Hydrodynamic Load Analysis and Experimental Study of Grouting Clamp under Wave and Ocean Current

Abstract

:1. Introduction

1.1. Current Status of Clamp Research

1.2. Research Status of Water Wave Theory

2. Hydrodynamic Load Analysis and Calculation of Clamp

2.1. Linear Wave Motion Characteristics

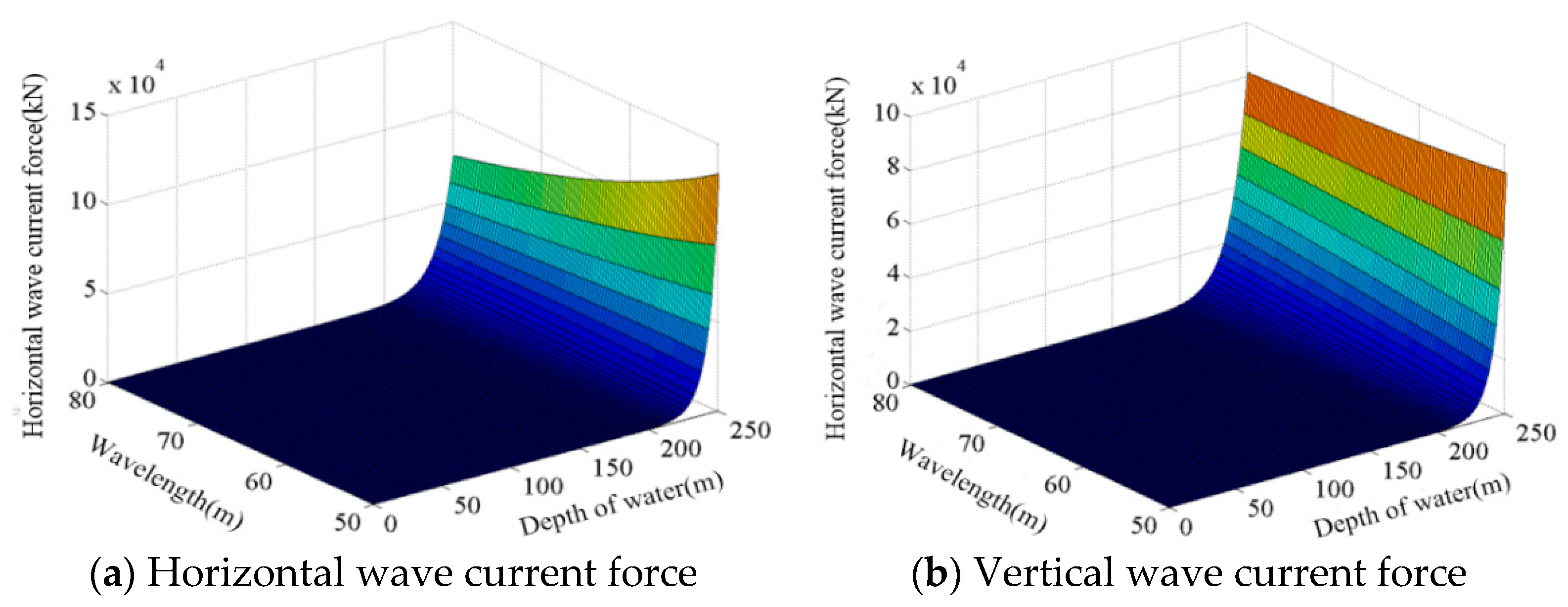

2.2. The Stress on the Hoop under the Joint Action of Wave and Current

2.2.1. Grouting Clamp on Vertical Steel Pipe

2.2.2. Grouting Clamp on Horizontal Steel Pipe (The Direction of Wave Flow Is the Radial Direction of Clamp)

3. Experimental Data Analysis of Mechanical Grouting Clamp

3.1. Experimental Method of Mechanical Grouting Clamp

3.1.1. Equipment Composition

3.1.2. Calculation of Wedge Tooth under the Slippage Force

3.2. Experimental Analysis of Wedge Tooth

3.3. Experimental Analysis of Mechanical Grouting Clamp

3.4. Experimental Analysis of Slipping Force of Mechanical Grouting Clamp

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ismail, Z.; Kong, K.K.; Othman, S.Z.; Law, K.H.; Khoo, S.Y.; Ong, G.C.; Shirazi, S.M. Evaluating accidents in the offshore drilling of petroleum. Measurement 2014, 51, 18–33. [Google Scholar] [CrossRef]

- Ding, Y.H.; Fu, Y.S.; Yang, J.X.; Qian, X.X. Finite element analysis of grouting prestressed lining structure of shield water conveyance tunnel. Water Resour. Hydropower Technol. 2018, 49, 103–108. [Google Scholar] [CrossRef]

