The Influence of Bulb Position on Hydraulic Performance of Submersible Tubular Pump Device

Abstract

:1. Introduction

2. Research Object

3. Numerical Simulation and Experimental Setup

3.1. Turbulence Model and Boundary Conditions

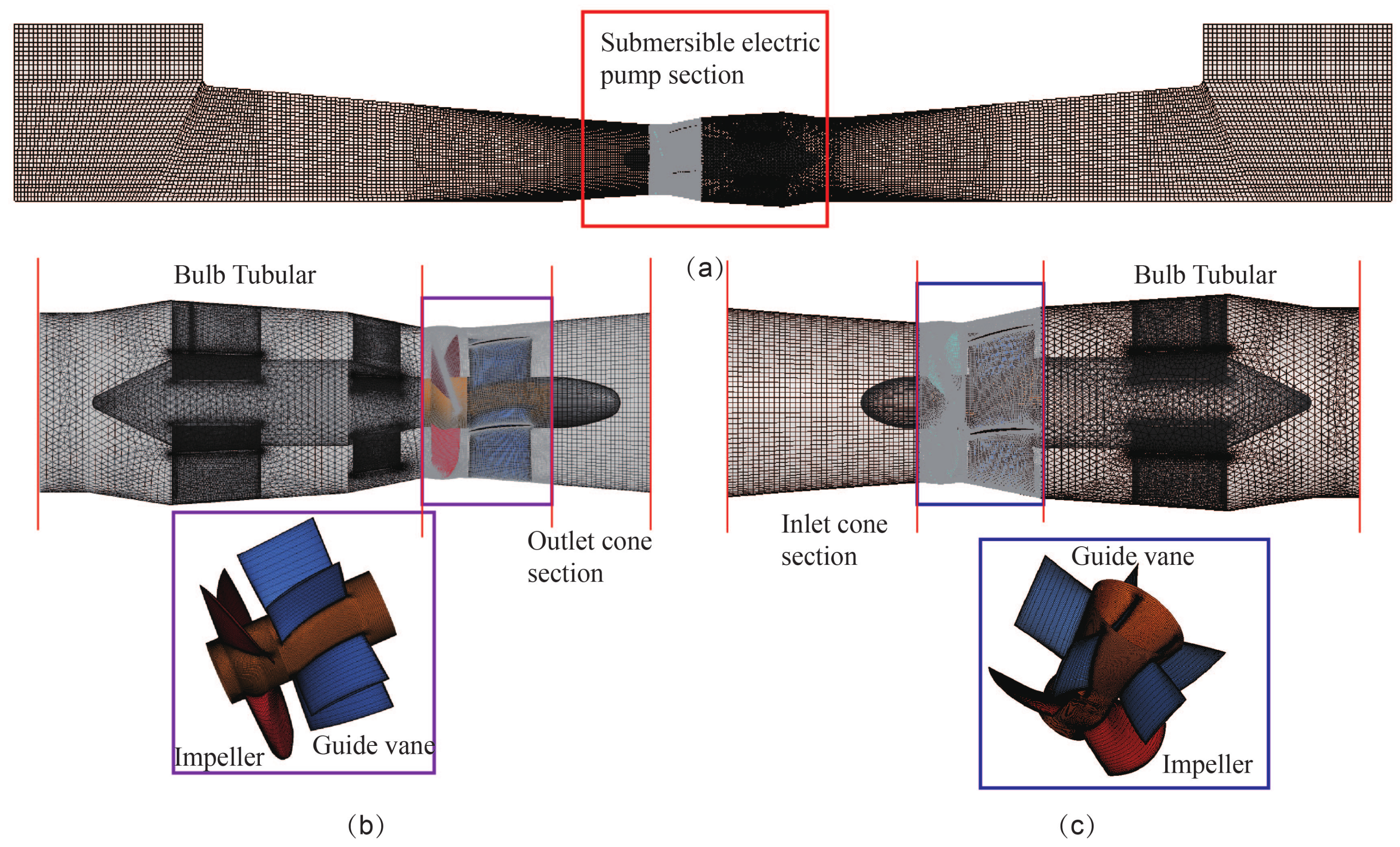

3.2. Computational Grid

3.3. Grid Independence Test

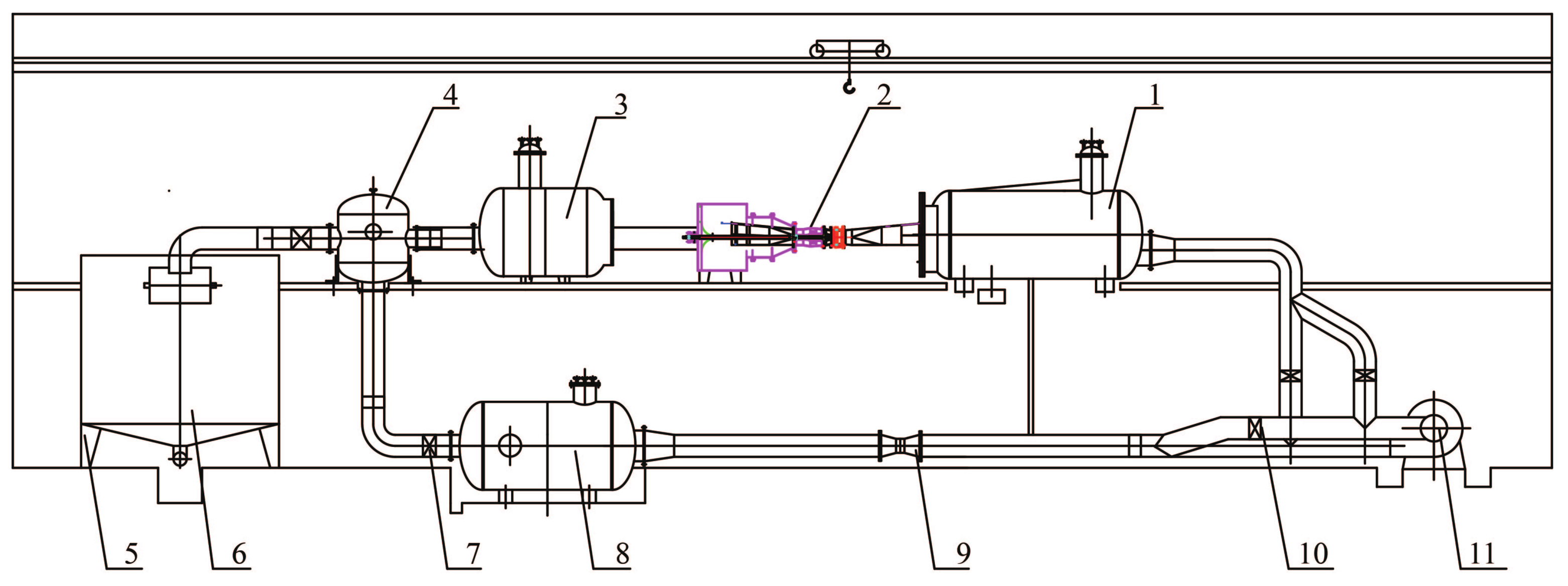

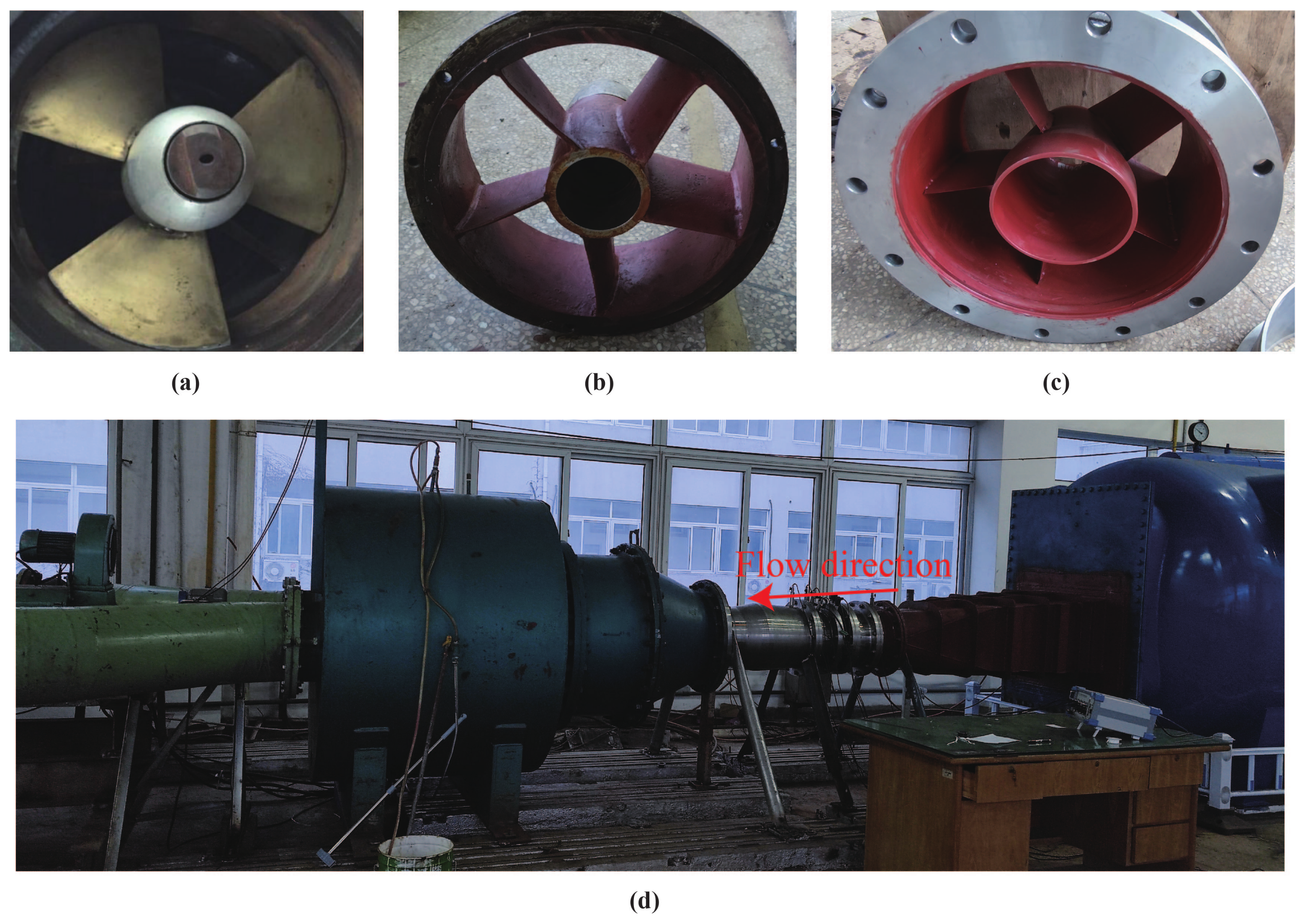

3.4. Model Test

4. Results and Discussion

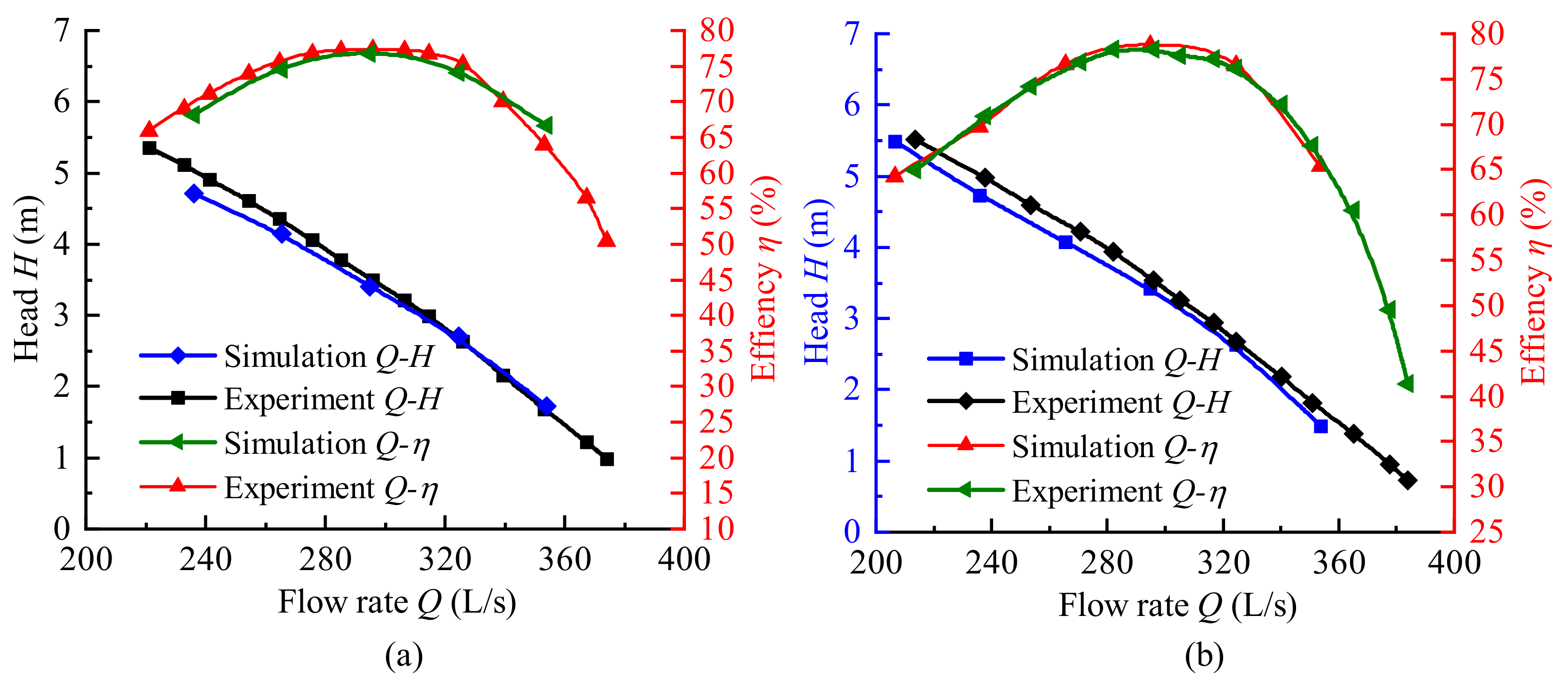

4.1. Comparison of External Characteristics

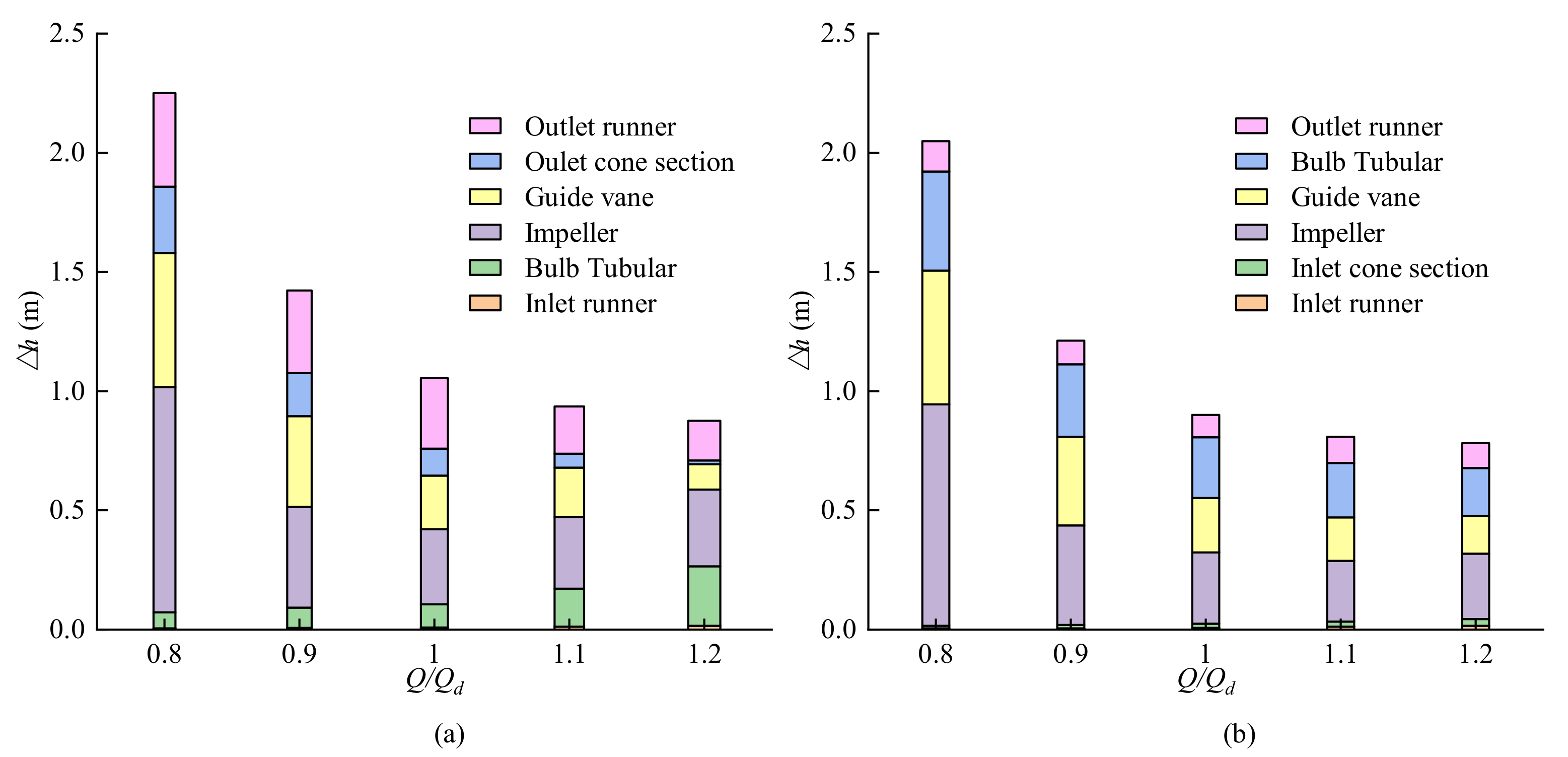

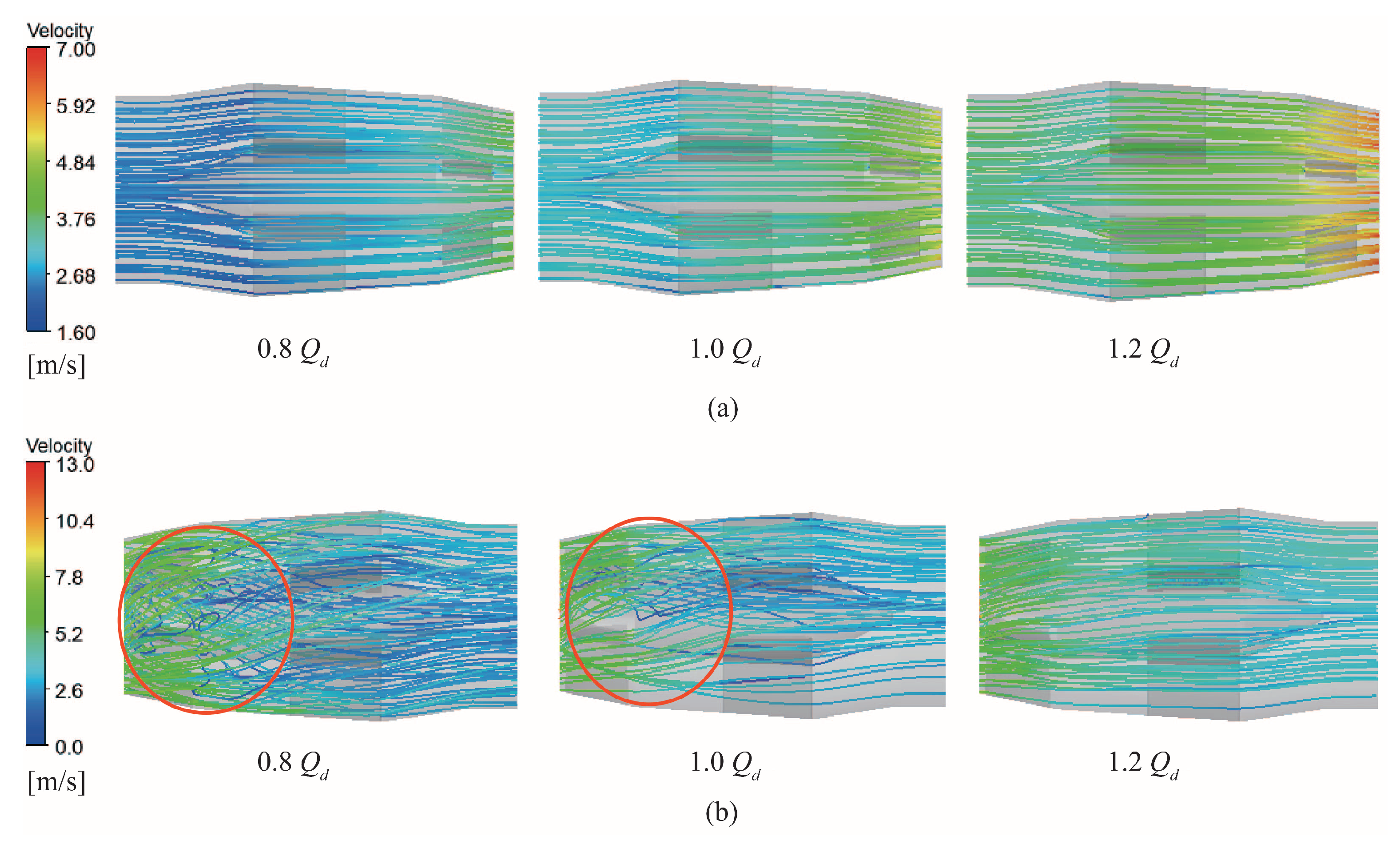

