An Overview on Bonded Marine Hoses for Sustainable Fluid Transfer and (Un)Loading Operations via Floating Offshore Structures (FOS)

Abstract

1. Introduction

2. Sustainable Fluid Transfer at SPM Mooring Terminals

2.1. Sustainable Fluid Transfer Operation

- The PLEM and the buoy are connected by flexible subsea hoses known as risers. The arrangement can take the form of a Chinese lantern, Lazy-S, Lazy Wave, or Steep-S depending on depth, sea state, buoy motions, and other factors.

- The buoy is connected to the tanker by floating hose strings.

- Marine breakaway coupling that enables for emergency pipeline disconnection to prevent hose/hawser breakage and associated oil spills.

- The tanker can rotate with relation to the mooring buoy thanks to the product swivel, valves, and piping that connect the geostatic and rotating components of the buoy.

2.2. Sustainable Incident Reporting on Hose Failure

2.3. Safety Precautions at SPM Mooring Terminals

- When not handling lines that are under load or strain, stay away from them.

- Avoid mooring winches, drums, and bitts that have lines attached to them. The handler must not stand too close to the warping drum, capstan, or bitt when handling the line.

- It is not advisable to stand on or around the bights of ropes.

- Avoid the snapback and whiplash zones (area covered by the broken end of the line under recoil). If activity in this zone is unavoidable, exposure time should be kept to a minimum.

- Keep loose things out of the way of the region where lines are handled.

- Do not attempt to physically stop the line from taking charge (uncontrolled running out of line under strain).

- When building quick towlines, the crew should communicate with the tugs verbally or with hand signals to inform the Tug Master of the line’s status. Watch out for towlines that have been rigged up quickly onboard.

- All mooring station workers must be aware and vigilant for any possibility of ropes/wires splitting after being secured onboard.

- Ropes should be protected against chafing on sharp edges.

- To avoid losing strength, avoid leading ropes at steep angles or turns.

- The officer on duty is responsible for keeping the bridge informed regarding clearances between vessels and other objects.

- If too much slack is lowered into the water, the ropes may foul the propellers/bow thrusters.

- When the propeller is not clear (i.e., without impediment) for engine movements, the officer on aft stations is responsible for informing the bridge.

- Anti-skid paint should be used to paint the operational area at the winches and the deck walks; the margins of these areas should be accentuated with a contrast colour.

2.4. Preparation & Arrangement of SPM Moorings

- For picking up rope, a messenger line has been requested.

- It must be fitted in an empty drum at the bow, large enough to hold a 120 m [or longer, depending on terminal advice] Pick Up Rope.

- The messenger must be 100 metres long (or as instructed by the terminal).

- The messenger should be 1”−3” wide, and at its end have one small shackle.

- The afterdeck specification to be used on the Tug Boat should be 02 × 200 Mt.

2.5. Mooring Procedures for SPMs

2.6. Hawser Connection on SPMs

2.7. The Criteria for SPMs and CALMs

- It should have an efficient anchoring mechanism that must keep the CALM buoy in place and assure its survival under harsh loading conditions, while also permitting efficient loading, discharging, and mooring under operational conditions:

- Take into account the waves, significant wave height and tides (if tidal).

- For the duration of the operational life, all components must have sufficient strength, fatigue life, and durability.

- Evaluate and manage corrosion during the design process. Ensure abrasion from bottom contact or contact with other lines must be minimised or possibly avoided.

- If necessary, ensure device self-orientation with incoming wave direction.

- It should be simple to monitor and maintain.

- Use your resources wisely and ensure the right hose type is used (see Table 1).

- Ensure the device’s survival and is free-floating as depicted in Figure 7.

- Reduce the amount of pollution that reaches the seabed or native flora and animals.

- By not interfering with the CALM buoy motion so that its performance for transfer loading or discharging via the hose system’s will not be affected.

- To allow the devices to be positioned near to each other in arrays, take up as little area as possible on the seabed.

- Loads on electrical lines and connections should be reduced or removed.

- Restrain the equipment from leaving its designated area.

2.8. Benefits of Having SPMs and CALMs

- The SPM and CALM systems are very economical, as they help to save cost, in terms of fuel and money, as the vessel may not need to come into the port.

- The SPM saves financial and clearance burdens which are usually incurred in the payment of fees, submission for checks, submission for regulation compliance, and waiting times at the port.

- SPMs saves production and transfer time, thereby ensuring a sustainable fluid transfer, especially during tight schedules or short operational time-bound windows to transfer fluid products and complete delivery jobs as scheduled.

- They have the ability of handling extra-large vessels such as VLFS.

- SPM systems has the ability of ease during mooring operations of high draft ships.

- SPM systems have the capacity of easily handling large quantity of cargo.

- They can be operated in shallow and moderate and deep water environments.

