1. Introduction

To cope with the challenges posed by energy depletion and climate change, countries around the world are vigorously turning towards renewable energy. Wind energy, which can be captured by wind turbines, has become one of the most important aspects of renewable energy [

1]. However, the development of onshore wind turbine systems has produced limitations due to the scarcity of land resources, unstable wind speeds, and noise nuisance. This has led to a shift of research focus from shore to offshore wind turbines. The advantages of offshore wind turbines can be found in utilizing high-speed, stable wind resources, and reducing wind shear and physical constraints caused by hills or artificial buildings [

2,

3].

Offshore wind turbines can be divided into two types according to different installation foundations. The first one is the fixed offshore wind turbine. For economic feasibility, it is usually installed at a maximum sea depth of 40–50 m. This, in turn, causes great limitations for countries with small shallow water areas [

4]. The other type is the floating offshore wind turbine (FOWT). Unlike fixed offshore wind turbines, FOWT is based on a floating structure that can keep the entire wind turbine stable at sea. A floating foundation offers the possibility of installing deep-sea wind turbines. The common floating foundations include the Spar, Barge, Tension-Leg Platform (TLP), and a semi-submersible type.

Although FOWTs have great development potential, they also bring about some challenges. Floating platform foundations are more easily excited by wind and wave loads than fixed ones. Consequently, this can lead to increased platform movement and structural fatigue load on turbines. The structural fatigue load increases the likelihood of damage and generator failure. Moreover, it increases maintenance costs. Therefore, to suppress the dynamic load and stabilize generated power [

5,

6,

7], it is particularly important to reduce the movement of the floating platform.

In recent years, the problem of structural load and power fluctuation caused by platform motion has attracted the attention of many researchers. A tuned mass damper (TMD), which is the structural control for the FOWT, has been employed to limit floating platform motion. The TMD design was optimized by adjusting the mass, frequency, and damping relations between the TMD and the FOWT. Furthermore, the TMD can be utilized to absorb the maximum vibration energy and consequently reduce the vibration load. However, the spring and damping characteristics of TMD cannot change with time. This limits the adaptability of TMD to external excitations of various frequencies and forms [

8,

9,

10,

11,

12,

13]. At the same time, the application of TMD increases installation costs with regard to different average wind speed regions. Some researchers also tried to apply the control theory to control the FOWT by constructing a new blade pitch controller and lowering the fluctuation of the platform pitch and power. Larsen and Hanson [

14] showed that when wind speed was higher than the rated value, the coupling between the blade pitch and the platform pitch resulted in negative damping. This, in turn, led to more platform pitch motion. To minimize negative damping, Jonkman [

15] proposed an additional control method for barge platform pitching in which the tower-top acceleration was fed back. It was found that the two objectives of power regulation and pitch reduction are mutually in conflict because they are essentially constrained to each other. A variable speed operation was proposed in [

16] to resolve the two conflicting control objectives by modifying the rated rotor speed of the generator according to the platform pitch speed. This variable speed operation effectively decreased the platform pitch. However, power and speed fluctuations were increased. Thus, Amik and Stol [

17,

18] developed a state feedback control method based on individual pitch control (IPC) and linear quadratic regulator for the barge type FOWT. Then, the authors extended this method to the TLP type and semi-submersible type FOWT. Even though IPC can reduce the blade root bending moment and achieve load control by independent pitch adjustment, this method is limited by the bandwidth caused by the blade dynamics [

19]. Moreover, the fluctuation caused by flap and edge vibration can also cause the blade to bear more structural load.

