Stereo Particle Image Velocimetry Measurement of the Flow around SUBOFF Submarine under Yaw Conditions

Abstract

:1. Introduction

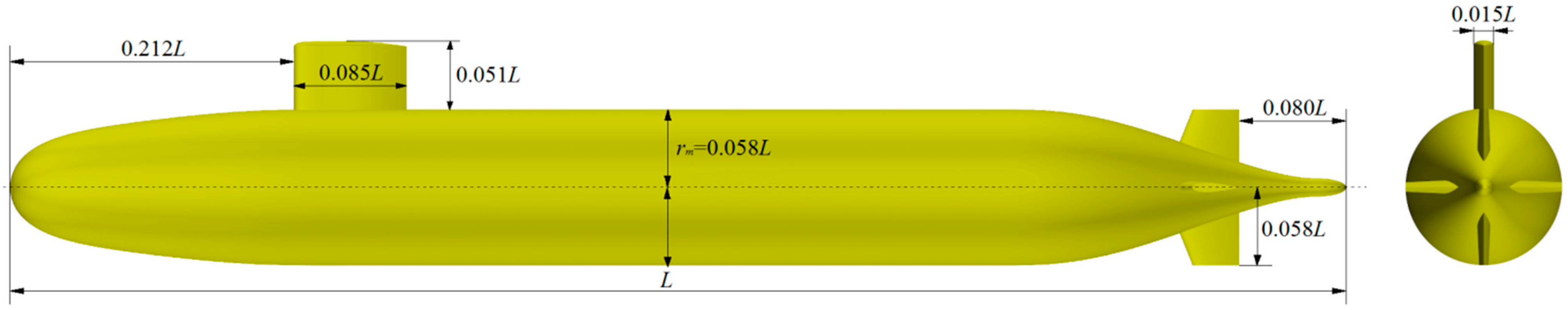

2. The SUBOFF Submarine Model

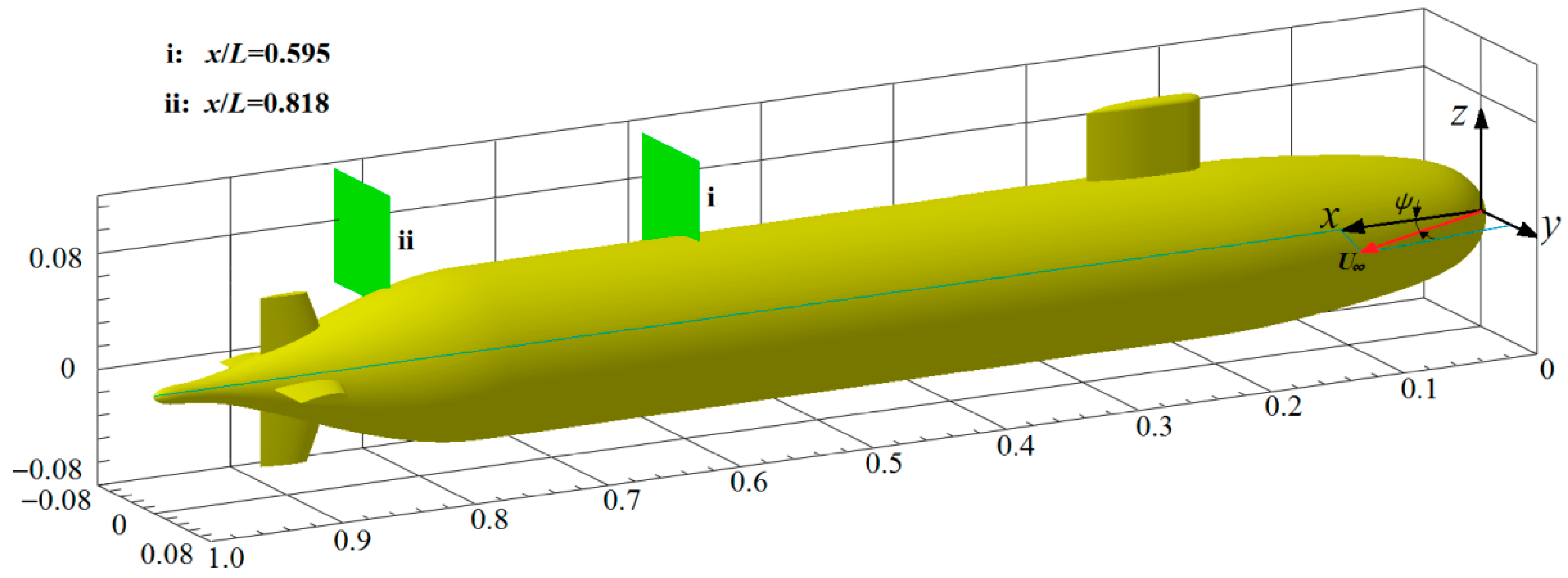

3. Measurements Planes and Coordinate System

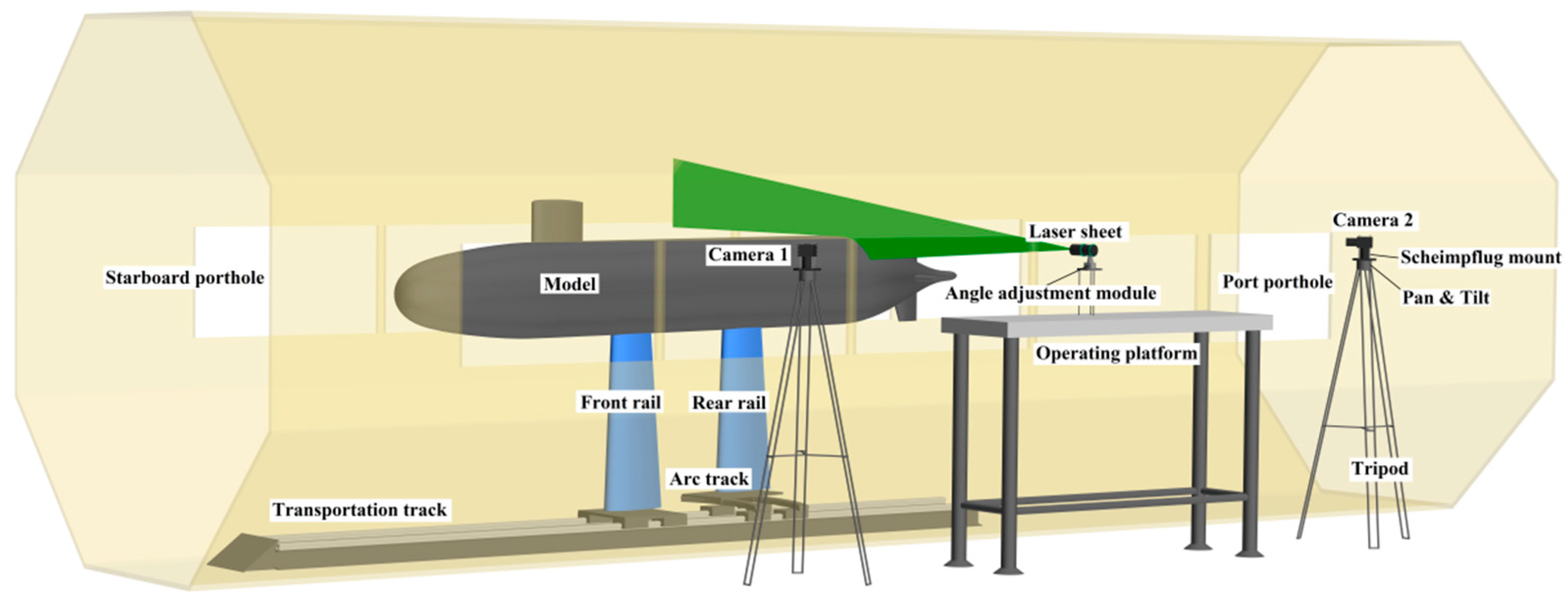

4. Experimental Facilities and Measuring Techniques

4.1. Facility

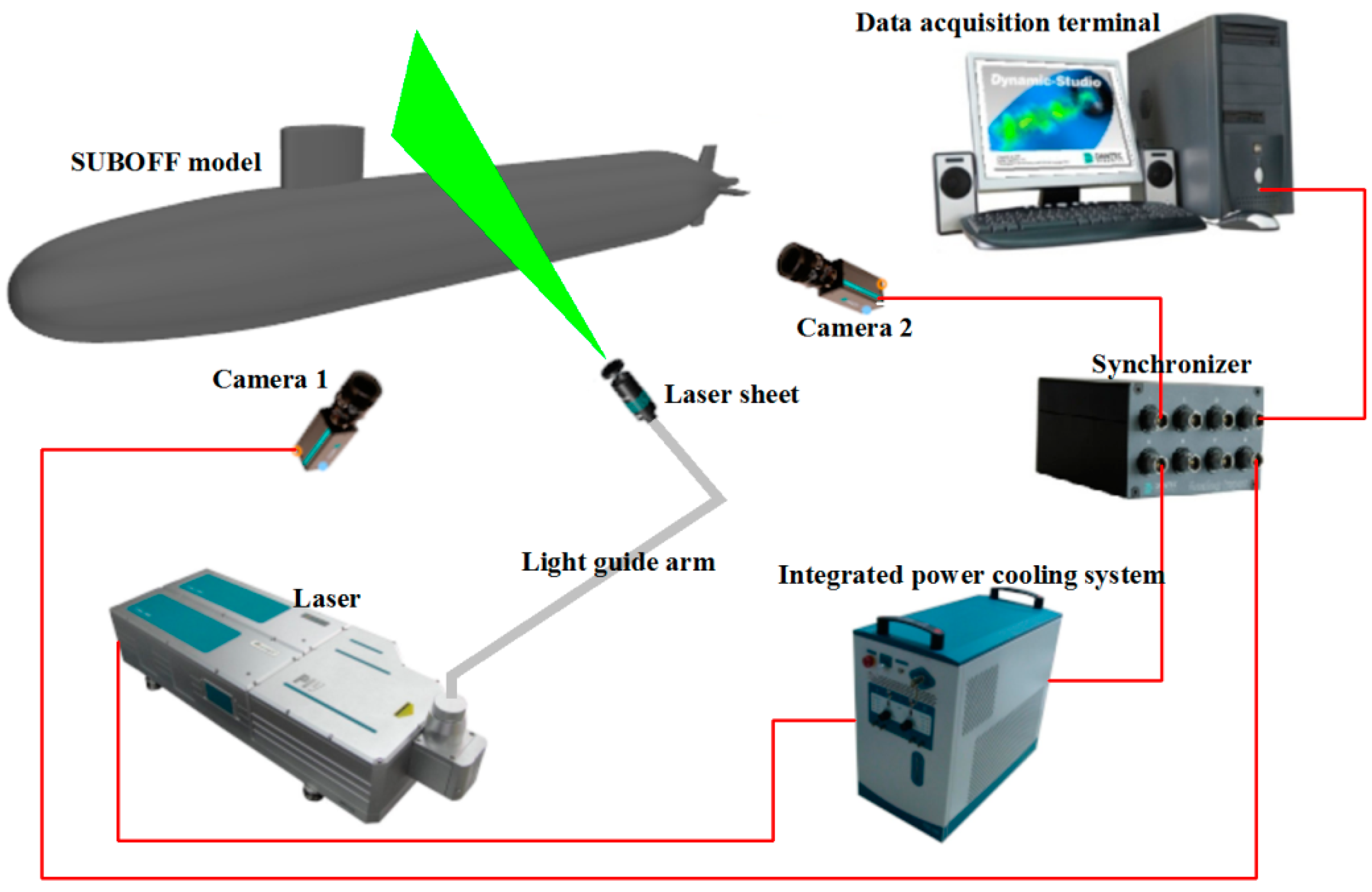

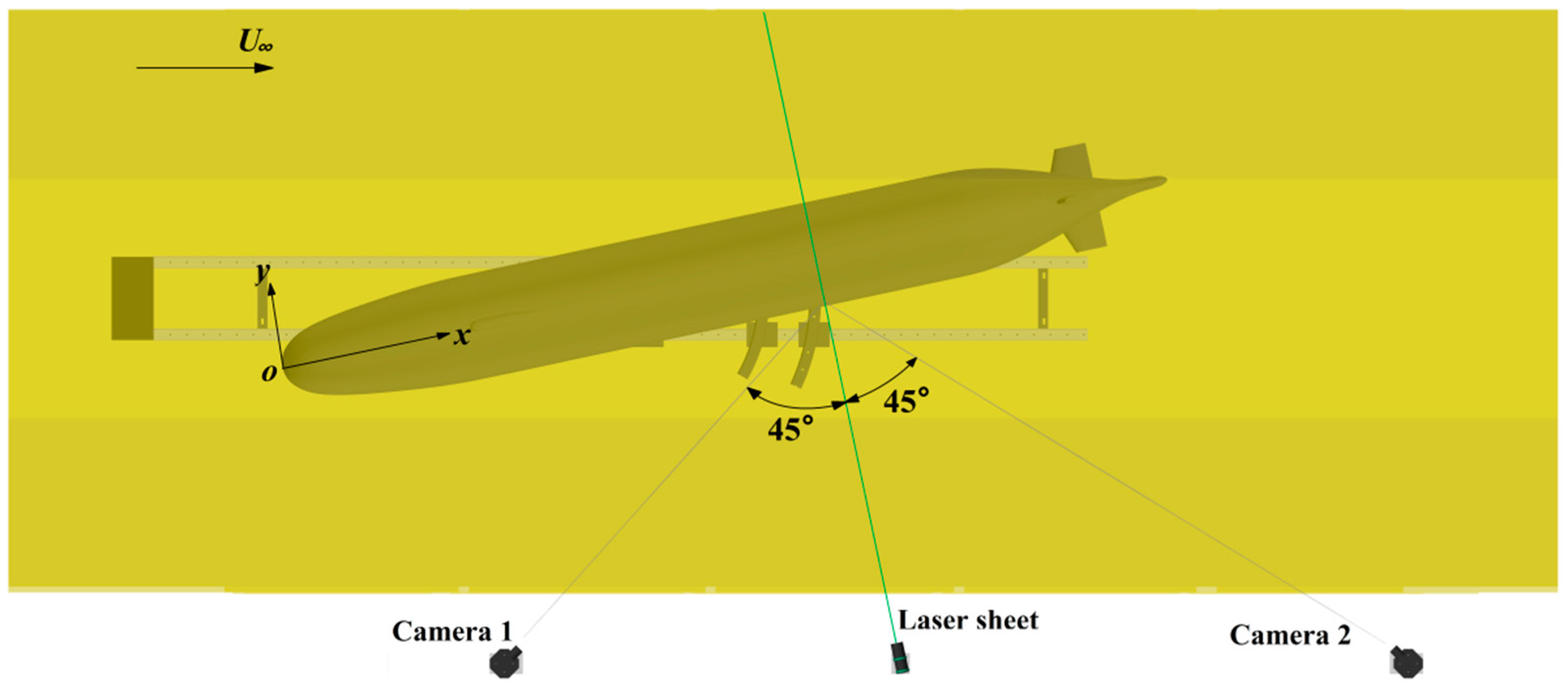

4.2. Stereo Particle Image Velocimetry System

4.3. SPIV Data Processing

5. Results and Discussion