3. Model Application of Bonded Marine Hoses

3.1. Configurations for Submarine Hoses

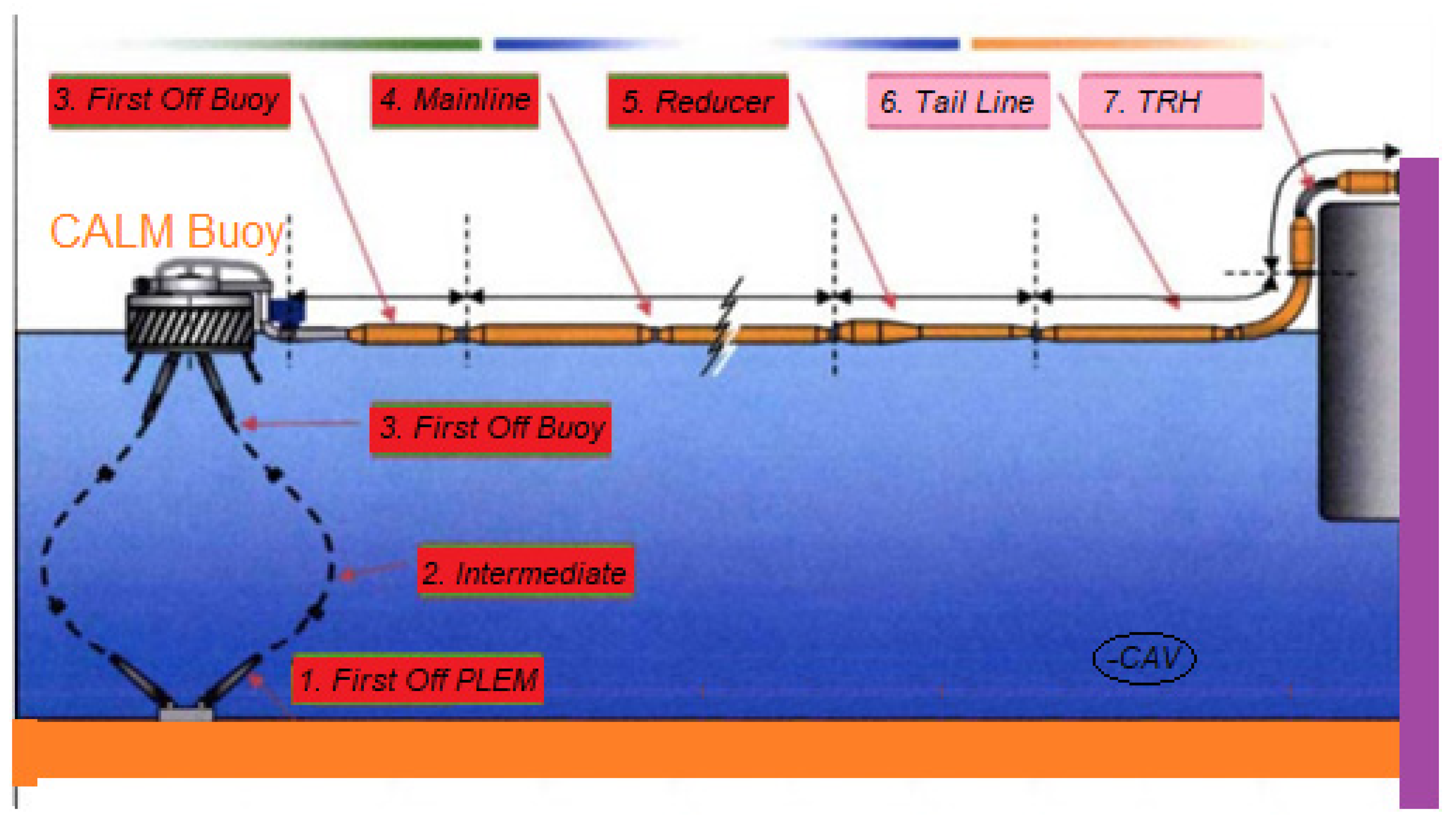

3.1.1. CALM Buoy Hose Configurations

3.1.2. Chinese-Lantern Hose Configurations

3.1.3. Lazy-S Hose Configurations

3.1.4. Steep-S Hose Configurations

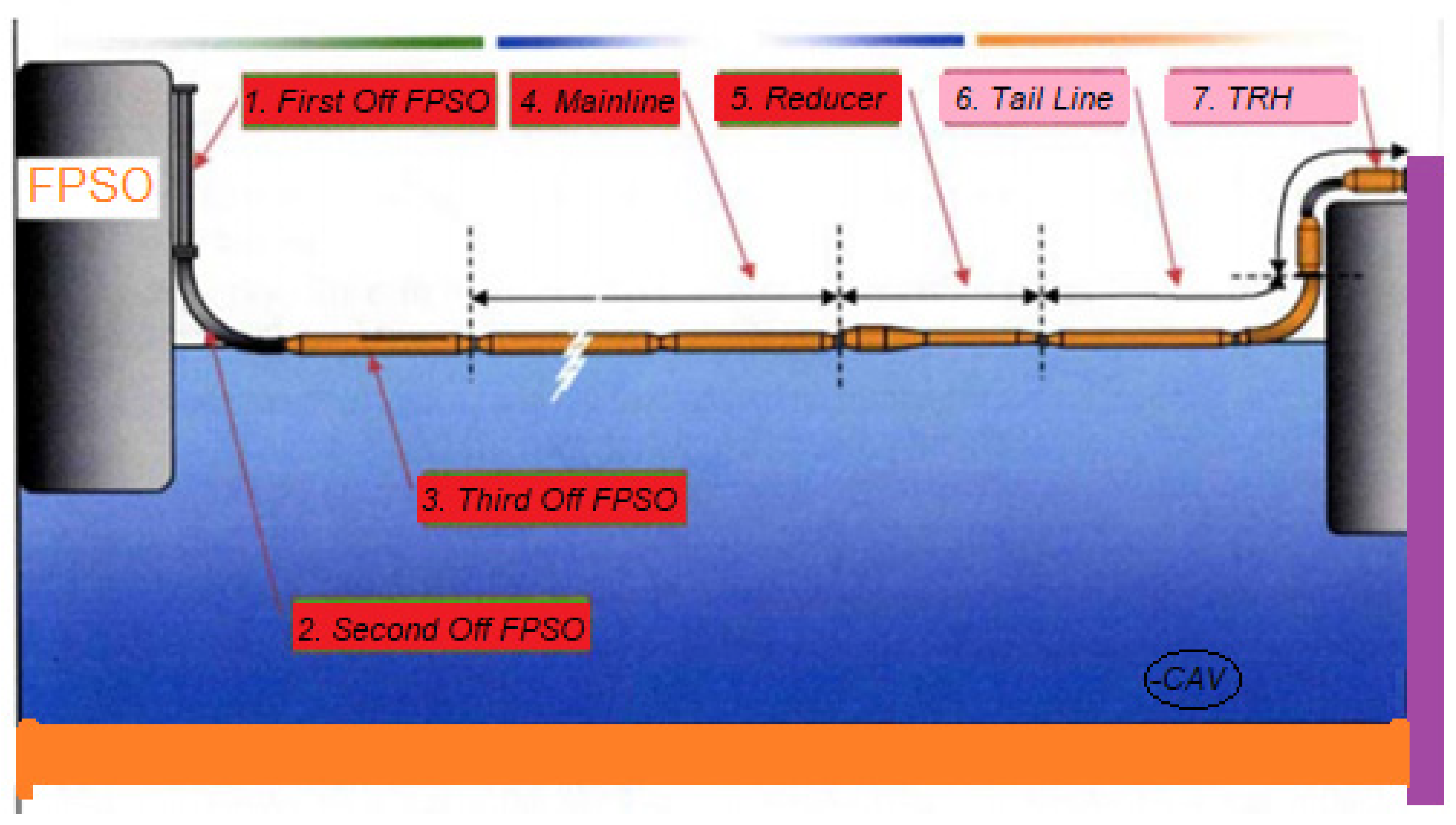

3.2. Configurations for Floating Hoses

3.2.1. SALM Buoy Hose Configurations

3.2.2. Floating Tandem Mooring Hose Configurations

3.2.3. Stored Hose (or Hose Reel) Tandem Mooring

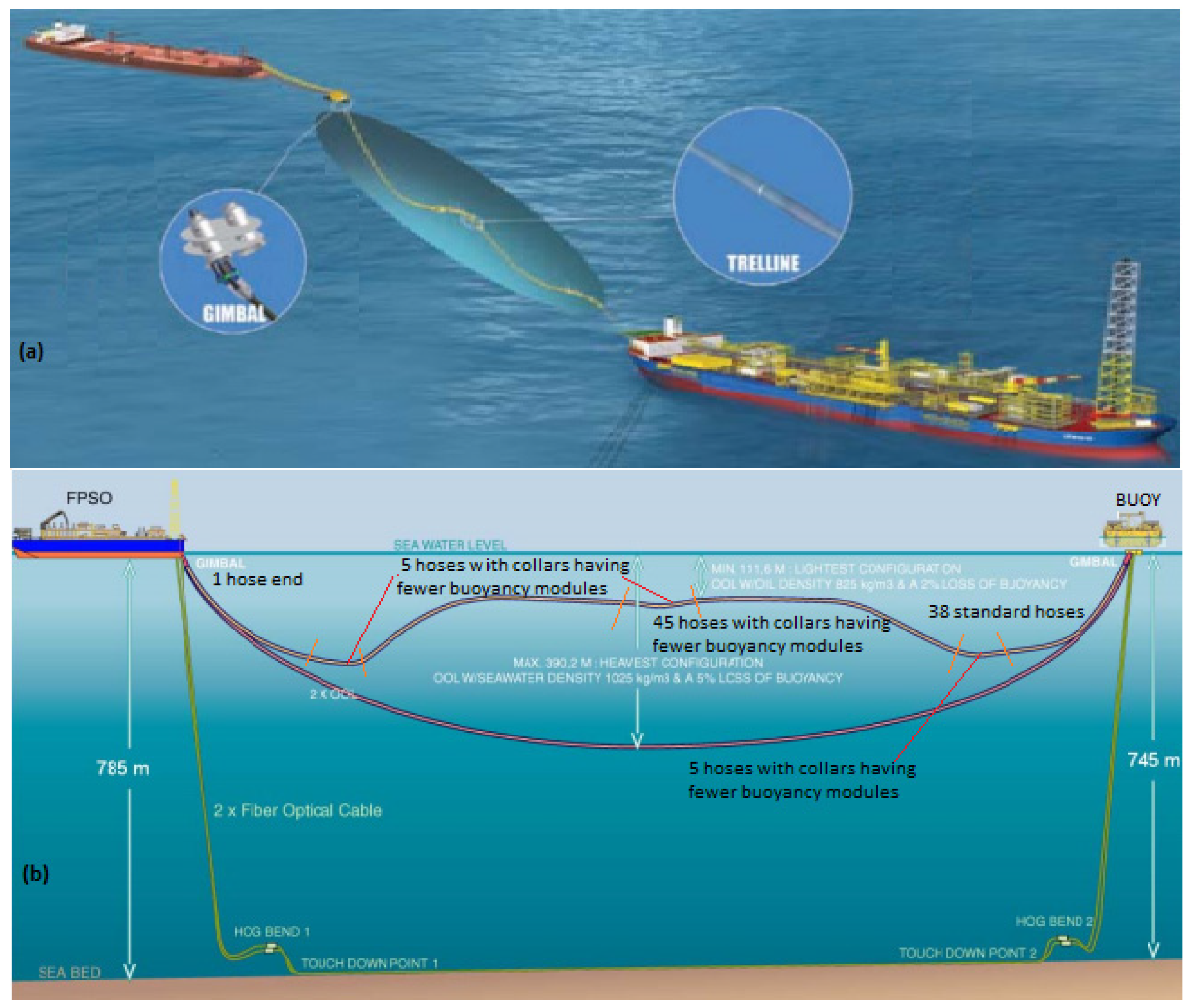

3.2.4. Deepwater Export Lines

3.3. Configurations for Catenary Hoses

3.3.1. Submarine Tandem Mooring Hose Configurations

3.3.2. Catenary Tandem Mooring Hose Configurations

3.3.3. Multi Buoy Mooring (MBM) Hose Configurations

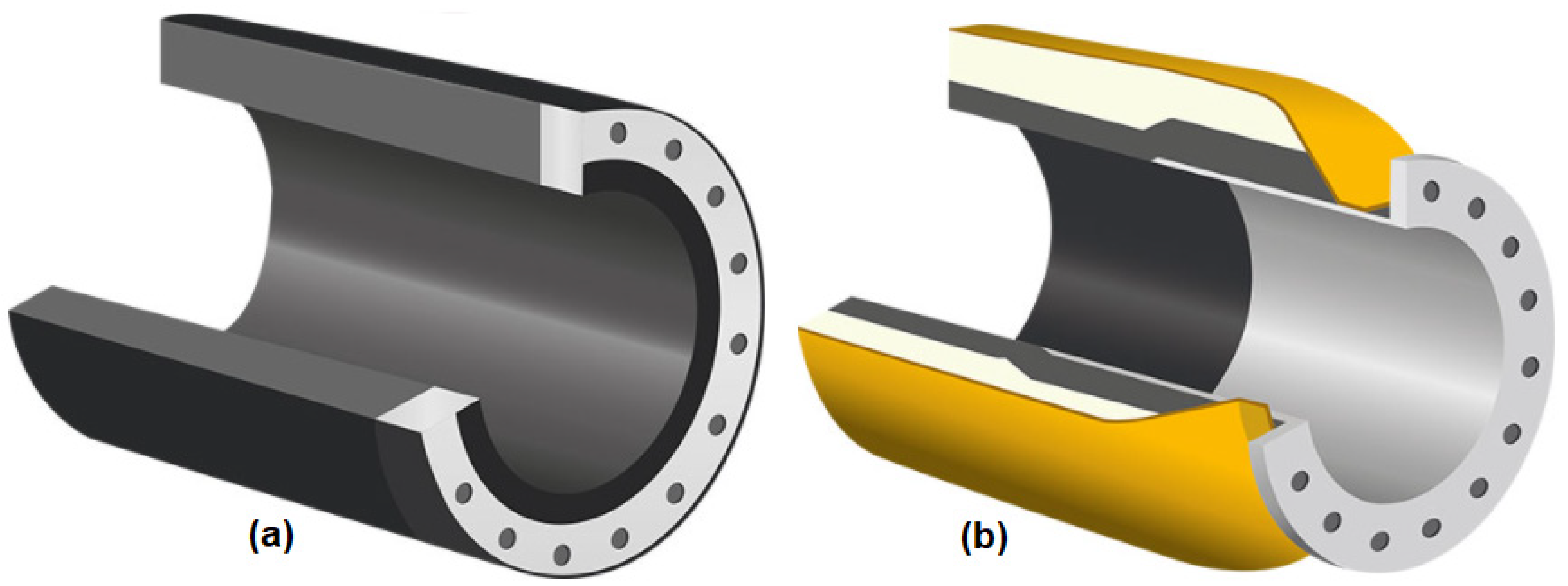

3.4. Types of Marine Hoses

3.4.1. Floating Hose String

3.4.2. Submarine Hose String (<100 m)

3.4.3. Catenary Hose String

3.4.4. Reeling Hose String

3.4.5. Deep Water Underwater Hose String (>300 m)

3.5. Marine Hose Hang-Off and Marine Breakaway Coupling

3.6. Marine Hose Arrays

- (a)

