A brief survey on the past works done is presented in this section. The authors in [

2] introduced different models of roll damping and studied different forward speed roll decay testing. The numerical simulations were compared with experimental results. For the numerical solution of coupled equations of heave, roll and pitch, the Runge Kutta method was used [

3]. The authors through experimental work explained that coupling of yaw and roll motion can induce and promote parametric roll events [

4]. The validation of the work was done with numerical simulations. An investigation on roll damping through forced oscillation model test was performed in [

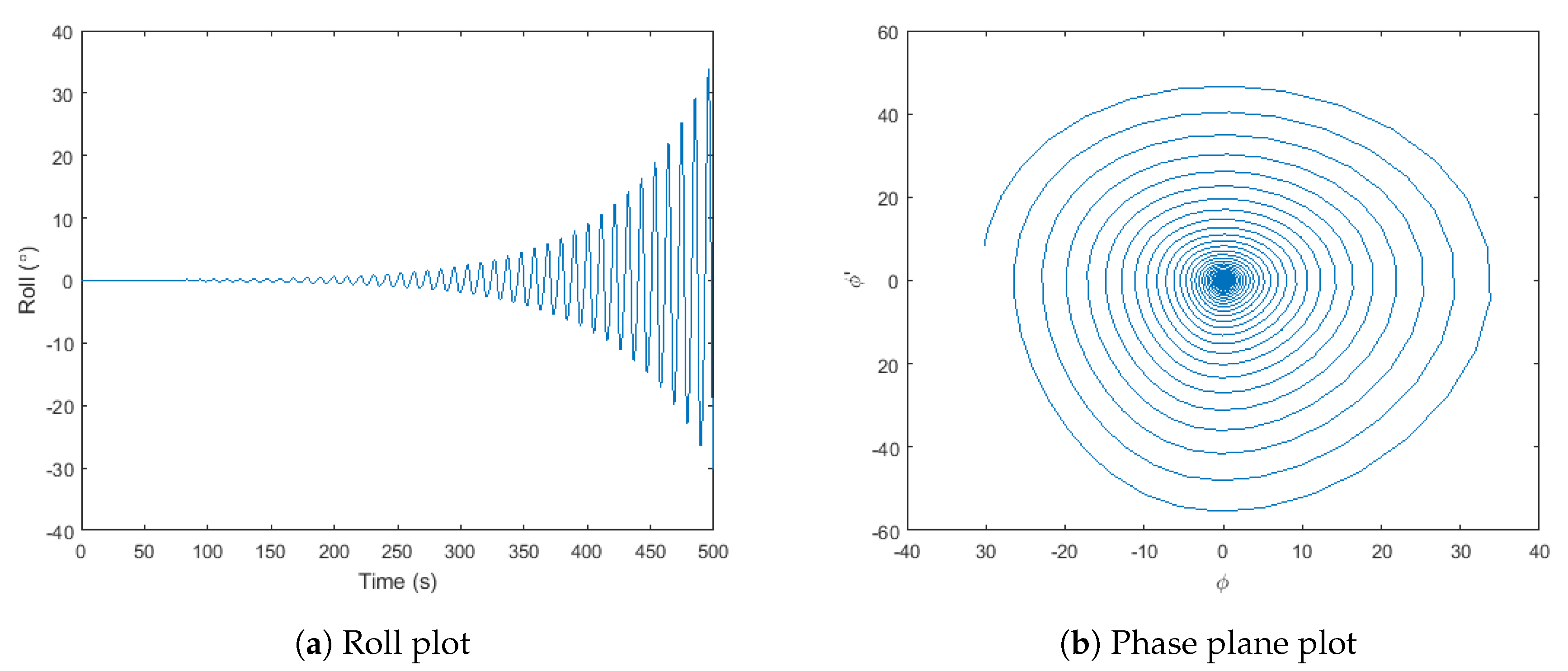

5]. The possibility of large roll amplitudes under conditions of parametric roll was compared between a numerical model and experimental results for different roll damping cases. The authors have presented their established one degree of freedom paramteric roll equation of motion in [

6], and vessel was simulated inn a random wave group. The influence of wave group height and wave group length was studied on the roll motion. A reliability method was proposed which can efficiently predict parametric roll as an extreme value stochastic process [