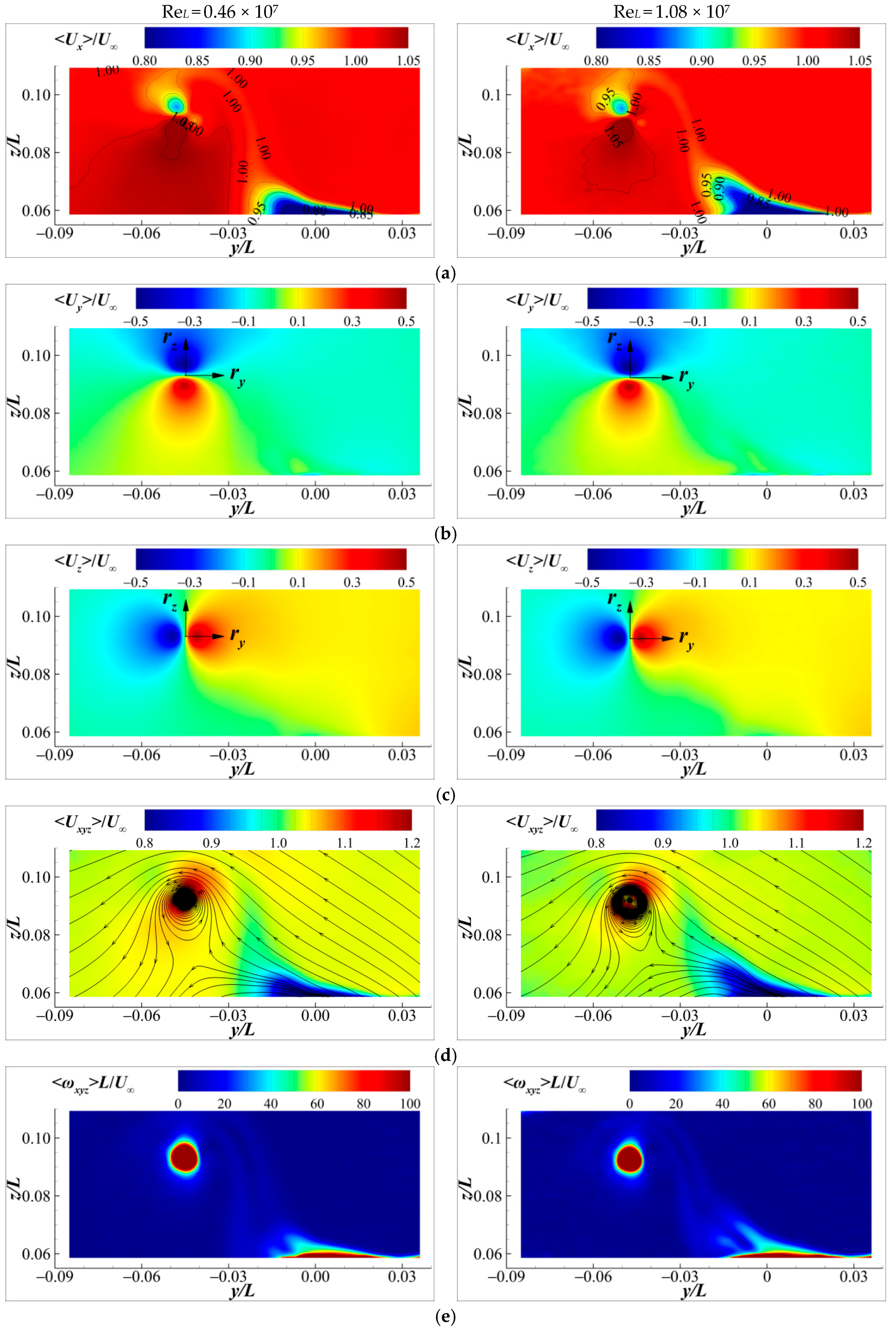

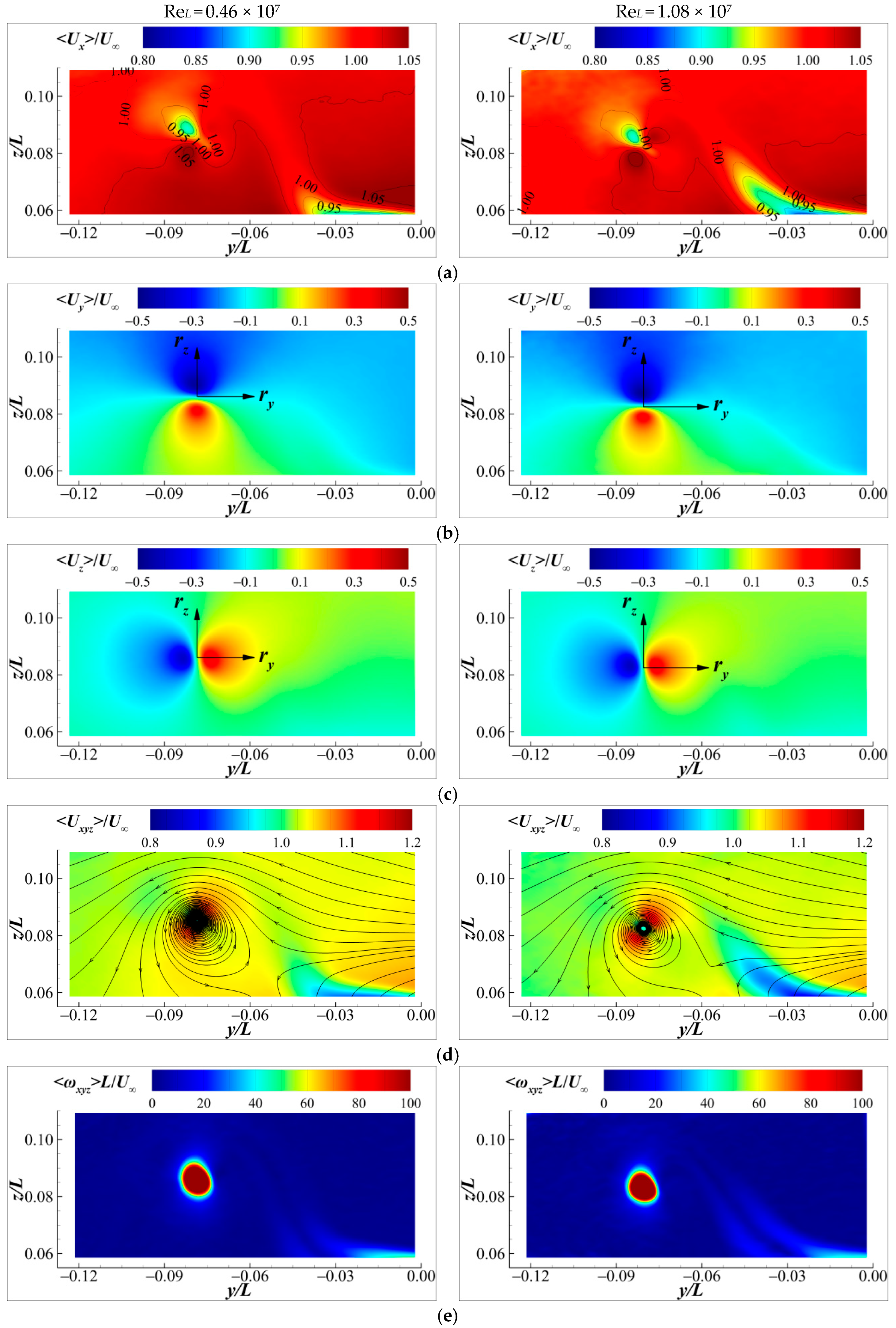

5.1. Velocity and Vorticity Fields

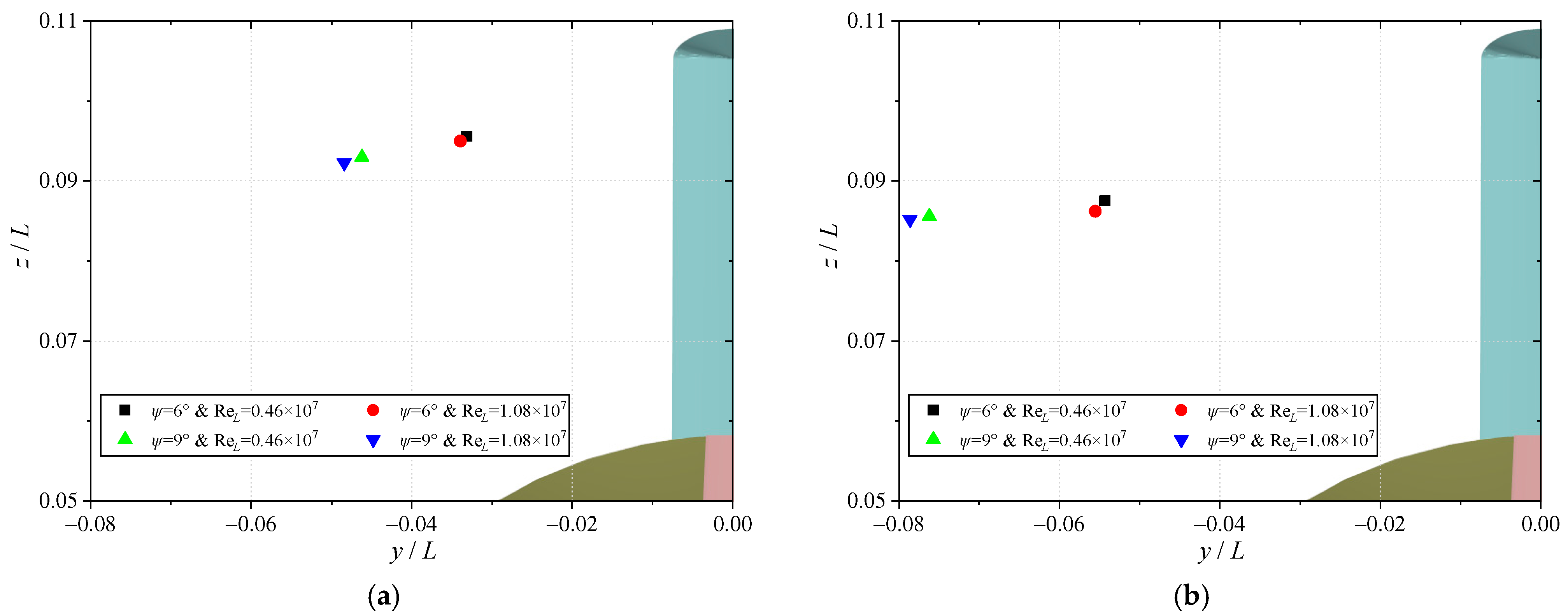

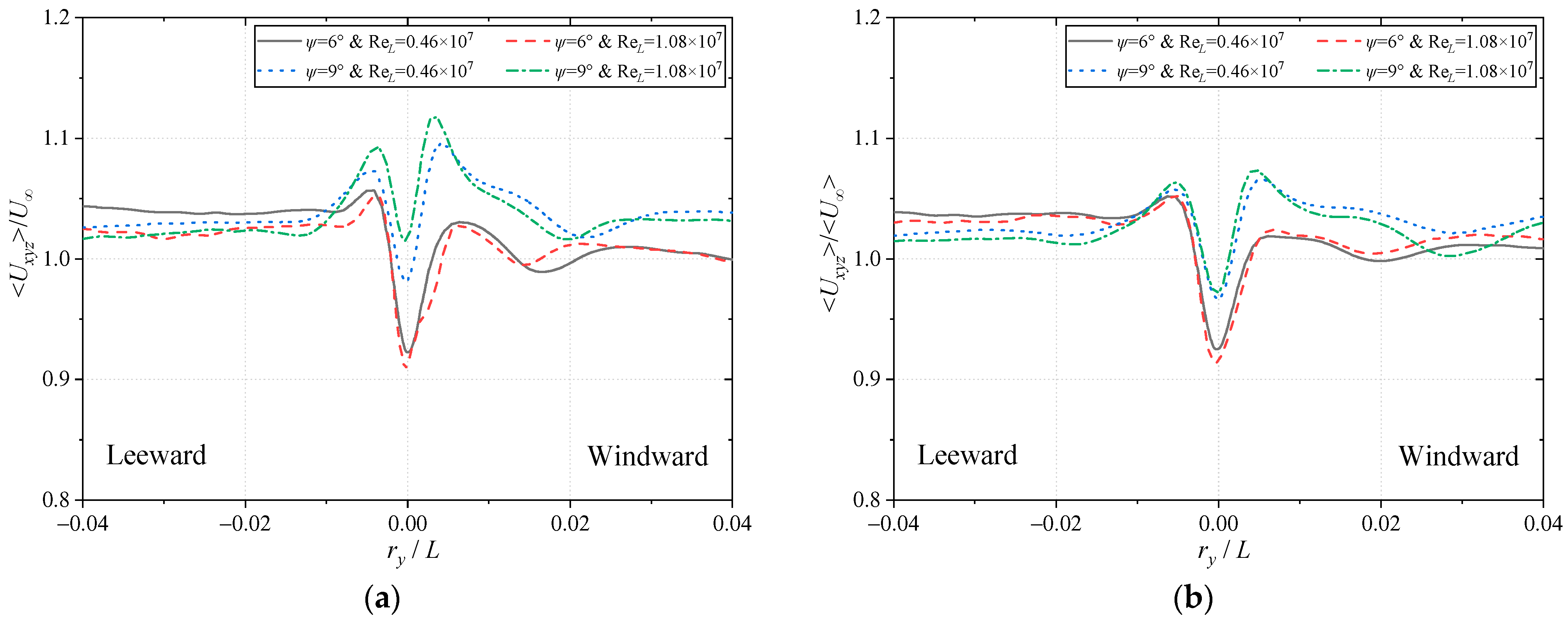

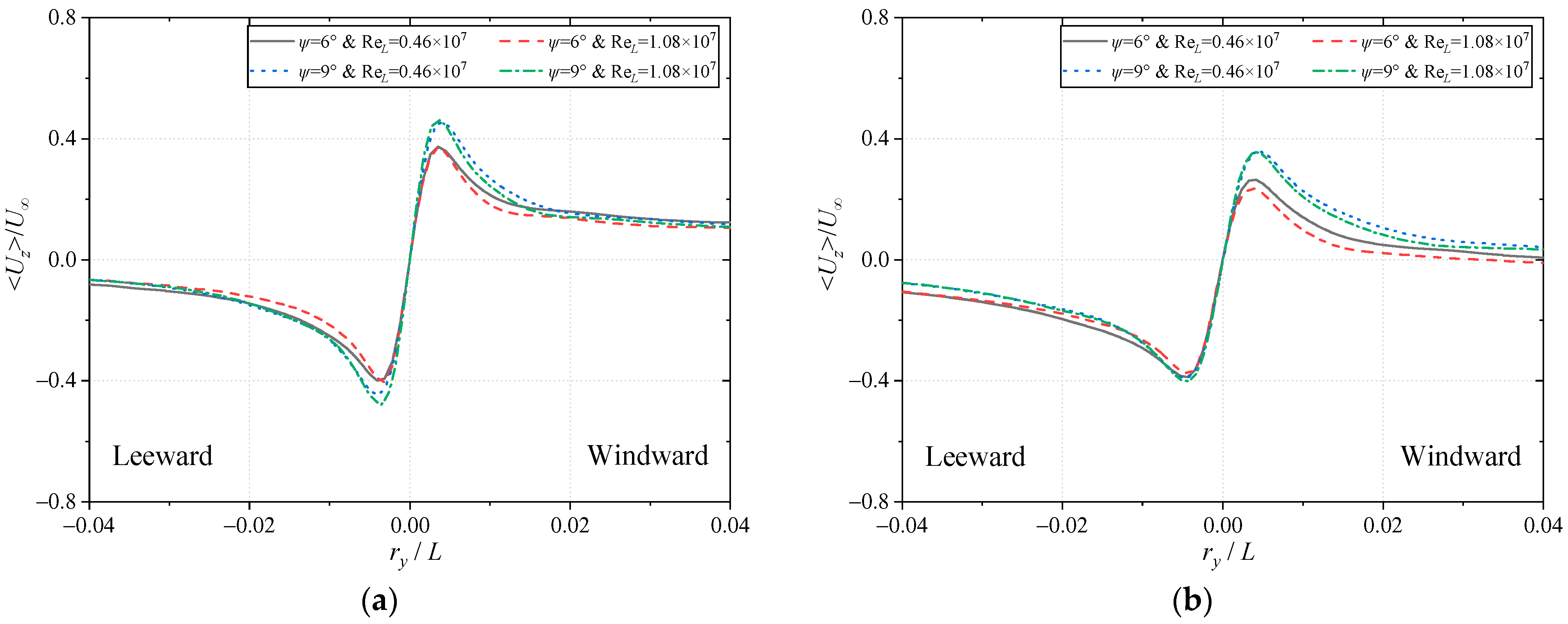

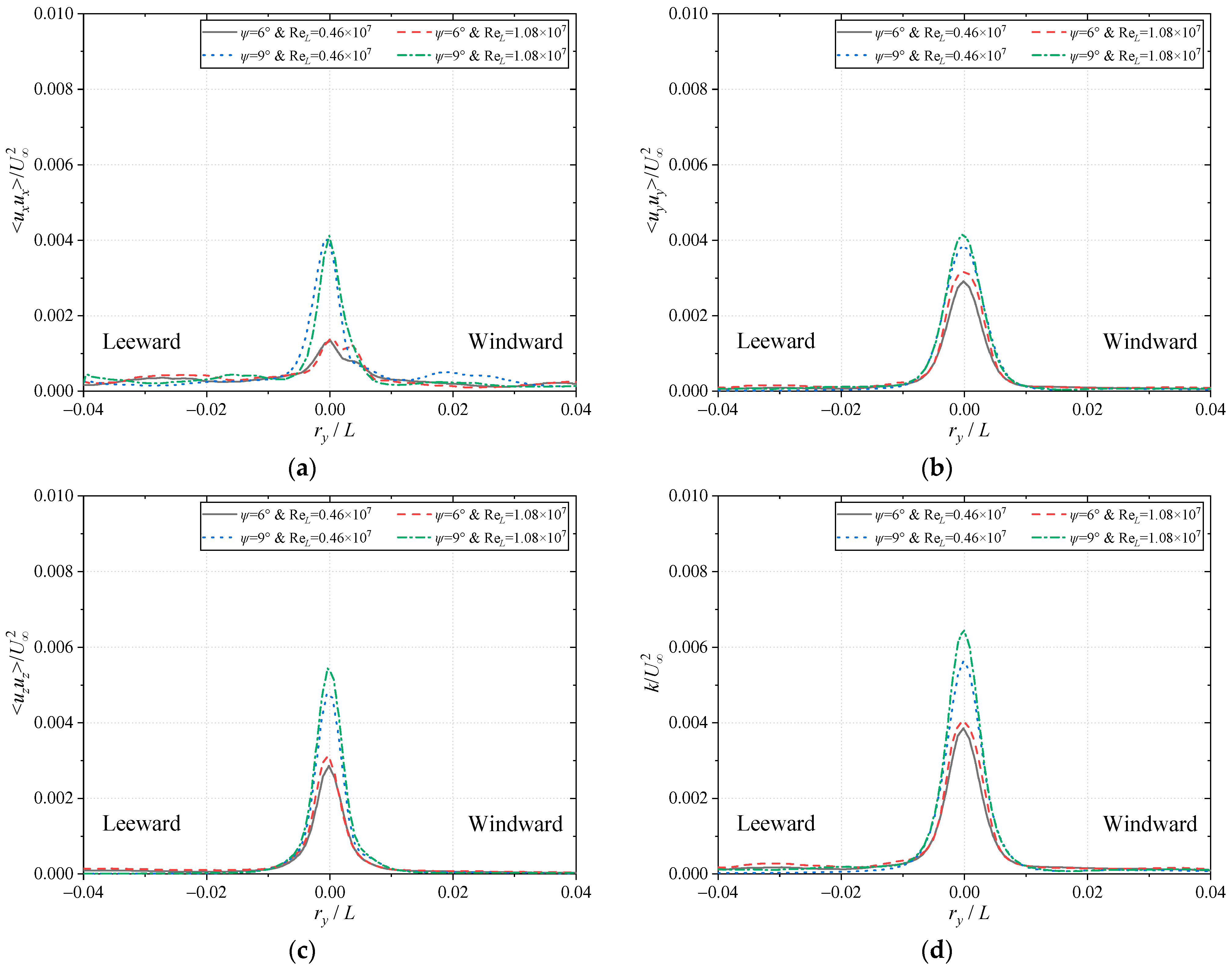

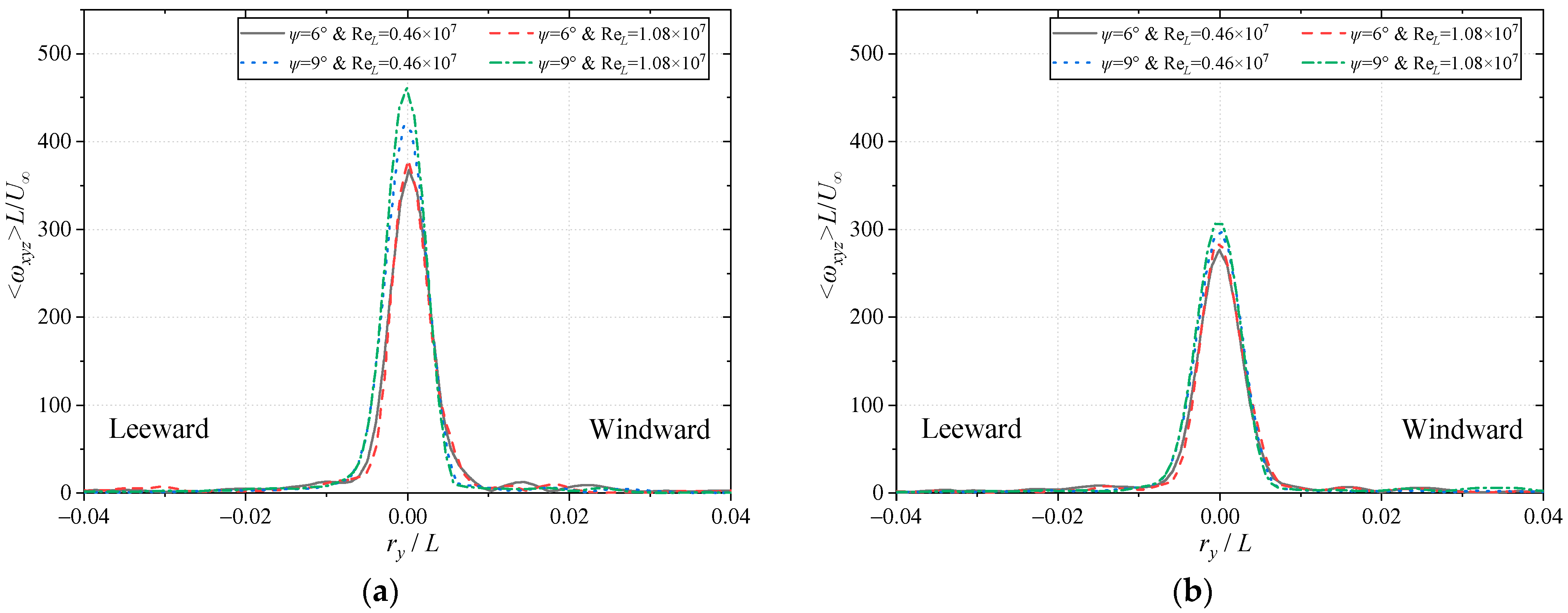

5.2. Characteristics of Sail-Tip Vortex

6. Conclusions

- (1)

- Under yaw conditions, the wake originating from the top of the sail rolls up to form the sail-tip vortex, whose center exhibits a core flow with a resultant velocity slightly lower than the freestream velocity. Along the