Analysis of Composite Scrubber with Built-In Silencer for Marine Engines

Abstract

1. Introduction

2. Mathematical Model and Calculation Conditions

2.1. Mathematical Model

2.1.1. CFD Mathematical Models

2.1.2. Acoustic Mathematical Model

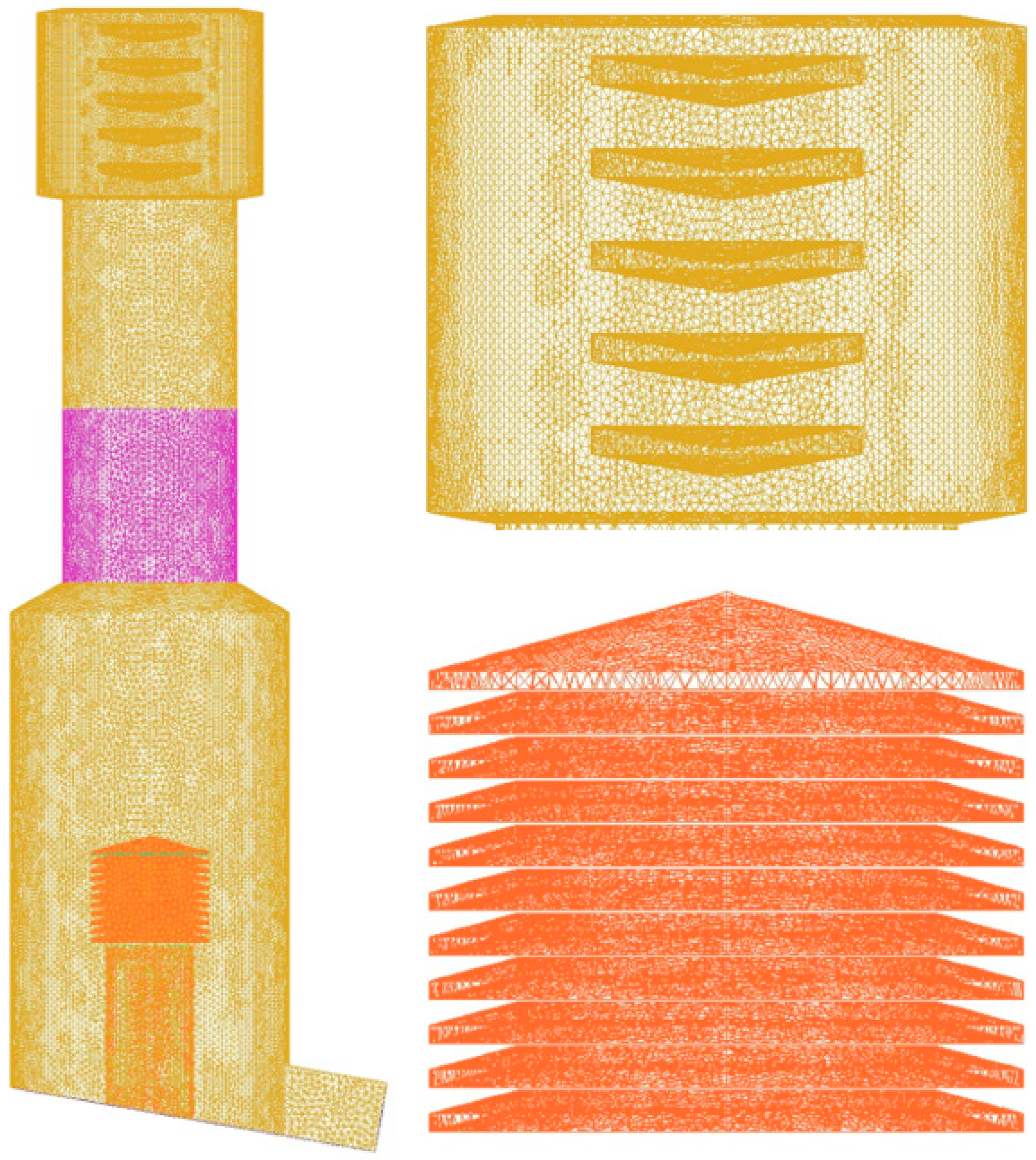

