Livelihood Assessment and Occupational Health Hazard of the Ship-Breaking Industry Workers at Chattogram, Bangladesh

Abstract

:1. Introduction

2. Materials and Methods

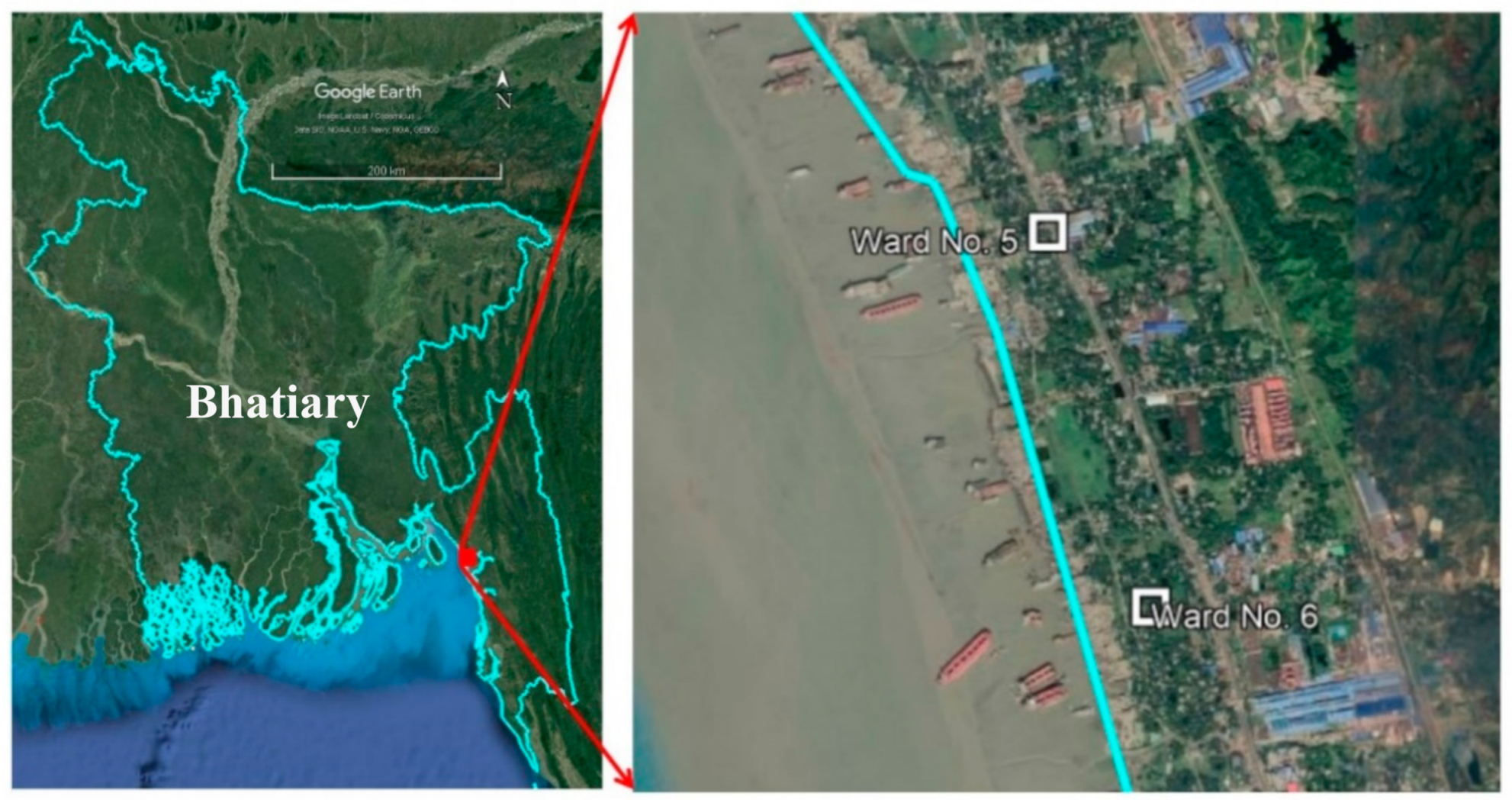

2.1. Location

2.2. Data Collection Method

2.2.1. Individual Interview

2.2.2. Focus Group Discussion

2.2.3. Livelihood Index Analysis

3. Results

3.1. Demographic Status of Shipbreaking Industry Workers

3.2. Livelihood Capitals of the Workers

3.2.1. Human Capitals

Age Distribution Patterns

Family Type

Educational Qualification

Home Division of the Workers

Working Hours and Experience of the Workers

3.2.2. Physical Capital

Housing Condition

Drinking-Water Sources

Sanitation and Working Conditions

3.2.3. Financial Capital

Income

Credit Access

3.2.4. Natural Capital

3.3. Livelihood Index

3.4. Occupational Health Hazards

Physical Injury and Protective Gear

3.5. Physical Problems

3.6. Risk Assessment of Ship-Breaking Yard Associated with the Operational Activity of Ship Dismantling

4. Discussion

“The main reason for physical hazards was because of a lack of protective gear. The goggles that the owner provided were not of decent quality. Then he said that sometimes they do not get any protective gear; they cut the ship with bare hands and sledgehammer”.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Demaria, F. Can the poor resist capital? Conflicts over ‘Accumulation by Contamination ‘at the ship-breaking yard of Alang (India). In Nature, Economy, and Society; Springer: New Delhi, India, 2016; pp. 273–304. [Google Scholar]

- Fakhruddin, A.N.M.; Talukdar, M.I.; Hossain, M.A. Environmental Impacts of Ship Breaking and Recycling Industry of Sitakunda, Chittagong, Bangladesh. Adv. Nat. Sci. 2015, 8, 51–58. [Google Scholar]

- Hossain, M.S.; Fakhruddin, A.N.M.; Chowdhury, M.A.Z.; Gan, S.H. Impact of ship-breaking activities on the coastal environment of Bangladesh and a management system for its sustainability. Environ. Sci. Policy 2016, 60, 84–94. [Google Scholar] [CrossRef]

- BSBA 2011: Safety Measures Taken for Workers. Bangladesh Ship Breakers Association. Available online: http://www.bsba.org.bd/page.php?id=13 (accessed on 10 June 2021).