The other choice is collective pitch control (CPC). Its control structure is relatively simple. Moreover, CPC has achieved good performance in speed regulation and power regulation of the rotor and generator. Wakui et al. [

20] proposed a multiple feedback control strategy by employing generator power and nacelle fore-and-aft speed for a spar type FOWT. The results indicate that this multifeedback control method reduced the power output fluctuation, platform pitch, and tower fatigue load. By using the same blade pitch control method, Bagherieh and Nagamune [

21] compared several controllers based on linear quadratic regulators (LQRs) with a baseline blade pitch PI controller. LQR variable gain and linear variable parametric (LVP) state feedback control techniques showed optimal performance. Variable gain provided the best power regulation, while LVP achieved the best platform pitch damping. PI, LQR, and LPV control methods are based on linearized FOWT dynamics. However, the FOWT is a typical complex dynamic system with strong nonlinearity and coupling. Many uncertain factors are present within the system, such as waves and wind speed. When the operating point is changed, the performance of the linear model controller may deteriorate. In such instances, it is necessary to use another set of controller parameters. This inevitably leads to a large number of adjustment parameters. Therefore, it is particularly important to improve the robustness of the system. Betti [

22] used a robust H∞ controller with a light detector and ranging above the rated wind speed to establish a simplified two-dimensional TLP model to stabilize the response. However, the simplified model shortens the wind and wave dynamics, thus affecting the actual experimental results. Due to the nonlinear and uncertain characteristics of the FOWT, it is necessary to further study its robust control method. Sliding mode control is effective for nonlinear systems and has strong robustness to disturbance and unmodeled dynamics. As such, it seems to be a good choice [

23]. Sliding mode control has been applied to onshore wind turbines [

24,

25]. However, chattering of the classical sliding mode can affect the control accuracy and may even cause system oscillation. By hiding the discontinuous sign function in higher-order time derivatives of the sliding variables, higher accuracy and less chattering than the conventional first-order sliding mode are obtained [

26,

27,

28]. As a type of high-order sliding mode, super-twisting second-order sliding mode control has been applied for variable-speed wind turbines [

29,

30]. Implementation of these controllers requires knowledge of the upper bound on the perturbation derivatives. However, the upper bound is unknown and hard to calculate in the FOWT system. In this case, conservative switching gain can cause sliding mode control chattering and generator torque saturation problems. Therefore, when the upper bound of the uncertainty derivative is unknown, an adaptive sliding mode control strategy should be considered for the wind turbine system [

19,

31,

32].

