Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study

Abstract

1. Introduction

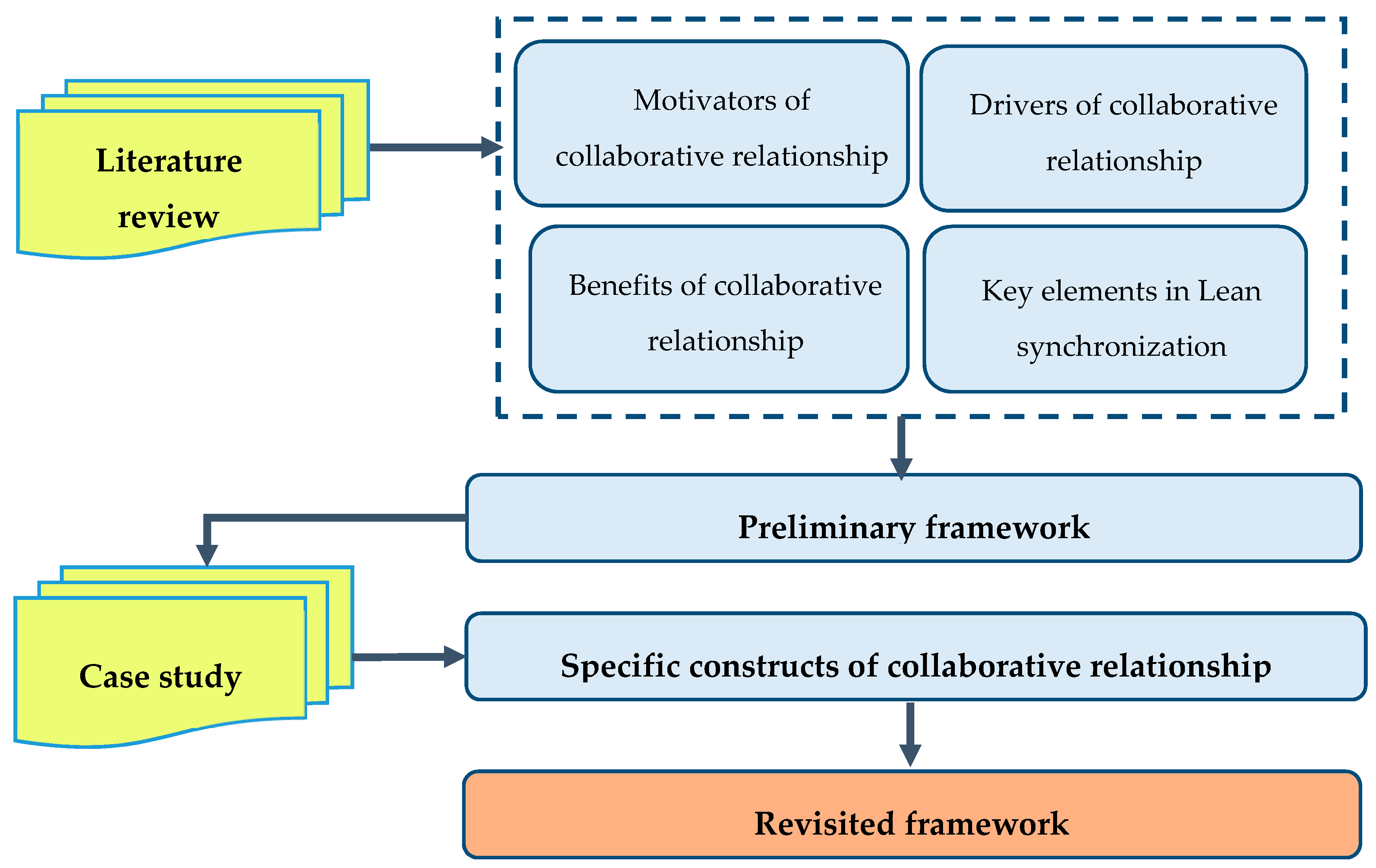

2. Literature Review

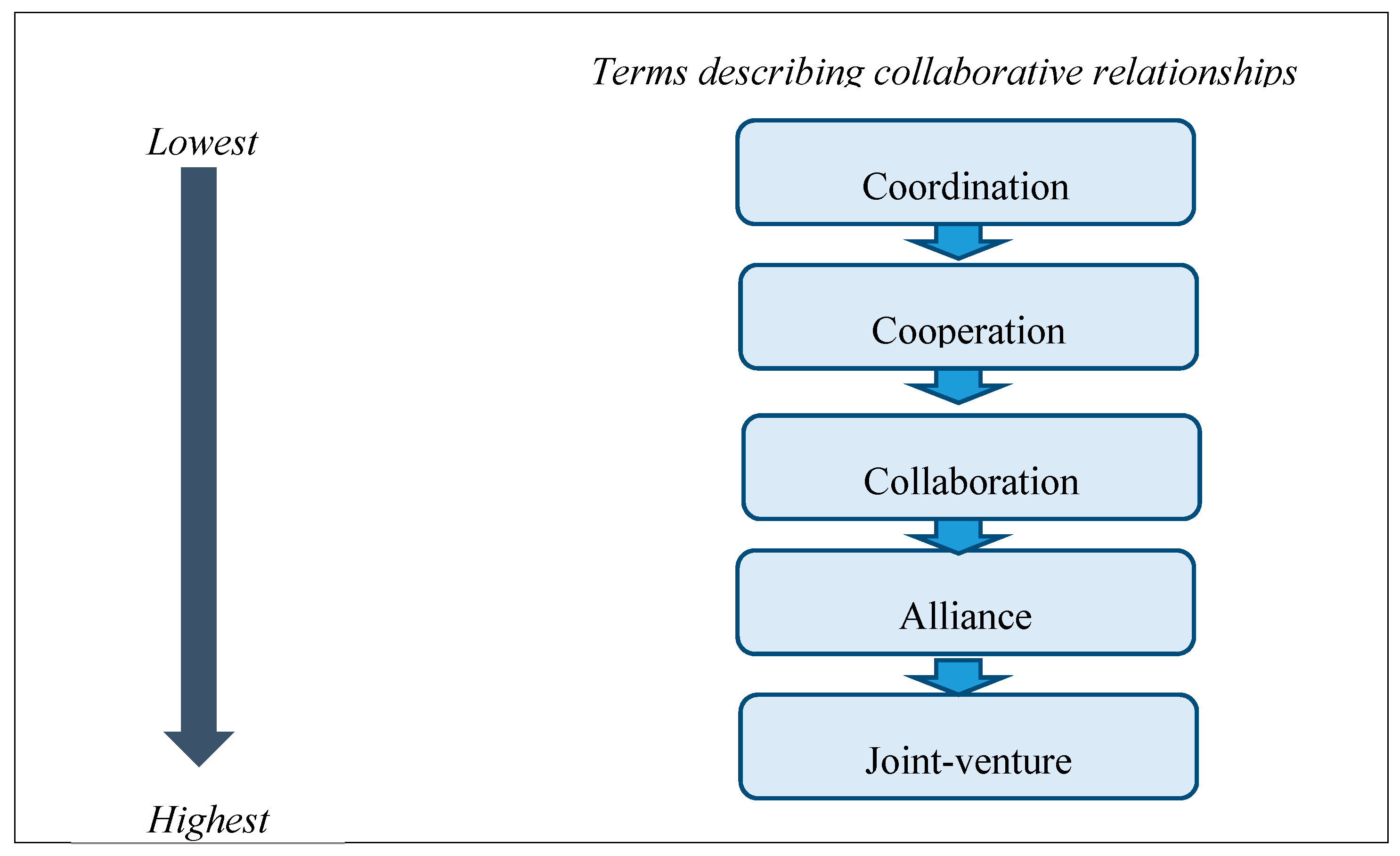

2.1. Supply Chain Collaboration

2.2. Drivers of Collaborative Relationships

2.3. Motivators of Collaborative Relationships

- Economic motivators: represent market-related factors that influence the supply chain and push companies to adopt collaborative initiatives. They include [25]:

- Intense competition: the fierce inter-company competition and the emergence of new firms are forcing companies to develop new practices to improve their efficiency and ensure competitiveness.

- Product and market characteristics: a consistent element in collaborative relationships is the challenge for companies to reduce their life cycle.

- Economic globalization: it represents a significant factor in the adoption of collaborative relationships.

- Market reaction: as companies establish collaborative initiatives in their markets, it can help them boost their competitiveness, and then other firms see the need to follow them.

- Organizational motivators: they are internal factors related to the company’s organization and among the supply chain companies that lead to the adoption of collaborative initiatives. Organizational motivators comprise supply chain problems, previous experiences, and pressure from the partners. They are associated with the companies’ structure, either internally or between companies, which allows for the adoption of collaborative relationships [14].

2.4. Benefits of Collaborative Relationships

2.5. Key Elements in Lean Synchronization with Suppliers

