1. Introduction

Natural gas is usually used worldwide for various purposes, such as electricity generation, domestic utilization, fertilizer production, chemical manufacturing plants, laboratory-based reactions, brick-manufacturing industry, etc. Many countries are using natural gas as fuel for chemical and petrochemical industries along with transport [

1]. Mainly methane is the major component of natural gas, while tiny quantities like ethane, propane, and Butane gases also exist [

2]. Natural gas has been reported as a clean and environmentally friendly fuel along with a high-efficiency rate [

3]. In the present era, the use of natural gas is increasing day by day in several sectors, specifically in power generation, which might be due to its cost-effectiveness and environmentally-friendly behavior compared to other regular fuels [

4,

5].

According to recent studies, natural gas consumption has been increased by 8% than that of prior. Due to increased natural gas use, the storage and maintenance of pipelines and their related systems have gotten greater importance for the concerning authorities [

6]. Gas leaks due to pipeline damage or poor management practices result in fire and explosions, which badly affect any country’s economy regarding property loss, serious health problems, casualties in site workers, and significant environmental degradation [

7]. Chemically, natural gas is very reactive due to its high oxidizing ability and halogen compounds, making it highly flammable when combined with air and ignition compounds [

8]. Usually, natural gas is brought out through pipes from oil wells to tanks and export terminals. It is either transferred in the form of natural gaseous (NG) or LNG Gas-carrying pipelines that are commonly passed through the cities and towns surrounding by the dense population [

9]. To manage pipeline damage and gas leakage factors professionally to protect any unpleasant incident is the hot burning topic for the researchers [

10,

11]. The previous researchers have used several strategies to minimize and/or mitigate the risk associated with the failure of the Gas supply and management system, but less research has been conducted on the Quantitative risk management approach (QRM). The present study was aimed to sight in-depth the QRM strategy to effectively manage the risk-causing factors related to the failure of the gas supply system [

7,

12].

Quantitative Risk Management (QRM) is an essential risk management program for the natural gas supply system and enhances safety performance [

13]. The procedure is critical in determining the cause-effect relationships between hazards and the operations [

14]. It can be both pro-active with some managerial procedures lowering the likelihood of an event occurring, and reactive with immediate response by the management procedures after an event has occurred to limit detrimental effect [