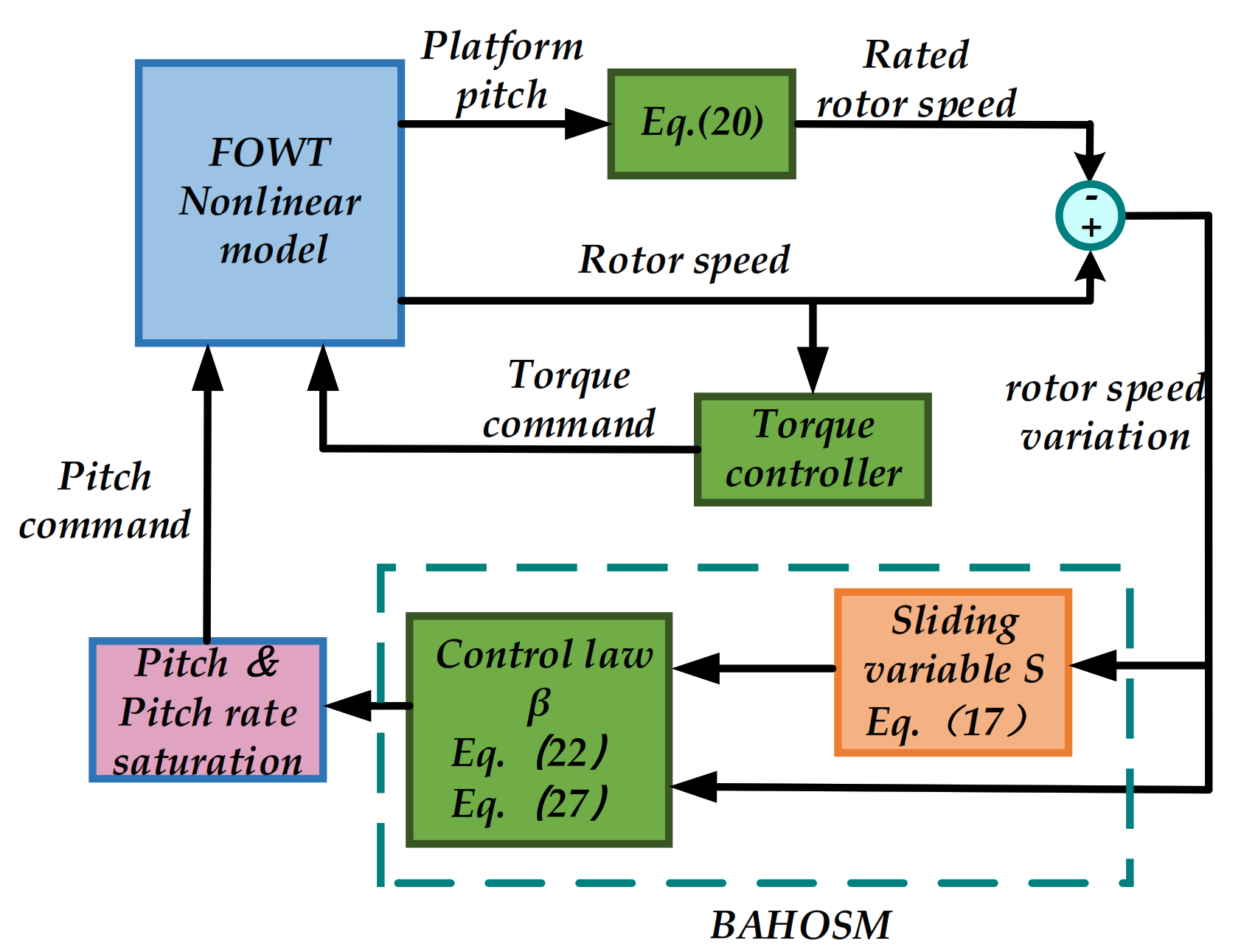

In this paper, a barrier function-based adaptive high-order sliding mode control strategy (BAHOSM) for the nonlinear and strongly coupled barge type FOWT is proposed. BAHOSM strategy ensures that the states of the FOWT converge in finite time to a given neighborhood of sliding variables. Their size does not depend on the upper bound of the uncertainty derivative [

33]. Collective pitch control of the FOWT blades, which allows the rotor speed to track the rated speed considering the platform motion, is carried out based on BAHOSM. With the help of the barrier function, the designed pitch controller can adaptively adjust the control gains according to the random disturbance of sea waves and wind speed. This, in turn, stabilizes platform operation and restrains both the structure dynamic load and power fluctuations.

This paper is organized as follows. In

Section 2, wind turbine and barge-type platform models are presented. Details of the BAHOSM control strategy and its application to the barge type FOWT are presented in

Section 3. In

Section 4, simulation results under the proposed control scheme, and PI control, are analyzed. Lastly, the concluding remarks are given in

Section 5.

3. Control Design

A FOWT represents a strong coupling and uncertain nonlinear system, which is not only affected by the structural elasticity of the tower and the blade, but also by the wind and the waves. Therefore, when the system operating point changes, the control performance of the linear model controllers, which are based on a certain operating point, deteriorate. To achieve robustness and nonlinear control, an adaptive high-order sliding mode control strategy is proposed in this section and described in detail. The blade pitch angle represents the control input, and the rated rotor speed that takes the platform displacement into account is the target to follow. Based on functional characteristics of the barrier function, a high-order sliding mode collective pitch controller can adaptively adjust the control parameters in the case of external random disturbance. The proposed control scheme aims to solve the problems of fatigue structure load and power fluctuation. Moreover, it improves the robustness of the FOWT control system. Given that this study was conducted in region 3, the generator torque was fixed at the rated, and the relationship between generator power, torque and rotor speed is , where is the gearbox ratio, is the rated generator torque.

The integral sliding mode surface is chosen as:

where

is the design parameter, and

is the rated rotor speed which accounts for the platform displacement.

