Green Technologies for Environmental Air and Water Impact Reduction in Ships: A Systematic Literature Review

Abstract

1. Introduction

- Q1:

- What are the main environmental challenges for adopting green technologies in the maritime sector?

- Q2:

- What key regulations drive the implementation of green technologies in the naval industry?

- Q3:

- What are the most relevant environmental indicators used in the naval industry to measure the impact of green technologies?

- Q4:

- What strategies does the naval industry implement to comply with leading environmental indicators, and which have proven most effective?

2. Methodology

2.1. Selection Criteria

- By Title and Abstract: A first evaluation was carried out by reading the titles and abstracts of the articles to exclude those that did not explicitly mention the topic of interest, in this case, green technologies applied to vessels.

- By Full Reading: In this stage, the documents were thoroughly reviewed to assess their relevance and alignment with the research objectives. Although some articles mentioned the keywords specified in Table 2, not all met the performance and quality evaluation criteria for the technologies and, thus, were excluded.

2.2. Databases

2.3. Search Strategy

- Group 1: Terms related to eco-innovation or green innovation.

- Group 2: Words associated with eco-products, eco-design, and green technologies.

- Group 3: Terms describing the naval sector, including vessels and shipbuilding industry.

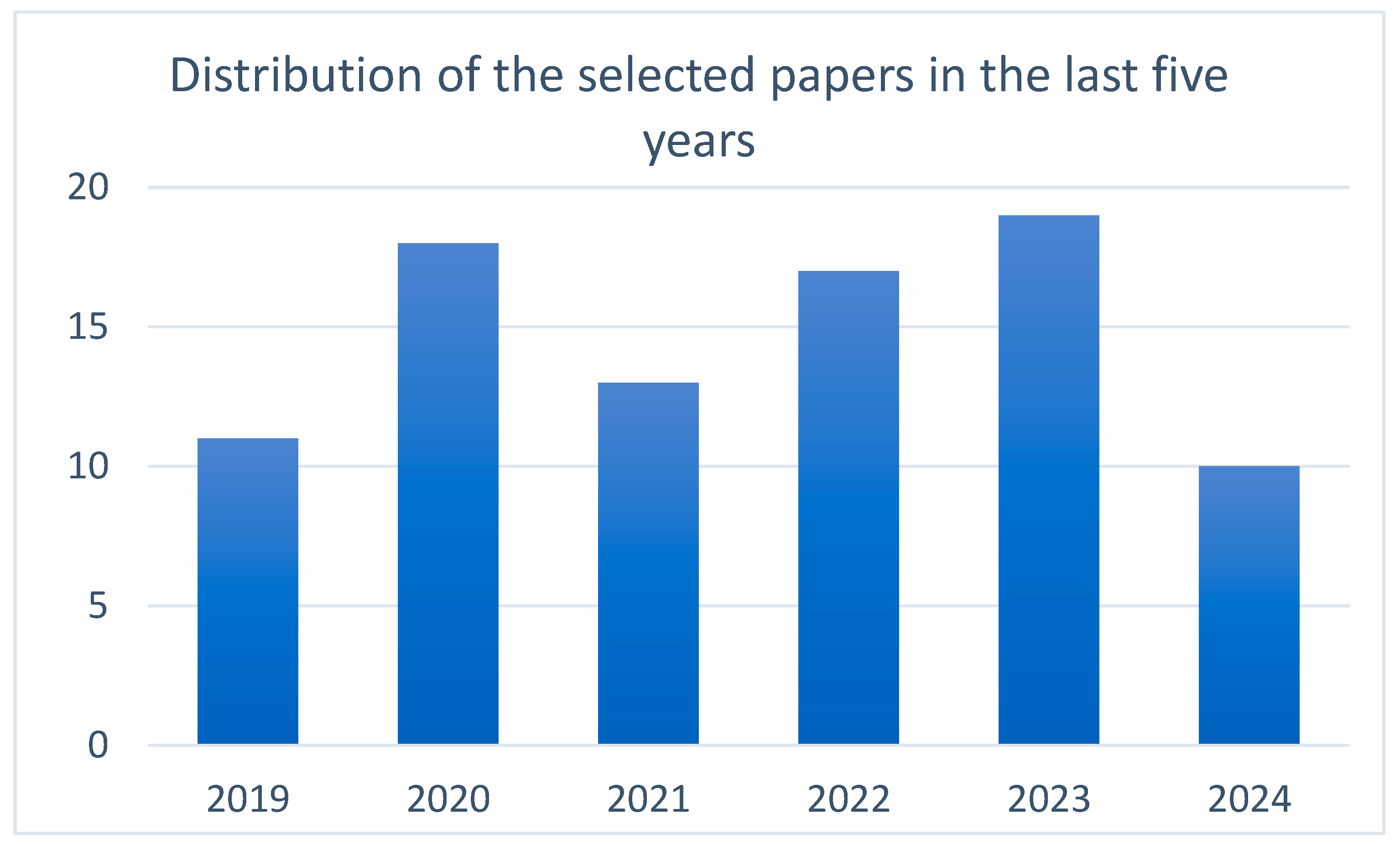

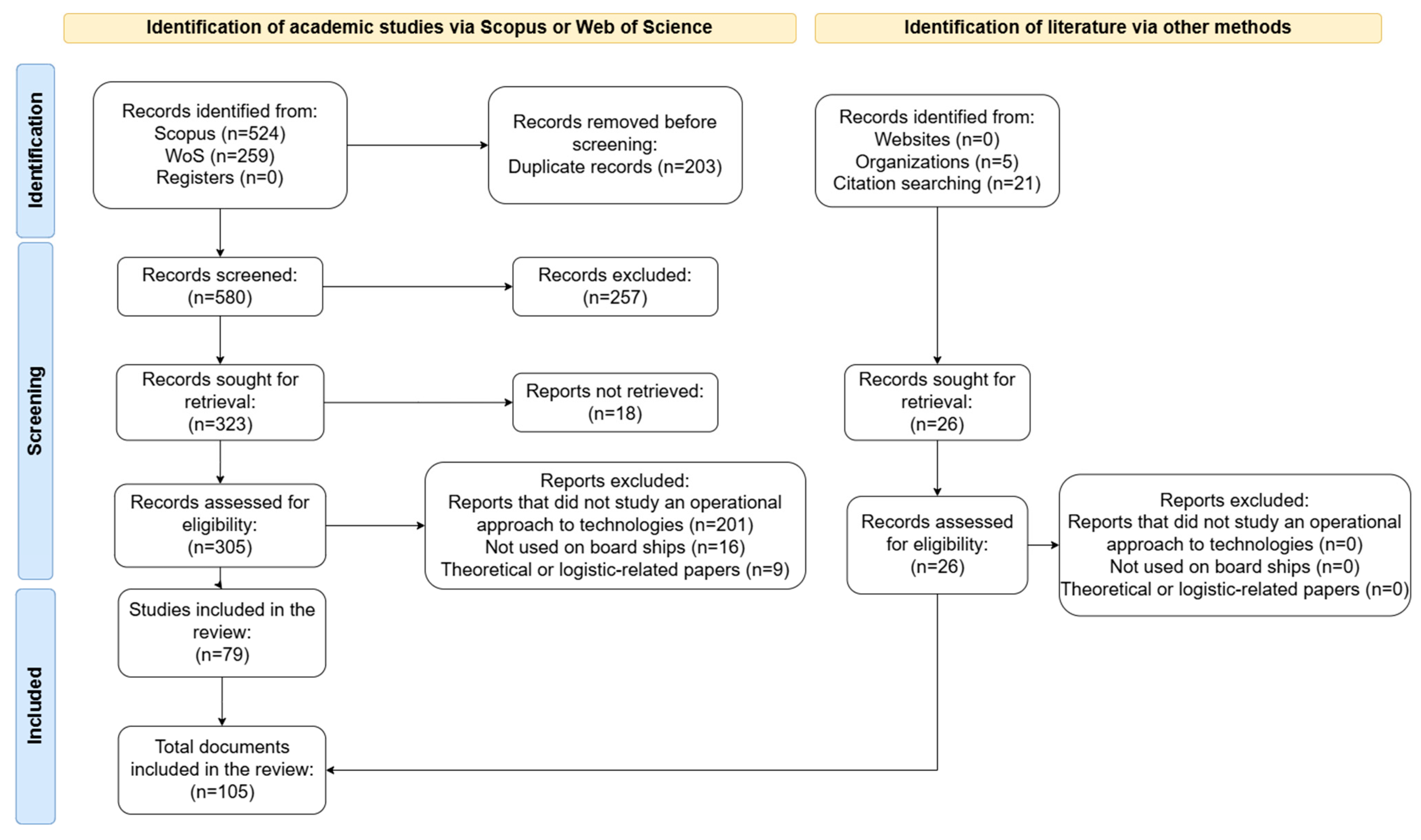

2.4. Selection Process

3. Results

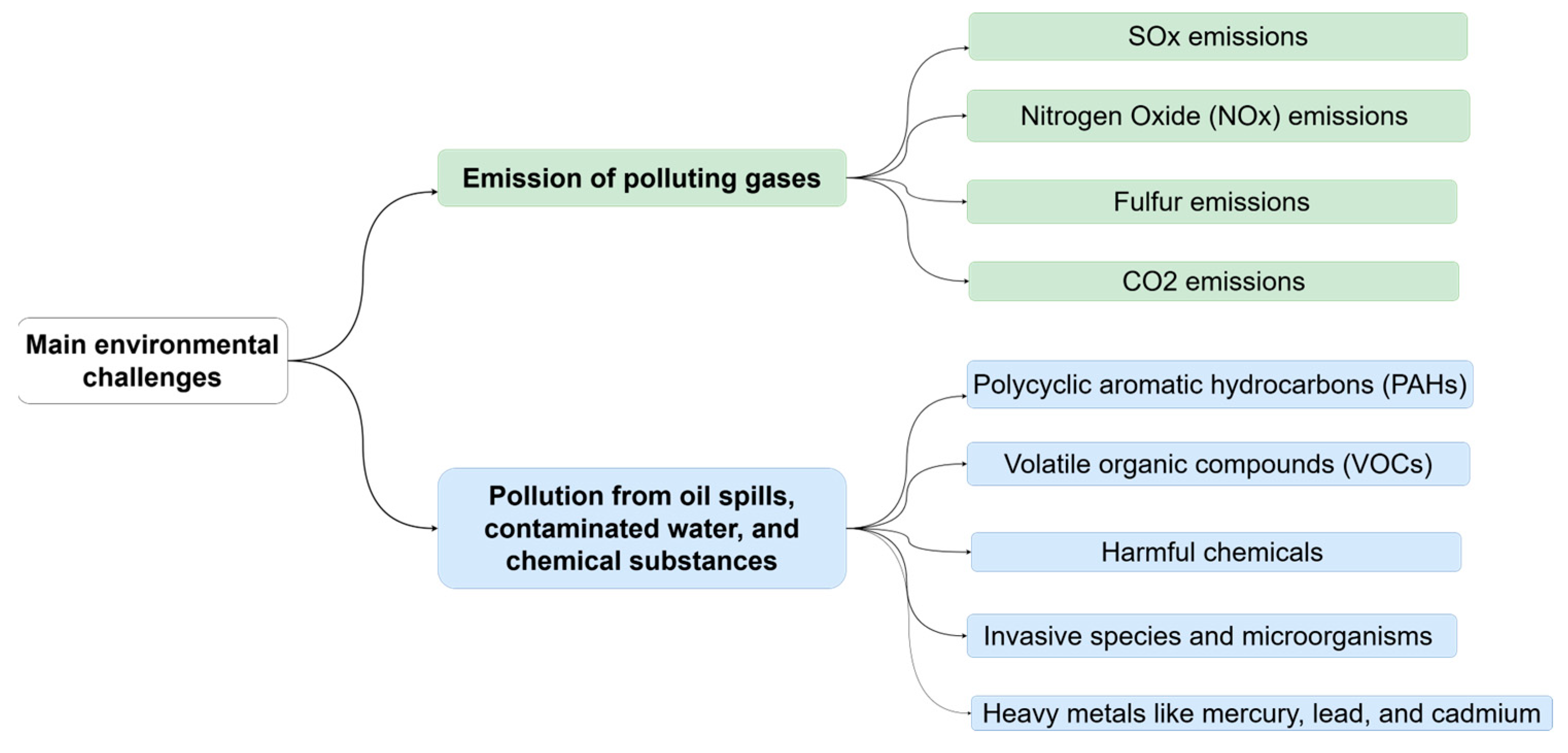

3.1. What Are the Main Environmental Challenges for Adopting Green Technologies in the Maritime Sector?

3.1.1. Emission of Polluting Gases

3.1.2. Pollution from Oil Spills, Contaminated Water, and Chemical Substances

3.2. What Key Regulations Drive the Implementation of Green Technologies in the Naval Industry?

3.3. What Are the Most Relevant Environmental Indicators Used in the Naval Industry to Measure the Impact of Green Technologies?

3.3.1. Impact on Air

3.3.2. Impact on Water

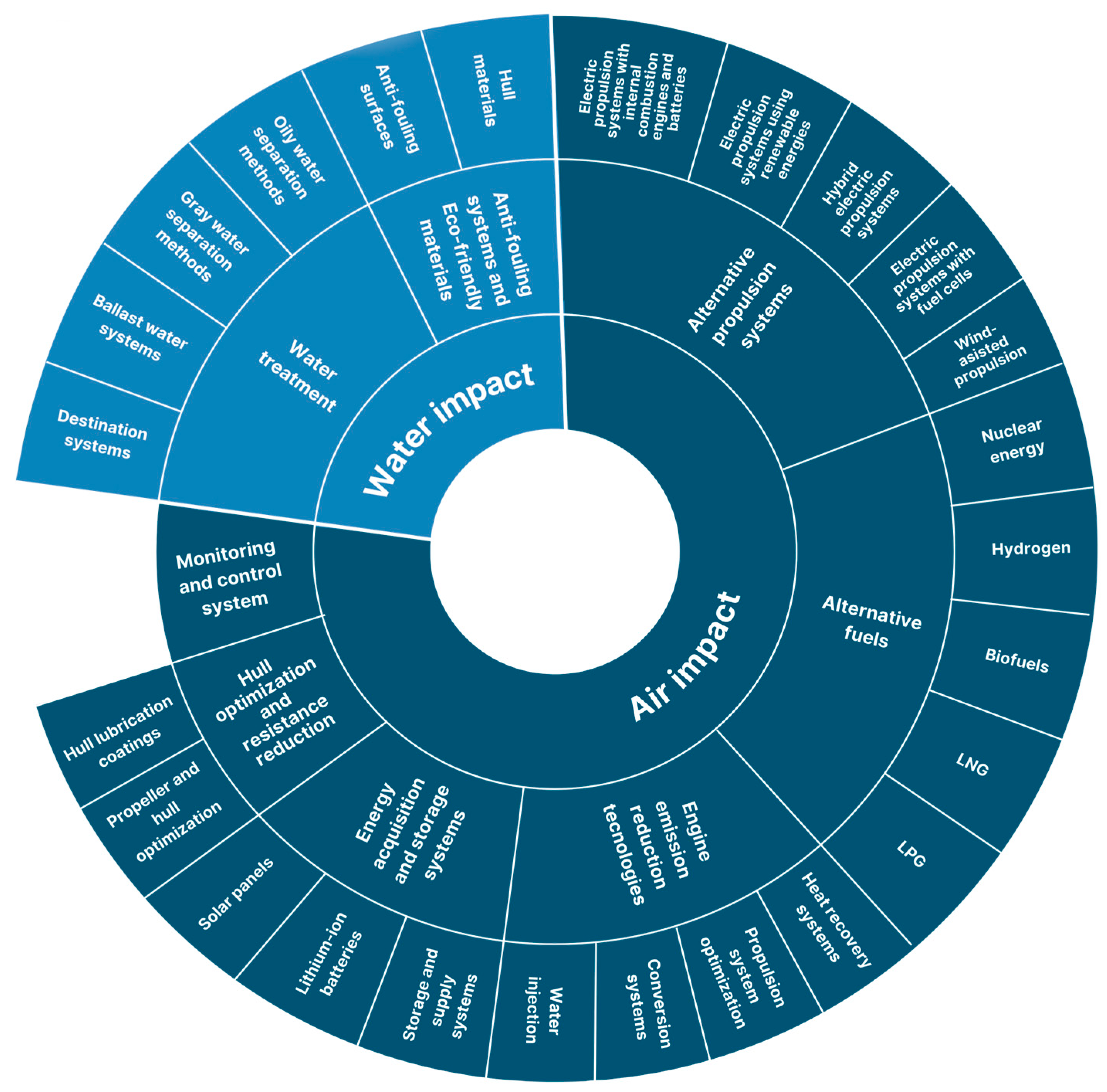

3.3.3. Technologies Associated with Indicators and Regulatory Instruments

3.4. What Strategies Does the Naval Industry Implement to Comply with Leading Environmental?

3.4.1. Technologies Impacting Air

Hull Optimization and Resistance Reduction

- Hull lubricating coatings: The resistance to a ship’s advance is mainly composed of hydrodynamic resistance in the water and aerodynamic resistance in the air. Advanced hull coatings play a crucial role in optimizing both aspects. As mentioned by McCarney [57], in the aquatic environment, these coatings improve the hydrodynamics of the ship, reducing the friction between the hull and the water, which allows for more efficient displacement. This application has been recognized by entities such as the Italian Navy, which, in its emissions reduction initiative, has implemented release coatings to lubricate the hull [58]. In parallel, in the air environment, the potential of “biomimetic air-retaining surfaces” that act as slipping agents on the hulls, based on the Salvinia Effect, providing a reduction of up to 20% in aerodynamic resistance, is highlighted [59]. This holistic approach to coating design demonstrates how a single technology can simultaneously address resistance to advance in the aquatic and aerial environments, contributing significantly to the vessel’s overall efficiency.