direction of flow evolution, the vorticity continuously dissipates. Further downstream, except for the sail-tip vortex center and the wake generated at the junction of the sail root and the hull, the vorticity originating from the sail almost completely dissipates. The influence of the sail and hull on the axial velocity gradually diminishes as the flow progresses downstream, and the velocity of the wake gradually increases along the hull’s axial direction, but there is almost no change in the lateral and vertical velocities. The vorticity magnitude and turbulent kinetic energy (TKE) of the wake are stronger at a larger yaw angle, and they are insignificantly affected by the Reynolds number within the range of 0.46 × 107 to 1.08 × 107 or by the flow velocity.

- (2)

- Under yaw conditions, as the flow evolves downstream, a downwash of the sail-tip vortex center becomes evident. With the increase in the yaw angle and Reynolds number, this downwash effect becomes more pronounced. From ψ = 6° to ψ = 9°, the vertical coordinates of the sail-tip vortex center decrease by approximately 1.2% to 2.9%. Additionally, a higher Reynolds number results in a slight deviation of the vortex center towards the suction side.

- (3)

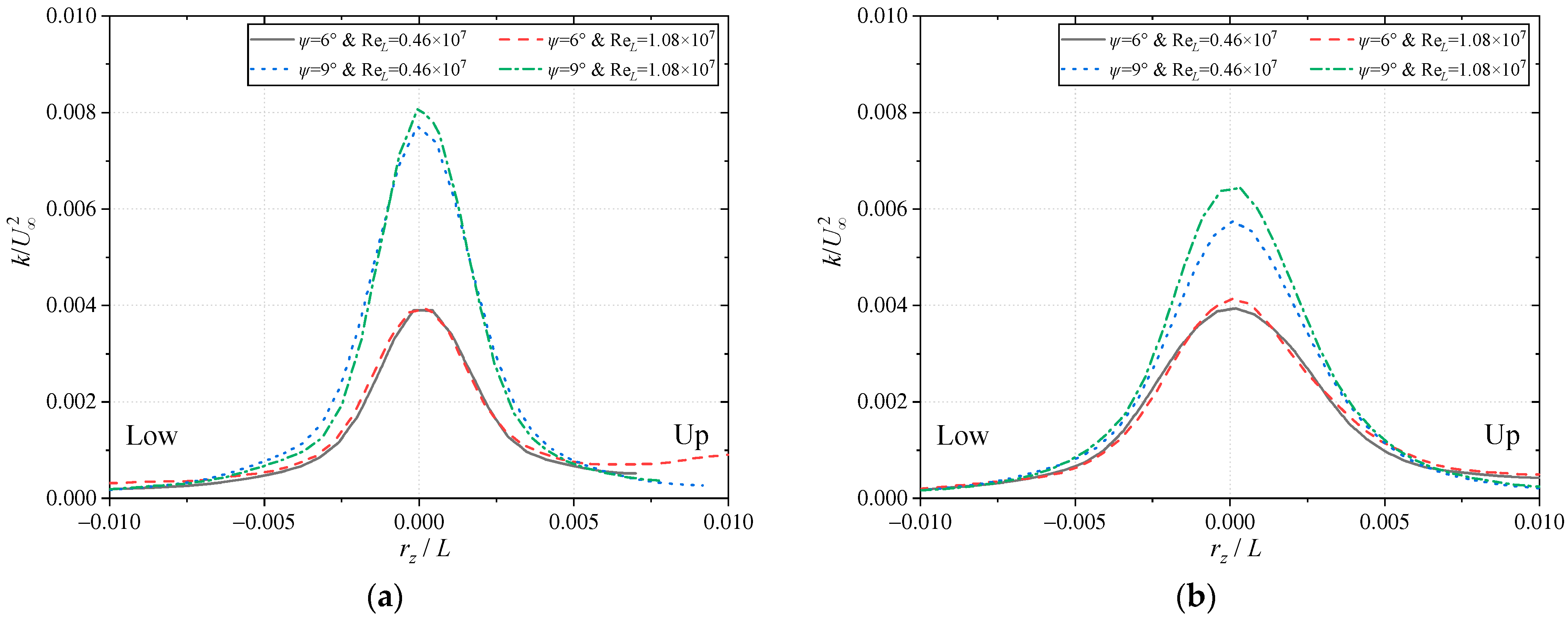

- The lateral velocities on the upper and lower sides, in proximity to the sail-tip vortex center, as well as the vertical velocities on the windward and leeward sides, exhibit an almost asymmetric distribution. The maximum absolute values of both the lateral and vertical velocities near the vortex center increase with an increase in the yaw angle. The change in Reynolds number has virtually no effect on the vertical velocity. The normal Reynolds stresses and the TKE peak at the vortex center, and these peak values slightly increase with an increase in Reynolds number, while they significantly increase with an increase in yaw angle. The lateral and vertical components of the normal Reynolds stresses make similar contributions to the TKE, and both are significantly greater than the axial component. The distribution of the vorticity magnitude is quite similar to that of the TKE.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, M.; Zhang, N.; Sun, H.; Zhang, X. Large Eddy Simulation of the Flow around a Generic Submarine under Straight-Ahead and 10° Yaw Conditions. J. Mar. Sci. Eng. 2023, 11, 2286. [Google Scholar] [CrossRef]

