A Survey on the Design and Mechanical Analysis of Cryogenic Hoses for Offshore Liquid CO2 Ship-to-Ship Transfer

Abstract

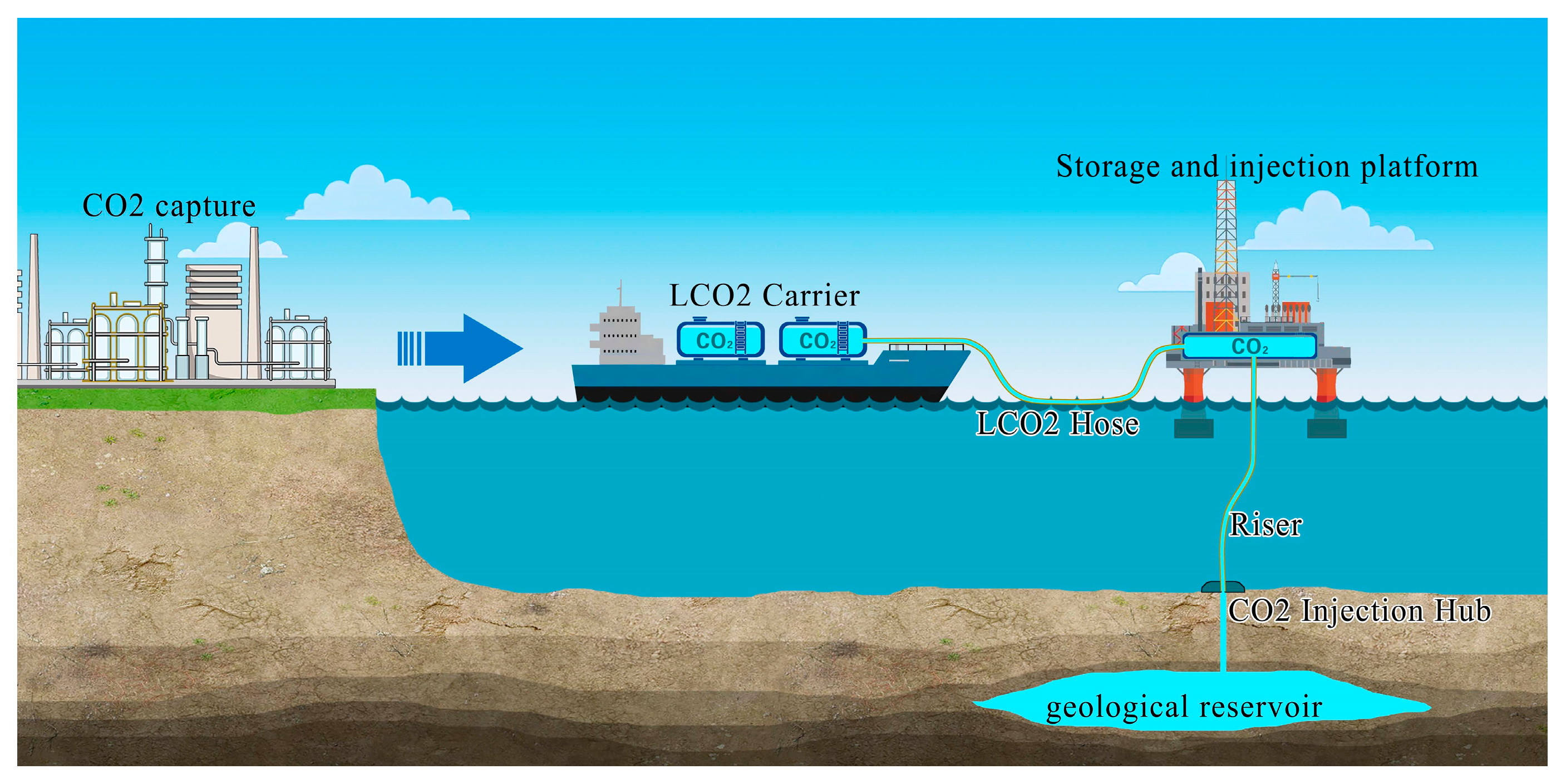

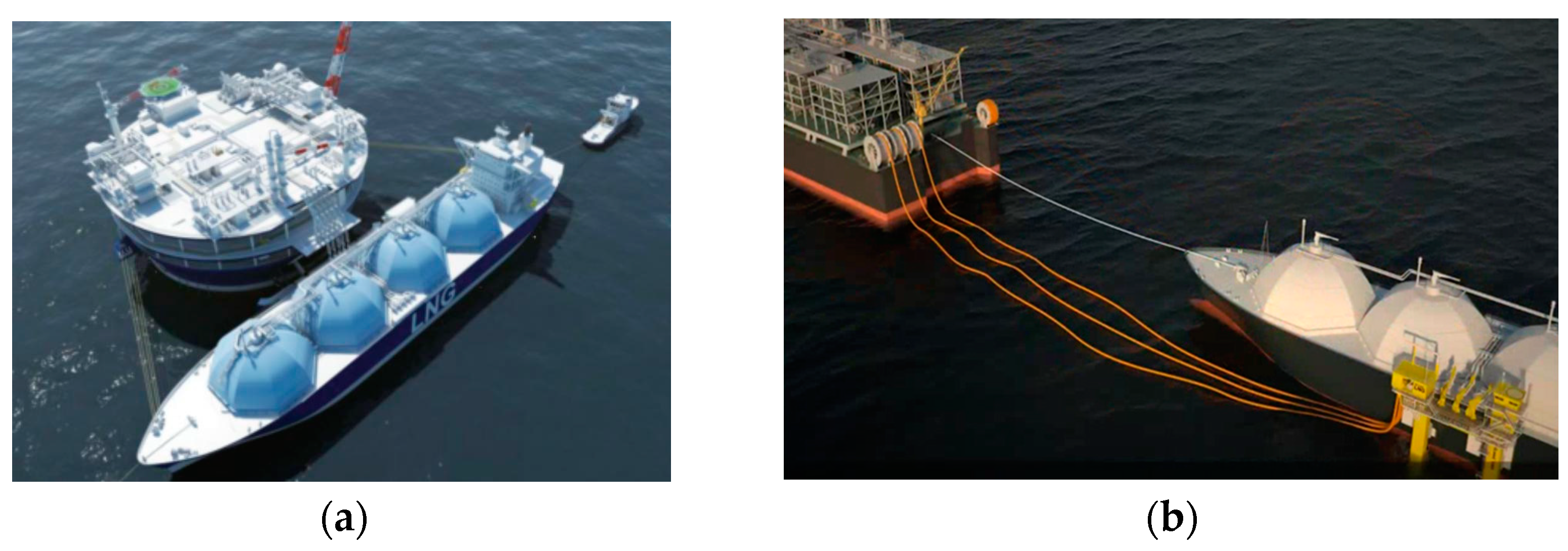

1. Introduction

2. Methodology

2.1. Data Source and Search Strategy

2.2. Inclusion and Exclusion Criteria

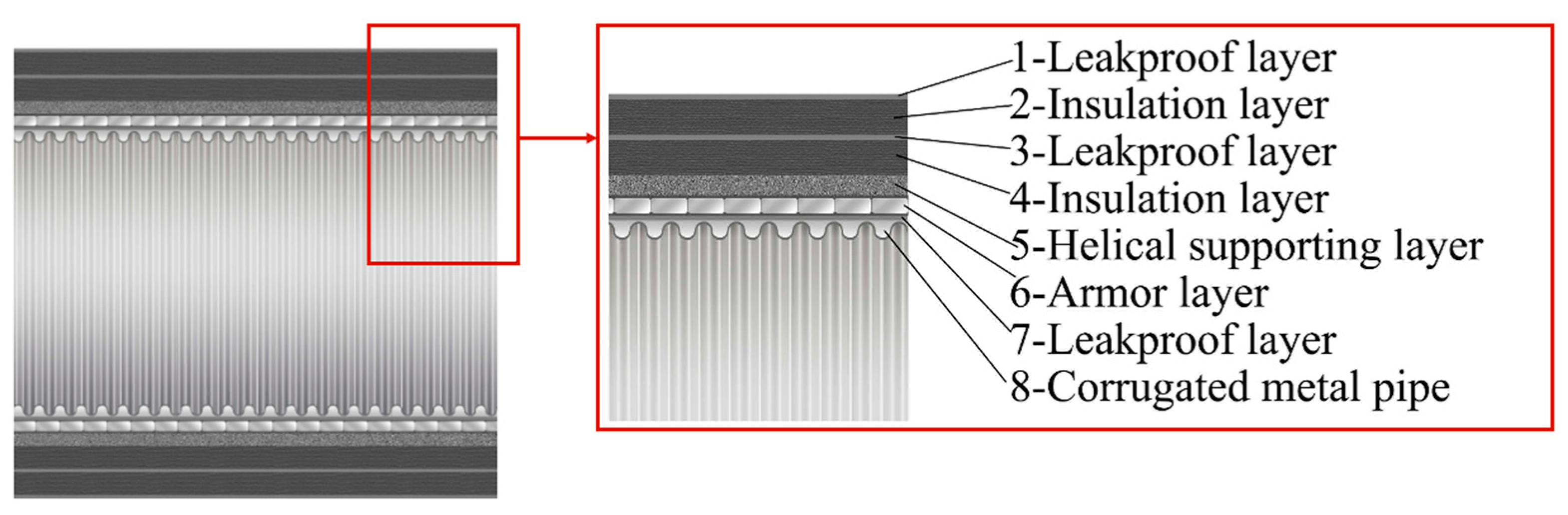

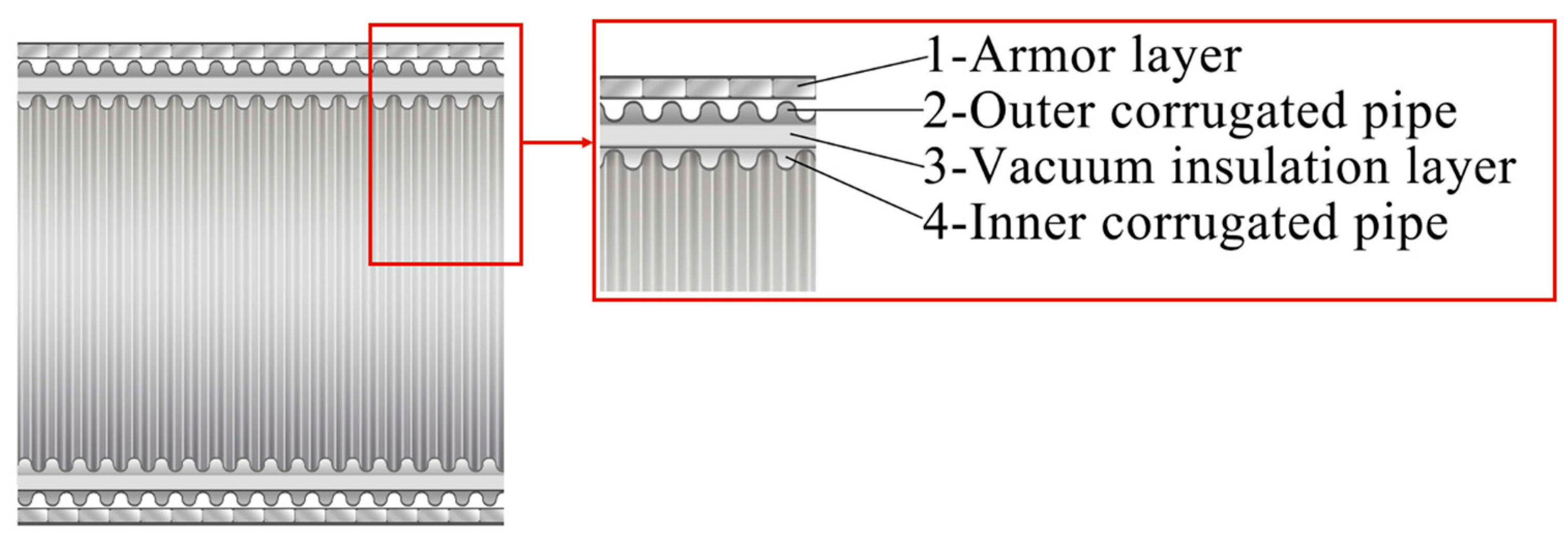

