Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods

Abstract

1. Introduction

2. The Reservoir Spatial Characteristics of Marine Carbonates in the Study Area

2.1. Overview of the Study Area

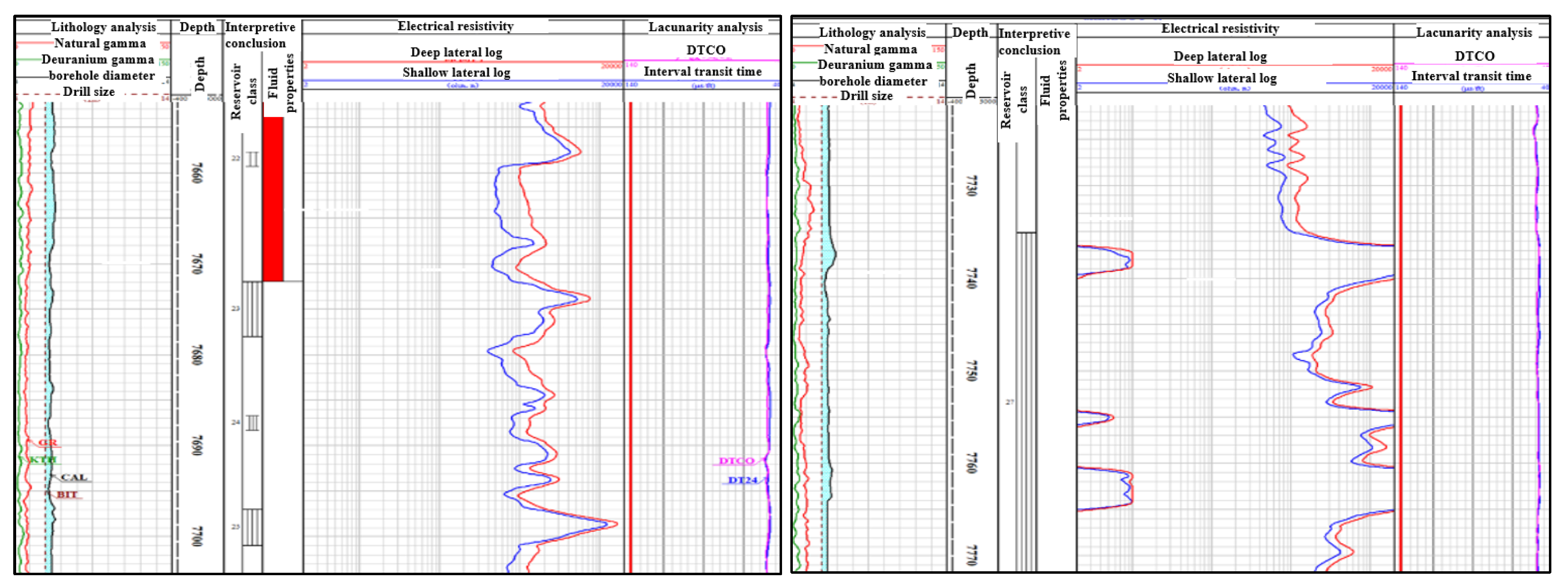

2.2. The Reservoir Spatial Characteristics of Marine Carbonates in the Study Area

2.2.1. Karst Caves

2.2.2. Dissolution Cavities

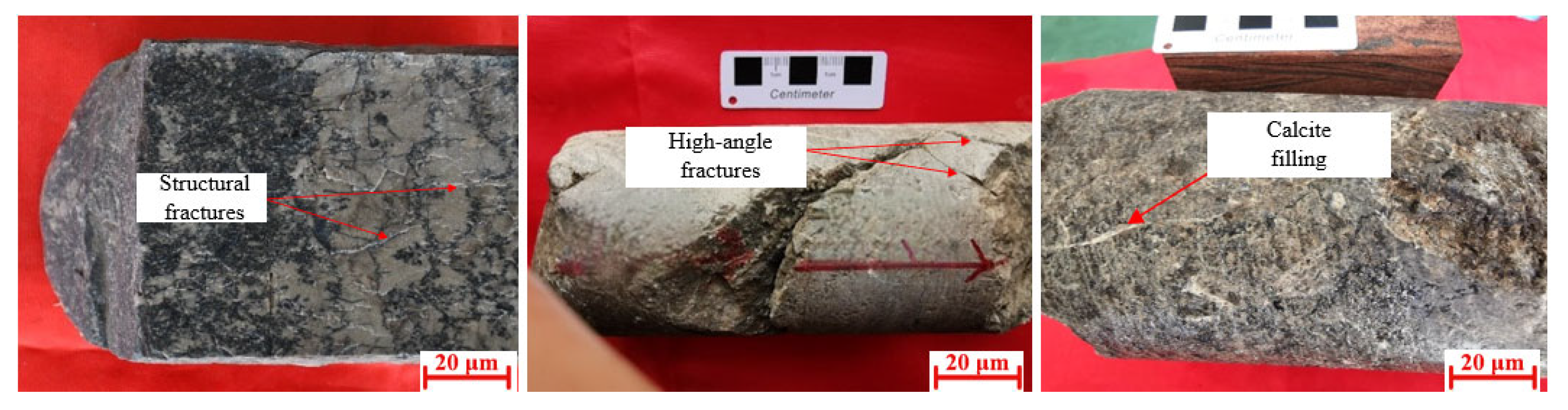

2.2.3. Fractures

3. Inter-Well Connectivity Patterns and Static Connectivity Analysis

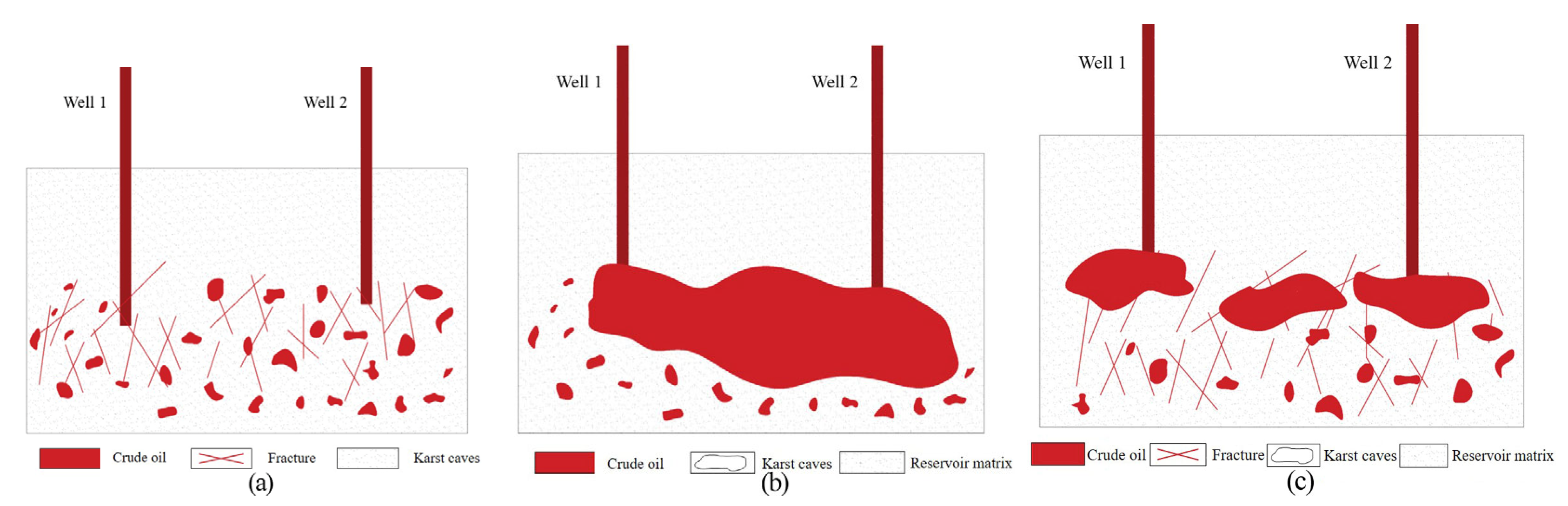

3.1. Inter-Well Connected Pattern

3.2. Principle of Quantitative Characterization of Static Connectivity

3.2.1. Connectivity Calculation Method Based on the Anisotropic Diffusion Equation

3.2.2. Local Connectivity Parameters