- Collaboration with suppliers: the implementation of lean practices relies primarily on long-term and reliable relationships with suppliers. Thus, the success of lean is based on collaboration with suppliers. Tuli and Shankar [6], and Huang et al. [7] have identified important drivers of significant stakeholders’ collaboration that include: trust, information sharing, goal congruence, resource sharing, coordinating actions, and willingness to collaborate. Boonsthonsatit and Jungthawan [38] argued that suppliers’ participation in lean, which results from collaboration, can improve the company’s performance and present opportunities to gain competitive advantages.

- Training: when a manufacturer is aware of the benefits of collaboration with its suppliers, it promotes the application of collaboration in the supply chain through training initiatives for the benefit of the suppliers. Training initiatives end up by suppliers appreciating how important collaboration is. Manfredsson et al. [2] have studied the outcomes of manufacturers providing training and sharing knowledge with its suppliers on promoting collaboration. The authors found that suppliers’ commitment and willingness to learn are crucial for the excellent implementation of lean practices. Training is proven to increase engagement regarding the application of lean tools and structure the way of working for continuous improvement [39].

- Resources: insufficient resources do not allow the implementation of lean supply chain practices. Some companies use expert consulting to implement these practices, so resources for consulting are essential [40].

- Proximity: JIT delivery is an obvious and important outcome of lean production. However, it is challenged by geographic dispersion. Thus, suppliers with proximity are perfect candidates for JIT delivery [41].