Rated generator speed function which considers platform displacement is represented as [

16,

40]:

where 1173.7 rpm is the rated generator speed,

and

are the platform pitch angle and platform pitch angular speed, respectively. In this study, positive platform pitch speed is defined as the downwind platform pitch to ensure a negative

value, which is set as −0.0375

. Multiplying both sides of Equation (18) by the rated torque of the generator (43,093.55 Nm), the following expression is obtained:

It can be observed that the FOWT power changes along with the platform pitch speed, and 5 MW results when

is zero. The low speed of the shaft at the rotor side can be expressed as:

where

is the gearbox ratio. By analyzing Equation (20), it can be concluded that when the rotor is pitched upwind, more energy is extracted from the wind by increasing the rated rotor speed. Thus, platform motion is suppressed. When the rotor is downwind pitched, less energy is extracted due to a reduction of the rated rotor speed. Hence, platform motion is once again restrained.

By substituting Equation (15) into an integral sliding surface expressed by Equation (17), the following expression is obtained:

where

are nominal values,

is the system uncertainty, and

is the unknown upper bound of the uncertainty derivative. Then, the control objectives can be achieved by constructing the appropriate control law.

Preliminary feedback for Equation (21) is carried out as:

Then, Equation (21) is converted as:

Conventional first-order sliding mode control can be adopted for Equation (23) to establish the sliding mode with respect to

s:

However, high-frequency switching can cause serious chattering of the blade pitch under this conventional first-order sliding mode. As the special high-order sliding mode algorithm, the standard super-twisting second-order sliding mode control can be used for the FOWT:

where

and

are the control gains. If two parameters are chosen as

and

, second-order sliding mode with respect to

can be established [

41]. Hence, finite-time stability of the closed-loop system can be achieved. However, it is hard to acquire the values of

M in the FOWT control system. Thus, in this paper, adaptive control gains are presented based on the barrier function. Characteristics of the barrier function can be obtained from [

42]. Here, the barrier function is chosen as:

where

is a positive constant, and

is a provided fixed value. Then, adaptive virtual control law

can be constructed as:

Adaptive control gain

L(

t, s) is conceived as:

where

is the time required for

to reach

. For any

, there exists a

.

is satisfied for any initial state

when

. Real sliding mode with respect to

s can be established after

, which means that the rotor speed of the FOWT can converge to the error range of the rated rotor speed

.

The proof for the above convergence conclusion includes two steps.

First, it should be proven that can reach in finite time . Under the assumption that is satisfied, adaptive control gain is determined by .

The following variable transformation is considered:

Derivatives for

,

are represented as:

The Lyapunov function is then chosen:

where

is a constant symmetric positive definite matrix,

. Then, the time derivative of

can be expressed as:

where

,

,

.

The time derivative of

is:

where

,

. Based on [

43], symmetric positive definite matrix

exits. Then,

,

are positive definite. In other words:

where

,

,

,

,

are minimum eigenvalue and maximum eigenvalue of the relative matrix, respectively. The parameter

is the first element of the matrix

.

The first part of the right side in Equation (34) is negative and the second part is positive. Here, the second part decreases with an increase in the adaptive control gain. The adaptive control gain becomes large enough to overcome uncertainties. Thus, the second part becomes very small. The third part is negative and further reduced when is negative. As previously discussed, the first part is larger than the second one, and the third part becomes smaller. Then, the right side of Equation (34) is negative and is satisfied, i.e., finite time stability is achieved. Moreover, continues to decrease and can reach .

It is proven in the first step that can reach when the time is . The next step is to prove that can be obtained after .

The Lyapunov function is chosen as:

Then:

where

. Then:

According to the barrier function of Equation (26):

The right side of Equation (38) is considered to define:

is a quadratic equation, and the two roots can be calculated as:

It is observed that the second root, which is the only one that has to be further investigated, is negative. According to Equation (40):

According to the well-known inequation

:

Then, the upper bound of

can be written as:

Finally, the inequality (44) can be deduced as:

If is satisfied, then is a positive definite. Thus, is satisfied for .Variable will always satisfy , and is smaller than for any derivative of .