3. Existing Cryogenic Hose Design

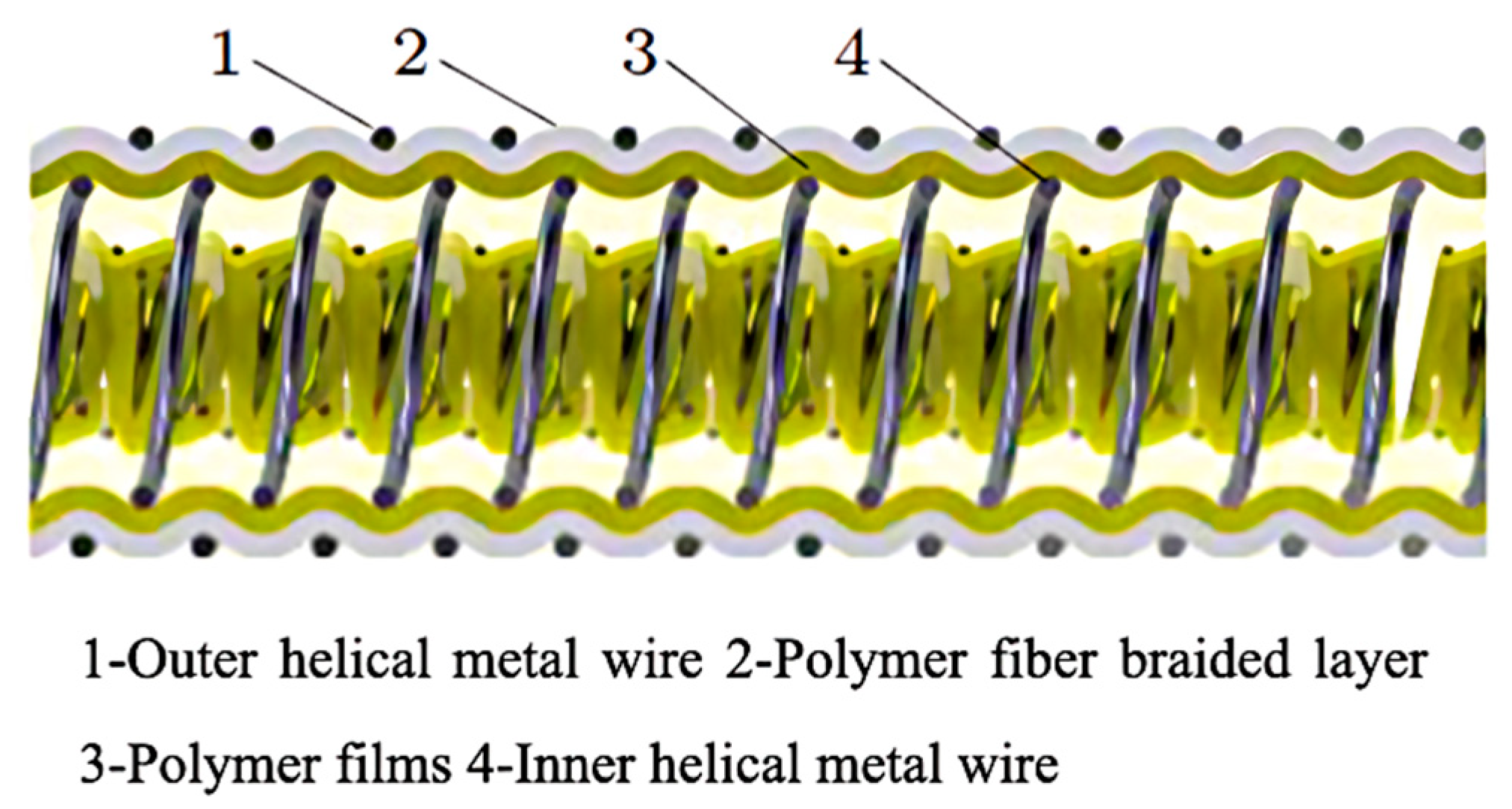

3.1. Reinforced Corrugated Hose

3.2. Vacuum-Insulated Corrugated Hose

3.3. Composite Cryogenic Hose

3.4. Comparison of Existing Hose Designs

4. Main Findings

4.1. Characteristics of LCO2 and Implications for LCO2 Hose Design

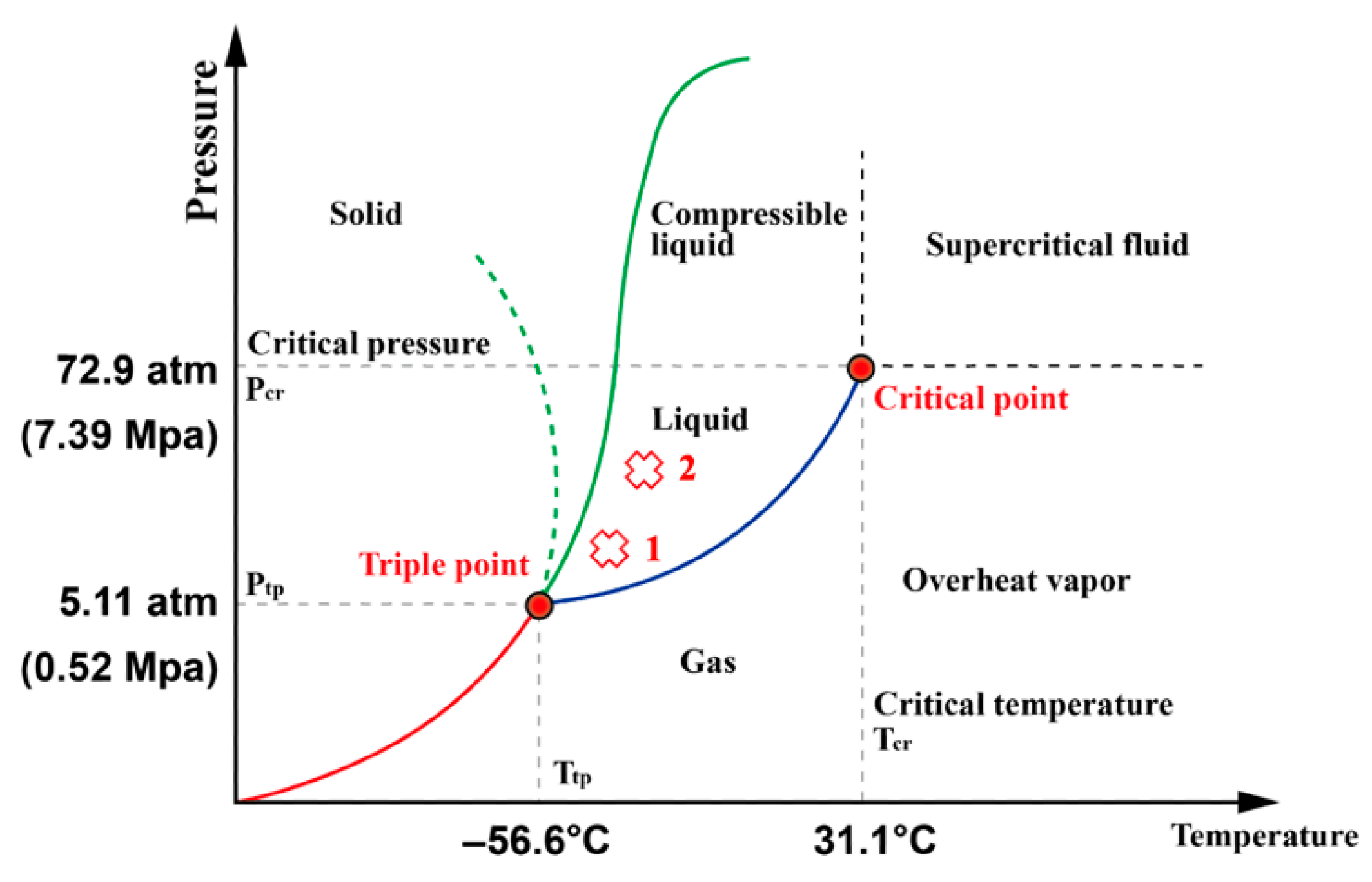