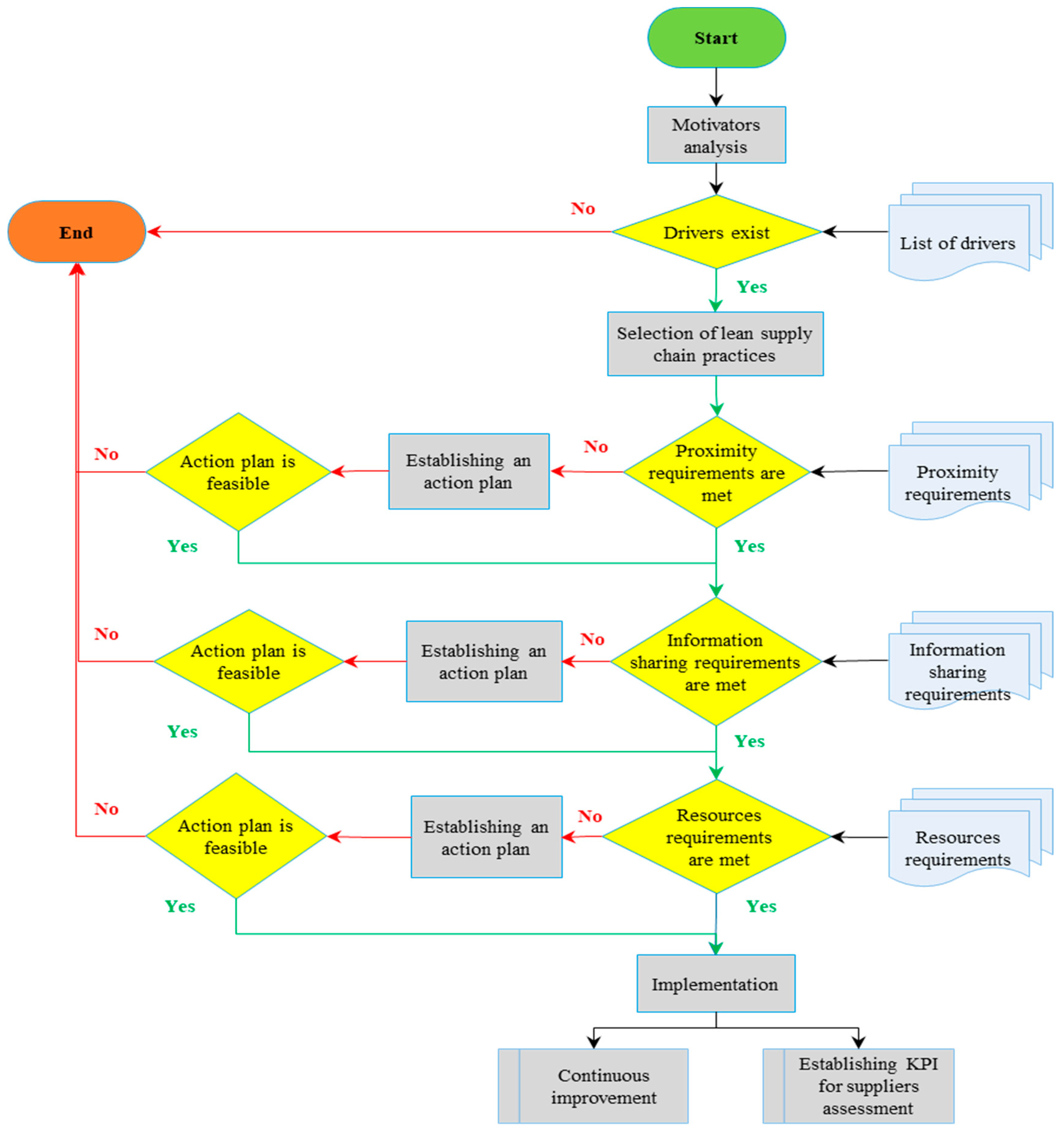

3. Materials and Methods

3.1. Case Study Description

3.2. Data Collection Process

4. Results

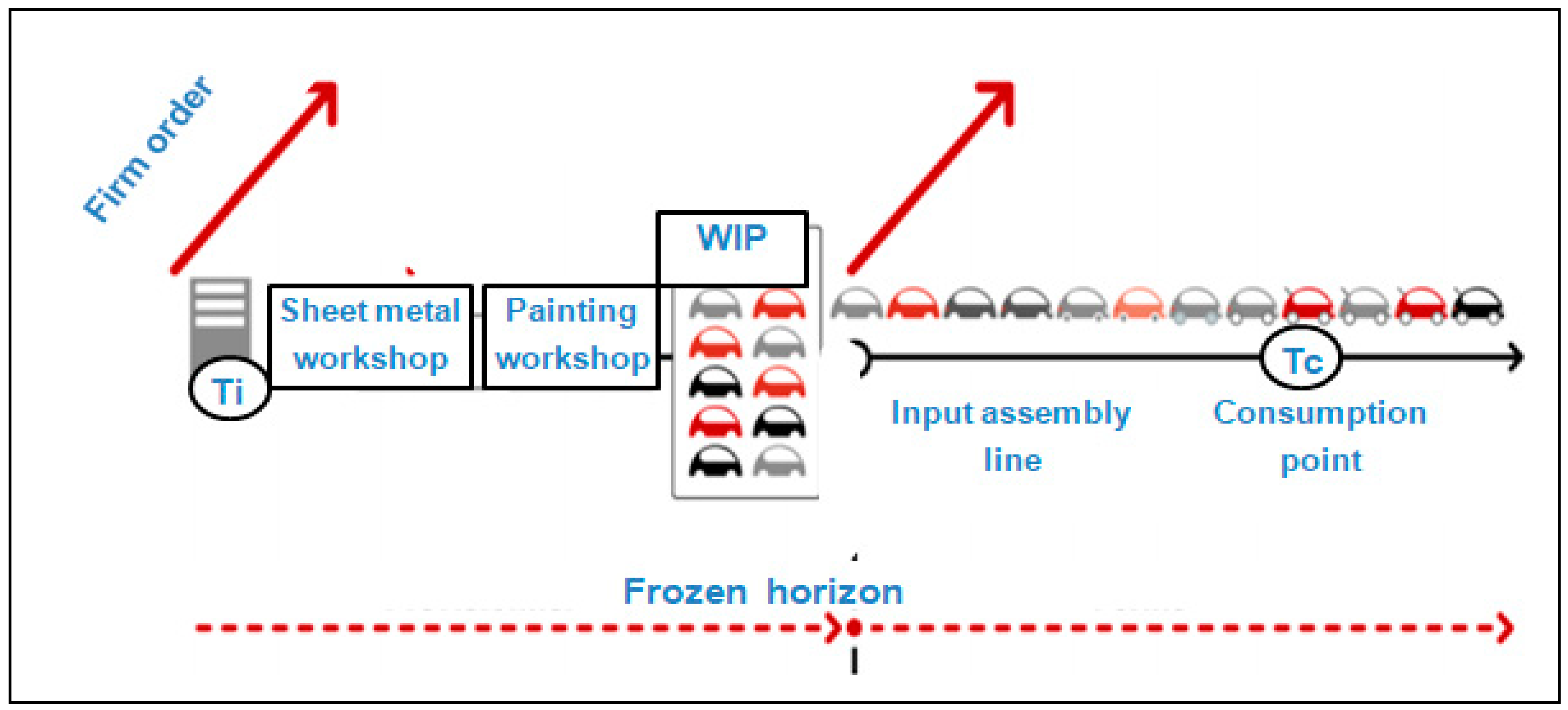

4.1. Application of the Preliminary Framework

4.2. S1: Synchronous Input Metal Sheet Study (Suppliers A, B, C, and E)

- Resource: the principal resource here is the handling unit. This unit must be multi-reference and be suitable to support all shapes of parts at the same time. For two suppliers, the current handling unit is inadequate for such flow. Regarding the estimated benefits, the investment amount is not justified.

- Planning achievement: this is about SSAR; unfortunately, in the Renault plant, this rate is below the required level.