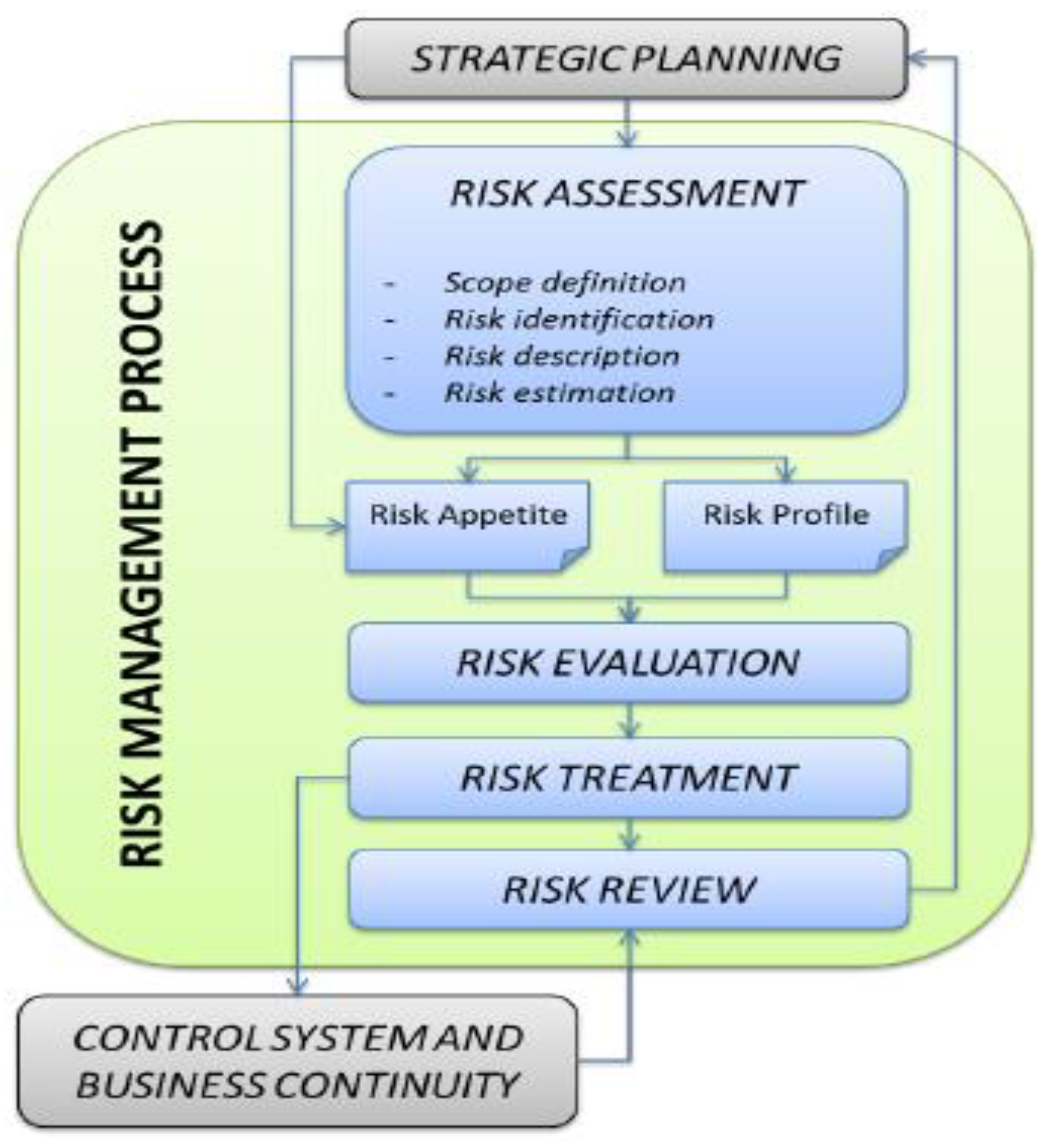

15]. Risks alter in frequency and severity with time, necessitating ongoing risk monitoring activities to be implemented. The management of risk includes the entire process of recognizing, regulating, and mitigating the consequences of unpredictably occurring or unpredictable events [

16]. According to Westney [

17], the risk management process is divided into four distinct phases: risk identification, risk evaluation, risk analysis, and risk mitigation. Risk identification is the first of these phases, where the risks that could influence the project’s goals are recognized as their characteristics [

11]. During the risk assessment step, it is established what the consequences of the identified risks will have. When it comes to the risk analysis phase, the risk is examined by assessing the likelihood of an event occurring and the consequences of the event occurring if it does [

12]. The final phase is the risk mitigation phase, which begins with a review of the risk analysis results to determine which hazards should be addressed first in order of importance [

18]. On the other hand, the majority of risk management researchers have concentrated on the risk identification and analysis phases [

19].

Natural gas pipeline accidents occurred due to corrosion, mechanical failure, excavation damage, natural hazards, and other unknown factors [

20]. It is thus imperative that a risk assessment must be carried out before the construction of natural gas pipelines. Risk assessment studies for the oil and gas installation designers are becoming common day by day, and even a few counties have made it a basic requirement for the oil and gas sectors [

21]. Quantitative risk evaluation is particularly significant for risk management and is used to evaluate the danger of natural gas transported by urban pipelines and enhance safety standards [

22]. The safety system in several industries has been significantly improved by using the QRM approach, but a wide research gap is still present in the oil and gas sector, which needs to be filled [

23]. The possible scenarios in the hazardous identifying stage are to identify acute dangers in terms of poisonous steam and flammable material leakage leading to various kinds of fire and exploitation. Risk assessment is the hazard identification, analysis, and control measure aimed to reduce or manage risk efficiently [

24]. Comprehensive research on risk allocation and management incorporates quantitative risk analysis for a developing plant. In each phase of the risk assessment process, several techniques are being used [

5,

12]. The present descriptive study was aimed to answer the following research questions;

What are the major risk-causing factors involved in the failure of the gas pipeline?

How the risks associated with the failure of gas pipelines can be quantified and managed in project planning?

How the Quantitative Risk Management technique can help to allocate and manage the pipeline failure associated risks?

2. Materials and Methods

The risk assessment procedure is based mostly on the chance of the detected risk occurring, and its potential risk implications are specifically analyzed through hypothetical scenarios of accidents [

2]. Concerning the proposed project, a risk matrix designed to integrate risk severity and probability factors has been used to primary hazards such as jet fire resulting from natural gas pipelines failure [

25]. The risk connected with the natural gas distribution network was semi-quantitatively evaluated by employing order of the magnitude data as a product of probability and seriousness/consequence (risk rate = severity/consequence factor × probability factor) [

25]. The significance of these project hazards was determined through categorization as high, medium, low, and very low based on the risk assessment [

26].

The Risk Matrix is a generally established and z tool for quantitative risk assessment (QRA). In light of its limitations, a risk event definition with certitude is favored over solely quantitative techniques. The use of this tool led to the priority of possible risk events as a consequence of a project pipeline failure, therefore laying the foundation for the development of risk mitigation measures and the construction of risk and emergency management strategies.

