1. Introduction

As offshore oilfield developments have been moving toward deeper water, floating structures are frequently used for drilling, well intervention, production, and storage at sea. Under environmental loads such as wind, waves, and current, the floating structure exhibits offsets different from the desired point for normal operations. Therefore, mooring systems are used to maintain a floating structure on the station within a specified tolerance, typically based on an offset limit determined from the configuration of the risers. If the mooring lines fail, it will cause operation interruption, oil spills, even casualty, and environmental issues. Therefore, mooring analysis should be carried out to ensure it has adequate strength against overloading.

In deep water application, the quasi-static analysis method for mooring line is not accurate and dynamic analysis, which accounts for the time-varying effects due to mass, damping, and fluid acceleration should be carried out. The lumped mass method is a straightforward and efficient method for mooring line analysis and has greater versatility than other methods [

1,

2]. Nakajima et al. [

3] employed the lumped mass method for the time domain dynamic analysis of 2D multicomponent mooring lines. They found time histories of dynamic tension predicted by the lumped mass method have good agreement with the experimental ones. Huang [

1] carried out the dynamic analysis of cables using the lumped mass method with the finite difference method and discussed the stability and convergence of the numerical scheme.

The differential motion equations of mooring lines in the time domain can be solved by explicit or implicit numerical integration schemes. For the implicit method such as Newmark beta and Wilson theta method, it involves iteration process at each time step. The modified Euler method, whose simplicity is one of the distinguishing features, is a numerical procedure that can be effectively used for dynamic analyses [

4,

5]. Hahn [

4] applied this method in the dynamic analysis of a structure and discussed its stability and accuracy. The application showed that this method is efficient and easy to use. On the other hand, the dynamic analysis of the mooring line in the time domain can consider the nonlinearity such as the geometric nonlinearity and hydrodynamic drag force.

The frequency domain method requires linearization for the nonlinear terms since it employs the linear principle of superposition. It is very efficient and useful for dynamic response problems with less severe nonlinearity. The geometric nonlinearity can be considered by assuming that dynamic deflections around the static equilibrium position are small. There are several linearization methods for the drag force. The linear form of drag force in a regular wave can be obtained by the equivalent energy method [

6]. In a random wave, statistical linearization is often used [

7,

8,

9]. It is based on the minimization of the expected square error between the nonlinear drag force and linearized drag force. Wu [

10] derived the equivalent linear form for a one-dimensional drag force in a random sea with a current. Additionally, the one-dimensional linearization is extended to a three-dimensional case by linearizing each component with this equivalent linear form. Hamilton [

11] pointed out that this approach is not strictly frame invariant, i.e., it depends upon the choice of reference axes. Langley [

12] found that this linearization method can lead to a significant underestimate of the drag force since coupling between perpendicular flow directions is neglected.

2. Governing Equations and Formulations

The time- or frequency domain dynamic analysis can be carried out to estimate the dynamic mooring line response. The mooring line is modeled as a set of concentrated masses connected by massless springs on the basis of the lumped mass method. The dynamical equations of mooring lines in the time domain and frequency domain are derivated, respectively.

A mooring line element in the global coordinate is shown in

Figure 1. The

i-th node’s position is

ri = [x

i, y

i, z

i]

T.

ei+1/2 is the unit vector parallel to the centerline of the segment between the

i-th node and (

i+1)-th node.

where

is the length of the segment between the

i-th node and (

i+1)-th node.

All forces along the mooring lines are assumed to be concentrated at the node.

Tension forces at the

i-th node include the tension forces in the line segments on either side of the node

i which are, respectively, indicated as

Ti+1/2 and

Ti−1/2.

where

E is the elastic module;

A is the cross-sectional area;

li+1/2 is the original length of the segment between the

i-th node and (

i+1)-th node;

li−1/2 is the original length of the segment between the

i-th node and (

i−1)-th node.

The tension force at node

i is expressed as follows:

Wave forces on the mooring line are computed using the Morison equation, which assumes the force to be linearly summation of inertia and drag forces. The wave–particle velocity at node

i is

ui = [

ux,i,

uy,i,

uz,i]

T. The normal wave–particle velocity

across the half of the upper segment that connects the

i-th node is

Similarly, the normal wave–particle acceleration across the half of the upper segment that connects the

i-th node is

The tangential wave particle velocity

across the half of the upper segment that connects the

i-th node is

and the corresponding acceleration across the half of the upper segment that connects the

i-th node is

The inertia or drag forces are usually computed separately for directions normal and tangent to the lines. As the tangential component is usually small and can be neglected, it is assumed that the tangential inertia coefficient is zero. The inertia force on the upper and lower half segment on the side of node

i is as follows:

where

is the normal and tangential inertia coefficient.