- Propeller and hull optimization: These strategies range from innovative hull-cleaning coatings to intelligent control systems and the optimization of key components, showcasing integrated approaches within the maritime industry. As mentioned in the work by Ning et al. [20], propeller optimization plays a fundamental role in improving vessel efficiency through enhanced design. For instance, Nasso et al. [60] presented a comprehensive design process for a fully electric wooden passenger boat. They also highlighted hull form design as a critical aspect to ensure efficient navigation in shallow-water lagoons. On the other hand, Tu H. et al. [61] established a method for predicting optimal trim using machine learning models, demonstrating its ability to rapidly identify the best trim settings for any container ship under varying operational conditions. Likewise, Ghadimi et al. [62] conducted a study focused on the implementation of hydrofoils to improve the hydrodynamic efficiency of trimarans, optimizing total resistance through an automated design model based on Computational Fluid Dynamics (CFD) and the Particle Swarm Optimization (PSO) algorithm. In addition to hydrofoils, research has been carried out on how spray rails enhance the hydrodynamic performance of high-speed boats. Results showed that these structural elements efficiently reduce viscous resistance by deflecting the water flow and minimizing the wetted surface area in the stagnation zone where water meets the hull [63].

Alternative Fuels

- LNG: Among the range of alternative fuels to petroleum-derived fossil fuels, liquefied natural gas (LNG) emerges as one of the main alternatives [57,64]. An increasing number of countries view LNG as an opportunity to diversify their energy imports [65]. LNG offers 20 to 30 percent reductions in CO2 emissions, minimizes SOx emissions and other pollutants, and achieves a 75 to 90 percent reduction in NOx compared to heavy fuel oil [59]. However, despite the advantages presented, liquefied natural gas has disadvantages, such as methane emissions, which are also considered GHGs, and much space is required for storage [20].

- LPG: On the other hand, Yeo et al. [66] argue that liquefied petroleum gas (LPG) is among the replacement options as a fuel with greater ecological efficiency and a lower price than other marine fuels. LPG has advantages in transportation, storage, and implementation costs and lower CO emissions [20], but it requires additional stability measures, and its application in medium and small engines has not been studied [66]. A recent study reinforces these claims, demonstrating through simulation that LPG engines in small fishing vessels emit significantly less CO2, CO, and soot than gasoline and diesel engines. However, they produce more NO than gasoline engines [67]. In addition, the economic feasibility analysis of the same study indicates that the conversion to LPG can reduce significant fuel costs in the life cycle of the vessels, with savings that vary depending on the type of vessel and the substitute fuel.

