Modeling of Heat Flux in a Heating Furnace

Abstract

:1. Introduction

- -

- Uniform desired properties along the length of the strip are considered for the rolling direction and transverse direction (yield strength, elongation, toughness);

- -

- The uniform geometric shape of the strip (thickness, width) along its entire length;

- -

2. Materials and Methods

- Temperature field in the furnace working space (heat inputs in individual furnace zones);

- Composition of the furnace atmosphere (excess combustion air, fuel composition, and fuel combustion);

- Inlet temperature of the slabs;

- Slab temperatures above the skids (condition of the furnace cooling system);

- Type of steel.

- -

- Type and characteristics of the charge material;

- -

- Fuel type, fuel composition, and heat inputs in different furnace zones;

- -

- Quantity of air in each furnace zone and air temperature;

- -

- Furnace temperature in each zone;

- -

- Inlet surface temperature of the charge material;

- -

- The oxygen content of the flue gas at the furnace flue gas outlet;

- -

- Rolling temperature behind the 5th rolling table;

- -

- Quantity of cooling water, as well as inlet and outlet water temperatures;

- -

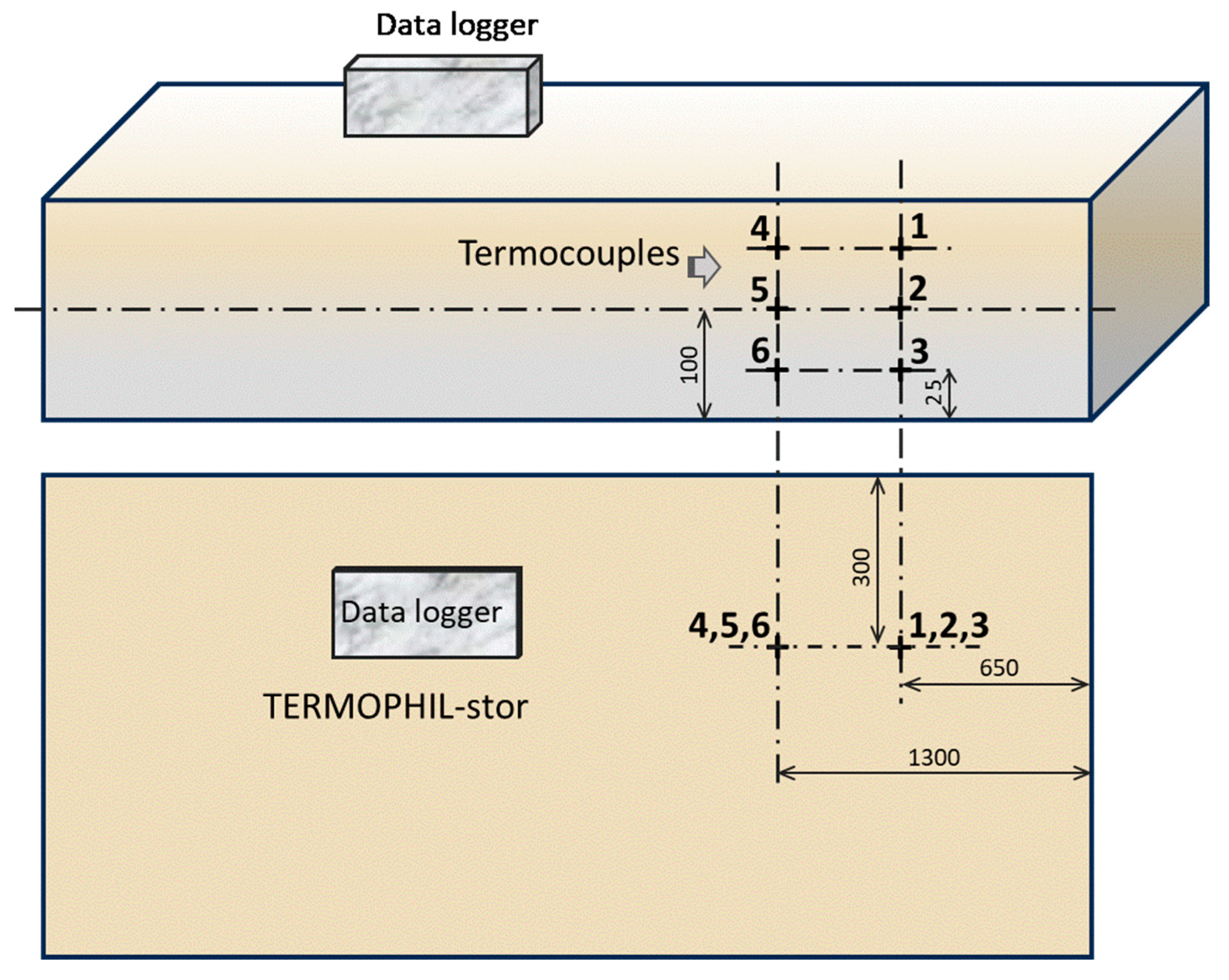

- Temperatures within the slab.