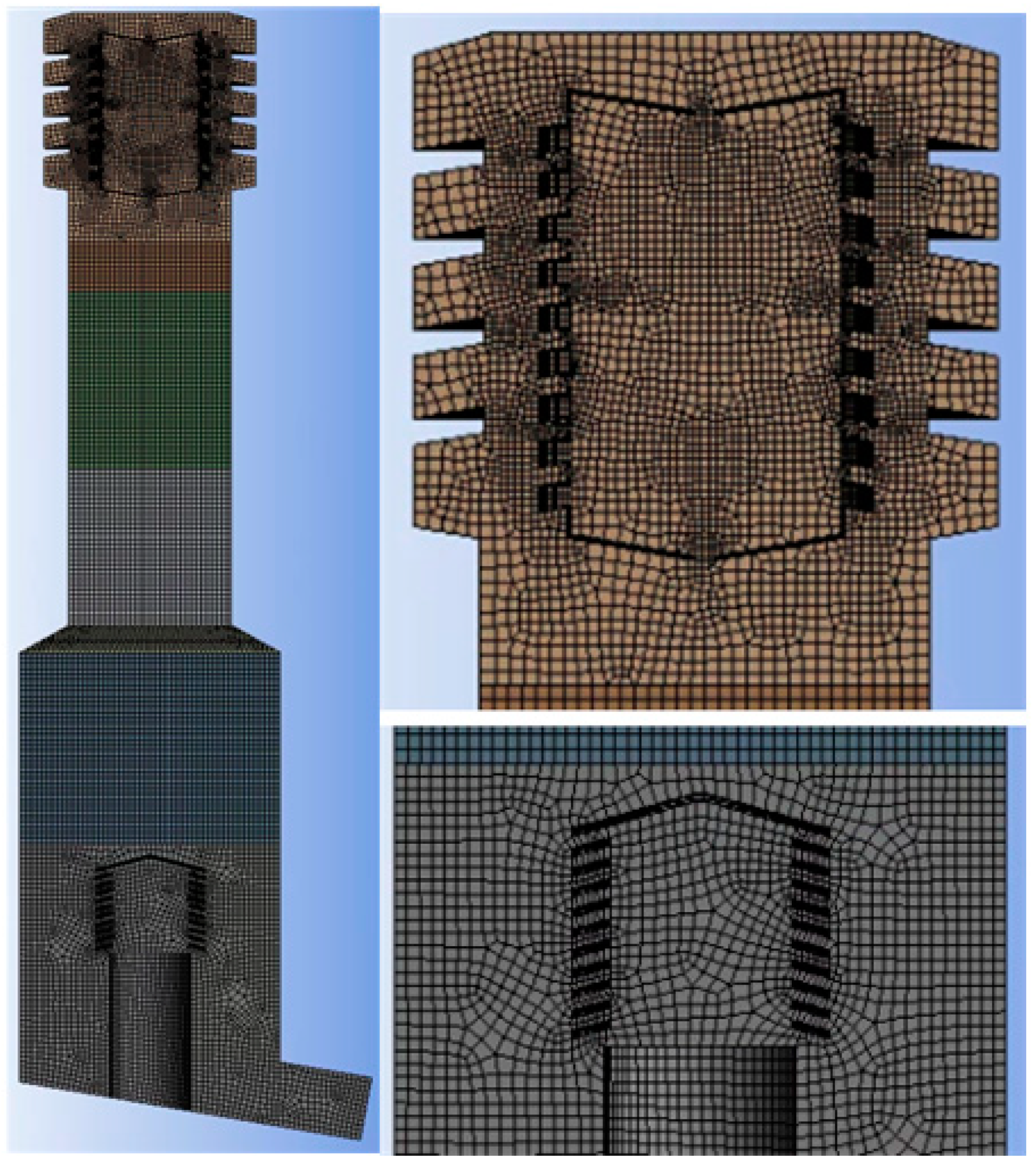

2.2. Calculation Grids

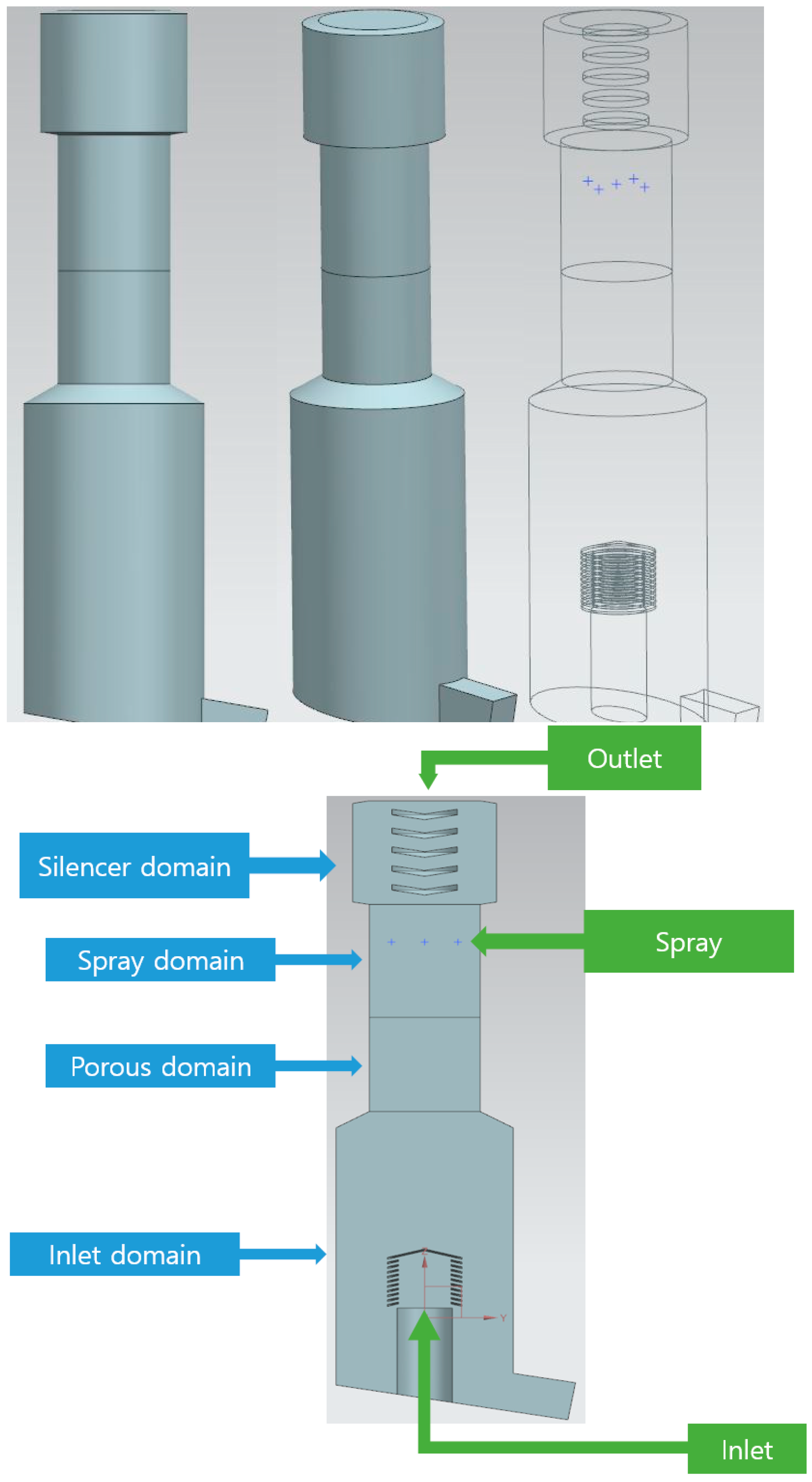

2.2.1. Flow Calculation

2.2.2. Acoustics Calculation

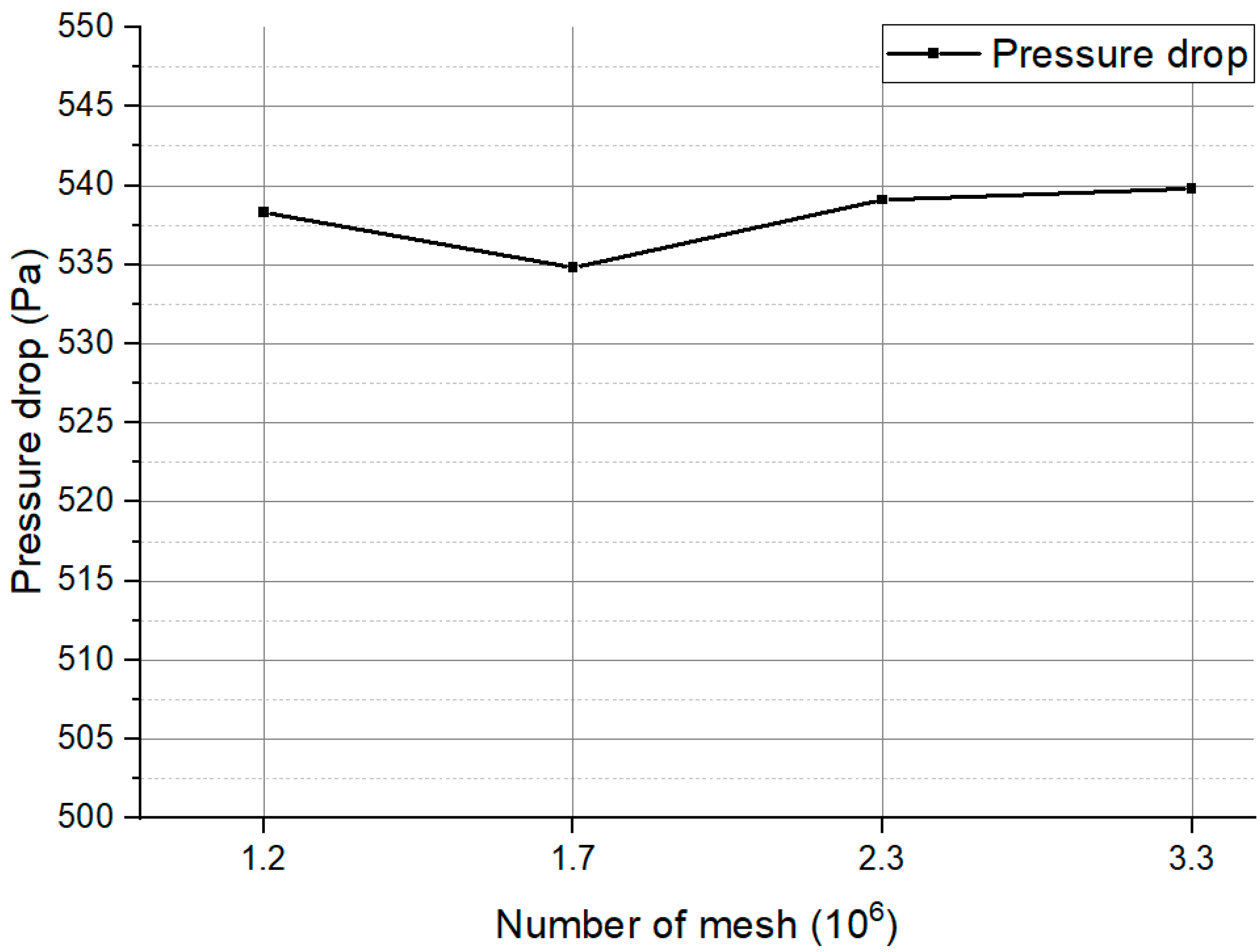

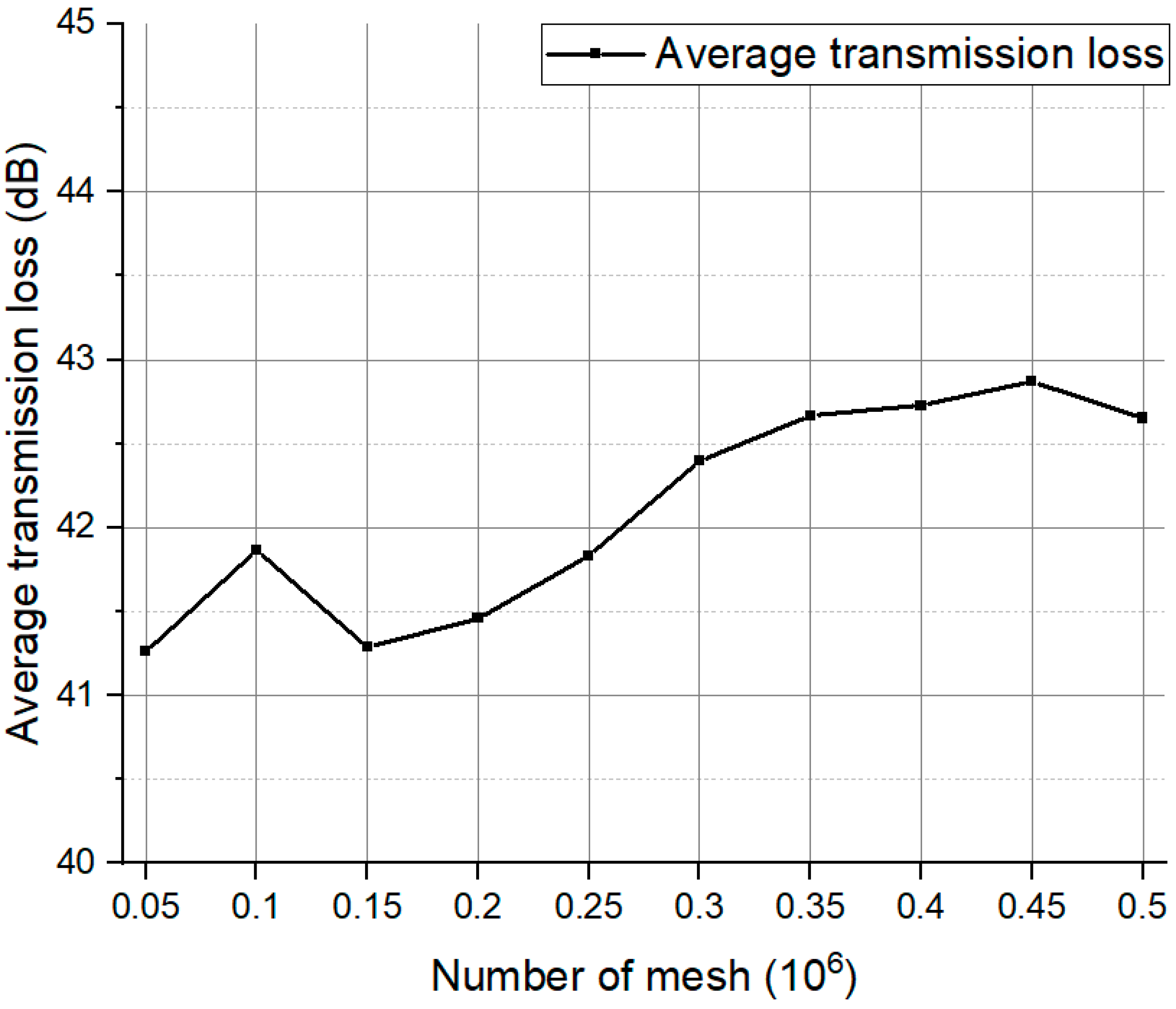