- Biofuels: Biofuels, whether first generation obtained from plants, second generation produced using non-food waste, or third generation derived from algae [50], can significantly contribute to the reduction of NOx, SOx, and greenhouse gas emissions [57,68]. It has been estimated that all types of biofuels could comply with upcoming maritime emissions regulations, offering equivalent or even lower life-cycle emissions compared to heavy fuel oil [59]. Examples include biogas and biomethane [69,70]. Biodiesel production from microalgae has also been evaluated, demonstrating significant advantages in terms of effectiveness and sustainability compared to other biodiesel sources. Biomethane, in particular, is produced through the anaerobic digestion of biomass and stands out due to its renewable nature and economic feasibility [71]. This reflects the great potential of these as alternative energy sources. Similarly, it was found that hydrogen could be produced through methods such as dark fermentation, photofermentation, biophotolysis, and microbial electrolysis cells, giving rise to a variant known as biohydrogen [71].

- Hydrogen: Hydrogen is another alternative that plays a vital role in decarbonization [57,72]. It is considered less sustainable than biohydrogen because its production mostly comes from fossil fuels. However, like its predecessor, its application in fuel cells and lower emissions during its use is its advantage. It is useful in adapted engines producing water vapor as an emission or through an electrochemical reaction in fuel cells generating electricity [50]. Addressing economic barriers is crucial for adoption, which requires holistic policies across different sectors and industries [73], such as hydrogen-methanol propulsion systems with pre-combustion carbon capture on board that could significantly reduce emissions compared to conventional technologies [74]. Within this framework, recent research has focused on implementing hydrogen technologies in the maritime sector, particularly on fishing vessels. The study addresses risk-based inspections (RBI) and maintenance planning to reduce safety-related uncertainties and optimize associated operations [75].

- Nuclear energy: On the other hand, Balcombe et al. [59] mention that nuclear energy produces very low greenhouse gas and air pollutant emissions at competitive prices. It is an attractive option for its stable value and high power density, obtained by heating steam with an on-board nuclear reactor [50]. Likewise, according to Kistner et al. [72], synthetic fuels emerge as a viable and promising alternative to decarbonize maritime transport, requiring a careful analysis of the associated technologies, economic aspects, and the necessary infrastructure for their successful implementation. As proof of its effectiveness, Kotrandenko et al. [76] point out that nuclear energy has been used successfully for more than 60 years in Arctic icebreakers, an Arctic container ship, and many naval vessels without any known significant accidents. More than 15% of existing icebreakers designed to operate in the Arctic and Antarctic are nuclear-powered.

Emission Reduction Technologies in Engines

- Water injection: Water injection reduces peak temperatures and NOx formation while optimizing parameters such as fuel injection, air/fuel ratio, and chamber geometry, decreasing emissions [78]. The optimization of the electronically controlled high-pressure common rail fuel injection technology improves fuel control and accumulation, improving efficiency in the combustion process and reducing the release of harmful substances [77].

- Conversion systems: Regarding secondary methods, Lion et al. [78] describe selective catalytic reduction (SCR) systems with or without plasma burners to improve their efficiency [79] that convert NOx into nitrogen and water through catalysts and wet treatment systems that wash the exhaust gases with seawater to remove SOx, particles, and NOx. Onboard capture is an attractive solution for short-term maritime decarbonization while carbon-free alternative fuels are being developed. Tan and Nielsen [16], Farrukh et al. [69], and Negri et al. [80] highlight the potential of bioelectrocatalysis, which employs microorganisms or enzymes as biological catalysts to fix and transform CO2 into fuels and chemicals, with advantages such as lower environmental impact and higher selectivity and stability. However, due to the large existing fleet still using sulfur fuels, ref. [81] proposes strategies such as the installation of scrubbers (SI) to clean the exhaust gases of these.

- Propulsion system optimization: Tang et al. [83] mention the optimization of hybrid propulsion systems using artificial intelligence techniques, an efficiency factor, and a correction function to maintain the energy balance of the battery, achieving fuel savings of up to 80%. Issa et al. [50] mention speed reduction, hull design optimization, air lubrication, propeller/rudder improvements, and waste heat recovery in the field of operational measures. Gritsenko et al. [82] experimentally verified that deactivating cylinders in diesel engines reduces consumption when the load is low. Xiaoliang et al. [77] describe optimizing the diesel combustion engine and improving high-pressure boost technology to reduce energy consumption. However, it is important to continue improving turbocharging systems with methods such as exhaust bypass and variable cross-section. The author also describes a new gas combustion technology that uses the pre-combustion of homogeneous materials, improving efficiency and reducing nitrogen oxides. High-pressure combustion and compression technologies in diesel engines ensure controlled combustion.

- Heat recovery systems: For their part, Li et al. [84], Ouyang et al. [85], and Theotokatos et al. [86] study the residual heat recovery systems for ship engines, which improve thermal efficiency and are recommended to be installed in medium and large vessels optimized for their current operating profile, where fuel cells combined with residual heat recovery are explored [84,87]. In turn, a device has been developed for small boats that takes advantage of the residual heat from the exhaust gases of diesel engines through the vortex tube effect. This innovative technology allows for energy-efficient seawater desalination with a compact design, and it is also applicable to medium-sized vessels; likewise, turbo-generator technologies equipped with bidirectional pulsed turbines have been evaluated [88]. The authors examine this technology in the context of marine thermoacoustic waste heat recovery systems (WHRSs) [89]. In addition to capturing the gases, certain technologies seek to recirculate them through two configurations: (a) Recirculation of the boiling gas from a cryogenic separation unit. Moreover, (b) Recirculation of the gas separated by a semipermeable membrane between the MCFCs and the cryogenic separation unit [90].

Alternative Propulsion Systems

- Wind-assisted propulsion: Wind-assisted propulsion through rotors, kites, suction wings, Flettner rotors, and rigid sails [69] also represents a viable option that could reduce CO2 emissions by up to 20% [50,91]. The research was also found on a self-adaptive sail based on real-time adjustment of the angle of attack and sail attitude to track wind direction during navigation [92]. It is important to note that these technologies are primarily developed as auxiliary systems to reduce fuel consumption and not as a total replacement [93], possibly due to wind not always being constant throughout navigation. The study made by [93] proposes an agent-based simulation model to analyze the adoption of three specific wind-assisted propulsion technologies (WPT): Wingsail (rigid sail), Ventifoil, and a third unspecified option. This model considers two stages in the adoption process, technological awareness and utility-based decision, and uses real data from vessels and WPT options to evaluate different policy interventions that could incentivize the adoption of these technologies in the maritime retrofitting industry.

- Electric propulsion systems with fuel cells: Another technology under development is fuel cells, which are electrochemical devices that directly convert the chemical energy of a fuel, usually hydrogen, into electrical energy. There are different types of fuel cells: proton exchange membranes (PEMFC), which operate at low temperatures, have high power density, and are suitable for portable and small-scale applications; high-temperature PEMFCs, which operate up to 200 °C and are less sensitive to impurities; molten carbonate (MCFC), which operate at high temperatures, can use various fuels, and are efficient but slow to start; and solid oxide (SOFC), which operate between 500 and 1000 °C, are flexible in terms of fuel and highly efficient but also slow to start [94]. They function through a reaction between hydrogen and oxygen, producing electricity and water as the only byproduct [95]. These systems offer benefits such as low noise emission, high efficiency, and lower environmental impact, making them suitable as a main source in maritime applications. In this regard, hybrid energy systems are proposed that combine solar panels, wind rotors, fuel cells, batteries, and diesel generators for large vessels [91]. Specifically for hydrogen cells, excellent environmental performance is evident, with 45–72% reductions in global warming potential compared to conventional technologies, facilitating the energy transition in maritime transport [96]. Using renewable hydrogen, greenhouse gas emissions are reduced by 91.4% compared to equivalent diesel vessels, demonstrating their viability for coastal research vessels [97]. According to Balcombe et al. [59], fuel cells produce low-carbon electricity, generating little noise and vibration compared to internal combustion engines. Specifically, solid oxide fuel cell (SOFC) technology is economically viable for maritime applications despite higher capital and maintenance costs due to its high energy efficiency and the use of LNG [72,90]. Projects with designs for comprehensive waste heat utilization systems in ships propelled by hydrogen fuel cells are highlighted, which improve energy efficiency, making this option even more appealing [87].

- Hybrid electric propulsion systems: In the field of naval electric propulsion, various studies have been conducted. Hayton [98] proposes implementing electric propulsion systems independently or in conjunction with internal combustion engines to take advantage of renewable sources and reduce fossil fuel consumption. Additionally, research has been conducted on the challenges these systems face due to load changes in adverse maritime conditions. The application of energy storage systems, such as batteries and supercapacitors, is explored to mitigate transients caused by these load changes, keeping electrical parameters within acceptable limits. These storage systems in intelligent hybrid power marine energy management could reduce operating costs, meet emission standards, and improve performance [5]. Also, Gelver et al. [99] propose an electric propulsion system for ships with a particular focus on a configuration that uses common DC buses, which is presented as an improvement over existing systems.

- Renewable energy electric propulsion system: However, sometimes the sources of this energy, such as solar panels, may not be as efficient during nighttime hours. This leads to considering more complete options such as hybrid systems with solar panels and fuel cells during the night [100].

- Electric propulsion system with energy generation from internal combustion engines and batteries: On the other hand, Candelo et al. [95] analyze a more complex system that combines generation by internal combustion engines and batteries. In the latter, the electric motor obtains energy from thermoelectric generators and a battery bank, also incorporating internal combustion generators, power converters, and DC and AC distribution bars, representing a more comprehensive approach to electric propulsion of vessels. Entirely electric ships also lead to considering and linking aspects beyond their propulsion, such as real-time digital twin applications and Power Hardware-in-the-Loop (PHIL) platforms in developing and validating advanced power electronics systems [101].

