Identifying Critical Indicators in the Evaluation of Third-Party Reverse Logistics Provider Using Best–Worst Method

Abstract

:1. Introduction

2. Related Literature Review

2.1. Analysis of Evaluation Indicators for 3PRLP

2.2. Analysis of Evaluation Methods for 3PRLP

2.3. Research Gap

3. Methodologies

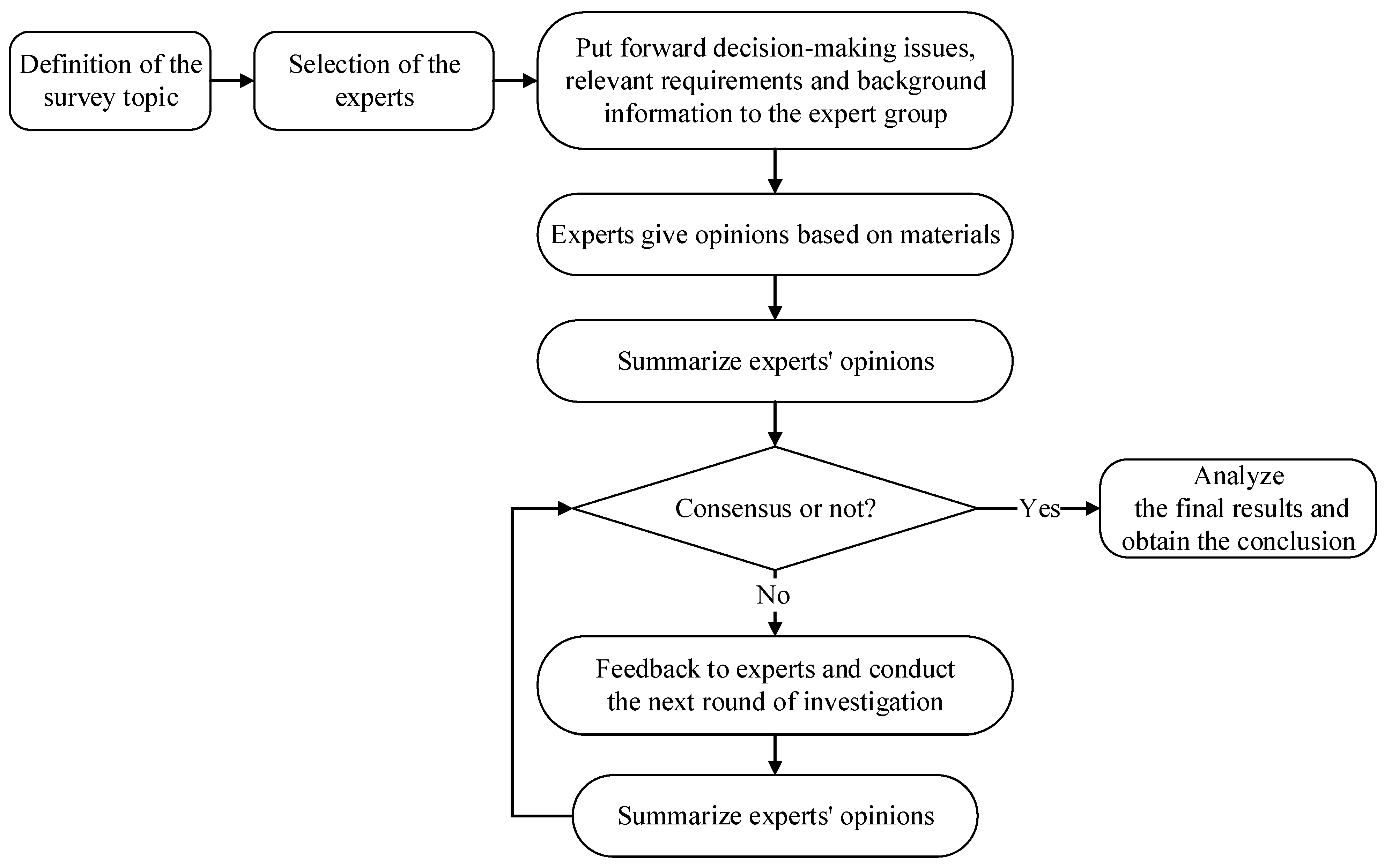

3.1. Delphi Method

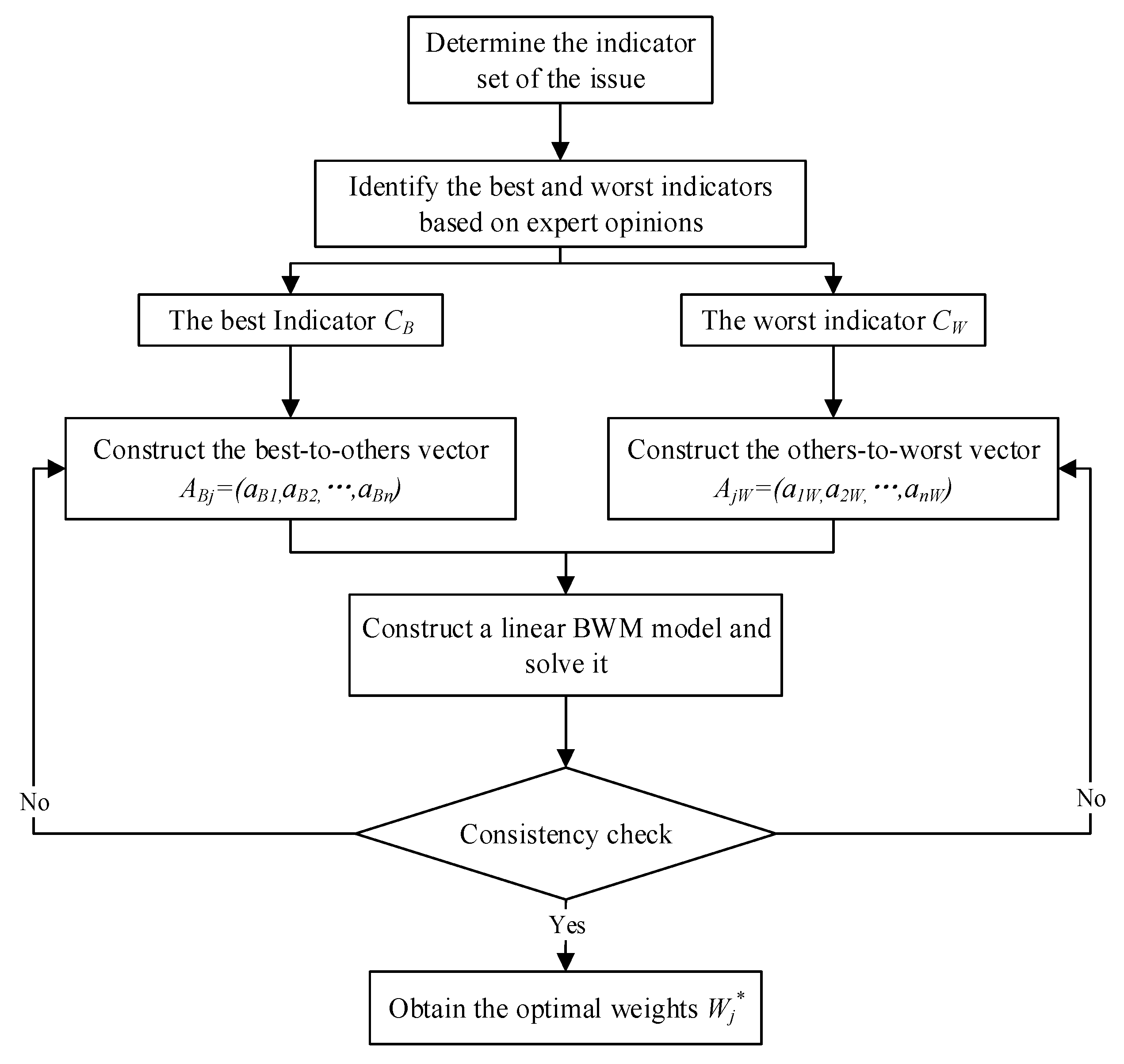

3.2. Best–Worst Method

4. Empirical Study

4.1. Establishing the Formal Decision Structure Based on the Delphi Method

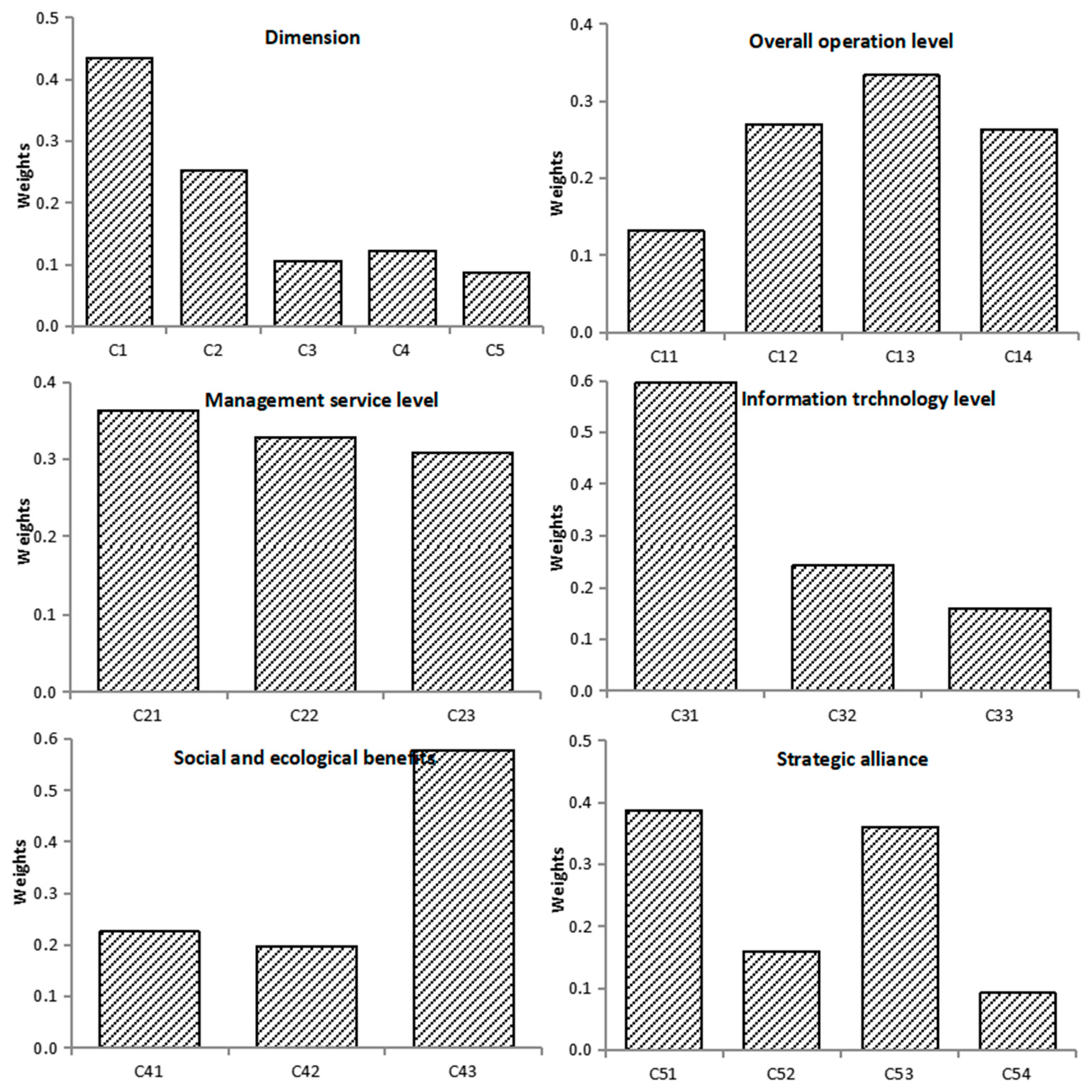

4.2. Identification of Critical Evaluation Indicators Based on BWM

5. Discussion and Implications

- (1)

- The overall operation level (C1) and management service level (C2) are the most critical evaluation dimensions in 3PRLP evaluation. This result has also been supported by other studies. Pei evaluated candidate 3PRLP based on the G2-weighted TOPSIS method. The result showed that the transportation capacity in the operation level was the key indicator, and the degree of informatization in the operation level was an important indicator [27]. Liu and Wu used the fuzzy analytic hierarchy process (FAHP) to study the selection of 3PRLP, and the results showed that service quality was an important evaluation dimension [25]. The overall operation level involves the operational efficiency, quality, reliability, and other aspects of the entire reverse logistics supply chain, which directly affects the reputation and customer satisfaction of 3PRLP. The management service level is related to whether a 3PRLP can establish a stable long-term cooperative relationship with the entrusted enterprise. Moreover, enterprises with high management service levels can not only ensure that their operational processes are fully optimized and monitored, but also quickly respond to service issues. Therefore, the entrusted enterprise should pay special attention to the importance of the overall operation level and management service level during the evaluation process. The evaluation of these dimensions can more comprehensively reflect the overall strength and business level of reverse logistics suppliers, which is of great significance for entrusted enterprises to formulate appropriate cooperation strategies and decisions.