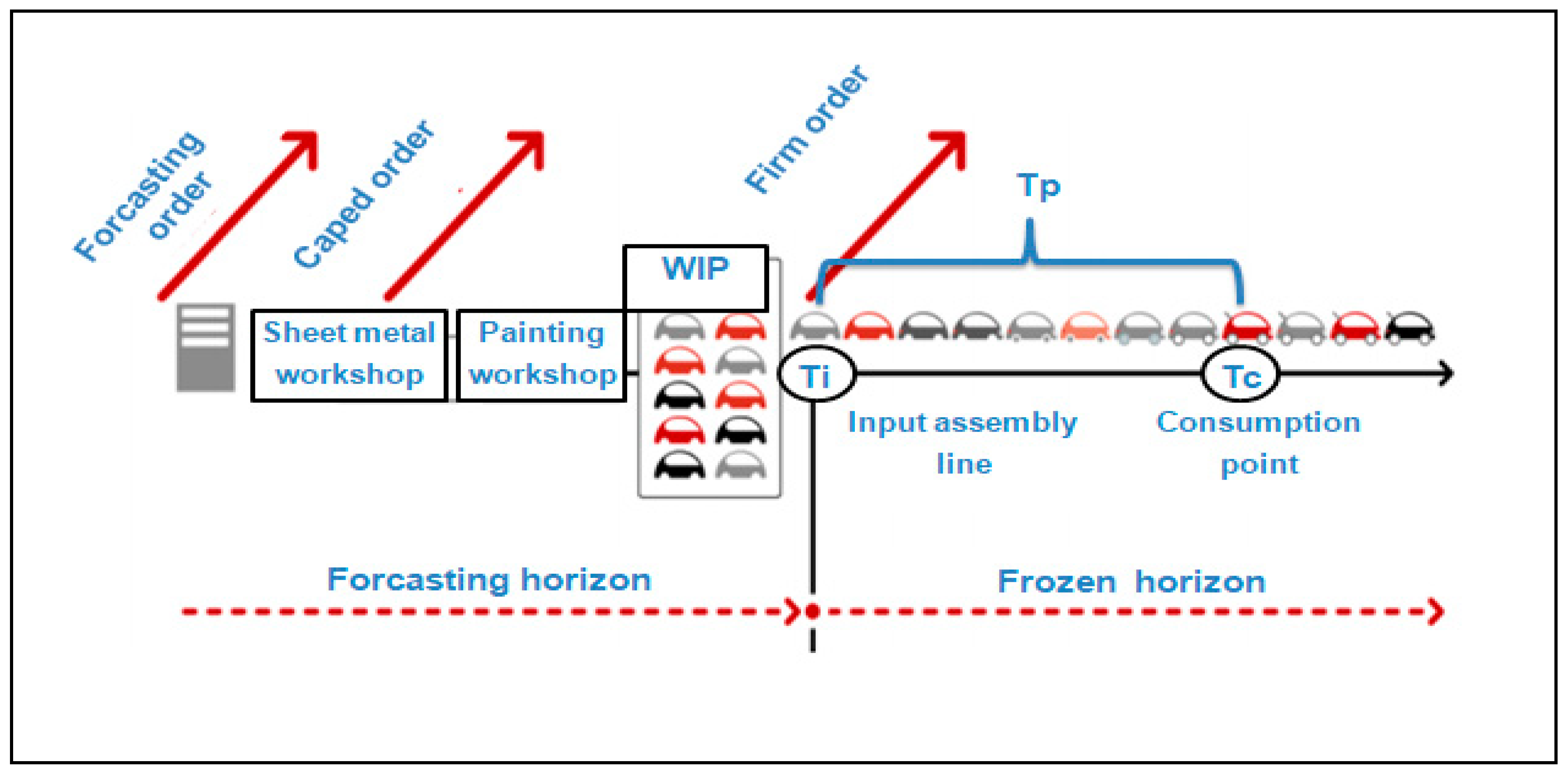

4.3. S2: Synchronous Input Assembly Line (Suppliers D)

4.3.1. Benefits

- Inventory Financial Cost: With the synchronous flow, there would be no stock of exhaust lines in the RENAULT plant, and zero stock is reached. The stock’s financial cost is calculated according to the rate of return on capital practiced by the banks. As Morocco’s interest rate is about 5%, and with an average annual inventory amount of EUR 149,292 financial savings from inventory is about EUR 74,646 per year.

- Inventory Deterioration Cost: It is incurred due to the deterioration of the parts while staying in stock. This cost depends on the nature of the part. Exhaust Systems, the subject of the present study, are very exposed to oxidation. As mentioned in Table 6, the cost related to waste because of oxidation is about EUR 6,600,000 per year. This represents the cumulative value of all the quantity of parts damaged during the year.

- Upstream Transport Cost: In push flow, Renault supports the upstream transport reserved for the exhaust system. In the case of synchronous flow, this type of transport will no longer be supported by the plant; consequently, all the cost is considered a benefit.

- Human Resource Cost: In push flow, the picking agent is present to prepare the handling unit adequate to the vehicle sequence. In synchronous flow, this task will be done by the supplier so that RENAULT will save the salary of the picking agent.

4.3.2. Requirements and Investments

- Proximity action plan: The first requirement to be studied is proximity. This supplier is located at 20 km from the plant. Depending on the part’s assembly point, the supplier has only 2 h (Tc-Ti = 120 min) to prepare and deliver a complete exhaust package. To overcome this constraint, the supplier was welcomed to the RENAULT plant’s premises, installing its production and delivery units according to the following guidelines:

- Installation of suppliers in the same industrial park as the manufacturer.

- The supplier will transfer its activity to the manufacturer’s plant.

- The supplier will use its resources to provide components.

- 2.

- Information sharing: Initially, the suppliers must be linked to the client factory’s information system via an internet application. The application requires an investment, in our case. Since the supplier is located in the client’s site, the solution was to link the supplier to the customer network via a physical cable by installing printers used to print requisition orders. Information on the progress of the firm film and the current vehicle sequences are provided daily by the IT department via email.

- 3.

- Resources: both human and material resources are concerned.

- Material resources: These are packages that must be multi-reference to support all the diversity of exhaust lines at the same time. There is also the tractor, which would be used to handle these packages to the workstation.

- Human resources: this consists of recruiting a workshop foreman and physical flow agent dedicated to this flow.

- Training: Working in synchronous flow differs from normal flow; this requires special training for all the team dedicated to this flow. RENAULT’s services provided the training.

- 4.

- Safety/environment specifications: Since RENAULT is ISO14000 certified, and the supplier settles on the customer’s site, the supplier must comply with the requirements of this certification. Requirements aim to protect welding stations through fire-resistant curtains, extraction at the source for the smoke emitted from the welding, either by extractors or by a suction torch. The supplier has agreed to take charge of all related investments.