3.2.3. Quantitative Connectivity Analysis Based on Multivariate Gaussian Functions

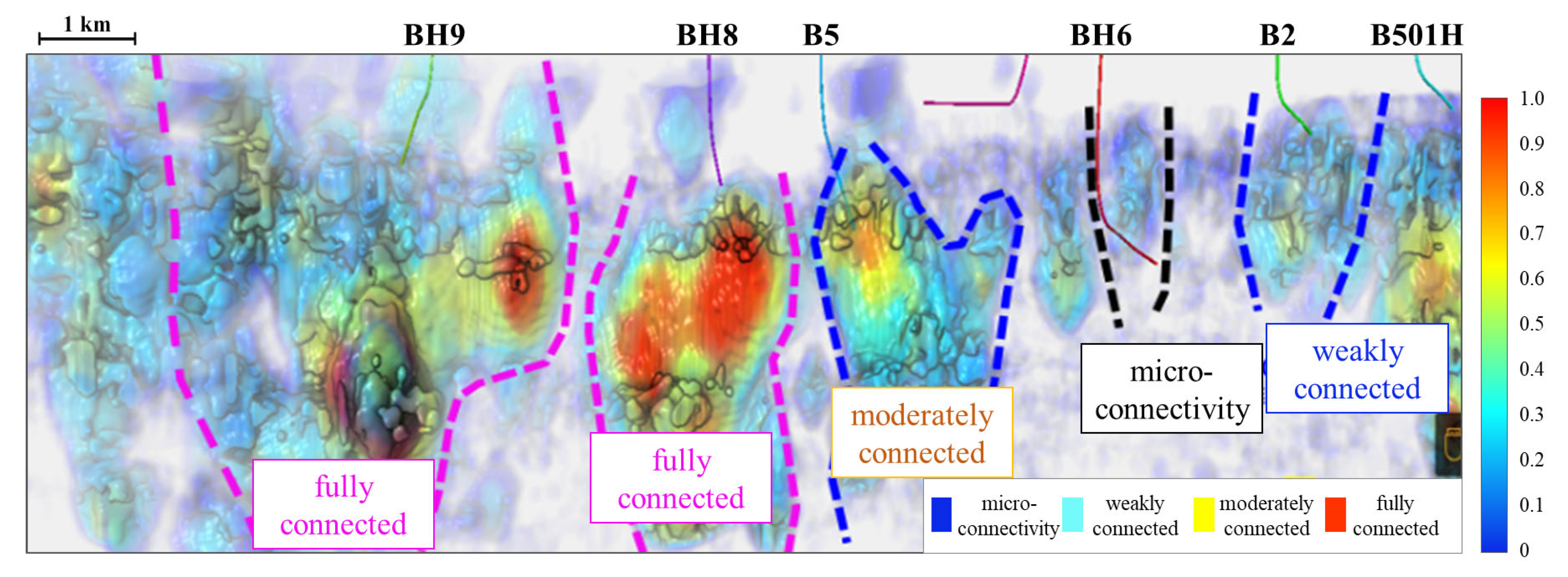

3.3. Quantitative Analysis of Static Connectivity

4. Quantitative Characterization of Carbonate Reservoir Connectivity Based on Production Dynamics

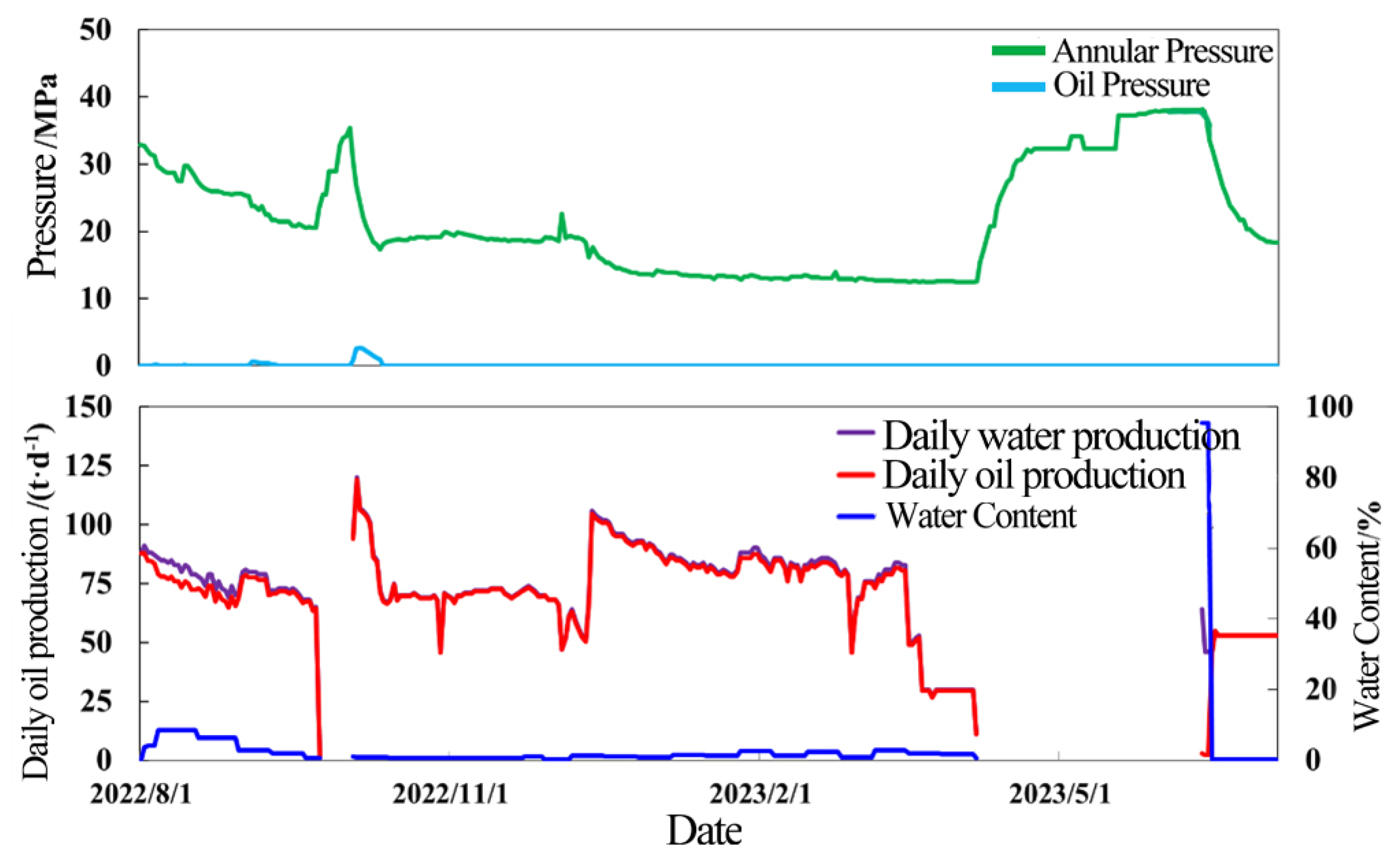

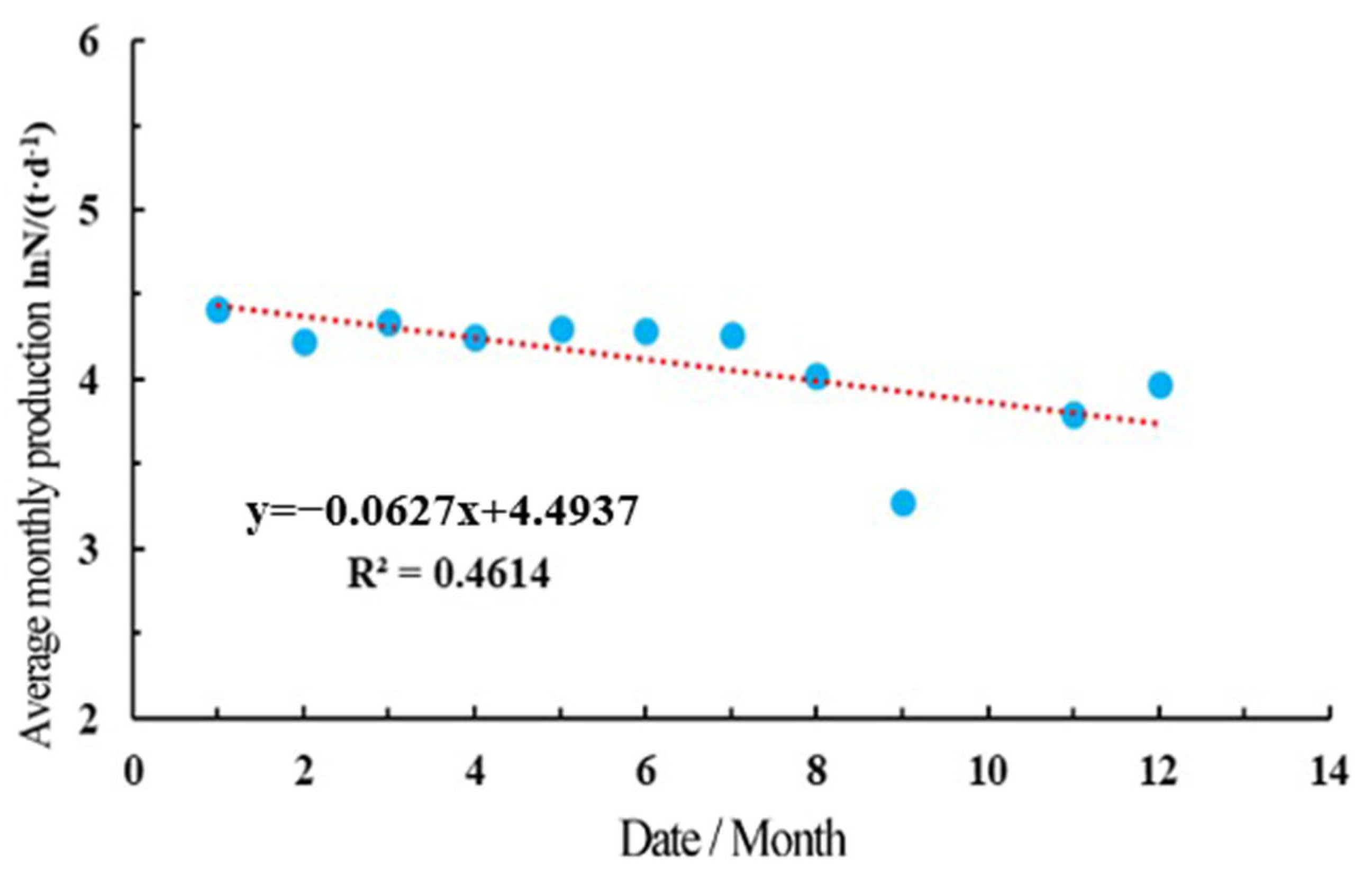

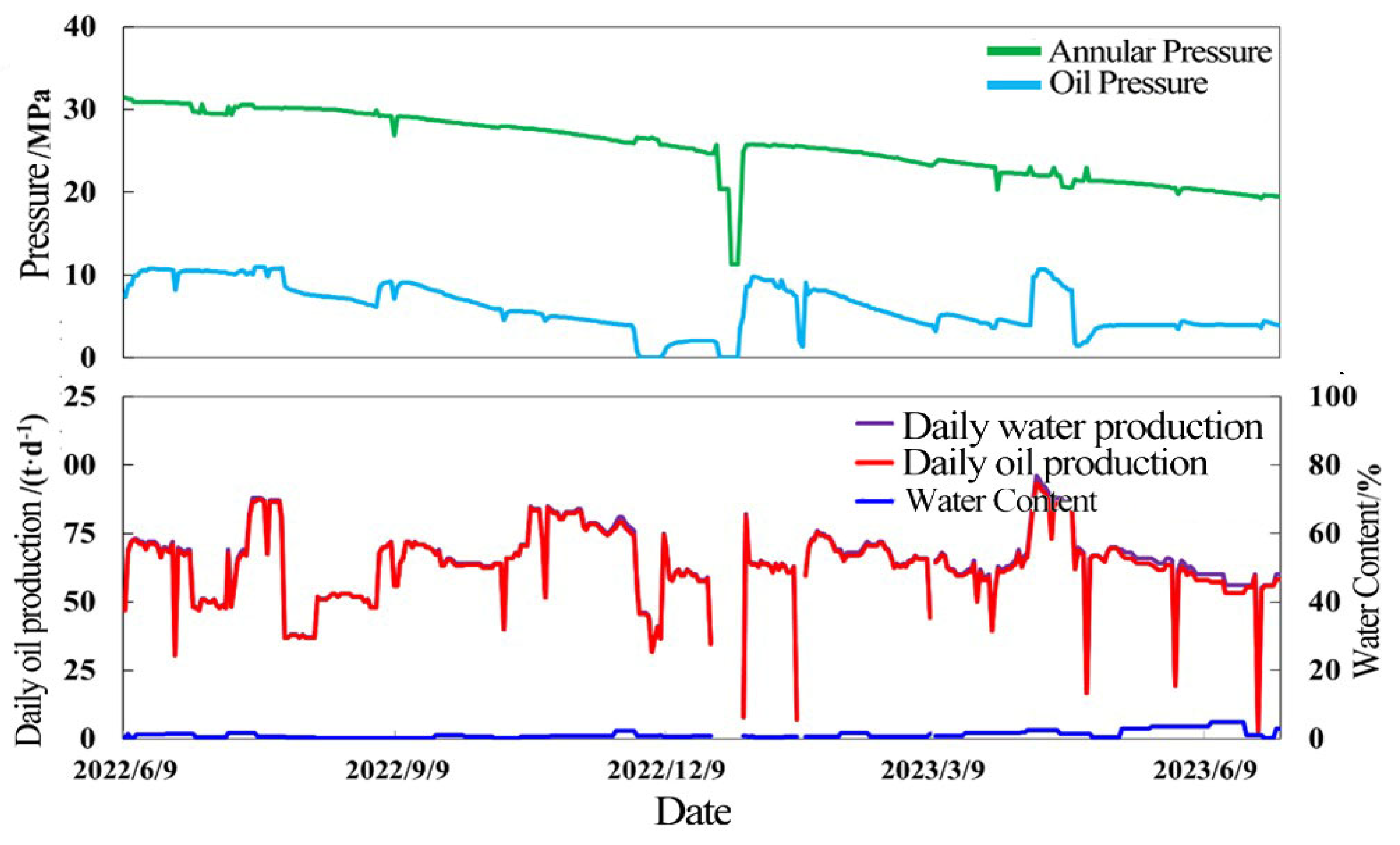

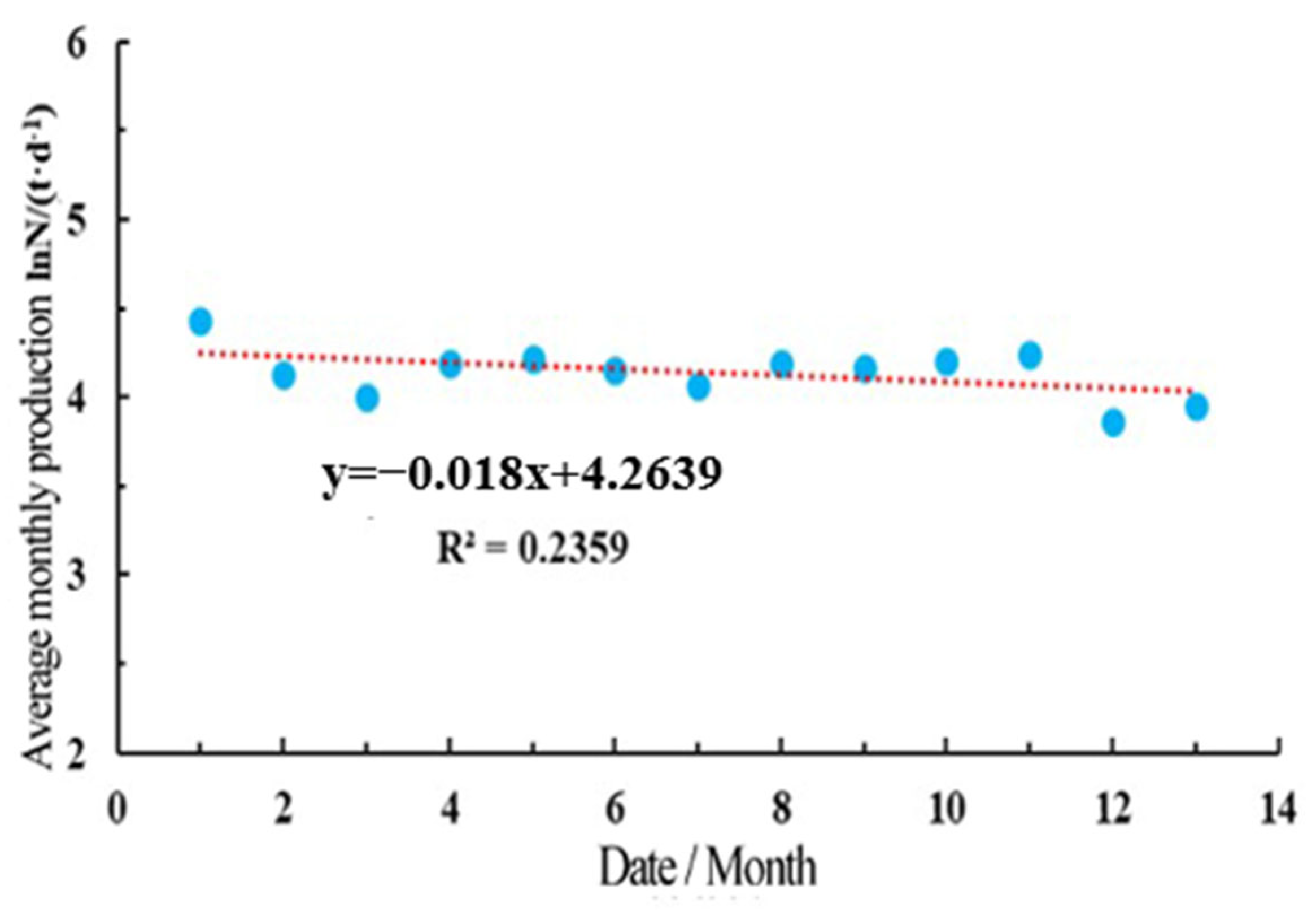

4.1. Production Characteristics of Fractured Reservoir

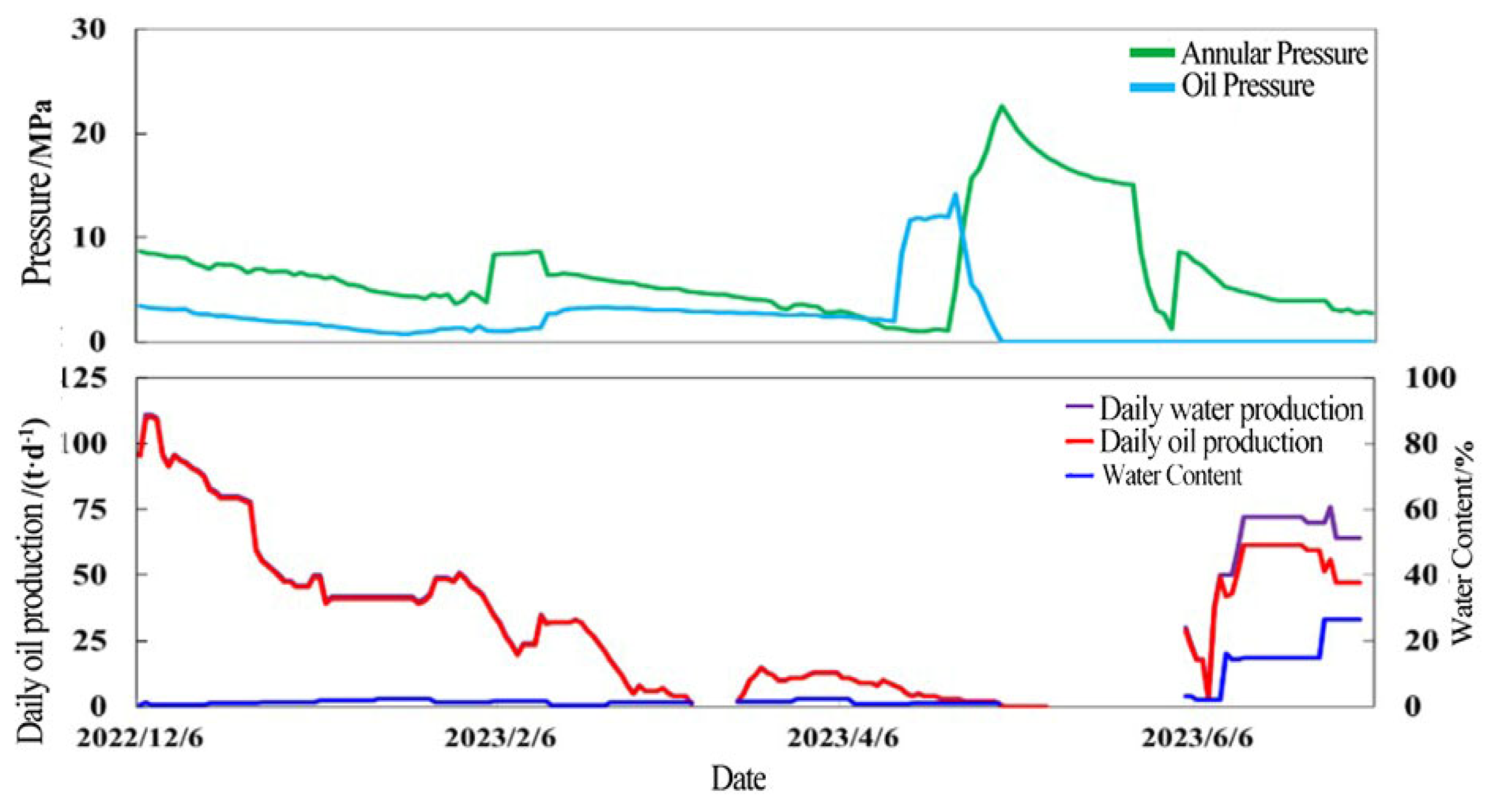

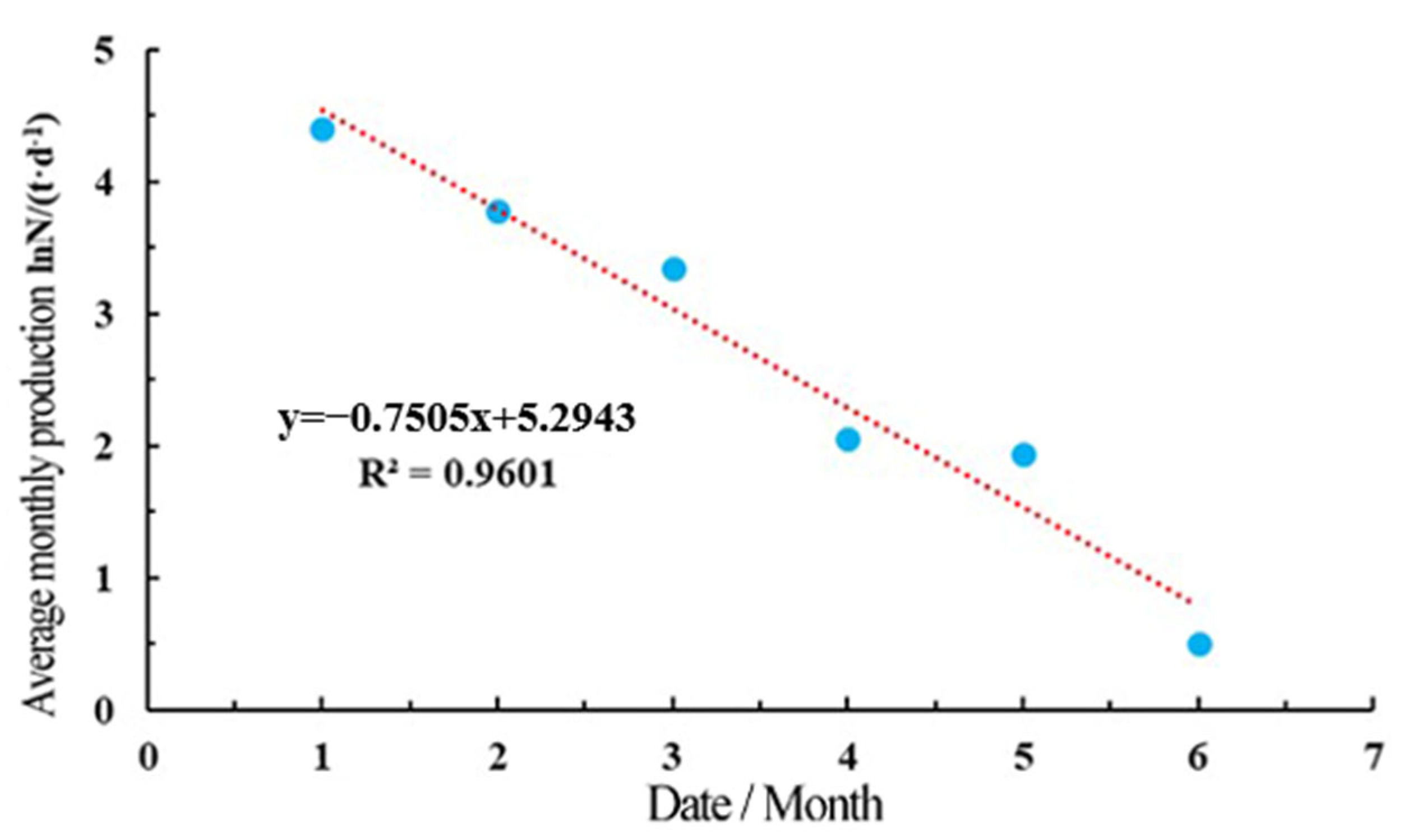

4.2. Production Characteristics of Cave Reservoir

4.3. Production Characteristics of Fractured-Vuggy Reservoirs

5. Quantitative Characterization of Carbonate Reservoir Connectivity Based on Production Dynamics