- (2)

- Transportation allocation capability (C13), network coverage (C12), and service price level (C14) are critical factors in 3PRLP evaluation. These three indicators are also the most important indicators under the overall operational level dimension. Among them, transportation allocation capacity is the most important of all evaluation indicators. It is the key to reflecting the timeliness, safety, and efficiency of cargo transportation, as well as an important factor affecting customer satisfaction. This result is consistent with the discovery of Li [26]. He determined the weight of evaluation indicators based on the grey TOPSIS method of rough sets, and found that transportation and quality were the most important indicators. In addition, network coverage is also a very important indicator for evaluating 3PRLP. Extensive network coverage can better meet customer needs and better achieve resource sharing, thereby improving operational efficiency. Service price level is an important indicator for evaluation, but it needs to be comprehensively considered in combination with other indicator elements. Under the same conditions, selecting suppliers with high service quality and efficiency may be relatively expensive. However, in the long run, high-quality service and efficient operation may bring more benefits to the enterprise. Therefore, when evaluating 3PRLP, the entrusted enterprise should take transportation and allocation capabilities as the core criteria for selecting third-party suppliers, while seeking a balance between cost and benefit based on comprehensive consideration of network coverage and service price level.

- (3)

- Service response speed (C21), recovery efficiency (C22), and service flexibility level (C23) are important indicators for 3PRLP evaluation. These three indicators are all secondary indicators under the management service dimension, with similar importance, indicating that these three indicators are closely related under this dimension. First of all, good service response speed can solve customer problems from the source, laying the foundation for in-depth service development. It is the key to carrying out recycling and flexible adjustment. Secondly, recovery efficiency can ensure that customers receive timely, accurate, and high-quality services. It is the fundamental guarantee for improving service response speed and flexibility. Finally, the level of service flexibility reflects the coordinated response ability of suppliers to handle various uncertain and unexpected situations. It is a comprehensive reflection of service response speed and recovery efficiency. Therefore, it is necessary for the entrusted enterprise to focus on the development of third-party suppliers in these three aspects to ensure the efficiency, quality, and flexibility of reverse logistics services.

- (4)

- Social ecological benefit (C4) is an important evaluation dimension for evaluation. In previous studies, Yang constructed a six-dimensional indicator system and assigned the weight of evaluation indicators based on the information entropy method [22]. The results showed that the carbon emission reduction indicator dimension had the highest importance. Similar to the above research, with the high attention paid to sustainable development issues, we all emphasized the importance of social and ecological benefits in 3PRLP evaluation. However, in contrast, this study does not identify social and ecological benefits as the most important indicator dimension. We believe that brand image and social responsibility are one of the important factors for enterprises to choose suitable suppliers, but not the critical factors. As a service-oriented enterprise, the value of 3PRLP should be reflected in their services and operations. The level of recyclability (C43), as the most important secondary indicator in the social and ecological benefits dimension, reflects the level of resource recycling by third-party suppliers. It has a significant impact on the sustainable development and environmental image of enterprises. Entrusted enterprises should pay attention to the importance of social and ecological benefits while measuring economic benefits. Therefore, in the process of 3PRLP evaluation, it is necessary not only to evaluate the reverse logistics capabilities of third-party suppliers, but also to pay attention to their recycling and reuse levels.

- (5)

- The indicators related to the level of information technology (C3) and strategic alliance (C5) are also indicators for 3PRLP evaluation. Among them, the weight of information integration and sharing capability (C31) in the information technology dimension is as high as 0.5963. It is the most important indicator under this dimension, but its global weight is not high. This is because the global weight of secondary indicators is affected by the weight of the first indicators, resulting in a lower final ranking. In addition, from the empirical research results, other secondary indicators under these two dimensions are not critical indicators, and their comprehensive rankings are not high [45]. In previous studies, Song et al. studied the selection of 3PRLP based on the intuitionistic fuzzy MCDM method. They ultimately determined that customer satisfaction and corporate reputation in cooperative alliances were the two most important criteria for entrusted enterprises to select third-party suppliers [18]. Liu et al. constructed a 3PRLP evaluation model based on entropy correction G1 combination weighting, and the final result showed that the technical indicator dimension had the highest importance [28]. As the elements of innovation and development, information technology level and strategic alliance have a certain degree of impact on the evaluation of third-party reverse logistics, but they will not play a decisive role in the evaluation results. 3PRLP is a service-oriented supplier, and efficient operational processes and high-quality service quality are more important and practical choices for entrusted enterprises.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Zhao, Q.Q. Review and prospect of reverse logistics research. J. Commer. Econ. 2020, 1, 66–70. [Google Scholar]

- Li, Y.J.; Feng, L.P.; Zhao, X.K.; Xu, F.C. Overview on reverse logistics management research in new era of operations management. Syst. Eng. Theory Pract. 2020, 40, 2008–2222. [Google Scholar]

- Meng, X.R. Study of Evaluation and Selection on Third Party Reverse Logistics Providers. In Proceedings of the 2008 International Seminar on Business and Information Management; IEEE: New York, NY, USA, 2008; Volume 1, pp. 518–521. [Google Scholar]

- Meng, X.R.; Zhang, Y.J.; Song, W. Analysis on 3PRL and Its Provider Selection. In Proceedings of the 2009 International Conference on Environmental Science and Information Application Technology; IEEE: New York, NY, USA, 2009; Volume 1, pp. 631–634. [Google Scholar]

- Abdel-Basset, M.; Gamal, A.; Elhoseny, M.; Chakrabortty, R.K.; Ryan, M. A Conceptual Hybrid Approach from a Multicriteria Perspective for Sustainable Third-Party Reverse Logistics Provider Identification. Sustainability 2021, 13, 4615. [Google Scholar] [CrossRef]

- Tang, H.L. Design and Application of Performance Evaluation Indicators for Reverse Logistics Outsourcing. China Townsh. Enterp. Account. 2007, 8, 26–27. [Google Scholar]

- Pamučar, D.; Ecer, F.; Cirovic, G.; Arlasheedi, M.A. Application of Improved Best Worst Method (BWM) in Real-World Problems. Mathematics 2020, 8, 1342. [Google Scholar] [CrossRef]

- Li, Z.P.; Jin, Y.F. Application of TOPSIS in Evaluation of Third Party Reverse Logistics Service Providers. Logist. Technol. 2013, 32, 179–181. [Google Scholar]

- Wu, N. Research on evaluation indicators of third-party reverse logistics suppliers under the low-carbon concept. J. Commer. Econ. 2010, 32, 44–45. [Google Scholar]

- Ma, L. Research on the construction of third-party reverse logistics supplier evaluation index system. Logist. Technol. 2014, 24, 77–79. [Google Scholar]