- Iqbal, K.S.; Zakaria, N.G.; Hossain, K.A. Identifying and Analysing Underlying Problems of Shipbuilding Industries in Bangladesh. J. Mech. Eng. 2010, 41, 147–158. [Google Scholar] [CrossRef] [Green Version]

- Rabbi, H.R.; Rahman, A. Ship breaking and recycling industry of Bangladesh; issues and challenges. Procedia Eng. 2017, 194, 254–259. [Google Scholar] [CrossRef]

- Gunbeyaz, S.A.; Kurt, R.E.; Baumler, R. A study on evaluating the status of current occupational training in the ship recycling industry in Bangladesh. WMU J. Marit. Aff. 2019, 18, 41–59. [Google Scholar] [CrossRef] [Green Version]

- Rahman, S.M.; Mayer, A.L. Policy compliance recommendations for international shipbreaking treaties for Bangladesh. Mar. Policy 2016, 73, 122–129. [Google Scholar] [CrossRef]

- Alam, S.; Faruque, A. Legal regulation of the shipbreaking industry in Bangladesh: The international regulatory framework and domestic implementation challenges. Mar. Policy 2014, 47, 46–56. [Google Scholar] [CrossRef]

- Roy, B. Health Problems among the Workers in the Ship-Breaking Industry; Department of Occupatioal and Environmental Health, Natioanl Institute of Preventive and Social Medicine (NIPSOM): Dhaka, Bangladesh, 2003.

- Chowdhury, S. Bangladesh’s ship breaking Industry: A Stakeholder Analysis. In Governance and Sustainability; Emerald Publishing Limited: Bingley, UK, 2020; pp. 173–184. [Google Scholar] [CrossRef]

- Lindenberg, M. Measuring household livelihood security at the family and community level in the developing world. World Dev. 2002, 30, 301–318. [Google Scholar] [CrossRef]

- Kutub, M.J.R.; Falgunee, N.; Nawfee, S.M.; Rabby, Y.W. Ship breaking industries and their impacts on the local people and environment of coastal areas of Bangladesh. Hum. Soc. Stud. 2017, 6, 35–58. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, P.A.; Ali, M.M.; Shahjahan, A.T.M. Impacts of Ship Breaking Industries on Environment and Socio-Economic Condition of Bangladesh-A Case Study of Sitakunda Shitolpur Ship Breaking Yard, Chittagong. Master’s Thesis, Chittagong University of Engineering & Technology, Chittagong, Bangladesh, 2015. [Google Scholar]