2.3. Calculation Reliability

2.3.1. Flow Calculation

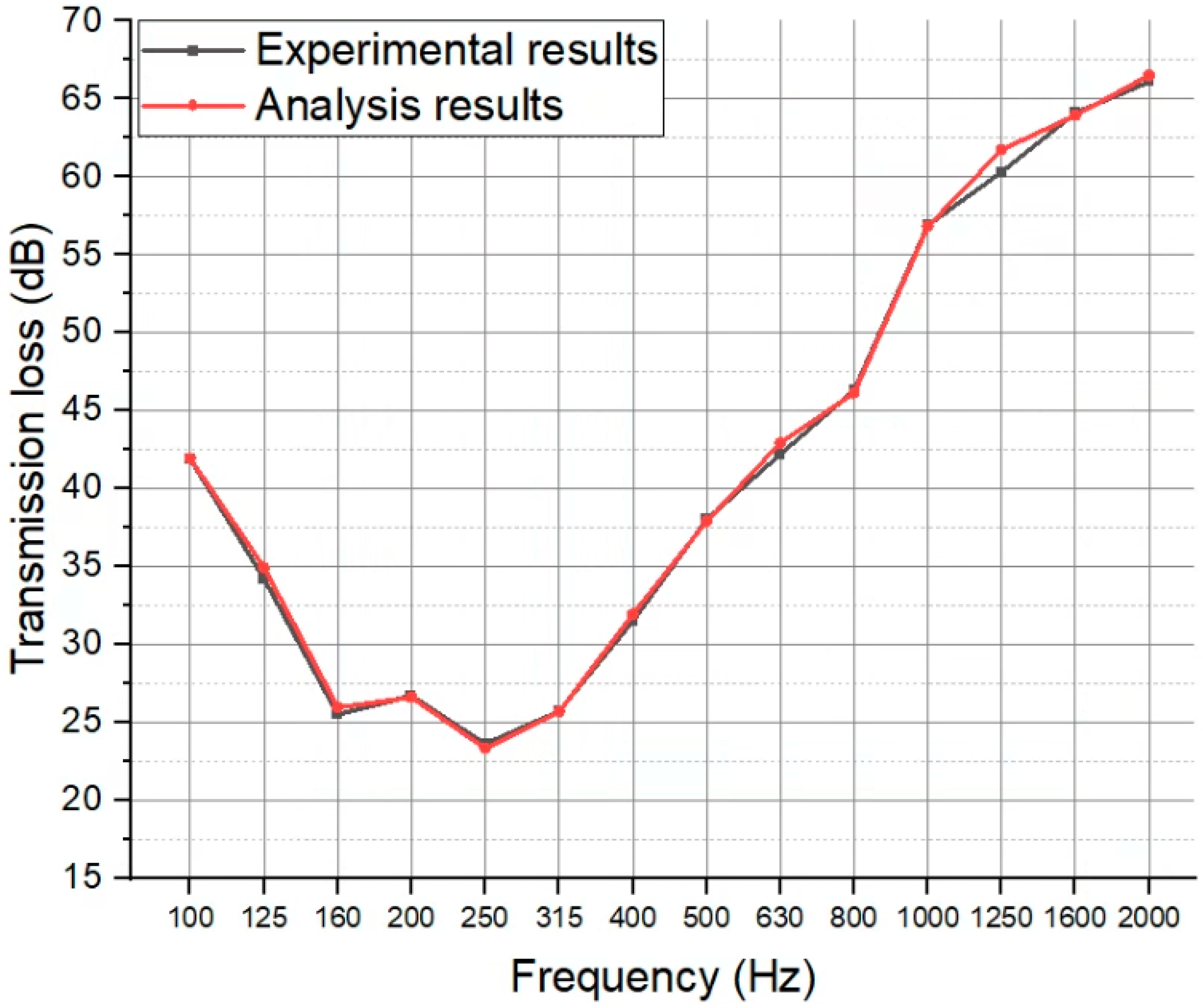

2.3.2. Acoustics Calculation

2.4. Calculation Condition

3. Result and Discussion

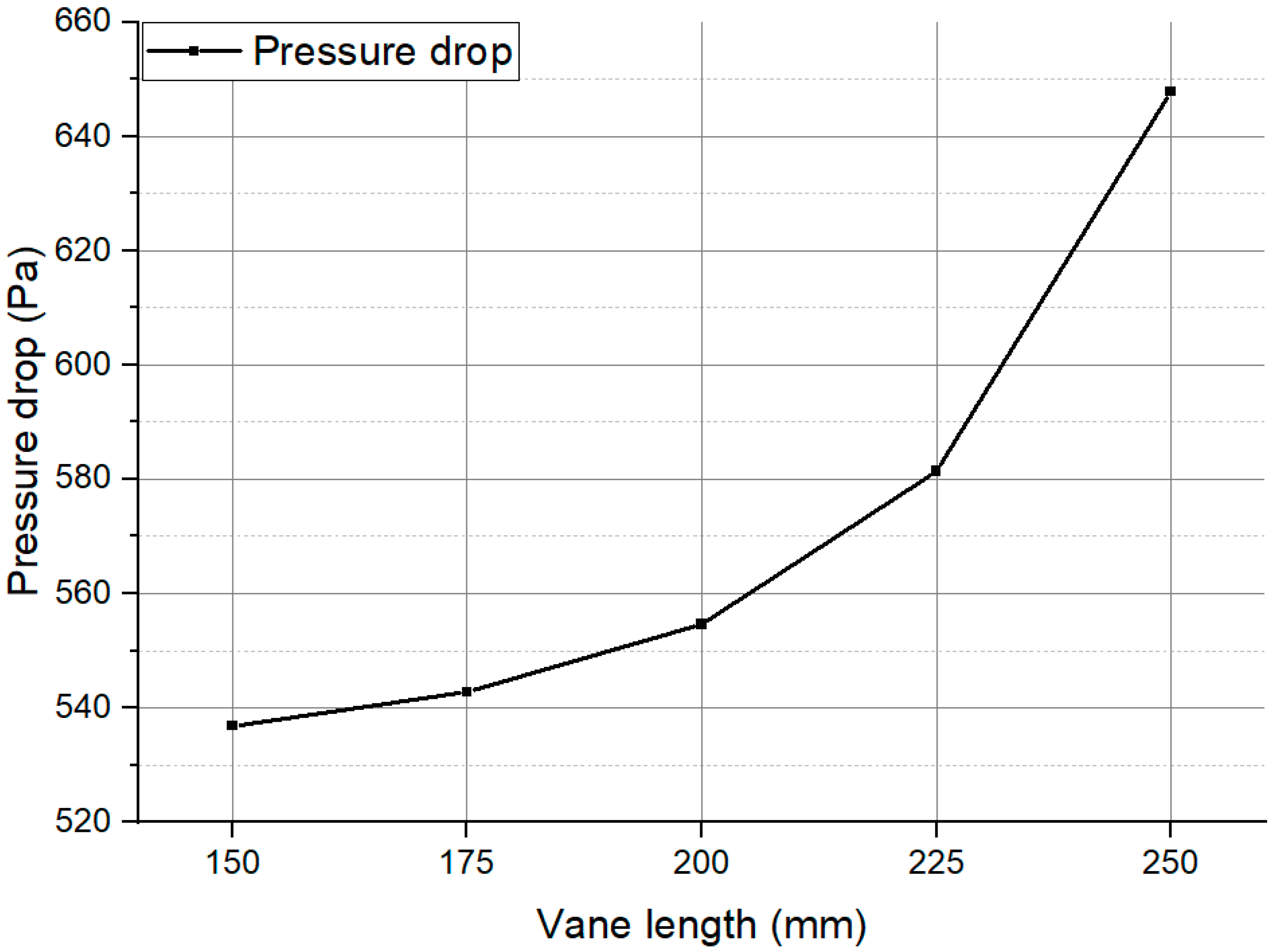

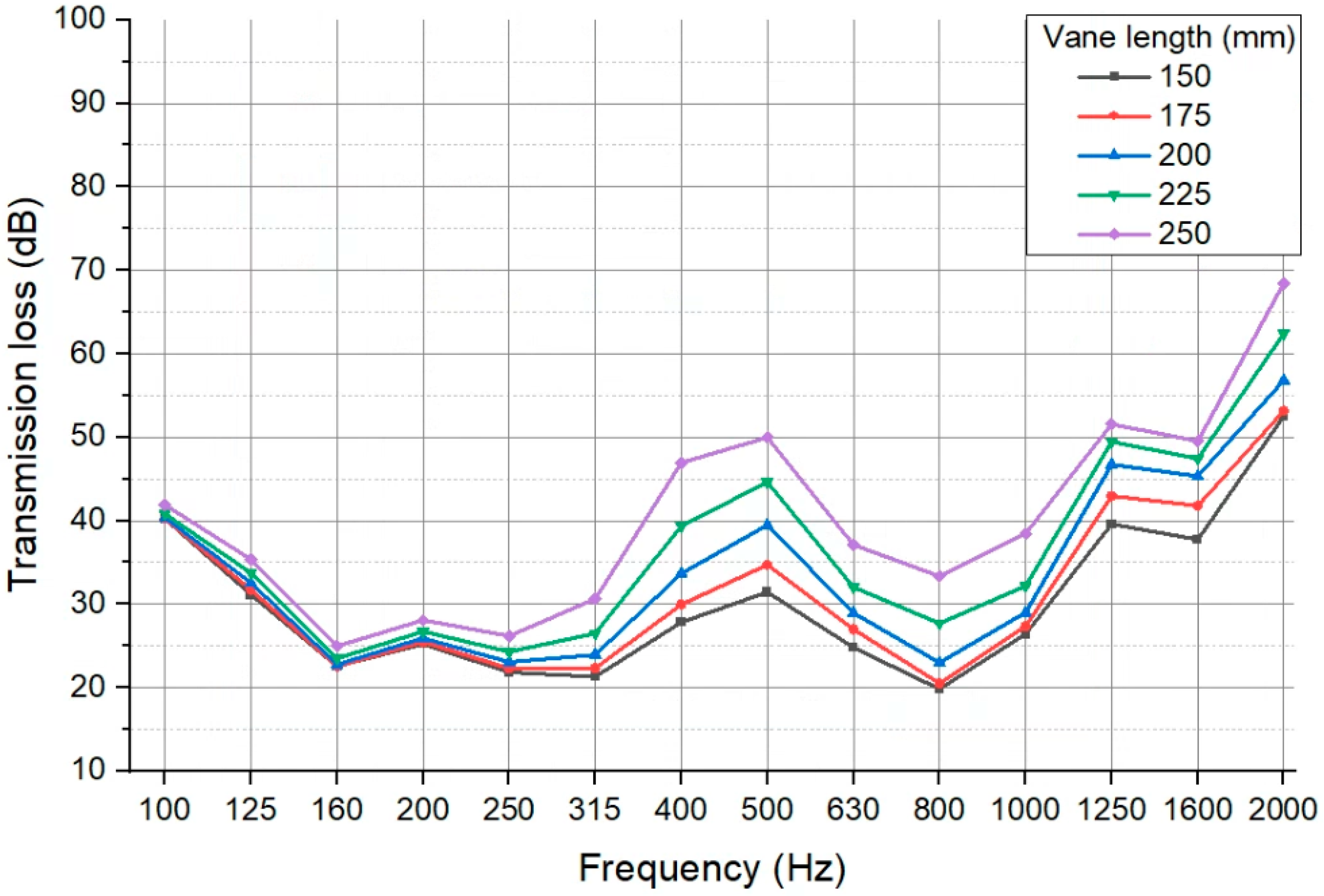

