A Study on the Air Cavity under a Stepped Planing Hull

Abstract

1. Introduction

2. Numerical Setup

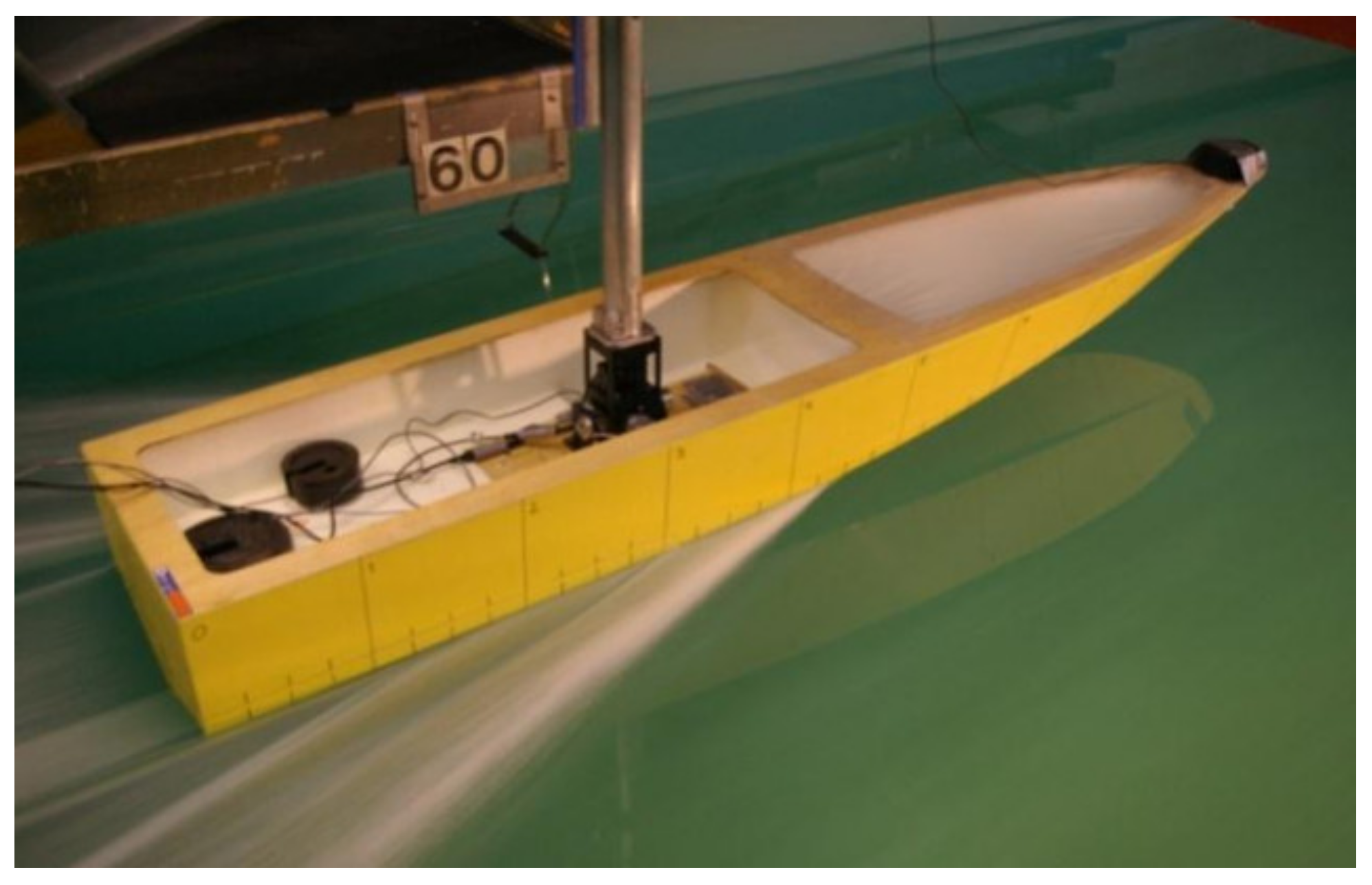

2.1. Test Facilities

- Length: 198 m

- Breadth: 4.57 m

- Depth: 1.68 m

- Maximum Carriage Speed: 15 m/s

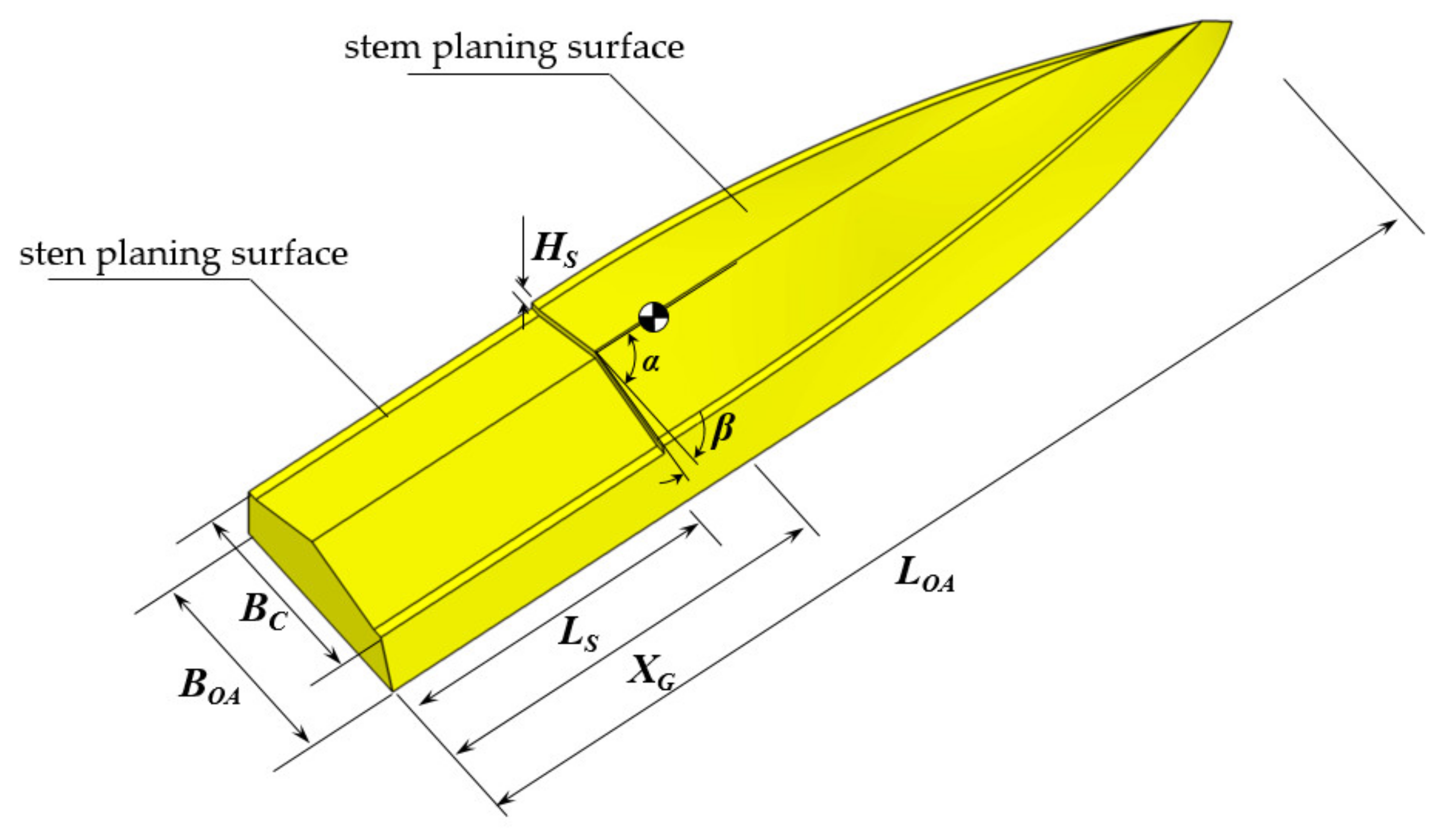

2.2. Description of Hull Geometry

2.3. Numerical Method

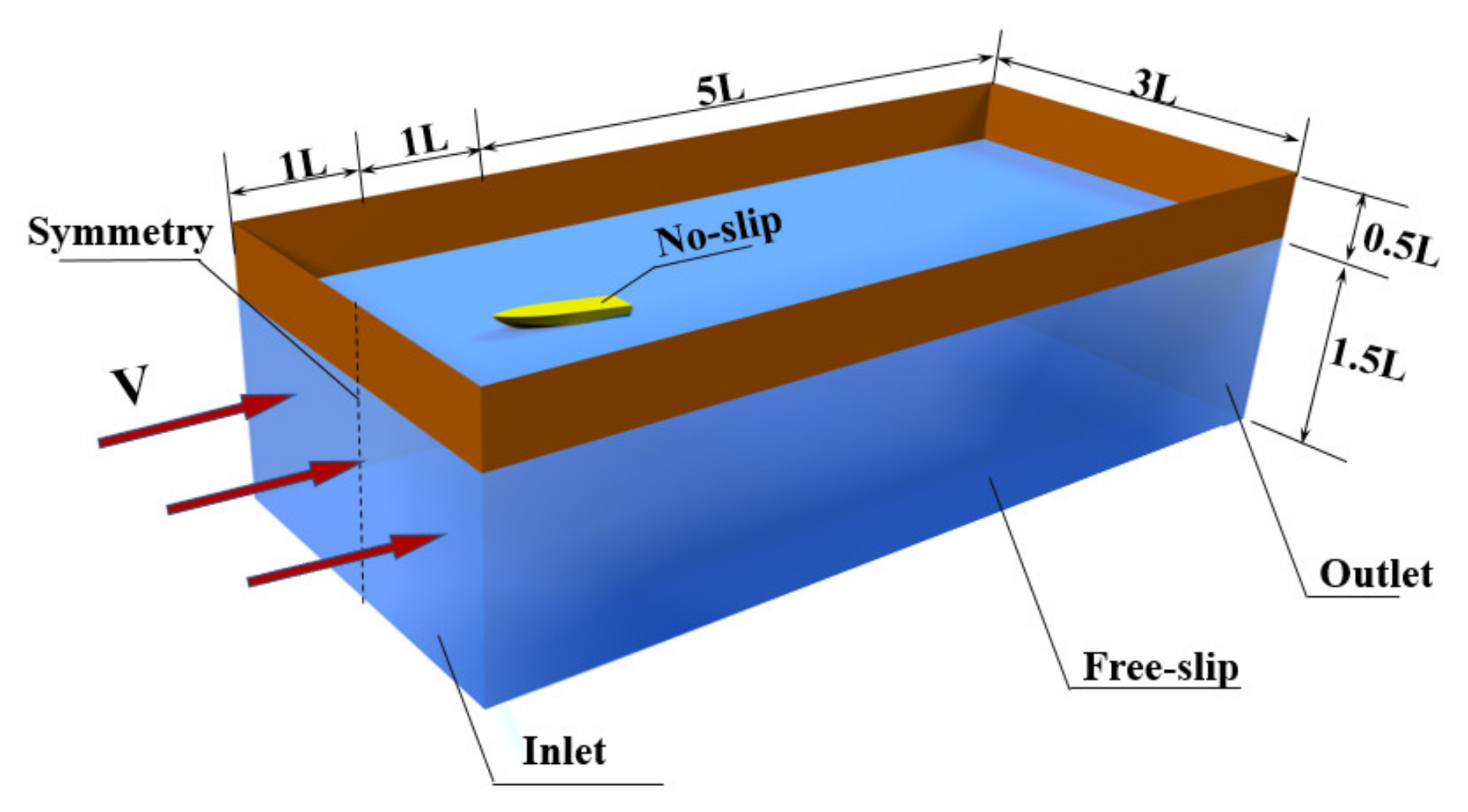

2.4. Domain and Boudary Conditions of the Numerical Tank

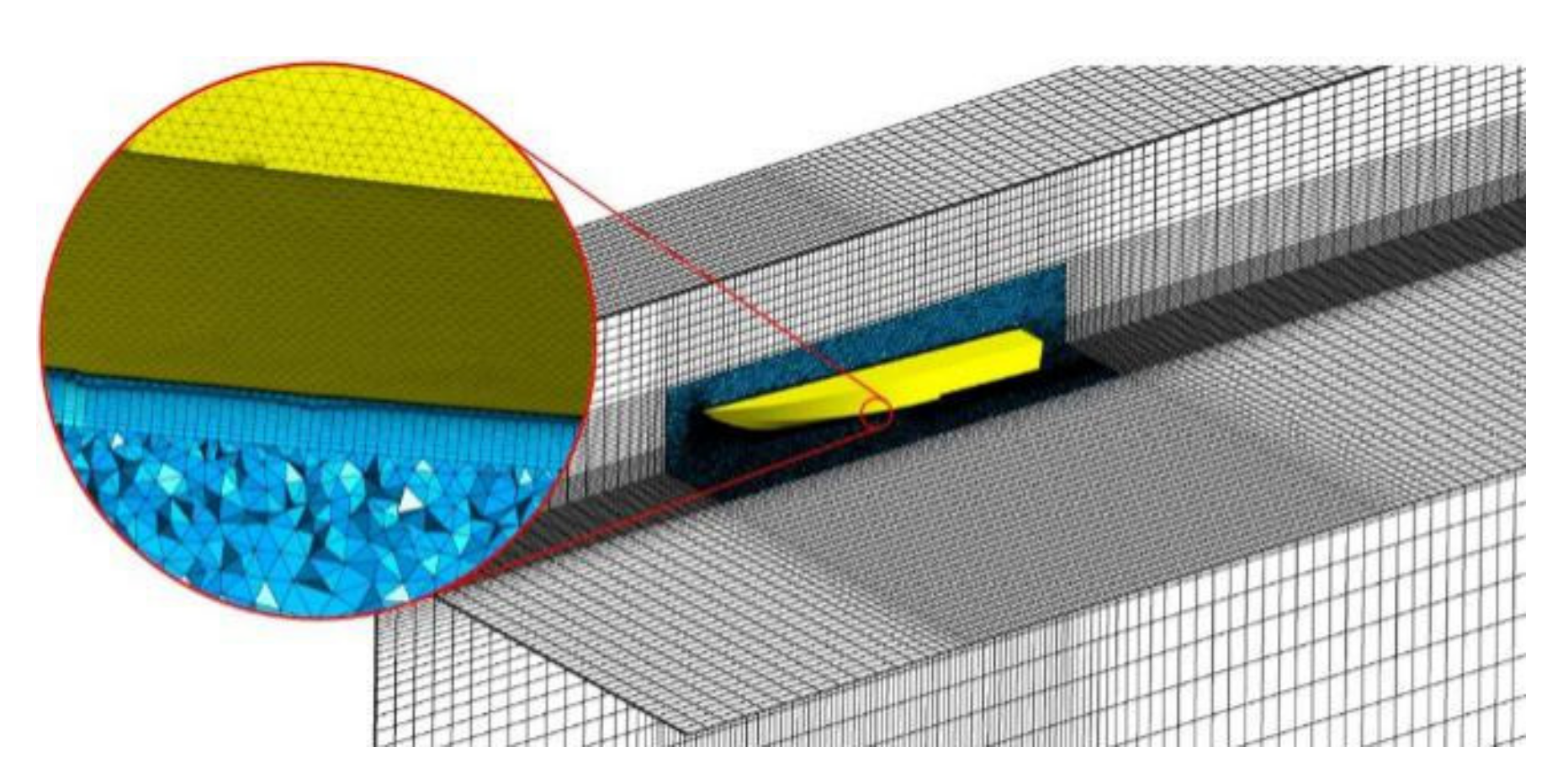

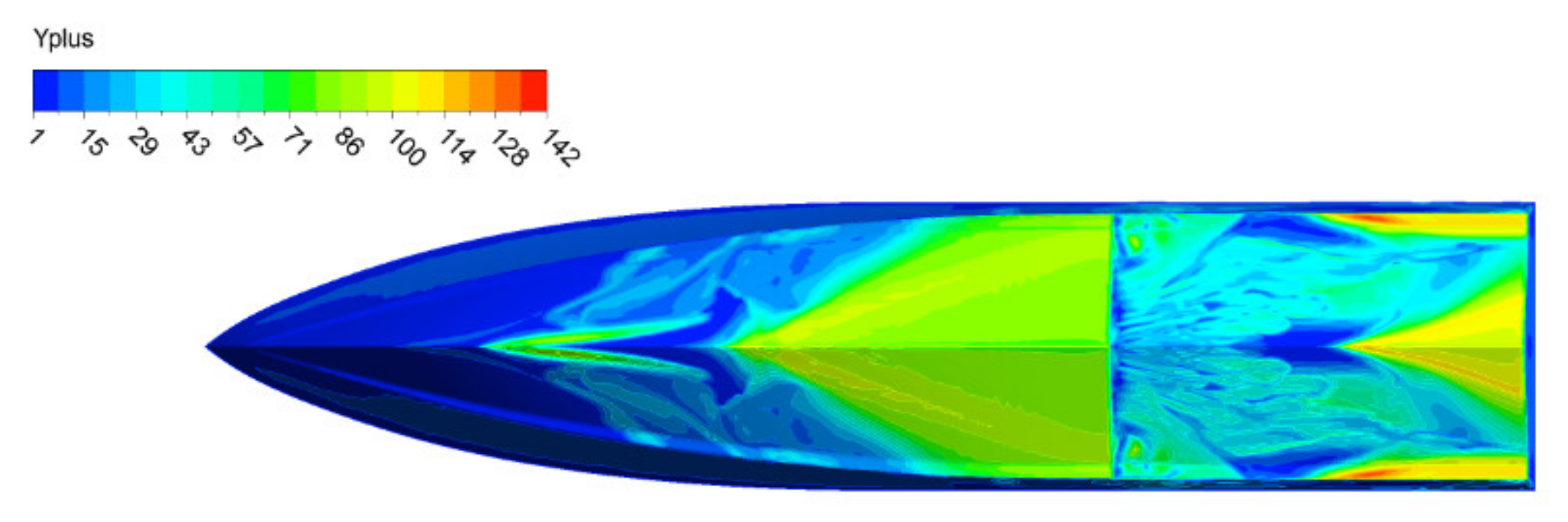

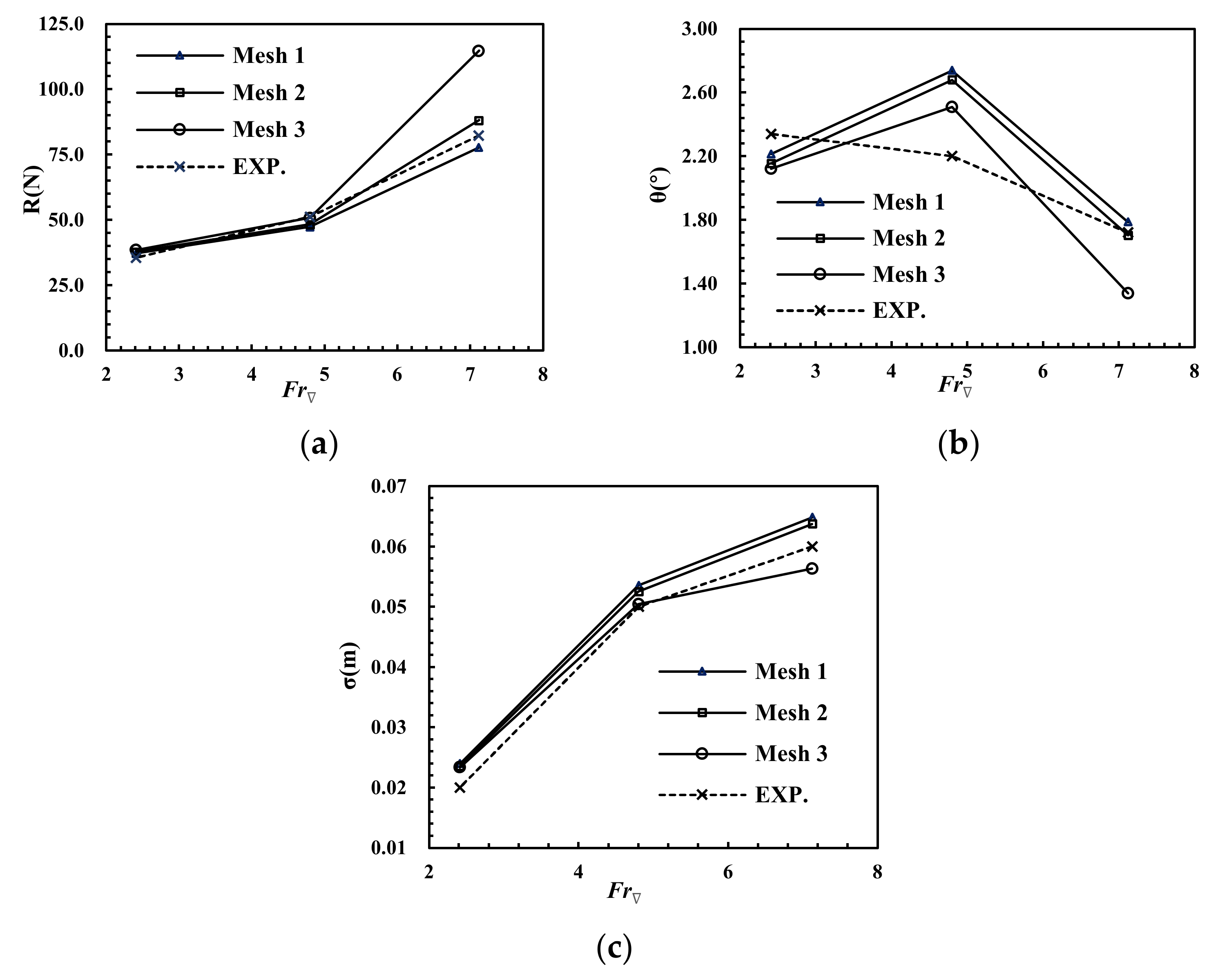

2.5. Mesh Generation

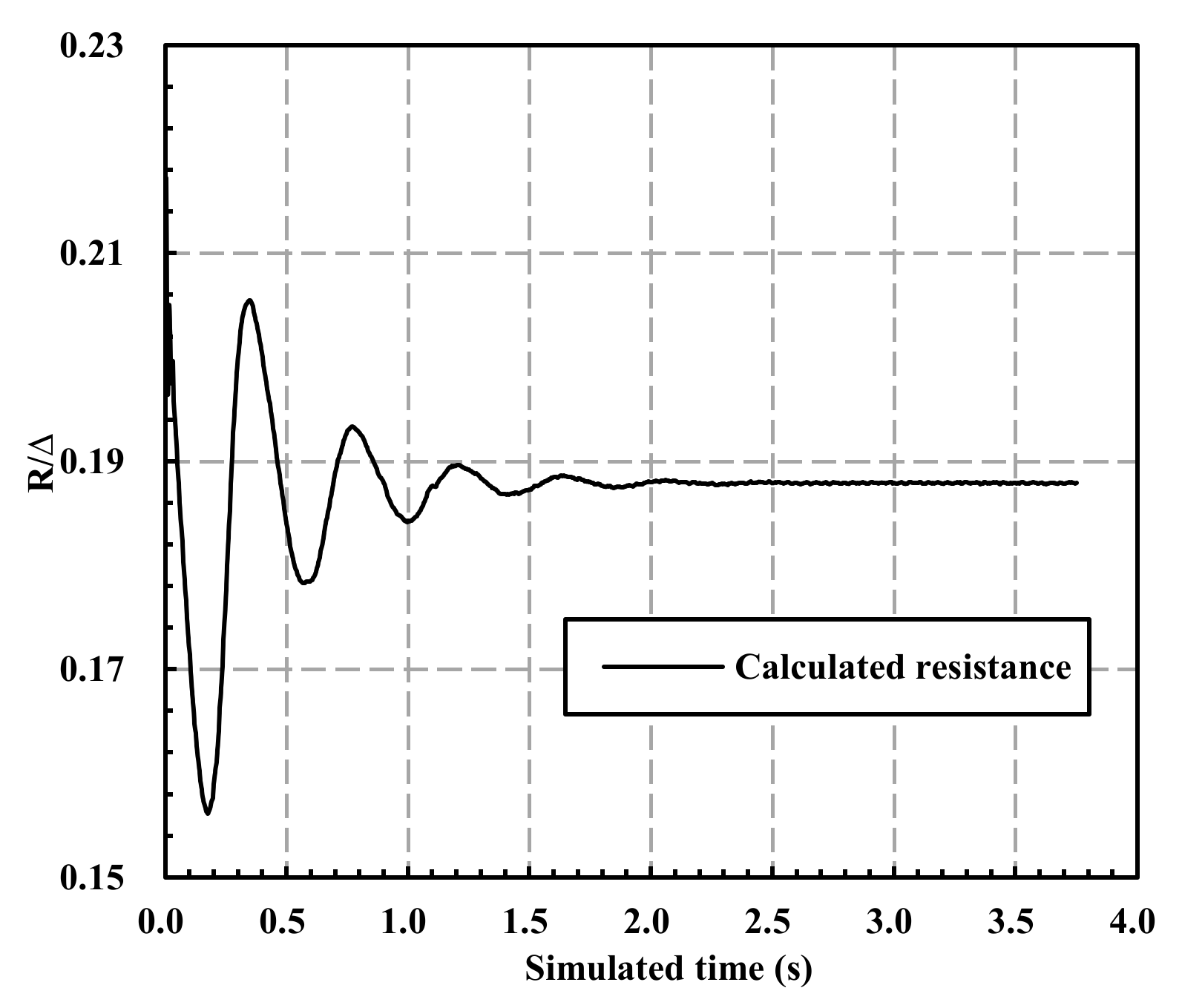

