Abstract

A reliable estimation of the floating condition of a roll on/roll off cargo (ROPAX) vessel after the accumulation of firewater on the vehicle deck is extremely important for making correct decisions on evacuation and abandonment. Thus, for the seafarer working on a ROPAX vessel, there is a demand for a time-dependent prediction of the floating condition of the vessel after the firewater accumulation. For this purpose, a new iterative computational approach, based on quasi-static theory, is presented. The approach is examined through the records observed in an accident of the M/V Dashun. The results show that the approach has good accuracy and feasibility provided that the actual heeling angle and cargo shift during the accident are carefully monitored.

1. Introduction

Ships designed to carry passengers and roll on/roll off cargo (ROPAX ships) are among functional types of ships. The flexibility, ability to integrate with other transport systems and operating speed, has become extremely popular in many routes [1]. Recent developments in the design of passenger ships have led to larger and larger vessels with an increasing capacity for carrying more passengers and crew [2]. The largest cruise ship can carry more than 8800 people to date. Throughout the history of commercial ROPAX traffic, fire accidents involving large passenger ships have been rare, and fortunately, they have seldom caused fatalities. However, if a large amount of firewater accumulates on the vehicle deck, the vessel may capsize, which could be rapid and disastrous, and probably accompanied by a large number of fatalities. As shown in Table 1, some of these accidents are still fresh in our memory, such as M/V Dashun in 1999 (282 fatalities) [3,4,5] and M/V Al Salam Boccaccio 98 in 2006 (1031 fatalities) [6].

Table 1.

Accidents of roll on/roll off cargo (ROPAX) vessels involving firewater accumulation over last 40 years (Source: DNV-GL, MSA, MAIB, FBMCI, PMA).

Over the last few years, the problem of water on deck of passenger vessels has drawn wide attention from the ocean engineering community, and many experimental studies have been conducted to date [11,12,13]. However, it is difficult to cover all the situations under limited laboratory conditions, especially in regard to water accumulation on a vehicle deck due to improper firefighting operations. This type of water accumulation is different from that caused by a damaged hull on the basis of the following factors: (1) the vessel is still intact below the waterline, (2) the flow into the vehicle deck is not affected by the waves outside but depends on the spraying capacity of water-drencher system, sometimes in combination with the use of fire hoses by seafarers, and (3) the flow out of the vessel exists during the water accumulation process if the elevation of water on the vehicle deck is higher than that outboard. Certainly, one of most common issues of the water accumulation caused by improper firefighting shared with that caused by a damaged hull is how to predict the floating condition of the vessel with an increase in the accumulation of water, based on which the decision on the evacuation of passengers and seafarers, the abandonment of the vessel or the continuation of sailing can be made. Lee et al. [14] developed a framework for survivability assessment of a damaged ship, taking into account the heeling angle and the range of stability. Jasionowski [15] presented a method for vulnerability analysis which can also be used for decision support when the flooding condition is already known. Choi et al. [16] proposed a DB(Database)-based supporting system on the basement of detected damage condition. Later, D. Spanos and A. Papanikolaou [17] evaluated the probability of slow (and fast) sinking/capsize of passenger ships, aiming to clarify the feasibility of safe operations/evacuation in flooding incidents. The same year, Varela et al. [18] presented a on-board decision support system for ship flooding emergency response according to the current ship status and existing damages. More recently, Hee Jin Kang et al. [19] designed a new concept for buoyancy support systems for damaged ships which considered the technical and economic matters, but is far from the usage in marine practice. However, these systems are based on the fact that the damage condition has been detected, and moreover, may not be suitable for the case of firewater accumulation.

Usually, the amount of water on a vehicle deck can be detected by the sensors of the flooding detection system [20], as required by SOLAS regulation II-1/22-1 [21], or by using professional commercial software, such as NAPA [22] and ANSYS-Fluent [23]. There are, nevertheless, still passenger vessels in service which are not equipped with flooding level sensors or not even equipped with such a detection system. Even if the detection system has been used onboard, in the case of a firewater accumulation condition, the flood level sensors may send a false signal because the water is widely sprayed to the vehicle deck through a water-drencher system rather than solely flooded from a damaged hole. Furthermore, for seafarers working on board these vessels, a commercial hydrostatic or hydrodynamic software may be not available for immediate use due to its sophistication and specialization. Therefore, a feasible and simple direct computational approach, which can predict the change in the floating condition of the vessel with an increase in the accumulation of firewater, is needed.

2. Mathematic Formulation and Computational Approach

2.1. Firewater Accumulation

According to the requirements of the SOLAS convention, two methods may be used for the discharge of water from a vehicle deck. One of them is that the water is discharged to the reservoir tank through pipelines and then discharged outboard by a bilge pump. The other is that the water is directly discharged outboard through deck scuppers. The latter is widely used in the design of ROPAX vessels due to its practicability and convenience. In this paper, the latter one is chosen in order to analyze the problem of water accumulation problem on a vehicle deck.