- -

- Dimensions: 8000 × 1540 × 200 mm

- -

- Weight: 15.5 t

Determination of Heat Fluxes on the Charge Surface

3. Results and Discussion

- -

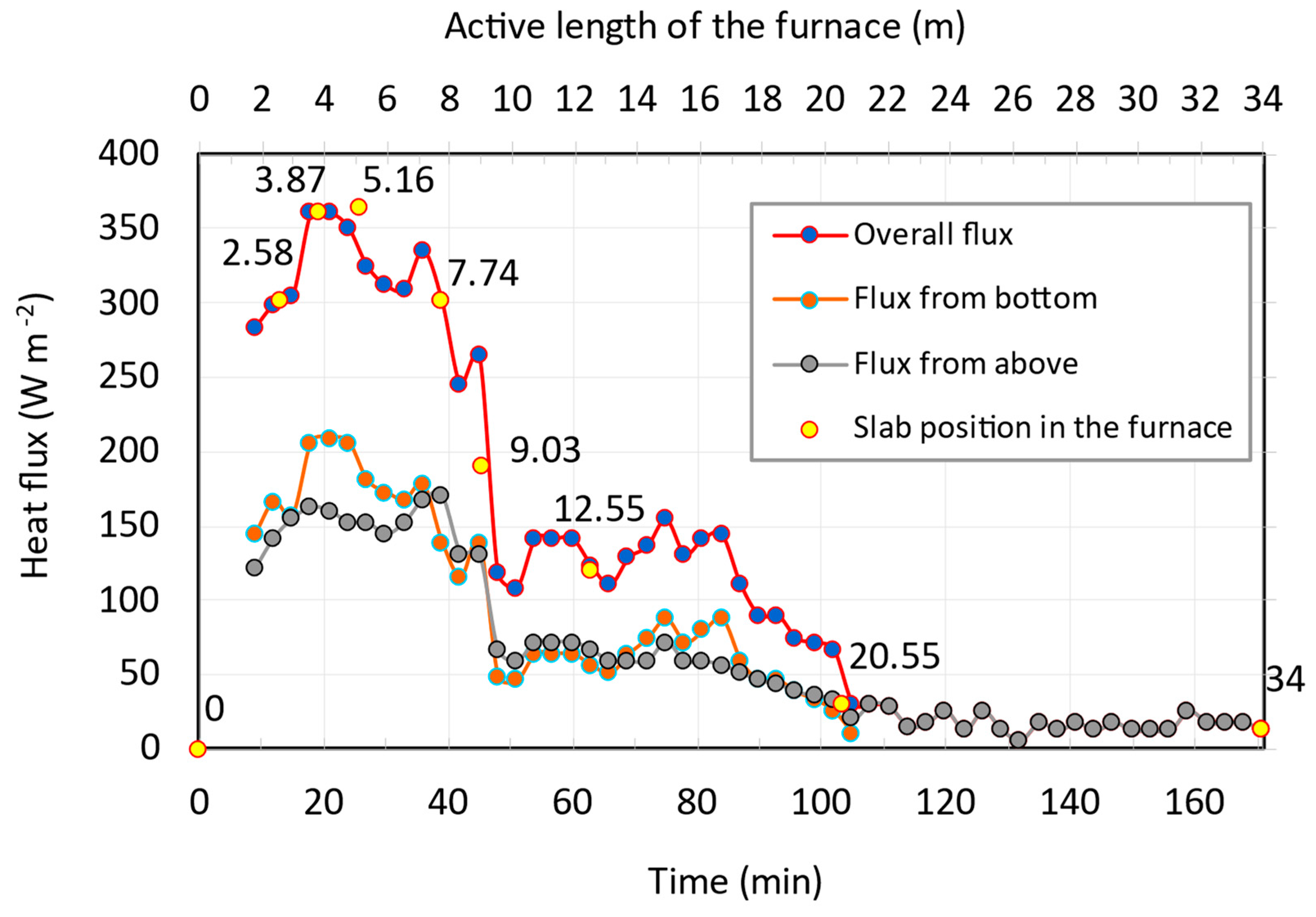

- The temperature courses in the slab in dependence on the duration of before reconstruction and after reconstruction of the pusher furnace;

- -

- The heat flux courses to the slab surface in dependence on the duration of heating before reconstruction and after reconstruction of the pusher furnace.