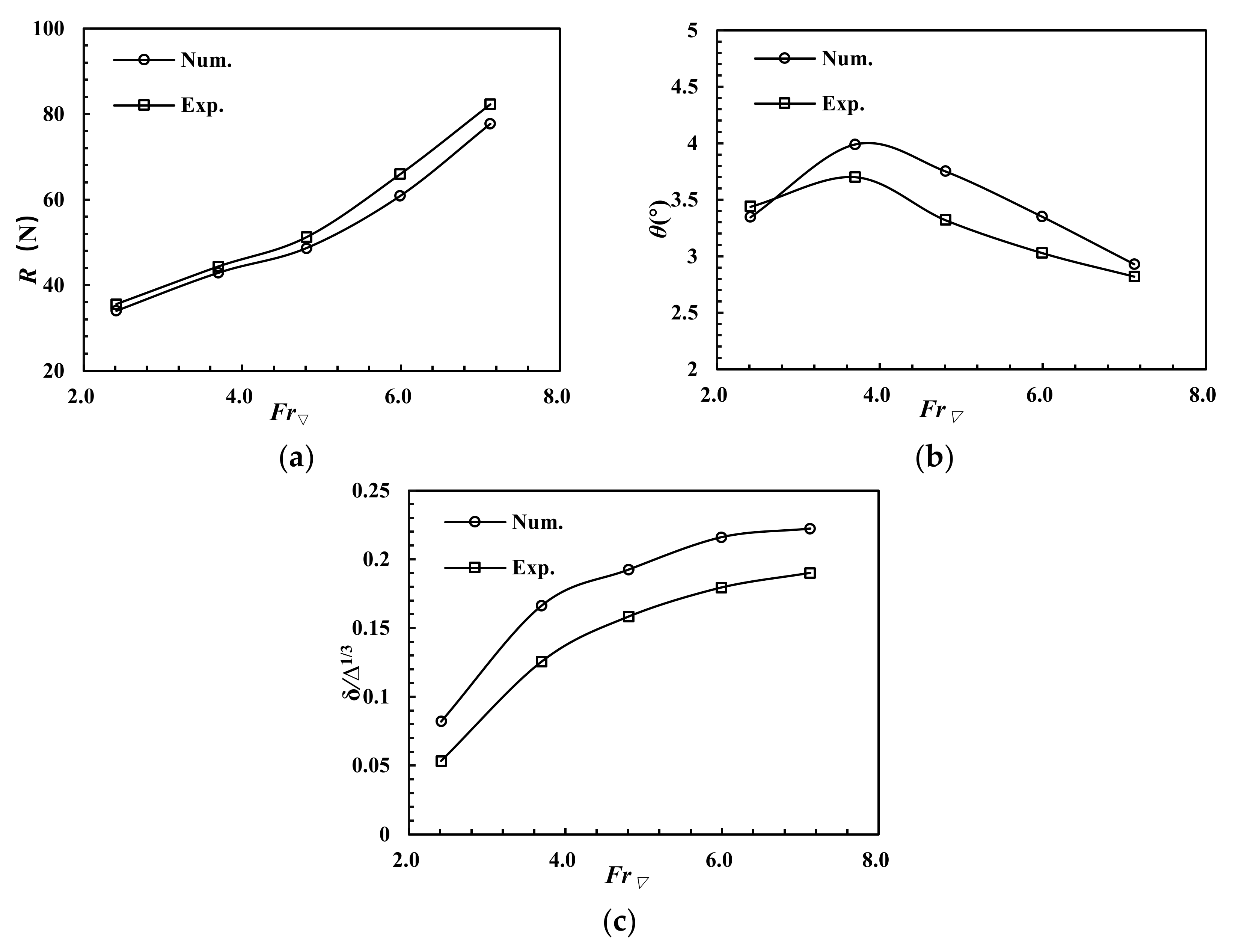

3. Numerical Results

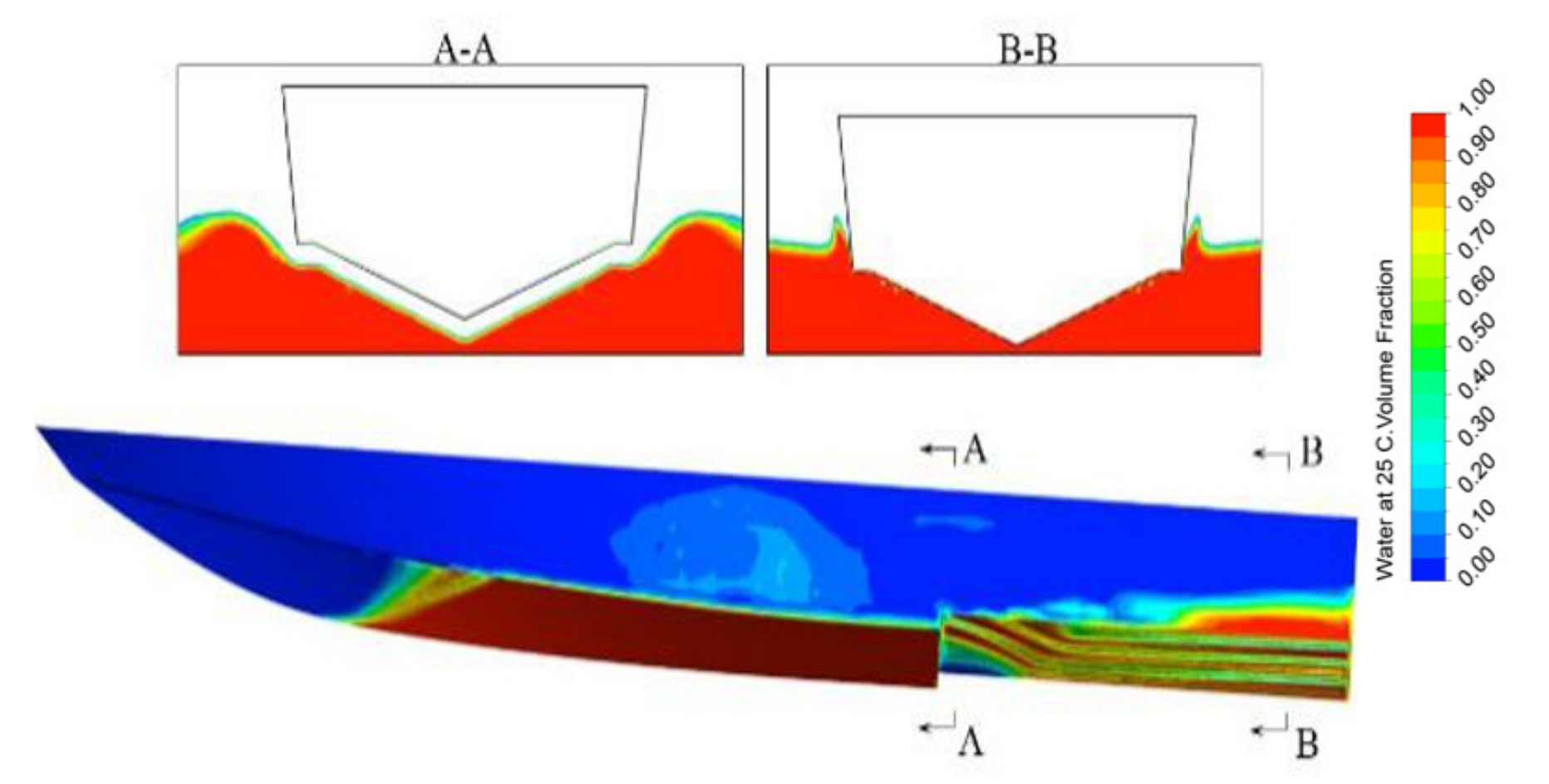

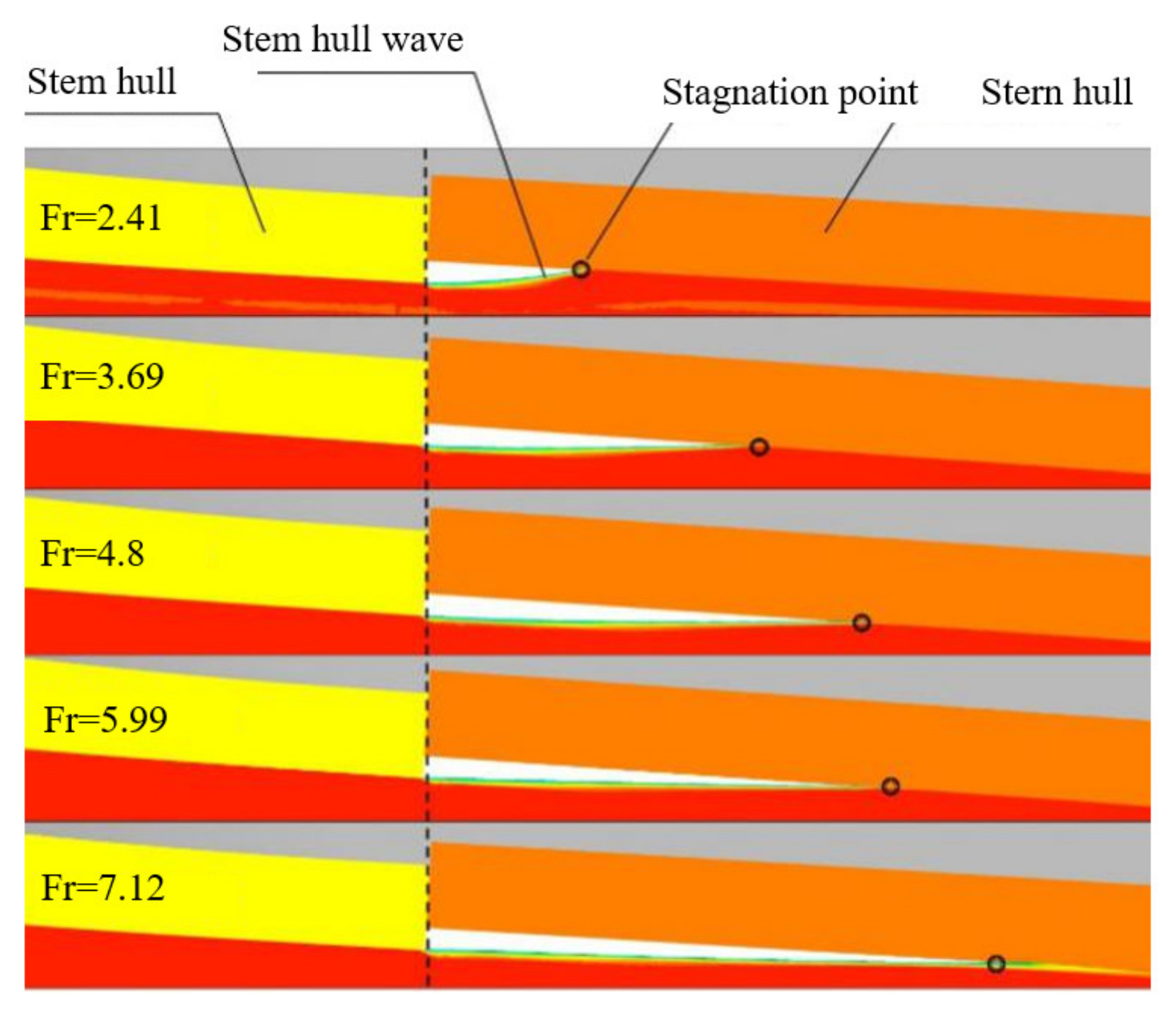

3.1. Cavity and Wave-Making

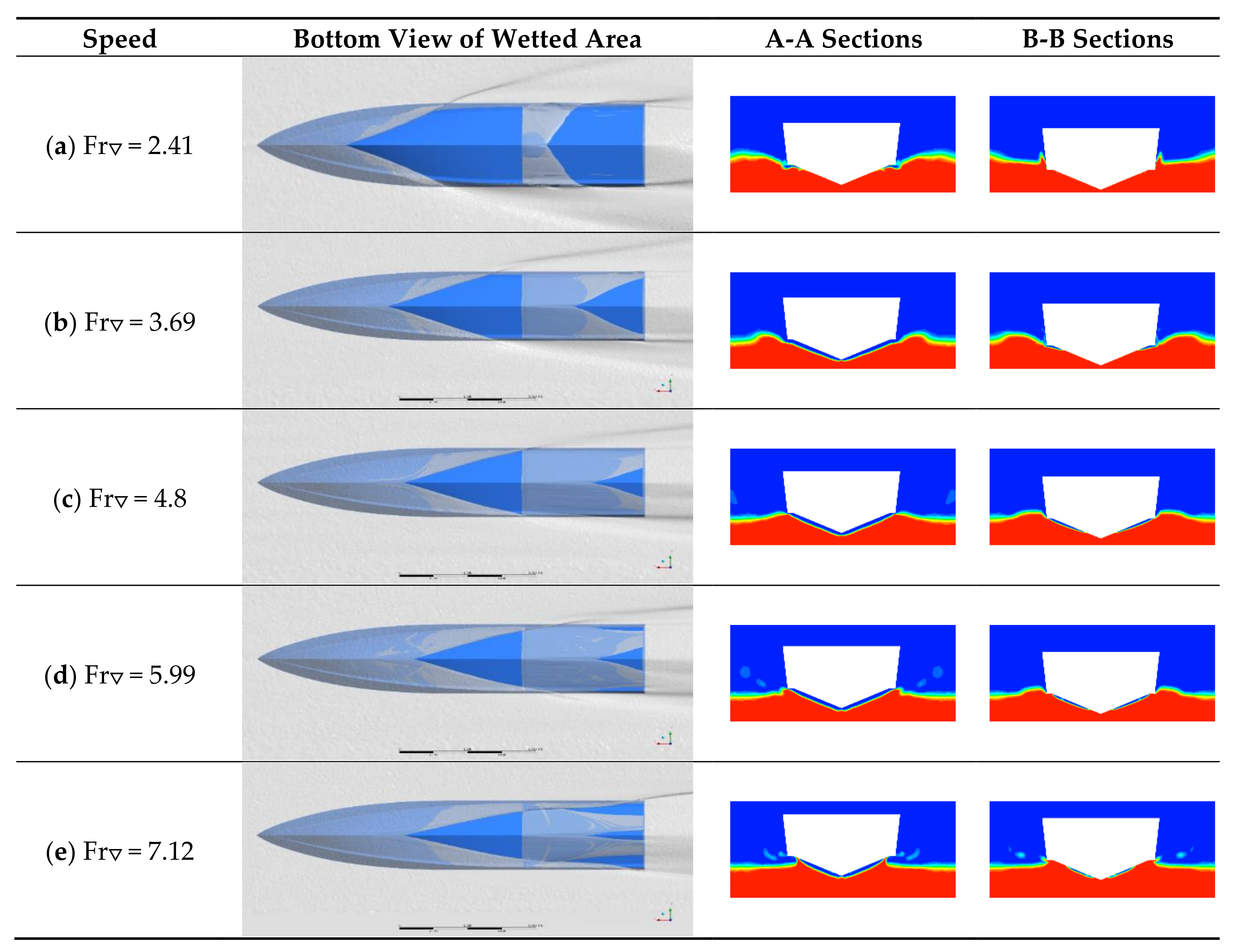

3.2. Evolution of Air Cavity Pattern and Wetted Area

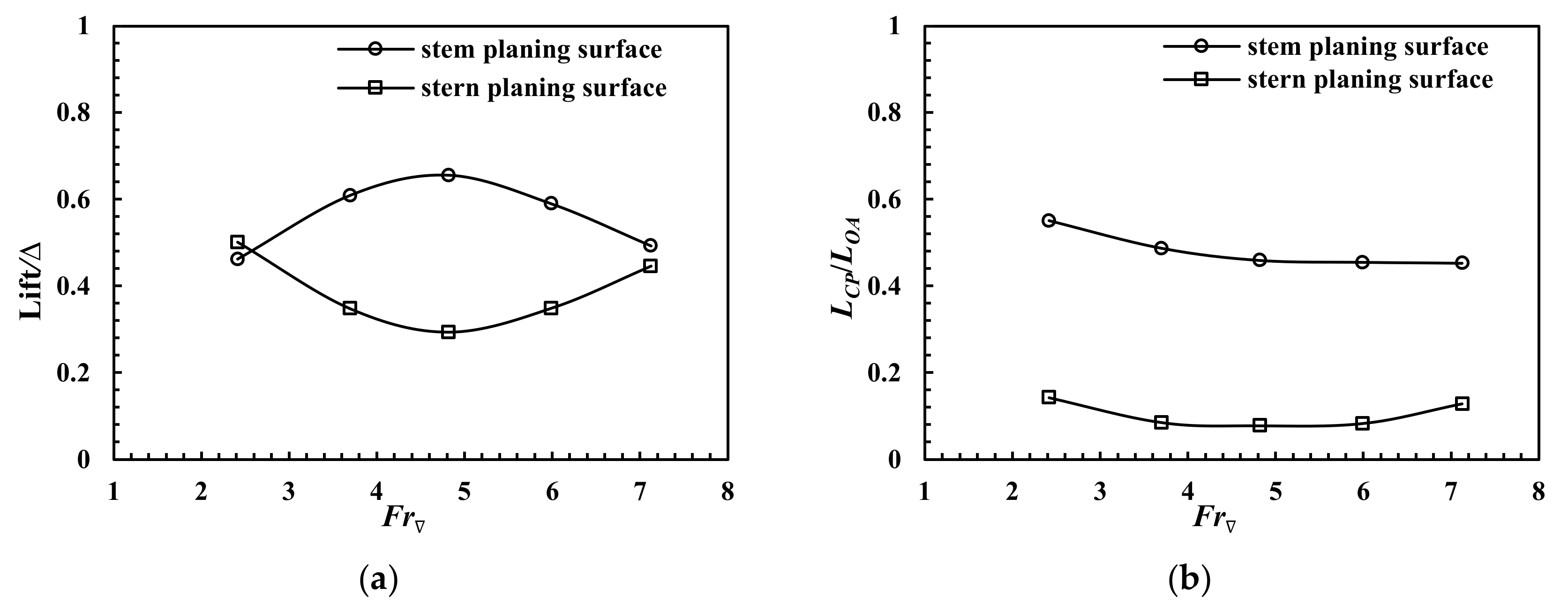

3.3. Pressure Characteristics and Load of Bottom under Cavity Cover

4. Conclusions

- (1)

- As a result of wave-making evolution, the occurrence of air cavity requires both step ends connecting with the atmosphere. The flattening wake suggests that the cavity gradually enlarges with the increase of speed. This enlargement trend increases the cavity cover and reduces the wetted area, which reduces the sailing resistance.