7]. The efficiency of the proposed method was compared with other numerical reliability scheme. Several numerical algorithms to predict the possibility of parametric roll resonance was designed in [

8]. The second order linear oscillatory system was used to model the roll angle of floating vessel. A coupled motion numerical model based on source method to study the diffraction and radiation forces on parametric roll was used in [

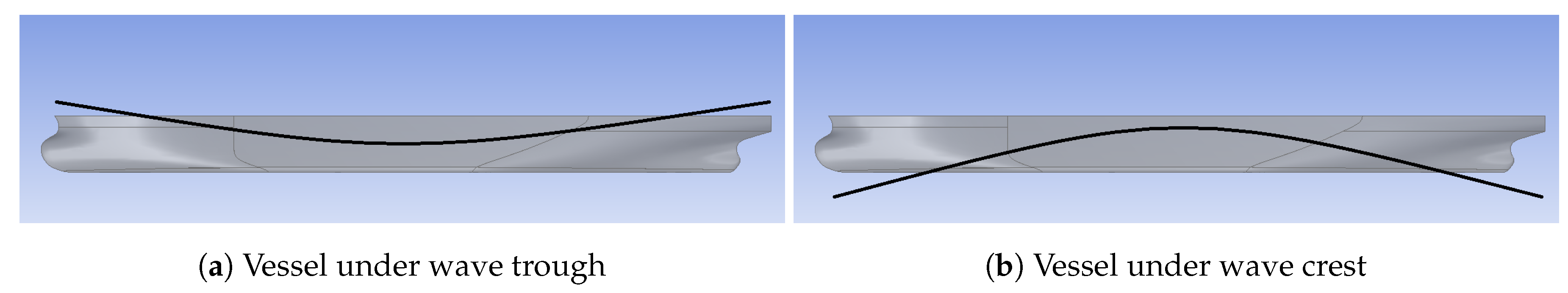

9]. Furthermore, the effect of these forces on the roll restoring lever arm was studied under different angle of heel and wave amplitude. The past research paper have presented a procedure to calculate the roll response through a time domain numerical model [

10]. The time domain numerical model was based on the exact underwater geometry which calculated the righting arm. This method considered the roll angle and surge velocity for statically balancing the vessel. The ship stability parameters, such as the center of buoyancy and sectional area, were calculated at every time step. An attempt to calculate the probability of occurrence of roll motion exceeding a limiting value through reliability method was presented in [