- Hose bore or internal diameter: The hose segments that travel from the water surface to the manifold on the tanker or FPSO frequently have a lower diameter due to the limited lifting capacity of the utilised derrick. As a result, tapered hoses with a smaller diameter in the longitudinal direction are required.

- (b)

- Bending stiffeners upon end reinforcements: Certain hose strings on FPSOs, tankers, buoys, or PLEMs that link the floating or hanging hose string to rigid piping require gradual reinforcing to avoid a concentration of bending loads near the concerned flange.

- (c)

- Length of hose-string: The length of the hose-string is a function of the water depth, the distance between the buoy and the FPSO and the choice of hose configuration for the loading and unloading operation.

- (d)

- Floatation material quantity and placement: Floating hose strings require enough buoyancy to stay afloat. Certain portions with a lot of ancillary equipment require a bigger buoyancy reserve. Floatation material is required at particular points on hose segments that change from hanging to floating or floating to submerged.

3.7. Marine Hose Categories

- Diameter: 150 mm < D < 600 mm

- Resistance to: Petroleum products with a 25% aromatic content

- Axial strength: 37 tons for D = 600 mm

- Pressure ratings: 15 bar, 19 bar and 21 bar (depends on design)

- vFlow at D < 400 mm: 21 m/s

- vFlow at D > 400 mm: 15 m/s

- Fluid temperature range: 82 °C >T> −20 °C

- Ambient temperature range: 52 °C >T> −29 °C

- Permanent elongations: < 0.7% (relates to materials)

- Temporary elongations: < 2.5% (relates to materials)

- Operating pressure: −0.85 bar gauge to designated pressure rating

3.8. Marine Hose and Marine Riser Categories

4. Hose Tests & Model Challenges

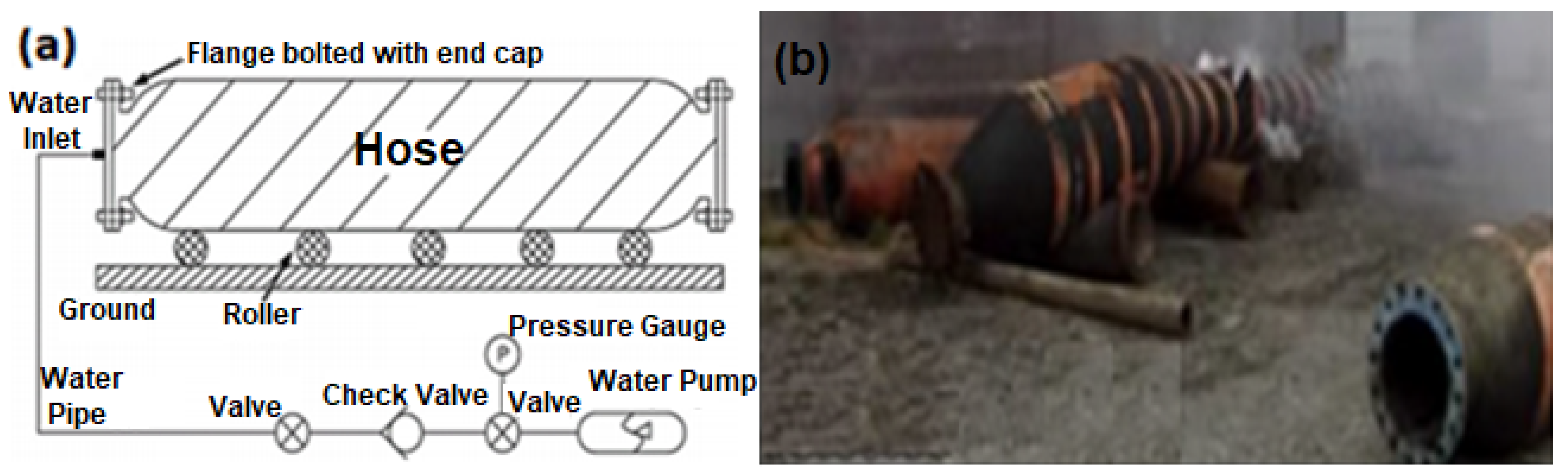

4.1. Hose Design Test Methods

4.1.1. Allowable Axial Load of Hose

4.1.2. Tensile Load of Hose

4.1.3. Torsional Load

4.1.4. Hydrostatic Pressure Load

4.1.5. Hose Crush Load

4.1.6. Burst Load

4.1.7. Bending Stiffness Load

4.2. Descriptive Hose Scenarios by Application

4.3. Hose Failure vs. Flexible Riser Failure Issues

4.4. Protection of Marine Hoses

4.4.1. Preventive Maintenance

4.4.2. Curative Maintenance

4.4.3. Corrective Maintenance

- Fail Repair—Repairing a failing asset to get it back up and running.

- Overhaul—Completely restoring any asset to its original operating condition as defined by maintenance standards.

- Salvage—Disposal of non-repairable parts and replacement with salvaged parts from non-repairable assets.

- Servicing—This is the process of making last stage of corrective maintenance by concluding fixes and minor adjustments after bigger corrective fixes or bigger remedial activities have been completed.

- Rebuild—Disassembly and replacement of worn components in accordance with original norms and specifications.

4.4.4. Storage Maintenance

4.5. Pros and Cons of Marine Hoses

5. Concluding Remarks

- Marine hose developments, current application of SPM hose connections, review on marine hoses, CALM buoys and SPM moorings.

- Sustainable fluid transfer, safety precautions at SPM mooring terminals, model application of marine hoses on different configurations.

- Overview on SPM, SALM, CALM, tandem moorings and other configurations for marine applications.

- Overview on hose testing, hose failure prevention, and comparisons between failure modes for marine hoses and other flexible risers.

- Discussion on marine hose storage, hose maintenance, hose design selection and application of MBCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PC Semi | Paired Column Semisubmersible |

| 6DoF | Six Degrees of Freedom |

| ALP | Anchor Leg Platform |

| CALM | Catenary Anchor Leg Mooring |

| CBM | Conventional Buoy Mooring |

| CODAM | Corrosion and Damage [a database by PSA Norway] |

| COIN | Corporate Operational Information System [a database by HSE UK] |

| DAF | Dynamic Amplification Factor |

| DC | Double Carcass |

| DP | Dynamic Positioning (or Dynamic Positioned) |

| FBD | Free Body Diagram |

| FEA | Finite Element Analysis |

| FEED | Front End Engineering Design |

| FEM | Finite Element Model |

| FOS | Floating Offshore Structure |

| FPSO | Floating Production Storage and Offloading |

| FSO | Floating Storage and Offloading |

| FSRU | Floating Storage and Regasification Unit |

| FSU | Floating Storage Unit |

| GoM | Gulf of Mexico |

| HEV | Hose End Valves |

| HP | High Pressure |

| HSE | Health and Safety Executive |

| LHS | Left Hand Side |

| MBC | Marine Breakaway Coupling |

| MBM | Multi Buoy Mooring (or Multiple Buoy Mooring) |

| MBR | Minimum Bend Radius |

| MFS | Marine Floating Structure |

| MWL | Minimum Water Level |

| OCIMF | Oil Companies International Marine Forum |

| OLL | Oil Offloading Lines |

| OMS | Offshore Monitoring System |

| PLEM | Pipeline End Manifold |

| PSA | Petroleum Safety Authority |

| RAO | Response Amplitude Operator |

| RHS | Right Hand Side |

| RIDDOR | Reporting of Injuries, Diseases and Dangerous Occurrences Regulations |

| RWP | Rated Working Pressure |

| SAL | Single Anchor Loading |

| SALM | Single Anchor Leg Mooring |

| SBM | Single Buoy Mooring |

| SCR | Steel Catenary Riser |

| SC | Single Carcass |

| SCS | Single Carcass Submarine Hoses |

| SDG | Sustainable Development Goals |

| SON | Standards Organisation of Nigeria |

| SPAR | Single Point Anchor Reservoir |

| SPM | Single Point Mooring |

| STL | Submerged Turret Loading |

| STS | Ship-to-Ship |

| SURP | Subsea Umbilicals, Risers and Pipelines |

| TDP | Touch Down Point |

| TLP | Tension Leg Platform |

| TM | Theoretical Model |

| TRH | Tanker Reeling Hose |

| TTR | Top Tensioned Riser |

| UK | United Kingdom |

| UN | United Nation |

| UV | Ultra-Violet |

| VIV | Vortex Induced Vibration |

| VLCC | Very Large Crude Carrier |

| VLFS | Very Large Floating Structures |

| SC | Single Carcass |

| DC | Double Carcass |

| SCS | Single Carcass Submarine Hoses |

| Saflote | Double Carcass floating hoses |

| Safgard | Double Carcass submarine hoses |

| Selflote | Single Carcass floating hoses |

References

- Gordon, R.B.; Ruiz-Rico, J.C.; Brongers, M.P.H.; Gomez, J. Volume 3: Operations, monitoring and maintenance; materials and joining. Integrity management and life extension for a CALM buoy oil export terminal. In Proceedings of the 2016 11th International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016; Paper No: IPC2016-64495, V003T04A041. pp. 1–10. [Google Scholar] [CrossRef]

- Bluewater. Buoyed Up: The Future of Tanker Loading/Offloading Operations; Bluewater Energy Services: Amsterdam, The Netherlands, 2009; Available online: https://www.bluewater.com/wp-content/uploads/2013/04/CALM-Buoy-brochure-English.pdf (accessed on 12 July 2021).