- Zhao, B.J.; Zhu, H.W.; Tang, D.Y.; Zhang, J.Y.; Long, B. Repair technology for fixtures of subsea oil and gas pipelines. Ocean Eng. 2013, 31, 95–100. [Google Scholar] [CrossRef]

- Djukic, L.P.; Sum, W.S.; Leong, K.H.; Hillier, W.D.; Eccleshall, T.W.; Leong, A.Y.L. Development of a fibre reinforced polymer composite clamp for metallic pipeline repairs. Mater. Des. 2015, 70, 68–80. [Google Scholar] [CrossRef]

- Sum, W.S.; Leong, K.H.; Djukic, L.P.; Nguyen, T.K.T.; Leong, A.Y.L.; Falzon, P.J. Design, testing and field deployment of a composite clamp for pipeline repairs. Plast. Rubber Compos. 2016, 45, 81–94. [Google Scholar] [CrossRef] [Green Version]

- Gunnar, S.; Atle, J. Design recommendations for grouted pile sleeve connections. Mar. Struct. 2018, 60, 1–14. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, C.H.; Zhao, Q.; Wang, X.; Yuan, G.K.; Liu, J.C. Finite Element Analysis of the Bending Performance of the Offshore Fan Foundation Grouting Joint. Struct. Eng. 2019, 35, 93–100. (In Chinese) [Google Scholar] [CrossRef]

- Gun, S.F.; Shen, X.W.; Li, F.; Wang, Q.Z.; Wei, Z.Z. Study on technique of grouted clamp for offshore platforms. Ocean Eng. 2001, 19, 32–37. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, R.G.; Zhang, Y.; Yan, G.H. Design of grouting clamps and grouting material selection and tests on jacket maintenance in hectometer water depth. Chin. Offshore Oil Gas 2016, 28, 128–132. [Google Scholar] [CrossRef]

- Shi, X.; Chen, J.R.; Yin, C.D.; Zhang, Y. Research on design of hoisting and installing grouted clamp for element pipe. Ocean Eng. 2019, 37, 127–133. [Google Scholar] [CrossRef]

- Boo, S.Y. Linear and nonlinear irregular waves and forces in a numerical wave tank. Ocean Eng. 2002, 29, 475–493. [Google Scholar] [CrossRef]

- Contento, G.; Lupieri, G. Numerical simulations of 2-D steady and unsteady breaking waves. Ocean Eng. 2015, 106, 298–316. [Google Scholar] [CrossRef]

- Robin, M.C.; Samuel, W.; Wheeler, M.H. Existence and qualitative theory for stratified solitary water waves. Anal. Non Lineaire 2018, 35, 517–576. [Google Scholar] [CrossRef] [Green Version]

- Bolduc, Q.A.; Gauthier, P.A.; Berry, A. Auralization of vibroacoustic models in engineering using Wave Field Synthesis: Application to plates and transmission loss. J. Sound Vib. 2017, 410, 64–86. [Google Scholar] [CrossRef]

- Grum, J. Book Review: Modern Tribology Handbook, Volume One: Principles of Tribology and Volume Two: Materials, Coatings, and Industrial Applications edited by Bharat Bhushan. Int. J. Microstruct. Mater. Prop. 2009, 4, 388. [Google Scholar] [CrossRef]

- Gawne, D.T. Tribology: Principles and Applications in Surface Finishing. Int. J. Surf. Eng. Coat. 2017, 3, 152–158. [Google Scholar] [CrossRef]

- You, J.M.; Chen, T.N. Statistical model of static friction coefficient of joint surface. Vib. Impact 2010, 12, 26–29. [Google Scholar] [CrossRef]

- Huang, D.W.; Wu, F.; Zhong, W.S.; Zhang, H.W. Numerical simulation of shallow water wave breaking based on displacement method. In Proceedings of the 30th Ntional Hydrodynamics Symposium and 15th National Hydrodynamics Symposium at Hefei University of Technology, Hefei, China, 16 August 2019; pp. 607–613. [Google Scholar]

- Ma, R.; Li, G.X. Spectral analysis of second-order Stokes waves. J. Fluid Mech. 1979, 94, 129–161. [Google Scholar] [CrossRef]

- Chen, X.B.; Li, J.; Chen, J.Y. Nonlinear wave load calculation of offshore fan based on current function theory. J. Hunan Univ. (Nat. Sci. Ed.) 2011, 38, 22–28. [Google Scholar]

- Tian, X.H.; Liu, S.X.; Li, J.X.; Yang, Z.W. Wave generation based on second-order theory in laboratory flume. J. Waterw. Harb. 2016, 37, 109–144. (In Chinese) [Google Scholar] [CrossRef]