5.1. Optimization of Connectivity Evaluation Index

5.2. DTW Dynamic Correlation Calculation

5.2.1. DTW Calculation Principle

5.2.2. DTW Calculation Steps

5.3. Quantitative Characterization of Reservoir Connectivity

Theory of Calculation

5.4. Reservoir Connectivity Evaluation in the Study Area

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiabei, X.; Dengfa, H. Distribution characteristics and controlling factors of global giant carbonate stratigraphic-lithologic oil and gas fields. Lithol. Reserv. 2022, 34, 187–200. [Google Scholar]

- Huaxin, C.; Zhihong, K.; Zhijiang, K. Stratified Structure and Formation Mechanism of Paleokarst Cave in Carbonate Reservoir of Tahe Oilfield. Geoscience 2022, 36, 695–708. [Google Scholar]

- Zhijiang, K.; Yang, L.; Bingyu, J. Key technologies for EOR in fractured-vuggy carbonate reservoirs. Oil Gas Geol. 2020, 41, 434–441. [Google Scholar]

- Liaoyuan, H. Study on the Connectivity of Fracture-Cavity Bodies and Remaining Oil Distribution in Yingshan Formation of Zhonggu 8 Well Block. China Univ. Pet. 2021. [Google Scholar]

- Elmo, D.; Rogers, S.; Stead, D.; Eberhardt, E. Discrete Fracture Network approach to characterise rock mass fragmentation and implications for geomechanical upscaling. Min. Technol. 2014, 123, 149–161. [Google Scholar] [CrossRef]

- Medici, G.; Ling, F.; Shang, J. Review of discrete fracture network characterization for geothermal energy extraction. Front. Earth Sci. 2023, 11, 1328397. [Google Scholar] [CrossRef]