- Yokohama. Seaflex Yokohama Offshore Loading & Discharge Hose. 2016. Available online: https://www.y-yokohama.com/global/product/mb/pdf/resource/seaflex.pdf (accessed on 29 June 2021).

- EMSTEC. Loading & Discharge Hoses for Offshore Moorings. Rosengarten: EMSTEC. 2016. Available online: https://www.emstec.net/fileadmin/files/product/downloads/EMSTEC_Loading_and_Discharge_HOM_2009__5th_Edition-open-file_10.pdf (accessed on 29 June 2021).

- ARPM. IP-2: Hose Handbook; Association for Rubber Products Manufacturers: Indianapolis, IN, USA, 2015; Available online: https://arpminc.com/publications/category/handbooks-and-guides (accessed on 17 September 2021).

- Rutkowski, G. A Comparison between conventional buoy mooring CBM, single point mooring SPM and single anchor loading SAL systems considering the hydro-meteorological condition limits for safe ship’s operation offshore. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2019, 13, 187–195. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Agbomerie, C.O.; Sotayo, A.; Wang, F.; Hou, X.; Ye, J. Recycling of renewable composite materials in the offshore industry. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 583–613. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Agbomerie, C.O.; Orok, E.O.; Ye, J. Economic aspects of fiber reinforced polymer composite recycling. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 377–397. [Google Scholar] [CrossRef]

- Ye, J.; Cai, H.; Liu, L.; Zhai, Z.; Amaechi, C.V.; Wang, Y.; Wan, L.; Yang, D.; Chen, X.; Ye, J. Microscale intrinsic properties of hybrid unidirectional/woven composite laminates: Part I experimental tests. Compos. Struct. 2021, 262, 113369. [Google Scholar] [CrossRef]

- Amaechi, C.V. Novel Design, Hydrodynamics and Mechanics of Marine Hoses for Oil/Gas Applications. Ph.D. Thesis, Lancaster University, Lancaster, UK, 2021. [Google Scholar]

- Amaechi, C.V.; Wang, F.; Hou, X.; Ye, J. Strength of submarine hoses in Chinese-lantern configuration from hydrodynamic loads on CALM buoy. Ocean Eng. 2019, 171, 429–442. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Ye, J.; Hou, X.; Wang, F.-C. Sensitivity studies on offshore submarine hoses on CALM buoy with comparisons for Chinese-lantern and lazy-S configuration OMAE2019-96755. In Proceedings of the 38th International Conference on Ocean, Offshore and Arctic Engineering, Glasgow, UK, 9–14 June 2019. [Google Scholar]

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Hou, X.; Ye, J. Composite risers for deep waters using a numerical modelling approach. Compos. Struct. 2019, 210, 486–499. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Ye, J. A numerical modeling approach to composite risers for deep waters. In ICCS20 20th International Conference on Composite Structures; Structural and Computational Mechanics Book Series; Ferreira, A.J.M., Larbi, W., Deu, J.-F., Tornabene, F., Fantuzzi, N., Eds.; Societa Editrice Esculapio: Bologna, Italy, 2017; pp. 262–263. [Google Scholar]

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Local and global design of composite risers on truss SPAR platform in deep waters. In Proceedings of the 5th International Conference on Mechanics of Composites, Lisbon, Portugal, 1–4 July 2019; pp. 1–3. [Google Scholar]

- Gillett, N. Design and Development of a Novel Deepwater Composite Riser. Bachelor’s Thesis, Lancaster University, Lancaster, UK, 2018. [Google Scholar]

- Goff, R.; Kay, J. Investigations into the immediate and underlying causes of failures of offshore riser emergency shutdown valves. In HSE Books; Health and Safety Executive (HSE): Derbyshire, UK, 2015. Available online: https://www.hse.gov.uk/research/rrpdf/rr1072.pdf (accessed on 27 August 2021).

- Goff, R.J. Learning from the Causes of Failures of Offshore Riser Emergency Shutdown Valves; Health and Safety Executive (HSE): Derbyshire, UK, 2016; pp. 1–7. Available online: https://www.icheme.org/media/11788/hazards-26-paper-51-learning-from-the-causes-of-failures-of-offshore-riser-emergency-shutdown-valves.pdf (accessed on 27 August 2021).

- Wang, F.; Chen, J.; Gao, S.; Tang, K.; Meng, X. Development and sea trial of real-time offshore pipeline installation monitoring system. Ocean Eng. 2017, 146, 468–476. [Google Scholar] [CrossRef]

- Chesterton, C. A Global and Local Analysis of Offshore Composite Material Reeling Pipeline Hose, with FPSO Mounted Reel Drum. Bachelor’s Thesis, Lancaster University, Lancaster, UK, 2020. [Google Scholar]

- Charlesworth, D.; D’All, B.; Zimmerlin, C.; Remita, E.; Langhelle, N.; Wang, T. Operational experience of the fatigue performance of a flexible riser with a flooded annulus. In Proceedings of the Offshore Technology Conference (OTC), Rio de Janeiro, Brazil, 4–6 October 2011. Paper Presented at the OTC: Brasil. [Google Scholar] [CrossRef]

- Dahl, C.S.; Andersen, B.A.M.; Gronne, M. Developments in managing flexible risers and pipelines, a suppliers perspective. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar] [CrossRef]

- Obrien, P.; Meldrum, E.; Overton, C.; Picksley, J.; Anderson, K.; MacLeod, I. Outcomes from the SureFlex joint industry project—An international initiative on flexible pipe integrity assurance. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar] [CrossRef]

- Amaechi, C.V. Numerical investigation on mooring line configurations of a Paired Column Semisubmersible for its global performance in deep water condition. Ocean Eng. 2021, in press. [Google Scholar]

- Amaechi, C.V. Dynamic analysis of tensioner model applied on global response with marine riser recoil and disconnect. Ocean Eng. 2021, in press. [Google Scholar]

- Amaechi, C.V. Parametric investigation on tensioner stroke analysis, recoil analysis and disconnect for the marine drilling riser of a Paired Column Semisubmersible under deep water waves. Ocean Eng. 2021, in press. [Google Scholar]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. Review on the design and mechanics of bonded marine hoses for Catenary Anchor Leg Mooring (CALM) buoys. Ocean. Eng. 2021, 242, 110062. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Mathematical modelling of marine bonded hoses for single point mooring (SPM) systems, with catenary anchor leg mooring (CALM) buoy application—A review. J. Mar. Sci. Eng. 2021, 9, 1179. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Numerical assessment on the dynamic behaviour of submarine hoses attached to CALM buoy configured as lazy-S under water waves. J. Mar. Sci. Eng. 2021, 9, 1130. [Google Scholar] [CrossRef]

- Amaechi, C.V. Numerical studies on CALM buoy motion responses and the effect of buoy geometry cum skirt dimensions with its hydrodynamic waves-current interactions. Ocean Eng. 2021, in press. [Google Scholar]

- Amaechi, C.V. Investigation on hydrodynamic characteristics, wave-current interaction, and sensitivity analysis of submarine hoses attached to a CALM buoy. J. Mar. Sci. Eng. 2021, 9. in press. [Google Scholar]

- Amaechi, C.V. Development of bonded marine hoses for sustainable loading or unloading operation in the offshore industry. Ships Offshore Struct. 2021, in press. [Google Scholar]

- Wilson, J.F. Dynamics of Offshore Structures, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Bai, Y.; Bai, Q. Subsea Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Wichers, I.J. Guide to Single Point Moorings; WMooring Inc.: Houston, TX, USA, 2013; Available online: http://www.wmooring.com/files/Guide_to_Single_Point_Moorings.pdf (accessed on 17 June 2021).

- Løtveit, S.A.; Muren, J.; Nilsen-Aas, C. Bonded Flexibles–State of the Art Bonded Flexible Pipes; 26583U-1161480945-354, Revision 2.0, Approved on 17.12.2018; PSA: Asker, Norway, 2018; pp. 1–75. Available online: https://www.4subsea.com/wp-content/uploads/2019/01/PSA-Norway-State-of-the-art-Bonded-Flexible-Pipes-2018_4Subsea.pdf (accessed on 17 June 2021).

- Muren, J.; Caveny, K.; Eriksen, M.; Viko, N.G.; MÜLler-Allers, J.; JØRgen, K.U. Un-Bonded Flexible Risers–Recent Field Experience and Actions for Increased Robustness; 0389-26583-U-0032, Revision 5.0; PSA: Asker, Norway, 2013; Volume 2, pp. 1–78. Available online: https://www.ptil.no/contentassets/c2a5bd00e8214411ad5c4966009d6ade/un-bonded-flexible-risers--recent-field-experience-and-actions--for-increased-robustness.pdf (accessed on 17 June 2021).