Then, the inertia forces on node

i including two lines segments on either side of the node are

where

, and the normal inertia coefficient

= 2.

The structural acceleration is not included in inertia forces, and it is usually accounted for by the inclusion of an added mass term in the mass matrix in the equation of motion.

where

, and the normally added mass coefficient

.

The added mass on node

i is

Therefore, the mass, including added mass matrix, is

where

represents the mass of two mooring line segments on each side of the

i-th node.

Additionally, the force including weight and buoyancy is

where the buoyancy is denoted by

, and

is the density of seawater.

The drag force on the upper and lower half segment on the side of node

i is calculated using Morrison’s equation. The tangential drag is assumed to be neglected as it is usually small.

where

is the normal drag coefficient.

is the normal relative velocity to the upper segment connected with node

i, respectively.

where

Vri is the relative velocity between the water–particle velocity from wave

ui and current

Vci at node

i and the velocity of node

.

The drag forces on the

i-th node including two line segments on either side of the node are

where

.

2.1. Dynamic Analysis in the Time Domain

The equation of motion is

where

M is the mass matrix of mooring lines including added mass, and

is the acceleration. The force consists of tension forces

T, inertia force F

I, drag force F

D, weight, and buoyancy

W.

The upper end connects with the vessel, and the bottom end is considered as a fixed point. The motion equation of mooring lines can be solved using numerical integration schemes. Here, the modified Euler method is applied.

and

are the known displacement and velocity of the mooring line, respectively, at time

. The displacement and velocity of the line,

and

, at the time

are evaluated as follows:

where

is the time step. The new displacements, velocities, and accelerations of all the nodes can be evaluated easily according to this scheme.

It can be seen that the modified Euler method is very simple, and it can lead to accurate response evaluations. It is explicit and straightforward, which is different from the Newmark beta method, which needs iteration for each step. This method is conditionally stable, and the time step should satisfy the condition of stability as follows:

where

T is the natural period of vibration of the line system.

2.2. Dynamic Analysis in the Frequency Domain

The dynamic analysis in the frequency domain is based on the linear system. There are nonlinear effects that can have an important influence on mooring line behavior. One is geometric nonlinearity, which is associated with large changes in the shape of the mooring line. The other is fluid loading, in which the Morrison equation is most frequently used to represent its effects on mooring lines. The drag force on the line is proportional to the square of the relative velocity between the water–particle velocity from the wave or current and the line’s velocity and hence is nonlinear. In addition, the contact of the line with the seabed is also nonlinear. These nonlinearities have to be linearized.

It is assumed that dynamic deflections around the static equilibrium position are small. The tangent stiffness matrix for the upper segment for node

i is

The drag force can be linearized by the statistical linearization method. The nonlinear term in drag force is replaced by the linear form

where

Ce is the equivalent linear coefficient, and

Fm is a constant force vector. The normal water–particle velocity from wave

is a Gaussian random process, the corresponding structure’s velocity

, and the relative velocity

is also a Gaussian random process. The

Ce and

Fm can be estimated from the minimization of the expected square error between the nonlinear and linearized forms. The expected square error is

Minimization of the error with respect to

Ce and

Fm leads to the following:

Since the relative velocity is normal to the centerline of the line, it has only two nonzero components in a coordinate system that has the tangent to the centerline as a basis vector. If the two components are uncorrelated, the evaluation of the expected values in the above equations can be simplified. We can choose the coordinate based on the principal directions of the relative velocity covariance matrix. One base vector of the coordinate system, denoted as axis 1, is in the direction of the maximum velocity variance and the other, denoted as axis 2, is in the direction of the minimum velocity variance. In this coordinate system, the two components of the relative velocity are uncorrelated, i.e., the covariance of vl and v2 is zero. Additionally, current velocity is in this coordinate system.