Figure 1 sums up the whole method for the assessment of risk as mentioned in previous studies [

9].

2.1. Hazard Identification

For this QRA, hazard identification includes a qualitative examination of the design and operations of the projects, including relevant HEGPL information. The work processes for the pipeline NATURAL GAS pipeline were studied for literature about global pipeline risk assessment, pipeline routes NATURAL GAS pipeline work processes were studied for literature pertaining to global pipeline risk assessment, pipeline routes, and configuration [

23]. From authentic, secondary sources of the upstream business such as OSHA, UNEP, API, OGP, and EGIF, information (including historical data) relates to prospective dangers linked with the transportation of hydrocarbons pipelines [

27].

Based on the results, possible hazards were detected, and qualitative knowledge of their probability and importance was gained due to the pipeline transportation of natural gas. It should be emphasized that many of these possible risks may be caused by natural disasters, such as earthquakes, floods, and similar causes of these dangers are likely to occur [

28].

Given the relevance of various risks in the context of operations of pipelines and tanks, the following risks were related to the proposed project detailed in the following sections.

2.2. Frequency Analysis

To assess the probability throughout the project life cycle, frequency analyses of the risks highlighted concerning the proposed project have been done. Risk frequencies were assessed based on the study of historical accident frequency data and professionally evaluated in respect to the proposed project [

29]. The following frequency categories and criteria were created based on the range of possibilities for distinct possible dangers during pipeline operations related to the proposed project (

Table 1).

2.3. Consequence Analysis

In addition, to evaluate the probable effects, on the staff, infrastructure, and the environment, of project-related hazards, risk prediction and effect analysis was conducted in conjunction with the frequency analysis. The evaluation of the impact on each potential occurrence was based, where applicable, on accident frequency, impact modeling, or expert judgment, in connection to the proposed project [

30]. In general, the impact analysis takes the following things into account:

Environmental and community affect nature;

Occupational safety and health;

Asset and property damage;

Business picture—Environmental and property damage recovery timeline;

Environmental and property damage restoration costs.

In the context of the impact of the risk occurrences during the operation of the natural gas pipeline, the next criteria for the impact rating (

Table 2) were established [

31]:

2.4. Risk Evaluation

Each detected risk was assessed in the light of its probability of occurrence and its degree of effects based on the ranking of probability and frequency. The relevance of this risk is stated as the product of probability and as the result of the risk event:

Table 3 shows all conceivable product outcomes for the five categories of probability and consequences, while

Table 4 sets risk meaning criteria in three areas that determine risk tolerance limits. Danger-prone activities were classed as low, medium, and high, thereby qualifying for a set of risk reduction/mitigation strategies depending on the intersecting location of a column with a row in the risk matrix [

32].

3. Results

3.1. Risk Assessment of Identified Project Hazards

As previously mentioned in the preceding section, two main risk categories have been identified concerning the planned natural gas pipeline system. To determine their importance regarding the severity and the chance of occurrence, detailed risk assessment research was carried out for these dangers [

33]. In the following sections, the specifics of the risk assessment study are summarized:

3.2. Pipeline Failure Causes

Due to the examination of the Data Group of the European Gas Pipeline Incident Database, pipeline failure causes and frequencies were examined for the planned pipeline project (EGIG). The EGIG is a partnership of 15 major gas transmission networks in Europe to provide a comprehensive foundation for the safety assessment of pipeline systems so that the frequency and probability of events are better understood [

34]. The 8th EGIG report showed 1249 nitrogen events between 1970 and 2010 and documented 76 nitrogen events within the past 3 years (2007–2010).

Figure 2 below shows the number of pipeline failure occurrences each year from 1970 to 2010 [

35].

Under the following scenarios, pipeline failure resulting in hydrogens leakage may occur

Internal corrosion;

External corrosion from protective system deficiencies, under-road traffic jams, and railways;

External interference due to construction equipment, non-authorized excavations, lack of soil marks;

Structural failure/mechanical problems;

Natural risks, such as seismic occurrences, slides, floods, etc.;

Structural failures.

Other possible causes of accidents in the pipeline may include external interference and construction faults at valve and pumping stations, which were explored in more depth in this study. Accidents from pipes are characterized as leaks or fractures based on the above-mentioned parameters. For the planned pipeline project, similar failures were anticipated.