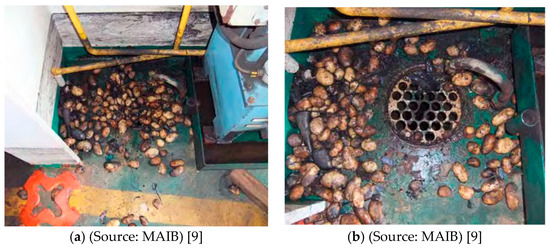

After the occurrence of fire on a vehicle deck, the water-drencher system that the deck is equipped with will be started at the control center of the vessel. Burning debris and loose cargoes will be flushed onto the vehicle deck, and probably drifted toward the openings of scuppers, causing these openings blocked (as shown in Figure 1). Subsequently, water will build up in the deck if sufficient suppers are blocked and the access to the openings for manually cleaning the debris becomes impracticable because of large amounts of heat and smoke.

Figure 1.

A deck scupper blocked by potatoes. (a) Blocked. (b) Removed.

As shown in Figure 2, the discharge capacity of the pipeline of a scupper mentioned above is determined by:

where H denotes the total elevation head difference between the water level on the vehicle deck and that outboard; hf, f, l, v, g and dr represent the frictional head loss, the coefficient of frictional head loss, the length of a drain pipeline, the average velocity of flow out, the acceleration due to gravity and the diameter of the pipeline, respectively; and hi, ai, and ki indicate the local head loss of part i, the quantity of part i, and the head loss coefficient of part i.

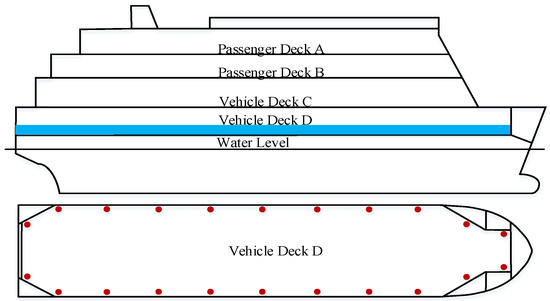

Figure 2.

Arrangement of the scuppers on vehicle deck D.

In most cases, the local head loss of a discharge pipeline is composed of valve loss, elbow loss, inlet loss and outlet loss. The total head loss can be written as:

where a1, a2, a3 and a4 are the quantities of check valves, elbows, inlets and outlets; and h1, h2, h3 and h4 are the local head losses of check valves, elbows, inlets and outlets, respectively.

The coefficient of frictional head loss f can be obtained through the Darcy–Weisbach equation:

where ε is the roughness of the pipeline, Re is the Reynolds number, μ is the coefficient of viscosity, and Qout is the volumetric flow rate of the flow out of the vessel.

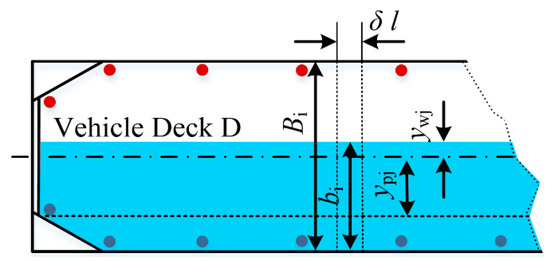

2.2. Firewater Accumulation without a Persistent Heeling Angle

Normally, firewater will accumulate on the side where the blocking condition is heavier than the other side, based on the assumption that the heeling process proceeds in a quasi-static way [24,25]. Then, the heeling angle can be considered to be equal to the vertical angle of the water triangular prism accumulated on deck [26,27]. For an accurate computation, the deformation of the whole water wedge due to the complicated ship structure should be taken into consideration. From stern to bow, the vehicle deck is longitudinally divided into sufficient sections at an interval δli, as shown in Figure 3 and Figure 4. If the interval of each step, δli, is adequately small, the deformation of each micro-triangular-prism due to the ship structure can then be neglected. At section i, the breadth of vehicle cargo space and the breadth of micro-triangular-prism are, respectively, Bi and bi. With an increase in water accumulation, the outer margin of the whole water wedge, ywj, will move from the starboard side to the port side. To maintain the same accuracy as the longitudinal step, the movement of every transverse step, δywj, is also set as the length of δli.

Figure 3.

Firewater accumulated on the starboard side.

Figure 4.

Illustration of the firewater computation.

For section i, bi can be ascertained by:

where ywj is positive on the starboard side, ranging from B/2 to −B/2. The letter B mentioned here is the maximum breadth of the vehicle cargo space.