Therefore, the above equations can be rewritten as follows:

where

is the probability density function of

. Considering

is a Gaussian random process and

vl and

v2 are uncorrelated, the probability density function is

The linearization needs the integration of double infinite integrals. Only a few special cases have the closed form of integration. For the one-dimensional drag force, the linearization results are

where

.

If there is no current, then the linearization coefficient for one-dimensional drag force is

For the case in which the drag force is three dimensional, the integrals require numerical integration. The infinite integrals can be transformed into finite integrals by trigonometric functions, and the finite integrals are evaluated by trapezoidal rule [

13]. Using the above linearization method, the linearized drag force at node

i can be obtained as follows:

where

is the orthogonal transformation from the local principal coordinate system to the global coordinate system.

where

After linearization, the equation of motion of mooring lines is transformed into the frequency domain in the form as follows:

Then, the right side of the equation of motion can be rewritten as

G(

ω)

η(

ω), where

G(

ω) is the force transfer function. the displacement responses can be obtained as

where

H(

ω) is the transfer function and

H(

ω) = (−

ω2M + i

ωQ +

K)

−1G(

ω).

Additionally, the velocity of lines is

The response spectral of displacement and top tension are

Mean square response of displacement and velocity are

Top tension can be obtained as

3. Numerical Case in the Time Domain

The codes for the dynamic analyses of mooring lines in the time domain were programmed using MATLAB. The numerical case analyses of single-component and multicomponent mooring lines were carried out. To verify this program, the results were compared with the results from commercial software, Orcaflex. The detailed properties of lines are listed in

Table 1. The harmonic excitations were applied on the top end of the lines. The horizontal and vertical harmonic excitations represent the motions at wave frequency and low frequency of a floating structure, respectively.

Three test cases were carried out and compared with the results from Orcaflex. The first case was a single-component mooring line only under harmonic excitation applied on its top end. There were no environmental loads and no seabed contact. In the second case, the environmental loads, wave, and current were applied to the line. The third case addressed multicomponent mooring lines. The lines were subjected to wave, current, and harmonic excitation. In addition, contact with seabed was also taken into account.

3.1. Single-Component Mooring Line under Harmonic Excitation

The dynamic response of a single-component mooring line, the R4 chain, was simulated. The mooring line was subjected to vertical, horizontal, and combined vertical and horizontal harmonic excitations, respectively. The given harmonic excitations are as follows:

The environmental loads were not taken into account here. The water depth is 400 m. The length of the line is 400 m. The top end is 10 m under the water surface. The configuration of the mooring line is shown in

Figure 2. Additionally, the results of dynamic analysis were compared with Orcaflex’s. There are 20 segments.

