Spatio-Temporal Compressive Behaviors of River Pebble Concrete and Sea Pebble Concrete in Island Offshore Engineering

Abstract

:1. Introduction

2. Materials and Methods

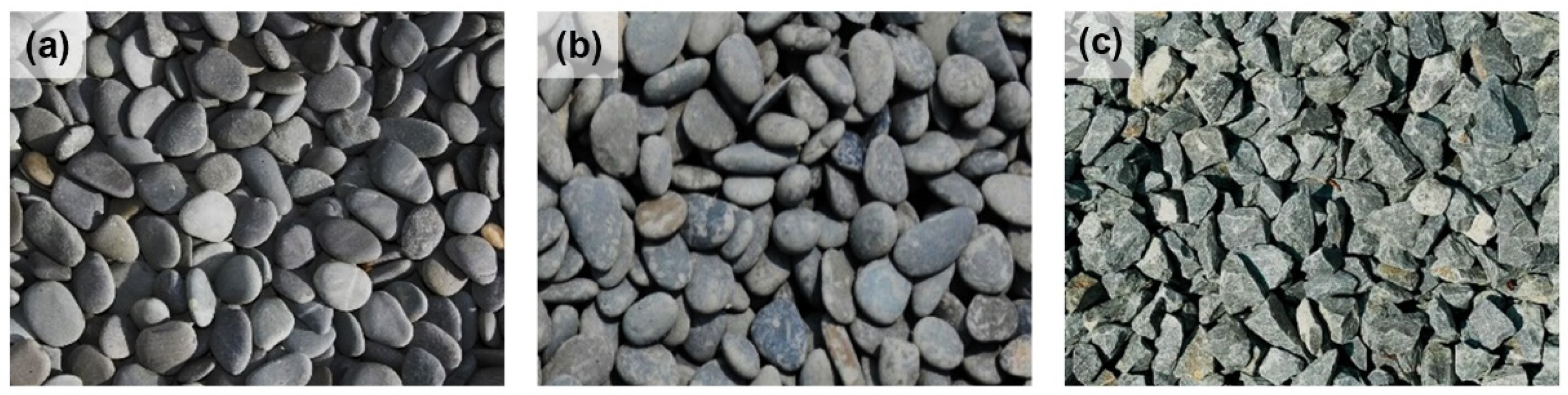

2.1. Raw Materials and Concrete Specimen Preparation

2.2. Experiment and Methods