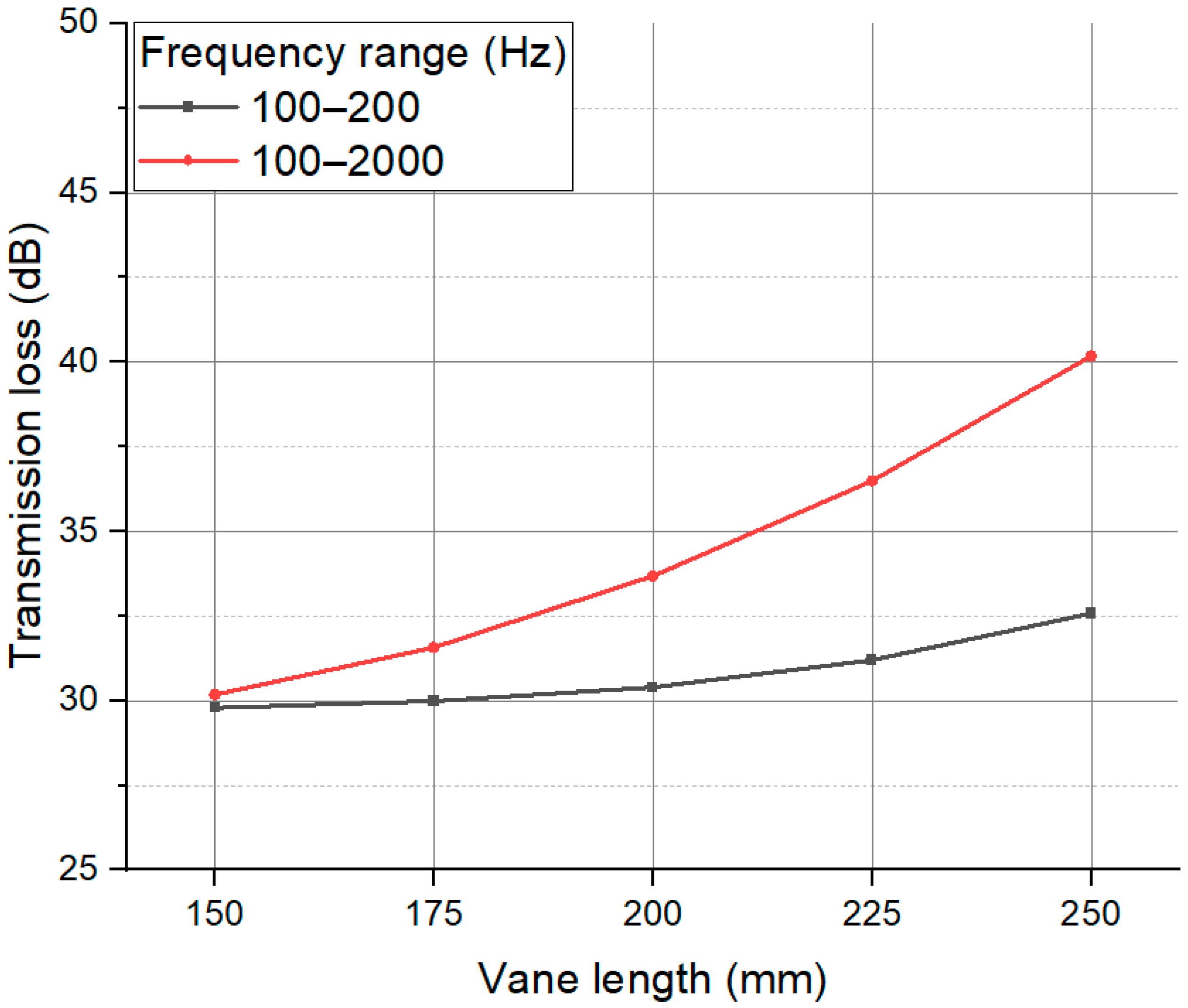

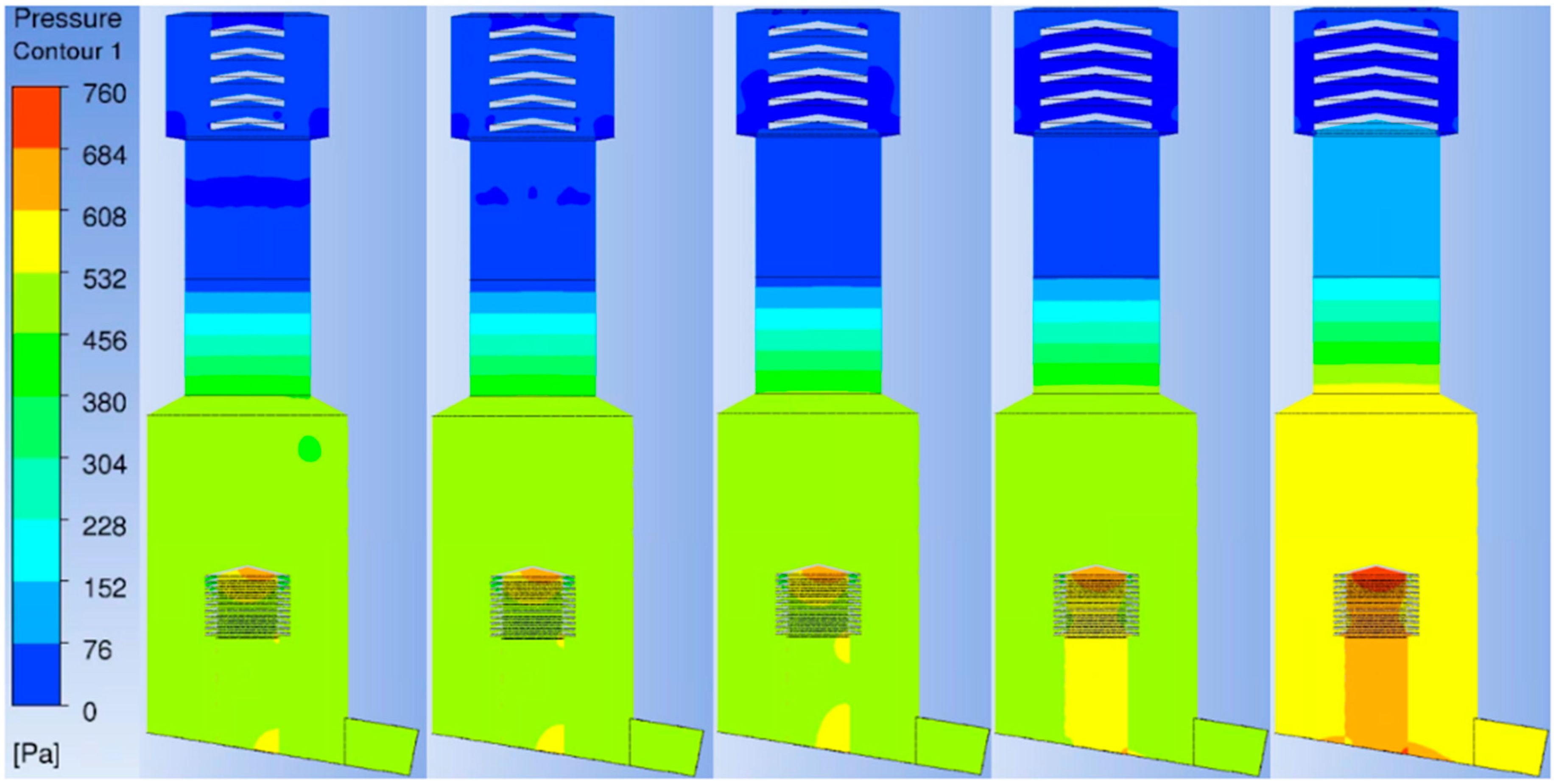

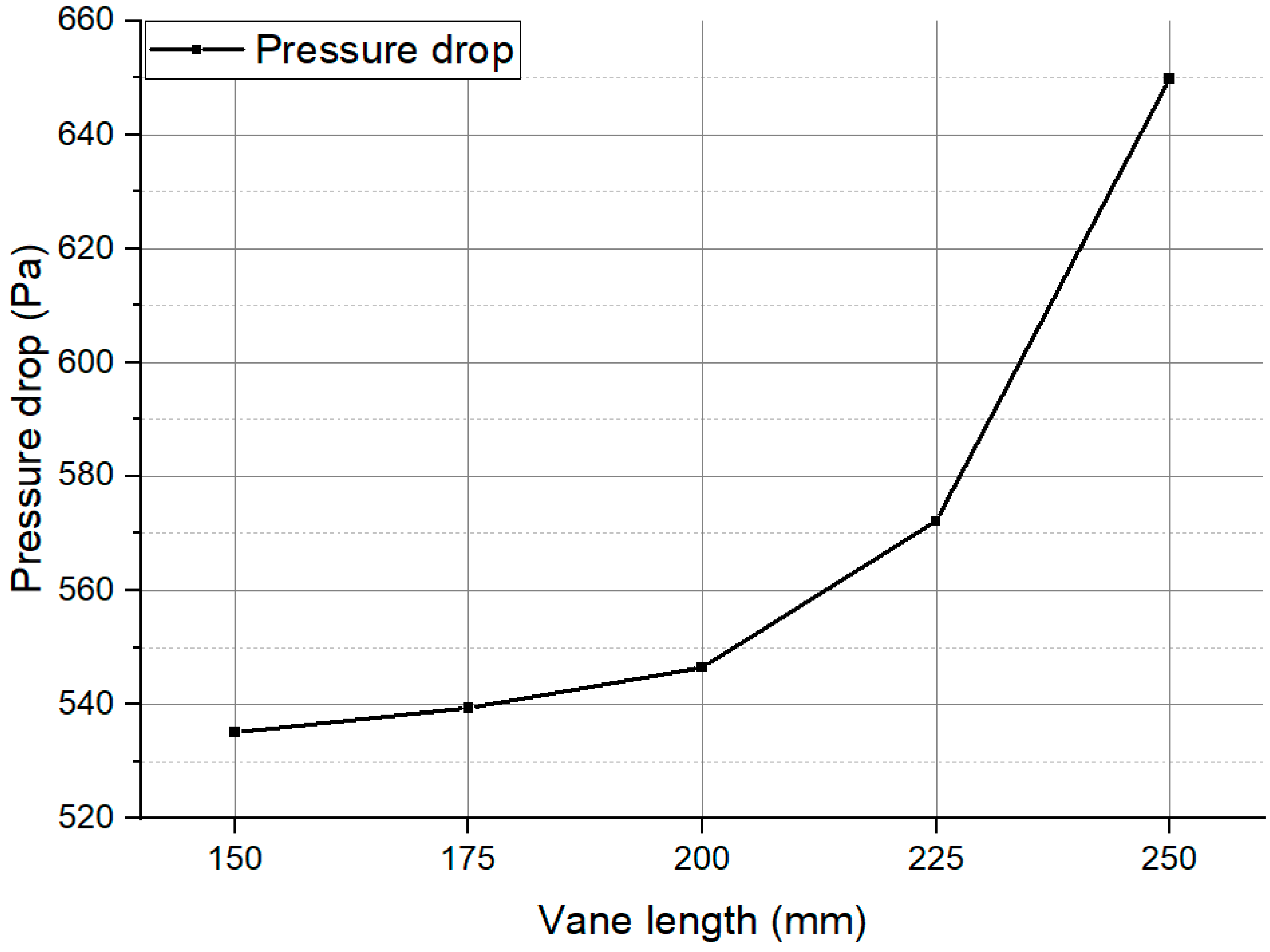

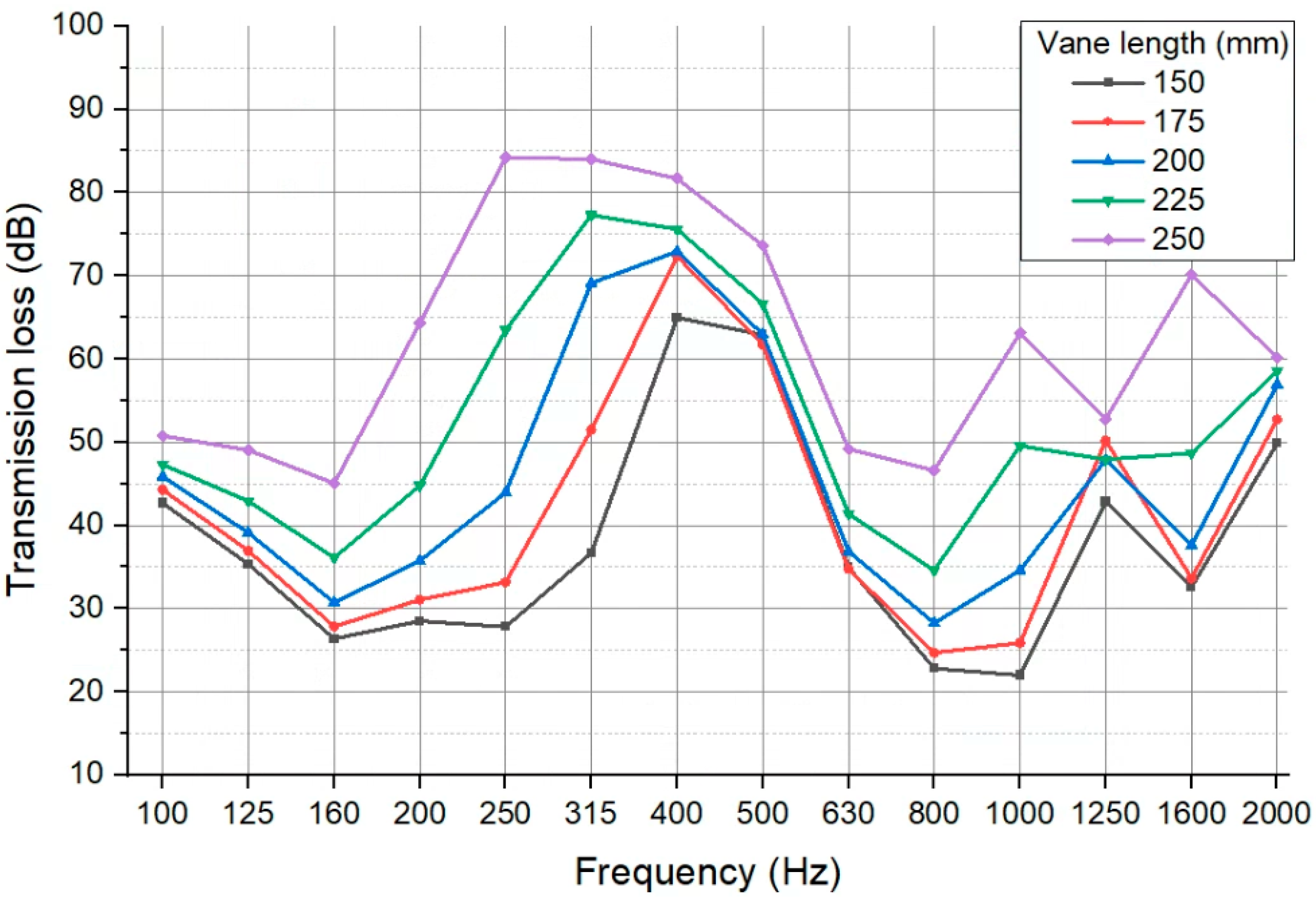

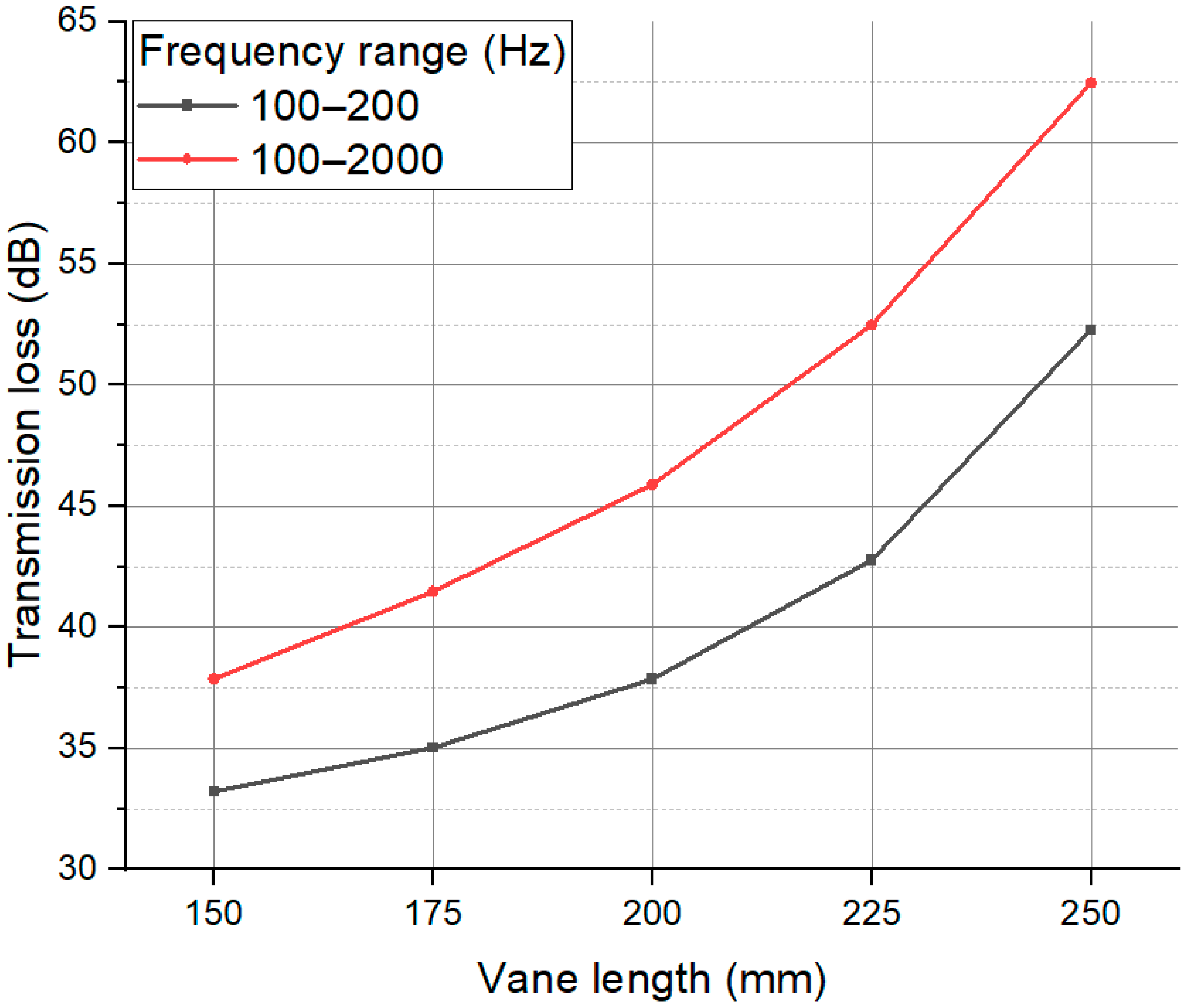

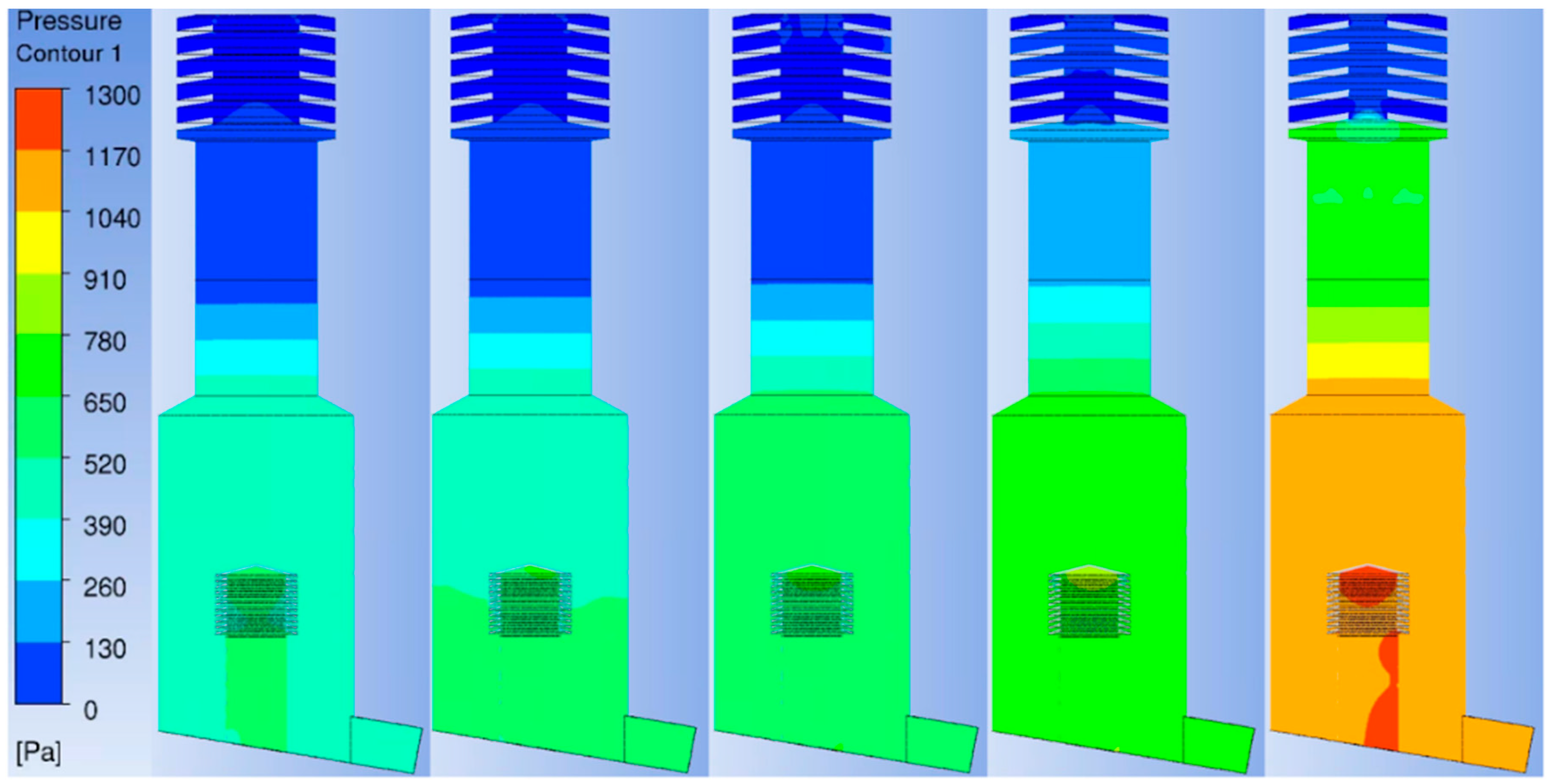

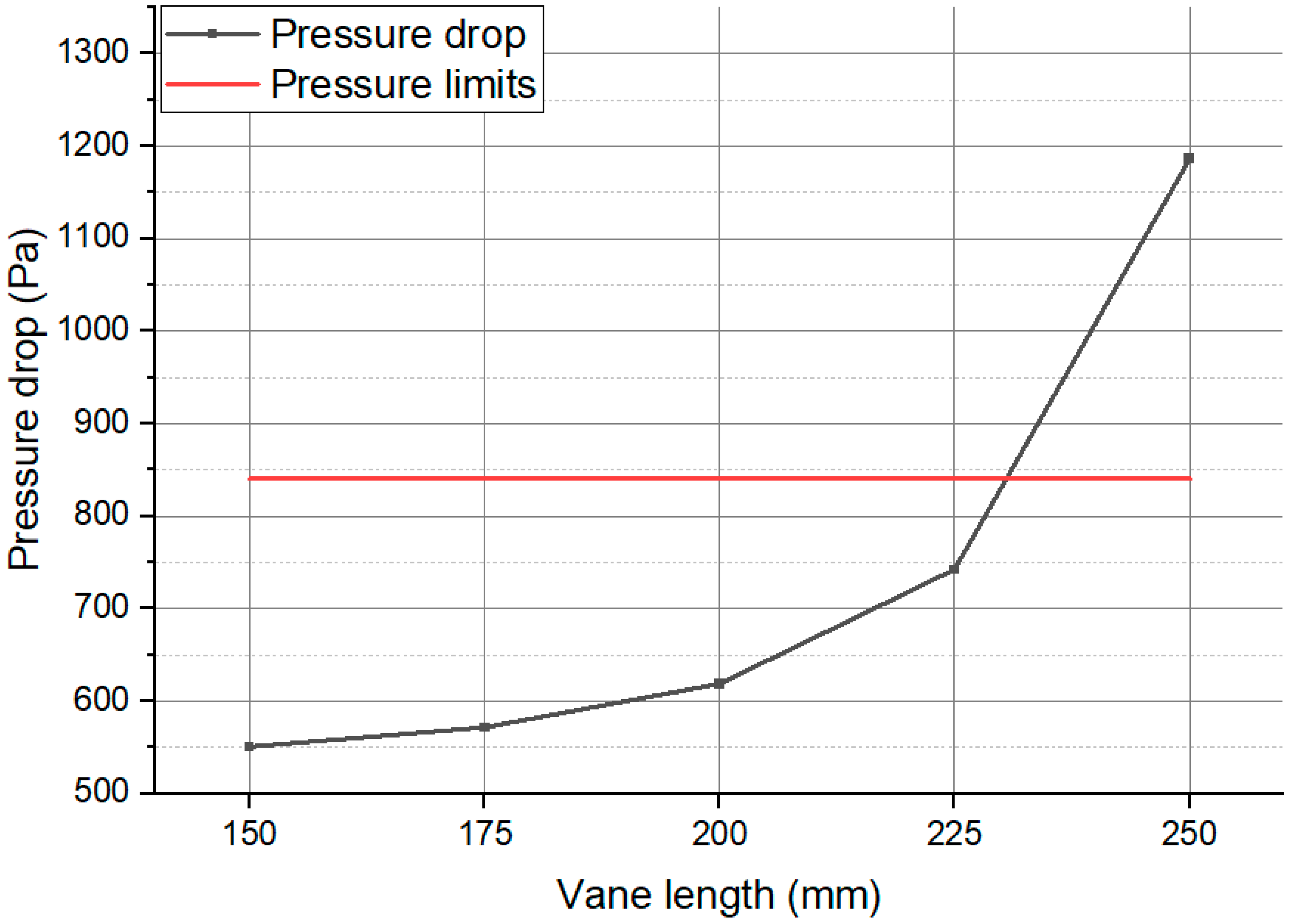