3.4.2. Monitoring Systems

- Monitoring and Control Systems: Studies have found that present technologies for assessing maritime traffic density are based on big data from vessel trajectories. This technology uses data from the Automatic Identification System (AIS), which is preprocessed to reflect actual trajectories, as explained by Dai et al. [123]. Other authors, such as Yang [124], have proposed the design of an energy parameter monitoring system that can monitor these parameters in real-time. These systems can also be applied to marine environmental monitoring, such as the one proposed by Hu et al. [125], which uses multiple data sources to provide real-time information and early warnings to support decision-making in marine environment management and protection [126]. In [127] is highlighted the use of “advanced control technologies, such as Linear Matrix Inequalities (LMI) and Model Predictive Control (MPC) paradigms, to control the movements of an autonomous ship at different stages of its journey”, tested in full-scale experiments. Regarding environmental monitoring, studies have advanced in a web development model based on the MVC (Model-View-Controller) software architecture, which facilitates data storage and visualization applied to tanks [125]. Additionally, research on electric propulsion for ships highlights the use of permanent magnet synchronous motors (PMSM) and proportional-integral (PI) scheme controllers to optimize the speed and torque of the propeller, demonstrating the effectiveness of these technologies in simulations [127]. The implementation of unmanned systems has also gained relevance, such as the case of the teleoperation of remotely operated vehicles, which leverage mixed reality technologies, sensory augmentation, and closed-loop control to intuitively and immersively visualize complex underwater environmental data [87].

3.4.3. Energy Acquisition and Storage Systems

- Solar panels: Huang et al. [91] and Chen et al. [102] highlight that photovoltaic solar panels are emerging as a promising alternative, although their main challenge lies in how to efficiently use this system to provide a stable energy supply to ships. A recent study on a short-route ferry in Turkey confirms this potential, demonstrating a reduction in emissions of 3 × 106 kg CO2 equivalent during its lifetime, with an investment recovery period of only 3 years. However, the study emphasizes the need to improve the energy conversion efficiency of solar panels to maximize benefits, especially on short routes [103].

- Lithium-ion batteries: Lithium-ion batteries are presented as a promising alternative for short-distance navigation [98], requiring a comprehensive analysis of their technical and safety characteristics for their applicability [104,105]. Recharging systems for electric propulsion powered by rechargeable lithium-ion batteries as an energy source have been proposed, focused on small vessels. The authors analyze these systems, highlighting that they generate no noise, vibrations, or pollution, providing a quality experience for passengers [95]. Additionally, to reinforce safety measures for the use of these technologies, an advanced fire detection system for ship batteries has also been developed [104].

- Energy storage and supply systems: Regarding energy storage systems for supply, studies have been conducted on innovative technologies that improve efficiency and reduce costs, such as automatic energy coupling and charging systems [98,106]; batteries on offshore platforms [20]; and compressed air energy storage (CAES) systems with piston machines in parallel mode [87]. In particular, Zhang et al. [107] highlight the need to mitigate the effects of unbalanced condensation in CAES technologies, as suspended particles in the air, both soluble and insoluble, alter the flow structure and increase flow resistance. Additionally, prototypes of integrated and off-grid mobile power supplies have been developed to provide power to ships docked in river anchorages [18]. This technology, also known as “cold ironing”, allows power to be supplied from land to ships. At the same time, they are docked in port, providing an opportunity to suspend the operation of auxiliary engines that emit pollution [108]. Combining these systems leads to the creation of microgrids; on-board microgrid systems, which integrate energy and communication networks, offer a solution to efficiently manage multiple energy sources and loads [109]. DC microgrids equipped with solid-state technologies and energy storage systems offer vessel owners greater flexibility in system energy management, reduced fuel consumption, and compliance with environmental regulations in ports [110]. Hybrid microgrids, which combine renewable energies with battery storage and diesel generators, demonstrate potential for optimizing costs and energy production [111].

3.4.4. Regarding Technologies with an Impact on Water

Anti-Fouling Paints and Eco-Friendly Materials

- Anti-fouling Surfaces: Recent studies by Maliowsi et al. [113] have demonstrated the good performance of a biocide-free silicone coating (FRC) in the Baltic Sea region under static conditions and high fouling pressure. This technology is part of bio-inspired antifouling surfaces, which mimic natural biological systems to prevent the accumulation of microorganisms and biological fouling (biofouling) on surfaces submerged in aquatic environments [112]. On the other hand, authors such as Felicia et al. [114] have studied the use of xerogel coatings, as well as Aquafast and Aquafast Pro, which are mechanically more stable and durable.

- Hull Materials: Materials used in vessel hulls often contain polluting agents, making it necessary to study alternative materials that have lower contamination without compromising material strength. For example, Zhou et al. [115] studied the bulk and in-situ mechanical properties of rubber-wood-plastic composites (RUBWPC) and their correlations, while Malinowski et al. [113] focused on polybutylene adipate-co-terephthalate (PBAT) modified with coconut fiber (CF) to analyze changes in selected properties of the modified polymer. Iwuozor et al. [116] proposed plant-based biomass composites (PBCs) for their feasibility and impact in the maritime sector. The authors explored the use of these materials in the manufacture of various naval components such as boats, hulls, decks, canoes, surfboards, load ropes, and oars. Similarly, Minillo et al. [117] studied through finite element analysis (FEA) the use of hybrid composites with natural fibers such as curaua, which is extracted from bromeliaceous plants and whose fiber diameter does not exceed 56 μm, and which can be applied in nautical products such as cleats.

Water Treatment Systems

- Oily Water Separation Method: Physically, methods such as gravity are used to separate oil from water by density difference, coagulation to increase the size of oil particles and facilitate their flotation, and filtration through porous media to retain oil droplets. Chemically, processes such as disinfection, electrochemical treatment, and advanced oxidation processes are applied to remove organic contaminants. Regarding biological processes, “activated sludge systems with suspended microbial flocs, membrane bioreactors, and integrated ecological treatments that leverage microbial metabolism” are employed [118].

- Greywater Separation Methods: Two main methods are commonly used: adsorption on porous and high surface area materials and electrochemical oxidation through redox reactions. In addition, other technologies include physical separation systems for grey and black water, flocculation-precipitation, membrane separation, and high-temperature and pressure treatments [119]. Moreover, Cecconet et al. [120] demonstrate that microbial fuel cells are an effective and viable option for greywater treatment, suggesting local reuse of the treated water while simultaneously reducing energy demand. Similarly, Kalnina et al. [121] studied technologies and methods for identifying microplastics in wastewater. These include Bengal rose staining to facilitate particle separation and identification, optical microscopy for visual recognition, and scanning electron microscopy (SEM) to analyze particle surfaces. Finally, to monitor contamination from ship discharges, “online systems based on Automatic Identification System information” have been designed [119].

- Ballast Water Systems: Ballast water systems often transport invasive organisms, which is why technology development begins with the study of these organisms to understand how to prevent contamination by alien species [112]. Addressing this issue, Wright et al. [42] and Ghita et al. [112] propose technologies for assessing organism populations in ballast water through (a) high-throughput sequencing, a DNA-based molecular technique that maps entire populations, and (b) conventional microscopy, which involves visual counting. Additionally, there are alternatives such as the modification of a retrofit ballast water system that includes three main processes: filtration, electrolysis, and neutralization. The renovated system is reliable and capable of treating turbid water with only 1–2% of the total flow passing through electrolysis [77].

- Desalination Systems: Regarding consumable water, it was found that residual heat from industrial steam boilers is used to distill saltwater for consumption. Saltwater separation methods are divided into two main categories: temperature-based and membrane-based [128]. In addition to producing freshwater, this design also provides hot water for daily use, ensuring high efficiency in waste heat recovery. Regarding membrane methods, recent research has achieved significant advances. One study highlights the incorporation of carbon nanotubes into polyamide (PA) membranes for seawater desalination. This innovation improves membrane robustness and anti-fouling performance [129].

4. The Ways Forward

5. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cret, L.; Baudry, M.; Lantz, F. How to implement the 2023 IMO GHG strategy? Insights on the importance of combining policy instruments and on the role of uncertainty. Mar. Policy 2024, 169, 106332. [Google Scholar] [CrossRef]

- Franz, S.; Campion, N.; Shapiro-Bengtsen, S.; Bramstoft, R.; Keles, D.; Münster, M. Requirements for a maritime transition in line with the Paris Agreement. iScience 2022, 25, 105630. [Google Scholar] [CrossRef]

- Fitzmaurice, M. The International Convention for the Prevention of Pollution from Ships (MARPOL). In Research Handbook on Ocean Governance Law; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 91–108. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, Y.; Iris, Ç. Integrated green technology adoption, ship speed optimization and slot management for shipping alliance under emission limits and uncertain fuel prices. J. Clean. Prod. 2025, 494, 144939. [Google Scholar] [CrossRef]

- Coppola, T.; Micoli, L.; Russo, R.; Sorrentino, V. Concept Risk Analysis of a Full-Electric Passenger Catamaran Ferry Equipped with Hydrogen-Fuelled PEM Fuel Cell and Battery Systems. Chem. Eng. Trans. 2024, 111, 469–474. [Google Scholar] [CrossRef]

- Agarwala, N. Is hydrogen a decarbonizing fuel for maritime shipping? Mar. Technol. Res. 2024, 6, 271244. [Google Scholar] [CrossRef]

- Wan, Z.; Nie, A.; Chen, J.; Pang, C.; Zhou, Y. Transforming ports for a low-carbon future: Innovations, challenges, and opportunities. Ocean Coast. Manag. 2025, 264, 107636. [Google Scholar] [CrossRef]

- Kanchiralla, F.M.; Brynolf, S.; Mjelde, A. Role of biofuels, electro-fuels, and blue fuels for shipping: Environmental and economic life cycle considerations. Energy Environ. Sci. 2024, 17, 6393–6418. [Google Scholar] [CrossRef]

- Du, J.; Qin, K.; Zhang, R.; Guo, L.; Wen, S. Multi-objective heterogeneous fleet deployment and scheduling with green technology adoption considered. Ocean Eng. 2024, 311, 118939. [Google Scholar] [CrossRef]

- Sun, M.; Tong, T.; Jiang, M.; Zhu, J.X. Innovation trends and evolutionary paths of green fuel technologies in maritime field: A global patent review. Int. J. Hydrogen Energy 2024, 71, 528–540. [Google Scholar] [CrossRef]