3.3. Pipeline Failure Potential Hazards

Gas combustible at concentrations between 5 and 15 percent when combined in the air (volume basis). The feature of the fire is similar to other hydrocarbon light fuels. Due to the difference in density between methane and air, natural gas boosts under ambient circumstances. Leakage or rupture of a pipeline might lead to different risks of fire, depending on instantaneous or delayed igniting. The IGEM/TD/21 (Gas Engineers and Managers Institutions) norm acknowledges that after discharge of a natural gas pipeline that ignites potential fire risks, the following [

36].

3.4. Ignition of a Leak (Immediate or Delayed) to Give a Jet Fire

In the event of leaks from the entered pipes, the transient flow from the overlying soil will be channeled via the voids. The ground will be thrown over the pipeline when the leak is significant enough [

37]. The jet will cause air to travel up and scatter based on the current wind direction and other weather variables. Gas levels up to their lower flammability limit (LFL) are dangerous since they may catch fire if the ignition source is available [

38]. The complete release time and impact/effect depend on the release’s speed, and the sectionalization valve separates the pipe segment. A jet fire may develop when the substance finds an igniting source within its flammable range. The velocity of the material emitted from the pipeline usually leads to vertically directed flames. Such flames are less hazardous than horizontal flames [

39].

3.5. Immediate Ignition of a Rupture to give a Fireball & Crater Fire

There will be fast depressurization in the area of the failure after a rupture or significant puncture. The surrounding ground is expelled for the underground pipes, like in this example, by forming a crater of dimensions and shapes that impact the comfortability of the released gas [

40]. A very turbulent mushroom-size casket is generated at the beginning of releases, which is fed by the gas jet and the air from the pen that follows in height above the release point owing to the source momentum and flourish. The discharge may also result in the injection into the cap and feather of expelled dirt. Eventually, the cap is dispersed because of increasing workouts, and the feather remains almost stable [

41].

A fireball will nearly instantaneously turn on when the huge quasi-instantaneous discharge of combustible gas is under pressure. The cloud must be lit before time is needed for the fireball to occur, such that an inflammation source must be near the release site at the moment of discharge. The energy released by the breakup of the pipeline generates a crater surrounding the place of breakage. From every end of the burst pipeline, gas pours into the hole. Once the fireball is dispersed, it is burned like fire (or trench). Crater fire usually develops when rupture gas ignition is delayed. However, the analysis of historical figures reveals that the concentration of gas in generated vapor clouds will, typically below, and there is a relatively little likelihood of vapor cloud fires. The cloud ignition is anticipated to take place below the 2.2 vol. percent lower flammability limit (LFL) [

42]. The cloud does not spread across the cloud if it is lit and only leads to localized ignition bags, making any possible source of burns improbable.

Furthermore, a very light gas with a molecular weight lower than the air and a low ignition probability (2 percent–4 percent) in gas pipe failure, as reported by EGIG, is likely to ignite natural gas. There is also space around the pipeline, and no place inside it can be restricted to the discharged gas (Refer Hazardous Chemical Databook, G Weiss, Noyes Data Corporation). In light of the debate above, the incidence of fireball is distant, so qualitative analysis is not regarded.

3.6. Pipeline Failure Frequency Analysis

There has also been an attempt to identify the principal failure frequencies of the natural gas pipeline resulting from the number of occurrences in a period separated by the total system exposure. The development of the major failure frequencies during the period of the last five years was shown in

Table 5 below based on the EGIG database.

As seen in the table above, the prime failure frequency (0.16) for the year 2006–2010 was almost half the number of failures reported for the whole period 1970–2010 (0.351). In addition, the total failure rate between 1970 and 2010 (0.11) was calculated to be somewhat below the stated failure rate of 0.372 for the 1970–2007 period.

Figure 3 shows the development of Primary Failure Frequencies for the whole period, covering the five years from 1970 to 2010.

The data in

Figure 3 shows a consistent decline in the main failure frequencies and failure frequencies in an average of 5 years. The main failure frequency in the whole time decreased from a rate of 0.87 per thousand km in 1970 to 0.35 per thousand km in 2010. The average moving primary failure rate fell by a factor of 6 over five years (0.86 to 0.16 per 1000 km year). Data from the UK Onshore Operators Association (UKOPA) reveal a similar rise, with unintentional release frequencies over a 25-folder period from 2002 to 2006 (0.028 vs. 0.706 per 1000 km of pipe each year), which is more than the same frequency during the years 1967 to 1971).

3.7. Pipeline Failure Frequency Analysis Incident Causes

Incidents involving natural gas pipeline failures, such as external interference, building problems, internal and exterior corrosion, soil movement, and hot tap, may be linked to the following important factors as stated in previous literature.

Figure 4 below shows the distribution of events with the reason [

43].