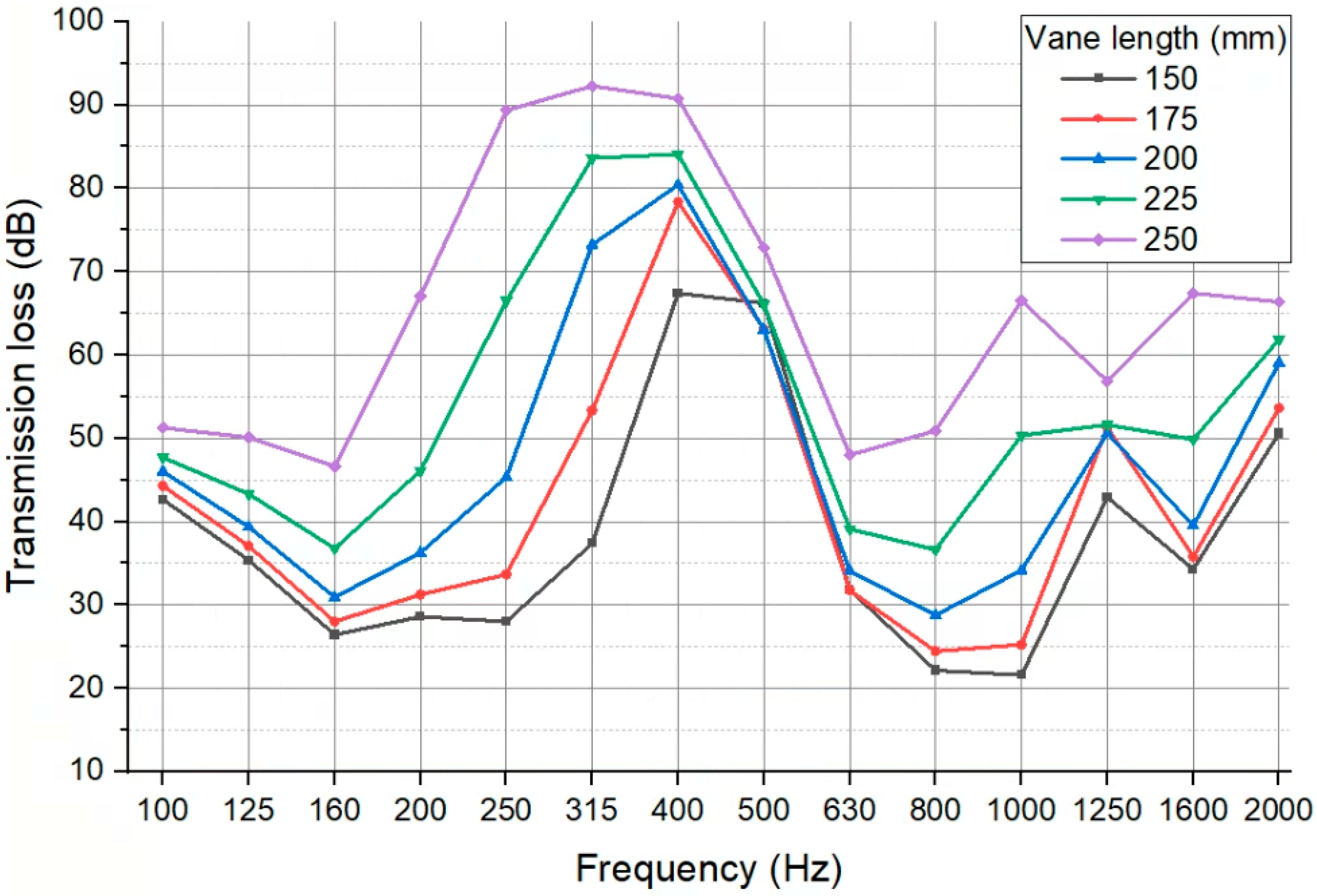

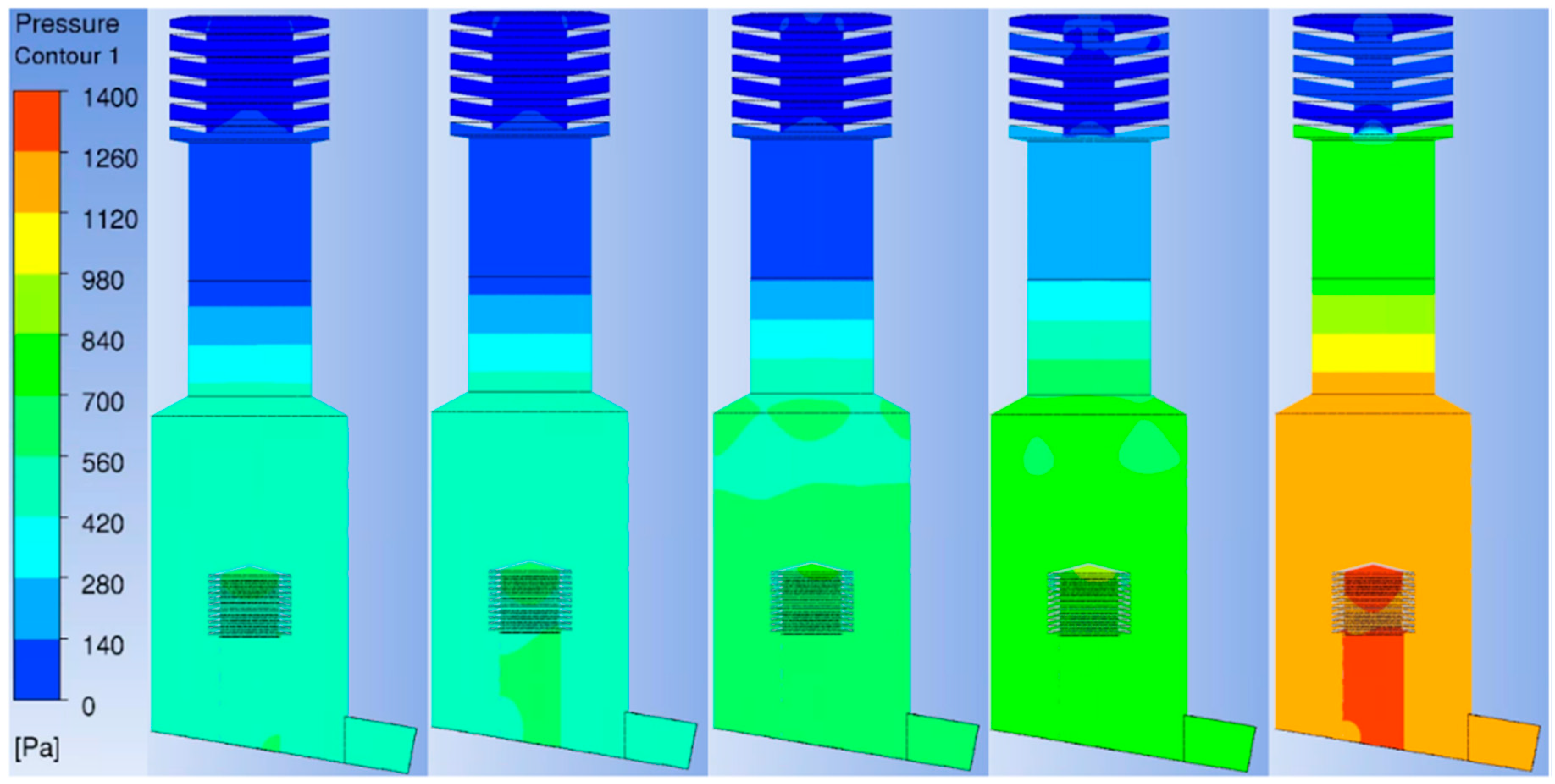

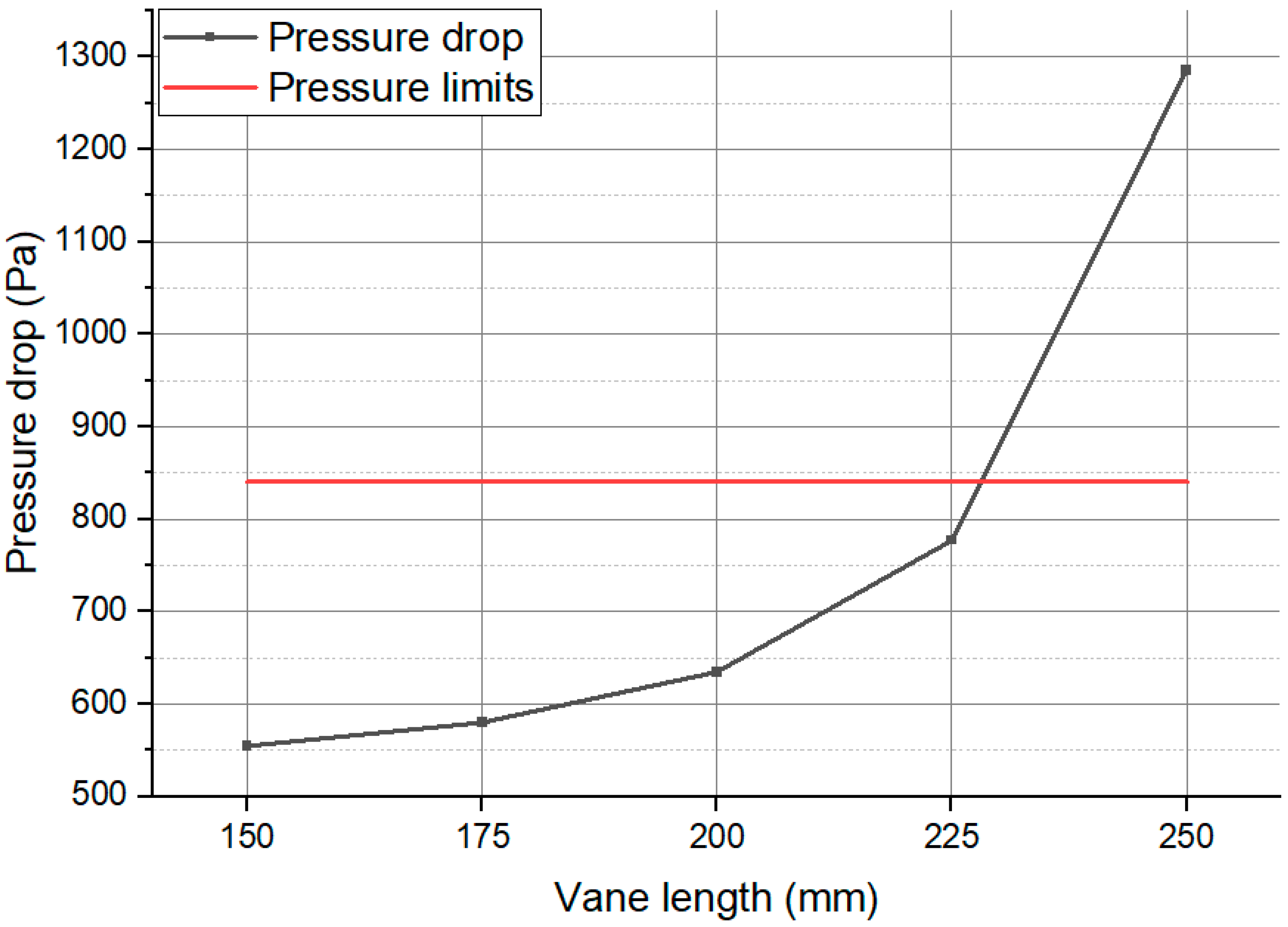

3.1. Inner Vane Type

3.2. Inner Vane Reverse Type

3.3. Outer Vane Type

3.4. Outer Vane Reverse Type

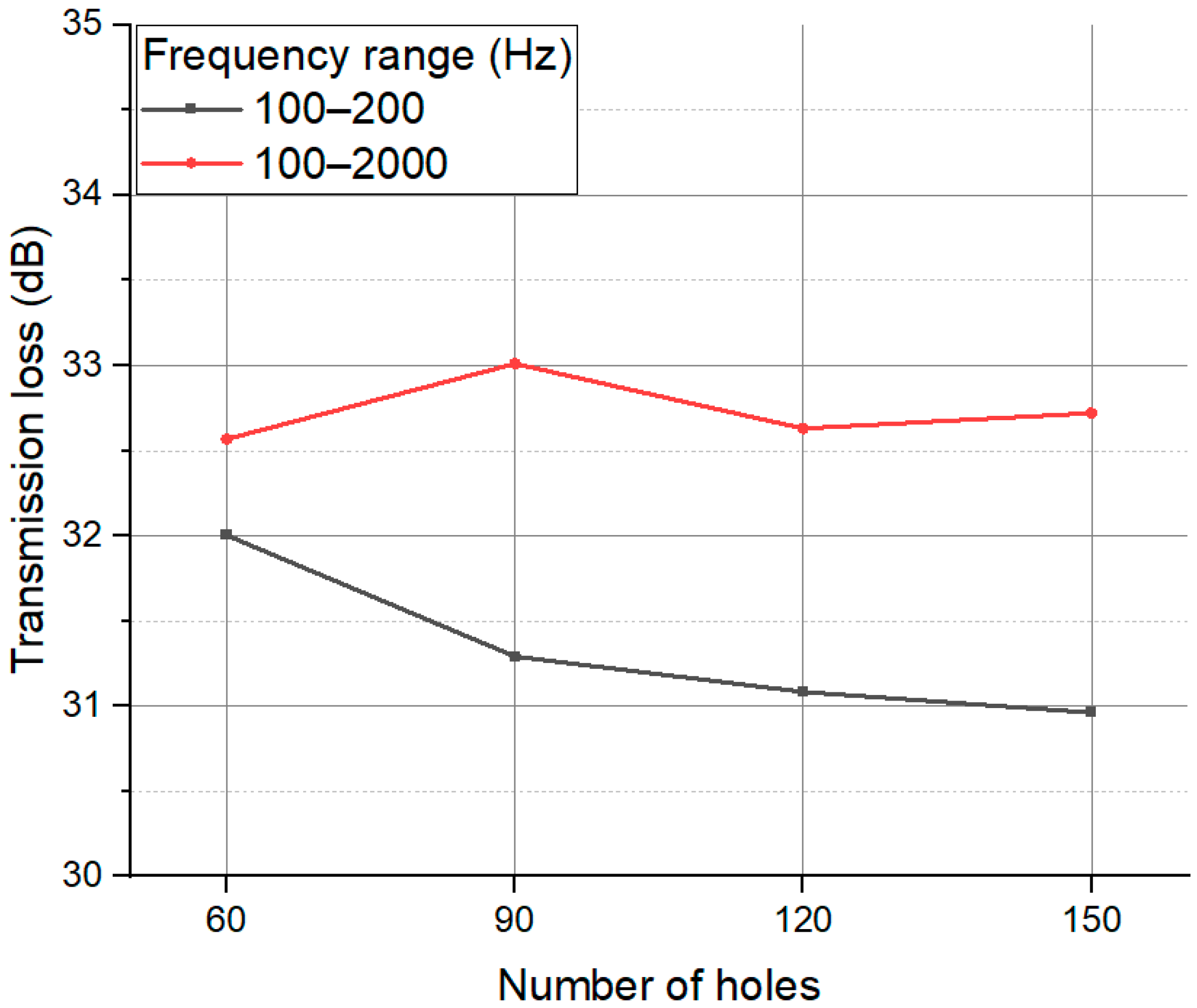