- Hu, S.; Zhang, X.; Xu, W.; Cai, M.; Xu, Y.; Chen, H. Experimental study of tube-array-based liquid piston air compressor for near-isothermal compressed air energy storage system. Appl. Energy 2024, 373, 23979. [Google Scholar] [CrossRef]

- Premsamarn, P.; Win, T.K.; Watanabe, D. Assessing the impact of emission control areas policy on ship emissions in the Gulf of Thailand using AIS data. Mar. Technol. Res. 2025, 7, 275311. [Google Scholar] [CrossRef]

- Sheng, D.; Meng, Q.; Li, Z.-C. Optimal vessel speed and fleet size for industrial shipping services under the emission control area regulation. Transp. Res. Part C Emerg. Technol. 2019, 105, 37–53. [Google Scholar] [CrossRef]

- Psaraftis, H.N.; Benamara, H.; Berge, S.P.; de Kat, J.O.; Fagerholt, K.; Fjørtoft, K.E.; Hellsten, E.; Hoffmann, J.; Louzis, K.; Mikelis, N.; et al. Sacrame. In Sustainable Shipping: A Cross-Disciplinary View; Psaraftis, H.N., Ed.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Tola, F.; Mosconi, E.M.; Marconi, M.; Gianvincenzi, M. Perspectives for the Development of a Circular Economy Model to Promote Ship Recycling Practices in the European Context: A Systemic Literature Review. Sustainability 2023, 15, 5919. [Google Scholar] [CrossRef]

- Tan, X.; Nielsen, J. The integration of bio-catalysis and electrocatalysis to produce fuels and chemicals from carbon dioxide. Chem. Soc. Rev. 2022, 51, 4763–4785. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, C.; Zhang, J.; Chen, Z.; Liu, M.; Aziz, F.; Kurniawan, T.A.; Yap, P.-S. Digitalization and innovation in green ports: A review of current issues, contributions and the way forward in promoting sustainable ports and maritime logistics. Sci. Total Environ. 2024, 912, 169075. [Google Scholar] [CrossRef]

- Zhou, Y.; Kumar, M.; Sarsaiya, S.; Sirohi, R.; Awasthi, S.K.; Sindhu, R.; Binod, P.; Pandey, A.; Bolan, N.S.; Zhang, Z.; et al. Challenges and opportunities in bioremediation of micro-nano plastics: A review. Sci. Total Environ. 2022, 802, 149823. [Google Scholar] [CrossRef]

- Baley, C.; Chamley, A.; Davies, P.; Dinham-Price, I.; Keryvin, V.; Marchandise, A.; Troalen, W. Sustainable polymer composite marine structures: Developments and challenges. Prog. Mater. Sci. 2024, 145, 101307. [Google Scholar] [CrossRef]

- Ning, Y.; Wang, L.; Yu, X.; Li, J. Recent development in the decarbonization of marine and offshore engineering systems. Ocean Eng. 2023, 280, 114883. [Google Scholar] [CrossRef]

- Pei, Z.; Kang, Y.; Long, F. Research and Development of Inland Green and Smart Ship Technologies in China. Appl. Sci. 2024, 14, 2316. [Google Scholar] [CrossRef]

- Qi, X.; Li, Z.; Zhao, C.; Zhang, Q.; Zhou, Y. Environmental impacts of Arctic shipping activities: A review. Ocean Coast. Manag. 2024, 247, 106936. [Google Scholar] [CrossRef]

- Pinar, O.; Rodríguez-Couto, S. Advancements in bilge wastewater treatment: A review for current and future trends. Sci. Total Environ. 2024, 951, 175587. [Google Scholar] [CrossRef]

- Hojnik, J.; Ruzzier, M.; Konečnik Ruzzier, M.; Sučić, B.; Soltwisch, B.; Rus, M. Review of EU projects with a focus on environmental quality: Innovation, eco-innovation, and circular-economy elements. Int. J. Innov. Stud. 2024, 8, 1–12. [Google Scholar] [CrossRef]

- Paipa, E.; Orozco, M.B.; Escalante, F.; Camargo, C.P.; Zapata, J.A. Exploring the Landscape of Eco-Innovation: A Bibliometric Analysis of Concepts and Trends in the Manufacturing and Shipbuilding Industries. Sustainability 2024, 16, 5188. [Google Scholar] [CrossRef]

- Ma, F.; Bao, H.; Nikolaeva, A.; Xia, J.; Guan, Z. Advancements in Marine Vessel Design: A Twenty-Four-Year Bibliometric Survey on Technological, Environmental, and Sustainable Progress. Sustainability 2024, 16, 11039. [Google Scholar] [CrossRef]

- Fofack-Garcia, R.; Mazé, C.; Safi, G.; Lejart, M.; Chauvac, N.; Thermes, M.; Ragueneau, O.; Le Loc’h, F.; Niquil, N. Socio-political acceptability of floating offshore wind farms in France: Challenges and perspectives for marine governance towards sustainability. Ocean Coast. Manag. 2023, 236, 106513. [Google Scholar] [CrossRef]

- Xiao, G.; Pan, L.; Lai, F. Application, opportunities, and challenges of digital technologies in the decarbonizing shipping industry: A bibliometric analysis. Front. Mar. Sci. 2025, 12, 1523267. [Google Scholar] [CrossRef]

- Lin, B.; Ma, R. Green technology innovations, urban innovation environment and CO2 emission reduction in China: Fresh evidence from a partially linear functional-coefficient panel model. Technol. Forecast. Soc. Change 2022, 176, 121434. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 372, 88. [Google Scholar] [CrossRef]

- Restrepos, J.; Branch, J.; Zapata, J.; Paipa, E.; Garnica, M. Industry 4.0 Technologies Applied to Inland Waterway Transport: Systematic Literature Review. Sensors 2022, 22, 3708. [Google Scholar] [CrossRef]

- Jalkanen, J.P.; Johansson, L.; Andersson, M.H.; Majamäki, E.; Sigray, P. Underwater noise emissions from ships during 2014–2020. Environ. Pollut. 2022, 311, 119766. [Google Scholar] [CrossRef]

- European Environment Agency. Hechos y Cifras: Informe Medioambiental Europeo del Transporte Marítimo; European Maritime Safety Agency: Luxembourg, 2025. [Google Scholar]

- Figenschau, N.; Lu, J.; Batalden, B.-M.; Panieri, G. Linking ship-associated emissions and resource development in the Arctic: Trends and predictions along the Northern Sea Route. Ocean Coast. Manag. 2024, 257, 107314. [Google Scholar] [CrossRef]

- International Maritime Organization. Resolution MEPC.377(80): 2023 IMO Strategy on Reduction of GHG Emissions from Ships; IMO: London, UK, 2023. [Google Scholar]

- Zhang, C.; Zhu, J.; Guo, H.; Xue, S.; Wang, X.; Wang, Z.; Chen, T.; Yang, L.; Zeng, X.; Su, P. Technical Requirements for 2023 IMO GHG Strategy. Sustainability 2024, 16, 2766. Available online: https://cdn.qualenergia.it/wp-content/uploads/2023/07/Resolution-MEPC.37780.pdf (accessed on 7 April 2025). [CrossRef]

- International Maritime Organization. The Global MTCC Network. Available online: https://www.imo.org/en/OurWork/PartnershipsProjects/Pages/IMO-EuropeanUnionProject.aspx (accessed on 7 April 2025).

- National Academies of Sciences, Engineering, and Medicine. Oil in the Sea IV: Inputs, Fates, and Effects; The National Academies Press: Washington, DC, USA, 2022. [Google Scholar] [CrossRef]

- Etkin, D.S.; Trends and Observations on 50 Years of Oil Spill Statistics. SSRN 2023. Available online: https://ssrn.com/abstract=4674400 (accessed on 7 April 2025).

- Park, K.H.; Lee, J.W.; Seo, Y. Design of cascade refrigerant process utilizing CO2 and NH3 to remove volatile organic compounds. J. CO2 Util. 2023, 70, 102439. [Google Scholar] [CrossRef]

- Onyena, A.P.; Nwaogbe, O.R. Assessment of water quality and heavy metal contamination in ballast water: Implications for marine ecosystems and human health. Mar. Technol. Res. 2024, 6, 270227. [Google Scholar] [CrossRef]

- Wright, D.A.; Mitchelmore, C.L.; Place, A.; Williams, E.; Orano-Dawson, C. Genomic and Microscopic Analysis of Ballast Water in the Great Lakes Region. Appl. Sci. 2019, 9, 2441. [Google Scholar] [CrossRef]

- Sadia, M.; Mahmood, A.; Ibrahim, M.; Irshad, M.K.; Quddusi, A.H.A.; Bokhari, A.; Mubashir, M.; Chuah, L.F.; Show, P.L. Microplastics pollution from wastewater treatment plants: A critical review on challenges, detection, sustainable removal techniques and circular economy. Environ. Technol. Innov. 2022, 28, 102946. [Google Scholar] [CrossRef]

- Harsha, M.L.; Verna, D.E.; Salas-Ortiz, Y.; Osborn, E.; Turcios Valle, E.; Goranov, A.I.; Hatcher, P.G.; Aguilar-Islas, A.M.; Tomco, P.L.; Podgorski, D.C. Examining the effectiveness of oiled ballast water treatment processes: Insights into hydrocarbon oxidation product formation and environmental implications. Environ. Sci. Adv. 2024, 3, 1746–1759. [Google Scholar] [CrossRef]

- Maulita, A.; Azizah, A.; Luturmas, F.B. The Impact of Environmental Management Accounting Adoption on The Shipping Industry’s Environmental Performance, Influenced by Green Shipping and Regulatory Pressure. Manag. Account. Rev. 2024, 23, 351–367. [Google Scholar] [CrossRef]

- Wiśnicki, B.; Wagner, N.; Wołejsza, P. Critical areas for successful adoption of technological innovations in sea shipping—The autonomous ship case study. Innov. Eur. J. Soc. Sci. Res. 2024, 37, 582–608. [Google Scholar] [CrossRef]

- Bai, X.; Hou, Y.; Yang, D. Choose clean energy or green technology? Empirical evidence from global ships. Transp. Res. Part E Logist. Transp. Rev. 2021, 151, 1366–5545. [Google Scholar] [CrossRef]

- Kırval, L.; Çalışkan, U.Y. Influence of the European Union (EU) on International Maritime Organization (IMO) about the Market-based Measures on Emissions. Int. J. Environ. Geoinf. 2022, 9, 146–153. [Google Scholar] [CrossRef]

- Salman, M. Exploring economic and cargo efficiencies in the global shipping sector: A convergence analysis. J. Clean. Prod. 2025, 501, 145298. [Google Scholar] [CrossRef]

- Issa, M.; Ilinca, A.; Martini, F. Ship Energy Efficiency and Maritime Sector Initiatives to Reduce Carbon Emissions. Energies 2022, 15, 7910. [Google Scholar] [CrossRef]

- United Nations. Progress Towards the Sustainable Development Goals: Towards a Rescue Plan for People and Planet; General Assembly Economic and Social Council, 2023. Available online: https://digitallibrary.un.org/record/4014344?ln=en&v=pdf (accessed on 7 April 2025).