- Drumond, G.P.; Pasqualino, I.; Pinheiro, B.; Estefen, S. Pipelines, risers and umbilicals failures: A literature review. Ocean Eng. 2018, 148, 412–425. [Google Scholar] [CrossRef]

- Simonsen, A. Inspection and Monitoring Techniques for Un-Bonded Flexible Risers and Pipelines. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2014. Available online: http://hdl.handle.net/11250/219671 (accessed on 27 August 2021).

- Muren, J. PSA—Norway Flexible Pipe: Failure Modes, Inspection, Testing and Monitoring. 2007. Available online: https://www.ptil.no/contentassets/a4c8365164094826a24499ef9f22742b/p5996rpt01rev02cseaflex_janmuren.pdf (accessed on 29 July 2021).

- Rabelo, A.S. Estudo do Comportamento de Mangueiras Termoplásticas de Umbilicais Submarinos Submetidas a Carregamentos Mecânicos (in Portuguese, meaning: ‘Study on the Behavior of Submarine Umbilical Thermoplastic Hoses when Submitted to Mechanical Loading’). Master’s Thesis, Universidade Federal do Rio de Janeiro (UFRJ) & COPPE, Rio de Janeiro, Brasil, 2013. Available online: https://w1files.solucaoatrio.net.br/atrio/ufrj-peno_upl//THESIS/6000252/2013_mestrando_alexandre_soares_rabelo_20200405214916875.pdf (accessed on 27 August 2021).

- Asmara, I.P.S.; Wibowo, V.A.P. Safety analysis of mooring hawser of FSO and SPM buoy in irregular waves. In Proceedings of the 2nd Maritime Safety International Conference (MASTIC), Surabaya, Indonesia, 18 July 2020; Volume 557, p. 012003. [Google Scholar]

- Edward, C.; Dev, A.K. Assessment of CALM buoys motion response and dominant OPB/IPB inducing parameters on fatigue failure of offshore mooring chains. In Practical Design of Ships and Other Floating Structures, Proceedings of PRADS 2009 Conference, Lecture Notes in Civil Engineering; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; Volume 64, pp. 548–579. [Google Scholar] [CrossRef]

- Jean, P.; Goessens, K.; L’hostis, D. Failure of chains by bending on deepwater mooring systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. Paper Number: OTC-17238-MS. [Google Scholar] [CrossRef]

- Fergestad, D.; Løtveit, S.A. Handbook on Design and Operation of Flexible Pipes; SINTEF: Trondheim, Norway, 2014; Available online: https://core.ac.uk/download/pdf/52134083.pdf (accessed on 17 June 2021).

- Brownsort, P. Ship Transport of CO2 for Enhanced Oil Recovery: Literature Survey; SCCS (Scottish Carbon Capture and Storage): Edinburgh, UK, 2015; pp. 1–43. Available online: http://www.sccs.org.uk/images/expertise/reports/co2-eor-jip/SCCS-CO2-EOR-JIP-WP15-Shipping.pdf (accessed on 29 July 2021).

- Ziccardi, J.J.; Robbins, H.J. Selection of hose systems for SPM tanker terminals. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 21–23 April 1970; pp. 83–94. [Google Scholar] [CrossRef]

- Tschoepe, E.C.; Wolfe, G.K. SPM Hose Test Program. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1981; pp. 71–80. [Google Scholar] [CrossRef]

- Zhang, S.-F.; Chen, C.; Zhang, Q.-X.; Zhang, N.-M.; Zhang, F. Wave loads computation for offshore floating hose based on partially immersed cylinder model of improved Morison formula. Open Pet. Eng. J. 2015, 8, 130–137. [Google Scholar] [CrossRef][Green Version]

- Gao, Q.; Zhang, P.; Duan, M.; Yang, X.; Shi, W.; An, C.; Li, Z. Investigation on structural behavior of ring-stiffened composite offshore rubber hose under internal pressure. Appl. Ocean Res. 2018, 79, 7–19. [Google Scholar] [CrossRef]

- Gao, P.; Gao, Q.; An, C.; Zeng, J. Analytical modeling for offshore composite rubber hose with spiral stiffeners under internal pressure. J. Reinf. Plast. Compos. 2021, 40, 352–364. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, M.; Ma, J.; Sun, G. Theoretical analysis of reinforcement layers in bonded flexible marine hose under internal pressure. Eng. Struct. 2018, 168, 384–398. [Google Scholar] [CrossRef]

- Brady, I.; Williams, S.; Golby, P. A study of the forces acting on hoses at a monobuoy due to environmental conditions. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–7 May 1974; pp. 1–10. [Google Scholar] [CrossRef]

- Pinkster, J.; Remery, G. The role of model tests in the design of single point mooring terminals. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1975; pp. 679–702. [Google Scholar] [CrossRef]

- Saito, H.; Mochizuki, T.; Fukai, T.; Okui, K. Actual measurement of external forces on marine hoses for SPM. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1980; pp. 89–97. [Google Scholar] [CrossRef]

- Nooij, S. Feasibility of IGW Technology in Offloading Hoses. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2006. Available online: http://resolver.tudelft.nl/uuid:4617e7a0-b5d8-4c86-94d5-8d2037b31769 (accessed on 12 October 2021).

- Ryu, S.; Duggal, A.S.; Heyl, C.N.; Liu, Y. Prediction of deepwater oil offloading buoy response and experimental validation. Int. J. Offshore Polar Eng. 2006, 16, 1–7. Available online: https://www.sofec.com/wp-content/uploads/white_papers/2006-ISOPE-Prediction-of-DW-Oil-Offloading-Buoy-Response.pdf (accessed on 12 October 2021).

- Doyle, S.; Aggidis, G.A. Experimental investigation and performance comparison of a 1 single OWC, array and M-OWC. Renew. Energy 2021, 168, 365–374. [Google Scholar] [CrossRef]

- Lassen, T.; Lem, A.I.; Imingen, G. Load response and finite element modelling of bonded offshore loading hoses. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, OMAE 2014, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Kang, Y.; Chai, S. Motion response analysis of FPSO’s CALM buoy offloading system. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering, St. John’s, NL, Canada. 31 May–5 June 2015; Prof. Robert, F. Beck Honoring Symposium on Marine Hydrodynamics; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 11, pp. 1–7. [Google Scholar] [CrossRef]

- Santala, M.J.; Wang, H. Component approach for confident predications of deepwater CALM buoy coupled Motions: Part 2—Analytical implementation. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; American Society of Mechanical Engineers: New York, NY, USA, 2005; Volume 1, pp. 367–375. [Google Scholar] [CrossRef]

- Le Cunff, C.; Ryu, S.; Duggal, A.; Ricbourg, C.; Heurtier, J.; Heyl, C.; Liu, Y.; Beauclair, O. Derivation of CALM buoy coupled motion RAOs in frequency domain and experimental validation. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007; pp. 1–8, Paper Number: ISOPE-I-07-402. Available online: https://www.sofec.com/wp-content/uploads/white_papers/2007-ISOPE-Derivation-of-CALM-Buoy-Coupled-Motion-RAOs-in-Frequency-Domain.pdf (accessed on 12 October 2021).

- Williams, N.A.; McDougal, W.G. Experimental validation of a new shallow water CALM buoy design. In International Conference on Ocean, Offshore and Arctic Engineering, Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 1, pp. 1–6. [Google Scholar] [CrossRef]

- Salem, A.G.; Ryu, S.; Duggal, A.S.; Datla, R.V. Linearization of quadratic drag to estimate CALM buoy pitch motion in frequency-domain and experimental validation. J. Offshore Mech. Arct. Eng. 2012, 134, 907–911. [Google Scholar] [CrossRef]

- Berhault, C.; Guerin, P.; le Buhan, P.; Heurtier, J.M. Investigations on hydrodynamic and mechanical coupling effects for deepwater offloading buoy. In Proceedings of the Fourteenth International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004; Volume 3, pp. 374–379. Available online: http://legacy.isope.org/publications/proceedings/ISOPE/ISOPE%202004/volume3/2004-pf-03.pdf (accessed on 12 October 2021).

- Cozijn, J.L.; Bunnik, T.H.J. Coupled Mooring Analysis for a Deep water CALM Buoy. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2004 23rd International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004; American Society of Mechanical Engineers: New York, NY, USA, 2004; Volume 1, pp. 663–673. [Google Scholar] [CrossRef]

- Young, R.A.; Brogren, E.E.; Chakrabarti, S.K. Behavior of loading hose models in laboratory waves and currents. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1980; pp. 421–428. [Google Scholar] [CrossRef]

- Le Cunff, C.; Ryu, S.; Heurtier, J.-M.; Duggal, A.S. Frequency-domain calculations of moored vessel motion including low frequency effect. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2008 27th International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; American Society of Mechanical Engineers: New York, NY, USA, 2008; Volume 1, pp. 689–696. [Google Scholar] [CrossRef]

- Amaechi, C.V. Experimental and analytical study on the hydrodynamic behaviour of CALM buoy for its motion response with hose-snaking phenomenon under water waves. J. Mar. Sci. Eng. 2021, in press. [Google Scholar]

- Amaechi, C.V. Numerical study on plastic deformation, plastic strains and bending of tubular pipes. Inventions 2021, in press. [Google Scholar]

- Amaechi, C.V.; Wang , F.; Ye, J. Understanding the fluid-structure interaction from wave diffraction forces on CALM buoys: Numerical and analytical solutions. Ships Offshore Struct. 2021. [Google Scholar] [CrossRef]

- Cozijn, H.; Uittenbogaard, R.; Brake, E.T. Heave, Roll and Pitch Damping of a Deepwater CALM Buoy with a Skirt. In Proceedings of the Fifteenth International Offshore and Polar Engineering Conference, Seoul, Korea, 19–24 June 2005; Volume 8, pp. 388–395. Available online: https://www.researchgate.net/publication/267364857_Heave_Roll_and_Pitch_Damping_of_a_Deepwater_CALM_Buoy_with_a_Skirt (accessed on 17 October 2021).