External interference was the main cause of pipeline failure in interpreting the above data, which contributed to around 48.4% of total construction fault incidence (16.7%) and corrosion-related difficulties (16.1 percent). Due to seismic disruptions, landslides, floods, etc., ground motion contributed only to 7.4% of the incidence caused by pipeline breakdown. The key frequencies for failures by reason were shown in

Figure 5 below for 1970–2010.

The reduction in the failure frequency of the years, mostly owing to technical improvements, is shown in

Figure 5. Sweating, inspection, in-line monitoring of conditions, and enhanced damage prevention and detection methods. Regarding the source of external interference, its linked main failure frequency declined to 0.17 per 1000 km per year between 1970 and 2010, while the 5-year moving average has been reduced to roughly 0.10 per 1 thousand kilometers per year since 1997. However, the predominant cause of pipeline failure continues to be external interference to this day, with over 50% of all instances ascribed to the former throughout the period 2006–2010.

The frequency of the pipeline breakdown. Due to interpretation of the European Gas Pipeline Incidence Database (EGIG) which represents about 2 million km of pipeline operations a year, the leaks or rupture of a proposed pipeline project are developed. EGIG has recorded a 4.76 × 10−4 km/year failure rate for the onshore gas tube with design pressure over 15 bar. Full boron rupture (FBR) accounts for 13 percent (6188 × 10−5 km/year) of instances with leaks (4.14 × 10−4 failures/km/year) representing 87 percent of them.

Based on the table and the categories of frequencies defined above (refer to

Table 5), it could therefore be concluded that HEGPL will likely take advantage of the failure frequency (leaks and/or breaks) for the proposed natural gas pipeline project not to address potential pipeline risks/hazards, e.g., jet fires.

An impressed current cathodic protection and appropriate outside coating should safeguard the pipeline from external corrosion;

Corrosion coupons and corrosion sensing samples will be given for internal and exterior corrosion monitoring as needed;

SCADA and leak detection system provision.

3.8. Pipeline Failure Frequency Analysis Damage Type

As noted above, pipeline failure potential dangers generally originate from pinhole cracks, troughs, and/or rupture induced by external disturbances, structural faults, corrosion, etc. As it has been established that an outside disturbance is one of the main reasons for pipeline incidents (EGIG database), the same has been considered when analyzing the frequency of failures regarding the type of damage and the pipeline’s diameter.

Figure 6 below shows the frequency of pipeline failure in response to outside interference, damage type, and diameter class [

44].

The graphic above shows that smaller-diameter pipelines are more vulnerable to external disturbances in comparison with bigger pipes. The thinner wall thickness of smaller-diameter pipes also adds to the higher frequency of failure for such pipes. Accordingly, based on the above facts, the failure frequency of the 30″ dia planned pipeline project is projected to below.

3.9. Pipeline Failure Ignition Probability

Fortunately, not all gas releases are ignited, and the effects of events are significantly limited. In the 1970–2010 timeframe, only 4.5% of the emissions of gas classified as events were ignited by the EGIG database. The presence of random ignition sources is a function of Ignition. In the EGIG data set, the relation between inflammation and leak size may be assessed. In

Table 6 and

Table 7, the leakage probability for gas pipelines is shown.

The following table illustrates that the chance of ignition of an incident of gas pipeline failure (pine hole cracks and holes), depending on the kind of leakage, is minimal.

Concerning the proposal, the chance of pipeline failure (rupture and leaks) is determined from the following equations following IGEM/TD/2 standard.

where

Pign = Probability of ignition,

P = Pipeline operating pressure (bar),

d = Pipeline diameter (m).

3.10. Pipeline Failure Consequence Analysis

Pipeline usually carries a significant inventory of high-pressure oil or gas; although distant accidentals are released, they are likely to have catastrophic or serious implications if the dangers associated with them are not well studied or managed. The consequences of potential failure of the pipelines are usually predicted in terms of the hypothesis and parameters such as weather conditions (stability class), the size and orientation of the leak hole and rupture, the pressure and temperature of a pipeline, the physicochemical properties of the released chemicals [

45].

As described previously, jet fire has been recognized and depends on the ignition time as the probable effect of the breakdown of the natural gas pipeline. Jet fires are usually gas jets, or atomization sprays discharged by high-pressure equipment. This may damage the fire apparatus at some distance and may cause death to staff and neighboring residents. Flammable gas clouds discharged under high pressure may occur as a result of a breach in the pipeline after the immediate ignition. However, the event is regarded distant as mentioned above and is not taken into account as part of this exercise.

