3.1. Results of the First Part of the Simulation

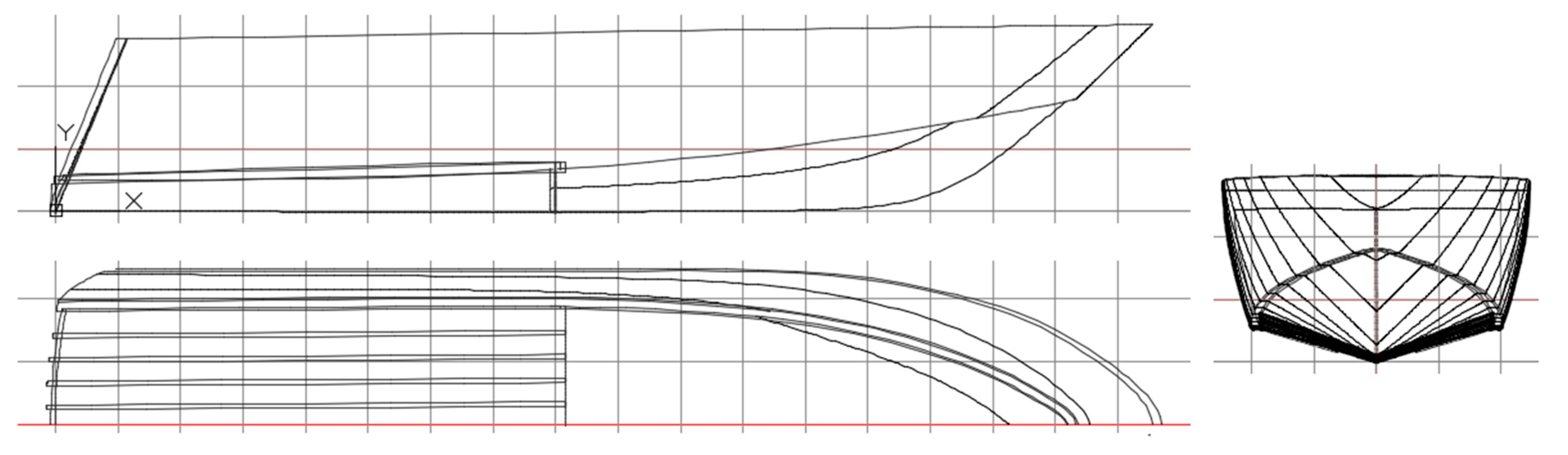

The first part of the simulation concerns the model without air injection. The curves of resistance, trim, and sinkage were compared with the ones of experimental tests. In adding to this information, the other purpose of this block of simulations is to have a starting point for the next campaign of simulation.

Figure 10 shows the comparison between experimental and numerical simulation. The maximum difference between the two curves is to the maximum velocity.

Usually, the increase of velocity could lead to a higher probability of numerical ventilation effect. This effect is caused by two main reason: the VoF method, at high Fn and with an overset mesh [

37], and the planing hull characteristics (the acute angle caused by the intersection between the hull and the free-surface) [

38]. Even if this phenomenon is known and studied, there are very few specific studies on a problem as complex as that relating to a cavity of air injected at high speed under a surface equipped with dynamic motions and with a mesh overset. This effect produces localized areas under the hull with the presence of the air which in reality does not exist. This presence of the air could lead to a reduction of the drag with respect to experimental tests. In this case the effect is localized and produces a difference lower than 7%.

Another two crucial parameters compared are the trim and the sinkage.

Figure 11 shows the behavior of the trim of the model during the different velocities. The trend of the curves is similar, with peaks of the CFD model more marked than the experimental test. Trim prediction is always the most challenging issue because it depends not only on the pressure but also on its distribution and, in particular, in this case, it is strictly related to the wetted length. However, even if the trend tends to change about Fn 0.8, the maximum difference is lower than 10%. In

Figure 12 the sinkage comparison is reported, the two curves have the same trend.

The CFD results of this campaign confirm that the settings used for the Virtual Towing Tank allow having results very similar to experimental tests. The comparison highlights the same trend for the three different quantities reported. Another important physic quantity is the wetted surface of the boat. This quantity is not a result of the experimental tests, but it can be evaluated with CFD simulations.

Figure 13 shows the ratio between the wetted surface area in static condition and during the corresponding speed. The graph highlights a drastic decrease of the wetted surface between 0.7 and 1 of the Froude number. In this condition, the wetted surface is about 65% of the static one. At the Froude number of 0.7, the hull starts to planing so there is a decreasing of the wetted surface. The complete planing is reached at a Froude number of about 1.0.

At the last value of this campaign of velocity, as mentioned above, an uncertainty analysis was conducted in order to evaluate the influence of the grid to the final result. At the value of Fn of 1.36, three different meshes were investigated with the number of cells in ratio of 1.4 (as suggested by ITTC [

35]).

Table 5 shows the results of the physical quantities investigated to the three different meshes. For all the parameters under investigation, the method used suggests a monotonic convergence (

Table 6). Thanks to the monotonic convergence, the safety factor of the Richardson expression (6) as suggested by Stern [

36] can be equal to 1. The same table shows that the maximum uncertainty is about 5.1% for the mesh used in this campaign of simulations. The maximum uncertainty is for the value of drag.

3.2. The Second Campaign of Simulation

In this part of the simulation, for each number of Froude simulated in the first campaign, the virtual tests were performed adding the air injection. Also in this case, the numerical simulations were compared with experimental tests and in adding, thanks to the Virtual Towing tank, the wetted surface was reported for each condition of air flow.