In the practice of ROPAX transportation, the permeability caused by the volume occupied by the wheels and carriages of vehicles, μp, should be taken into account [28]. The weight of the micro-triangular-prism at section i, pi, and the total weight of all the firewater accumulated after a period of time t, P(t), can be expressed as:

where ρ is the water density, I is the quantity of the total longitudinal sections and θ(t) is the final static heeling angle caused by the water weight.

The equilibrium between the heeling moment and the upright moment of the vessel can be established as:

where yp(t) is the transverse center of the whole water wedge, Δ is the displacement of the vessel, GMc is the initial metacentric height corrected by free surface, KG is the center of gravity of the vessel, Zp(t) is, under a dangerous assumption that all the water accumulated can flow from one side to the other, the center of gravity of the water on vehicle deck, Zv is the height of vehicle deck above baseline, and Sv is the area of the vehicle deck, respectively.

Then, ypj can be obtained as:

Then, the governing Equation (11) can be expressed as:

2.3. Firewater Accumulation with a Persistent Heeling Angle

The shift of vehicle cargoes will significantly affect the accumulation of water on the deck and the floating condition of the vessel, which may happen during the firefighting with water. The firewater poses a danger to the security and lashings of vehicle cargoes on the vehicle deck in the following ways: (1) an increase in the weight of water-absorbing cargoes in vehicles exposed to water-drencher system, (2) an increase in the lashing load of the higher side of vehicles due to heeling, and (3) the decrease in the friction force caused by the wet deck. Equation (14) should be corrected as follows:

where θ0 is the persistent heeling caused by cargo shift.

2.4. A Time-Dependent Prediction of Floating Condition of Roll On/Roll Off Cargo (ROPAX) Vessels after Firewater Accumulation on the Vehicle Deck

The weight of the total firewater accumulated, P(t), is directly related to the final static heeling angle, θ(t). The change in P(t) depends on the total volume of the flow into the vehicle deck and that of the flow out.

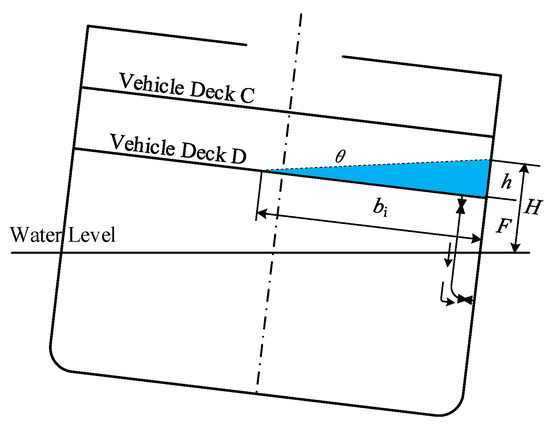

With an increase in water accumulation, as shown in Figure 5, the freeboard of vehicle deck D, F(P(t)), and the height of the water triangular wedge, h(P(t)), will change. Subsequently, H(P(t)) will be affected as:

where b is the breadth of the longitudinal triangular prism of water along the length of the vehicle deck D, and to be on safe side, is ascertained by max(bi). TPC is the tonnage per centimeter of the vessel.

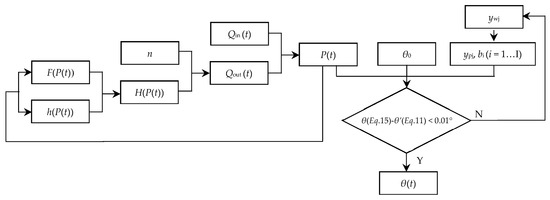

Figure 5.

The flow chart for a time-dependent prediction of the floating condition of after the firewater accumulation on vehicle deck D.

3. The Firewater Accumulation in the Accident of the M/V Dashun

In order to calculate the volumetric flow rate of the flow out of the vehicle deck, and then the speed of firewater accumulation after the blockage of the scuppers, and finally to examine the approach, the loading condition of the M/V Dashun at the time of the accident is selected as an example in this section. The total water discharge speed of the vehicle deck is separately computed according to actual heeling condition, for making a comparison. The approach is then examined by the records of the accident.

3.1. Fire Water Accumulation

According to [5], 11 scuppers are evenly distributed on either side of the vehicle deck D. By referring to [29], the coefficients of local loss ki of the swing check valve, elbow, inlet and outlet are listed in Table 2.

Table 2.

The particulars of the scuppers on vehicle deck D of the M/V Dashun.