The following hypothesis risk scenarios (

Table 8) have been examined in view of the pipeline failure effects and the frequency analysis which is used for modeling the proposed Pipeline Project:

The above-mentioned danger scenarios are modeled on ALOHA2 and evaluated in terms of the level of concern of the thermal radiation (LOC). The modeling of the danger of pipelines using ALOHA has been regarded to take predominant local weather conditions as outlined in the baseline chapter. The primary component of natural gas is methane, as shown in the modeling of the hazards presented by the planned pipeline breakdown. The level of concern for thermal radiation (LOC) is the threshold of thermal radiation, generally over which danger might occur. ALOHA calculates a threatening area for each LOC selected, in which thermal radiation is projected to surpass that LOC at some point after the release starts. These areas are shown as red, orange, and yellow, with red being the most dangerous on a single Threat Zone map. The danger zone provided by ALOHA is a thermal level that also shows the consequences of thermal radiation on those exposed to the thermal level but who may take cover within one minute. To establish the default danger areas, ALOHA employs three (kilowatt per m2) threshold values:

Case I: Natural gas discharge and ignition of 30″ (0.5″) pipeline leakage hole size.

The fire hazard zone layout for release and igniting of pipeline natural gas—0.5 inches in diameter—is as follows: Pipeline leakage.

3.11. Zone Threat

Modeling the threat: Pool fire thermal radiation

Red: <10 m—(60 s) (10.0 kW/sq m) = possibly deadly).

Orange: —(5.0 kW/(sq m) Equals second-degree burns of 60 s) Orange:

Yellow: <10 m = (2.0 kW/(m2) = 60 s for discomfort)

At a maximum radial distance < 10 m from the source with possible deadly consequences within one minute, there will be the biggest risk to release and light up natural gas from pipeline leakage (hole size—0.5″ dia)

Case II: Natural gas discharge and ignite from 30″ diaphragm leak pipeline size (1″ dia).

Figure 7 and

Figure 8 below illustrates the Jet Fire Threat Area Paragraph for the discharge and ignition of the natural gas from a size leak—diameter 1.0 inch.

3.12. Zone Threat

Modeling the threat: Pool fire thermal radiation

Red: <10 m—(60 s) (10.0 kW/sq m) = possibly deadly).

Orange: —(5.0 kW/(sq m) Equals second-degree burns of 60 s) Orange:

Yellow: 11—(2.0 kW/(sq m) Equals 60 s of agony)

The biggest risk for releasing and igniting pipeline leakage natural gas (hole size−1″ dia) occurs within 1 min at a radial radius <10 m to the source with potentially deadly consequences.

Case III: 30″ dia pipeline breakage discharge and ignition of natural gas.

Figure 8 shows the Jet fire hazard zone map for the discharge/inflammation of natural gas from 30″ dia pipe breakage.

Threat zone:

Modeling the threat: Pool fire thermal radiation

Red: 369 m—(10.0 kW/(sq m) = lifetime within 60 s)

Orange: 514 m—(5.0 kW/(m2) = burns of 2 degrees in 60 s)

Yellow: 793 m—(2.0 kW/(m2) = 60 s pain) Yellow:

With a maximum radial radius of 369 m from the source with probable deadly consequences within one minute, the greatest risk of releasing and igniting natural gas from a 30-inch pipeline rupture may be encountered.

3.13. Disaster Management Plan

Objective

To avoid or reduce significant incidents that might come from probable failures of the pipeline, a DMP’s main purpose is to ensure a safe, effective and coordinated response by the ERT (Instrumental Emergency Response Team), together with other local and government agencies/departments.

Reducing the danger to human life, environment, and common property resources via an efficient and effective intervention;

Environmental protection;

Public safety protection;

Early and efficient reaction in the whole use of available resources.

Purpose

The DMP aims at managing and controlling crises throughout project operations successfully.

This DMP guarantees an efficient and appropriate emergency response team;

Defined roles and responsibilities of essential support and staff;

Availability and sufficiency of emergency infrastructure and resources.

3.13.1. HEGPL Emergency/Crisis Management Team

In the context of fire, accidents, and technical problems, the Pipeline division of HEGPL will build an emergency/crisis management team. The team consists of the operational staff who may be summoned 24 h a day, backed as necessary by senior management. The function and duties of several Pipelines Division Emergency Coordinators are detailed below.

3.13.2. Chief Incident Controller (CIC)

The Chief Incident Controller (CIC) is responsible, overall and before, during and after an emergency or a public tragedy, for safeguarding staff, site and public. The CIC is present in the Headquarters (Mumbai). The Chief Incident Controller’s responsibilities must include:

- (a)

ERDMP review and upgrading, as and when required;

- (b)

Evaluation of situation and emergency declaration;

- (c)

Activation of the Centre for Emergency Control;

- (d)

Taking decisions to seek assistance for mutual aid members and other outside agencies, such as the Police, Fire Brigade, Hospitals, etc.;

- (e)

Direct Site Incident Controller (SIC) to take necessary measures and deputize the situation with crisis coordinators.