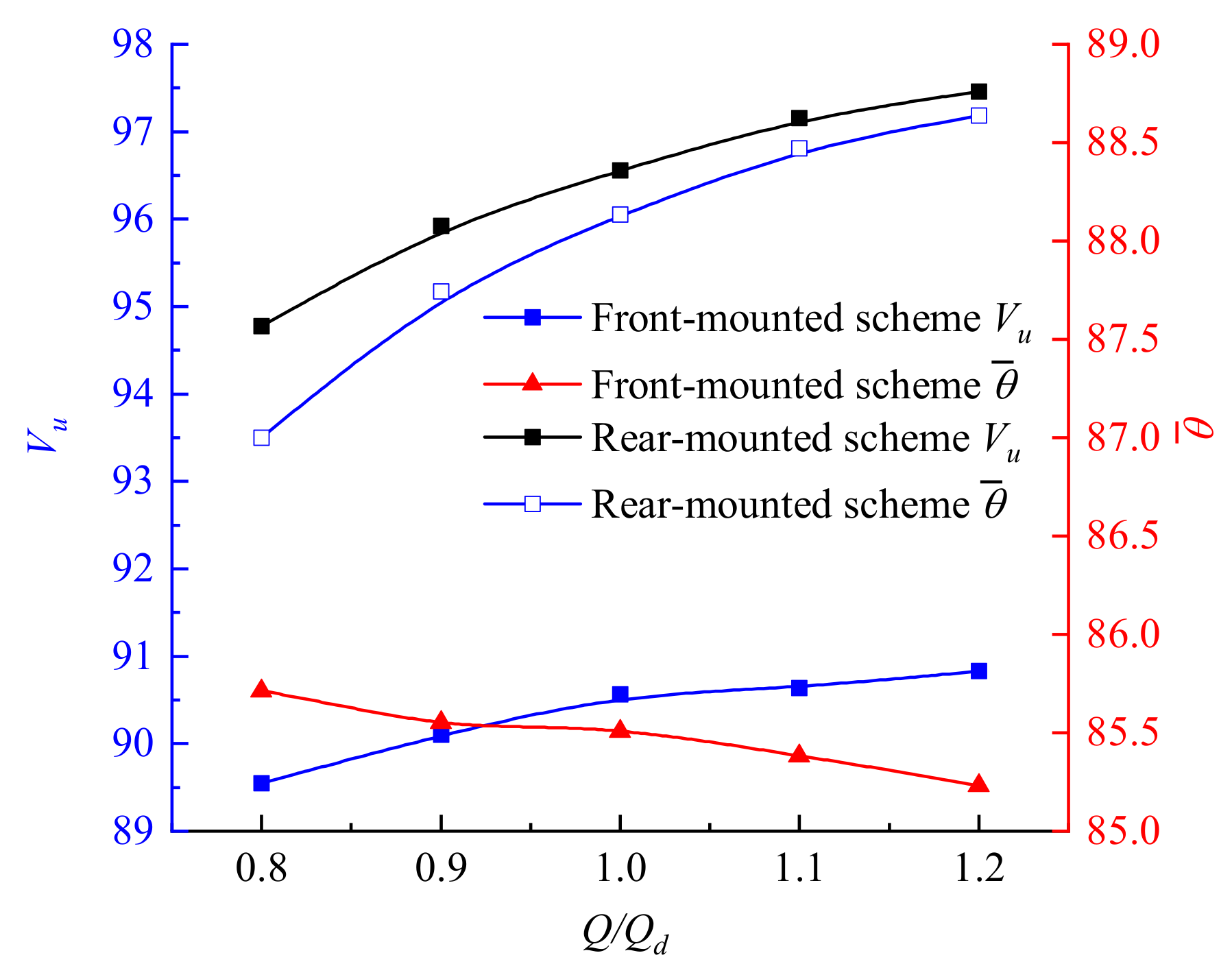

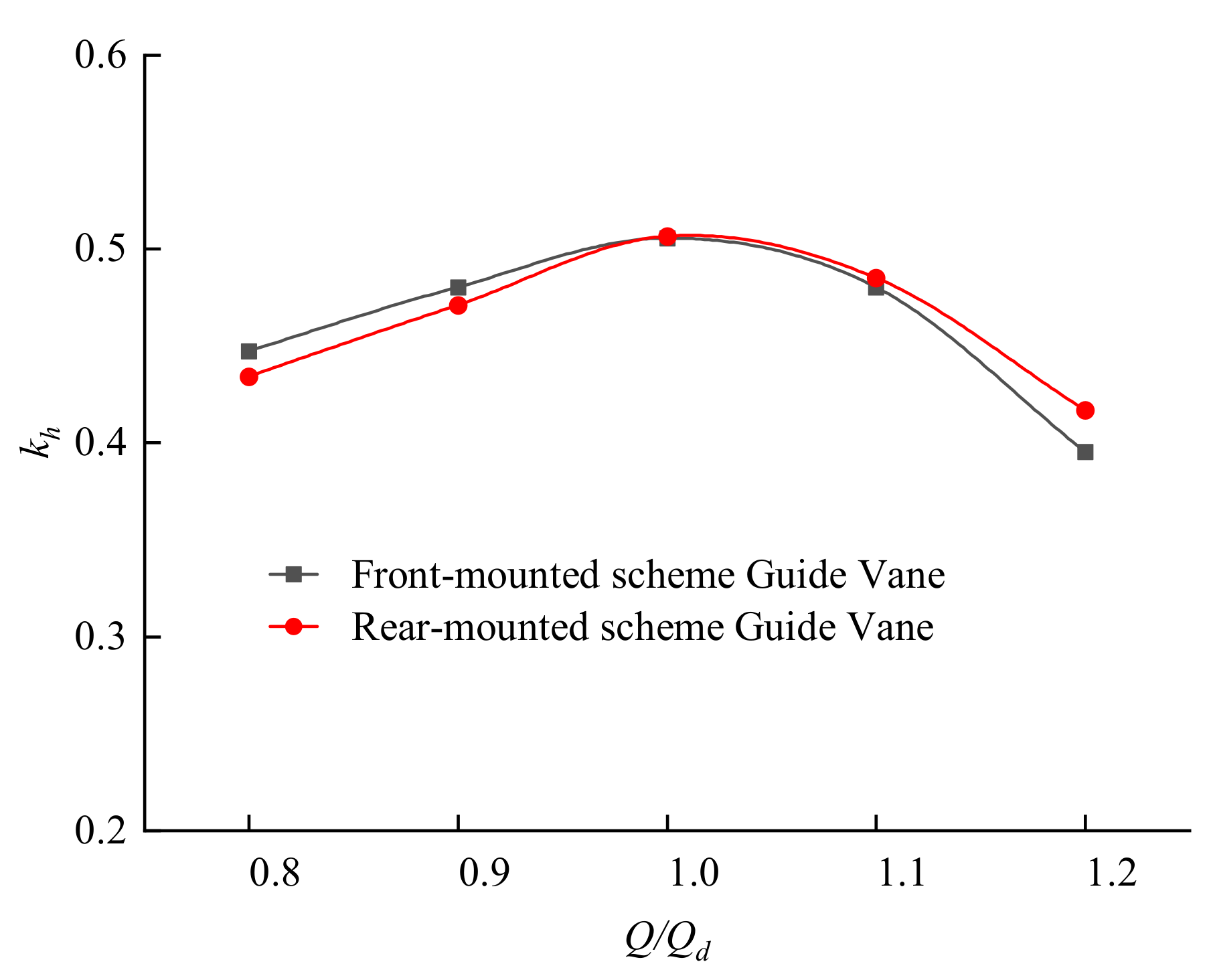

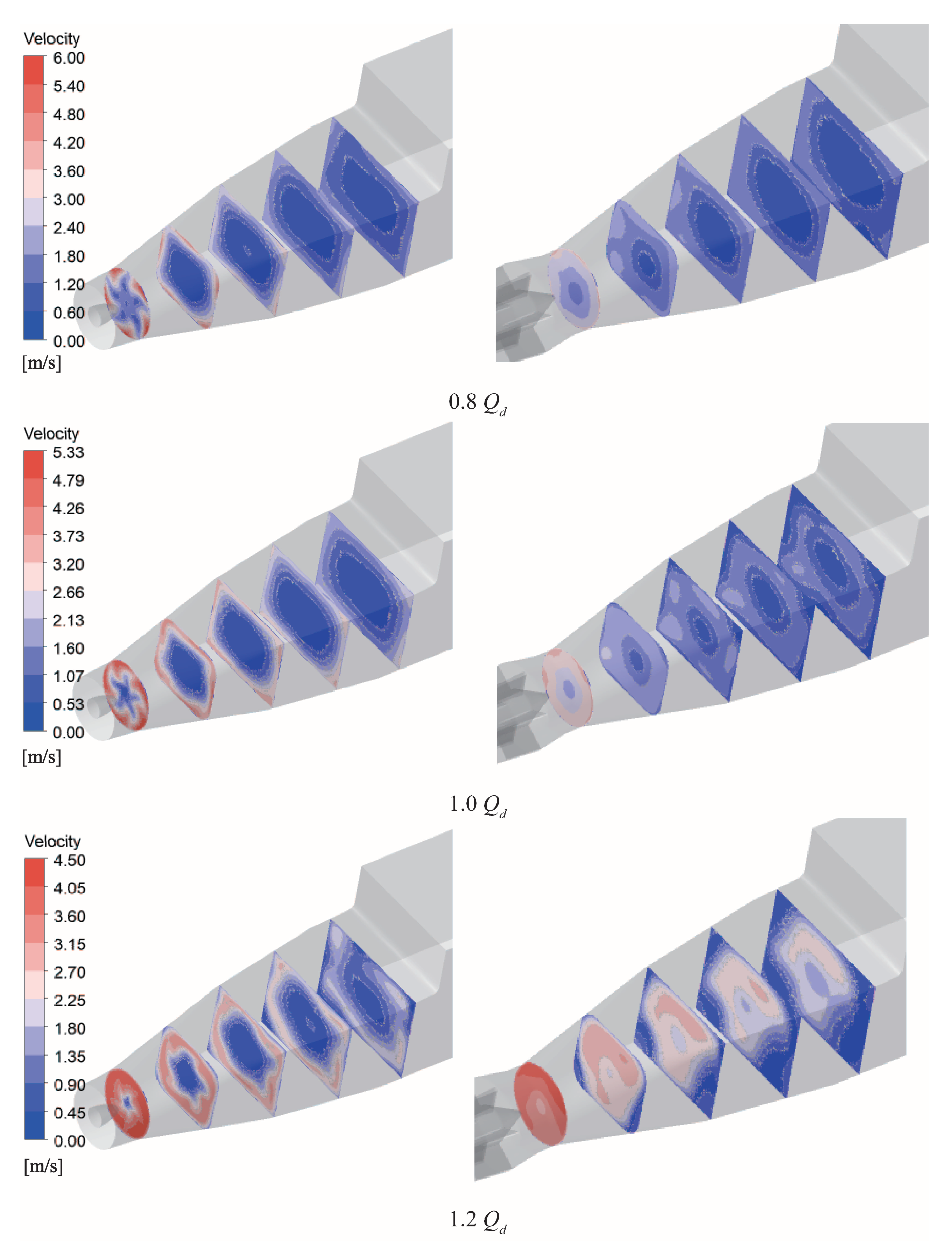

4.2. Analysis of Hydraulic Loss and Flow Field

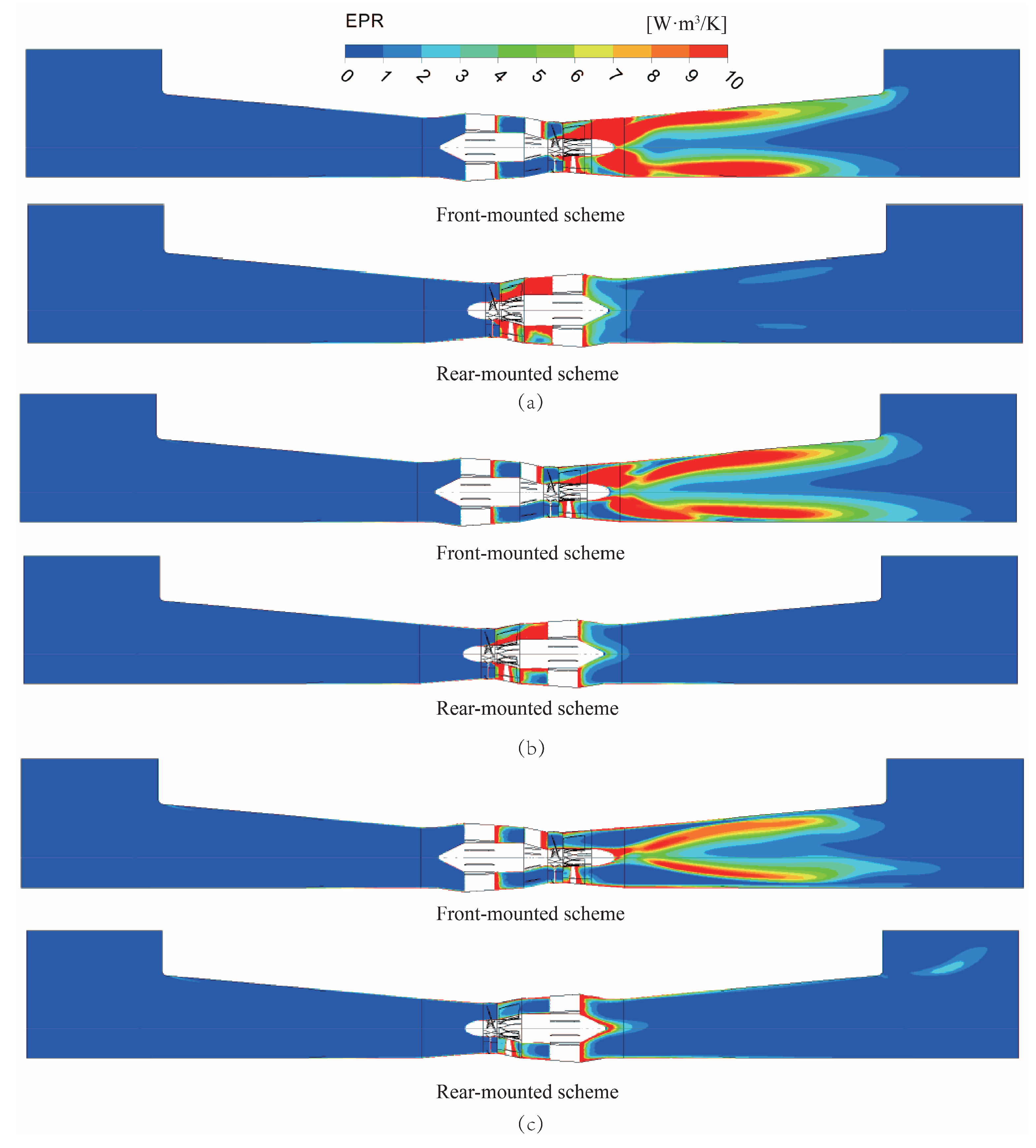

4.3. Entropy Generation Analysis

5. Conclusions

- In the case of a well-designed diffusion guide vane, the efficiency under the rear-mounted scheme was higher than that under the front-mounted scheme. The maximum efficiency under the rear-mounted solution was about 78.4%, and the maximum efficiency under the front-mounted solution was about 77.5%.

- Although the front-mounted scheme can reduce the hydraulic loss of the bulb section, it may worsen