3. Results and Discussion

3.1. Compressive Strength

3.2. Full-Field Deformation Measurement and Crack Analysis

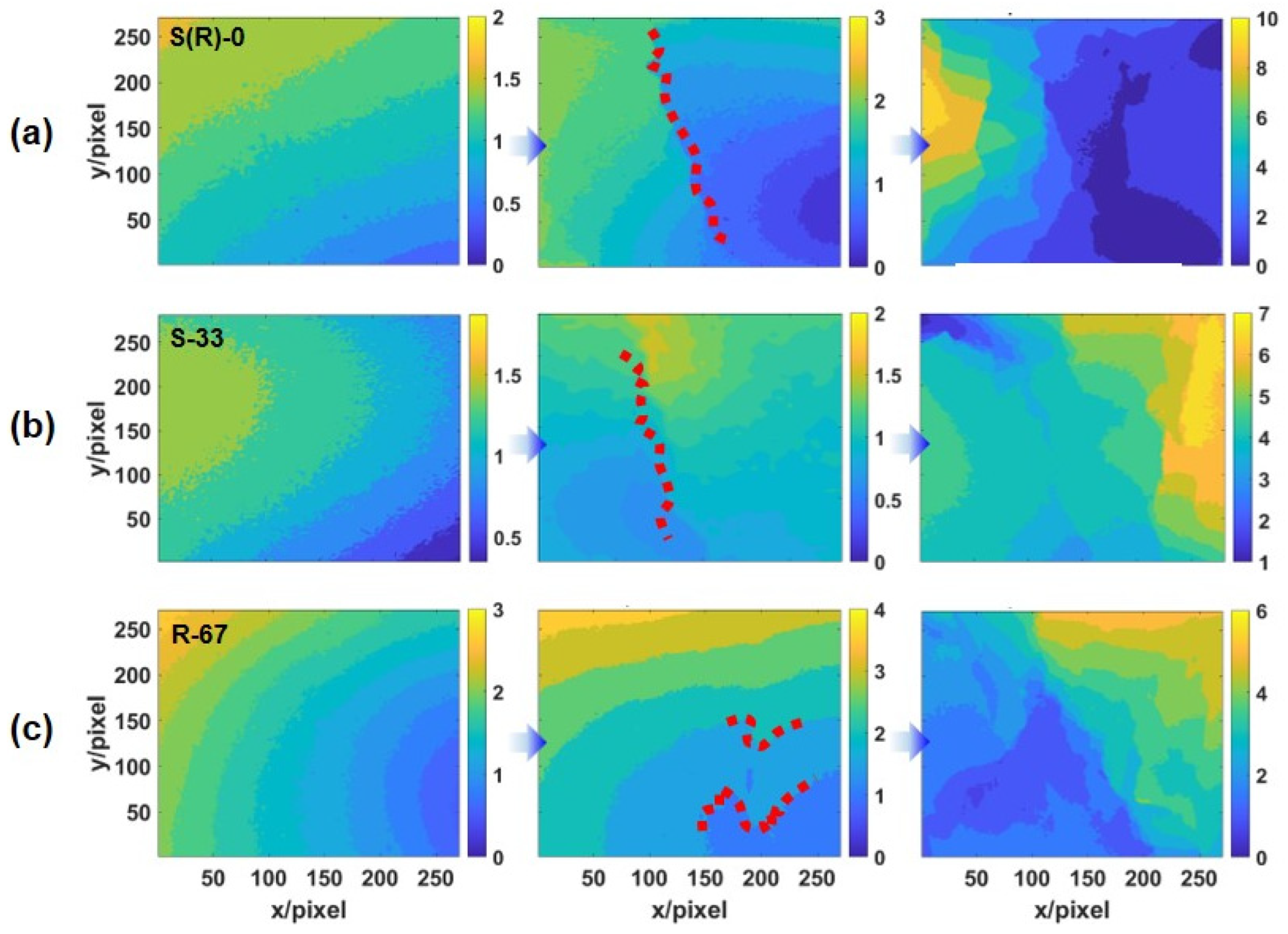

3.2.1. Displacement Fields during the Compressive Loading Process

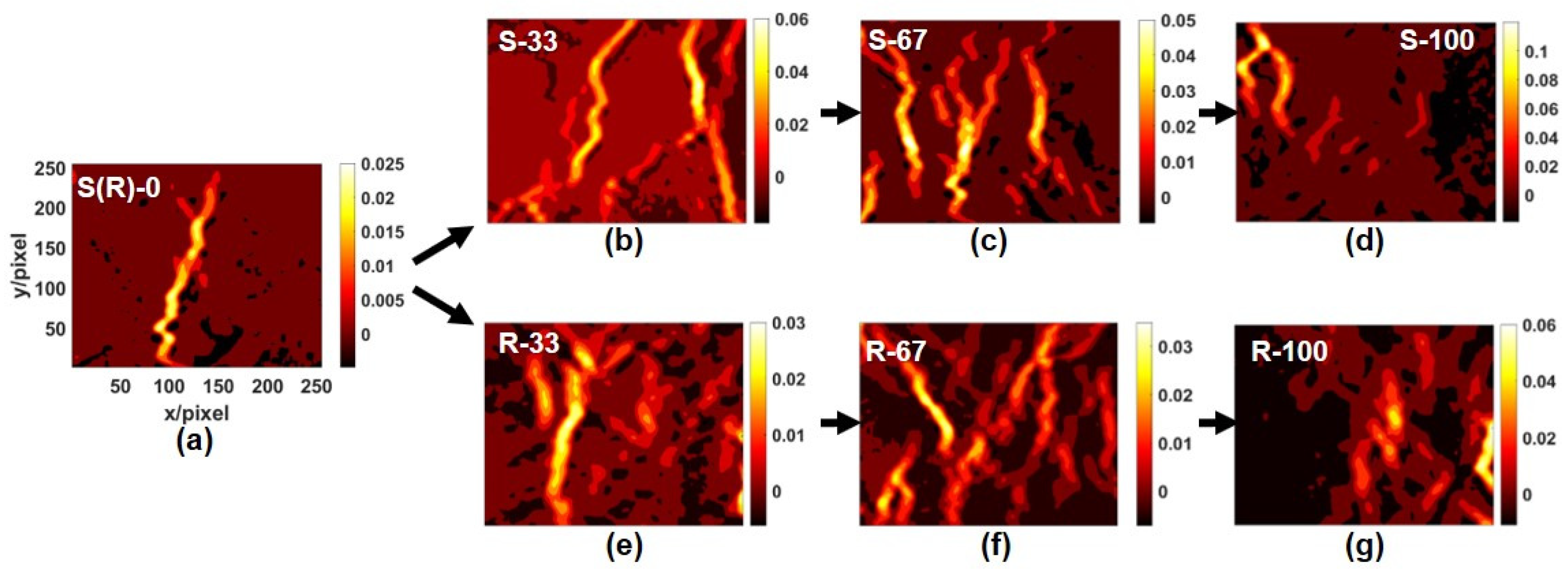

3.2.2. Strain Field Analysis at Failure Stage