4.1.1. Physical and Chemical Properties

4.1.2. LCO2 Transportation Conditions

4.1.3. Practical Implications for LCO2 Hose Design

4.2. LCO2 Cryogenic Hose Design Methods

4.2.1. Design Requirements for LCO2 Hoses

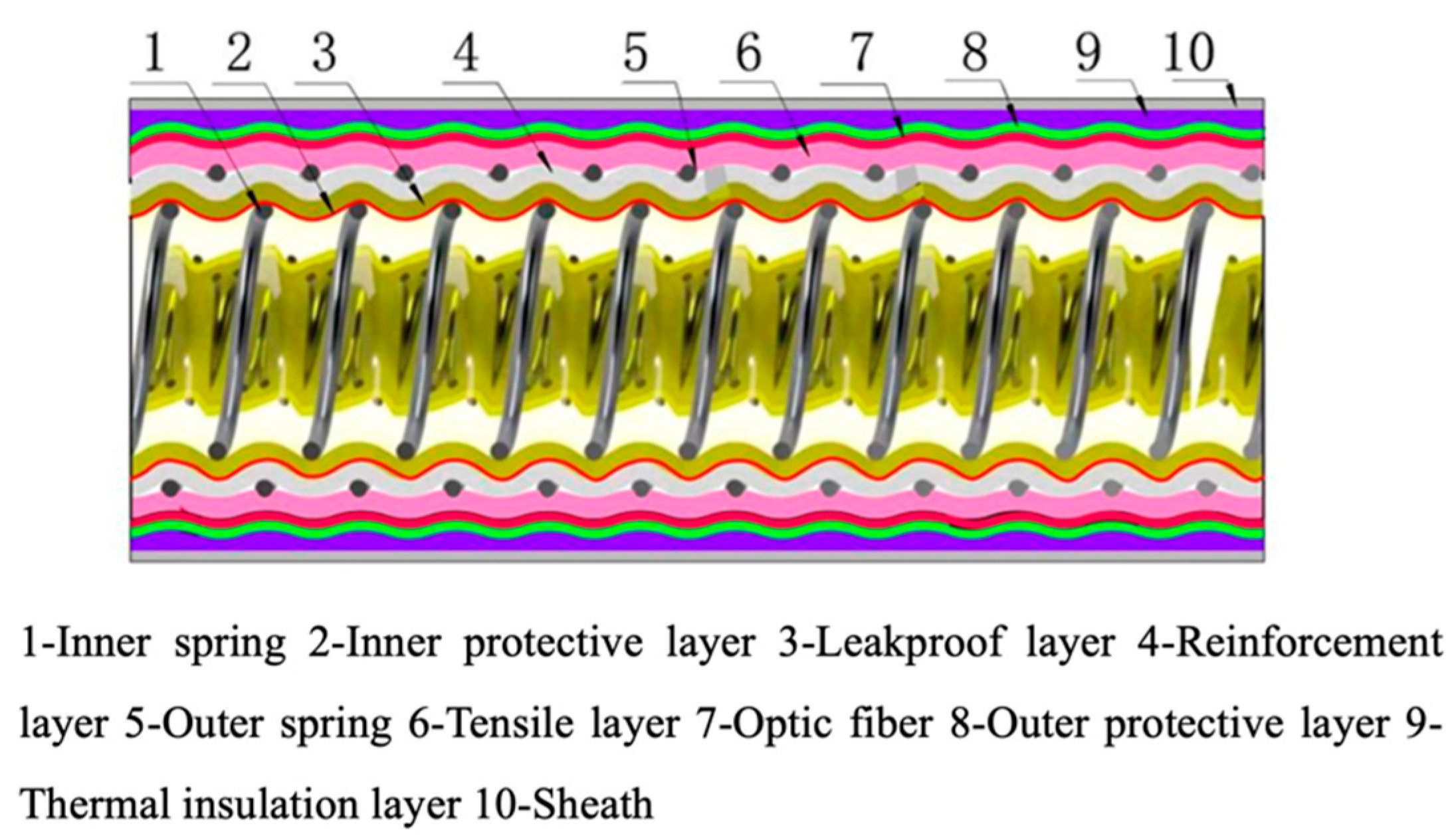

4.2.2. Conceptual LCO2 Cryogenic Hose Design

4.2.3. Hose Material Selection

4.2.4. Anti-Corrosion Measures

4.2.5. Integration of Leak Detection System

4.3. Mechanical Analysis of the LCO2 Cryogenic Hose

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, Q.; Wei, S.; Du, J.; Wu, P. Research Progress and Perspectives on Carbon Capture, Utilization, and Storage (CCUS) Technologies in China and the USA: A Bibliometric Analysis. Environ. Sci. Pollut. Res. 2023, 30, 76437–76454. [Google Scholar] [CrossRef] [PubMed]