- (2)

- When entering the triangle planing stage, the extra chine wetted reduces the cover of the cavity but leads to a slight increase in overall wetted area. The increasing bottom load causes the pressure move towards to the gravity center and thus reduce the longitudinal stability of the hull.

- (3)

- Due to the hydrodynamic characteristics of the stepped planing hull in triangle planing stage tend to increase the hull wetted area and decrease the longitudinal stability, it is suggested that the design speed should be limited to the speed at which the stepped planing hull enters triangle planing stage. For this stepped planing hull, the limited Froude number is Fr▽ = 5.99.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, E.; Pavkov, M.; McCue-Weil, L. The Systematic Variation of Step Configuration and Displacement for a Double-step Planing Craft. J. Ship Prod. Des. 2014, 30, 89–97. [Google Scholar] [CrossRef]

- Garland, W.R. Stepped planing hull investigation. Trans. Soc. Nav. Archit. Mar. Eng. 2011, 119, 448–458. [Google Scholar]

- Savitsky, D.; Morabito, M. Surface Wave Contours Associated With the Forebody Wake of Stepped Planing Hulls. Mar. Technol. 2009, 47, 1–16. [Google Scholar]

- Taunton, D.J.; Hudson, D.A.; Shenoi, R.A. Characteristics of a series of high speed hard chine planing hulls—Part 1: Performance in calm water. Int. J. Small Craft Technol. 2010, 152, 55–75. [Google Scholar]

- Huo, C.; Yang, J.; Dong, W.C. Factors of influencing resistance performance of double-stepped planing craft in calm water. J. Nav. Univ. Eng. 2012, 5, 21–24. [Google Scholar]

- Li, R.C.; Liu, Y.H.; Chai, J.C. Influence of LCG and displacement on resistance performance of double-stepped deep-V planing Craft. China Water Transp. 2016, 16, 1–3. [Google Scholar]