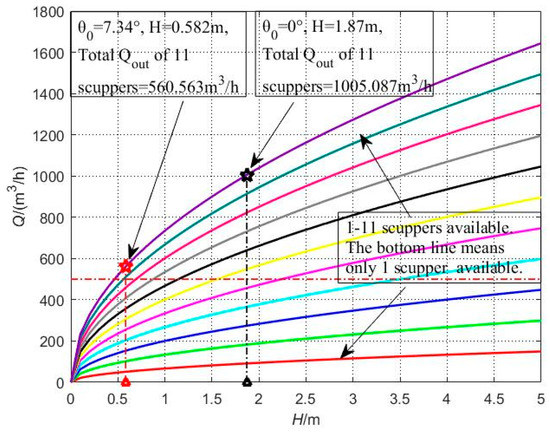

Then, the total elevation head difference H and Darcy–Weisbach equation can be expressed as:

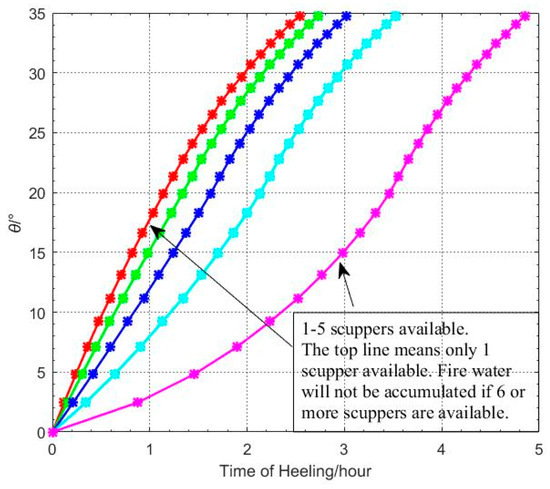

Before the accumulation of firewater, the total elevation head difference H is, if there is no a persistent heeling, determined by the initial freeboard of the vehicle deck D, F0. According to the actual loading condition of the M/V Dashun, as shown in Table 3, it can be revealed that the average velocity of flow out v = 2.06927836 m/s, and the coefficient of frictional head loss f = 0.05233750 when the firewater initially accumulated on the vehicle deck D. Then, the volumetric flow rate of the flow out for a single scupper Qout = 91.37157275 m3/h at the beginning. The total discharge capacity of vehicle deck D at different H can then be computed as shown in Figure 6. In the case of the accident of the M/V Dashun, the total volumetric flow rate of the flow into vehicle deck D, including that sprayed from the water-drencher system and the flow from the upper vehicle deck through the vehicle passage ramp, Qin, is calculated as 500 m3/h at least [30]. As shown in Figure 6, if all 11 scuppers are available, the firewater will not accumulate. However, the firewater will surely accumulate if only 5 or less scuppers are available.

Table 3.

The particulars of the loading conditions of the M/V Dashun at the time of the accident.

Figure 6.

Scupper discharge capacity of vehicle deck D.

Actually, there was a heavy cargo shift in the accident of the M/V Dashun. The fire was caused by the collision of two shifted vehicles after a leakage of gas oil from a damaged vehicle tank. The investigating team suggested that the persistent heeling angle caused by the shift of vehicle cargoes on deck D was less than 10° since the average shift of vehicles was less than 2 m [3]. Later, from a more reasonable perspective, Jiang et al. suggested that the average shift of vehicles was approximately 1.5 m and that the persistent heeling angle caused by the shift should be 7.34° on the port side [5]. In view of this calculation, there would be a high probability that the water would accumulate on vehicle deck after the decrease of total elevation head, because the blockage of only 2 of 11 scuppers will make this happen.

3.2. The Accident of the M/V Dashun

Since the accident of the M/V Dashun occurred almost 20 years ago, only a few of the records were, as listed in Table 4, available for the computation of the firewater accumulation and its influence on the floating condition of the vessel. Moreover, the Code of Safe Practice for Cargo Stowage and Securing (the CSS Code) does not apply when the heeling angle of the vessel is greater than 30°. According to the Report of the Investigation and Analysis of the ‘11.24’ Accident [3], the vehicles on deck D may have been overturned, and ballast operations were carried out after the vessel was heeled to 30°. However, the details of the conditions of overturned vehicles and the ballast operations were not recorded by the vessel. In view of the limitation on records, the firewater accumulation in the accident of the M/V Dashun is not computed when the static heeling angle is greater than 30° in this paper.

Table 4.

A brief description of the accident of the M/V Dashun [3].