3.3. Influence of Pebble Substitution Rates on Compressive Deformation Behaviors

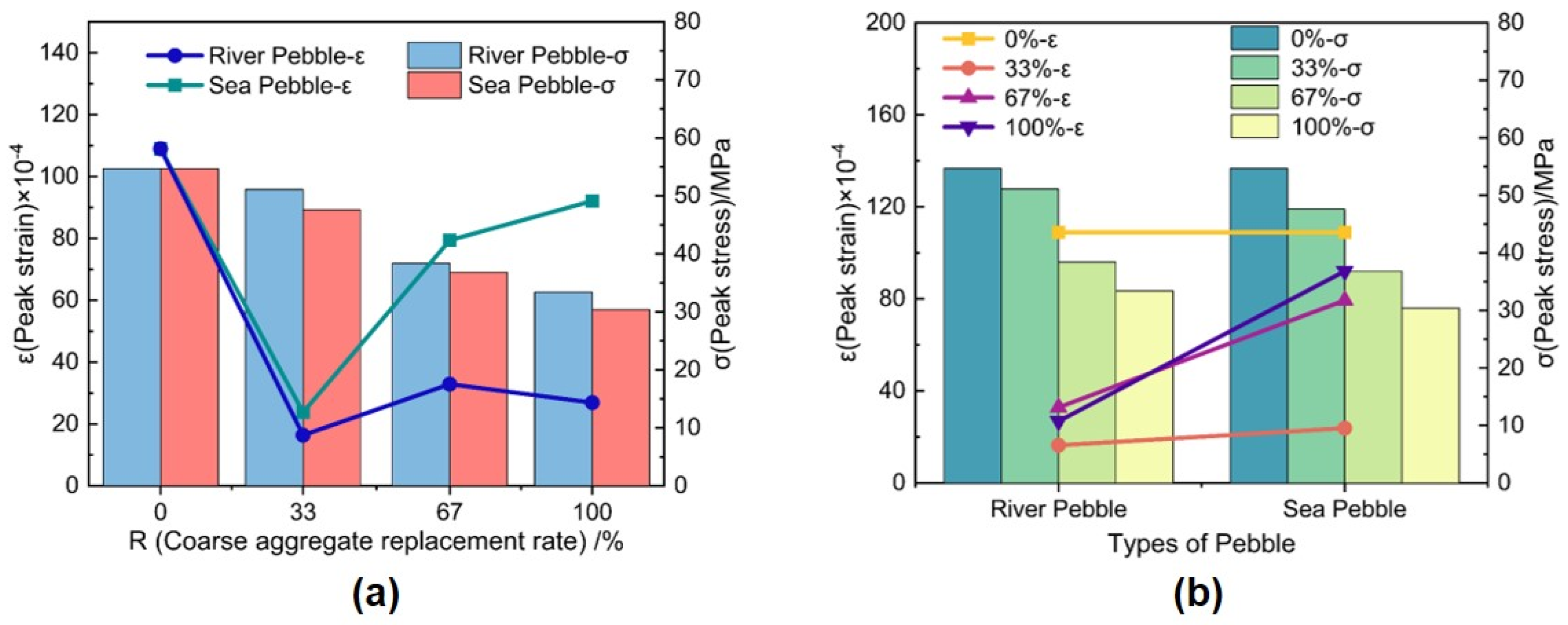

3.3.1. Peak Strain and Peak Stress

3.3.2. Crack Distribution and Interfacial Characteristics

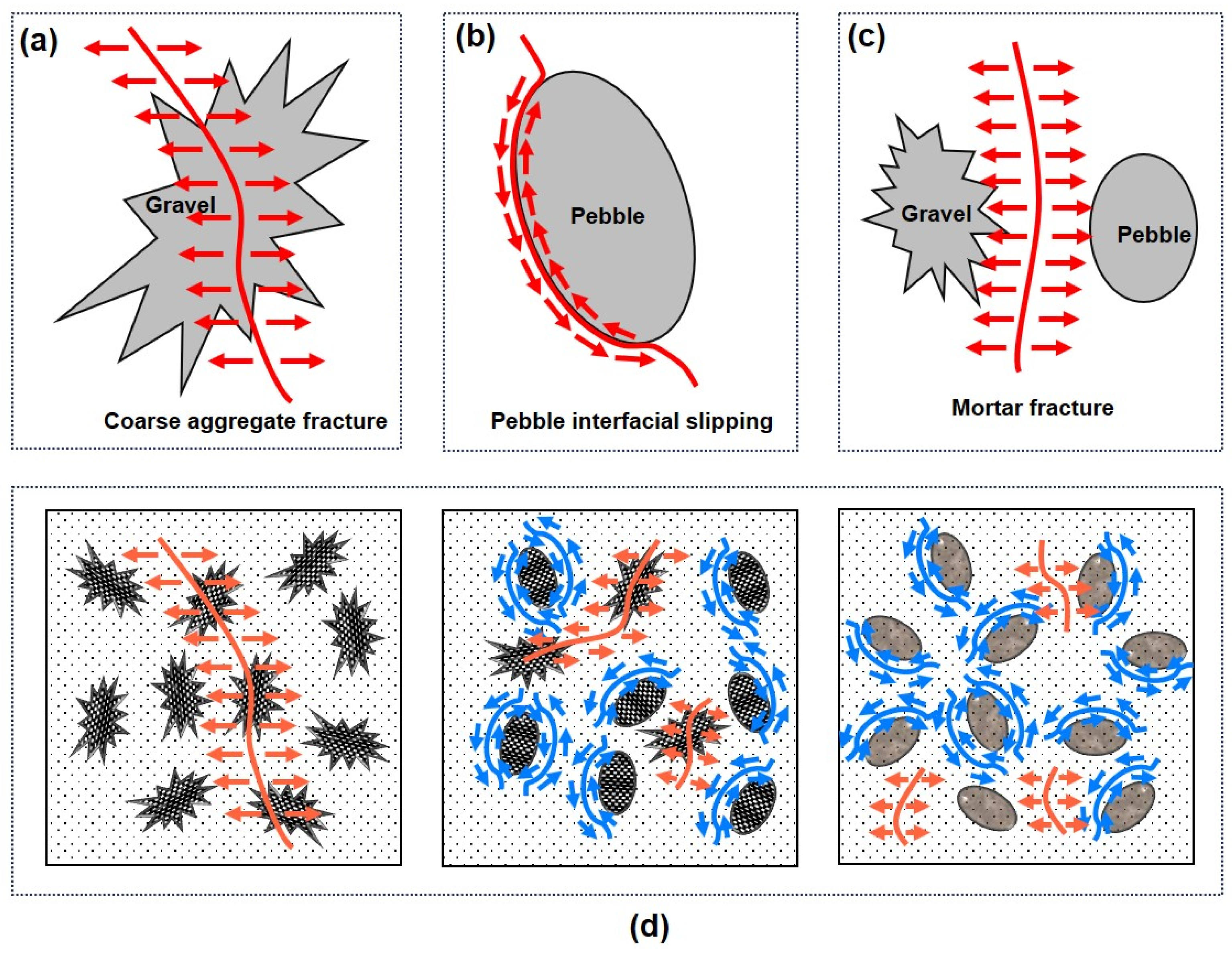

3.3.3. Compressive Failure Mode

4. Conclusions

- (1)

- The compressive strength and peak stress of the RPC/SPC generally decreased with increasing pebble substitution rates compared to traditional GC. Particularly, peak strains in both RPC and SPC initially decreased and then increased with higher pebble substitution rates.