- Xiaohong, S.; Qirui, W.; Di, X. A resistance regression formula for double-stepped planning craft. Chin. J. Ship Res. 2010, 5, 59–63. [Google Scholar]

- Jiang, Y.; Sun, H.B.; Zou, J.; Yang, D.M.; Hu, A.K. Influence of Angle-Variable Stern Flap on Resistance Performance of Stepped Planing Hull. J. Shanghai Jiaotong Univ. 2017, 51, 320–325. [Google Scholar]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F. A critical CAE analysis of the bottom shape of a multi stepped air cavity planing hull. Appl. Ocean Res. 2019, 82, 130–142. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F.; Strasser, C. Numerical and experimental investigation of a planing Air Cavity Ship and its air layer evolution. Ocean Eng. 2018, 152, 130–143. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F. An experimental comparison between different artificial air cavity designs for a planing hull. Ocean Eng. 2017, 140, 233–243. [Google Scholar] [CrossRef]

- Makasyeyev, M.V. Numerical modeling of cavity flow on bottom of a stepped planing hull. In Proceedings of the 7th International Symposium on Cavitation (CAV 2009), Ann Arbour, MI, USA, 16–20 August 2009. [Google Scholar]

- Guo, Z.; Ma, Q.; Hu, X. Seakeeping Analysis of a Wave-Piercing Catamaran Using URANS-Based Method. Int. J. Offshore Polar Eng. 2016, 26, 48–56. [Google Scholar] [CrossRef]