- De Pryck, K.; Boettcher, M. The Rise, Fall and Rebirth of Ocean Carbon Sequestration as a Climate “Solution”. Glob. Environ. Change 2024, 85, 102820. [Google Scholar] [CrossRef]

- Jung, J.Y.; Huh, C.; Kang, S.G.; Seo, Y.; Chang, D. CO2 Transport Strategy and Its Cost Estimation for the Offshore CCS in Korea. Appl. Energy 2013, 111, 1054–1060. [Google Scholar] [CrossRef]

- The Maritime Executive 55 Vessels Required by 2030 for Emerging CO2 Transport and Storage. Available online: https://maritime-executive.com/article/55-vessels-required-by-2030-for-emerging-co2-transport-and-storage (accessed on 17 February 2025).

- Equinor The Northern Lights Project. Available online: https://www.equinor.com/energy/northern-lights (accessed on 15 February 2025).

- INEOS PROJECT GREENSAND. Available online: https://www.ineos.com/inch-magazine/articles/issue-25/project-greensand/ (accessed on 10 February 2025).

- Greensand Greensand Paving the Way for Mitigating Climate Change with CCS. Available online: https://www.projectgreensand.com/en/first-carbon-storage (accessed on 10 February 2025).

- Perenco the Poseidon Project. Available online: https://perenco-ccs.com/the-poseidon-project/ (accessed on 10 February 2025).

- Technip Energies. Technip Energies, DeepC Store and Mitsui O.S.K. Lines Join Forces for a Floating Carbon Capture & Storage Hub Development. Available online: https://www.ten.com/en/media/news/technip-energies-deepc-store-and-mitsui-osk-lines-join-forces-floating-carbon-capture (accessed on 15 February 2025).

- DNV CO2 Offshore Injection. Available online: https://www.dnv.com/article/co2-offshore-injection-joint-industry-project/ (accessed on 10 February 2025).

- Vopak. Knowledge Sharing Report—CO2 Liquid Logistics Shipping Concept Business Model. 2011. Available online: https://www.globalccsinstitute.com/archive/hub/publications/19011/co2-liquid-logistics-shipping-concept-llsc-overall-supply-chain-optimization.pdf (accessed on 10 February 2025).

- Yokozawa, H.; Ito, A. Application for Estimating Motion Behaviors of FPSO/FSRU and Shuttle Tanker in alongside and Tandem Mooring Conditions. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Halkidiki, Greece, 12–16 June 2005; Volume 1A. [Google Scholar]

- Engel, F.; Kather, A. Improvements on the Liquefaction of a Pipeline CO2 Stream for Ship Transport. Int. J. Greenh. Gas Control 2018, 72, 214–221. [Google Scholar] [CrossRef]

- Continental. Leading the Charge in Renewable Energy—Marine Hoses and Transfer Systems for LCO2 and Ammonia. Available online: https://www.continental-industry.com/getmedia/d5d73c27-bf2d-4c18-a5d6-b1067fabe1fe/CT-Marine-Hoses-Transfer-Systems-Carbon-Ammonia.pdf (accessed on 11 February 2025).

- EN1474-2; British Standard European Norm (BSEN). Installation and Equipment for Liquefied Natural Gas—Design and Testing of Marine Transfer Systems Part 2: Design and Testing of Transfer Hoses. British Standards Institution: London, UK, 2020.

- Ferreira, A.L.F.; Morooka, C.K. Evaluation of Response of a Floating Cryogenic Hose in Offloading Operation Between Flng Unit and Lng Carrier in Tandem. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, St. John’s, NL, Canada, 31 May–5 June 2015; Volume 5A, pp. 1–10. [Google Scholar]

- Abbasi, T.; Hults, J.E.; Mesnage, O.; Simoes, V.; Gerez, J.; Hardiman, R.; Vlekken, J.; Roosbroeck, J. LNG Flexible Integrated with Fiber Optic Distributed Leak System Enhancing Safety, Integrity Monitoring and Life Assessments. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 22–25 March 2016; OTCA: Brasília, Brazil, 2016. [Google Scholar]

- Eide, J.; Haakonsen, R.; Oya, T.V.; Frohne, C. Offshore Tandem Loading of LNG—From Idea to System Approval. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; Volume 3. [Google Scholar]

- Humphreys, V.; Jones, N. Offshore LNG Transfer, a Practical System Based on Proven Oil Transfer Principles. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 3–6 May 2004; Volume 1. [Google Scholar]

- Chen, Q.; Sun, Q.; Yan, J.; Cui, Y.; Yang, L.; Yang, X.; Wu, Z. Development and Recent Progress of Hoses for Cryogenic Liquid Transportation. Polymers 2024, 16, 905. [Google Scholar] [CrossRef]

- Lagarrigue, V.; Hermary, J.; Mauries, B. Qualification of a Cryogenic Floating Flexible Hose Enabling Safe and Reliable Offshore LNG Transfer for Tandem FLNG Offloading Systems. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; Volume 5. [Google Scholar]

- Lagarrigue, V.; Herniary, J. Re-Shaping LNG Transfer. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018; Volume 1. [Google Scholar]

- Suzuki, T.; Toriumi, M.; Sakemi, T.; Masui, N.; Yano, S.; Fujita, H.; Furukawa, H. Conceptual Design of CO2 Transportation System for CCS. Energy Procedia 2013, 37, 2986–2996. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology Cryogenics Material Properties. Available online: https://trc.nist.gov/cryogenics/materials/materialproperties.htm (accessed on 12 February 2025).