- (2)

- The elastic deformation stage in the stress-strain curves of both RPC and SPC at lower pebble substitution rates (i.e., R-33 and S-33) was similar to that of GC, but the failure stages were steeper. However, obvious load-hardening stages were observed in the stress-strain curves of RPC and SPC at higher substitution rates (i.e., R-67, R-100, S-67, and S-100).

- (3)

- Based on the measured full-field displacement and corresponding strain fields, the spatial-–temporal distribution of cracks was tracked in the concretes. It revealed a single penetrated crack in GC, whereas RPC/SPC exhibited several dispersed local shorter cracks. Correspondingly, the failure mode in GC was coarse aggregate and mortar matrix fracture, while PC showed obvious pebble interfacial slipping.

- (4)

- Comparing RPC and SPC, their compressive deformation and failure behavior characteristics were similar, although the compressive strengths of RPC were relatively higher. Specifically, peak strains of SPC at higher substitution rates (e.g., 67% and 100%) were larger than RPC, consistent with the spatial distribution and local characteristics of strain fields and cracks. However, SPC showed increased numbers and width of generated cracks compared to RPC.

- (5)

- In practical applications, if the feasibility of RPC has been verified, SPC could be employed in offshore or island engineering projects instead of RPC to some extent. Otherwise, strengthening solutions should be considered for RPC/SPC according to the compressive mechanical property requirements of some concrete design codes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lao, J.-C.; Huang, B.-T.; Xu, L.-Y.; Khan, M.; Fang, Y.; Dai, J.-G. Seawater Sea-Sand Engineered Geopolymer Composites (EGC) with High Strength and High Ductility. Cem. Concr. Compos. 2023, 138, 104998. [Google Scholar] [CrossRef]

- Bader, M.A. Performance of Concrete in a Coastal Environment. Cem. Concr. Compos. 2003, 25, 539–548. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Feng, W.; Tang, Y.; Yang, Y.; Cheng, Y.; Qiu, J.; Zhang, H.; Isleem, H.F.; Tayeh, B.A.; Namdar, A. Mechanical Behavior and Constitutive Model of Sustainable Concrete: Seawater and Sea-Sand Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 364, 130010. [Google Scholar] [CrossRef]

- Feng, N.Q.; Yan, J.H.; Peng, G.F. Ecological Environment and Concrete Technology in China. KEM 2006, 302–303, 12–18. [Google Scholar] [CrossRef]

- Huang, Y.; Li, X.; Lu, Y.; Wang, H.; Wang, Q.; Sun, H.; Li, D. Effect of Mix Component on the Mechanical Properties of Coral Concrete under Axial Compression. Constr. Build. Mater. 2019, 223, 736–754. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Sun, Y. Mechanical Properties of Sea Sand Recycled Aggregate Concrete under Axial Compression. Constr. Build. Mater. 2018, 175, 55–63. [Google Scholar] [CrossRef]

- Ribeiro, S.; Ribeiro, D.D.C.; Dias, M.B.D.S.; Garcia, G.C.R.; Santos, É.M.B.D. Study of the Fracture Behavior of Mortar and Concretes with Crushed Rock or Pebble Aggregates. Mater. Res. 2011, 14, 46–52. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, Z. Mechanical Properties of Recycled Concrete Made with Different Types of Coarse Aggregate. Constr. Build. Mater. 2017, 134, 497–506. [Google Scholar] [CrossRef]

- SL 677–2014; Specifications for Hydraulic Concrete Construction. Ministry of Water Resources of the People’s Republic of China, China Water & Power Press: Beijing, China, 2014.

- JTS 202–2011; Specifications for Concrete Construction of Port and Waterway Engineering. Ministry of Transport of the People’s Republic of China, People’s Communications Press Co., Ltd.: Beijing, China, 2011.