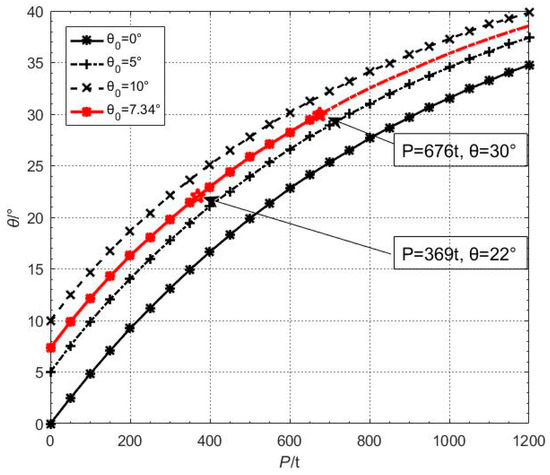

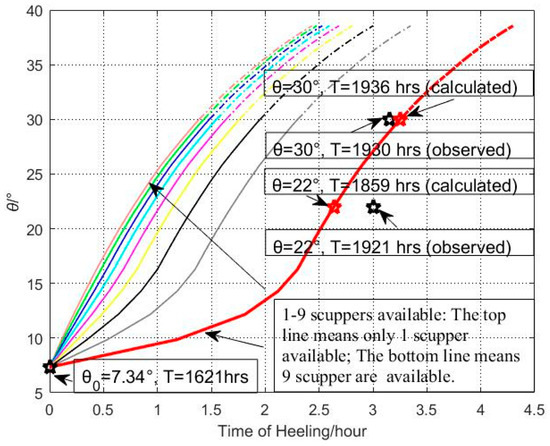

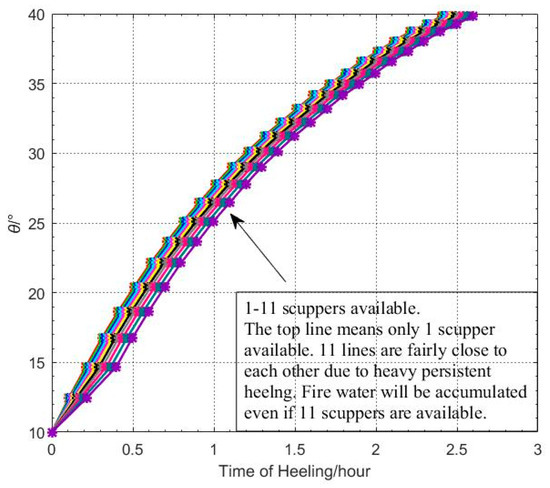

As shown in Figure 7, the red line indicates the computation results of the change in the heeling angle with the increase of accumulated firewater. The red line in Figure 8 shows the change of the heeling angle with the passing of time. According to the results of the computation, 2 of 11 scuppers are definitely blocked on the port side of the M/V Dashun, which means that the blocking condition in vehicle deck D is not as serious as what was concluded in [5,6] and that the accumulation of firewater is mainly caused by the influence of the persistent heeling due to cargo shift. According to computation results, it was 1936 h local time when the vessel was heeled to 30°. In the records observed in the accident, it was 1930 h local time the vessel was heeled to approximately 30° on the port side. The error for this record is approximately 6 min within a total time consumption of 189 min. According to [31], a salvage boat, “Yanjiu13”, arrived at the scene of the accident at about 1910, and tried to throw a heaving line to M/V Dashun at about 1921 local time after communication with it. During this period, the heeling angle of the M/V Dashun was about 21° to 22° on the port side. Therefore, the maximum error of the computation result of the heeling angle of 22°, as shown in Figure 8, is 22 min within total time consumption 180 min, and the minimum error is about 11 min. For making a correct decision on a further operation after the firewater accumulation, this computational approach is feasible and practicable. What should be mentioned here is that the calculation of the persist heeling angle caused by cargo shift, the total volumetric flow into vehicle deck D, and the heeling angle observed in severe weather may give a contribution to the error of the approach. However, these errors will be minimized in a modern ROPAX vessel equipped with precision instruments.

Figure 7.

The firewater accumulation of the M/V Dashun accident.

Figure 8.

The heeling time of the M/V Dashun accident after the blockage of 2 of 11 scuppers.

4. Discussion

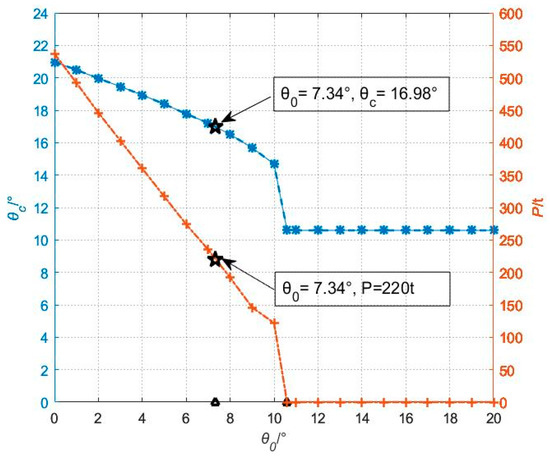

4.1. A Critical Static Heeling Angle for Firefighting Operation with Water

Since the persistent heeling will, as shown in Figure 9 and Figure 10, significantly affect the discharge capacity of scuppers, a critical static heeling angle, θc, should be determined and identified during firefighting with water. When the vessel heels to the angel of θc, the elevation head difference Hc is zero, which means that the average velocity of the flow out, v = 0 m/s, and that any further action of firefighting with water will increase the accumulation of firewater on deck and make the circumstances more dangerous.

where P(θ0) and b(θ0) are the total weight of water accumulated on deck and the corresponding max(bi), respectively, when the persistent heeling θ0 is set as a variable and the total elevation head difference is set as a constant (H = 0). P(θ0) and b(θ0) can be computed from Equations (13) and (17).