Therefore, real sliding mode with respect to is established in finite time. The rotor speed can track the prescribed value with an unknown upper bound of the uncertainty derivative. Thus, the stability of the entire control system is guaranteed.

The proposed BAHOSM control scheme is depicted in

Figure 1.

In addition, the traditional PI control method, which is shown in

Figure 2, is used to compare the control performance.

4. Simulation Results

The proposed BAHOSM collective pitch control scheme was built to verify the effectiveness based on the FAST and MATLAB/Simulink platforms. The wind turbine model was a 5 MW ITIBarge4 FOWT model.

In the study, all 24 degrees of freedom in FAST were enabled, simulation runtime was 600 s, and the integration algorithm in Simulink was ode4 (Euler) with a fixed step size set to 0.0125 s. Considering the actual physical application of the wind turbine, the operating interval of the blade pitch angle was set to [0°, 90°] and the pitch rate was limited to 8°/s. In addition, the wind input signal was generated by the TurbSim software. The following two external environments are shown in

Table 2. In

Figure 3, the change process of the two external environments is shown.

Table 2.

External environmental parameters.

Table 2.

External environmental parameters.

| Case | Average Wind Speed (m/s) | Turbulence Intensity (%) | Significant Wave Height (m) | Peak Spectral Period (s) |

|---|

| Case 1 | 18 | 15 | 3.25 | 9.7 |

| Case 2 | 20 | 15 | 3.72 | 13.4 |

Figure 3.

(a) Wind speed and waves for Case 1, and (b) wind speed and waves for Case 2.

Figure 3.

(a) Wind speed and waves for Case 1, and (b) wind speed and waves for Case 2.

The control parameters of the proposed BAHOSM control strategy were set as . To compare the control performance, PI control is executed, and the control parameters of the PI controller were chosen as .

The performance of the controller was measured by the root mean squares (RMS) and damage equivalent load (DEL) of several variables. RMS is represented as [

20]:

where

and

are the total number and the index of the sampled system output. The smaller the RMS of the rotor speed and the generator power, the better the speed and the power are regulated. Similarly, for the platform pitch, roll, and yaw, the smaller the RMS, the more stable the platform. This also reduces the tower base side-side, fore-aft, and torsional moment.

In addition, mechanical stresses of the tower base and the blades were analyzed via MLife. The blade is the key part in the direct extraction of wind energy. Thus, its mechanical stress should be analyzed. The stress of the tower base is amplified by the wave action, and it affects the important parts, such as the tower tube which is characterized by the strong coupling. Therefore, it is also very important to analyze the mechanical stress of the tower base. Here, the damage equivalent load (DEL) was used to quantify the described forces and moments. In this paper, the analysis focuses on the bending moments of the blade root and tower base. The calculated life was 20 years, the frequency of DEL was 1 Hz, and the Wohler index was set as 4 and 10 for the tower and the blade, respectively. Furthermore, the DEL normalized performance metric was calculated and compared with the performance obtained by PI (the metric is always equal to 1). When the normalized value is less than 1, the BAHOSM control strategy performs better relative to PI and vice-versa

4.1. Rotor Speed and Generator Power Regulation

Responses of the rotor speed and the power under the two control strategies are shown in

Figure 4 and

Figure 5. It can be observed that both control strategies control the system, with the actual speed and the actual power fluctuating above and below the rated value (rated rotor speed is 12.1 rpm and the rated power is 5 MW). With the BAHOSM control strategy, power and speed fluctuations are much smaller. RMS values of the corresponding indicators in the two cases are shown in

Table 3 and

Table 4.

Figure 4.

Rotor speed (a) and generator power response (b) in Case 1.

Figure 4.

Rotor speed (a) and generator power response (b) in Case 1.

Table 3.

RMS values of the rotor speed and generator power for Case 1.

Table 3.