- Xin, G.Q. Study on the Building of Performance Evaluation Index System for the Third Party Reverse Logistics Enterprise under Circular Economy. In Proceedings of the Fourth International Conference on Operations and Supply Chain Management (ICOSCM), Hong Kong, China, 25–31 July 2010; Volume 4, pp. 927–930. [Google Scholar]

- Liu, Y.M.; Zhou, P.; Li, L.Y.; Zhu, F. An Interactive Decision-Making Method for Third-Party Logistics Provider Selection under Hybrid Multi-Criteria. Symmetry 2020, 12, 729. [Google Scholar] [CrossRef]

- Li, M.; Zhao, T. Decision-making of the Third Party Reverse Logistics Provider Selection. J. Northwest AF Univ. (Soc. Sci. Ed.) 2006, 4, 73–77. [Google Scholar]

- Li, J.; Wang, Y.M. Evaluation and Selection of Third Party Reverse Logistics Suppliers Based on CCSD/TOPSIS. Logist. Technol. 2015, 34, 145−147+168. [Google Scholar]

- Senthil, S.; Srirangacharyulu, B.; Ramesh, A. A robust hybrid multi-criteria decision making methodology for contractor evaluation and selection in third-party reverse logistics. Expert Syst. Appl. 2014, 41, 50–58. [Google Scholar] [CrossRef]

- Wu, R.; Yu, Y.G. Selection of the Third Party Reverse Logistics Providers based on AHP and DEA. J. Anhui Agric. Sci. 2008, 36, 14767–14769. [Google Scholar]

- Guo, Z.X.; Zhang, Y.T.; Tian, Y.; Cao, X.M.; Wang, Z.Z. Selection of reverse logistics suppliers based on intuitionistic fuzzy multiple attribute decision making. J. Hebei Univ. (Nat. Sci. Ed.) 2021, 41, 638–644. [Google Scholar]

- Song, J.K.; Jiang, L.N.; Liu, Z.C.; Leng, X.L.; He, Z.G. Selection of Third-Party Reverse Logistics Service Provider Based on Intuitionistic Fuzzy Multi-Criteria Decision Making. Systems 2022, 10, 188. [Google Scholar] [CrossRef]

- Dickson, G.W. An Analysis of Vendor Selection and the Buying Process. J. Purch. 1996, 21, 5–17. [Google Scholar]

- Wen, F. Study on Selecting and Evaluating Third-party Reverse Logistics Enterprises. Sci. Technol. Prog. Policy 2009, 26, 152–155. [Google Scholar]

- Wang, K.J. Indicators for Third Party Reverse Logistics Supplier Evaluation in Remanufacturing. Logist. Technol. 2011, 30, 82−84+97. [Google Scholar]

- Yang, W.T. Research on Multi-Objective Decision-Making in the Selection of Third Party Reverse Logistics Supplier. J. Langfang Norm. Univ. (Nat. Sci. Ed.) 2016, 16, 61–66. [Google Scholar]

- Zarbakhshnia, N.; Soleimani, H.; Ghaderi, H. Sustainable third-party reverse logistics provider evaluation and selection using fuzzy SWARA and developed fuzzy COPRAS in the presence of risk criteria. Appl. Soft Comput. 2018, 65, 307–319. [Google Scholar] [CrossRef]

- Liu, B.P.; Zhang, K.; Li, G.H. Third-party Reverse Logistics Supplier Optimization Method Based on TFN-AHP and Entropy Combination Model. In Proceedings of the 25th Annual International Conference on Management Science and Engineering (ICMSE), Frankfurt, Germany, 7–20 August 2018; pp. 40–46. [Google Scholar]

- Liu, P.; Wu, M.J. Selection of third-party reverse logistics service providers based on FAHP. China Mark. 2019, 5, 170–173. [Google Scholar]

- Li, X.L. Rough Set-based Grey-Topsis Approach to the Third Party Reverse Logistic Vendor Selection. Sci. Technol. Manag. Res. 2013, 33, 67–71. [Google Scholar]

- Pei, X. Evaluation of Third Party Reverse Logistics Service Providers Based on G2-weighted TOPSIS. Logist. Technol. 2015, 34, 145−147+160. [Google Scholar]

- Liu, Q.S.; Wang, X.Z.; Hou, Y.Z. Research on Third Party Reverse Logistics Provider Evaluation Based on Entropy. Sci. Technol. Manag. Res. 2013, 33, 179−182+192. [Google Scholar]

- Pan, A.J. Selection of Automotive Third Party Reverse Logistics Suppliers Based on the MCDM. Logist. Technol. 2017, 36, 117−120+164. [Google Scholar]

- Li, J.; Wang, Y.M. Evaluation of Third Party Reverse Logistics Suppliers Based on Fuzzy-QFD. Logist. Technol. 2015, 34, 165–168. [Google Scholar]

- Wu, N. Application of Weighted Fuzzy Clustering in the Selection of Third Party Reverse Logistics Suppliers. Mod. Prop. Manag. 2010, 9, 33–35. [Google Scholar]

- Zhou, Z.F. Research on Selection of Third-Party Reverse Logistics Supplier Based on Fuzzy Analytic Hierarchy Process Method. Adv. Mater. Res. 2012, 472, 3395–3398. [Google Scholar] [CrossRef]

- Sheng, X.H.; Yang, W.P.; Chen, L.H.; Yang, H.Y. Research on the Choice of the Third-Party Reverse Logistics Enterprise Based on the Method of AHP and Goal Programming. Adv. Mater. Res. 2012, 452, 581–585. [Google Scholar] [CrossRef]

- Guo, W.D. Selection model of third-party reverse logistics service providers under supply chain management. In Proceeding of the 2012 24th Chinese Control and Decision Conference (CCDC), Taiyuan, China, 23–25 May 2012; pp. 1761–1764. [Google Scholar]

- Wang, C.N.; Nguyen, N.I.T.; Dang, T.T.; Lu, C.M. A Compromised Decision-Making Approach to Third-Party Logistics Selection in Sustainable Supply Chain Using Fuzzy AHP and Fuzzy VIKOR Methods. Mathematics 2021, 9, 886. [Google Scholar] [CrossRef]

- Wang, C.N.; Dang, T.T.; Nguyen, N.I.T. Outsourcing Reverse Logistics for E-Commerce Retailers: A Two-Stage Fuzzy Optimization Approach. Axioms 2021, 10, 34. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. An analysis of integrated robust hybrid model for third-party reverse logistics partner selection under fuzzy environment. Resour. Conserv. Recycl. 2016, 108, 63–81. [Google Scholar] [CrossRef]