the flow state of the impeller inlet. The rear of the bulb has better water inlet conditions and the impeller is more efficient. The bulb body is located on the water outlet side, which plays the role of recovering the guide vane outlet circulation and rectification, reducing the hydraulic loss of the water outlet channel.

- The entropy generation under the front-mounted scheme was mainly on the outer wall of the outlet flow channel, as the drained water inside the outlet flow channel was squeezed around, causing large-scale entropy production in the outer wall area. The high value area of the entropy production rate under the rear-mounted solution was in the bulb section, and the bulb support also caused higher entropy production. For the bulb rear-mounted submersible tubular pump device, how to reduce the hydraulic loss of the bulb segment and the bulb support while, at the same time, exerting its rectification function will be key to optimizing its design in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, R. Study on Application of Tubular Pumps in the Project of South to North Water Transfer Project. Drain. Irrig. Mach. 2004, 5, 1–6. [Google Scholar]

- Rentian, Z.; Shan, H.; Bu, G.; Zhou, W.; Zhu, H.; Yao, L. Structural features of bulb tubular pumps in first phase of South-to-North Water Diversion Eastern Route Project in China. J. Drain. Irrig. Mach. Eng. 2016, 34, 767–775. [Google Scholar]

- Zhang, R. Performance analysis of bulb tubular pumps in the first phase of South-to-North Water Diversion Eastern Route Project in China. J. Drain. Irrig. Mach. Eng. 2017, 35, 32–41. [Google Scholar]

- Zhang, D.; Dai, Z.; Liao, R.; Cheng, M.; Xia, J. Characteristic experiment on flow pump set model and energy-saving. Energy Res. Util. 2003, 3, 22–24. [Google Scholar]

- Yang, H.; Huang, L.; Xia, J.; Wang, J. The Choice of Umbrella-Gear Transmission Routing Through Pump Unit’s Structure Types in Luyang Pumping Station