Figure 14 shows the first two flow rates with the relative curves of experimental tests. In both cases, the CFD results of air injection have a trend lower than experimental tests. In general, the air injection to these flow rates produces a decrease of resistance in the magnitude of 1% on average for the experimental tests. For CFD results, this decrease of resistance, on average, is in the magnitude of 5%. The difference between experimental tests and numerical simulations is lower than 15% in all the points. The difference between experimental tests and numerical simulations could be caused by the great mixture of air and water to these values of flow rate. The VoF scheme, with the HRIC model tends to underestimate the mix of air and water in the rails and underestimate the wetted surface, introducing a more positive effect on drag than experimental tests.

Thanks to CFD it is possible to evaluate the differences in terms of reduction of the wetted surface with the air injection. The reduction of the wetted surface allows decreasing the frictional resistance of the model. On average, the reduction of wetted surface for 5500 L/min and 6500 L/min is about 60%.

Figure 15 shows the trend to different velocities for both the flow rates. The first two flow rates investigated suggest that no great difference there is between 5500 L/min and 6500 L/min. The air under the hull probably is not entirely developed and the effect in terms of drag is very low in both flow rates.

Figure 16 shows the drag curves for 7500 L/min and 8500 L/min flow rates and the relative ones without air injection. In both cases, the CFD results of air injection have a trend lower than experimental tests. In general, the air injection to flow rate of 7500 L/min produces a decrease of resistance in the magnitude of 2% on average for the experimental tests. For CFD results, this decrease is about 7%. In the case of 8500 L/min, the reduction is about 8% for experimental tests and 11% for CFD results. The difference between experimental tests and numerical simulations is lower than 15% in all the points.

Figure 17 shows the wetted surface at different Fn for flow rates of 7500 and 8500 L/min. The decrease of the wetted surface area is respectively 62% and 65%. To the flow rate of 8500 L/min the decrease of drag is appreciable in experimental tests and in CFD simulations. The flow of air under the hull starts to cover a higher percentage of bottom of the hull. This value of flow rate seems to be the turning point, lower than this value the effects are negligible.

Figure 18 shows the drag curves for 9500 L/min and 10,500 L/min flow rates and the relative ones without air injection. In this case, the CFD curves have a trend lower than the experimental ones, but the difference is reduced to lower than 10%. In general, the air injection to flow rate of 9500 L/min produces a decrease of resistance in the magnitude of 11% on average for the experimental tests. For CFD results, this decrease is about 15%. For a flow rate of 10,500 L/min the decrease is 13% for the experimental test and 17% for CFD results.

Comparing to similar experiences carried out on the same hull but without the presence of the rails (i.e., [

31,

32]), in this study, the agreement between experimental and numerical data is lower for all the ventilated cases. This result probably depends on the difficulty of the interface models used to predict the real ventilated hull surface. In particular, the HRIC scheme tends to underestimate the air-water mixing in correspondence of hull discontinuity, and consequently to overestimate the ventilated surface, leading a reduction in the drag prediction. This numerical phenomenon must be properly evaluated as it was not a problem for flat bottom hulls.

Figure 19 shows the trend to different velocities for flow rates to 9500 and 10,500 L/min. The decrease of the wetted surface area is respectively 68% and 69%. The flow rates are the higher ones and the air under the hull cover almost the entire bottom.

Figure 20 shows the trend of drag reduction to different flow rates at the same Fn. The curves show that with the increase of the Froude number the curves tend to an high level of reduction of resistance. The curves show that to Fn number of 0.639 and 0.766, the decrease of resistance is almost equal to zero and also with the increase of the flow rates this behaviour remains the same.

To the Fn number of 0.894 the starting point of increase of percentage reduction is the flow rate of 6500 L/min. This starting point it is also visible for the Froude number equal to 1.149 but it is translated to the flow rate of 7500 L/min. To the highest values of Froude number, the curves seem flat and the flow rates does not affect the reduction of drag. To these values of Fn, there is not great need to push the flow rate until to 10,500 in order to obtain the desidered effects.

The advantage of this hull grows with increasing speed, up to a peak reduction of 24% (at Fn 1.362 and 9500 L/min). For a speed of Fn < 1, the ventilation is not particularly effective and tends not to lead to benefits. For Fn ≥ 1, on the other hand, the benefits grow rapidly and the most advantageous air flow rates are those at 9500 L/min, above which the gain is reduced again.

In

Figure 21 are reported all the wetted surfaces, for each Fn, in three different conditions, respectively, the no-air condition and the minimum and maximum tested flow rates. In the pictures, the water is represented by the color red and the air by the color blue. The figure highlights that to all the Froude numbers, the flow rate of 5500 L/min is not enough to wet the bottom of the hull completely. At this flow rate, for little Froude numbers, the air tends to escape from the sides, while for high Froude numbers there is a tendency of the air to be dragged up to the stern, remaining at the center of the boat. At the same time, at high speeds, air and water are less mixed. For this reason, for the Froude number higher than 1.27, the air does not escape from the sides of the boat and on the bilge area there is a channel of a stable water. From the same figure, it is possible to see that the ideal condition seems to be reached with the condition of 10,500 L/min at the Froude number of 1.15. In this case, the bottom of the hull and the area around the bilge are almost wholly wetted by the air without mixing with water.

The longitudinal rails at low flow rates cannot retain the air and consequently are a disadvantage more than an advantage since they increase the wetted surface.