- Dumitrache, L.; Roy, A.; Bird, A.; Goktas, B.; Sorgi, C.; Stanley, R.; De Gennaro, V.; Eswein, E.; Abbott, J. A Multidisciplinary Approach to Production Optimization through Hydraulic Fracturing Stimulation and Geomechanical Modelling in Clair Field. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022. [Google Scholar]

- Lingling, Y.; Quanwen, L.; Xuefen, L. Research on 3D geological modeling of fractured-vuggy carbonate reservoirs. In Proceedings of the 7th International Conference on Advances in Energy Resources and Environment Engineering (ICAESEE 2021), Guangzhou, China, 19–21 November 2021. [Google Scholar]

- Huichao, Y.; Gaizhuo, Z.; Qiang, W.; Fangpeng, C.; Bicheng, Y.; Shangxian, Y.; Soltanian, M.R.; Thanh, H.V.; Zhenxue, D. Unraveling Overlying Rock Fracturing Evolvement for Mining Water Inflow Channel Prediction: A Spatiotemporal Analysis Using ConvLSTM Image Reconstruction. IEEE Trans. Geosci. Remote Sens. 2024. [Google Scholar] [CrossRef]

- Ren, M.; Wang, Z.; Jiang, Q.; Hu, G.; Fan, T.; Fan, H. The carbonate reservoir characteristics and pore genesis in the Middle Permian Maokou Formation, Southern Sichuan Basin. J. Northeast. Pet. Univ. 2021, 45, 32–43. [Google Scholar]

- Zhang, J.; Yang, M.; Xie, R.; Wang, M.; Wang, H.; Luo, Z. Probability-constrained identification of Ordovician small-scale fractured-vuggy reservoirs in Blocks 4–6. Oil Gas Geol. 2022, 43, 219–228. [Google Scholar]

- Sun, L.; Wang, X.; Jin, X.; Li, J.; Wu, S. Three-dimensional characterization and quantitative connectivity analysis of micro/nanopore space. Pet. Explor. Dev. 2016, 43, 490–498. [Google Scholar] [CrossRef]