- Hossain, M.S.; Chowdhury, S.R.; Jabbar, S.A.; Saifullah, S.M.; Rahman, M.A. Occupational health hazards of ship scrapping workers at Chittagong coastal zone, Bangladesh. Chiang Mai J. Sci. 2008, 35, 370–381. [Google Scholar]

- Muhibbullah, M. Health Hazards and Risks Vulnerability of Shipbreaking Workers: A Case Study on Sitakunda Shipbreaking Industrial Area of Bangladesh Global Advanced Research. J. Geogr. Reg. Plan. 2013, 2, 172–184. [Google Scholar]

- Sarraf, M.; Stuer-Lauridsen, F.; Dyoulgerov, M.; Bloch, R.; Wingfield, S.; Watkinson, R. The Ship Breaking and Recycling Industry in Bangladesh and Pakistan. 2010. Available online: http://crossasia-repository.ub.uni-heidelberg.de/3749/1/Ship%20Breaking%20and%20Recycling%20Industry.pdf (accessed on 11 June 2021).

- Billah, M.M.; Kader, M.A.; Siddiqui, A.A.M.; Shoeb, S. Studies on fisheries status and socio-economic condition of fishing community in Bhatiary coastal area Chittagong, Bangladesh. J. Entomol. Zool. Stud. 2018, 6, 673–679. [Google Scholar]

- Ali, M.H.; Hossain, M.D.; Hasan, A.N.G.M.; Bashar, M.A. Assessment of the livelihood status of the fish farmers in some selected areas of Bagmara upazilla under Rajshahi district. J. Bangladesh Agric. Univ. 2008, 6, 367–374. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.M.M.; Islam, M.M. Ship Breaking Activities and Its Impact on the Coastal Zone of Chittagong, Bangladesh: Towards Sustainable Management; Advocacy & Publication Unit, Young Power in Social Action (YPSA): Chittagong, Bangladesh, 2006. [Google Scholar]

- Alam, G.M. An Assessment of the Livelihood Vulnerability of the Riverbank Erosion Hazard and Its Impact on Food Security for Rural Households in Bangladesh. Ph.D. Thesis, University of Southern Queensland, Darling Heights, QLD, Australia, 2016. [Google Scholar]

- Sujauddin, M.; Koide, R.; Komatsu, T.; Hossain, M.M.; Tokoro, C.; Murakami, S. Characterization of ship breaking industry in Bangladesh. J. Mater. Cycles Waste Manag. 2015, 17, 72–83. [Google Scholar] [CrossRef]

- YPSA. Ship Breaking in Bangladesh. Youth Power in Social Action.. 2014. Available online: http://www.Shipbreakingbd.info/ (accessed on 13 June 2021).

- Rousmaniere, P.; Raj, N. Shipbreaking in the developing world: Problems and prospects. Int. J. Occup. Environ. Health 2007, 13, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Stern, D.; Liu, X.; Cai, W.; Wang, C. An analysis of the costs of energy saving and CO2 mitigation in rural households in China. J. Clean. Prod. 2017, 165, 734–745. [Google Scholar] [CrossRef]

| Types of Capitals | Measuring Indicators of Livelihood Capitals |

|---|---|

| Education, training facilities, working experience, nutritious food consumption. |

| Housing condition, water facilities, sanitation, agricultural equipment, livestock and poultry ownership, road structure. |

| Land ownership, sources of water, and access to the forest. |

| Credit facilities, savings, and household income. |

| Good relation with yard owner, good relation with relatives, participation in a social gathering. |

| Degree of Probability | Rating | Severity of Consequences | Rating |

|---|---|---|---|

| Frequent, once per week | 4 | Major | 4 |

| Occasional, the occurrence of risk is once a month | 3 | Serious | 3 |

| Seldom, the occurrence of risk is once in 3–6 months | 2 | Minor | 2 |

| Unlikely, the occurrence of risk is once in a year or more | 1 | Incidental | 1 |