- Duggal, A.; Ryu, S. The dynamics of deepwater offloading buoys. In WIT Transactions on the Built Environment. Fluid Structure Interaction and Moving Boundary Problem; WIT Press: Southampton, UK, 2005; Available online: https://www.witpress.com/Secure/elibrary/papers/FSI05/FSI05026FU.pdf (accessed on 17 October 2021).

- Kang, Y.; Sun, L.; Kang, Z.; Chai, S. Coupled analysis of FPSO and CALM buoy offloading system in West Africa. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 8, p. OMAE2014-23118. [Google Scholar] [CrossRef]

- O’Sullivan, M. Predicting interactive effects of CALM buoys with deepwater offloading systems. Offshore Mag. 2003, 63. Available online: https://www.offshore-mag.com/production/article/16755731/predicting-interactive-effects-of-calm-buoys-with-deepwater-offloading-systems (accessed on 17 October 2021).

- Sao, K.; Numata, T.; Kikuno, S. Basic equation and SALM buoy motion. J. Soc. Nav. Arch. Jpn. 1987, 1987, 257–266. [Google Scholar] [CrossRef][Green Version]

- Obokata, J. On the basic design of single point mooring (1st report)—Applications of the dynamic stability analysis to the primary planning of the system. J. Soc. Nav. Archit. Jpn. 1987, 161, 183–195. [Google Scholar] [CrossRef]

- Obokata, J.; Nakajima, T. On the basic design of single point mooring system (2nd report)—Estimation of the mooring force. J. Soc. Nav. Archit. Jpn. 1988, 163, 252–260. [Google Scholar] [CrossRef]

- Oliveira, M.C. Ultradeepwater Monobuoys. In International Conference on Offshore Mechanics and Arctic Engineering, Proceedings of the ASME 2003 22nd International Conference on Offshore Mechanics and Arctic Engineering, Cancun, Mexico, 8–13 June 2003; American Society of Mechanical Engineers: New York, NY, USA, 2003; Volume 1, pp. 169–178. [Google Scholar] [CrossRef]

- Quash, J.; Burgess, S. Improving Underbuoy Hose System Design Using Relaxed Storm Design Criteria. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 1979; pp. 1827–1836. [Google Scholar] [CrossRef]

- Bruschi, R.; Vitali, L.; Marchionni, L.; Parrella, A.; Mancini, A. Pipe technology and installation equipment for frontier deep water projects. Ocean Eng. 2015, 108, 369–392. [Google Scholar] [CrossRef]

- Roveri, F.E.; Volnei Luís Sagrilo, S.; Cicilia, F.B. A case study on the evaluation of floating hose forces in a CALM system. In Proceedings of the Twelfth International Offshore and Polar Engineering Conference, Kitakyushu, Japan, 26–31 May 2002; Volume 3, pp. 190–197. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE02/All-ISOPE02/ISOPE-I-02-030/8329 (accessed on 12 October 2021).

- Sagrilo, L.; Siqueira, M.; Ellwanger, G.; Lima, E.; Ferreira, M.; Mourelle, M. A coupled approach for dynamic analysis of CALM systems. Appl. Ocean Res. 2002, 24, 47–58. [Google Scholar] [CrossRef]

- Butler, H.O. An Analysis of the Failure of Composite Flexible Risers. Bachelor’s Thesis, Lancaster University, Lancaster, UK, 2021. [Google Scholar]

- Hanonge, D.; Luppi, A. Special session: Advances in flexible riser technology: Challenges of flexible riser systems in shallow waters. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010. [Google Scholar] [CrossRef]

- Gonzalez, G.M.; de Sousa, J.R.M.; Sagrilo, L.V.S. A study on the axial behavior of bonded flexible marine hoses. Mar. Syst. Ocean Technol. 2016, 11, 31–43. [Google Scholar] [CrossRef]

- Ali, M.O.A.; Jae, I.A. and Hwa, M.G.Z. Effects of water depth, mooring line diameter and hydrodynamic coefficients on the behaviour of deepwater FPSOs. Ain Shams Eng. J. 2020, 11, 727–739. [Google Scholar] [CrossRef]

- Ricbourg, C.; Berhault, C.; Camhi, A.; Lecuyer, B.; Marcer, R. Numerical and experimental investigations on deepwater CALM buoys hydrodynamics Loads. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006; pp. 1–8. [Google Scholar] [CrossRef]

- Trelleborg. Surface Buoyancy Brochure; Report BC-SUR-v1.3-EN; Trelleborg: Trelleborg, Sweden, 2017; pp. 1–24. Available online: https://www.trelleborg.com/en/marine-and-infrastructure/products-solutions-and-services/marine/surface-buoyancy (accessed on 25 October 2021).

- Trelleborg. Oil & Gas Solutions: Oil & Gas Hoses for Enhanced Fluid Transfer Solutions; Trelleborg: Clemont-Ferrand, France, 2016. [Google Scholar]

- Rampi, L.; Lavagna, P.; Mayau, D. TRELLINE? A cost-effective alternative for oil offloading lines (OOLs). In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Prischi, N.; Mazuet, F.; Frichou, A.; Lagarrigue, V. SS-offshore offloading systems and operations bonded flexible oil offloading lines, a cost effective alternative to traditional oil offloading lines. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2012. [Google Scholar] [CrossRef]

- Mayau, D.; Rampi, L. Trelline—A new flexible deepwater offloading line (OLL). In Proceedings of the Sixteenth International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 28 May–2 June 2006; Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE06/All-ISOPE06/ISOPE-I-06-127/9875 (accessed on 12 October 2021).

- OCIMF. Guide to Manufacturing and Purchasing Hoses for Offshore Moorings (GMPHOM); Witherby Seamanship International Ltd.: Livingstone, UK, 2009. [Google Scholar]

- OCIMF. Guideline for the Handing, Storage, Inspection and Testing of the Hose, 2nd ed.; Witherby & Co., Ltd.: London, UK, 1995. [Google Scholar]

- OCIMF. Single Point Mooring Maintenance and Operations Guide (SMOG); Witherby & Co., Ltd.: London, UK, 1995. [Google Scholar]

- MBC. The effectiveness of Marine Breakaway Couplings in Minimising Risk to FPSO Transfer Operations: From the Perspective of Reeled or In-Air Catenary Reeled Configurations. 2018. Available online: https://www.marinebreakawaycouplings.com/wp-content/uploads/2019/01/FPSO-MBC-on-reel-whitepaper-marinebreakawaycouplings-August-2018.pdf (accessed on 12 October 2021).

- O’Donoghue, T.; Halliwell, A.R. Floating hose-strings attached to a CALM buoy. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1988; pp. 313–320. [Google Scholar] [CrossRef]

- O’Donoghue, T.; Halliwell, A. Vertical bending moments and axial forces in a floating marine hose-string. Eng. Struct. 1990, 12, 124–133. [Google Scholar] [CrossRef]

- O’Donoghue, T. The Dynamic Behaviour of a Surface Hose Attached to a CALM Buoy. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 1987. Available online: https://www.ros.hw.ac.uk/handle/10399/1045?show=full (accessed on 17 May 2021).

- Bree, J.; Halliwell, A.R.; O’Donoghue, T. Snaking of floating marine oil hose attached to SPM buoy. J. Eng. Mech. 1989, 115, 265–284. [Google Scholar] [CrossRef]

- SBMO. Loading/Offshore Terminals—SBMO CALM Brochure; SBM Offshore: Amsterdam, The Netherlands, 2012; pp. 1–20. Available online: https://www.scribd.com/document/396757606/SBMO-Loading-Offloading-Original-2052 (accessed on 17 October 2021).

- SBMO. Normand Installer Deep Water Installation Vessel Brochure; SBM Offshore: Amsterdam, The Netherlands, 2012; pp. 1–12. Available online: https://www.sbmoffshore.com/sites/sbm-offshore/files/sbm-offshore/our-know-how/lifecycle-value/sbmo-nii-original-2158.pdf (accessed on 17 October 2021).

- Brown, M.J.; Elliot, L. A design tool for static underbuoy hose-systems. Appl. Ocean. Res. 1987, 9, 171–180. [Google Scholar] [CrossRef]

- Bluewater. Conventional Buoy Mooring Systems; Bluewater Energy Services: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Bluewater. Turret Buoy; Bluewater Energy Services: Amsterdam, The Netherlands, 2016; Available online: https://www.bluewater.com/products-technology/mooring-systems/spread-mooring/turntable-buoy/ (accessed on 19 August 2021).

- Bluewater. Bluewater Turret Buoy—Technical Description; Bluewater Energy Services: Amsterdam, The Netherlands, 2013; Available online: https://www.bluewater.com/wp-content/uploads/2013/03/turretbuoy_folder.pdf (accessed on 19 August 2021).