- The Engineering ToolBox The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/ (accessed on 12 February 2025).

- Zhao, C.; Wang, J.; Li, X.; Huang, J.; Chen, H.; Bi, J.; Liu, S.; Lu, G.; Song, K.; Guo, S. Progress in Corrosion Protection Research for Supercritical CO2 Transportation Pipelines. Coatings 2024, 14, 1378. [Google Scholar] [CrossRef]

- The Engineering ToolBox Carbon Dioxide—Liquid Properties. Available online: https://www.engineeringtoolbox.com/carbon-dioxide-d_1000.html (accessed on 15 February 2025).

- Kim, T.W.; Yoon, H.C.; Lee, J.Y. Review on Carbon Capture and Storage (CCS) from Source to Sink; Part 1: Essential Aspects for CO2 Pipeline Transportation. Int. J. Greenh. Gas Control 2024, 137, 104208. [Google Scholar] [CrossRef]

- Roussanaly, S.; Deng, H.; Skaugen, G.; Gundersen, T. At What Pressure Shall CO2 Be Transported by Ship? An In-Depth Cost Comparison of 7 and 15 Barg Shipping. Energies 2021, 14, 5635. [Google Scholar] [CrossRef]

- EN13766; British Standard European Norm (BSEN). Thermoplastic Multi-Layer (Non-Vulcanized) Hoses and Hose Assemblies for the Transfer of Liquid Petroleum Gas and Liquified Natural Gas—Specification. British Standards Institution: London, UK, 2010.

- ISO 21012:2018; Cryogenic Vessels-Hoses. ISO: Geneva, Switzerland, 2018.

- Li, C.; Chen, Z.; Dong, W.; Lin, L.; Zhu, X.; Liu, Q.; Zhang, Y.; Zhai, N.; Zhou, Z.; Wang, Y.; et al. A Review of Silicon-Based Aerogel Thermal Insulation Materials: Performance Optimization through Composition and Microstructure. J. Non-Cryst. Solids 2021, 553, 120517. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, W.Z.; Li, Y.M.; Tao, W.Q. Experimental Study of the Thermal Conductivity of Polyurethane Foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-Based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Yu, W.; Lu, W.; Han, X.; Cai, H. Aluminum Silicate Fibers Reinforced Wood-Plastic Composites: A Strengthening Strategy Based on the Interfacial Interactions between Inorganic Fibers and Organic Agricultural Wastes. Bioresources 2021, 16, 3678. [Google Scholar] [CrossRef]

- Xiang, Y.; Yuan, Y.; Zhou, P.; Liu, G.; Lyu, W.; Li, M.; Zhang, C.; Zhou, Q.; Zhao, X.; Yan, W. Metal Corrosion in Carbon Capture, Utilization, and Storage: Progress and Challenges. Chin. J. Eng. Sci. 2023, 25, 197–208. [Google Scholar] [CrossRef]

- Oosterkamp, A.; Ramsen, J. State-of-the-Art Overview of CO2 Pipeline Transport with Relevance to Offshore Pipelines. Report to the Research Council of Norway. Report Number POL-O-2007-138-A. 2008. Available online: https://www.researchgate.net/profile/Antonie-Oosterkamp/publication/228688545_State-of-the-Art_Overview_of_CO_2_Pipeline_Transport_with_Relevance_to_Offshore_Pipelines/links/0deec5270ceae8bb47000000/State-of-the-Art-Overview-of-CO-2-Pipeline-Transport-with-Relevance-to-Offshore-Pipelines.pdf (accessed on 10 February 2025).

- Raganati, F.; Miccio, F.; Ammendola, P. Adsorption of Carbon Dioxide for Post-Combustion Capture: A Review. Energy Fuels 2021, 35, 12845–12868. [Google Scholar] [CrossRef]

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber-Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Morikawa, S.R.K.; Braga, A.M.B.; Camerini, C.S.; Kato, C.C.; Llerena, R.A.; Camerini, M.G.; Simões, T.B. New Advances in Flexible Riser Monitoring Techniques Using Optical Fiber Sensors. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Rio de Janeiro, Brazil, 1–6 July 2012; Volume 3. [Google Scholar]

- Lally, E.M.; Reaves, M.; Horrell, E.; Klute, S.; Froggatt, M.E. Fiber Optic Shape Sensing for Monitoring of Flexible Structures. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 12–15 March 2012; Volume 8345. [Google Scholar]

- Andersen, M. Method of Mounting a Sensor Arrangement in a Tubular Member, and Use of the Method. US Patent 7,024,941, 11 April 2006. [Google Scholar]

- Buitrago, J.; Slocum, S.T.; Hudak, S.J.; Long, R. Cryogenic Structural Performance of Corrugated Pipe. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Shanghai, China, 6–11 June 2010; Volume 6, pp. 331–342. [Google Scholar]

- Gao, S.; An, C.; Wei, D.; Li, Y.; Estefen, S.F.; Yang, R. Mechanical Structure Behavior of a Double Carcass Floating Hose Under Tensile Load. In Proceedings of the 33rd International Ocean and Polar Engineering Conference, Ottawa, ON, Canada, 18–23 June 2023. ISOPE-I-23-463. [Google Scholar]

- Ying, X.; Yan, J.; Zhang, K.; Yang, Z.; Cao, H.; Bu, Y. Study on Competition Mechanism of Deformation Modes of U-Shaped Bellows Under Internal Pressure. Mar. Struct. 2023, 92, 1–18. [Google Scholar] [CrossRef]

- Huang, G.; Wu, W. Armored Steel Wire Stress Monitoring Strategy of a Flexible Hose in LNG Tandem Offloading Operation. Ocean Eng. 2023, 281, 114775. [Google Scholar] [CrossRef]

- Hu, H.; Yan, J.; Zhou, B.; Yang, Z.; Yang, L.; Fan, J. Thermal and Mechanical Coupled Analysis of Marine Composite Cryogenic Pipeline. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Glasgow, UK, 9–14 June 2019; Volume 5A. [Google Scholar]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gu, Z.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Finite Element Modelling on the Mechanical Behaviour of Marine Bonded Composite Hose (MBCH) Under Burst and Collapse. J. Mar. Sci. Eng. 2022, 10, 151. [Google Scholar] [CrossRef]