- Teng, S.; Xi, H. Experimental evaluation of vortex tube and its application in a novel trigenerative compressed air energy storage system. Energy Convers. Manag. 2022, 268, 115972. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Z.; Xiao, S. Research on Energy Efficiency Design Index Calculation Method for the Hybrid Ship. J. Phys. Conf. Ser. 2021, 2029, 012087. [Google Scholar] [CrossRef]

- Prastowo, H.; Pitana, T.; Artana, K.B.; Ariana, I.M.; Pramana, A.T. Development of Measurement Tool for Energy Efficiency Operational Indicator (EEOI). IOP Conf. Ser. Earth Environ. Sci. 2024, 1423, 012026. [Google Scholar] [CrossRef]

- Bortali, M.; Rabouli, M.; Yessari, M.; Hajjaji, A. Assessment of harbor sediment contamination for a path to valorize dredged material. Arab. J. Chem. 2023, 16, 105208. [Google Scholar] [CrossRef]

- Kong, L.; Wang, X.; Xiang, Q.; Li, Y.; Cheng, J.; Chen, H.; Liu, Y.; Han, J.; Zhang, N. Distribution characteristics and ecological risk assessment of butyltins in sediments at typical dumping sites in China. Reg. Stud. Mar. Sci. 2023, 66, 103127. [Google Scholar] [CrossRef]

- McCarney, J. Evolution in the engine room: A review of technologies to deliver decarbonised, sustainable shipping: Technology options for the shipping sector to meet international ship emissions limits. Johns. Matthey Technol. Rev. 2020, 64, 374–392. [Google Scholar] [CrossRef]

- Bignone, A.; Benetello, G. Italian Navy Green Fleet—Energy Saving Measures: A Solution to Increase Overall Efficiency of a Military Ship of “Bergamini” FREMM Class. In Technology and Science for the Ships of the Future, 6th ed.; IOS Press: Genoa, Italy, 2022; pp. 710–716. [Google Scholar] [CrossRef]

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkes, A.; Staffell, I. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- Nasso, C.; la Monaca, U.; Bertagna, S.; Braidotti, L.; Mauro, F.; Trincas, G.; Marinó, A.; Bucci, V. Integrated design of an eco-friendly wooden passenger craft for inland navigation. Int. Shipbuild. Prog. 2019, 66, 35–55. [Google Scholar] [CrossRef]

- Tu, H.; Xia, K.; Zhao, E.; Mu, L.; Sun, J. Optimum trim prediction for container ships based on machine learning. Ocean Eng. 2023, 277, 111322. [Google Scholar] [CrossRef]

- Ghadimi, A.; Ghadimi, P.; Ghassemi, H. Hydrofoil Installation and Performance Optimisation for Ship Resistance Reduction in Trimaran Through Particle Swarm Optimisation Method. Pol. Marit. Res. 2025, 32, 54–63. [Google Scholar] [CrossRef]

- Sulman, M.; Mancini, S.; Bilandi, R.N.; Vitiello, L. Hydrodynamic Performance of High-Speed Craft: A CFD Study on Spray Rails. J. Mar. Sci. Eng. 2025, 13, 438. [Google Scholar] [CrossRef]

- Md Arif, U.G.; Loo, C.-Y.; Kang, H.-S.; Punurai, W.; Quen, L.K.; Lai, G.N.-Y.; Chong, W.-T. Suppression of hydrodynamic sloshing in liquefied natural gas tank with floating baffle: Experimental and numerical studies. In Proceedings of the International Conference on Sustainable Energy and Green Technology, Bangkok, Thailand, 11–14 December 2019. [Google Scholar] [CrossRef]

- Kiebzak, P.W.; Czerniawski, F.K. LNG Market—Passing Trend or Effective Solution During Energy Transition—Global Market Forecast for 2020–2030. In Proceedings of the SPE Europec Featured at EAGE Conference and Exhibition, Virtual, 1–3 December 2020. [Google Scholar] [CrossRef]

- Yeo, S.-J.; Kim, J.; Lee, W.-J. Potential economic and environmental advantages of liquid petroleum gas as a marine fuel through analysis of registered ships in South Korea. J. Clean. Prod. 2022, 330, 129955. [Google Scholar] [CrossRef]

- Kim, J.K.; Yeo, S.; Choi, J.-H.; Lee, W.-J. LPG, Gasoline, and Diesel Engines for Small Marine Vessels: A Comparative Analysis of Eco-Friendliness and Economic Feasibility. Energies 2024, 17, 450. [Google Scholar] [CrossRef]

- Rahayu, S.M.N.; Hananto, A.L.; Herawan, S.G.; Asy’ari, M.Z.; Sule, A.; Idris, M.; Hermansyah, D.; Balogun, S.A.; Ali, E.A.B. A Review of Automotive Green Technology: Potential of Butanol as Biofuel in Gasoline Engine. Mech. Eng. Soc. Ind. 2022, 2, 82–97. [Google Scholar] [CrossRef]

- Farrukh, S.; Li, M.; Kouris, G.D.; Wu, D.; Dearn, K.; Yerasimou, Z.; Diamantis, P.; Andrianos, K. Pathways to Decarbonization of Deep-Sea Shipping: An Aframax Case Study. Energies 2023, 16, 7640. [Google Scholar] [CrossRef]

- Mallouppas, G.; Yfantis, E.A.; Ioannou, C.; Paradeisiotis, A.; Ktoris, A. Application of Biogas and Biomethane as Maritime Fuels: A Review of Research, Technology Development, Innovation Proposals, and Market Potentials. Energies 2023, 16, 2066. [Google Scholar] [CrossRef]

- Leropoulos, L.; Greenman, J. The future role of MFCs in biomass energy. Front. Energy Res. 2023, 11, 1108389. [Google Scholar] [CrossRef]

- Kistner, L.; Bensmann, A.; Minke, C.; Hanke-Rauschenbach, R. Comprehensive techno-economic assessment of power technologies and synthetic fuels under discussion for ship applications. Renew. Sustain. Energy Rev. 2023, 183, 113459. [Google Scholar] [CrossRef]

- Latapí, M.; Davíðsdóttir, B.; Jóhannsdóttir, L. Drivers and barriers for the large-scale adoption of hydrogen fuel cells by Nordic shipping companies. Int. J. Hydrogen Energy 2023, 48, 6099–6119. [Google Scholar] [CrossRef]

- Malmgren, E.; Brynolf, S.; Fridell, E.; Grahn, M.; Andersson, K. The environmental performance of a fossil-free ship propulsion system with onboard carbon capture—A life cycle assessment of the HyMethShip concept. Sustain. Energy Fuels 2021, 5, 2753–2770. [Google Scholar] [CrossRef]

- Giannini, L.; Jafarzadeh, S.; Campari, A.; Ustolin, F.; Paltrinieri, N. Inspection planning in the marine sector, a case study of a hydrogen-fueled fishing vessel. In Proceedings of the ASME 2023 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023; Volume 3, p. 86854. [Google Scholar] [CrossRef]

- Kondratenko, A.; Kujala, P.; Hirdaris, S. Holistic and sustainable design optimization of Arctic ships. Ocean Eng. 2023, 275, 114095. [Google Scholar] [CrossRef]

- Xiaoliang, D. Ship Energy Saving And Emission Reduction. E3S Web Conf. 2020, 165, 01017. [Google Scholar] [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A review of emissions reduction technologies for low and medium speed marine Diesel engines and their potential for waste heat recovery. Energy Convers. Manag. 2020, 207, 112553. [Google Scholar] [CrossRef]

- Kim, S.-A. A Study on the Predictive Maintenance Algorithms Considering Load Characteristics of PMSMs to Drive EGR Blowers for Smart Ships. Energies 2021, 14, 5744. [Google Scholar] [CrossRef]

- Negri, V.; Charalambous, M.; Medrano-García, J.; Guillén-Gosálbez, G. Navigating within the safe operating space with carbon capture on-board. ACS Sustain. Chem. Eng. 2022, 10, 17134–17142. [Google Scholar] [CrossRef]

- Zhang, M.; Zeng, X.; Tan, Z. Joint decision of green technology adoption and sailing pattern for a coastal ship under ECAs. Transp. Policy 2024, 146, 102–113. [Google Scholar] [CrossRef]

- Gritsenko, A.; Glemba, K.; Petelin, A. A study of the environmental qualities of diesel engines and their efficiency when a portion of their cylinders are deactivated in small-load modes. J. King Saud Univ. Eng. Sci. 2021, 33, 70–79. [Google Scholar] [CrossRef]

- Tang, W.; Roman, D.; Dickie, R.; Robu, V.; Flynn, D. Prognostics and health management for the optimization of marine hybrid energy systems. Energies 2020, 13, 4676. [Google Scholar] [CrossRef]

- Li, H.; Liu, C.; Xu, Z.; Liu, J.; Du, Z.; Li, M.; Dong, J.; Han, Z.; Xu, M.; Pan, X. Performance comparison of thermal power generation–organic Rankine cycle combined cycle system for ships waste heat utilization under different bottom cycle ratios. Environ. Prog. Sustain. Energy 2023, 42, e13993. [Google Scholar] [CrossRef]

- Ouyang, T.A.Z.Z.; Lu, J.; Su, Z.; Li, J.; Huang, H. Waste heat cascade utilisation of solid oxide fuel cell for marine applications. J. Clean. Prod. 2020, 275, 124133. [Google Scholar] [CrossRef]