- Alfagomma. Industrial Hose & Fittings; Alphagomma SpA: Vimercate, Italy, 2016. [Google Scholar]

- Fluid-Tec. Anflex Industrial Hose; Fluid-Tec Engineering & Trading: Singapore, 2015. [Google Scholar]

- ContiTech. Continental Marine Hose Brochure; Dunlop Oil & Marine, Continental Contitech Oil & Gas: Grimsby, UK, 2020; Available online: https://aosoffshore.com/wp-content/uploads/2020/02/ContiTech_Marine-Brochure.pdf (accessed on 17 February 2021).

- ContiTech. Offshore Product Catalogue: GMPHOM 2009 Hoses Brochure; Dunlop Oil & Marine, Continental Contitech Oil & Gas: Grimsby, UK, 2020; Available online: https://www.jst-group.com/wp-content/uploads/2020/01/Brochure-Dunlop-Oil-and-Marine-GMPHOM.pdf (accessed on 19 August 2021).

- OIL. Offloading Hoses—OIL Hoses Brochure; Offspring International Limited: Dudley, UK, 2020; Available online: https://www.offspringinternational.com/wp-content/uploads/2020/06/OIL-Offloading-Hoses-Brochure-2020-W.pdf (accessed on 19 August 2021).

- OIL. Mooring and Offloading Systems; Offspring International Limited: Dudley, UK, 2015; Volume 1, Available online: http://www.offspringinternational.com/wp-content/uploads/2015/04/OIL-SPM-Brochure-2015.pdf (accessed on 17 February 2021).

- OIL. Mooring and Offloading Systems; Offspring International Limited: Dudley, UK, 2019; Volume 2, Available online: https://www.offspringinternational.com/wp-content/uploads/2019/08/OIL-SPM-Brochure-2019-4-W.pdf (accessed on 19 August 2021).

- ABS. Rules for Building and Classing—Single Point Moorings; American Bureau of Shipping: New York, NY, USA, 2021. [Google Scholar]

- DNVGL. DNVGL-OS-E403 Offshore Loading Buoys, No. July; Det Norske Veritas & Germanischer Lloyd: Oslo, Norway, 2015. [Google Scholar]

- API. API 17K: Specification for Bonded Flexible Pipe, 3rd ed.; American Petroleum Institute, API Publishing Services: Washington, DC, USA, 2016. [Google Scholar]

- API. API 17J: Specification for Unbonded Flexible Pipe, 4th ed.; American Petroleum Institute, API Publishing Services: Washington, DC, USA, 2014. [Google Scholar]

- API. API Spec. 7K. Specification for Drilling and Well Service Equipment, 6th ed.; American Petroleum Institute, API Publishing Services: Washington, DC, USA, 2015. [Google Scholar]

- API. API RP 17B. Recommended Practice for Flexible Pipe, 5th ed.; American Petroleum Institute, API Publishing Services: Washington, DC, USA, 2014. [Google Scholar]

- TWI. What is Corrective Maintenance? (Definition, Pros, Cons and Examples); TWI: Cambridge, UK, 2020; Available online: https://www.twi-global.com/technical-knowledge/faqs/what-is-corrective-maintenance#WhenisCorrectiveMaintenanceNeeded (accessed on 17 October 2021).

- USArmy. Engineering Design Handbook: Maintainability Guide for Design; The United States Army, Department of the Army, United States Army Material Command: Washington, DC, USA, 1972; pp. 1–440. Available online: https://apps.dtic.mil/sti/pdfs/AD0754202.pdf (accessed on 1 February 2021).

- Trelleborg. Oil Applications: Offshore Transfer of Crude Oil and Refined Petroleum Products/Hose Selection; Trelleborg: Clemont-Ferrand, France, 2016; Available online: https://www.trelleborg.com/en/fluidhandling/products-and-solutions/oil-transfer/oil (accessed on 17 October 2021).

- Trelleborg. TRELLINE Catalogue; Trelleborg: Clemont-Ferrand, France, 2014; Available online: http://www2.trelleborg.com/Global/WorldOfTrelleborg/Fluid%20handling/TRELLINE%20Catalogue.pdf (accessed on 12 October 2021).

- Trelleborg. REELINE Catalogue; Trelleborg: Clemont-Ferrand, France, 2012; Available online: http://www2.trelleborg.com/Global/WorldOfTrelleborg/Fluid%20handling/REELINE_catalogue.pdf (accessed on 12 October 2021).

- Trelleborg. SEALINE Catalogue; Trelleborg: Clemont-Ferrand, France, 2014; Available online: https://pdf.directindustry.com/pdf/trelleborg-industrial-hose/sealine/23376-644442.html (accessed on 12 October 2021).

- ContiTech. Hose Data Tables: GMPHOM 2009 Hoses Brochure; Dunlop Oil & Marine and Continental Contitech Oil & Gas: Grimsby, UK, 2014. [Google Scholar]

- ContiTech. Hose Information Manual—Dunlop Oil & Marine Hoses; Dunlop Oil & Marine, Continental Contitech Oil & Gas: Grimsby, UK, 2017; pp. 1–65. [Google Scholar]

- Dunlop. Offshore Hose Design; Report No. RD 178 [cited: 1987]; Dunlop Oil and Marine Division: Grimsby, UK, 1986. [Google Scholar]

- Dunlop. DOM Hose Design Manual; Report No. RD 675; Dunlop Oil and Marine (DOM) Limited: Grimsby, UK, 1991. [Google Scholar]

- Woodley-Dyne, W. Developments in Terminal Handling of Oil Cargoes. Pipes Pipelines Int. 1969, 14, 38–40. Available online: https://trid.trb.org/view/1011 (accessed on 12 October 2021).

- Muller, S.E.; Prince, C.A. Operating experiences—Offshore storage and loading facilities. In Proceedings of the SPE European Meeting, London, UK, 2–3 April 1973. Paper Number: SPE-4340-MS. [Google Scholar] [CrossRef]

- Mauriès, B.; Lagarrigue, V.; Harmary, J. Qualification of an innovative offshore LNG tandem offloading system using cryogenic floating hoses. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 20–22 March 2013; Paper Number: OMC-2013-097. Available online: https://www.igu.org/wp-content/uploads/2016/06/storage-5-benjamin_mauries.pdf (accessed on 1 February 2021).

- Hervouet, R.; Makin, T.; King, P.A.; Ross, N.; Nicholls, D.J. Birch field extended well test: An economic approach to future field development. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 1989. Paper Number: OTC-6080-MS. [Google Scholar] [CrossRef]

- Amaechi, C.V. Numerical assessment of marine hose load response during reeling and free-hanging operations under ocean waves. Mar. Struct. 2021, in press. [Google Scholar]

- Amaechi, C.V. Analytical cum numerical solutions on added mass and damping of a CALM buoy towards understanding the fluid-structure interaction of marine bonded hose under random waves. Mar. Struct. 2021, in press. [Google Scholar]

- Amaechi, C.V. Liner wrinkling, helix spring deformation and mechanical behaviour of Marine Bonded Composite Hoses (MBCH) using local design pressure under burst and collapse. J. Mar. Sci. Eng. 2021, 9. in press. [Google Scholar]

- Amaechi, C.V. Effect of marine riser integration for characteristic motion response studies on a Paired Column Semisubmersible in deep waters. Mar. Struct. 2021, in press. [Google Scholar]

- Doyle, S.; Aggidis, G.A. Development of Multi-Oscillating Water Columns as Wave Energy Converters. Renew. Sustain. Energy Rev. 2019, 107, 75–86. [Google Scholar] [CrossRef]

- Odijie, A.C.; Wang, F.; Ye, J. A review of floating semisubmersible hull systems: Column stabilized unit. Ocean Eng. 2017, 144, 191–202. [Google Scholar] [CrossRef]

| Hose Description | Hose Design |

|---|---|

| Double Carcass Floating Hose End-reinforced Half (or first-off Buoy) |  |

| Double Carcass Floating Hose Main Line |  |

| Double Carcass Submarine Hose End-Reinforced (no floats) |  |

| Double Carcass Submarine Hose Main Line (no floats) |  |

| Double Carcass Submarine Hose End-Reinforced with floats |  |

| Double Carcass Submarine Hose Main Line with floats |  |

| Double Carcass Submarine Hose Main Line with Half floats |  |

| Double Carcass Tail floating |  |

| Double Carcass Reducing floating |  |

| Double Carcass Controlled buoyancy |  |

| FPSO | Transportation | Hose Diameter (Inches) | Hose Type (Single/Dual Carcass) | Industry Brand | Sea |

|---|---|---|---|---|---|

| HYSYS101 | Floating | 12 | Single Carcass | Yokohama | Bohai Sea |

| HYSYS102 | Floating | 16 | Single Carcass | Goodyear | Bohai Sea |

| HYSYS109 | Reeling | 16, 20 | Single Carcass & Dual Carcass | Yokohama & Dunlop | Bohai Sea |

| HYSYS112 | Reeling | 16, 20 | Double Carcass | Dunlop | Bohai Sea |

| HYSYS113 | Reeling | 16, 20 | Double Carcass | Dunlop | Bohai Sea |

| HYSYS117 | Reeling | 16, 24 | Double Carcass | Goodyear | Bohai Sea |

| HYSYS161 | Reeling | 8 | Double Carcass | Goodyear | Bohai Sea |

| HYSYS103 | Reeling | 16 | Single Carcass | Yokohama | South China Sea |

| HYSYS104 | Floating | 12, 16 | Single Carcass | Yokohama | South China Sea |

| HYSYS106 | Floating | 16, 20 | Single Carcass | Yokohama | South China Sea |

| HYSYS107 | Floating | 16 | Single Carcass | Yokohama | South China Sea |

| HYSYS110 | Reeling | 16, 20 | Double Carcass | Dunlop | South China Sea |

| HYSYS111 | Floating | 16 | Single Carcass | Yokohama | South China Sea |

| HYSYS115 | Reeling | 16 | Double Carcass | Goodyear | South China Sea |

| HYSYS116 | Reeling | 16 | Double Carcass | Goodyear | South China Sea |

| No. | Location | Description | Hose Type | Optional Type | Characteristics | Application |