3.13.3. Site Incident Coordinator (SIC)

The site incident controller (SIC) should report the incident to the Chief Controller. The SIC is accessible for consultation and general direction at the primary emergency control center. In each shift 12 h, SIC is to be nominated by the entity. The SIC’s responsibilities must include:

- (a)

The SIC shall maintain a workable Emergency Control Planning Program, shall organize and train ERDMP organizations;

- (b)

The SIC shall be able to make prompt decisions and take full responsibility;

- (c)

The SIC shall communicate between the various groups from the Emergency Control Centre to coordinate activities between groups;

- (d)

The SIC must furthermore, when expert help is necessary for the purposes mentioned above, coordinate it;

- (e)

Or the SIC shall, in collaboration with CIC, decide to request help from the members of mutual assistance and from other authorities such as the Police, the Fire brigade, hospitals, etc.

3.13.4. Crisis Coordinators

Administration and Communication Coordinator.

The administrative responsibilities of the communication supervisor include

- (a)

coordinating with the members of reciprocal aid and other external agencies;

- (b)

directing them to the desired locations at the arrival of external agencies;

- (c)

activating the medical center, and providing the injured with first-aid services;

- (d)

arrange ambulance and coordination with hospitals for prompt care for the victim;

- (e)

ensure headcounts in assembly points;

- (f)

arrange for the provision of sparse firefighting proceedings for additional medication and pharmaceuticals;

- (g)

mobilize transport to various teams to facilitate response measures;

- (h)

to give different teams administrative and logistical help;

- (i)

and to plan for evacuation, in collaboration with civil authorities, such as Police, municipal authority, panchayat [

46].

3.13.5. Fire Safety Coordinator and Fire Team

The fire and security coordinator’s responsibilities must include:

- (a)

Activating emergency sirens as required by the practices codes;

- (b)

Taking over all firefighting, rescue operations, and security issues;

- (c)

Ensuring the appointment and release of key staff of firefighting operations crews as per emergency procedures;

- (d)

Assessing their team’s function and communicating for refilling or redeploying by SIC and/or administrative controllers;

- (e)

Direct the fire bridge personnel and the mutual aid members to the roles they want as well as the appropriate positioning of their staff and equipment;

- (f)

Determine a reciprocal aid need and instruct a fire station, which in turn contacts each other with mutual aid members.

3.13.6. Search Party Leader

Depending on the scenario, the search party leader will:

- (a)

The scenario with telecom devices and staff indicated will immediately be rushed into the crisis.

- (b)

Ensure that the upstream and downstream leak-containing valves are closed once the location is located.

- (c)

Assess the situation and provide the SIC with input on additional support/mobilization.

- (d)

Indicate local supplies of water for combat.

- (e)

Ensure safety on-site by putting chowkidar, patrol officer, local or home police.

- (f)

Move work and, if required, erect barrier dams to prevent oil spills.

3.14. Emergency Classification

As described in the QRA research, the severity of possible emergencies arising from accidents in the pipeline is given due attention. Not all emergency situations demand the mobilization of the same resources or emergencies. Emergency situations demand the mobilization of the same resources or emergencies [

47]. The HEGPL Emergency/Crisis Management Team effectively implements the appropriate emergency response procedures, and emergencies are divided into three levels, dependent on their severity and potential impact. In the ensuring Sectons, the emergency levels/tiers determined by virtue of their severity were explored using the emergency categorization ‘decision tree’.

3.14.1. Level 1 Emergency

Can be handled successfully and securely and confined by available resources within the site, location, and installation;

- (a)

does not influence the site, location, or installation.

3.14.2. Level 2 Emergency

Cannot be managed or contained on the premises or installation by available resources in an emergency or an event that requires additional support;

Has or may not have an effect beyond the premises, location, or installation, and where external support by the partner in the mutual help can be involved;

Is likely to pose a risk to life.

3.14.3. Level 3 Emergency

This is an emergency or event with a catastrophic effect that may harm the people, property, and environment both inside and beyond the facility. The administration of districts is responsible for managing and controlling the facility. Although the emergency level III is within the competence of the district authority before they enter, the emergency management unit should be responsible for it.

Note: Level I and Level II are usually treated as an emergency on-site, and Level III as an emergency off-site. It is deemed off-site in the event of a ROW emergency.