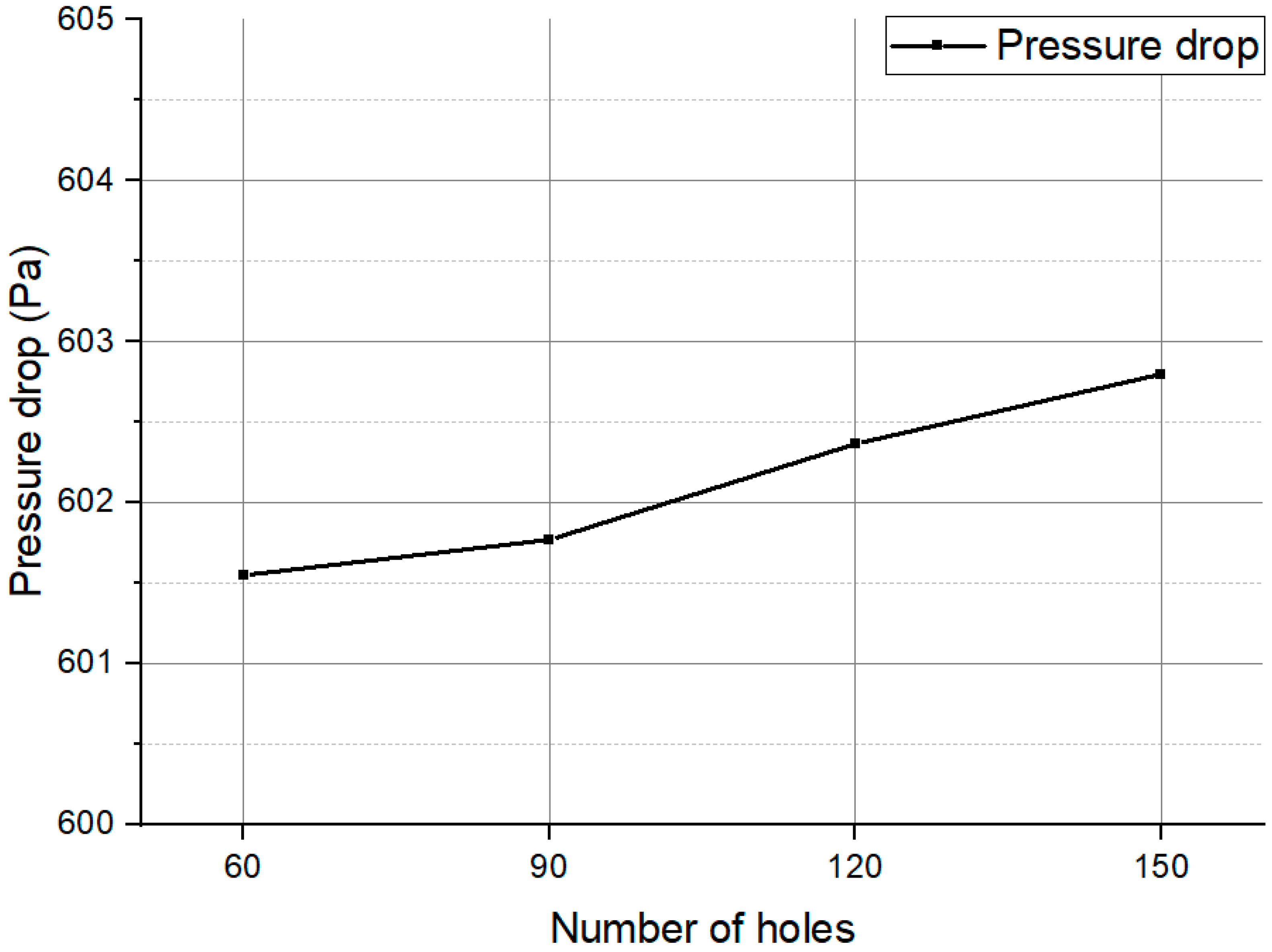

3.5. Inner Resonate Type

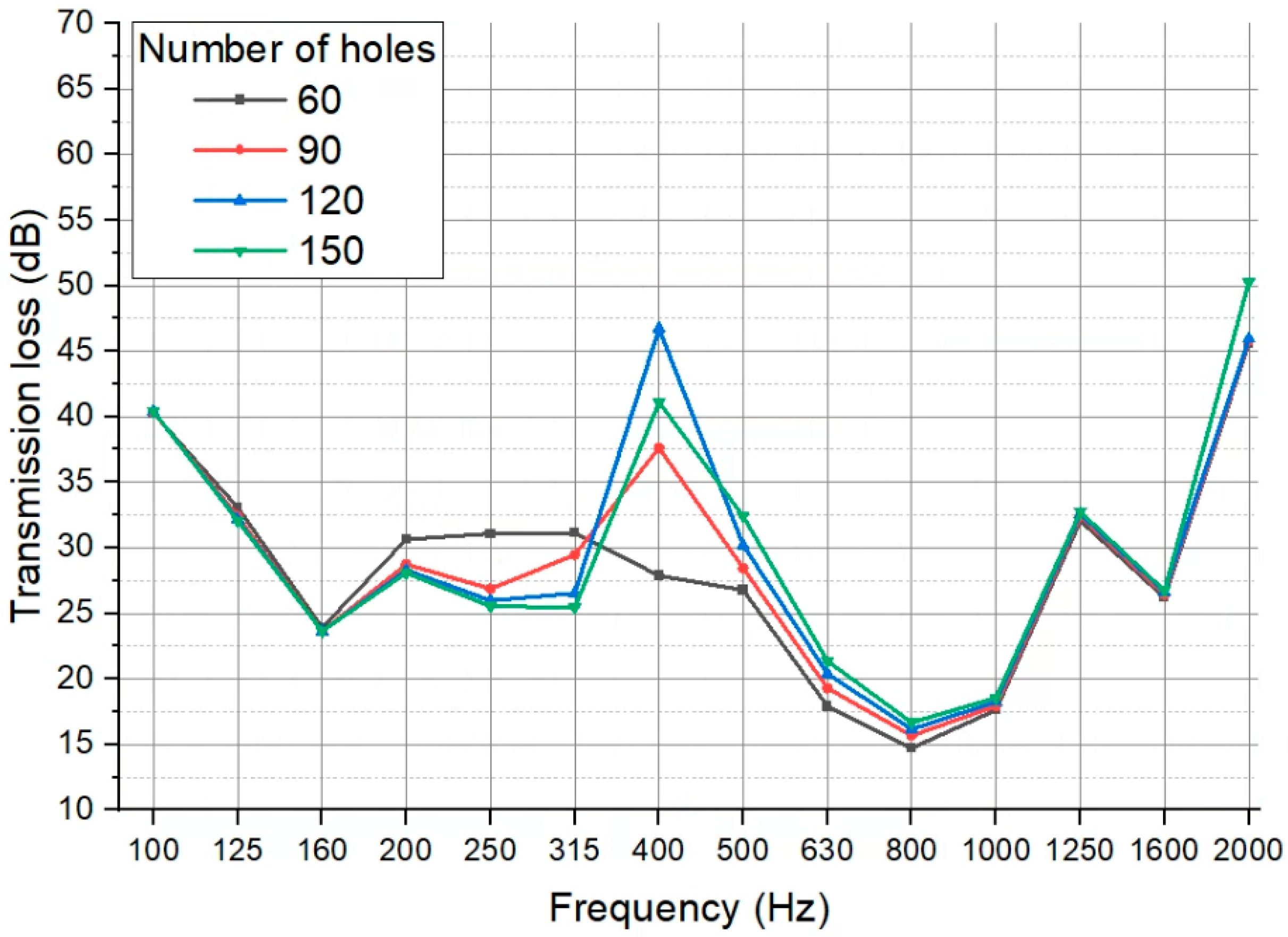

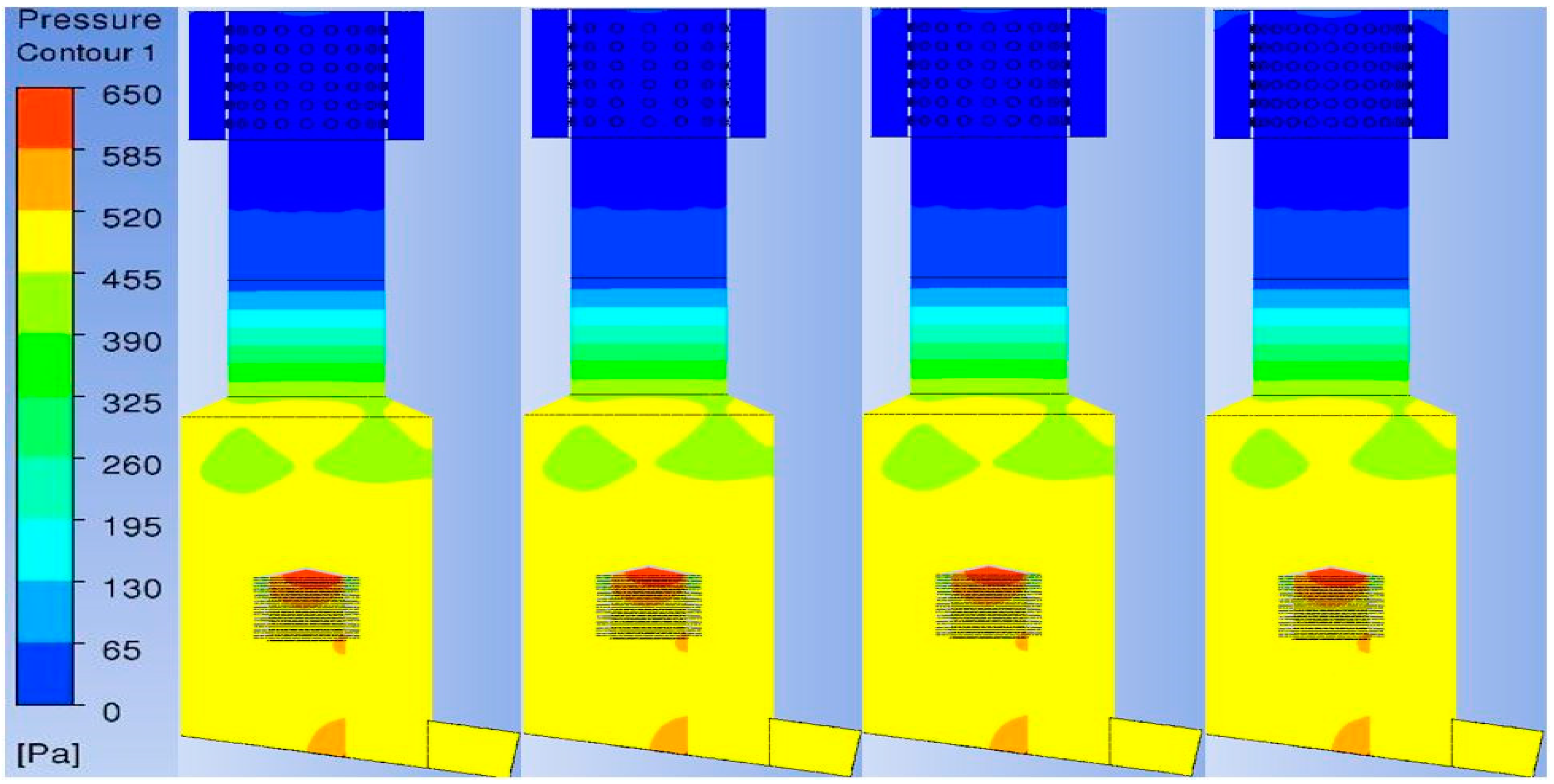

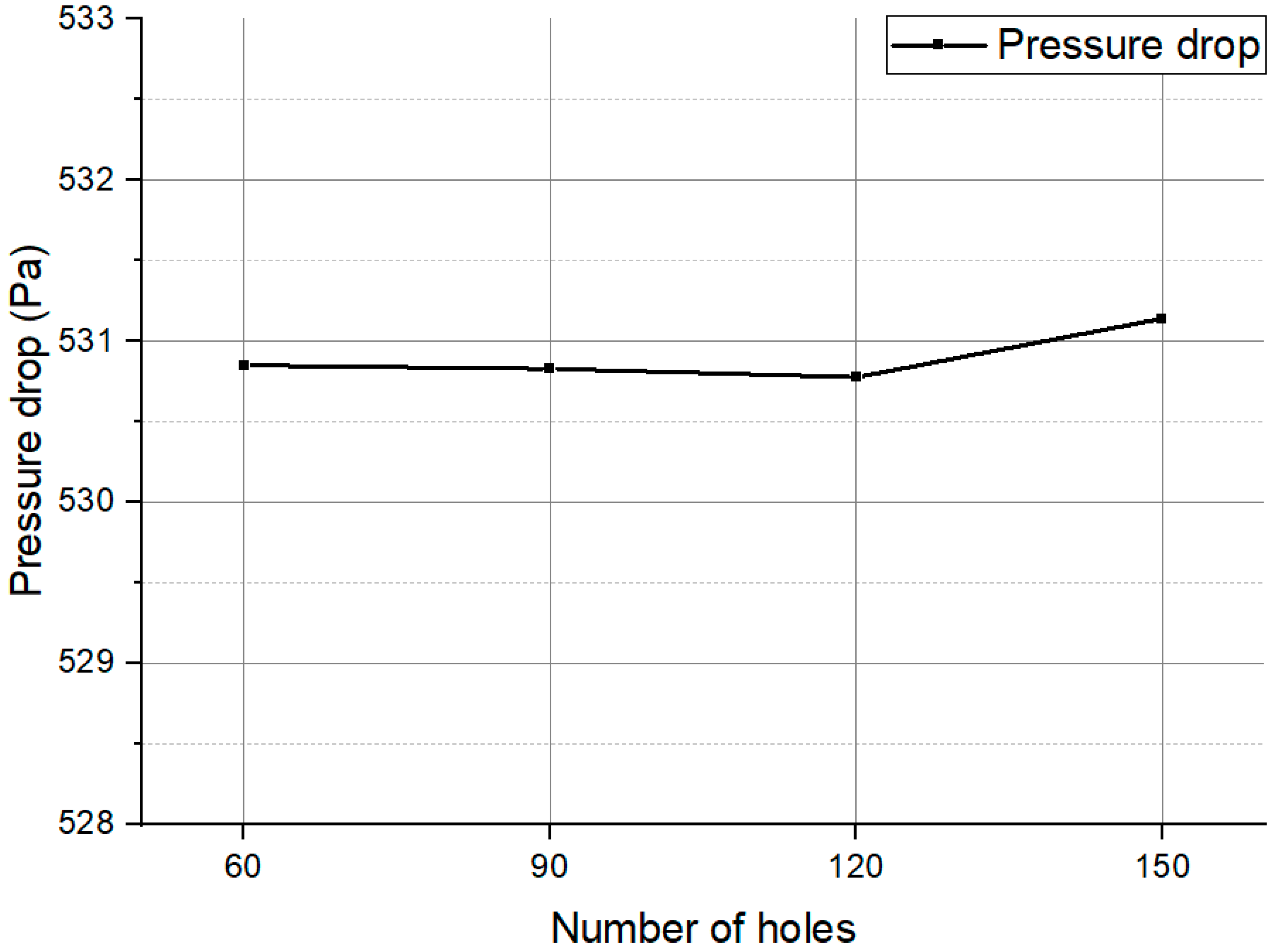

3.6. Outer Resonate Type

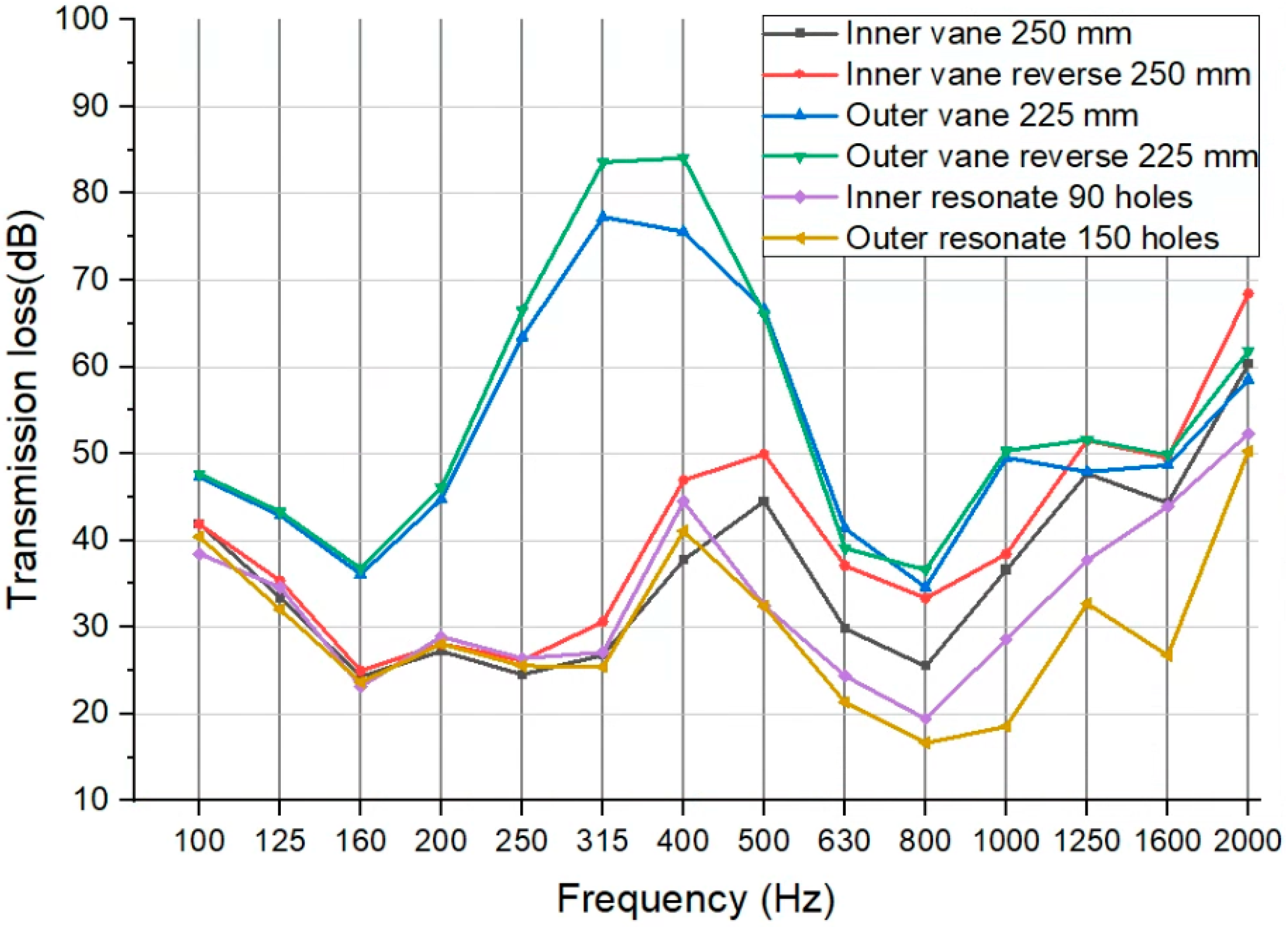

3.7. Comparison of Optimal Cases by Type

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.M.; Kwon, B.M.; Park, K. Flow characteristics according to internal structure of square wet scrubber. J. Korean Soc. Mar. Eng. 2019, 43, 1–7. [Google Scholar]