|---|---|---|---|---|---|---|

| 1 | FPSO Connection | Off take connection | Floating | Reel | Reinforced hose end, at one end | Connected to shuttle tanker bow loading point or FPSO |

| 2 | Reduced Buoyancy | Reducer | Floating | Reel | Reduced buoyancy or Neutral | Often next to 2–3 hose sections on the string |

| 3 | Mainline | Mainline | Floating | Reel | Fairly flexible | Main part of the floating hose string |

| 4 | Operational Taper | Taper | Floating | Reel | Integral reducing bore | Connection of smaller bore tail hose and larger bore mainline |

| 5 | Tail | Tail Hose | Floating | Reel | Electrically discontinuous | Smaller bore diameter compared to mainline. Links tanker end to handle rail hose |

| 6 | Rail | Rail Hose | Floating Rail | Reel | Higher flexibility during lug lifting | Over rail hose for connecting to the manifolds of conventional midships |

| No. | Location | Description | Hose Type | Optional Type | Characteristics | Application |

|---|---|---|---|---|---|---|

| 1 | FPSO Connection | Off take connection or bow connector hose | Submarine | Reel | Reinforced hose end, at one end | Connected to shuttle tanker bow loading point or FPSO |

| 2 | Mainline | Mainline | Submarine | Reel | Reduced buoyancy or Neutral | Main part of the catenary |

| 3 | Rail Hose | Rail Hose | Submarine | Reel | Higher flexibility during lug lifting | Over rail hose for connecting to the manifolds of conventional midships |

| No. | Location | Description | Hose Type | Optional Type | Characteristics | Application |

|---|---|---|---|---|---|---|

| 1 | PLEM Connection | PLEM connection | Submarine | --- | Reinforced hose end, at one end | Connected to shuttle tanker bow loading point or FPSO |

| 2 | Mainline | Mainline | Submarine | --- | Reduced buoyancy or Neutral | Main part of the floating hose string |

| 3 | Operational Taper | Taper | Submarine | --- | Integral reducing bore | Connection of smaller bore tail hose and larger bore mainline |

| 4 | Tail | Tail Hose | Submarine | --- | Electrically discontinuous | Smaller bore diameter compared to mainline. Links tanker end to handle rail hose |

| 5 | Rail | Rail Hose | Submarine | --- | Higher flexibility during lug lifting | Over rail hose for connecting to the manifolds of conventional midships |

| Hang-Off System | Pros | Cons | Limitation |

|---|---|---|---|

| Flex Joint | Decoupling the riser from the platform pitch and roll motions, which reduces the stresses in the upper region of the riser and supporting porch structure; better accommodating variations in riser performance characteristics; a reliable technical solution particularly for fatigue design | A relatively sophisticated component; requires good fatigue design and more checks on the stress effect. | Appropriate inspection procedures needed under high temperature and pressure fluctuation environment |

| Tapered Stress Joint (TSJ) | A one-piece metallic component without any moving parts—less complicated than a flex joint. | As the riser size increases or the severity in the platform pitch and roll motions increases, the TSJ becomes more challenging | Suitable in cases where the relative rotation between the platform and the riser is not excessive. |

| Pull Tube | Avoiding the use of any subsea mechanical connections on the riser which is economical and simple | Little room for flexibility; potential for wear between the riser and the end of the pull tube, and requires good inspection procedures. |

| Name of FPSO | MBC Size (″) | Coupling Type | Hose Type |

|---|---|---|---|

| Enfield | 16 | CDC | Floating hose string |

| Ngujima Yin | 16 | CDC | Floating hose string |

| Seillean | 12 | CDC | Floating hose string |

| Anchieta | 20 | CDC | Floating hose string |

| Seillean | 8 | CDC | Floating hose string |

| Girassol | 6 | SCC | Floating hose string |

| Girassol | 6 | SCC | Floating hose string |

| White Rose | 20 | SCC | In air Catenary |

| McCulloch | 16 | SCC | In air Catenary |

| Guillemot/Teal | 16 | SCC | In air Catenary |

| Guillemot/Teal | 16 | SCC | In air Catenary |

| Curlew | 16 | SCC | In air Catenary |

| Triton | 16 | SCC | In air Catenary |

| Triton | 16 | SCC | In air Catenary |

| Bleo Holm | 16 | SCC | Submerged Catenary |

| Ettrick | 16 | SCC | Submerged Catenary |

| Golfinho | 20 | CDC | Floating hose string |

| Wenchang LPG | 6 | DNCC F/F | Floating hose string |

| Wenchang | 16 | SCC | Floating hose string |

| Wenchang 2 | 16 | SCC | Floating hose string |

| Bongkot | 10 | SCC | Floating hose string |

| Bongkot | 10 | SCC | Floating hose string |

| Sakhalin | 16 | CDC | Floating hose string |

| Sakhalin | 16 | CDC | Floating hose string |

| Kraken | 16 | CDC | Submerged Catenary |

| Aoka Mizu | 16 | SCC | Submerged Catenary |

| Sable | 16 | SCC | Submerged Catenary |

| P17 | 20 | CDC | Floating hose string |

| Capixaba | 20 | CDC | Floating hose string |

| Okha | 16 | CDC | Floating hose string |

| Nganhurra | 16 | CDC | Floating hose string |

| Marlim Sul | 20 | CDC | Floating hose string |

| Prelude | 16 | CDC | Floating hose string |

| Culzean | 16 | CDC | Floating hose string |

| Free Hanging | Steep-S | Lazy-S | Steep Wave | Lazy Wave | Pliant Wave | Weight Added Wave | Touch Down Chain Added Wave | Chinese Lantern | |

|---|---|---|---|---|---|---|---|---|---|

| Dynamic behaviour | |||||||||

| Hostile weather, shallow water | Poor | Limited | Good | Good- | Poor | Good | Good- | Good | Good |

| Hostile weather, deep water | Limited | Good | Good | Good+ | Good- | Good+ | Limited | Good- | Good |

| Fair weather, shallow water | Limited | Good- | Good+ | Good | Good- | Good | Good- | Good | Good |

| Fair weather, deep water | Good | Good | Good | Excellent | Excellent | Excellent | Good | Excellent | Good |

| Installation ease | Excellent | Poor | Good | Good- | Excellent | Good | Good- | Good | Good |

| Economic profile | |||||||||

| One line | Excellent | Limited | Good- | Good- | Good+ | Excellent | Good- | Good+ | --- |

| Several lines | Excellent | Good- | Good+ | Good- | Limited | Good- | Good | Good+ | Limited |

| Adaptability—No. Lines | Excellent | Excellent | Excellent | Good- | Limited | Good- | Good | Good+ | Limited |

| Advantages | Disadvantages |

|---|---|

|

|

| Parameters | Hose Product Lines by Trelleborg | Hose Product Lines by Dunlop | ||||||

|---|---|---|---|---|---|---|---|---|

| Hose Selection | Sealine | Kleline | Reeline | Trelline | Saflote | Safgard | Selflote | SCS |

| Typical Floating Configurations | ||||||||

| CALM | X | X | X | X | X | X | ||

| TANDEM | X | X | X | X | X | X | ||

| SALM | X | X | X | X | X | X | ||

| REEL | X | X | ||||||

| Typical submarine configurations | ||||||||

| ALP | X | |||||||

| SHIP-TO-SHIP | X | X | X | X | ||||

| SHIP-TO-SHORE | X | X | X | X | X | |||

| CBM/MBM | X | X | X | X | X | |||

| CHINESE-LANTERN | X | X | X | X | X | X | X | |

| LAZY-S | X | X | X | X | X | X | X | |

| STEEP-S | X | X | X | X | X | X | X | |

| FLOWLINE | X | X | X | X | X | X | X | |

| RISER | X | X | X | X | X | X | ||

| JUMPER | X | X | X | X | X | X | ||

| REEL | X | X | X | X | ||||

| DEEP WATER OOL | X | X | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. An Overview on Bonded Marine Hoses for Sustainable Fluid Transfer and (Un)Loading Operations via Floating Offshore Structures (FOS). J. Mar. Sci. Eng. 2021, 9, 1236. https://doi.org/10.3390/jmse9111236

Amaechi CV, Chesterton C, Butler HO, Wang F, Ye J. An Overview on Bonded Marine Hoses for Sustainable Fluid Transfer and (Un)Loading Operations via Floating Offshore Structures (FOS). Journal of Marine Science and Engineering. 2021; 9(11):1236. https://doi.org/10.3390/jmse9111236

Chicago/Turabian StyleAmaechi, Chiemela Victor, Cole Chesterton, Harrison Obed Butler, Facheng Wang, and Jianqiao Ye. 2021. "An Overview on Bonded Marine Hoses for Sustainable Fluid Transfer and (Un)Loading Operations via Floating Offshore Structures (FOS)" Journal of Marine Science and Engineering 9, no. 11: 1236. https://doi.org/10.3390/jmse9111236

APA StyleAmaechi, C. V., Chesterton, C., Butler, H. O., Wang, F., & Ye, J. (2021). An Overview on Bonded Marine Hoses for Sustainable Fluid Transfer and (Un)Loading Operations via Floating Offshore Structures (FOS). Journal of Marine Science and Engineering, 9(11), 1236. https://doi.org/10.3390/jmse9111236