- Tian, G.; Qi, C.; Yuchan, Z.; Lv, J. Quantitative characterization of connectivity of fractured vuggy carbonate reservoirs. Petrochem. Ind. Technol. 2021, 28, 116–117. [Google Scholar]

- Zhihong, K.; Lin, C.; Xinbian, L.; Yang, M. Fluid dynamic connectivity of karst carbonate reservoir with fracture & cave system in Tahe Oilfield. Earth Sci. Front. 2012, 19, 110–120. [Google Scholar]

- Zhao, H.; Li, B.; Zhou, Y.; Zhang, Q.; Liu, H.; Wang, W.; Wang, X. A connectivity prediction model for fault-karst reservoirs based on high-speed non-Darcy flow. Acta Pet. Sin. 2022, 43, 1026–1034. [Google Scholar]

- Fanjing, K. Connectivity of Ordovician fractured vuggy reservoirs in Zhonggu 8 area, Tazhong. In Proceedings of the International Field Exploration and Development Conference, Qingdao, China, 20–22 October 2021; Volume I, pp. 48–49. [Google Scholar]

- Zhonghua, C.; Shouyu, X.; Changmin, X. Study on the Connectivity of Ordovician Fault-karst Reservoir in Yueman Block Halahatang Oilfield. J. Gansu Sci. 2023, 35, 22–30. [Google Scholar]

- Zhesi, C.; Qiyu, C.; Jian, L.; Xiaogang, M.; Gang, L. Characterizing subsurface structures from hard and soft data with multiple-condition fusion neural network. Water Resour. Res. 2024, 60, e2024WR038170. [Google Scholar]

- Li, J.; Kong, X.C.; Song, M.S.; Wang, Y.; Wang, H.; Liu, X.L. Study on the influence of reservoir rock micro-pore structure on rock mechanical properties and crack propagation. Rock Soil Mech. 2019, 40, 4149–4156. [Google Scholar]

- Gou, Q.; Xu, S.; Hao, F.; Yang, F.; Wang, Y.; Lu, Y.; Gao, M. Study on characterization of micro-fracture of shale based on micro-CT. Acta Geol. Sin. 2019, 93, 2372–2382. [Google Scholar]

- Dinh, A.; Tiab, D. Inferring Interwell Connectivity from Well Bottomhole-Pressure Fluctuations in Waterfloods. SPE Reserv. Eval. Eng. 2008, 11, 874–881. [Google Scholar] [CrossRef]

- Jinzi, L. Potential for Evaluation of Interwell Connectivity under the Effect of Intraformational Bed in Reservoirs Utilizing Machine Learning Methods. Geofluids 2020, 2020, 1651549. [Google Scholar]

- Zhang, X.; Huang, Z.; Lei, Q.; Yao, J.; Gong, L.; Sun, S.; Li, Y. Connectivity, permeability, and flow channelization in fractured karst reservoirs: A numerical investigation based on a two-dimensional discrete fracture-cave network model. Adv. Water Resour. 2022, 161, 104142. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Hu, Y.; Li, B.; Deng, X.; Liu, Z. Integrated dynamic evaluation of depletion-drive performance in naturally fractured-vuggy carbonate reservoirs using DPSO–FCM clustering. Fuel 2016, 181, 996–1010. [Google Scholar] [CrossRef]

- Patidar, A.K.; Joshi, D.; Dristant, U.; Choudhury, T. A review of tracer testing techniques in porous media specially attributed to the oil and gas industry. J. Pet. Explor. Prod. Technol. 2022, 12, 3339–3356. [Google Scholar] [CrossRef]

- Dong, X.; Liping, C.; Xiaofeng, X.; Gui, T.; Yongbo, H.; Boyun, G.; Mingjie, L.; Chenxu, Y.; Gao, L. Coupling model of wellbore heat transfer and cuttings bed height during horizontal well drilling. Phys. Fluids 2024, 36, 097163. [Google Scholar]

- Zhenxue, D.; Wolfsberg, A.; Lu, Z.; Ritzi, R., Jr. Representing aquifer architecture in macrodispersivity models with an analytical solution of the transition probability matrix. Geophys. Res. Lett. 2007, 34, L20406. [Google Scholar] [CrossRef]

- Ning, C.; Sun, L.; Hu, S.; Xu, H.; Pan, W.; Li, Y.; Zhao, K. Karst types and characteristics of the Ordovician fracture-cavity type carbonate reservoirs in Halahatang oilfield, Tarim Basin. Acta Pet. Sin. 2021, 42, 15–32. [Google Scholar]

- Du, X.; Dong, S.; Zeng, L.; He, J.; Sun, F. Study of automatic extraction porosity using cast thin sections for carbonates. Geol. Rev. 2021, 67, 1910–1921. [Google Scholar]

- Zhang, S.; Wang, X.; Ren, X.; Xiong, Y.; Lin, W. Identification Method for Carbonate Rock Supergene Karst Characteristics. Well Logging Technol. 2022, 46, 274–282. [Google Scholar]

- Xuan, C.; Wanghan, L.; Dian, B.; Zhang, L.; Chen, L.; Yang, M.; Jia, Y. Filling Ages Identifications and its reservoirs are significant for filling materials of Ordovician Palaeo-karst Caves in Tahe Oilfield. Earth Sci. Front. 2023, 30, 65–75. [Google Scholar]

- Wu, M.; Chai, X.; Zhou, B.; Li, H.; Yan, N.; Peng, P. Connectivity Characterization of Fractured-Vuggy Carbonate Reservoirs and Application. Xinjiang Pet. Geol. 2022, 43, 188–193. [Google Scholar]

- Liu, Y.; Rong, Y.S.; Yang, M. Detailed classification and evaluation of reserves in fracture-cavity units for carbonate fracture-cavity reservoirs. Pet. Geol. Exp. 2018, 40, 431–438. [Google Scholar]

- Müller, M. Information Retrieval for Music and Motion; Springer: Berlin/Heidelberg, Germany, 2007; pp. 69–84. [Google Scholar]

- Li, H. Time works well: Dynamic time warping based on time weighting for time series data mining. Inf. Sci. 2021, 547, 592–608. [Google Scholar] [CrossRef]

- Hong, J.Y.; Park, S.H.; Baek, J.G. SSDTW: Shape segment dynamic time warping. Expert Syst. Appl. 2020, 150, 113291. [Google Scholar] [CrossRef]

- Hernandez-Mejia, J.L.; Pisel, J.; Jo, H.; Pyrcz, M.J. Dynamic time warping for well injection and production history connectivity characterization. Comput. Geosci. 2023, 27, 159–178. [Google Scholar] [CrossRef]