- Jia, F.; Wang, X.Y. BWM-RST Method for Decision Analysis of New Product Attributes Combination. Soft Sci. 2016, 30, 109–113. [Google Scholar]

- Mahajan, V.; Linstone, H.A.; Turoff, M. The Delphi Method: Techniques and Applications. J. Mark. Res. 1976, 13, 317. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Liu, J.H.; Yu, Y.; Yu, J.X.; Ge, S.W.; Wu, S.B.; Zhou, W. Risk assessment method based on BWM group decision-making weighting and FMEA. J. Saf. Sci. Technol. 2022, 18, 37–43. [Google Scholar]

- Rezaei, J. Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega 2016, 64, 126–130. [Google Scholar] [CrossRef]

- Tseng, C.C.; Zeng, J.Y.; Hsieh, M.L.; Hsu, C.H. Analysis of Innovation Drivers of New and Old Kinetic Energy Conversion Using a Hybrid Multiple-Criteria Decision-Making Model in the Post-COVID-19 Era: A Chinese Case. Mathematics 2022, 10, 3755. [Google Scholar] [CrossRef]

- Zhu, J.; Feng, J.G.; Gao, Y.Q.; Guo, Z.C.; Zheng, H. Comprehensive evaluation model for happy rivers and lakes based on BWM-CRITIC-TOPSIS. Adv. Sci. Technol. Water Resour. 2022, 42, 8−14+20. [Google Scholar]

- Jia, P.; Dong, J. Evaluation of Extension Excellence of Logistics Service Supply Chain Performance Indicators Based on BSC. Stat. Decis. 2018, 34, 44–48. [Google Scholar]

| Dimension | Indicator | Indicator Description | References |

|---|---|---|---|

| Overall operation level | Inventory turnover rate | Measure the processing efficiency of reverse logistics systems and enterprise inventory management capability | [20,22] |

| Network coverage | Coverage of logistics node configuration and route arrangement | [13,14,21,22,25] | |

| Transportation allocation capacity | Ability to transport and allocate vehicles, the sign of whether an enterprise can achieve efficient operation | [8,15,16,17,19,25] | |

| Average processing time | Time spent processing a reverse logistics event (including returns, repairs, recalls, etc.) | [12,14] | |

| Service price level | Price level of services provided by 3PRLP | [12,13,17,20,21,23,25] | |

| Resource recovery cost | Expenses consumed in enterprise resource recovery | [17,21,23] | |

| Management service level | Service response speed | The time from accepting the customer’s reverse logistics business to the customer’s resolution | [8,9,10,11,15,17] |

| Recovery efficiency | Degree to which the expected effect of resource recovery is achieved within a certain period of time | [9,10,20] | |

| Industry experience | Time spent in the reverse logistics industry | [9,10,13] | |

| Service flexibility level | Ability to react and coordinate with changes in reverse logistics service volume or processing time | [11,26] | |

| Coordination and communication ability | Coordinated operation ability and efficiency of reverse logistics system | [9,10,17] | |

| Information technology level | Cost of information | The sum of various costs incurred by enterprises to obtain or reset information | [17,25] |

| Information integration and sharing capability | Information sharing between enterprises and reverse logistics suppliers, avoid shortages and bullwhip effects | [8,14,26] | |

| Degree of information standardization | Standardization degree of each module of reverse logistics information system | [9,10] | |

| Rate of R&D investment | Research and development of new technologies and materials | [9,10,14] | |

| Proportion of professional | Personnel specialized in scientific research and technical research | [12,14,21,24] | |

| Technical innovation capability | Ability to improve and enhance existing services | [8,9,10,11,14,22,24,25] | |

| Social and ecological benefits | Rate of resource utilization | Degree of recycling of resources | [9,10,22] |

| Investment rate of environmental protection funds | Investment in environmental protection, reflect the environmental protection level of the enterprise | [21,26] | |

| Comprehensive degree of environmental pollution | Impact of implementing reverse logistics activities on the environment | [10,21] | |

| Enterprise environmental protection awareness | Recognition of green concepts such as “green win-win and sustainable development” | [8,17,27] | |

| Level of recyclability | Recycling level of waste and other resources | [8,9,10,20] | |

| Strategic alliance | Compatibility of strategic objectives | Compatibility with the strategic planning of the entrusted enterprise | [13,14,16,18] |

| Compatibility of corporate culture | Coordination and adaptive compatibility with the environment of the entrusted enterprise | [14,15,17] | |

| Compatibility of management system | Degree of coordination with the structure and composition of the entrusted enterprise management system | [14,18] | |

| Sharing of benefits and risks | Sharing benefits and risks with entrusted enterprise | [13,14,15,16] | |

| Historical cooperation status | Whether there is a long-term and stable cooperative relationship with the entrusted enterprise | [13,16,21] |

| Preferences | Linguistic Terms |

|---|---|

| 1 | Indicates that is as important as |

| 2 | Indicates that is between equally important and slightly important compared to |

| 3 | Indicates that is slightly important compared to |

| 4 | Indicates that is between slightly important and highly important compared to |

| 5 | Indicates that is highly important compared to |

| 6 | Indicates that is between highly important and very important compared to |

| 7 | Indicates that is very important compared to |

| 8 | Indicates that is between very important and completely important compared to |

| 9 | Indicates that is completely important compared to |

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| Consistency Index | 0.44 | 1.00 | 1.63 | 2.30 | 3.00 | 3.73 | 4.47 | 5.23 |

| Expert | Title | Gender | Age | Field of Expertise | Seniority |

|---|---|---|---|---|---|

| A | Associate professor | Male | 61 | Third-party logistics | 30~35 |

| B | Associate professor | Male | 52 | Supply chain management | 25~30 |

| C | Associate professor | Male | 35 | Supply chain and logistics management | 10~15 |

| D | Associate research fellow | Male | 43 | Green logistics and supply chain | 15~20 |

| E | Senior manager | Male | 50 | Enterprise management | 20~30 |

| Dimension | Indicator | Necessity Scoring | Mean Value | Standard Deviation | CDI | Whether to Eliminate | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | ||||||

| Overall operation level | Inventory turnover rate | 8 | 5 | 7 | 9 | 7 | 7.2000 | 1.4832 | 0.2060 | No |

| Network coverage | 7 | 8 | 8 | 7 | 8 | 7.6000 | 0.5477 | 0.0721 | No | |

| Transportation allocation capacity | 9 | 8 | 10 | 8 | 9 | 8.8000 | 0.8367 | 0.0951 | No | |

| Average processing time | 5 | 5 | 5 | 4 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes | |

| Service price level | 6 | 7 | 7 | 6 | 6 | 6.4000 | 0.5477 | 0.0856 | No | |

| Resource recovery cost | 5 | 6 | 5 | 7 | 4 | 5.4000 | 1.1402 | 0.2111 | No | |

| Management service level | Service response speed | 9 | 8 | 9 | 8 | 10 | 8.8000 | 0.8367 | 0.0951 | No |

| Recovery efficiency | 7 | 9 | 6 | 5 | 7 | 6.8000 | 1.4832 | 0.2181 | No | |

| Industry experience | 4 | 5 | 3 | 4 | 5 | 4.2000 | 0.8367 | 0.1992 | No | |

| Service flexibility level | 7 | 8 | 7 | 7 | 8 | 7.4000 | 0.5477 | 0.0740 | No | |

| Coordination and communication ability | 5 | 6 | 5 | 5 | 5 | 5.2000 | 0.4472 | 0.0860 | Yes | |

| Information technology level | Cost of information | 7 | 5 | 3 | 6 | 5 | 5.2000 | 1.4832 | 0.2852 | No |

| Information integration and sharing capability | 8 | 9 | 8 | 9 | 8 | 8.4000 | 0.5477 | 0.0652 | No | |

| Degree of information standardization | 6 | 6 | 8 | 5 | 7 | 6.4000 | 1.1402 | 0.1782 | No | |

| Rate of R&D investment | 3 | 5 | 7 | 4 | 6 | 5.0000 | 1.5811 | 0.3162 | No | |

| Proportion of professionals | 5 | 5 | 4 | 5 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes | |

| Technical innovation capability | 8 | 7 | 8 | 9 | 8 | 8.0000 | 0.7071 | 0.0884 | No | |

| Social and ecological benefits | Rate of resource utilization | 4 | 5 | 3 | 3 | 5 | 4.0000 | 1.0000 | 0.2500 | No |

| Investment rate of environmental protection funds | 8 | 7 | 8 | 9 | 8 | 8.0000 | 0.7071 | 0.0884 | No | |

| Comprehensive degree of environmental pollution | 6 | 7 | 6 | 5 | 6 | 6.0000 | 0.7071 | 0.1179 | No | |

| Enterprise environmental protection awareness | 5 | 6 | 5 | 6 | 6 | 5.6000 | 0.5477 | 0.0978 | Yes | |

| Level of recyclability | 10 | 8 | 9 | 9 | 8 | 8.8000 | 0.8367 | 0.0951 | No | |

| Strategic alliance | Compatibility of strategic objectives | 8 | 9 | 9 | 8 | 8 | 8.4000 | 0.5477 | 0.0652 | No |

| Compatibility of corporate culture | 6 | 10 | 7 | 8 | 6 | 7.4000 | 1.6733 | 0.2261 | No | |

| Compatibility of management system | 6 | 4 | 5 | 6 | 5 | 5.2000 | 0.8367 | 0.1609 | No | |

| Sharing of benefits and risks | 7 | 7 | 6 | 7 | 7 | 6.8000 | 0.4472 | 0.0658 | No | |

| Historical cooperation status | 7 | 6 | 7 | 7 | 6 | 6.6000 | 0.5477 | 0.0830 | No | |

| Dimension | Indicator | Necessity Scoring | Mean Value | Standard Deviation | CDI | Whether to Eliminate | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | ||||||

| Overall operation level | Inventory turnover rate | 7 | 8 | 7 | 8 | 7 | 7.4000 | 0.5477 | 0.0740 | No |

| Network coverage | 7 | 8 | 8 | 7 | 8 | 7.6000 | 0.5477 | 0.0721 | No | |

| Transportation allocation capacity | 9 | 8 | 10 | 8 | 9 | 8.8000 | 0.8367 | 0.0951 | No | |

| Average processing time | 5 | 5 | 5 | 4 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes | |

| Service price level | 6 | 7 | 7 | 6 | 6 | 6.4000 | 0.5477 | 0.0856 | No | |

| Resource recovery cost | 5 | 6 | 5 | 5 | 5 | 5.2000 | 0.4472 | 0.0860 | Yes | |

| Management service level | Service response speed | 9 | 8 | 9 | 8 | 10 | 8.8000 | 0.8367 | 0.0951 | No |

| Recovery efficiency | 7 | 8 | 7 | 7 | 8 | 7.4000 | 0.5477 | 0.0740 | No | |

| Industry experience | 4 | 5 | 5 | 5 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes | |

| Service flexibility level | 7 | 8 | 7 | 7 | 8 | 7.4000 | 0.5477 | 0.0740 | No | |

| Coordination and communication ability | 5 | 6 | 5 | 5 | 5 | 5.2000 | 0.4472 | 0.0860 | Yes | |

| Information technology level | Cost of information | 5 | 5 | 4 | 5 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes |

| Information integration and sharing capability | 8 | 9 | 8 | 9 | 8 | 8.4000 | 0.5477 | 0.0652 | No | |

| Degree of information standardization | 6 | 6 | 7 | 6 | 7 | 6.4000 | 0.5477 | 0.0856 | No | |

| Rate of R&D investment | 5 | 5 | 6 | 5 | 5 | 5.2000 | 0.4472 | 0.0860 | Yes | |

| Proportion of professionals | 5 | 5 | 4 | 5 | 5 | 4.8000 | 0.4472 | 0.0932 | Yes | |

| Technical innovation capability | 8 | 7 | 8 | 9 | 8 | 8.0000 | 0.7071 | 0.0884 | No | |

| Social and ecological benefits | Rate of resource utilization | 5 | 4 | 4 | 3 | 5 | 4.2000 | 0.8367 | 0.1992 | Yes |

| Investment rate of environmental protection funds | 8 | 7 | 8 | 9 | 8 | 8.0000 | 0.7071 | 0.0884 | No | |

| Comprehensive degree of environmental pollution | 6 | 7 | 6 | 7 | 6 | 6.4000 | 0.5477 | 0.0856 | No | |

| Enterprise environmental protection awareness | 5 | 6 | 5 | 6 | 6 | 5.6000 | 0.5477 | 0.0978 | Yes | |

| Level of recyclability | 10 | 8 | 9 | 9 | 8 | 8.8000 | 0.8367 | 0.0951 | No | |

| Strategic alliance | Compatibility of strategic objectives | 8 | 9 | 9 | 8 | 8 | 8.4000 | 0.5477 | 0.0652 | No |

| Compatibility of corporate culture | 8 | 7 | 7 | 8 | 7 | 7.4000 | 0.5477 | 0.0740 | No | |

| Compatibility of management system | 6 | 6 | 5 | 6 | 5 | 5.6000 | 0.5477 | 0.0978 | Yes | |

