sediment, which contain 26.3% of sand fraction. The decrease in void ratio was from 2.7 to 2.1 over two days, as illustrated in

Figure 10. Such an observation could be explained by the initial water content ω

0, considering that the higher the water content, the higher the void ratio is. For the RH sediment, initial water content equals to 142%, which makes it 1.3 times that of the RA sediment’s ω

0. The IS sample, with the lowest organic matter, shows a slow decrease in void ratio versus time. Note its drainage needed more time than the other sediments as seen in

Figure 4a. Sediment SA, with its ω

0 = 101.8% and ω

0 = 1.57 L

L, sustained little volume change within an hour; its void ratio varied from 2.5 to 2.3 before stabilizing.

Figure 10 shows the instantaneous rearrangement of particles of sandy soil highlighted with a rapid decrease in void ratios for sediments RA and RH. In turn, the colloidal behavior of the clayey materials in the IS sediment and kaolin clay (KA) resulted in a slow decrease. The variation in void ratio versus time illustrated in

Figure 10 is correlated by a power-type evolution given by Equation (11) given in

Table 7.

Based on the variation in void ratio for all samples with comparable initial water content, it is concluded that soil texture mostly governs soil particle rearrangement during drainage.