- Barbaca, L.; Pearce, B.W.; Brandner, P.A. Numerical analysis of ventilated cavity flow over a 2-D wall mounted fence. Ocean Eng. 2017, 141, 143–153. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, H.; Zou, J.; Hu, A.; Yang, J. Experimental and numerical investigations on hydrodynamic and aerodynamic characteristics of the tunnel of planing trimaran. Appl. Ocean Res. 2017, 63, 1–10. [Google Scholar] [CrossRef]

- Veysi, S.T.; Bakhtiari, M.; Ghassemi, H.; Ghiasi, M. Toward numerical modeling of the stepped and non-stepped planing hull. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 1635–1645. [Google Scholar] [CrossRef]

- Matveev, K.I. Two-dimensional modeling of stepped planing hulls with open and pressurized air cavities. Int. J. Naval Archit. Ocean Eng. 2012, 4, 162–171. [Google Scholar] [CrossRef]

- Matveev, K.I. Hydrodynamic modeling of semi-planing hulls with air cavities. Int. J. Naval Archit. Ocean Eng. 2015, 3, 500–508. [Google Scholar] [CrossRef]

- Guo, R.X.; Liu, X.W. Experimental investigation on the resistance reduction of stepped planing craft by formation of air cavity. J. Hydrodyn. 2002, 17, 440–447. [Google Scholar]

- Menter, F.R.; Langtry, R.; Völker, S. Transition Modelling for General Purpose CFD Codes. Flow Turbul. Combust. 2006, 77, 277–303. [Google Scholar] [CrossRef]

- Eça, L.; Hoekstra, M. A procedure for the estimation of the numerical uncertainty of CFD calculations based on grid refinement studies. J. Comput. Phys. 2014, 262, 104–130. [Google Scholar] [CrossRef]

- Eça, L.; Hoekstra, M. Discretizetion Uncertainty Estimation Based on Least Squares Version of the Grid Convergence Index. In Proceedings of the 2nd Workshop on CFD Uncertainty Analysis, Lisbon, Portugal, 16–18 October 2006. [Google Scholar]

- Hirdaris, S.E.; Bai, W.; Dessi, D.; Ergin, A.; Gu, X.; Hermundstad, O.A.; Huijsmans, R.; Iijima, K.; Nielsen, U.D.; Parunov, J.; et al. Loads for use in the design of ships and offshore structures. Ocean Eng. 2014, 78, 131–174. [Google Scholar] [CrossRef]

- ITTC QM. Uncertainty analysis in CFD verification and validation methodology and procedures. In Proceedings of the 23rd International Towing Tank Conference, Venice, Italy, 8–14 September 2002. [Google Scholar]

- Stern, F.; Longo, J.; Penna, R.; Olivieri, A.; Ratcliffe, T.; Coleman, H. International Collaboration on Benchmark CFD Validation Data for Surface Combatant DTMB Model 5415. In Proceedings of the Twenty-Third Symposium on Naval Hydrodynamics, Val de Reuil, France, 17–22 September 2000. [Google Scholar]

- De Luca, F.; Mancini, S.; Miranda, S.; Pensa, C. An Extended Verification and Validation Study of CFD Simulations for Planing Hulls. J. Ship Res. 2016, 60, 101–118. [Google Scholar] [CrossRef]

- Thomas, G.; Davis, M.R.; Holloway, D.S.; Roberts, T. The effect of slamming and whipping on the fatigue life of a high speed catamaran. Aust. J. Mech. Eng. 2006, 3, 165–174. [Google Scholar] [CrossRef]

- Alavi Mehr, J.; Lavroff, J.; Davis, M.R.; Holloway, D.S.; Thomas, G.A. An experimental investigation on slamming kinematics, impulse and energytransfer for high-speed catamarans equipped with Ride Control Systems. Ocean Eng. 2014, 178, 410–422. [Google Scholar] [CrossRef]

| Main Dimensions | Symbol | Value |

|---|---|---|

| Overall length (m) | LOA | 2.0 |

| Main hull beam (m) | BOA | 0.46 |

| Chine beam BC (m) | BC | 0.392 |

| Draft (m) | T | 0.09 |

| Longitudinal center of gravity (m) | LCG | 0.66 |

| Deadrise angle (°) | β | 22.5 |

| Longitudinal location of step (m) | LS | 0.622 |

| Step height (m) | H | 0.02 |

| Angle between step projection line and longitudinal mid-section (°) | α | 90 |

| Plan | Mesh Size Parameters | Mesh Number | ||||

|---|---|---|---|---|---|---|

| Surface Mesh () | Inner Domain Mesh Size () | Non-Dimensional Near-Wall Mesh Size (y+) | Surface Mesh Size (1 × 106) | Inner Domain Mesh Size (1 × 106) | Total Mesh (1 × 106) | |

| Mesh 1 () | 2.00 | 4.00 | 90–150 | 0.087 | 2.67 | 3.78 |

| Mesh 2 () | 2.83 | 5.66 | 90–150 | 0.056 | 2.02 | 3.03 |

| Mesh 3 () | 4.00 | 8.00 | 90–150 | 0.035 | 1.51 | 2.52 |

| Coefficient | Fr∇ | ||||||

|---|---|---|---|---|---|---|---|

| 7.12 | 0.39 | 2.71 | 0.56 | 8.08 | 17.16 | 5.51 | |

| Resistance | 4.8 | 0.37 | 2.88 | 0.72 | 1.03 | 2.50 | 7.62 |

| 2.41 | 0.81 | 0.60 | 0.77 | 7.02 | 17.79 | 4.61 | |

| 7.12 | 0.23 | 4.23 | 2.33 | 1.47 | 8.30 | 3.89 | |

| Trim angle | 4.8 | 0.35 | 3.06 | 0.89 | 1.43 | 3.18 | 24.50 |

| 2.41 | 1.75 | NA | NA | NA | NA | 5.45 | |

| 7.12 | 0.15 | 5.52 | 4.77 | 0.32 | 3.34 | 8.06 | |

| Sinkage | 4.8 | 0.48 | 2.12 | 0.09 | 1.88 | 2.20 | 7.07 |

| 2.41 | 7.12 | NA | NA | NA | NA | 19.91 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Sun, Z.; Jiang, Y.; Gao, Z. A Study on the Air Cavity under a Stepped Planing Hull. J. Mar. Sci. Eng. 2019, 7, 468. https://doi.org/10.3390/jmse7120468

Yang D, Sun Z, Jiang Y, Gao Z. A Study on the Air Cavity under a Stepped Planing Hull. Journal of Marine Science and Engineering. 2019; 7(12):468. https://doi.org/10.3390/jmse7120468

Chicago/Turabian StyleYang, Dongmei, Zhiyuan Sun, Yi Jiang, and Zeyang Gao. 2019. "A Study on the Air Cavity under a Stepped Planing Hull" Journal of Marine Science and Engineering 7, no. 12: 468. https://doi.org/10.3390/jmse7120468

APA StyleYang, D., Sun, Z., Jiang, Y., & Gao, Z. (2019). A Study on the Air Cavity under a Stepped Planing Hull. Journal of Marine Science and Engineering, 7(12), 468. https://doi.org/10.3390/jmse7120468