- Bayle, P.M.; Blenkinsopp, C.E.; Conley, D.; Masselink, G.; Beuzen, T.; Almar, R. Performance of a Dynamic Cobble Berm Revetment for Coastal Protection, under Increasing Water Level. Coast. Eng. 2020, 159, 103712. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, G.; Wu, Y.; Dai, M.; Jiang, M.; Xie, J. Recycled Aggregate Seawater–Sea Sand Concrete and Its Durability after Immersion in Seawater. J. Build. Eng. 2023, 65, 105780. [Google Scholar] [CrossRef]

- Meddah, M.S.; Zitouni, S.; Belâabes, S. Effect of Content and Particle Size Distribution of Coarse Aggregate on the Compressive Strength of Concrete. Constr. Build. Mater. 2010, 24, 505–512. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, B.; Dai, Q.; Yu, X. Investigation of Internal Curing Effects on Microstructure and Permeability of Interface Transition Zones in Cement Mortar with SEM Imaging, Transport Simulation and Hydration Modeling Techniques. Constr. Build. Mater. 2015, 76, 366–379. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, C.; Ye, P. The Compressive Strength and Flexural Strength Test of Recycled Pebble Aggregate Concrete. Appl. Mech. Mater. 2013, 357–360, 1433–1436. [Google Scholar] [CrossRef]

- Jun, Y.; Kim, J.H.; Han, S.H.; Kim, T. Influence of Seawater on Alkali-Activated Slag Concrete. Mater Struct 2021, 54, 121. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hamada, H.; Yamaji, T. Performance of Seawater-Mixed Concrete in the Tidal Environment. Cem. Concr. Res. 2004, 34, 593–601. [Google Scholar] [CrossRef]

- Da Silva, M.A.; Pepe, M.; De Andrade, R.G.M.; Pfeil, M.S.; Toledo Filho, R.D. Rheological and Mechanical Behavior of High Strength Steel Fiber-River Gravel Self Compacting Concrete. Constr. Build. Mater. 2017, 150, 606–618. [Google Scholar] [CrossRef]

- Chen, Z.; Mo, L.; Song, C.; Zhang, Y. Investigation on Compression Properties of Seawater-Sea Sand Concrete. Adv. Concr. Constr. 2021, 12, 93–103. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhou, S.; Wei, H.B.; Li, W.J.; Xiu, R.; Zhu, B. Mechanical Properties, Permeability and Freeze-Thaw Durability of Low Sand Rate Pervious Concrete. J. Phys. Conf. Ser. 2021, 1765, 012022. [Google Scholar] [CrossRef]

- Ohtsu, M.; Watanabe, H. Quantitative Damage Estimation of Concrete by Acoustic Emission. Constr. Build. Mater. 2001, 15, 217–224. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A Review on Microstructural Study and Compressive Strength of Geopolymer Mortar, Paste and Concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, X.; Yu, M.; Yao, J. An Analytical Approach to Predict Fracture Parameters of Coral Aggregate Concrete Immersed in Seawater. Ocean Eng. 2019, 191, 106508. [Google Scholar] [CrossRef]

- Li, D.; Huang, P.; Chen, Z.; Yao, G.; Guo, X.; Zheng, X.; Yang, Y. Experimental Study on Fracture and Fatigue Crack Propagation Processes in Concrete Based on DIC Technology. Eng. Fract. Mech. 2020, 235, 107166. [Google Scholar] [CrossRef]

- Le, D.B.; Tran, S.D.; Torero, J.L.; Dao, V.T.N. Application of Digital Image Correlation System for Reliable Deformation Measurement of Concrete Structures at High Temperatures. Eng. Struct. 2019, 192, 181–189. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Xiao, J. Deformation Field and Crack Analyses of Concrete Using Digital Image Correlation Method. Front. Struct. Civ. Eng. 2019, 13, 1183–1199. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, W.; Zhu, W.; Xu, Y. Local Damage Detection of Membranes Based on Bayesian Operational Modal Analysis and Three-Dimensional Digital Image Correlation. Mech. Syst. Signal Process. 2019, 131, 633–648. [Google Scholar] [CrossRef]