| Sharing of benefits and risks | 7 | 7 | 6 | 7 | 7 | 6.8000 | 0.4472 | 0.0658 | No | |

| Historical cooperation status | 7 | 6 | 7 | 7 | 6 | 6.6000 | 0.5477 | 0.0830 | No | |

| Dimension | Code | Indicator | Code |

|---|---|---|---|

| Overall operation level | C1 | Inventory turnover rate | C11 |

| Network coverage | C12 | ||

| Transportation allocation capacity | C13 | ||

| Service price level | C14 | ||

| Management service level | C2 | Service response speed | C21 |

| Recovery efficiency | C22 | ||

| Service flexibility level | C23 | ||

| Information technology level | C3 | Information integration and sharing capability | C31 |

| Degree of information standardization | C32 | ||

| Technical innovation capability | C33 | ||

| Social and ecological benefits | C4 | Investment rate of environmental protection funds | C41 |

| Comprehensive degree of environmental pollution | C42 | ||

| Level of recyclability | C43 | ||

| Strategic alliance | C5 | Compatibility of strategic objectives | C51 |

| Compatibility of corporate culture | C52 | ||

| Sharing of benefits and risks | C53 | ||

| Historical cooperation status | C54 |

| Dimension | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Best-to-Others | Expert Preferences (1–9 scale) | Others-to-Worst | Expert Preferences (1–9 scale) | ||||||||

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | ||

| C1 | C1 | C1 | C1 | C1 | The worst indicator | C5 | C5 | C3 | C3 | C3 | |

| C1 | 1 | 1 | 1 | 1 | 1 | C1 | 8 | 8 | 5 | 7 | 8 |

| C2 | 2 | 3 | 2 | 2 | 2 | C2 | 5 | 2 | 4 | 6 | 4 |

| C3 | 2 | 4 | 5 | 7 | 8 | C3 | 5 | 3 | 1 | 1 | 1 |

| C4 | 3 | 5 | 3 | 6 | 4 | C4 | 4 | 4 | 2 | 2 | 2 |

| C5 | 8 | 8 | 4 | 4 | 5 | C5 | 1 | 1 | 2 | 3 | 2 |

| Secondary indicator (Overall operation level) | |||||||||||

| C13 | C13 | C12 | C14 | C13 | The worst indicator | C14 | C11 | C11 | C11 | C11 | |

| C11 | 2 | 7 | 7 | 8 | 7 | C11 | 4 | 1 | 1 | 1 | 1 |

| C12 | 2 | 3 | 1 | 5 | 3 | C12 | 3 | 4 | 7 | 2 | 4 |

| C13 | 1 | 1 | 5 | 5 | 1 | C13 | 5 | 7 | 2 | 2 | 7 |

| C14 | 5 | 4 | 4 | 1 | 2 | C14 | 1 | 2 | 3 | 8 | 4 |

| Secondary indicator (Management service level) | |||||||||||

| C22 | C21 | C22 | C21 | C23 | The worst indicator | C23 | C22 | C23 | C22 | C22 | |

| C21 | 3 | 1 | 5 | 1 | 3 | C21 | 3 | 6 | 2 | 9 | 3 |

| C22 | 1 | 6 | 1 | 9 | 6 | C22 | 6 | 1 | 7 | 1 | 1 |

| C23 | 6 | 2 | 7 | 2 | 1 | C23 | 1 | 5 | 1 | 8 | 6 |

| Secondary indicator (Information technology level) | |||||||||||

| C31 | C31 | C32 | C31 | C31 | The worst indicator | C33 | C32 | C32 | C32 | C33 | |

| C31 | 1 | 1 | 4 | 1 | 1 | C31 | 6 | 5 | 2 | 6 | 8 |

| C32 | 5 | 5 | 1 | 6 | 5 | C32 | 2 | 1 | 6 | 1 | 2 |

| C33 | 6 | 3 | 6 | 3 | 8 | C33 | 1 | 2 | 1 | 3 | 1 |

| Secondary indicator (Social and ecological benefits) | |||||||||||

| C43 | C43 | C43 | C41 | C43 | The worst indicator | C41 | C42 | C41 | C42 | C41 | |

| C41 | 4 | 3 | 7 | 1 | 6 | C41 | 1 | 4 | 1 | 3 | 1 |

| C42 | 2 | 7 | 3 | 3 | 3 | C42 | 3 | 1 | 3 | 1 | 2 |

| C43 | 1 | 1 | 1 | 2 | 1 | C43 | 4 | 7 | 7 | 2 | 6 |

| Secondary indicator (Strategic alliance) | |||||||||||

| C53 | C53 | C51 | C53 | C51 | The worst indicator | C52 | C54 | C52 | C54 | C54 | |