- Reynolds, K.J. Exhaust Gas Cleaning Systems Selection Guide, Prepared for Ship Operations Cooperative Program (SOCP); The Glosten Associates: Seattle, WA, USA, 2011. [Google Scholar]

- Han, B.W.; Kim, H.J.; Kim, Y.J.; Han, K.S. Removal characteristics of gaseous contaminants by a wet scrubber with different packing materials. J. Korean Soc. Atmos. Environ. 2007, 23, 744–751. [Google Scholar] [CrossRef]

- Byeon, S.H.; Lee, B.K.; Mohan, B.R. Removal of ammonia and particulate matter using a modified turbulent wet scrubbing system. Sep. Purif. Technol. 2012, 98, 221–229. [Google Scholar] [CrossRef]

- Lee, B.K.; Mohan, B.R.; Byeon, S.H.; Lim, K.S.; Hong, E.P. Evaluating the performance of a turbulent wet scrubber for scrubbing particulate matter. J. Air Waste Manag. Assoc. 2012, 43, 499–506. [Google Scholar] [CrossRef]

- Son, K.; Lee, J.Y.; Park, K. The effect of spray flow rate, aspect ratio, and filling rate of wet scrubber on smoke reduction. J. Korean Soc. Mar. Eng. 2015, 39, 217–222. [Google Scholar]

- Lee, W.J.; Kim, I.S.; Choi, Y.S.; Choi, J.H. A numerical study on the basic design of scrubber for marine diesel engines. J. Korean Soc. Mar. Environ. Saf. 2017, 23, 549–557. [Google Scholar] [CrossRef]

- Hu, S.Y.; Gao, Y.; Feng, G.; Hu, F.; Liu, C.; Li, J. Experimental study of the dust-removal performance of a wet scrubber. Int. J. Coal Sci. Technol. 2021, 8, 228–239. [Google Scholar] [CrossRef]

- Fang, P.; Cen, C.; Tang, Z.; Zhong, P.; Chen, D.; Chen, Z. Simultaneous removal of SO2 and NOX by wet scrubbing using urea solution. Chem. Eng. J. 2011, 168, 52–59. [Google Scholar] [CrossRef]

- Fang, P.; Cen, C.P.; Wang, X.M.; Tang, Z.J.; Tang, Z.X.; Chen, D.S. Simultaneous removal of SO2, NO and HG0 by wet scrubbing using urea + KMnO4 solution. Fuel Process. Technol. 2013, 106, 645–653. [Google Scholar] [CrossRef]

- Raghunath, C.V.; Mondal, M.K. Experimental scale multi component absorption of SO2 and NO by NH3/NaClO scrubbing. Chem. Eng. J. 2017, 314, 537–547. [Google Scholar] [CrossRef]

- Yang, S.; Pan, X.; Han, Z.; Zhao, D.; Liu, B.; Zheng, D. Removal of NOX and SO2 from simulated ship emissions using wet scrubbing based on seawater electrolysis technology. Chem. Eng. J. 2018, 331, 8–15. [Google Scholar] [CrossRef]

- Meikpa, B.C.; Kundu, G.; Biswas, M.N. Modeling of a novel multi-stage bubble column scrubber for flue gas desulfurization. Chem. Eng. J. 2002, 86, 331–342. [Google Scholar] [CrossRef]

- D’Addio, L.; Carotenuto, C.; Balachandran, W.; Lancia, A.; Di Natale, F. Experimental analysis on the capture of submicron particles (PM0.5) by wet electrostatic scrubbing. Chem. Eng. Sci. 2014, 106, 222–230. [Google Scholar] [CrossRef]

- Park, H.W.; Choi, S.S.; Park, D.W. Simultaneous treatment of NO and SO2 with aqueous NaClO2 solution in a wet scrubber combined with a plasma electrostatic precipitator. J. Hazard. Mater. 2015, 285, 117–126. [Google Scholar] [CrossRef]

- Lim, J.Y.; Kim, H.S.; Bang, S.Y.; Bum, B.S.; Kim, J.H. Effects on the removal of sulfur compounds by microbubble supply to circulation tank in a scrubber. J. Odor Indoor Environ. 2019, 18, 10–17. [Google Scholar] [CrossRef]

- Sun, W.; Shao, Y.; Zhao, L.; Wang, Q. Co-removal of CO2 and particulate matter from industrial flue gas by connecting an ammonia scrubber and a granular bed filter. J. Clean. Prod. 2020, 257, 120511. [Google Scholar] [CrossRef]

- Xie, R.; Ji, J.; Guo, K.; Lei, D.; Fan, Q.; Leung, D.Y.C.; Huang, H. Wet scrubber coupled with UV/PMS process for efficient removal of gaseous VOCs: Roles of sulfate and hydroxyl radicals. Chem. Eng. J. 2019, 356, 632–640. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, N.S.; Jin, B.M.; You, J.C.; Do, C.S. Sound insulation case of diesel engine low frequency exhaust noise problem. In Proceedings of the Annual Autumn Meeting, Mokpo, Korea, 3–4 November 2011; pp. 634–637. [Google Scholar]

- Hwang, W.G.; Lee, Y.Y.; Oh, J.E.; Kim, K.S.; Song, Y.H. A Study on the Transmission Loss and Back pressure of Muffler Elements. J. Korean Soc. Precis. Eng. 2002, 19, 147–153. [Google Scholar]

- Kwon, J.; Jeong, W.B.; Hong, C.S. Effects of Fluid Velocity on Acoustic Transmission Loss of Simple Expansion Chamber. Trans. Korean Soc. Noise Vib. Eng. 2012, 22, 994–1002. [Google Scholar] [CrossRef]

- Kim, Y.W.; Jeong, W.B. Numerical Analysis of Noise Reduction and Back-pressure for a Simple Expansion Chamber with a Partition. Trans. Korean Soc. Noise Vib. Eng. 2014, 24, 883–889. [Google Scholar] [CrossRef][Green Version]

- Yi, C.S.; Lee, T.E.; Lee, C.W. Numerical analysis of the Internal Flow of 8kW Grade Diesel Generator Muffler. J. Korean Soc. Manuf. Process. Eng. 2018, 17, 45–50. [Google Scholar] [CrossRef]

- Secgin, E.; Arslan, H.; Birgören, B. A statistical design optimization study of a multi-chamber reactive type silencer using simplex centroid mixture design. J. Low Freq. Noise Vib. Act. Control 2020, 40, 623–638. [Google Scholar] [CrossRef]

- Nursal, R.S.; Hashim, A.H.; Nordin, N.I.; Hamid, M.A.A.; Danuri, M.R. CFD Analysis of the Effects of Exhaust Backpressure Generated by Four-Stroke Marine Diesel Generator After Modification of Silencer and Exhaust Flow Design. ARPN J. Eng. Appl. Sci. 2017, 12, 1271–1280. [Google Scholar]

- Kakade, S.K.; Sayyad, F.B. Optimization of Exhaust Silencer for Weight and Size by Using Noise Simulation for Acoustic Performance. J. Inf. Comput. Sci. 2017, 10, 49–60. [Google Scholar]

- Kim, S.A. Silencer structure for exhaust noise attenuation performance in the high frequency range. J. Korean Soc. Fish. Ocean Technol. 2018, 54, 255–261. [Google Scholar] [CrossRef]

- ANSYS CFX-Theory Guide V14.0. Available online: https://www.researchgate.net/publication/321628826_Study_on_Design_of_Pressure_Chamber_in_a_Linear-Jet_Type_Air_Curtain_System_for_Prevention_of_Smoke_Spread/fulltext/5a29ec470f7e9b63e5353c2d/Study-on-Design-of-Pressure-Chamber-in-a-Linear-Jet-Type-Air-Curtain-System-for-Prevention-of-Smoke-Spread.pdf (accessed on 1 September 2021).

- ANSYS AACTx_R170_L. V17.0. Available online: https://www.ansys.com/news-center/press-releases/01-27-16-ansys-unveils-release-17-0 (accessed on 1 September 2021).

- Strigle, R.F., Jr. Random and Structured Packings. In Packed Tower Design and Applications, 2nd ed.; Gulf Publishing Company: Houston, TX, USA, 1987. [Google Scholar]

- Kang, D.J.; Lee, W.S.; Lee, J.W.; Hong, J.K.; Jo, Y.H.; Lee, S.J. Survey of the Soundproof Materials Effect—On Absorptive Materials. In Survey of the Soundproof Materials Effect; Air Quality Research Department, National Institute of Environmental Research: Hwangyong-ro, Korea, 2004; MONO1200503777. Available online: http://dl.nanet.go.kr/law/SearchDetailView.do?cn=MONO1200503777 (accessed on 6 September 2021).

| Cases | Type | Variable | Shape | |

|---|---|---|---|---|

| Case 1 | Inner vane type | Vane length (mm) | 150 |  |

| Case 2 | 175 | |||

| Case 3 | 200 | |||

| Case 4 | 225 | |||

| Case 5 | 250 | |||

| Case 6 | Inner vane reverse type | Vane length (mm) | 150 |  |

| Case 7 | 175 | |||

| Case 8 | 200 | |||

| Case 9 | 225 | |||

| Case 10 | 250 | |||

| Case 11 | Outer vane type | Vane length (mm) | 150 |  |

| Case 12 | 175 | |||

| Case 13 | 200 | |||

| Case 14 | 225 | |||

| Case 15 | 250 | |||

| Case 16 | Outer vane reverse type | Vane length (mm) | 150 |  |

| Case 17 | 175 | |||

| Case 18 | 200 | |||

| Case 19 | 225 | |||

| Case 20 | 250 | |||

| Case 21 | Inner resonate type | Number of holes | 60 |  |

| Case 22 | 90 | |||

| Case 23 | 120 | |||

| Case 24 | 150 | |||

| Case 25 | Outer resonate type | Number of holes | 60 |  |

| Case 26 | 90 | |||

| Case 27 | 120 | |||

| Case 28 | 150 | |||

| Engine Model | YANMAR 6-MAL |

|---|---|

| Number of cylinder | 4 |

| Bore × stroke (mm) | 200 × 240 |

| Combustion chamber type | Direct injection |

| Rated output (hp) | 640 |

| Rated speed (rpm) | 900 |

| Allowable pressure (Pa) | 1200 |

| Analysis Type | Steady-State | |

|---|---|---|

| Turbulence model | SST (Shear Stress Transport) | |

| Constituent material | Air, water vapor, water liquid | |

| Wall condensation model | Concentration boundary layer model | |

| H2O/H2Ol component pair details | Liquid evaporation model | |

| Particle injection | Cone angle (°) | 30 |

| Particle diameter (mm) | 2 | |

| Particle mass flow rate (kg/s) | 1.1 | |

| The number of injection Regions | 5 | |

| Initial conditions | Static pressure (atm) | 1 |

| Temperature (°C) | 30 | |

| Air inlet | Mass flow rate (kg/s) | 0.55 |

| Static temperature (°C) | 230 | |

| Air outlet | Opening pressure (atm) | 1 |

| Porous domain | Volume porosity | 0.902 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, M.-r.; Park, K. Analysis of Composite Scrubber with Built-In Silencer for Marine Engines. J. Mar. Sci. Eng. 2021, 9, 962. https://doi.org/10.3390/jmse9090962

Ryu M-r, Park K. Analysis of Composite Scrubber with Built-In Silencer for Marine Engines. Journal of Marine Science and Engineering. 2021; 9(9):962. https://doi.org/10.3390/jmse9090962

Chicago/Turabian StyleRyu, Myeong-rok, and Kweonha Park. 2021. "Analysis of Composite Scrubber with Built-In Silencer for Marine Engines" Journal of Marine Science and Engineering 9, no. 9: 962. https://doi.org/10.3390/jmse9090962

APA StyleRyu, M.-r., & Park, K. (2021). Analysis of Composite Scrubber with Built-In Silencer for Marine Engines. Journal of Marine Science and Engineering, 9(9), 962. https://doi.org/10.3390/jmse9090962