Figure 9.

Heeling angle and heeling time θ0 = 0°.

Figure 10.

Heeling angle and heeling time θ0 = 10°.

The studies of the critical amount of water on deck for capsizing a ROPAX vessel in a damaged case was well developed through the static equivalency method (SEM) by Vassalos, D., Andrew Kendrick, Pawłowski, M. et al. [11,32,33]. In a case of firefighting with water, as per the suggestion of Stefan Krueger, the limiting amount of water on deck needs to be determined at the time when the roll period doubles and the vessel still has a significant remaining stability margin against capsizing [13]. Compared with the flooding water in a damaged case, the firewater is much more controllable and manageable, which gives the master of the vessel sufficient room to make the decision whether or not to continue to fight the fire with water after the heeling angle reaches the critical value identified in this paper. In the practice of firefighting with water, it is suggested that the heeling angle after firewater accumulation is, however, well monitored to avoid the shift or overlapping of vehicle cargoes. In the case of the M/V Commodore Clipper, the maximum heeling angle of the vessel was controlled within 5° by stopping and starting the water-drencher system alternately until the vessel arrived in the port of destination [9].

According to the loading condition of the M/V Dashun, 220 t of accumulated firewater would have made the heeling angle of the vessel reach the critical value, θc = 16.98°, after the cargo shift had caused a persistent heeling angle θ0 = 7.34° on the port side (as shown in Figure 11).

Figure 11.

Critical heeling angle, θc, and the corresponding firewater weight, P.

4.2. The Guidelines of the International Maritime Organization (IMO) and the Problems at Present

Fires aboard ROPAX ships are gaining increasing interest and prompting the development of new rules and regulations as well as new methods to reduce the risk of fires on board such vessels, which is of great importance [34]. From 27 May to 5 June 2009, the International Maritime Organization (IMO) approved guidelines for the drainage of fire-fighting water from closed vehicles and Ro-Ro spaces and special category spaces of passenger and cargo ships (the Guidelines) at the 86th MSC session [35]. When fixed water-based fire-extinguishing systems are provided for the protection of closed vehicle and Ro-Ro spaces and special category spaces, adequate drainage facilities, as required by the guidelines and SOLAS regulation II-2/20.6.1.4, should be provided to prevent the accumulation of significant quantities of water on decks and the build-up of free surfaces. In addition, SOLAS regulation II-2/20.6.1.5 requires effective measures to be taken to ensure that floating debris does not cause a blockage of the drains. The drainage system on each side of the deck should have an aggregate capacity of not less than 125% of the maximum flow rate of the fixed fire-extinguishing system water pumps plus the flow from two fire hoses (four if required by SOLAS regulation II-2/19.3.1.2).

Since its implementation, the Guidelines have played a good role in preventing firewater accumulation on Ro-Ro decks. But the risk of firewater accumulation still exist, especially when the vessel is in port. It should be noted that the fire extinguishing system (usually low-pressure CO2) is ineffective when the ship is in port, as external and internal ramps are open and can in many cases not be closed quickly in the case of a fire [36]. To avoid a major fire accident, many ports throughout the world have been equipped with fireboats with a large spraying capacity. For example, the M/V Daxiao 01, one of the firefighting boats with the maximum water spraying capacity in China at present, has been equipped with a main water firefighting gun with spraying capacity 3600 m3/h. If firefighting boats with such a large water spraying capacity are fully engaged in the firefighting of ROPAX vessels, the situation may become deteriorated even though the drainage system has been designed as per the requirements of SOLAS regulations (Figure 12).

Figure 12.

Two fire boats engaged in the firefighting of the M/V Liaohai.

5. Conclusions

The accumulation of firewater on vehicle deck is a vicious cycle for the safety of ROPAX vessels. When there is a severe blockage of vehicle deck scuppers or a large persistent heeling angle or both, accumulation of firewater will occur, the total elevation head and the subsequent water discharge speed will decrease, and finally, the water accumulation speed will be faster. Therefore, for seafarers, some common facts can be understood from another perspective. Foreign firefighting assistance by a port fireboat may save a ship that is on fire, and also may make it capsize. A persistent heeling caused by cargo shift will affect not only the ship’s stability but also the firewater discharge.

A computational approach for time-dependent prediction of the floating condition of ROPAX vessels after firewater accumulation on vehicle deck is presented. The approach will provide valuable information for decision-making. In addition, for avoiding the firewater accumulation, a critical static heeling angle is identified and computed. The approach can be utilized for other different sizes of ROPAX vessels if the vehicle deck of the vessels is equipped with the same water discharge system. The master of the vessel should be well aware of the negative consequence of the action of firefighting with water when persistent heeling has been greater than the critical static heeling angle mentioned in this paper.