| C51 | 2 | 3 | 1 | 3 | 1 | C51 | 3 | 3 | 8 | 3 | 8 |

| C52 | 5 | 2 | 8 | 3 | 3 | C52 | 1 | 4 | 1 | 3 | 3 |

| C53 | 1 | 1 | 5 | 1 | 5 | C53 | 5 | 8 | 2 | 7 | 2 |

| C54 | 3 | 8 | 4 | 7 | 8 | C54 | 2 | 1 | 3 | 1 | 1 |

| Dimension | Optimal Weights | Mean of Weight | ||||

|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | ||

| C1 | 0.3894 | 0.4963 | 0.4169 | 0.4594 | 0.4754 | 0.4475 |

| C2 | 0.2124 | 0.1898 | 0.2357 | 0.2645 | 0.2459 | 0.2297 |

| C3 | 0.2124 | 0.1460 | 0.0725 | 0.0557 | 0.0574 | 0.1088 |

| C4 | 0.1416 | 0.1168 | 0.1571 | 0.0882 | 0.1229 | 0.1253 |

| C5 | 0.0442 | 0.0511 | 0.1178 | 0.1322 | 0.0984 | 0.0887 |

| 0.0354 | 0.0876 | 0.0544 | 0.0696 | 0.0164 | Results are reliable. | |

| Dimension | Indicator | Optimal Weights | Mean of Weight | ||||

|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | |||

| C1 | C11 | 0.2453 | 0.0702 | 0.0785 | 0.0787 | 0.0606 | 0.1067 |

| C12 | 0.2453 | 0.2105 | 0.6152 | 0.1348 | 0.1818 | 0.2775 | |

| C13 | 0.4340 | 0.5614 | 0.1361 | 0.1348 | 0.4849 | 0.3502 | |

| C14 | 0.0754 | 0.1579 | 0.1702 | 0.6517 | 0.2727 | 0.2656 | |

| 0.0566 | 0.0702 | 0.0785 | 0.0787 | 0.0606 | Results are reliable. | ||

| C2 | C21 | 0.2400 | 0.5833 | 0.1571 | 0.5972 | 0.2400 | 0.3635 |

| C22 | 0.6600 | 0.0833 | 0.7429 | 0.0556 | 0.1000 | 0.3284 | |

| C23 | 0.1000 | 0.3334 | 0.1000 | 0.3472 | 0.6600 | 0.3081 | |

| 0.0600 | 0.0833 | 0.0429 | 0.0972 | 0.0600 | Results are reliable. | ||

| C3 | C31 | 0.7302 | 0.6500 | 0.1852 | 0.6600 | 0.7533 | 0.5957 |

| C32 | 0.1587 | 0.1250 | 0.7037 | 0.1000 | 0.1558 | 0.2486 | |

| C33 | 0.1111 | 0.2250 | 0.1111 | 0.2400 | 0.0909 | 0.1556 | |

| 0.0635 | 0.0250 | 0.0370 | 0.0600 | 0.0260 | Results are reliable. | ||

| C4 | C41 | 0.1250 | 0.2500 | 0.0909 | 0.5416 | 0.1111 | 0.2237 |

| C42 | 0.3125 | 0.0833 | 0.2364 | 0.1667 | 0.2222 | 0.2042 | |

| C43 | 0.5625 | 0.6667 | 0.6727 | 0.2917 | 0.6667 | 0.5721 | |

| 0.0625 | 0.0833 | 0.0364 | 0.0417 | 0.0000 | Results are reliable. | ||

| C5 | C51 | 0.2539 | 0.1728 | 0.6250 | 0.1912 | 0.5979 | 0.3682 |

| C52 | 0.0923 | 0.2593 | 0.0721 | 0.1912 | 0.2062 | 0.1642 | |

| C53 | 0.4846 | 0.5062 | 0.1346 | 0.5441 | 0.1237 | 0.3586 | |

| C54 | 0.1692 | 0.0617 | 0.1683 | 0.0735 | 0.0722 | 0.1090 | |

| 0.0231 | 0.0123 | 0.0481 | 0.0294 | 0.0206 | Results are reliable. | ||

| Dimension | Weight of Dimension | Sorting | Indicator | Local Weight | Global Weight | Comprehensive Sorting |

|---|---|---|---|---|---|---|

| Overall operation level C1 | 0.4475 | 1 | Inventory turnover rate C11 | 0.1067 | 0.0477 | 9 |

| Network coverage C12 | 0.2775 | 0.1242 | 2 | |||

| Transportation allocation capacity C13 | 0.3502 | 0.1567 | 1 | |||

| Service price level C14 | 0.2656 | 0.1188 | 3 | |||

| Management service level C2 | 0.2297 | 2 | Service response speed C21 | 0.3635 | 0.0835 | 4 |

| Recovery efficiency C22 | 0.3284 | 0.0754 | 5 | |||

| Service flexibility level C23 | 0.3081 | 0.0708 | 7 | |||

| Information technology level C3 | 0.1088 | 4 | Information integration and sharing capability C31 | 0.5957 | 0.0648 | 8 |

| Degree of information standardization C32 | 0.2487 | 0.0271 | 13 | |||

| Technical innovation capability C33 | 0.1556 | 0.0169 | 15 | |||

| Social and ecological benefits C4 | 0.1253 | 3 | Investment rate of environmental protection funds C41 | 0.2237 | 0.0280 | 12 |

| Comprehensive degree of environmental pollution C42 | 0.2042 | 0.0256 | 14 | |||

| Level of recyclability C43 | 0.5721 | 0.0717 | 6 | |||

| Strategic alliance C5 | 0.0887 | 5 | Compatibility of strategic objectives C51 | 0.3682 | 0.0327 | 10 |

| Compatibility of corporate culture C52 | 0.1642 | 0.0146 | 16 | |||

| Sharing of benefits and risks C53 | 0.3586 | 0.0318 | 11 | |||

| Historical cooperation status C54 | 0.1090 | 0.0097 | 17 |

| Code | Indicator | BWM Model | AHP Model | ||

|---|---|---|---|---|---|

| Weight | Sorting | Weight | Sorting | ||

| C11 | Inventory turnover rate | 0.0574 | 9 | 0.0517 | 9 |

| C12 | Network coverage | 0.1173 | 2 | 0.1230 | 2 |

| C13 | Transportation allocation capacity | 0.1449 | 1 | 0.1740 | 1 |

| C14 | Service price level | 0.1145 | 3 | 0.1034 | 4 |

| C21 | Service response speed | 0.0915 | 4 | 0.1162 | 3 |

| C22 | Recovery efficiency | 0.0827 | 5 | 0.0922 | 5 |

| C23 | Service flexibility level | 0.0775 | 6 | 0.0732 | 6 |

| C31 | Information integration and sharing capability | 0.0626 | 8 | 0.0622 | 7 |

| C32 | Degree of information standardization | 0.0256 | 13 | 0.0261 | 10 |

| C33 | Technical innovation capability | 0.0168 | 15 | 0.0164 | 15 |

| C41 | Investment rate of environmental protection funds | 0.0277 | 12 | 0.0254 | 11 |

| C42 | Comprehensive degree of environmental pollution | 0.0242 | 14 | 0.0222 | 12 |

| C43 | Level of recyclability | 0.0709 | 7 | 0.0581 | 8 |

| C51 | Compatibility of strategic objectives | 0.0334 | 10 | 0.0201 | 13 |

| C52 | Compatibility of corporate culture | 0.0138 | 16 | 0.0108 | 16 |

| C53 | Sharing of benefits and risks | 0.0312 | 11 | 0.0181 | 14 |

| C54 | Historical cooperation status | 0.0080 | 17 | 0.0069 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Tang, L.; Zhang, J. Identifying Critical Indicators in the Evaluation of Third-Party Reverse Logistics Provider Using Best–Worst Method. Information 2023, 14, 291. https://doi.org/10.3390/info14050291

Zhang C, Tang L, Zhang J. Identifying Critical Indicators in the Evaluation of Third-Party Reverse Logistics Provider Using Best–Worst Method. Information. 2023; 14(5):291. https://doi.org/10.3390/info14050291

Chicago/Turabian StyleZhang, Changlu, Liqian Tang, and Jian Zhang. 2023. "Identifying Critical Indicators in the Evaluation of Third-Party Reverse Logistics Provider Using Best–Worst Method" Information 14, no. 5: 291. https://doi.org/10.3390/info14050291

APA StyleZhang, C., Tang, L., & Zhang, J. (2023). Identifying Critical Indicators in the Evaluation of Third-Party Reverse Logistics Provider Using Best–Worst Method. Information, 14(5), 291. https://doi.org/10.3390/info14050291