- Meng, F.; Fan, X.; Chen, S.Y.; Ye, Y.Y.; Jiang, H.; Pan, W.; Wu, F.; Zhang, H.; Chen, Y.; Semnani, A. Automatic Well-Log Depth Shift with Multilevel Wavelet Decomposition Network and Dynamic Time Warping. Geoenergy Sci. Eng. 2024, 246, 213583. [Google Scholar] [CrossRef]

- Dürrenmatt, D.J.; Del Giudice, D.; Rieckermann, J. Dynamic time warping improves sewer flow monitoring. Water Res. 2013, 47, 3803–3816. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, W.; Qu, Z.; Guo, T.; Sun, Y.; Rabiei, M.; Cao, Q. Feasibility evaluation of hydraulic fracturing in hydrate-bearing sediments based on analytic hierarchy process-entropy method (AHP-EM). J. Nat. Gas Sci. Eng. 2020, 81, 103434. [Google Scholar] [CrossRef]

- Saaty, T.L. A scaling method for priorities in hierarchical structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Liu, J.; Deng, G.; Gu, H.; Yan, Z. 3D seismic intelligent prediction of fault-controlled fractured-vuggy reservoirs in carbonate reservoirs based on a deep learning method. J. Geophys. Eng. 2024, 21, 345–358. [Google Scholar] [CrossRef]

- Wang, J.; Qi, X.; Liu, H.; Yang, M.; Li, X.; Liu, H.; Zhang, T. Mechanisms of remaining oil formation by water flooding and enhanced oil recovery by reversing water injection in fractured-vuggy reservoirs. Pet. Explor. Dev. 2022, 49, 1110–1125. [Google Scholar] [CrossRef]

| Factor i Compared with Factor j | Quantized Value |

|---|---|

| Equally importance | 1 |

| Slightly importance | 3 |

| Stronger importance | 5 |

| Strongly importance | 7 |

| Extremely importance | 9 |

| Two-adjacent discriminant Median | 2,4,6,8 |

| Order of Matrix | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| ri | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| Index | Oil Pressure | Flow Pressure | Production Capacity | Dynamic Liquid Level | ci | ri | cr | Weights wi |

|---|---|---|---|---|---|---|---|---|

| Oil pressure | 1 | 2 | 1/2 | 3 | 0.00484 | 0.90 | 0.00542 | 0.2717 |

| Flow pressure | 1/2 | 1 | 1/3 | 2 | 0.1569 | |||

| Production capacity | 2 | 3 | 1 | 5 | 0.4832 | |||

| Dynamic liquid level | 1/3 | 1/2 | 1/5 | 1 | 0.0882 |

| Connecting Well Number | Dynamic Feature Similarity | |||

|---|---|---|---|---|

| Wellhole Flowing Pressure | Oil Pressure | Production Capacity | Dynamic Liquid Level | |

| A32-H5, A32-H7 | 0.419 | 0.070 | 3.388 | 60.601 |

| A32-H1, A32-H9 | 0.827 | 0.138 | 7.571 | 110.171 |

| A32-H1, A32-H5 | 1.181 | 0.197 | 10.940 | 119.244 |

| A32-H1, A32-H7 | 0.945 | 0.157 | 8.533 | 140.959 |

| A32-H9, A32-H5 | 1.614 | 0.269 | 9.778 | 142.933 |

| A32-H9, A32-H7 | 1.418 | 0.236 | 9.843 | 122.357 |

| Connecting Well Number | Dynamic Feature Similarity | |||

|---|---|---|---|---|

| Wellhole Flowing Pressure | Oil Pressure | Production Capacity | Dynamic Liquid Level | |

| BH8, BH9 | 0.739 | - | 4.561 | 128.880 |

| B501H, BH2 | 1.294 | 0.088 | - | 141.182 |

| BH2, B5 | 1.172 | - | 6.345 | - |

| BH6, B5 | 0.910 | - | - | 93.955 |

| BH6, BH9 | - | 0.179 | - | - |

| B5, BH8 | - | 0.673 | - | - |

| BH2, BH9 | - | - | 3.586 | - |

| B501H, BH8 | - | - | 6.982 | - |

| Dynamic Similarity Index | Connecting Well Number | Dynamic Feature Similarity |

|---|---|---|

| Wellhole flowing pressure | B501-H1, BH4 | 0.889 |

| Oil pressure | BH4, B501-H1 | 0.937 |

| B504H, B501-H1 | 0.608 | |

| Production capacity | B501-H1, BH4 | 5.824 |

| Dynamic liquid level | B501-H1, BH4 | 103.464 |

| Connecting Well Number | Connectivity Coefficient Ic | Connecting Well Number | Connectivity Coefficient Ic |

|---|---|---|---|

| A32-H5, A32-H7 | 1.746 | B501H, BH2 | 1.249 |

| A32-H1, A32-H9 | 1.470 | BH2, B5 | 1.317 |

| A32-H1, A32-H5 | 1.267 | BH6, B5 | 0.942 |

| A32-H1, A32-H7 | 1.388 | BH6, BH9 | 1.090 |

| A32-H9, A32-H5 | 1.226 | BH2, BH9 | 1.310 |

| A32-H9, A32-H7 | 1.271 | B501H, BH8 | 1.214 |

| BH8, BH9 | 1.565 | B501-H1, BH4 | 1.380 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lin, C.; Ren, L.; Sun, C.; Li, J.; Wang, Z.; Xu, G. Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods. J. Mar. Sci. Eng. 2025, 13, 435. https://doi.org/10.3390/jmse13030435

Zhang Y, Lin C, Ren L, Sun C, Li J, Wang Z, Xu G. Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods. Journal of Marine Science and Engineering. 2025; 13(3):435. https://doi.org/10.3390/jmse13030435

Chicago/Turabian StyleZhang, Yintao, Chengyan Lin, Lihua Ren, Chong Sun, Jing Li, Zhicheng Wang, and Guojin Xu. 2025. "Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods" Journal of Marine Science and Engineering 13, no. 3: 435. https://doi.org/10.3390/jmse13030435

APA StyleZhang, Y., Lin, C., Ren, L., Sun, C., Li, J., Wang, Z., & Xu, G. (2025). Study on Connectivity of Fractured-Vuggy Marine Carbonate Reservoirs Based on Dynamic and Static Methods. Journal of Marine Science and Engineering, 13(3), 435. https://doi.org/10.3390/jmse13030435