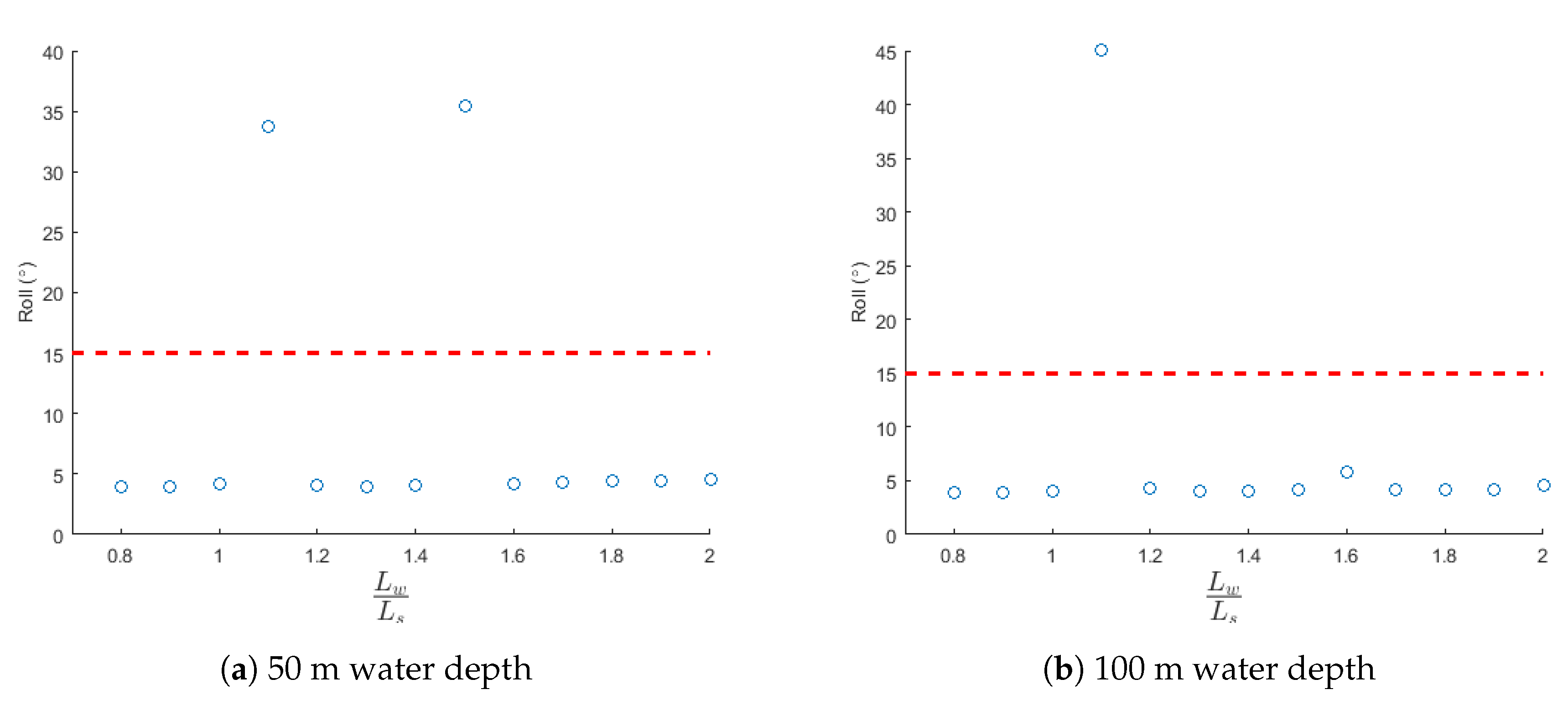

11]. The effect of partially standing waves on offloading operations through mathematical modeling was presented in [

12]. The results of the reliability method was compared to other numerical simulation. The operational conditions and various sea-states were calculated for parametric roll resonance. Parametric rolling being a threat to the safety of the ships were studied through numerical simulations [

13]. The simulations were performed in both regular and irregular waves. The simulations employed two different time domain method which were in good agreement with Mathieu’s equation. The authors discussed on the extreme roll motions which unexpectedly cause many accidents and fiscal losses [

14]. Algorithms were designed which detected signals to evaluate the frequency of parametric rolling on vessels. A partly non linear time domain numerical model was used for prediction of parametric roll resonance in regular waves. The non linear incident wave and hydrostatic restoring forces and moment are evaluated considering the instantaneous wetted surface area [

15].

The downtime analysis using a hindcast metocean time series was performed in [

16]. The limiting metocean criteria for any task was based on significant height or time period or both. The authors in [

17] have concluded that incorporating uncertainty and dynamic behavior allows for a better decision on possible operating options. The accuracy of a proposed probabilistic approach was verified with mathematical tests [

18]. The approach included detailed study of three components, viz, mechanical, probabilistic and prediction. Ample number of trials and simulations were performed to assess the validity of the proposed approach. The authors have presented an approach to assess the operational risks and re-validating them through Process Hazard Analyses (PHAs) and other techniques in [

19]. The authors have further suggested that operational risk assessment is crucial for prevention of loss. The maintenance operations can be improved through effective solutions which convert data into useful sources. These useful sources can help mitigate cost and safety concerns [

20]. One research article discussed poor visibility in seabed operations can instil downtime due to delayed schedule of work and thereby production costs were affected [

21]. The challenge to reduce the operational downtime and achieve appropriate reliability level was discussed in [

22]. The authors have discussed operational downtime of a floating platform in extreme cold regions and further determined the causes responsible for it. An integrated work flow was proposed to counter act the downtime problem due to unplanned shutdown of a subsea production system [

23]. The hydrodynamic interaction between vessels and the effect of motion responses on offloading operations were studied in [

24]. It is concluded from past works that there is no much work done in down-time cost estimation. A research gap exists to connect motion responses to cost. Also, authors have developed research related to vessel interaction and fluid behavior. However, there is no much literature available to link the vessel behavior and wave interaction to economical performance shuttle tanker. Thus, this paper will focus on one particular study co-relating the parametric rolling to global loss in revenue of oil production.