- Bardi, F.C.; Tang, H.; Kulkarni, M.; Yin, X. Structural Analysis of Cryogenic Flexible Hose. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 593–606. [Google Scholar]

- Ying, X.; Geng, D.; Cao, H.; Zhang, K.; Bu, Y.; Yang, Z.; Yan, J. Equivalent Mechanical Properties of Spiral Skeleton Composite Flexible Low-Temperature Pipeline Based on NIAH. Zhendong Yu Chongji/J. Vib. Shock 2023, 42, 10–16. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, M.; Ma, J.; Sun, G. Theoretical Analysis of Reinforcement Layers in Bonded Flexible Marine Hose under Internal Pressure. Eng. Struct. 2018, 168, 384–398. [Google Scholar] [CrossRef]

- Yan, J.; Ying, X.; Cao, H.; Xiong, F.; Zhang, K.; Yang, Z. Mechanism of Mechanical Analysis on Torsional Buckling of U-Shaped Bellows in FLNG Cryogenic Hoses. J. Mar. Sci. Eng. 2022, 10, 1405. [Google Scholar] [CrossRef]

- Pisarenco, M.; van der Linden, B.; Tijsseling, A.; Ory, E.; Dam, J. Friction Factor Estimation for Turbulent Flows in Corrugated Pipes with Rough Walls. J. Offshore Mech. Arct. Eng. 2010, 133, 011101. [Google Scholar] [CrossRef]

- Calomino, F.; Alfonsi, G.; Gaudio, R.; D’Ippolito, A.; Lauria, A.; Tafarojnoruz, A.; Artese, S. Experimental and Numerical Study of Free-Surface Flows in a Corrugated Pipe. Water 2018, 10, 638. [Google Scholar] [CrossRef]

- Calomino, F.; Tafarojnoruz, A.; De Marchis, M.; Gaudio, R.; Napoli, E. Experimental and Numerical Study on the Flow Field and Friction Factor in a Pressurized Corrugated Pipe. J. Hydraul. Eng. 2015, 141, 04015027. [Google Scholar] [CrossRef]

- Jaiman, R.K.; Oakley, O.H.; Adkins, J.D. CFD Modeling of Corrugated Flexible Pipe. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. [Google Scholar]

- Munkejord, S.T.; Hammer, M.; Løvseth, S.W. CO2 Transport: Data and Models—A Review. Appl. Energy 2016, 169, 499–523. [Google Scholar] [CrossRef]

- Lu, W.; Hu, H.; Qi, G. Effect of Pipe Diameter and Inlet Parameters on Liquid CO2 Flow in Transportation by Pipeline with Large Height Difference. Processes 2019, 7, 756. [Google Scholar] [CrossRef]

- Seo, Y.S.; Chung, S.M.; Park, J.C. Multiphase-Thermal Flow Simulation in a Straight Vacuum-Insulated LH2 Pipe: Fuel Gas Supply System in a LH2-Fueled Ship. J. Mar. Sci. Eng. 2024, 12, 914. [Google Scholar] [CrossRef]

- Setoodeh, H.; Shabestary, A.M.; Ding, W.; Lucas, D.; Hampel, U. CFD-Modelling of Boiling in a Heated Pipe Including Flow Pattern Transition. Appl. Therm. Eng. 2022, 204, 117962. [Google Scholar] [CrossRef]

- S Paramanantham, S.S.; Ha, C.T.; Park, W.G. Numerical Investigation of Single and Multiple Bubble Condensing Behaviors in Subcooled Flow Boiling Based on Homogeneous Mixture Model. Int. J. Mech. Sci. 2018, 136, 220–233. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, R.; Zhang, X.; Qiu, L.; Xie, J. Numerical Modeling of Flow Film Boiling in Cryogenic Chilldown Process Using the AIAD Framework. Int. J. Heat Mass. Transf. 2018, 124, 269–278. [Google Scholar] [CrossRef]

- Zhu, H.; Gao, Y.; Zhao, H. Coupling Vibration Response of a Curved Flexible Riser Under the Combination of Internal Slug Flow and External Shear Current. J. Fluids Struct. 2019, 91, 102724. [Google Scholar] [CrossRef]

- An, C.; Zhao, D.; Gao, Y.; Yang, Y.; Li, T. Dynamic Response Analysis of Offshore Floating Hose Strings Under Wave Load. Int. J. Marit. Eng. 2022, 164, 343–355. [Google Scholar] [CrossRef]

- Païdoussis, M.P. Fluid-Structure Interactions: Slender Structures and Axial Flow (Volume 1); Academic Press: Cambridge, MA, USA, 2014; Volume 1, ISBN 9780123973122. [Google Scholar]

- Łuczko, J.; Czerwiński, A. Nonlinear Three-Dimensional Dynamics of Flexible Pipes Conveying Fluids. J. Fluids Struct. 2017, 70, 235–260. [Google Scholar] [CrossRef]

- Gao, P.; Gao, Q.; An, C.; Zeng, J. Analytical Modeling for Offshore Composite Rubber Hose with Spiral Stiffeners under Internal Pressure. J. Reinf. Plast. Compos. 2021, 40, 352–364. [Google Scholar] [CrossRef]

- Li, F.; An, C.; Duan, M.; Su, J. In-Plane and out-of-Plane Dynamics of Curved Pipes Conveying Fluid by Integral Transform Method. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 542. [Google Scholar] [CrossRef]

- Fu, G.m.; Tuo, Y.h.; Su, J.; Wang, K.; Li, L.; Sun, B.j. Nonlinear Dynamics of Viscoelastic Pipe Conveying Pulsating Fluid Subjected to Base Excitation. China Ocean Eng. 2023, 37, 781–793. [Google Scholar] [CrossRef]

- Liu, M.; Li, F.; Cheng, H.; Li, E.; Yan, J.; Lu, H.; Bu, Y.; Tang, T.; Lu, Z. Thermal Stress Analysis of the LNG Corrugated Cryogenic Hose During Gas Pre-Cooling Process. In Proceedings of the Thirty-fourth (2024) International Ocean and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2024. [Google Scholar]