- Joubert, P.N. Some Aspects of Submarine Design Part 1: Hydrodynamics; Technical Report DSTO-TR-1622; Australia Defence Science and Technology Organization: Canberra, Australia, 2004. [Google Scholar]

- Joubert, P.N. Some Aspects of Submarine Design Part 2: Shape of a Submarine 2026; Technical Report DSTO-TR-1920; Australia Defence Science and Technology Organization: Canberra, Australia, 2006. [Google Scholar]

- Quick, H.; Widjaja, R.; Anderson, B.; Woodyatt, B.; Snowden, A.D.; Lam, S. Phase I Experimental Testing of a generic Submarine Model in the DSTO Low Speed Wind Tunnel; Technical Report DSTO-TN-1101; Australia Defence Science and Technology Organization: Canberra, Australia, 2012. [Google Scholar]

- Kumar, C.; Manovski, P.; Giacobello, M. Particle image velocimetry measurements on a generic sub-marine hull form. In Proceedings of the 18th Australasian Fluid Mechanics Conference, Launceston, TAS, Australia, 3–7 December 2012. [Google Scholar]

- Anderson, B.; Chapuis, M.; Erm, L.; Fureby, C.; Giacobello, M.; Henbest, S.; Jones, D.; Jones, M.; Kumar, C.; Liefvendahl, M.; et al. Experimental and computational investigation of a generic conventional submarine hull form. In Proceedings of the 29th Symposium on Naval Hydrodynamics, Gothenburg, Sweden, 26–31 August 2012. [Google Scholar]

- Jones, M.B.; Erm, L.P.; Valiyf, A.; Henbest, S.M. Skin-Friction Measurements on a Model Submarine; Technical Report DSTO-TR-2898; Australia Defence Science and Technology Organization: Canberra, Australia, 2013. [Google Scholar]

- Lee, S.K. Topology of the flow around a conventional submarine hull. In Proceedings of the 19th Australasian Fluid Mechanics Conference, Melbourne, Australia, 8–11 December 2014. [Google Scholar]

- Manovski, P.; Giacobello, M.; Jacquemin, P. Smoke Flow Visualization and Particle Image Velocimetry Measurements over a Generic Submarine Model; Technical Report DSTO-TR-2944; Australia Defence Science and Technology Organization: Canberra, Australia, 2014. [Google Scholar]

- Fureby, C.; Anderson, B.; Clarke, D.; Erm, L.; Henbest, S.; Giacobello, M.; Jones, D.; Nguyen, M.; Johansson, M.; Jones, M.; et al. Experimental and numerical study of a generic conventional submarine at 10° yaw. Ocean Eng. 2016, 116, 1–20. [Google Scholar] [CrossRef]

- Quick, H.; Woodyatt, B. Phase II Experimental Testing of a Generic Submarine Model in the DSTO Low Speed Wind Tunnel; Technical Report DSTO-TN-1274; Australia Defence Science and Technology Organization: Canberra, Australia, 2014. [Google Scholar]

- Manovski, P.; Jones, M.B.; Henbest, S.M.; Xue, Y.; Giacobello, M.; de Silva, C. Boundary layer measurements over a body of revolution using long-distance particle image velocimetry. Int. J. Heat Fluid Flow 2020, 83, 108591. [Google Scholar] [CrossRef]

- Bettle, M.C. Validating design methods for sizing submarine tailfns. In Proceedings of the Warship 2014: Naval Submarines and UUV’s, Bath, UK, 18–19 June 2014. [Google Scholar]

- Overpelt, B.; Nienhuis, B.; Anderson, B. Free running maneuvering model tests on a modern generic SSK Class submarine (BB2). In Proceedings of the Pacific International Maritime Conference, Sidney, Australia, 6–8 October 2015. [Google Scholar]

- Lee, S.-K. Longitudinal development of flow-separation lines on slender bodies in translation. J. Fluid Mech. 2018, 837, 627–639. [Google Scholar] [CrossRef]

- Lee, S.-K.; Manovski, P.; Kumar, C. Wake of a cruciform appendage on a generic submarine at 10° yaw. J. Mar. Sci. Technol. 2019, 25, 787–799. [Google Scholar] [CrossRef]

- Lee, S.K.; Jones, M.B. Surface-pressure pattern of separating flows over inclined slender bodies. Phys. Fluids 2020, 32, 095123. [Google Scholar] [CrossRef]

- Xue, Y.; Kumar, C.; Lee, S.-K.; Giacobello, M.; Manovski, P. Identification and analysis of the meandering of a fin-tip vortex using Proper Orthogonal Decomposition (POD). Int. J. Heat Fluid Flow 2020, 82, 108556. [Google Scholar] [CrossRef]

- Fu, T.C.; Atsavapranee, P.; Hess, D.E. PIV Measurements of the Cross-Flow Velocity Field around a Turning Submarine Model (ONR Body-1). Part 1. Eexperimental Setup; Carderock Division: Bethesda, MD, USA, 2002. [Google Scholar]

- Zhang, J.; Zhao, F.; Hong, F.W.; Xu, J. Towing PIV and its application on the juncture forms of stern appendage with main-body. In Proceedings of the 12th Proceedings of the SPIE, Orlando, FL, USA, 3–6 September 2003; Volume 5058, pp. 208–213.