- Wang, K.; Wang, Z.; Wang, Y.J. Load Analysis and Experimental Research of Grouting Clamp under the Ocean. J. Jilin Inst. Chem. Tech. 2019, 36, 25–32. [Google Scholar] [CrossRef]

- Bing, C.; Lin, L.; Greated, C.A.; Kang, H.G. Investigation of wave forces on partially submerged horizontal cylinders by numerical simulation. Ocean Eng. 2015, 107, 23–31. [Google Scholar] [CrossRef]

- Shi, X.; Ma, Y.; Zho, L.; Zhang, C.J. Testing of actual size expansion self-stressing grouting clamp bearing performance. Ocean Eng. 2018, 36, 122–127. [Google Scholar] [CrossRef]

- Jiao, G.X.; Zhou, L.; Shi, X.; Fang, K. Bearing Performance Test of Large-scale Model of Expandable Self-stressed Grouting Clamp. J. Ocean Univ. China (Nat. Sci. Ed.) 2017, 47, 111–118. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, H.H.; Li, C.; Wang, S.Q.; Xu, H. Experimental study on sliding bearing capacity of short bolt type self-stressed grouting clamp. Ocean Eng. 2015, 33, 113–117. [Google Scholar] [CrossRef]

- Dallyn, P.; El-Hamalawi, A.; Palmeri, A.; Knight, R. Experimental testing of grouted connections for offshore substructures: A critical review. Structures 2015, 3, 90–108. [Google Scholar] [CrossRef] [Green Version]

- Kogut, L.; Etsion, I. Elastic-plastic contact analysis of a sphere and a rigid flat. J. Appl. Mech. Sep. 2002, 69, 657–662. [Google Scholar] [CrossRef] [Green Version]

- Dallyn, P.; El-Hamalawi, A.; Palmeri, A.; Knight, R. Experimental investigation on the development of wear in grouted connections for offshore wind turbine generators. Eng. Struct. 2016, 113, 89–102. [Google Scholar] [CrossRef] [Green Version]

- Ziavos, N.I.; Hemida, H.; Dirar, S.; Papaelias, M.; Metje, N.; Baniotopoulos, C. 2020. Structural health monitoring of grouted connections for offshore wind turbines by means of acoustic emission: An experimental study. Renew. Energy 2020, 147, 130–140. [Google Scholar] [CrossRef]

- Tziavos, N.I.; Hemida, H.; Metje, N.; Baniotopoulos, C. Non-linear finite element analysis of grouted connections for offshore monopile wind turbines. Ocean Eng. 2019, 171, 633–645. [Google Scholar] [CrossRef] [Green Version]

- Lamport, W.B.; Jirsa, J.O.; Yura, J.A. Strength and behavior of grouted pile-to-sleeve connections. J. Struct. Eng. 1991, 117, 2477–2498. [Google Scholar] [CrossRef]

| Recurrence Period (year) | Average Wave Height h (m) | Wave Period T (s) | Wavelength L (m) | Wave Velocity (m/s) |

|---|---|---|---|---|

| 50 | 2.83 | 7.76 | 74.1 | 9.55 |

| Transverse loading force (kN) | 5 | 10 | 15 |

| Maximum longitudinal loading force (kN) | 6.5 | 11.4 | 16.8 |

| Spanner torque (N∙m) | 11 | 13 | 15 |

| Pre tightening force of single bolt (N∙m) | 4583.3 | 5416.7 | 6250 |

| Total preload (N) | 73,333.3 | 86,666.7 | 100,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Shang, Z.-q.; Wang, T.; Wang, Z. Hydrodynamic Load Analysis and Experimental Study of Grouting Clamp under Wave and Ocean Current. J. Mar. Sci. Eng. 2020, 8, 512. https://doi.org/10.3390/jmse8070512

Zhang B, Shang Z-q, Wang T, Wang Z. Hydrodynamic Load Analysis and Experimental Study of Grouting Clamp under Wave and Ocean Current. Journal of Marine Science and Engineering. 2020; 8(7):512. https://doi.org/10.3390/jmse8070512

Chicago/Turabian StyleZhang, Bo, Zhi-quan Shang, Tao Wang, and Zhuo Wang. 2020. "Hydrodynamic Load Analysis and Experimental Study of Grouting Clamp under Wave and Ocean Current" Journal of Marine Science and Engineering 8, no. 7: 512. https://doi.org/10.3390/jmse8070512

APA StyleZhang, B., Shang, Z.-q., Wang, T., & Wang, Z. (2020). Hydrodynamic Load Analysis and Experimental Study of Grouting Clamp under Wave and Ocean Current. Journal of Marine Science and Engineering, 8(7), 512. https://doi.org/10.3390/jmse8070512