The stability of the vessel will be dramatically decreased by the free surface of the water accumulated on the vehicle deck. Unfavorable weather conditions will, if encountered, further deteriorate the heeling of the ROPAX vessel. Due to the complicated matter of dynamic interactions, the floodwater motions, namely sloshing, may be important for wide rooms [37,38]. The studies concerning the floodwater effects on ship motions have been conducted [39,40] for years in a damage condition, while those concerning the firewater effects on ship motions are relatively rare and still required.

Author Contributions

Conceptualization, Methodology, Software, Formal Analysis, Validation, Investigation, Data Curation, Writing—Original Draft Preparation, Writing—Review and Editing: H.W.; Supervision, Writing—Review & Editing, Validation, Investigation: Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Liaoning Provincial Natural Science Foundation of China, grant number 2015020626.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Endrina, N.; Rasero, J.C.; Konovessis, D. Risk analysis for RoPax vessels: A case of study for the Strait of Gibraltar. Ocean Eng. 2018, 151, 141–151. [Google Scholar] [CrossRef]

- Wilson, P.A. Basic Naval Architecture Ship Stability, 1st ed.; Springer International Publishing AG: Gewerbestrasse, Switzerland, 2018; pp. 141–142. [Google Scholar]

- China Maritime Safety Agency. Books for Marine Investigators—Investigation and Analysis of Typical Shipping Accidents, 1st ed.; Dalian Maritime University Press: Dalian, China, 2003; pp. 88–126. [Google Scholar]

- Sun, H. The Mathematical Model of Ship’s Stability in Waves and Its Application in Ro-Ro Ships. Master’s Thesis, Dalian Maritime University, Dalian, China, 2002. [Google Scholar]

- Jiang, H.; Tian, B. Stability analysis of the capsizing accident of ROPAX vessel Dashun. In Proceedings of Nautical Science and Technology of Dalian Institute of Navigation; Chen, D., Ed.; Dalian Maritime University Press: Dalian, China, 2002; pp. 143–147. [Google Scholar]

- Garibaldi, R.; Smith, N. Preliminary Investigation Report on the Sinking of MV AL-SALAM-BOCCACCIO-98; Panama Maritime Authority: Panama City, Republic of Panama, 2006; pp. 1–3. [Google Scholar]

- Skjong, R. Report FSA of HLA on Passenger Vessels—Annex I Passenger Vessel Evacuation Descriptions; DNV-GL: Oslo, Norway, 1999; pp. 5–26. [Google Scholar]

- Dalian Maritime Safety Agency. Case analysis of firefighting assistance and emergency management of M/V Liaohai. China Emerg. Manag. 2004, 5, 34–38. [Google Scholar]

- Marine Accident Investigation Branch (MAIB). Report on the Investigation of the Fire on the Main Vehicle Deck of Commodore Clipper; MAIB: Southampton, UK, 2011; pp. 13–39. [Google Scholar]

- Federal Bureau of Maritime Casualty Investigation (FBMCI). Investigation Report of Fire on the Ro-Ro Passenger Vessel LISCO GLORIA; FBMCI: Hamburg, Germany, 2012; pp. 30–128. [Google Scholar]

- Vassalos, D. The water on deck problem of damaged RO-RO ferries. In Contemporary Ideas on Ship Stability; Elsevier Science Ltd.: Okford, UK, 2000; pp. 163–185. [Google Scholar]

- Pawłowski, M. A modified static equivalency method for Roll-on/Roll-off vessels. J. Ship Res. 2007, 51, 39–46. [Google Scholar]

- Krueger, S.; Nafouti, O.; Mains, C. A New Approach for the Water-On-Deck-Problem of RoRo-Passenger Ships. In Proceedings of the 12th International Conference on the Stability of Ships and Ocean Vehicles (STAB 2015), Glasgow, UK, 14–19 June 2015; University of Strathclyde: Glasgow, UK, 2015; pp. 215–225. [Google Scholar]

- Lee, D.; Lee, S.S.; Park, B.J.; Kim, S.Y. A study on the framework for survivability assessment system of damaged ships. Ocean Eng. 2005, 32, 1122–1132. [Google Scholar] [CrossRef]

- Jasionowski, A. Decision support for ship flooding crisis management. Ocean Eng. 2011, 38, 1568–1581. [Google Scholar] [CrossRef]

- Choi, J.; Lee, D.; Kang, H.J.; Kim, S.Y.; Shin, S.C. Damage scenarios and onboard support system for damaged ships. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 236–244. [Google Scholar] [CrossRef][Green Version]