3.15. Emergency Response Measures

3.15.1. Declaration of Emergency

Emergency Level I and Level II—The Chief Incident Controller must proclaim the emergency.

The District Authority must declare an emergency under Level III Emergency.

An emergency begins as a little occurrence that, over time, may become a significant event. The emergency charts must be implemented in the beginning phases. If the situation gets beyond control (inside or in the main station), the emergency plan on-site will be triggered by the chief incident controller at the appropriate level. Security employees will battle the crisis throughout idle shifts and vacations, as per the ERDMP Organization Chart, while also providing advice and management of a scenario to many emergency control professionals. Mainly, the line patrollers and DRG security guards have been deployed to transmit information for emergency management. The ROW residents are also informed about the dangers of the pipeline and who they may notify in an emergency. In the event of an emergency and an evacuation by the controller of the site, the incidence is determined to be essential; the situation is transferred to the regional authorities for the application of the off-site emergency plan. The mainline ROW is also used to deliver an out-of-site emergency plan to the district authority [

48]. The District crisis management group under the leadership of the District Collector/DDMA must now be responsible for emergency management (within or in the mainline). In addition to preparing a site-based emergency plan, it is the legislative obligation of the occupier of all hazardous substances handling industries to provide the district authorities with appropriate information to develop an off-site emergency plan. The fire and emergency reporter should explain where the fire team arrives at the scene should be led. The person should seek to reduce the situation, to extinguish the fire using the surrounding equipment until the fire crew arrives [

8,

31].

3.15.2. Information to Public

To avert panic, it is vital to supply the people with correct information. Some people only want to know what’s going on, while other residents have to know what they can do to protect themselves and others right now. Nevertheless, in less critical circumstances, the newspaper pieces give thorough information for the public to better comprehend gas leaks and their processes. To serve as a speaker, one individual should be identified. It is extremely suggested that the selected person have public information, community, and media expertise. The speaker may identify the persons with expertise in the media and the implications of the incident. This spokesperson should consequently be part of the line of command. Other response team members should be directed to this one individual to address all communication and public relations concerns (Chief Incident Controller).

In case of an emergency, only employees and other linked individuals such as firefighters or safety should be permitted to access the station, and the pumping station should not be permitted to enter the ambulance crew and outside unknown individuals and workers.

The area has to be sealed off in the event of any emergency on the mainline. Smoking should not be permitted to enter the area in this region, and other unauthorized people should be strongly prevented.

General suggestions on what the public should take upon listening to the warning.

There should be no right-of-way consideration (ROW).

If gas leakage occurs on or near ROW The closest police/IOC station will be contacted.

If any gas leak is discovered, then the people must remain away, not light matches, smoke bidi or cigarettes, at a minimum 400 m from the leaking spot should not carry normal torches, lighting should not carry near the point of leaking.

All agricultural operations, tractor usage should leak occur in the fields.

Field irrigation and the pump operation shall be halted until HEGPL staff grant permission.

3.15.3. Termination of Emergency

Emergency termination should start after the procedure has concluded the emergency phase. It should focus on providing the workers, surrounding units, district authorities participating in offshore operations, etc. with correct information.

Levels I and II: After evaluating the circumstances, the Chief Incident Controller announces that the emergency is terminated. The district authorities should proclaim Level-III termination of an emergency by the appropriate information distribution method, to reach everyone.

4. Conclusions

The risk zones estimated using ANOVA for specific heat radiation intensities have been shown in Table below for different hypothetical scenarios evaluated with regard to pipeline leaks and ruptures.

| Case No | Pipeline Failure Leak | Hole Size (inch) | Distance to 10.0 KW/m2 (m) | Distance to 5.0 KW/m2 (m) | Distance to 2.0 KW/m2 (m) |

| I |

30″ pipeline leak

|

0.50

|

<10

|

<10

|

<10

|

| II |

30″ pipeline leak

|

1.00

|

<10

|

<10

|

11

|

| III |

30″ pipeline rupture

|

30

|

369

|

514

|

793

|

Based on these findings, it can be concluded that the risk falls within ALARP and that, while operating and maintaining the Natural Gas Pipeline, appropriate security, and emergency response measures are put in place by HEGPL, any possible risks to that effect can be managed or handled effectively and safely.

Continuous focus on employer and employee safety knowledge is essential to reducing accidents in an organization. The risks at the gas collection station and the accompanying pipeline network are based on the new gas compression and evacuation installations at the collection station and do not cover additional installations surrounding the station. As such, it is impossible to evaluate an overall danger surrounding the facility and the criteria for risk tolerance. A further research study may be conducted to identify the total QRA study and make comparisons to risk factors, including current facilities.