- Theotokatos, G.; Rentizelas, A.; Guan, C.; Ancic, I. Waste heat recovery steam systems techno-economic and environmental investigation for ocean-going vessels considering actual operating profiles. J. Clean. Prod. 2020, 267, 121837. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S. Comprehensive utilization system of waste heat of hydrogen fuel cell powered ship. IOP Conf. Ser. Earth Environ. Sci. 2020, 474, 052037. [Google Scholar] [CrossRef]

- Zang, T.; Liu, Y.; Xu, B.; Qian, Y.; Li, X. Small and Medium-sized Ship Exhaust Heat Recovery Device Based on Vortex Tube Effect Verification. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 032108. [Google Scholar] [CrossRef]

- Korobko, V.; Serbin, S.; Le, H.C. Exploration of a model thermoacoustic turbogenerator with a bidirectional turbine. Pol. Marit. Res. 2023, 30, 102–109. [Google Scholar] [CrossRef]

- Bosio, B.; Archetti, M.; Audasso, E.; Bove, D. Process analysis of a molten carbonate fuel cell on-board application to reduce vessel CO2 emissions. Chem. Eng. Process. Process Intensif. 2023, 190, 109415. [Google Scholar] [CrossRef]

- Huang, M.; He, W.; Incecik, A.; Cichon, A.; Królczyk, G.; Li, Z. Renewable energy storage and sustainable design of hybrid energy powered ships: A case study. J. Energy Storage 2021, 43, 103266. [Google Scholar] [CrossRef]

- Yan, C.; Liu, X. A Wind Direction Tracking Control Method Based on the Sail’s Angle of Attack and Attitude. IOP Conf. Ser. Earth Environ. Sci. 2020, 474, 022038. [Google Scholar] [CrossRef]

- Chica, M.; Hermann, R.R.; Lin, N. Adopting different wind-assisted ship propulsion technologies as fleet retrofit: An agent-based modeling approach. Technol. Forecast. Soc. Change 2023, 192, 122559. [Google Scholar] [CrossRef]

- Godula Jopek, A.; Westenberger, A. Fuel Cell Types: PEMFC/DMFC/AFC/PAFC/MCFC/SOFC. Encycl. Energy Storage 2022, 2, 250–265. [Google Scholar] [CrossRef]

- Candelo, J.E.; Maldonado, L.B.; Sanabria, E.P.; Pestana, H.V.; García, J.J. Technological alternatives for electric propulsion systems in the waterway sector. Energies 2023, 16, 7700. [Google Scholar] [CrossRef]

- Fernández, A.; Santos, G.; Pinedo, J.; Santos, E.; Ruiz, I.; Laso, J.; Lyne, A.; Ortiz, A.; Ortiz, I.; Irabien, Á.; et al. Environmental sustainability of alternative marine propulsion technologies powered by hydrogen—A life cycle assessment approach. Sci. Total Environ. 2022, 820, 153189. [Google Scholar] [CrossRef]

- Madsen, R.; Klebanoff, L.; Caughlan, S.; Pratt, J.; Leach, T.; Appelgate, T., Jr.; Kelety, S.; Wintervoll, H.-C.; Haugom, G.; Teo, A.; et al. Feasibility of the Zero-V: A zero-emissions hydrogen fuel-cell coastal research vessel. Int. J. Hydrogen Energy 2020, 45, 25328–25343. [Google Scholar] [CrossRef]

- Hayton, M. Marine electrification is the future: A tugboat case study. In Proceedings of PIANC Smart Rivers 2022; Springer Nature: Singapore, 2022; pp. 868–879. [Google Scholar] [CrossRef]

- Gelver, F.A.S.V.A.S.A. Ship electromotive system with common DC buses. E3S Web Conf. 2019, 135, 02009. [Google Scholar] [CrossRef]

- Maaruf, M.; Khalid, M. Hybrid solar/PEM fuel cell/and water electrolyzer energy system for all-electric ship. In Proceedings of the 2022 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 25–26 April 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Shekhar, A.; Rituraj, G.; Van Der Sande, R.; Ahmadi, M.; Deshmukh, R.; Bauer, P.; Nougain, V.; Lekić, A.; Palensky, P. Development of reliable power electronic systems using real time digital twin based power hardware-in-the-loop testbed. In Proceedings of the 2023 IEEE Belgrade PowerTech, Belgrade, Serbia, 25–29 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, L.; Wang, J.; Xu, C. The Application of Solar Photovoltaic Power Generation System in Ships. J. Coast. Res. 2019, 94, 525–529. [Google Scholar] [CrossRef]

- Wang, H.; Oguz, E.; Jeong, B.; Zhou, P. Life cycle and economic assessment of a solar panel array applied to a short route ferry. J. Clean. Prod. 2019, 219, 471–484. [Google Scholar] [CrossRef]

- Wei, L.; Zhou, Z.; Wang, Z. Fire Monitoring System for Power Batteries on Ship. J. Phys. Conf. Ser. 2021, 1802, 022022. [Google Scholar] [CrossRef]

- Perčić, M.; Frković, L.; Pukšec, T.; Ćosić, B.L.O.; Vladimir, N. Life-cycle assessment and life-cycle cost assessment of power batteries for all-electric vessels for short-sea navigation. Energies 2022, 251, 123895. [Google Scholar] [CrossRef]

- Qian, Y.; Chen, Q.; Wang, Y.; Hu, P.; Ding, K. A New Pattern of Automatic Docking Scheme between Shore Power and Ship. In Proceedings of the 2020 4th International Conference on Power and Energy Engineering (ICPEE), Xiamen, China, 19–21 November 2020; pp. 79–83. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Chen, J.; Jin, Z.; Dykas, S. Numerical study of heterogeneous condensation in the de Laval nozzle to guide the compressor performance optimization in a compressed air energy storage system. Appl. Energy 2024, 356, 122361. [Google Scholar] [CrossRef]

- Piccoli, T.A.F.M.; Bosich, D.; Bevilacqua, P.; Sulligoi, G. Environmental Assessment and Regulatory Aspects of Cold Ironing Planning for a Maritime Route in the Adriatic Sea. Energies 2021, 14, 5836. [Google Scholar] [CrossRef]

- Fang, S.; Wang, Y.; Gou, B.; Xu, Y. Toward Future Green Maritime Transportation: An Overview of Seaport Microgrids and All-Electric Ships. IEEE Trans. Veh. Technol. 2019, 69, 207–219. [Google Scholar] [CrossRef]

- Kim, S.; Kucka, J.; Ulissi, G.; Kim, S.-N.; Dujic, D. Solid-state technologies for flexible and efficient marine DC microgrids. IEEE Trans. Smart Grid 2021, 12, 2860–2868. [Google Scholar] [CrossRef]

- Iqbal, R.; Liu, Y.; Zeng, Y.; Zhang, Q.; Zeeshan, M. Comparative study based on techno-economics analysis of different shipboard microgrid systems comprising PV/wind/fuel cell/battery/diesel generator with two battery technologies: A step toward green maritime transportation. Renew. Energy 2024, 221, 119670. [Google Scholar] [CrossRef]

- Ghita, S.; Hnatiuc, B.; Hnatiuc, M.; Sabau, A. Biological contamination of naval steel surface after non-thermal plasma treatment. Adv. Top. Optoelectron. Microelectron. Nanotechnol. X 2020, 11718, 760–767. [Google Scholar] [CrossRef]

- Malinowski, R.; Krasowska, K.; Sikorska, W.; Moraczewski, K.; Kaczor, D.; Kosmalska, D.; Krolikowski, B. Studies on Manufacturing, Mechanical Properties and Structure of Poly(butylene adipate-co-terephthalate)-based Green Composites Modified by Coconut Fibers. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 1095–1105. [Google Scholar] [CrossRef]

- Felicia, W.Y.M.; Thu, S.P.P. A Numerical Study to Compare the Antifouling Potential of Two Bio-inspired Antifouling Topographies Derived from the Pilot Whale Skin and the Zebra Mussels. J. Phys. Conf. Ser. 2023, 2523, 012044. [Google Scholar] [CrossRef]

- Zhou, L.H.; Liu, D.Y. Design and Implementation of Mobile Integrated Off-grid Energy Storage Power Supply for Ship. IOP Conf. Ser. Earth Environ. Sci. 2020, 615, 012075. [Google Scholar] [CrossRef]

- Iwuozor, K.O.; Micheal, T.T.; Micheal, K.T.; Emmanuel, S.S.; Emenike, E.C.; Adeniyi, A.G. Plant biomass-based composites in the maritime industry: A review. Mar. Struct. 2024, 96, 103609. [Google Scholar] [CrossRef]

- Minillo, L.Q.; de Castro Cardoso, B.C.; Ortenzi, A. Design of nautical cleat for small–medium boats using hybrid curaua–glass fiber–reinforced epoxy. Mater. Today Proc. 2021, 34, 341–349. [Google Scholar] [CrossRef]

- Han, M.; Zhang, J.; Chu, W.; Chen, J.; Zhou, G. Research Progress and Prospects of Marine Oily Wastewater Treatment: A Review. Water 2019, 11, 2517. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, W.; Guo, Y.; Li, J.; Wei, F. Environmental impact, treatment technology and monitoring system of ship domestic sewage: A review. Sci. Total Environ. 2022, 811, 151410. [Google Scholar] [CrossRef] [PubMed]

- Cecconet, D.; Bolognesi, S.; Piacentini, L.; Callegari, A.; Capodaglio, A.G. Bioelectrochemical greywater treatment for non-potable reuse and energy recovery. Water 2021, 13, 295. [Google Scholar] [CrossRef]

- Kalnina, R.; Demjanenko, I.; Smilgainis, K.; Lukins, K.; Bankovics, A.; Drunka, R. Microplastics in ship sewage and solutions to limit their spread: A case study. Water 2022, 14, 3701. [Google Scholar] [CrossRef]

- Dewan, M.H.; Godina, R. Seafarers Involvement in Implementing Energy Efficiency Operational Measures in Maritime Industry. Procedia Comput. Sci. 2023, 217, 1699–1709. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, L.; Jia, S.; Pang, H. Shipping Density Assessment Based on Trajectory Big Data. IOP Conf. Ser. Earth Environ. Sci. 2019, 310, 022032. [Google Scholar] [CrossRef]