4.3.3. Final Decision and Implementation

- Performance measurement: from the previous literature review, an appropriate performance measurement system is a vital driver in a supply chain relation [53]. According to Bigliardi and Bottani [54], supplier performance measurement indicators are among a whole supply chain performance measurement system. They are summarized in: efficiency, responsiveness, reliability, and price offered [55]. For RENAULT, equipment suppliers’ performance is measured by service rate, document accuracy, logistic quality, product quality, and price productivity. These indicators join those identified in the literature. In the specific case of synchronous flow, the supplier is judged only on the logistics quality, price, and product quality. This difference comes from the fact that integration with the supplier reaches the ultimate point in the synchronous flow, which is reflected in the performance indicators. The respect of the delivery time is no longer a significant criterion since the delivery delay is intolerable. The supplier delivers the components directly for use, so there is no margin to absorb any delay. Documentation accuracy serves to guarantee the documentary reliability, which is used to feed the stock status. In synchronous flow, the stock no longer exists, so this indicator is no longer useful. Table 9 illustrates the evolution of indicators from a high flow to synchronous flow.

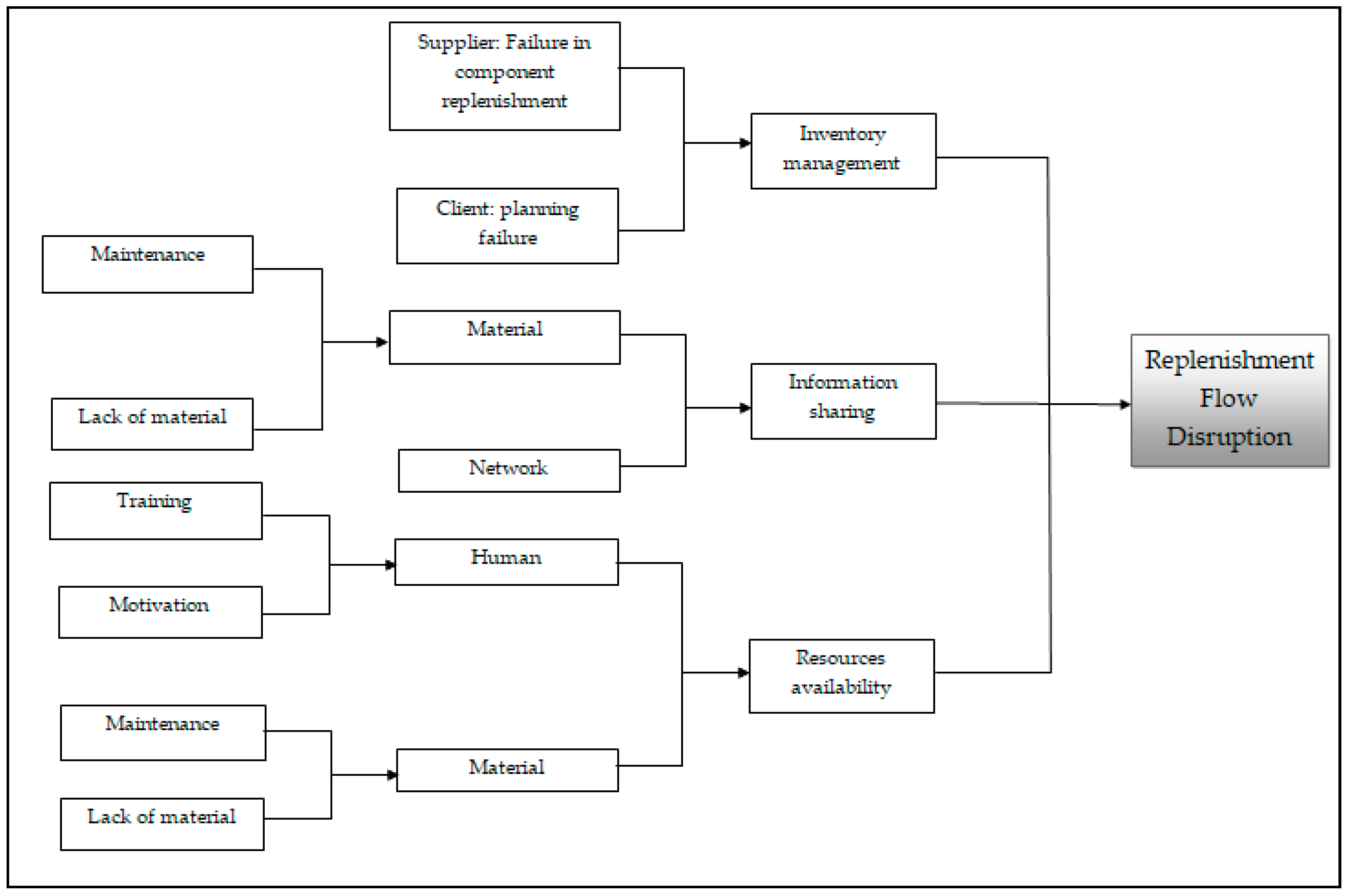

- Continuous improvement: To ensure continuous improvement, it is necessary to permanently and systematically identify the failures and risks which can block the fluidity of the flow. Hence, we have proposed an audit tool and a tool for risk management.

- Self-audit tool

- Risk management tool

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sahoo, S. Assessing lean implementation and benefits within Indian automotive component manufacturing SMEs. Benchmarking Int. J. 2020, 27, 1042–1084. [Google Scholar] [CrossRef]

- Manfredsson, P.; Hilletofth, P.; Reitsma, E. Involving suppliers in a lean training program. In Proceedings of the 9th International Conference on Operations and Supply Chain Management, Cranfield, UK, 15–18 December 2019. [Google Scholar]

- Ambe, I.M.; Badenhorst-Weiss, J.A. An automotive supply chain model for a demand-driven environment. J. Transp. Supply Chain Manag. 2011, 5, 1–22. [Google Scholar] [CrossRef]

- Kotcharin, S.; Eldridge, S.; Freeman, J. The relationship between lean supply chain strategy and supplier integration and competitive capabilities in Thailand’s automotive supplier. In Proceedings of the Decision Sciences Institute 43rd Annual Meeting, San Francisco, CA, USA, 16–22 November 2012. [Google Scholar]

- Guo, Y.; Xu, Z. A model of lean supplier management based on the lean production. Res. Pract. Issues Enterp. Inf. Syst. II 2007, 254, 717–726. [Google Scholar]

- Tuli, P.; Shankar, R. Collaborative and lean new product development approach: A case study in the automotive product design. Int. J. Prod. Res. 2015, 53, 2457–2471. [Google Scholar] [CrossRef]