- Spanos, D.; Papanikolaou, A. On the time for the abandonment of flooded passenger ships due to collision damages. J. Mar. Sci. Technol. 2014, 19, 327–337. [Google Scholar] [CrossRef]

- Varela, J.M.; Rodrigues, J.M.; Guedes Soares, C. On-board decision support system for ship flooding emergency response. Procedia Comput. Sci. 2014, 29, 1688–1700. [Google Scholar] [CrossRef]

- Kang, H.J.; Kim, I.; Choi, J.; Lee, G.J.; Park, B.J. A concept study for the buoyancy support system based on the fixed fire-fighting system for damaged ships. Ocean Eng. 2018, 155, 361–370. [Google Scholar] [CrossRef]

- Ruponen, P.; Pulkkinen, A.; Laaksonen, J.A. A method for breach assessment onboard a damaged passenger ship. Appl. Ocean Res. 2017, 64, 236–248. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). Guidelines for Flooding Detection Systems on Passenger Ships; IMO: London, UK, 2008. [Google Scholar]

- Ruponen, P. Progressive Flooding of a Damaged Passenger Ship. Ph.D. Thesis, Helsinki University of Technology, Espoo, Finland, 2007. [Google Scholar]

- Gao, Z.; Wang, Y.; Su, Y.; Chen, L. Numerical study of damaged ship’s compartment sinking with air compression effect. Ocean Eng. 2018, 147, 68–76. [Google Scholar] [CrossRef]

- Braidotti, L.; Mauro, F. A new calculation technique for onboard progressive flooding simulation. Ship Tech. Res. 2019, 66, 150–162. [Google Scholar] [CrossRef]

- Pawłowski, M. Accumulation of water on the vehicle deck. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2003, 217, 201–211. [Google Scholar] [CrossRef]

- Fujiwara, T.; Haraguchi, T. Roll Motion of Ro-Ro Passenger Ship with Flooded Vehicle Deck. Int. J. Offshore Polar Eng. 2005, 15, 109–116. [Google Scholar]

- Fujiwara, T.; Haraguchi, T. On Estimation of Ship Rolling Motion with Flooded Water on Vehicle Deck. In Proceedings of the 12th International Offshore and Polar Engineering Conference (ISOPE2002), Kitakyushu, Japan, 26–31 May 2002; International Society of Offshore and Polar Engineers: Cupertino, CA, USA, 2002. [Google Scholar]

- International Maritime Organization (IMO). The International Convention for the Safety of Life at Sea (Consolidated Edition 2014), 6th ed.; IMO: London, UK, 2014; p. 64. [Google Scholar]

- White, F.M. Pressure Distribution in a Fluid. In Fluid Mechanics, 8th ed.; McGraw-Hill: Boston, MA, USA, 2016; pp. 362–385. [Google Scholar]

- Wang, S. Lessons learned from major maritime accident of “11.24”. Mar. Technol. 2001, 1, 5–6. [Google Scholar]

- Zheng, X. The sinking of M/V Dashun. Labour Prot. 2000, 11, 6–12. [Google Scholar]

- Kendrick, A.; Molyneux, W.D.; Taschereau, A.; Peirce, T. Exploration of the applicability of the static equivalence method using experimental data. In Contemporary Ideas on Ship Stability; Elsevier Science Ltd.: Okford, UK, 2000; pp. 303–313. [Google Scholar]

- Pawłowski, M.; Tuzcu, C. The stability of a damaged roll-on roll-off vessel with water on deck. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2009, 223, 211–226. [Google Scholar] [CrossRef]

- Salem, A. Vehicle-deck fires aboard RoPax ships: A comparison between numerical modelling and experimental results. Pol. Marit. Res. 2019, 26, 155–162. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). Guidelines for the Drainage of Fire-Fighting Water from Closed Vehicle and Ro-Ro Spaces and Special Category Spaces of Passenger and Cargo Ships; IMO: London, UK, 2009. [Google Scholar]

- Veritas, D.N. Fires on Ro-Ro Decks; DNV: Oslo, Norway, 2005; pp. 1–3. [Google Scholar]

- Ruponen, P.; Manderbacka, T.; Lindroth, D. On the calculation of the righting lever curve for a damaged ship. Ocean Eng. 2018, 149, 313–324. [Google Scholar] [CrossRef]

- Gao, Q.; Vassalos, D. Numerical study of damage ship hydrodynamics. Ocean Eng. 2012, 55, 199–205. [Google Scholar] [CrossRef]

- Acanfora, M.; Cirillo, A. On the development of a fast modeling of floodwater effects on ship motions in waves. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2017, 231, 877–887. [Google Scholar] [CrossRef]

- Acanfora, M.; Begovic, E.; De Luca, F. A Fast Simulation Method for Damaged Ship Dynamics. J. Mar. Sci. Technol. 2019, 7, 111. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).