- Sun, Q.; Zhang, Y.; Lv, Y.; Peng, D.; Zhang, S.; Lu, Z. Comparative Analysis of Heat Transfer in a Type B LNG Tank Pre-Cooling Process Using Various Refrigerants. Energies 2024, 17, 4013. [Google Scholar] [CrossRef]

- Wu, C.; Liu, J.; Zhang, J. Transient Thermal Analysis on Pre-Cooling Process of LNG Cryogenic Corrugated Hose. Geoenergy Sci. Eng. 2024, 232, 212434. [Google Scholar] [CrossRef]

- Yang, L.; Liu, M.; Liu, Y.; Li, F.; Fan, J.; Liu, F.; Lu, Z.; Yang, J.; Yan, J. Thermal-Fluid-Structure Coupling Analysis of Flexible Corrugated Hose. China Ocean Eng. 2022, 36, 658–665. [Google Scholar] [CrossRef]

| Hose Type | Flexibility | Thermal Insulation | Axial Tensile Strength | Pressure Rating | Weight |

|---|---|---|---|---|---|

| Reinforced Corrugated Hose | Medium | High | High | High | High |

| Vacuum-Insulated Hose | Medium | Very High | High | High | High |

| Composite Hose | Very High | Low | Medium | Medium | Low |

| Cryoline Composite Hose | High | High | Medium | Medium | Medium |

| Material | Density (kg/m3) | Boiling Point (°C) | Corrosiveness |

|---|---|---|---|

| LCO2 | 1101 | −78.5 | Dissolves in water under high pressure to form carbonic acid, which is strongly corrosive to metal materials [26] |

| LNG | 421 | −162.5 | Not corrosive |

| LPG (Liquefied petroleum gas) | 580 | −42 | Mildly corrosive to metal materials |

| LN (Liquefied nitrogen) | 810 | −196 | Not corrosive |

| Hose Type | Anti-Corrosion | Thermal Insulation | Flexibility | Floating Ability |

|---|---|---|---|---|

| Reinforced Corrugated Hose | Low | High | Medium | High |

| Vacuum-Insulated Hose | Low | Very High | Medium | Medium |

| Composite Hose | High | Low | Very High | Low |

| Cryoline Composite Hose | High | High | High | High |

| Function | Requirements |

|---|---|

| Maximum allowable working pressure | 3.5 MPa |

| Minimum burst pressure | 17.5 MPa (5 times of maximum allowable pressure [15]) |

| Flexibility (minimum bending radius) | Around 5 times the internal diameter [30] |

| Corrosion resistance | Does not cause corrosion failure over service life |

| Thermal ingress | <60 W/m |

| Low temperature resistance | −53 °C (all components of the hose must retain toughness at the lowest design temperature [31]) |

| Maximum flow rate | 4000 |

| Layer | Materials | Function |

|---|---|---|

| Inner and outer spring | 321 stainless steel (ss), 304 ss, 304 L ss, 310 S ss, 316 L ss | Provide radial and axial stiffness to withstand internal pressure while ensuring adequate flexibility to achieve the required minimum bend radius; prevent corrosion caused by LCO2 exposure, especially in the presence of moisture |

| Inner and outer protective layer, Reinforcement layer, Tensile layer | UHMWPE, Aramid, PBO woven fabric, Carbon fiber | Provide structural reinforcement to resist internal pressure, axial tension, and mechanical stress |

| Leakproof layer | UHMWPE film, FEP film, PTFE film | Serve as a barrier to prevent fluid leakage in the event of internal layer failure |

| Thermal insulation layer | Aerogel, Polyurethane foam, Asbestos foam, Aluminosilicate fiber blanket | Minimize heat transfer to maintain cryogenic temperature and prevent LCO2 vaporization |

| Sheath | Polyamide, Polyurethane, Polyethylene, UHMWPE, mLLDPE | Protect against external damage and ensure structural integrity by maintaining layer cohesion |

| Material | Thermal Conductivity (W/m·K) | Density (kg/m3) | Working Temperature (°C) | Properties |

|---|---|---|---|---|

| Aerogel [32] | 0.015 | 3 | −196~1300 | Good inhibition effects on thermal conduction, convection, and radiation |

| Polyurethane foam [33] | 0.12 | 50 | −110~130 | Low water absorption and good non-metallic bonding properties |

| Asbestos foam [34] | 0.06 | 160 | −120~400 | Cost-effective, easy to mold, and chemically stable |

| Aluminosilicate fiber blanket [35] | 0.03 | 80 | <800 | Stable chemical properties, easy to mold, while offering good insulating performance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Li, F.; Bu, Y.; Yin, Y.; Lu, H.; Mao, H.; Zhou, X.; Lu, Z.; Yan, J. A Survey on the Design and Mechanical Analysis of Cryogenic Hoses for Offshore Liquid CO2 Ship-to-Ship Transfer. J. Mar. Sci. Eng. 2025, 13, 790. https://doi.org/10.3390/jmse13040790

Cheng H, Li F, Bu Y, Yin Y, Lu H, Mao H, Zhou X, Lu Z, Yan J. A Survey on the Design and Mechanical Analysis of Cryogenic Hoses for Offshore Liquid CO2 Ship-to-Ship Transfer. Journal of Marine Science and Engineering. 2025; 13(4):790. https://doi.org/10.3390/jmse13040790

Chicago/Turabian StyleCheng, Hao, Fangqiu Li, Yufeng Bu, Yuanchao Yin, Hailong Lu, Houbin Mao, Xun Zhou, Zhaokuan Lu, and Jun Yan. 2025. "A Survey on the Design and Mechanical Analysis of Cryogenic Hoses for Offshore Liquid CO2 Ship-to-Ship Transfer" Journal of Marine Science and Engineering 13, no. 4: 790. https://doi.org/10.3390/jmse13040790

APA StyleCheng, H., Li, F., Bu, Y., Yin, Y., Lu, H., Mao, H., Zhou, X., Lu, Z., & Yan, J. (2025). A Survey on the Design and Mechanical Analysis of Cryogenic Hoses for Offshore Liquid CO2 Ship-to-Ship Transfer. Journal of Marine Science and Engineering, 13(4), 790. https://doi.org/10.3390/jmse13040790