- DeMoss, J.; Simpson, R. Measurements of the steady skin friction and crossflow separation location on an ellipsoidal model in yaw or pitch over a range of roll angles. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. [Google Scholar]

- Huggins, A.; Packwood, A.R. Wind tunnel experiments on a fully appended laminar flow submersible for oceanographic survey. Ocean Eng. 1995, 22, 207–221. [Google Scholar] [CrossRef]

- Huang, T.; Liu, H.L.; Groves, N.; Forlini, T.; Blanton, J.; Gowing, S. Measurements of Flows Over an Axisymmetric Body With Various Appendages in a Wind Tunnel: The DARPA Suboff Experimental Program. In Proceedings of the 19th Symposium on Naval Hydrodynamics, Seoul, Republic of Korea, 23–28 August 1992. [Google Scholar]

- Beigi, S.M.; Shateri, A.; Manshadi, M.D. Experimental study of the submarine’s wake improvement by displacement of stern planes. Ships Offshore Struct. 2021, 17, 2103–2115. [Google Scholar] [CrossRef]

- Khan, M.K.; Korulla, M.; Nagarajan, V.; Sha, O.P. Surface pressure measurements on a generic submarine hull form at high angles of incidence. J. Mar. Sci. Technol. 2022, 27, 677–694. [Google Scholar] [CrossRef]

- Khan, M.K.; Korulla, M.; Nagarajan, V.; Sha, O.P. Steady velocity measurements in the stern wake of submarine hull form at high angles of incidence. Ocean Eng. 2023, 277, 114281. [Google Scholar] [CrossRef]

- Tian, Y.K.; Zhang, X.; Wang, X.; Sun, H.L.; Zhang, N. Measurements of wall shear stress and separation location on underwater vehicle with MEMS sensor arrays. In Proceedings of the 6th International Conference on Advanced Model Measurement Technology for the Maritime Industry, Roma, Italy, 9–11 October 2019. [Google Scholar]

- Ellis, C.L.; Clarke, D.B.; Butler, D.; Brandner, P. Complementary CFD study of generic submarine model tests in a cavitation tunnel. In Proceedings of the 20th Australasian Fluid Mechanics Conference, Perth, Australia, 5–8 December 2016. [Google Scholar]

- Liu, Z.-H.; Xiong, Y.; Wang, Z.-Z.; Wang, S.; Tu, C.-X. Numerical simulation and experimental study of the new method of horseshoe vortex control. J. Hydrodyn. 2010, 22, 572–581. [Google Scholar] [CrossRef]

- Gowing, S. Pressure and Shear Stress Measurement Uncertainty for DARPA SUBOFF Experiment; Departmental Report DRTC/SHD-1298-06; Ship Hydromechanics Department: Delft, The Netherlands, 1990. [Google Scholar]

- Manshadi, M.D.; Hejranfar, K.; Farajollahi, A.H. Effect of vortex generators on hydrodynamic behavior of an underwater axisymmetric hull at high angles of attack. J. Vis. 2017, 20, 559–579. [Google Scholar] [CrossRef]

- ITTC. Guideline on the Uncertainty Analysis for Particle Image Velocimetry; International Towing Tank Conference Report 7.5-01-03-03; ITTC: Vienna, Austria, 2014. [Google Scholar]

- Jiménez, J.M.; Hultmark, M.; Smits, A.J. The intermediate wake of a body of revolution at high Reynolds numbers. J. Fluid Mech. 2010, 659, 516–539. [Google Scholar] [CrossRef]

- Jiménez, J.M.; Reynolds, R.T.; Smits, A.J. The Effects of Fins on the Intermediate Wake of a Submarine Model. J. Fluids Eng. 2010, 132, 031102. [Google Scholar] [CrossRef]

- Jiménez, J.M.; Smits, A.J. Tip and Junction Vortices Generated by the Sail of a Yawed Submarine Model at Low Reynolds Numbers. J. Fluids Eng. 2011, 133, 034501. [Google Scholar] [CrossRef]

- Ashok, A.; Smits, A.J. The turbulent wake of a submarine model at varying pitch and yaw angle. In Proceedings of the 65th Annual Meeting of the APS Division of Fluid Dynamics, San Diego, CA, USA, 18–20 November 2012. [Google Scholar]

- Ashok, A.; Smits, A.J. The turbulent wake of a submarine model in pitch and yaw. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013. [Google Scholar]

- Ashok, A.; Buren, T.V.; Smits, A.J. Asymmetries in the high Reynolds number wake of a submarine model in pitch. In Proceedings of the 67th Annual Meeting of the APS Division of Fluid Dynamics, San Francisco, CA, USA, 23–25 November 2014. [Google Scholar]

- Ashok, A.; Buren, T.V.; Smits, A.J. The structure of the wake generated by a submarine model in yaw. Exp. Fluids 2015, 56, 123. [Google Scholar] [CrossRef]

- Ashok, A.; Buren, T.V.; Smits, A.J. Asymmetries in the wake of a submarine model in pitch. J. Fluid Mech. 2015, 774, 416–442. [Google Scholar] [CrossRef]

- Wang, L.; Martin, J.E.; Felli, M.; Carrica, P.M. Experiments and CFD for the propeller wake of a generic submarine operating near the surface. Ocean. Eng. 2020, 206, 107304. [Google Scholar] [CrossRef]

- Wang, L.; Carrica, P.M.; Felli, M. Experimental and CFD Study of the Streamwise Evolution of Propeller Tip Vortices. In Proceedings of the 33rd Symposium on Naval Hydrodynamics, Osaka, Japan, 18–23 October 2020. [Google Scholar]

- Wang, L.; Martin, J.E.; Carrica, P.M.; Felli, M.; Falchi, M. Experiments and CFD for DARPA Suboff Appended with Propeller E1658 Operating Near the Surface. In Proceedings of the Sixth International Symposium on Marine Propulsors, Rome, Italy, 26–30 May 2019. [Google Scholar]

- Liu, Y.Y.; Pan, C.; Liu, J.H. Intermittent behavior of a bypass transition of boundary layers over an axisymmetric body of revolution. Ocean. Eng. 2023, 286, 115689. [Google Scholar] [CrossRef]

- Groves, N.C.; Huang, T.T.; Chang, M.S. Geometric Characteristics of DARPA SUBOFF Models; DTRC.SHD-1298-01; David Taylor Research Center: Bethesda, MD, USA, 1989. [Google Scholar]

- Raffel, M.; Willert, C.E.; Wereley, S.T.; Kompenhans, J. Particle Image Velocimetry: A Practical Guide, 3rd ed.; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- Sciacchitano, A.; Wieneke, B. PIV uncertainty propagation. Meas. Sci. Technol. 2016, 27, 084006. [Google Scholar] [CrossRef]

| Measurement Plane | ReL | ψ = 6° | ψ = 9° | ||

|---|---|---|---|---|---|

| y/L | z/L | y/L | z/L | ||

| x/L = 0.595 | 0.46 × 107 | −0.0331 | 0.0956 | −0.0462 | 0.0930 |

| 1.08 × 107 | −0.0339 | 0.0950 | −0.0484 | 0.0923 | |

| x/L = 0.818 | 0.46 × 107 | −0.0543 | 0.0875 | −0.0762 | 0.0856 |

| 1.08 × 107 | −0.0555 | 0.0862 | −0.0786 | 0.0852 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Zhang, N.; Li, Z.; Liu, J.; Yu, L.; Zheng, W.; Zhang, X. Stereo Particle Image Velocimetry Measurement of the Flow around SUBOFF Submarine under Yaw Conditions. J. Mar. Sci. Eng. 2024, 12, 1576. https://doi.org/10.3390/jmse12091576

Chen M, Zhang N, Li Z, Liu J, Yu L, Zheng W, Zhang X. Stereo Particle Image Velocimetry Measurement of the Flow around SUBOFF Submarine under Yaw Conditions. Journal of Marine Science and Engineering. 2024; 12(9):1576. https://doi.org/10.3390/jmse12091576

Chicago/Turabian StyleChen, Mo, Nan Zhang, Ziyan Li, Junliang Liu, Lan Yu, Wentao Zheng, and Xuan Zhang. 2024. "Stereo Particle Image Velocimetry Measurement of the Flow around SUBOFF Submarine under Yaw Conditions" Journal of Marine Science and Engineering 12, no. 9: 1576. https://doi.org/10.3390/jmse12091576