| Content | Level of Content | Ward No. 5 | Ward No. 6 |

|---|---|---|---|

| Frequency (%) | Frequency (%) | ||

| Gender | Male | 100 | 100 |

| Female | 0 | 0 | |

| Marital Status | Married | 63 | 58 |

| Single | 37 | 42 | |

| The main occupation of the workers | Crane operator | 39.21 | 14.28 |

| Guard | 1.96 | 0.00% | |

| Cutter | 9.8 | 6.4935 | |

| Loader | 58.82 | 53.24 | |

| Helper | 25.49 | 25.97 | |

| Alternative occupation | Day labor | 35.29 | 28.57 |

| Driver | 1.96 | 7.79 | |

| Fisherman | 19.61 | 20.78 | |

| Small businessman | 9.80 | 6.49 | |

| Student | 1.96 | 2.60 | |

| Rickshaw puller | 15.69 | 23.38 | |

| No job | 15.69 | 10.39 |

| Natural Capital | Ward No 5 | Ward No 6 | ||

|---|---|---|---|---|

| Yes | No | Yes | No | |

| Access to natural resources | 64.71% | 35.29% | 59.74% | 38.96% |

| Agricultural land | 27.45% | 72.55% | 37.66% | 61.04% |

| Source of water | 29.41% | 70.59% | 29.87% | 70.13% |

| Forest access | 45.10% | 52.94% | 33.77% | 66.23% |

| Workers Households of Ward 5 (n = 51) (Maximum Possible Score (51 × 3 = 153) | Workers Households of Ward 6 (n = 77) (Maximum Possible Score (77 × 3 = 231) | Workers Households of Both Ward (n = 128) (Maximum Possible Score (128 × 3 = 384) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Measuring Indicators of Livelihood Capitals (n = 20) | Bhatiari Ward No. 5 | Bhatiari Ward No. 6 | Overall | ||||||

| Indicators | Obtained Score | Livelihood Index | Change in Livelihood Capitals | Obtained Score | Livelihood Index | Change in Livelihood Capitals | Obtained Score | Livelihood Index | Change in Livelihood Capitals |

| Physical Capital | 24.61 | 16.08 | 8.52 | 39.05 | 16.90 | 22.14 | 63.66 | 16.57 | 47.08 |

| Housing Condition | 23.33 | 15.25 | 8.08 | 36.33 | 15.72 | 20.60 | 59.66 | 15.53 | 44.12 |

| water Facilities | 25 | 16.33 | 8.66 | 39 | 16.88 | 22.11 | 64 | 16.66 | 47.33 |

| Sanitation | 25.33 | 16.55 | 8.77 | 38 | 16.45 | 21.54 | 63.33 | 16.49 | 46.84 |

| Fishing Equipment | 23.66 | 15.46 | 8.19 | 35.33 | 15.29 | 20.03 | 59 | 15.36 | 43.63 |

| Livestock and poultry | 23.33 | 15.25 | 8.08 | 43 | 18.61 | 24.38 | 66.33 | 17.27 | 49.05 |

| Road structure | 27 | 17.64 | 9.35 | 42.66 | 18.47 | 24.19 | 69.66 | 18.14 | 51.52 |

| Financial Capital | 26.77 | 17.50 | 9.27 | 40.77 | 17.65 | 23.12 | 63.55 | 16.55 | 47 |

| Income | 29 | 18.95 | 10.04 | 43 | 18.61 | 24.38 | 72 | 18.75 | 53 |

| Savings | 25.66 | 16.77 | 8.89 | 38.33 | 16.59 | 21.73 | 76 | 19.79 | 56.20 |

| Credit facilities | 25.66 | 16.77 | 8.89 | 41 | 17.74 | 23.25 | 42.66 | 11.11 | 31.55 |

| Human Capital | 27.41 | 17.91 | 9.49 | 42.66 | 18.47 | 24.19 | 70.08 | 18.25 | 51.83 |

| Education | 26.33 | 17.21 | 9.12 | 43.33 | 18.75 | 24.57 | 69.66 | 18.14 | 51.52 |

| Training facilities | 25.66 | 16.77 | 8.89 | 40.66 | 17.60 | 23.06 | 66.33 | 17.27 | 49.05 |

| Working experience | 31.33 | 20.47 | 10.85 | 45.66 | 19.76 | 25.89 | 77 | 20.05 | 56.94 |

| Food consumption | 26.33 | 17.21 | 9.12 | 41 | 17.74 | 23.25 | 67.33 | 17.53 | 49.79 |