Project of the Channel Which Leading Huaihe River Into Sea. Drain. Irrig. Mach. 2004, 22, 9–13. [Google Scholar]

- Lu, L.-G.; Huang, J.-J.; Chen, J.; Chen, A.P.; Wang, X.-M.; Zou, J.-G. Numerical study of 3D flow in a bulb Tubular pump system. Drain. Irrig. Mach. 2007, 25, 15–20. [Google Scholar]

- Lu, L.G.; Chen, J.; Liang, J.D.; Leng, Y. Optimal hydraulic design of bulb tubular pump system. J. Hydraul. Eng. 2008, 39, 355–360. [Google Scholar]

- Lu, W.; Wang, D.; Shi, W.; Liu, J.; Xu, L. Comparison of hydraulic performance between submersible tubular pump device with motor front and rear arrangements. J. Drain. Irrig. Mach. Eng. 2020, 38, 325–331. [Google Scholar]

- Tang, F.; Liu, C.; Zhou, J.; Yuan, J.; Li, C. Experimental Research on Scale Model of Low Head Tubular Axial-Flow Pumps Installation. Pump Technol. 2004, 4, 28–31. [Google Scholar]

- Tang, F.; Liu, C.; Xie, W.; Yuan, J.; Zhou, J.; Li, C. Experimental Studies on Hydraulic Models for a Reversible, Tubular, and Submersible Axial-flow Pump Installation. Trans. Chin. Soc. Agric. Mach. 2004, 35, 74–77. [Google Scholar]

- Wu, C.; Jin, Y.; Wang, D.; Yang, H.; Yang, F.; Liu, C. Study and application of large bidirectional submersible tubular pump system. J. Hydroelectr. Eng. 2012, 31, 265–270, 293. [Google Scholar]