RMS values of the rotor speed and generator power for Case 1.

| | RMS | Rotor Speed

(rpm) | Generator Power

(KW) |

|---|

| Control Strategy | |

|---|

| BAHOSM | 12.10 | 5295 |

| PI | 12.19 | 5335 |

Figure 5.

Rotor speed (a) and generator power response (b) in Case 2.

Figure 5.

Rotor speed (a) and generator power response (b) in Case 2.

Table 4.

RMS values of the rotor speed and generator power for Case 2.

Table 4.

RMS values of the rotor speed and generator power for Case 2.

| | RMS | Rotor Speed

(rpm) | Generator Power

(KW) |

|---|

| Control Strategy | |

|---|

| BAHOSM | 12.08 | 5288 |

| PI | 12.08 | 5391 |

4.2. Control Effect on Platform Motion

The time-series response of the platform motion under BAHOSM and PI control is shown in

Figure 6 and

Figure 7 for the two cases. The BAHOSM control strategy makes the platform pitch and roll less responsive for both cases.

In

Figure 8, the RMS of the platform pitch, roll, and yaw is shown. In case 1, the platform pitch, platform roll, and platform yaw decrease by 16%, 19%, and 8%, respectively. In case 2, the platform pitch and platform roll decrease by 7%, and 14%, respectively, while the platform yaw increases by 0.1%. It can be observed that the pitch and roll motion angle of the platform are significantly reduced under the BAHOSM control strategy.

Figure 6.

Platform motion response in Case 1.

Figure 6.

Platform motion response in Case 1.

Figure 7.

Platform motion response in Case 2.

Figure 7.

Platform motion response in Case 2.

Figure 8.

RMS of the platform motion in case 1 (a) and case 2 (b).

Figure 8.

RMS of the platform motion in case 1 (a) and case 2 (b).

4.3. Control Effect on the Load

In

Figure 9 and

Figure 10, normalized DEL data at the blade root and tower base are compared for the two control strategies. Fundamentally, most loads acting on the wind turbine components (such as nacelle towers) ultimately come from blade loads. Thus, reducing the blade root loads on FOWTs is essential. It should be noted that the BAHOSM control strategy is effective in suppressing the loads at the blade root in both environments. In case 1, blade root edgewise moment and blade root moment flap wise are reduced by 6% and 9%, respectively. The BAHOSM control strategy reduces the tower base fore-aft moment by 6% and the tower base torque by 4% compared to the PI control strategy. However, the side-to-side moment increases by 5%, which was not expected in this design. In case 2, the BAHOSM control strategy can reduce the side-to-side moment by 4% and the tower base torsional moment by 6%, while the tower base fore-aft moment does not change significantly.

4.4. Control Gain and Sliding Surface

Blade pitch angle, control gain, and sliding mode variables under the BAHOSM control strategy are shown in

Figure 11 and

Figure 12. The blade pitch angle actuator produces more response under BAHOSM control strategy. Pitch behavior is acceptable since this design sets the blade pitch at a certain pitch range and a certain pitch rate. Moreover, this does not increase the blade root load. The BAHOSM control gain can be automatically changed with the wind speed and waves. It can be observed that the sliding variables also converge to a near-zero value after a period of transition. When the wind speed exceeds 25 m/s, for safety reasons, the wind turbine assembly must have a mechanical brake. Due to the strongly coupled character of FOWT systems, blade pitch and platform motion are affected by each other and the movement of the platform is influenced by external waves. Therefore, the range of blade pitch is not only depended on the wind, but also affected by the waves. Although the wind speed at the height of the hub is 25 m/s, due to the influence of sea waves, the wind speed does not reach the conditions for triggering the mechanical brake, so the blade pitch is operating normally.

Figure 13 shows two external examples of the blade pitch rate normalized performance index. The application of the BAHOSM control strategy results in increasing blade pitch use, while making the blade pitch system more sensitive. Despite the increased blade pitch rate, the effect of blade pitch rate is acceptable when the blade pitch angle operating range is set to [0°, 90°], the pitch rate is limited to 8°/s, and the blade root moment DEL is not increased.