- Huang, Y.; Han, W.; Macbeth, D. The complexity of collaboration in supply chain networks: An exploratory study of the Chinese automotive sector. Supply Chain Manag. Int. J. 2020, 25, 393–410. [Google Scholar] [CrossRef]

- El Farouk, I.I.; Jawab, F. Synchronous flow in automotive industry: Case study of RENAULT. In Proceedings of the 2017 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Rabat, Morocco, 27–28 April 2017; pp. 199–203. [Google Scholar]

- Lynch, J. Contemporary Operations and Logistics: Achieving Excellence in Turbulent Times. In Contemporary Operations and Logistics: Achieving Excellence in Turbulent Times; Springer International Publishing: New York, NY, USA, 2019; pp. 193–218. [Google Scholar]

- Mofokeng, T.M.; Chinomona, R. Supply chain partnership, supply chain collaboration and supply chain integration as the antecedents of supply chain performance. South Afr. J. Bus. Manag. 2019, 50, 1–10. [Google Scholar] [CrossRef]

- Singh, P.J.; Power, D. The nature and effectiveness of collaboration between firms, their customers and suppliers: A supply chain perspective. Supply Chain Manag. Int. J. 2009, 14, 189–200. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Sridharan, R. Design for supply chain collaboration. Bus. Process. Manag. J. 2008, 14, 401–418. [Google Scholar] [CrossRef]

- Derrouiche, R.; Neubert, G.; Bouras, A. Supply chain management: A framework to characterize the collaborative strategies. Int. J. Comput. Integr. Manuf. 2008, 21, 426–439. [Google Scholar] [CrossRef]

- De Freitas, D.C.; de Oliveira, L.G.; Alcântara, R.L.C. A theoretical framework to adopt collaborative initiatives in supply chains. Gest. Prod. 2019, 26, 1–15. [Google Scholar] [CrossRef]

- Frichi, Y.; Kacem, A.B.; Jawab, F.; Kamach, O.; Chafik, S. Improving Interhospital Medical Patient Transportation in Morocco: A Forecasting Collaborative Approach. In Transportation, Logistics, and Supply Chain Management in Home Healthcare: Emerging Research and Opportunities; Euchi, J., Ed.; IGI Global: Hershey, PA, USA, 2020; pp. 136–162. [Google Scholar]

- Arif, J.; Azzouz, K.; Mouzouna, Y.; Jawab, F. Design on improvement of traceability process in the outsourcing of logistics’ activities using the internet of things (IoT) applications. Int. J. Adv. Sci. Technol. 2020, 29, 1093–1108. [Google Scholar]

- Singh, H.; Garg, R.K.; Sachdeva, A. Supply chain collaboration: A state-of-the-art literature review. Uncertain Supply Chain Manag. 2018, 6, 149–180. [Google Scholar] [CrossRef]

- Marqui, A.C.; de Moura, K.S.; Alcântara, R.L.C. Collaborative supply chain: A conceptual model for operationalisation. Int. J. Manag. Decis. Mak. 2013, 12, 195–214. [Google Scholar] [CrossRef]

- Ma, K.; Pal, R.; Gustafsson, E. What modelling research on supply chain collaboration informs us? Identifying key themes and future directions through a literature review. Int. J. Prod. Res. 2018, 57, 2203–2225. [Google Scholar] [CrossRef]

- Spekman, R.E.; Spear, J.; Kamauff, J. Supply chain competency: Learning as a key component. Supply Chain Manag. An Int. J. 2002, 7, 41–55. [Google Scholar] [CrossRef]

- Jawab, F.; Talbi, A.; Bouami, D. Le réapprovisionnement continu dans les réseaux industriels, vers une meilleure gestion des interfaces de la « supply chain ». Rev. des Sci. Gest. 2006, 2, 123–137. [Google Scholar]

- Jawab, F.; Bouami, D. La démarche supply chain management enjeux et stratégies, cas du commerce électronique et de la grande distribution. Rev. Sci. Gest. Dir. Gest. 2004, 1, 95–109. [Google Scholar] [CrossRef]

- Ahn, G.; Park, Y.J.; Hur, S. Probabilistic graphical framework for estimating collaboration levels in cloud manufacturing. Sustainability 2017, 9, 277. [Google Scholar] [CrossRef]

- Saenz, M.J.; Ubaghs, E.; Cuevas, A.I. Vertical Collaboration and Horizontal Collaboration in Supply Chain. In Enabling Horizontal Collaboration Through Continuous Relational Learning; Springer: Cham, Switzerland, 2015; pp. 7–10. [Google Scholar]

- De Freitas, D.C.; de Oliveira, L.G.; Alcantara, R.L.C. Collaborative initiatives: Motivators, barriers and benefits. Rev. Adm. Mackenzie 2018, 19. [Google Scholar] [CrossRef]

- Al-Doori, J.A. The impact of supply chain collaboration on performance in automotive industry: Empirical Evidence. J. Ind. Eng. Manag. 2019, 12, 241–253. [Google Scholar] [CrossRef]

- Vargas, A.; Patel, S.; Patel, D. Towards a business model framework to increase collaboration in the freight industry. Logistics 2018, 2, 22. [Google Scholar] [CrossRef]

- Arif, J.; el Farouk, I.I.; Mouzouna, Y.; Jawab, F. The use of internet of things (IoT) applications in the logistics outsourcing: Smart RFID tag as an example. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 291–300. [Google Scholar]

- Wu, I.L.; Chuang, C.H.; Hsu, C.H. Information sharing and collaborative behaviors in enabling supply chain performance: A social exchange perspective. Int. J. Prod. Econ. 2014, 148, 122–132. [Google Scholar] [CrossRef]

- Panahifar, F.; Byrne, P.; Salam, M.A.; Heavey, C. Supply chain collaboration and firm performance: The critical role of information sharing and trust. J. Enterp. Inf. Manag. 2017, 31, 358–379. [Google Scholar] [CrossRef]

- Ogunmola, O.S.; Arogundade, K.K. Effects of supply chain DESIGN and collaboration on customers’ satisfaction of instant noodles in Ekiti State, Nigeria. Logistics 2019, 3, 2. [Google Scholar] [CrossRef]

- Vanichchinchai, A. The effect of lean manufacturing on a supply chain relationship and performance. Sustainability 2019, 11, 5751. [Google Scholar] [CrossRef]