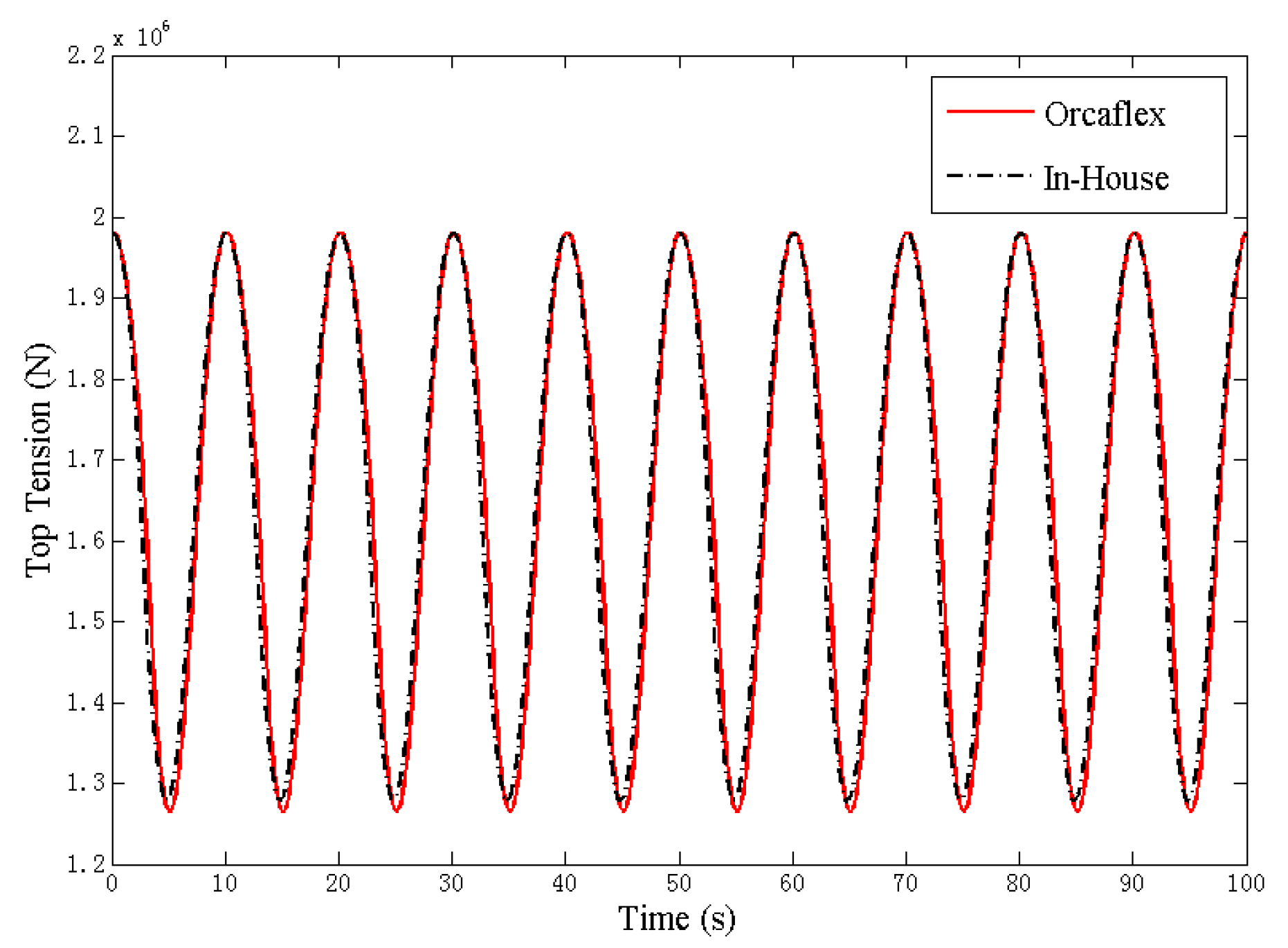

Figure 3,

Figure 4 and

Figure 5 show the dynamic response of a single-component mooring line under vertical, horizontal, and combined vertical and horizontal harmonic excitations. According to the results, the codes agree well with the outputs of Orcaflex, and the top tension range is 1% greater in Orcaflex.

3.2. Single-Component Mooring Line under Harmonic Excitation with Wave and Current

In this case, the environmental loads from wave and current were applied to the lines. The wave is an airy wave that has a wave height of 7.0 m and a period of 8.0 s. The current is 1 m/s in the x-direction and linear decay, along with the depth until zero at the seabed. Additionally, the mooring line was still subjected to three harmonic excitations, i.e., vertical, horizontal, and combined vertical and horizontal harmonic excitations. Both the results of mooring line dynamic analysis by the in-house code and Orcaflex are shown in

Figure 6,

Figure 7 and

Figure 8. It can be seen that the agreement is well, and the difference is within 1%.

3.3. Multicomponent Mooring Line

This code can also carry out the dynamic analysis for multicomponent mooring lines. Here, a test case of a multicomponent mooring line (R4 chain-Spiral Strand wire-R4 chain) was simulated. The line length is 100, 400, and 1480 m, respectively. The configuration of the multicomponent mooring line is shown in

Figure 9. The first part of the 100 m R4 chain was divided into five segments, and the second part of the spiral strand wire was divided into six segments. The third part of the R4 chain considered the seabed contraction, in which parts on the touch-down zone were meshed by 10 m per segment (in total 58 segments), and other parts, always on the seabed, were coarsely meshed by 100 m per segment. The given harmonic excitations are as follows:

Wave and current were the same as used in the single-component mooring line. In addition, seabed interaction was also considered. For the mooring line resting on the seabed, a modified bilinear spring is used to model the vertical contact force Fs on a node [

14], which has the form in Equation (50). Friction effects are considered to be less significant for the system analyzed and are neglected. A gradual transition is proposed to account for numerical stability. The effects of wave and current are considered, using the same parameters in the single line case.

where

a,

b,

c, and

d is suitably chosen constants. In particular,

d should be the value such that

Fs is close to 0 when z is a suitable distance away from the seabed.