- Aliabadian, Z.; Zhao, G.-F.; Russell, A.R. Crack Development in Transversely Isotropic Sandstone Discs Subjected to Brazilian Tests Observed Using Digital Image Correlation. Int. J. Rock Mech. Min. Sci. 2019, 119, 211–221. [Google Scholar] [CrossRef]

- Bolivar, J.; Frégonèse, M.; Réthoré, J.; Duret-Thual, C.; Combrade, P. Evaluation of Multiple Stress Corrosion Crack Interactions by In-Situ Digital Image Correlation. Corros. Sci. 2017, 128, 120–129. [Google Scholar] [CrossRef]

- Lakavath, C.; Joshi, S.S.; Prakash, S.S. Investigation of the Effect of Steel Fibers on the Shear Crack-Opening and Crack-Slip Behavior of Prestressed Concrete Beams Using Digital Image Correlation. Eng. Struct. 2019, 193, 28–42. [Google Scholar] [CrossRef]

- GB/T 14685–2011; Standardization Administration of China, Pebble and Crushed Stone for Construction. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011.

- JGJ52–2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. Ministry of Construction of the People’s Republic of China, China Architecture & Building Press: Beijing, China, 2006.

- JGJ55-2011; Specification for mix proportion design of ordinary concrete. China Academy of Building Science, China Architecture & Building Press: Beijing, China, 2011.

- GB/T 50081-2002; Standard for test method of mechanical properties on ordinary concrete. Ministry of Construction of the People’s Republic of China, China Architecture & Building Press: Beijing, China, 2002.

| Coarse Aggregate | River Pebble | Sea Pebble | Gravel |

|---|---|---|---|

| Gradation (mm) | 5~25 | 5~25 | 5~25 |

| Apparent density (kg/m3) | 2845 | 2780 | 2603 |

| Bulk density (kg/m3) | 1736 | 1694 | 1549 |

| Water absorption (%) | 1.3 | 1.1 | 1.05 |

| Moisture content (%) | 0.01 | 0.04 | 0.01 |

| Crushing index (%) | 12.1 | 11.7 | 9.6 |

| Specimen | SR (%) | Cement | Water | Sand | Gravel | Pebble |

|---|---|---|---|---|---|---|

| S(R)-0 | 0 | 388 | 190 | 569 | 1156 | 0 |

| R-33 | 33 | 370 | 177.5 | 569 | 774.5 | 381.5 |

| R-67 | 67 | 370 | 177.5 | 569 | 381.5 | 774.5 |

| R-100 | 100 | 370 | 177.5 | 569 | 0 | 1156.0 |

| S-33 | 33 | 370 | 177.5 | 569 | 774.5 | 381.5 |

| S-67 | 67 | 370 | 177.5 | 569 | 381.5 | 774.5 |

| S-100 | 100 | 370 | 177.5 | 569 | 0 | 1156.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zhao, Y.; Feng, X.; Lei, Y.; Zhang, W. Spatio-Temporal Compressive Behaviors of River Pebble Concrete and Sea Pebble Concrete in Island Offshore Engineering. J. Mar. Sci. Eng. 2024, 12, 1395. https://doi.org/10.3390/jmse12081395

Yuan Y, Zhao Y, Feng X, Lei Y, Zhang W. Spatio-Temporal Compressive Behaviors of River Pebble Concrete and Sea Pebble Concrete in Island Offshore Engineering. Journal of Marine Science and Engineering. 2024; 12(8):1395. https://doi.org/10.3390/jmse12081395

Chicago/Turabian StyleYuan, Yuan, Yian Zhao, Xiaotian Feng, Yanhua Lei, and Wenbing Zhang. 2024. "Spatio-Temporal Compressive Behaviors of River Pebble Concrete and Sea Pebble Concrete in Island Offshore Engineering" Journal of Marine Science and Engineering 12, no. 8: 1395. https://doi.org/10.3390/jmse12081395

APA StyleYuan, Y., Zhao, Y., Feng, X., Lei, Y., & Zhang, W. (2024). Spatio-Temporal Compressive Behaviors of River Pebble Concrete and Sea Pebble Concrete in Island Offshore Engineering. Journal of Marine Science and Engineering, 12(8), 1395. https://doi.org/10.3390/jmse12081395