- Arif, J.; Jawab, F. Outsourcing of logistics’ activities: Impact analysis on logistics service performance. In Proceedings of the 2018 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Tangier, Morocco, 26–27 April 2018; pp. 88–92. [Google Scholar]

- Giard, V.; Mendy, G. De l’approvisionnement synchrone à la production synchrone dans la chaine logistique. Rev. Française Gest. 2007, 2, 68–88. [Google Scholar] [CrossRef]

- Colomb, P.; Devulder, C. Mise en place des flux synchrones dans l’industrie automobile: Cas d’un équipementier sur le site de Renault Brésil. Logistique Manag. 1998, 6, 31–40. [Google Scholar] [CrossRef]

- Gallois, P.-M.; Devulder, C.; Ferreira, S. Global synchronous manufacturing and logistics organization: A success story. Supply Chain Forum Int. J. 2000, 1, 59–69. [Google Scholar] [CrossRef]

- Singh, R.K.; Modgil, S. Assessment of lean supply chain practices in Indian automotive industry. Glob. Bus. Rev. 2020, 1–39. [Google Scholar] [CrossRef]

- Boonsthonsatit, K.; Jungthawan, S. Lean supply chain management-based value stream mapping in a case of Thailand automotive industry. In Proceedings of the 2015 4th IEEE International Conference on Advanced Logistics and Transport, IEEE ICALT 2015, Valenciennes, France, 20–22 May 2015; pp. 65–69. [Google Scholar]

- Mayer, J.A.; Borchardt, M.; Pereira, G.M. Methodology for the collaboration in supply chains with a focus on continuous improvement. Ing. Investig. 2016, 36, 51–59. [Google Scholar] [CrossRef][Green Version]

- Salonitis, K.; Tsinopoulos, C. Drivers and barriers of lean implementation in the Greek manufacturing sector. In Proceedings of the 49th CIRP Conference on Manufacturing Systems, Stuttgart, Germany, 25–27 May 2016; Volume 57, pp. 189–194. [Google Scholar]

- Wu, Y.C. Lean manufacturing: A perspective of lean suppliers. Int. J. Oper. Prod. Manag. 2003, 23, 1349–1376. [Google Scholar]

- Schuh, G.; Stüer, P. Framework for lean management in industrial services. In IFIP Advances in Information and Communication Technology in Production Management Systems; Springer: Berlin/Heidelberg, Germany, 2012; pp. 392–398. [Google Scholar]

- Piekkari, R.; Welch, C.; Paavilainen, E. The case study as disciplinary convention: Evidence from international business journals. Organ. Res. Methods 2009, 12, 567–589. [Google Scholar] [CrossRef]

- Seawright, J.; Gerring, J. Case selection techniques in case study research: A menu of qualitative and quantitative options. Political Res. Q. 2008, 61, 294–308. [Google Scholar] [CrossRef]

- Tomski, P. On Case Study Method in Entrepreneurship Research. Zesz. Nauk. Politech. Częstochowskiej Zarządzanie 2017, 27, 189–198. [Google Scholar] [CrossRef]

- Jasti, N.V.K.; Kodali, R. A literature review of empirical research methodology in lean manufacturing. Int. J. Oper. Prod. Manag. 2014, 34, 1080–1122. [Google Scholar] [CrossRef]

- Achrol, R.S.; Stern, L.W. Environmental determinants of decision-making uncertainty in marketing channels. J. Mark. Res. 1988, 25, 36–50. [Google Scholar] [CrossRef]

- Frichi, Y.; Jawab, F.; Boutahari, S. An exploratory qualitative study of the influence of hospital logistics factors on quality of care and patient satisfaction at public hospitals in Morocco. Adv. Sci. Technol. Eng. Syst. J. 2019, 4, 414–422. [Google Scholar] [CrossRef]

- Glöckner, H.-H.; Pieters, R.; de Rooij, W. Importance of the Kraljic matrix as a strategic tool for modern purchasing. LogForum 2005, 1, 1–11. [Google Scholar]

- Saueressig, G.G.; de Paris, A.; Bauer, J.M.; Luchese, J.; Sellitto, M.A.; Antunes, J.A.V. Strategic materials positioning matrix: An application in the automotive industry in Southern Brazil. Int. J. Ind. Eng. Manag. 2017, 8, 77–89. [Google Scholar]

- Gelderman, C.J.; Donald, D.R.M. Application of Kraljic’s purchasing portfolio matrix in an undeveloped logistics infrastructure: The staatsolie suriname case. J. Transnatl. Manag. 2008, 13, 77–92. [Google Scholar] [CrossRef]

- Caniëls, M.C.J.; Gelderman, C.J. Purchasing strategies in the Kraljic matrix—A power and dependence perspective. J. Purch. Supply Manag. 2005, 11, 141–155. [Google Scholar] [CrossRef]

- Moufad, I.; Jawab, F. A study framework for assessing the performance of the urban freight transport based on PLS approach. Arch. Transp. 2019, 49, 69–85. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E. Supply chain performance measurement: A literature review and pilot study among Italian manufacturing companies. Int. J. Eng. Sci. Technol. 2014, 6, 1–16. [Google Scholar] [CrossRef]

- Moufad, I.; Jawab, F. The determinants of the performance of the urban freight transport—An empirical analysis. In Proceedings of the 2018 International Colloquium on Logistics and Supply Chain Management, LOGISTIQUA, Tangier, Morocco, 26–27 April 2018; pp. 99–104. [Google Scholar]

- Arif, J.; El Farouk, I.I.; Jawab, F. Logistic Outsourcing: From the Contracts Complexity to the Logistic Services Performance. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bandung, Indonesia, 6–8 March 2018; pp. 3247–3257. [Google Scholar]

| Drivers of Collaborative Relationships | Reference |

|---|---|

| [18] |

| [25] |

| [10] |

| [26] |

| [30] |

| [17] |

| [29] |

| Supplier | A | B | C | D | E | |

|---|---|---|---|---|---|---|

| Characteristic | ||||||

| Category | Multinational company | Multinational company | Multinational company | Local company | Multinational company | |

| Activity | Climate, electronics, and interior systems. | Sheet metal transformation by cutting, stamping, and manufacturing of metal parts. Plastic and leather | Automotive products: air conditioners, heaters, electrical and electronic devices, fuel management systems, and ITS devices. | Stamping, exhaust system, and bulkhead | Design, manufacture, sale, after-sales service of plastic systems for the management of on-board fluids and gases and their components | |