| Social Capital | 34.55 | 22.58 | 11.97 | 52.55 | 22.75 | 29.80 | 87.11 | 22.68 | 64.42 |

| Relation with relatives | 26.66 | 17.42 | 9.23 | 40 | 17.31 | 22.68 | 66.66 | 17.36 | 49.30 |

| Relation with the yard owner | 34 | 22.22 | 11.77 | 52 | 22.51 | 29.48 | 86 | 22.39 | 63.60 |

| Participation in a social gathering | 43 | 28.10 | 14.89 | 65.66 | 28.42 | 37.23 | 108.66 | 28.29 | 80.36 |

| Natural Capital | 33.16 | 21.67 | 11.48 | 46.66 | 20.20 | 26.46 | 79 | 20.57 | 58.42 |

| Access to natural resources | 37 | 24.18 | 12.81 | 50 | 21.64 | 28.35 | 87 | 22.65 | 64.34 |

| Sources of water | 32 | 20.91 | 11.08 | 45.66 | 19.76 | 25.89 | 74.33 | 19.35 | 54.97 |

| Land ownership | 27 | 17.64 | 9.35 | 41.33 | 17.89 | 23.44 | 68.33 | 17.795 | 50.53 |

| Forest access | 36.66 | 23.96 | 12.70 | 49.66 | 21.50 | 28.16 | 86.33 | 22.48 | 63.85 |

| Physical Problems | Ward No. 5 | Ward No. 6 | Overall |

|---|---|---|---|

| Eye problem | |||

| Redness | 23.53% | 33.77% | 29.69% |

| Tearing | 3.92% | 0.00% | 1.56% |

| Burning sensation | 17.65% | 19.48% | 18.75% |

| Blurring vision | 27.45% | 23.38% | 25.00% |

| Respiratory Problem | |||

| Asthma | 19.61% | 29.87% | 25.78% |

| Pneumonia | 9.80% | 16.88% | 14.06% |

| Cough | 17.65% | 14.29% | 15.63% |

| Chest pain | 35.29% | 31.17% | 32.81% |

| Abdominal Problem | |||

| Anorexia | 9.80% | 12.99% | 11.72% |

| Nausea | 23.53% | 16.88% | 19.53% |

| Vomiting | 15.69% | 20.78% | 18.75% |

| Abdominal pain | 31.37% | 31.17% | 31.25% |

| Gastric | 25.49% | 20.78% | 22.66% |

| Urinary problem | |||

| Dysuria | 9.80% | 12.98% | 11.72% |

| Muscle problem | |||

| Backache | 15.69% | 23.38% | 20.31% |

| Neck ache | 23.53% | 33.77% | 29.69% |

| Knee joint pain | 17.65% | 10.39% | 13.28% |

| Skin problem | |||

| Itching | 23.53% | 31.17% | 28.13% |

| Lesion | 13.73% | 19.48% | 17.19% |

| Nutritional problem | |||

| Vertigo | 11.76% | 12.99% | 12.50% |

| Headache | 23.53% | 23.38% | 23.44% |

| Weakness | 56.86% | 58.44% | 57.81% |

| Operation | Hazards Description | Causal Risk Factor | Severity | Probability | Risk | Level of Risk |

|---|---|---|---|---|---|---|

| Materials Dismantling | Stung by sharp object, Burning, explosion, fire | Pipe containing gases, machinery dismantling | 2 | 3 | 6 | High risk |

| Beaching | Health hazards | Beaching & disembarking | 2 | 1 | 2 | Low risk |

| Cutting operation | Falling on the same level-stumbling, slipping | Slipping on wet surfaces or something laying or fastening on the walking surface | 3 | 2 | 6 | High risk |

| Hazardous mechanical situations due to equipment | Failure of machinery and equipment | 2 | 4 | 8 | High risk | |

| Hazardous substances and wastes | Welding fumes | 4 | 4 | 16 | Extreme risk | |

| Fire, explosion, and health hazards | Ignition & Cutting | 3 | 4 | 12 | Extreme risk | |

| Fire and explosion by explosives flammable materials | Shut-down | 3 | 4 | 12 | Extreme risk | |

| Fire extinguisher near cutting, fireguard, and health | Cutting process | 2 | 4 | 8 | High risk | |