- Yang, S. Research on Design, Detection and Realization of Monitoring System Based on Ship Power Grid Parameter. J. Phys. Conf. Ser. 2021, 2023, 012048. [Google Scholar] [CrossRef]

- Hu, W.; Ren, H.; Wang, M. Ship Cargo Compartment Environment Measurement and Control System Based on SSM Framework. IOP Conf. Ser. Earth Environ. Sci. 2019, 252, 042075. [Google Scholar] [CrossRef]

- Chen, C.; Sun, Y.; Tan, J. Research on Marine Disaster Prevention and Mitigation Information Platform System Based on Big Data. IOP Conf. Ser. Earth Environ. Sci. 2021, 632, 022082. [Google Scholar] [CrossRef]

- Miller, A.; Rybczak, M.; Rak, A. Towards the Autonomy: Control Systems for the Ship in Confined and Open Waters. Sensors 2021, 21, 2286. [Google Scholar] [CrossRef] [PubMed]

- Pham, N.H. Proposed Research on Saline-Water Distillation for Living by Utilizing Waste Heat from Industrial Steam Boilers. In Proceedings of the 2020 5th International Conference on Green Technology and Sustainable Development (GTSD), Ho Chi Minh City, Vietnam, 27–28 November 2020; pp. 505–510. [Google Scholar] [CrossRef]

- Fajardo, J.; Morelos, A.; Cruz, R.; Matsumoto, A.; Ueno, Y.T.N.; Kitamura, K.; Miyakawa, H.; Tejima, S.; Takeuchi, K. Antifouling performance of spiral wound type module made of carbon nanotubes/polyamide composite RO membrane for seawater desalination. Desalination 2022, 523, 115445. [Google Scholar] [CrossRef]

- Henriques, J.; Gato, L.; La Sala, V.; Carrelhas, A. Acoustic noise emission of air turbines for wave energy conversion: Assessment and analysis. Renew. Energy 2023, 212, 897–907. [Google Scholar] [CrossRef]

- ISO 3746:2010; Acoustics—Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure—Survey Method Using an Enveloping Measurement Surface over a Reflecting Plane. International Organization for Standardization: Geneva, Switzerland, 2010.

- Hua, W.; Sha, Y.; Zhang, X.; Cao, H. Research progress of carbon capture and storage (CCS) technology based on the shipping industry. Ocean Eng. 2023, 281, 114929. [Google Scholar] [CrossRef]

- Hayat, M.A.; Alhadhrami, K.; Elshurafa, A.M. Which bioenergy with carbon capture and storage (BECCS) pathways can provide net-negative emissions? Int. J. Greenh. Gas Control. 2024, 135, 104164. [Google Scholar] [CrossRef]

| Criterion | Description |

|---|---|

| Time Range | Documents published between 2019 and 2024 to ensure updated information aligned with recent trends and advancements. |

| Academic Nature and Accessibility | Academic documents were selected, including peer-reviewed scientific articles and literature reviews, recognized scientific proceedings, and official documents issued by regulatory organizations such as the IMO and other entities in the sector. |

| Thematic Relevance | Documents directly related to the research topic, specifically green technologies applied to vessels. |

| Language | Documents are available in Spanish or English. |

| Quality and Reputation of Sources | Consideration is given to the impact factor and reputation of sources, prioritizing internationally recognized journals and publishers in the field. |

| Group | Keywords |

|---|---|

| Group 1 | eco-innovation, ecoinnovation, green innovation, environmental innovations, green innovations, ecological innovations, ecological innovation |

| Group 2 | ecodesign, eco-design, green design, sustainable design, ecoproduct, ecoproducts, environmental technology, green technology, green technology innovation, eco-friendly product, sustainable products, sustainable technology, eco-product, eco-products |

| Group 3 | naval industry, shipbuilding, shipbuilding industry, shipyard, shipyards, ships, ship, boats, boat, vessels, vessel, naval vessels, fluvial, maritime, watercraft, small craft, yacht, sailing, pushboat, barge, ferry, riverboat |

| Data Source | URL | |

|---|---|---|

| Scopus | www.scopus.com | 27 March 2024 |

| Web of science | www.clarivate.com | 27 March 2024 |

| Digital Library | Group | Algorithm Search |

|---|---|---|

| Scopus | 1 o 2 y 3 | (TITLE-ABS-KEY (“eco-innovation” OR “ecoinnovation” OR “Green Innovation” OR “Environmental Innovations” OR “Green Innovations” OR “Ecological Innovations” OR “Ecological Innovation”) OR TITLE-ABS-KEY (“Ecodesign” OR “Eco-design” OR “Green Design” OR “ecoproduct” OR “ecoproducts” OR “Environmental Technology” OR “Green Technology” OR “Green Technology Innovation” OR “eco-friendly product” OR “Sustainable Products” OR “Sustainable Technology”) AND TITLE-ABS-KEY (“naval industry” OR “Shipbuilding” OR “Shipbuilding Industry” OR “shipyard” OR “Ships” OR “Ship” OR “Boats” OR “boat” OR “Vessels” OR “Vessel” OR “Naval Vessels” OR “fluvial” OR “Maritime” OR “Watercraft” OR “Small craft” OR “yatch” OR “sailing” OR “Pushboat” OR “barge” OR “ferry” OR “riverboat”)) AND PUBYEAR > 2018 AND PUBYEAR < 2025 |

| Web of science | 1 o 2 y 3 | “eco-innovation”OR”ecoinnovation”OR”Green Innovation”OR”Environmental Innovations”OR”Green Innovations”OR”Ecological Innovations”OR “Ecological Innovation” OR “Ecodesign”OR”Eco-design”OR”Green Design”OR”ecoproduct”OR”ecoproducts”OR”Environmental Technology”OR”Green Technology” OR ”Green Technology Innovation”OR”eco-friendly product”OR”Sustainable Products”OR”Sustainable Technology” (All Fields) and “naval industry” OR”Shipbuilding”OR”Shipbuilding Industry”OR”shipyard”OR”Ships”OR”Ship”OR”Boats”OR”boat”OR”Vessels”OR”Vessel”OR”Naval Vessels” OR “fluvial” OR “Maritime” OR “Watercraft” OR “Small craft” OR “yatch” OR “sailing” OR “Pushboat” OR “barge” OR “ferry” OR “riverboat” (All Fields) and 2019 or 2020 or 2021 or 2022 or 2023 or 2024 (Publication Years) |

| Category | Applicable Technologies | Regulation/Standard | References |

|---|---|---|---|

| Emission Reduction | Lubricating Hull Coatings | EEXI, EEDI | [57,58,59] |

| Propeller and Hull Shape Optimization | EEXI, EEDI | [20,60,61,62,63] | |

| Clean Energy Technologies | Liquefied Natural Gas (LNG) | EEXI, EEDI, EEOI | [20,57,59,64,65] |

| Liquefied Petroleum Gas (LPG) | EEXI, EEDI, EEOI | [20,66,67] | |

| Biofuels | EEXI, EEDI, EEOI | [50,57,59,68,69,70,71] | |

| Hydrogen | EEXI, EEDI, EEOI | [50,57,72,73,74,75] | |

| Nuclear Energy | EEXI, EEDI, EEOI | [50,59,72,76] | |

| Propulsion System Optimization | Water Injection | EEXI, EEDI | [77,78] |

| Conversion Systems | EEXI, EEDI | [16,69,78,79,80,81] | |

| Propulsion System Optimization | EEXI, EEDI | [50,77,82,83] | |

| Heat Recovery Systems | EEXI, EEDI | [84,85,86,87,88,89,90] | |

| Assisted Propulsion | Wind-Assisted Propulsion | EEXI, EED | [50,69,91,92,93] |

| Electric and Storage Systems | Electric Propulsion Systems with Fuel Cells | EEXI, EEDI, EEOI | [59,72,87,90,91,94,95,96,97] |

| Hybrid Electric Propulsion Systems | EEXI, EEDI, EEOI | [5,98,99] | |

| Renewable Electric Propulsion | EEXI, EEDI, EEOI | [100] | |

| Electric Propulsion (IC Engine + Batteries) | EEXI, EEDI, EEOI | [95,101] | |

| Solar Power and Energy Storage | Solar Panels | EEXI, EEDI | [91,102,103] |

| Lithium-Ion Batteries | EEXI, EEDI | [95,98,104,105] | |

| Energy Storage and Supply Systems | EEXI, EEDI | [18,20,87,98,106,107,108,109,110,111] | |

| Pollution Control and Environmental Protection | Anti-fouling Surfaces | International Convention on the Control of Harmful Anti-fouling Systems on Ships | [112,113,114] |

| Hull Materials | International Convention on the Control of Harmful Anti-fouling Systems on Ships | [113,115,116,117] | |

| Water Management | Ballast Water Systems | International Convention for the Control and Management of Ships’ Ballast Water and Sediments | [118] |

| Water Management and Pollution | Oily Water Separation Method | MARPOL Annex I | [119,120,121] |

| Greywater Separation Methods | MARPOL Annex IV | [42,77,112] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paipa-Sanabria, E.; González-Montoya, D.; Coronado-Hernández, J.R. Green Technologies for Environmental Air and Water Impact Reduction in Ships: A Systematic Literature Review. J. Mar. Sci. Eng. 2025, 13, 839. https://doi.org/10.3390/jmse13050839

Paipa-Sanabria E, González-Montoya D, Coronado-Hernández JR. Green Technologies for Environmental Air and Water Impact Reduction in Ships: A Systematic Literature Review. Journal of Marine Science and Engineering. 2025; 13(5):839. https://doi.org/10.3390/jmse13050839

Chicago/Turabian StylePaipa-Sanabria, Edwin, Daniel González-Montoya, and Jairo R. Coronado-Hernández. 2025. "Green Technologies for Environmental Air and Water Impact Reduction in Ships: A Systematic Literature Review" Journal of Marine Science and Engineering 13, no. 5: 839. https://doi.org/10.3390/jmse13050839

APA StylePaipa-Sanabria, E., González-Montoya, D., & Coronado-Hernández, J. R. (2025). Green Technologies for Environmental Air and Water Impact Reduction in Ships: A Systematic Literature Review. Journal of Marine Science and Engineering, 13(5), 839. https://doi.org/10.3390/jmse13050839