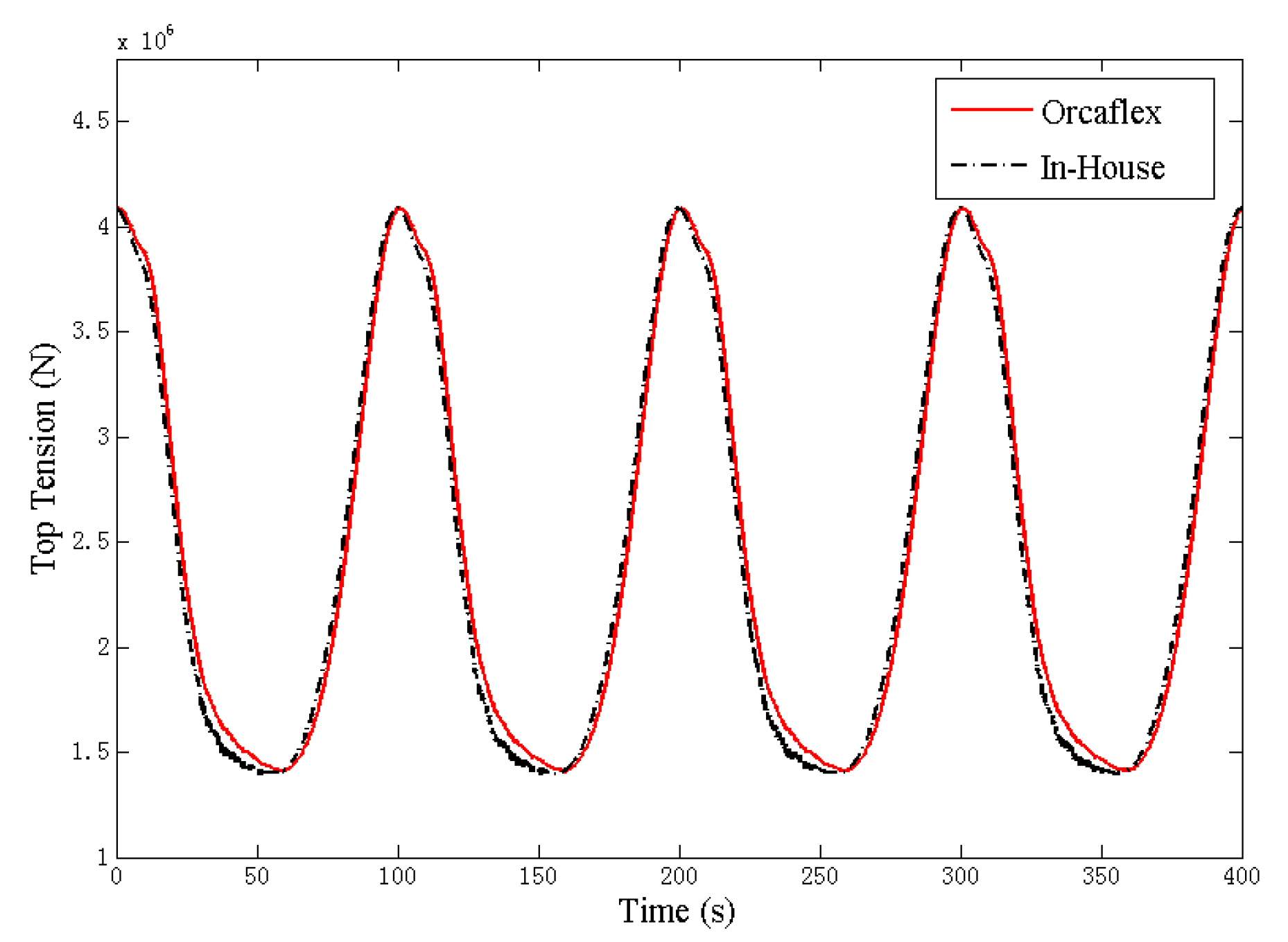

Dynamic response of multicomponent mooring line under vertical, horizontal, and combined vertical and horizontal harmonic excitations are shown in

Figure 10,

Figure 11 and

Figure 12. According to the results of the dynamic analysis in the time domain, it can be seen that this program can perform as well as the commercial software, and the difference is within 3%.