| Fire, explosion, and health hazards | Cylinder Handling | 2 | 4 | 8 | High risk | |

| Loud noise exposer | Excess noise associated with grinding, hammering, metal cutting, and other activities | 4 | 2 | 8 | High risk | |

| Onboard cutting | Hazardous standard of workplace | Lack of PPE, Negligence of safety measures while working | 4 | 2 | 8 | High risk |

| Materials mobility, loading and Unloading | Struck by materials while, Unloading causing injuries, hand cuts, finger injuries | Handling heavy objects, repetitive strain injuries, excessive workloads | 3 | 2 | 6 | High risk |

| Health injuries | Cutting sheet, Handling | 2 | 2 | 6 | Moderate risk | |

| Health injuries by chemical | Chemical shifting | 1 | 2 | 2 | Low risk | |

| Health and Fire | Oil Transfer | 3 | 2 | 6 | High risk | |

| The heavy object fell on the body | Poor maintenance of winch, crane/wire, negligence of safety measures while working | 4 | 4 | 16 | Extreme risk | |

| Storage & preservation of hazardous waste | Fume inhalation | Oil and chemical, sludge | 4 | 3 | 12 | Extreme risk |

| Hazardous materials and chemicals, including heavy metals in ship transducers, ballast, and paint coatings; mercury in fluorescent light tubes, thermometers, electrical switches, light fittings, fire detectors. | Exposure to hazardous liquids or gases or material substances, combustible materials | 4 | 3 | 12 | Extreme risk | |

| Health injuries & fire | Oil and fuel | 4 | 3 | 12 | Extreme risk | |

| Health injuries | Asbestos in hanger liners, mastic under isolation, cloth under isolation, cable, lagging and insulation on pipes and hull, adhesive, gaskets on piping connections, and valve packing | 4 | 3 | 12 | Extreme risk | |

| Health hazards | Polychlorinated biphenyls (PCBs) in rubber products such as hoses, plastic foam isolation, cables, silver paint, habitability paint, plates on top of the hull bottom, and primary paint on hull steel | 4 | 3 | 12 | Extreme risk | |

| Storage & preservation of non-hazardous waste | Health hazards | Cutting sheet | 2 | 2 | 4 | Moderate risk |

| Health hazards | Machinery & Equipment | 1 | 2 | 2 | Low risk | |

| Health hazards | Spares | 1 | 1 | 1 | Low risk | |

| Clearing of materials | Manual handling, dust, cuts from objects | Materials handling | 2 | 1 | 2 | Low risk |

| Use of mechanical hammer | Exposure to dust, noise pollution, vibrations | Cutting | 2 | 3 | 6 | High risk |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahamad, A.F.; Schneider, P.; Khanum, R.; Mozumder, M.M.H.; Mitu, S.J.; Shamsuzzaman, M.M. Livelihood Assessment and Occupational Health Hazard of the Ship-Breaking Industry Workers at Chattogram, Bangladesh. J. Mar. Sci. Eng. 2021, 9, 718. https://doi.org/10.3390/jmse9070718

Ahamad AF, Schneider P, Khanum R, Mozumder MMH, Mitu SJ, Shamsuzzaman MM. Livelihood Assessment and Occupational Health Hazard of the Ship-Breaking Industry Workers at Chattogram, Bangladesh. Journal of Marine Science and Engineering. 2021; 9(7):718. https://doi.org/10.3390/jmse9070718

Chicago/Turabian StyleAhamad, Abu Faisal, Petra Schneider, Romaza Khanum, Mohammad Mojibul Hoque Mozumder, Sabrina Jannat Mitu, and Md. Mostafa Shamsuzzaman. 2021. "Livelihood Assessment and Occupational Health Hazard of the Ship-Breaking Industry Workers at Chattogram, Bangladesh" Journal of Marine Science and Engineering 9, no. 7: 718. https://doi.org/10.3390/jmse9070718

APA StyleAhamad, A. F., Schneider, P., Khanum, R., Mozumder, M. M. H., Mitu, S. J., & Shamsuzzaman, M. M. (2021). Livelihood Assessment and Occupational Health Hazard of the Ship-Breaking Industry Workers at Chattogram, Bangladesh. Journal of Marine Science and Engineering, 9(7), 718. https://doi.org/10.3390/jmse9070718