| Global Size (Number of employees) | 27,000 | 6113 | 170,932 | 120 | 32,000 | |

| Specific Characteristic of the studies companies | ||||||

| Component | Interior trim elements | Plastic and leather | Air conditioners | Exhaust system | Fuel system | |

| Diversity (number of parts) | 6 | 155 | 9 | 12 | 6 | |

| Use point | Assembly line | Assembly line | Assembly line | Assembly line | Assembly line | |

| Participant | Collected Data |

|---|---|

| Supplier Project manager | Location requirements |

| Handling unit requirements | |

| Cost structure | |

| Plant supply manager | Suppliers selection |

| Purchasing department | Suppliers Categorization |

| Negotiation elements | |

| Transport manager | Current transportation value |

| Supply manager | Average inventory level of each component |

| IT department | RENAULT’s network connection device |

| Necessary configuration of the logistic system | |

| HR department | Requirements to manage supplier staff in plant |

| Environment department | Environment requirements |

| Engineering department | Flow circulation requirements |

| Packaging requirements | |

| Handling requirements |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| Economic motivators | Optimization of inventory level within the supply chain | Optimization of inventory level in the supply chain | Optimization of inventory level in the supply chain | Optimization of inventory level in the supply chain | Optimization of inventory level in the supply chain |

| Organizational motivators | Flexibility and reactivity | Flexibility and reactivity | Flexibility and reactivity | Flexibility and reactivity | Flexibility and reactivity |

| Suppliers Categorization | strategic | strategic | strategic | strategic | strategic |

| Presence of Drivers | yes | yes | yes | yes | yes |

| Proximity to plant | 500 km | 400 km | 400 km | 20 km | 230 km |

| Proximity Action plan | Study a second type of synchronous flow with a firm request from sheet metal workshop | Study a second type of synchronous flow with a firm request from sheet metal workshop | Study a second type of synchronous flow with a firm request from sheet metal workshop | Study the possibility of locating the supplier in the plant. | Study a second type of synchronous flow with a firm request from sheet metal workshop |

| A | B | C | E | |

|---|---|---|---|---|

| Benefits in inventory | EUR 27,000 | EUR 21,000 | EUR 20,000 | EUR 20,000 |

| Information sharing requirement | ✓ | ✓ | ✓ | ✓ |

| Resources requirements | ✗ | ✓ | ✓ | ✗ |

| Action plan = investment to adapt handling unit | EUR 255,000 | 0 | 0 | EUR 22,000 |

| SSAR | ✗ | ✗ | ✗ | ✗ |

| Final decision | ✗ | ✗ | ✗ | ✗ |

| N° | Elements | Annual Amount (Euros) |

|---|---|---|

| 1 | Financial cost | 74,646 |

| 2 | Inventory deterioration cost | 6,600,000 |

| 3 | Upstream transportation fees | 67,782 |

| 4 | Human resource for Handling | 37,752 |

| N° | Investments | Element | Annual Amount (Euros) | Total Annual Amount (Euros) |

|---|---|---|---|---|

| 1 | Proximity action plan | room layout rent | 0 | 0 |

| 2 | Information sharing requirement | printer | 4500 | 4500 |

| other information sharing | 0 | |||

| 3 | Resources | Human | 206,000 | |

| team leader | 10,000 | |||

| handling agent | 180,000 | |||

| training | 0 | |||

| Physical | ||||

| Handling Equipment | 6000 | |||

| Picking trolley | 10,000 | |||

| 4 | Environment | Fire-resistant curtains, extraction at the source for the smoke emitted from the welding, either by extractors or by a suction torch. | 0 | 0 |

| Annual Amount (Euros) | Balance (Euros) | |

|---|---|---|

| Benefits | 67,129,986 | 6,502,499 |

| Investment | 210,500 | |

| Final decision | OK for implementation | |

| Indicators | Objective | Push Flow | Synchronous Flow |

|---|---|---|---|

| Service rate | Measure respect of delivery time | ✓ | ✗ |

| Documentation accuracy | Guarantee inventory update reliability | ✓ | ✗ |

| Logistic quality | Measure logistical incidents, such as chain shutdown or missing | ✓ | ✓ |

| Price | Capacity to optimize continuously the cost structure | ✓ | ✓ |

| Product quality | Compliance with quality requirements. | ✓ | ✓ |

| Self-Audit Checklist | |||

|---|---|---|---|

| Process | Supply Mount Point in a Synchronous Flow | ||

| N° | Parameters | Questions | Actor |

| 1 | Firm film | What is the information procedure you are applying in case of changing the firm film? | Logistic department |

| 2 | How do you guarantee the real-time information-sharing on the film firm with the supplier? | Logistic department | |

| 3 | Information | What is the frequency of preventive control you have planned for the printer? | Supplier |

| 4 | Do you have a back-up printer on-site? | Supplier | |

| 5 | How do you ensure the printer’s continuous supply of consumables? | Supplier | |

| 6 | Do you meet the quality requirements of consumables used? | Supplier | |

| 7 | How do you act in any failure of network connection? | Supplier | |

| 8 | How a network failure is handled? | IT | |

| 9 | Handling | How do you guarantee the maintenance of the delivery trolleys? | Supplier |

| 10 | How do you guarantee the maintenance of self-propelled tractors? | Supplier | |

| 11 | How is your trolley loop calculated? How do you update it? | Supplier | |

| 12 | Procedure | How do you ensure the application of business requirements at the workplace? | Supplier |

| 13 | Human resources | How do you manage the versatility of the picking post? | Supplier |

| 14 | Do you guarantee that the picking agent is constantly present next to the printer? | Supplier | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibn El Farouk, I.; Moufad, I.; Frichi, Y.; Arif, J.; Jawab, F. Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study. Information 2020, 11, 431. https://doi.org/10.3390/info11090431

Ibn El Farouk I, Moufad I, Frichi Y, Arif J, Jawab F. Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study. Information. 2020; 11(9):431. https://doi.org/10.3390/info11090431

Chicago/Turabian StyleIbn El Farouk, Imane, Imane Moufad, Youness Frichi, Jabir Arif, and Fouad Jawab. 2020. "Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study" Information 11, no. 9: 431. https://doi.org/10.3390/info11090431

APA StyleIbn El Farouk, I., Moufad, I., Frichi, Y., Arif, J., & Jawab, F. (2020). Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study. Information, 11(9), 431. https://doi.org/10.3390/info11090431