- Xu, H. Tubular Pumping Station; China Water Conservancy and Hydropower Press: Beijing, China, 2008. [Google Scholar]

- Yang, F.; Jin, Y.; Liu, C.; Tang, F.; Cheng, L.; Yang, H. Numerical analysis and performance test on diving tubular pumping system with symmetric aerofoil blade. Trans. Chin. Soc. Agric. Eng. 2012, 28, 60–67. [Google Scholar]

- Dai, J.; Dai, Q.; Wang, H. Effect of Diffuser Blade Position on Hydraulic Performance of Bulb Tubular Pump. Water Resour. Power 2017, 35, 168–171. [Google Scholar]

- Jin, Y.; Liu, C.; Tang, F. 3D Numerical Simulation of Turbulent Flow in Postpositional Bulb Tubular Pump. J. Mech. Eng. 2010, 46, 167–174. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, C.; Tang, F.; Zhou, J. Influence of Supporting Shape on the Hydraulic Performance of Bulb Tubular Pumps. Transac. Chin. Soc. Agric. Mach. 2009, 40, 78–82. [Google Scholar]

- Xia, C.; Cheng, L.; Jiang, H.; Xin, J. Hydraulic performance analysis and optimization on flow passage components of diving tubular pumping system. Trans. Chin. Soc. Agric. Eng. 2018, 34, 45–51. [Google Scholar]

- Shi, W.; Zhang, D.; Guan, X.; Cao, W. Optimization and experimental investigation on post bulb type tubular pump device model. J. Hydraul. Eng. 2010, 41, 1248–1253. [Google Scholar]

- Tang, F.; Shi, L.; Lei, C.; Yang, H.; Yang, F. Multidisciplinary Design Optimization of Axial-flow Pump Blades. Trans. Chin. Soc. Agric. Mach. 2014, 45, 96–100. [Google Scholar]

- Tang, F. Design of Waterjet Axial Flow Pump and Numerical Analysis of Turbulent Flow. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2007. [Google Scholar]

- Langtry, R.B.; Menter, F.R. Correlation-Based Transition Modeling for Unstructured Parallelized Computational Fluid Dynamics Codes. AIAA J. 2009, 47, 2894–2906. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Roache, P.J. Conservatism of the Grid Convergence Index in Finite Volume Computations on Steady-State Fluid Flow and Heat Transfer. J. Fluids Eng. 2003, 125, 731–732. [Google Scholar] [CrossRef]

- Jin, Y. Research on Numerical Simulation and Three-dimensional LDV Measurement of Tubular Pump Internal Flow. Ph.D. Thesis, Yangzhou University, Yangzhou, China, 2010. [Google Scholar]

- Liu, C. Water Pumps and Water Pumping Stations; China Water Conservancy and Hydropower Press: Beijing, China, 2009. [Google Scholar]

- Zhu, H.; Yuan, S.; Liu, H.; Shi, W. Numerical simulation of three-dimensional turbulent flow in volute outlet channel of large pumping station. Trans. Chin. Soc. Agric. Mach. 2007, 38, 49–53. [Google Scholar]

- Wang, Z.; Peng, G.; Zhou, L.; Hu, D. Hydraulic performance of a large slanted axial-flow pump. Eng. Comput. 2010, 27, 243–256. [Google Scholar] [CrossRef]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes. J. Appl. Phys. 1996, 79, 1191–1218. [Google Scholar] [CrossRef] [Green Version]

- Herwig, H.; Kock, F. Direct and indirect methods of calculating entropy generation rates in turbulent convective heat transfer problems. Heat Mass Transf. 2007, 43, 207–215. [Google Scholar] [CrossRef]

- Kock, F.; Herwig, H. Local entropy production in turbulent shear flows: A high-Reynolds number model with wall functions. Int. J. Heat Mass Transf. 2004, 47, 2205–2215. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Xu, X.; Wang, H. Energy Conversion Characteristic within Impeller of Low Specific Speed Centrifugal Pump. Trans. Chin. Soc. Agric. Mach. 2011, 42, 75–81. [Google Scholar]

| Scheme | Number of Grids (106) | Head (m) | GCI (%) | |

|---|---|---|---|---|

| Front-mounted scheme | Fine | 8.64 | 3.421 | 0.97 |

| Medium | 6.63 | 3.413 | 2.29 | |

| Coarse | 4.63 | 3.389 | ||

| Rear-mounted scheme | Fine | 8.53 | 3.431 | 1.23 |

| Medium | 6.53 | 3.423 | 1.54 | |

| Coarse | 4.54 | 3.409 |

| Measuring Items | Instrument | Instrument Model | Measuring Range | Calibration Accuracy |

|---|---|---|---|---|

| Head | Differential pressure transmitter | EJA110A | 0–200 kPa | ±0.1% |

| Flow rate | Electromagnetic Flowmeter | E-mag | DN400 mm | ±0.2% |

| Torque and rotation speed | Speed and torque sensor | JC2C | 200 N·m | ±0.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Yu, J.; Tang, F. The Influence of Bulb Position on Hydraulic Performance of Submersible Tubular Pump Device. J. Mar. Sci. Eng. 2021, 9, 831. https://doi.org/10.3390/jmse9080831

Sun Z, Yu J, Tang F. The Influence of Bulb Position on Hydraulic Performance of Submersible Tubular Pump Device. Journal of Marine Science and Engineering. 2021; 9(8):831. https://doi.org/10.3390/jmse9080831

Chicago/Turabian StyleSun, Zhuangzhuang, Jie Yu, and Fangping Tang. 2021. "The Influence of Bulb Position on Hydraulic Performance of Submersible Tubular Pump Device" Journal of Marine Science and Engineering 9, no. 8: 831. https://doi.org/10.3390/jmse9080831

APA StyleSun, Z., Yu, J., & Tang, F. (2021). The Influence of Bulb Position on Hydraulic Performance of Submersible Tubular Pump Device. Journal of Marine Science and Engineering, 9(8), 831. https://doi.org/10.3390/jmse9080831