- -

- The heat fluxes from the bottom and top are approximately equal up to a distance of 1DZ;

- -

- The heat fluxes from the bottom are slightly higher than the heat fluxes from the top in the 2DZ, ensuring higher surface temperatures for the slabs at the bottom and the top at the end of the 2DZ.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Varga, A. Intensifying the process of heating slabs in pusher furnaces. Trans. Technol. Univ. Košice 1992, 2, 264–276. [Google Scholar]

- Brunklaus, J.H. Building of Industrial Furnaces, 2nd ed.; Vulkan-Verlag: Essen, Germany, 1962. [Google Scholar]

- Tatič, M.; Lukáč, L.; Súčik, G. Industrial Furnaces in Metallurgical Secondary Production, 1st ed.; TU of Košice: Košice, Slovakia, 2021. [Google Scholar]

- Tatič, M. Modernization of the pusher furnace lining in VSŽ a.s. Acta Metall. Slovaca 1997, 2, 469–476. [Google Scholar]

- Horbaj, P.; Črnko, J.; Lazić, L. Effect of varying the power and frequency of insulation maintenance on the heat consumption of a pusher furnace. Hutnícke Listy 1992, 47, 26–28. [Google Scholar]

- Kollerova, I. The Study of the Wear of the Pusher Furnace Bottom with Steel Scales. Ph.D. Thesis, Technical University of Ostrava, VŠB Ostrava, Czech Republic, March 2010. [Google Scholar]

- Varga, A.; Tatič, M.; Lazić, L. Application of roof radiant burners in large pusher-type furnaces. Metalurgija 2009, 48, 203–207. [Google Scholar]

- Benduch, A.; Boryca, J. The verification of the influence of heating steel charge parameters on the thickness of scale layer. Adv. Sci. Technol. Res. J. 2013, 7, 1–5. [Google Scholar] [CrossRef]

- Kostúr, K. Minimization of costs when heating the slabs in the pusher furnace. Hutnícke Listy 1994, 49, 43–47. [Google Scholar]

- Setiawan, A.F.; Arsana, I.M.; Soeryanto, S. Performance Analysis of Reheating Furnace on Billet Heating Production of Reinforced Iron. In Proceedings of the International Joint Conference on Science and Engineering 2022 (IJCSE 2022), Advances in Engineering Research, Surabaya, Indonesia, 10–11 September 2022. [Google Scholar]

- Jaklič, A.; Vode, F.; Koleno, T. Online simulation model of the slab-reheating process in a pusher-type furnace. Appl. Therm. Eng. 2007, 27, 1105–1114. [Google Scholar] [CrossRef]

- Steinboeck, A.; Wild, D.; Kiefer, T.; Kugi, A. A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media. Int. J. Heat Mass Transf. 2010, 53, 25–26. [Google Scholar] [CrossRef]

- Feliu Batlle, V.; Rivas Pérez, R.; Castillo, F.; Mora, I.Y. Fractional Order Temperature Control of a Steel Slab Reheating Furnace Robust to Delay Changes. In Proceedings of the 5th IFAC Workshop on Fractional Differentiation and its Applications, FDA’12, Nanjing, China, 14–17 May 2012. [Google Scholar]

- Prieler, R.; Mayr, B.; Demuth, M.; Holleis, B.; Hochenauer, C.H. Prediction of the heating characteristic of billets in a walking hearth type reheating furnace using CFD. Int. J. Heat Mass Transf. 2016, 53, 675–688. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Sundén, B.; Yang, R.; Baleta, J.; Vujanović, M. Analysis of slab heating characteristics in a reheating furnace. Energy Convers. Manag. 2017, 149, 928–936. [Google Scholar] [CrossRef]

- Radhika, S.B.; Nasar, A. Internal Model Control based Preheating Zone Temperature Control for Varying Time Delay Uncertainty of the Reheating Furnace. Int. J. Sci. Res. (IJSR) 2015, 4, 78–82. [Google Scholar]

- Marino, P.; Pignotti, A.; Solis, D. Numerical model of steel slab reheating in pusher furnaces. Lat. Am. Appl. Res. 2002, 32, 257–261. [Google Scholar]

- Marino, P.; Pignotti, A.; Solis, D. Control of Pusher furnaces for steel slab reheating using a numerical model. Lat. Am. Appl. Res. 2004, 34, 249–255. [Google Scholar]

- Andreev, S. System of Energy-Saving Optimal Control of Metal Heating Process in Heat Treatment Furnaces of Rolling Mills. Machines 2019, 7, 60. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Luo, X. Optimal set values of zone modeling in the simulation of a walking beam type reheating furnace on the steady-state operating regime. Appl. Therm. Eng. 2016, 101, 191–201. [Google Scholar] [CrossRef]

- STN 41 1375; Steel 11 375 Non-Alloy Steel of The usual Qualities Suitable For Welding For Steel Constructions. Available online: https://docplayer.cz/19932075-Csn-41-1523-nelegovana-konstrukcni-jemnozrnna-11-523-stn-41-1523-ocel-vhodna-ke-svarovani-znacka.html (accessed on 1 July 2023).

- Rédr, M.; Příhoda, M. Fundamentals of Thermal Engineering, 1st ed.; SNTL: Praha, Czech Republic, 1991. [Google Scholar]

- Sazima, M.; Kmoníček, V.; Schneller, J. Heat, 1st ed.; SNTL: Praha, Czech Republic, 1989. [Google Scholar]

- Cengel, Y.; Ghajar, A. Heat and Mass Transfer: Fundamentals and Applications, 6th ed.; McGraw Hill: New York, NY, USA, 2019. [Google Scholar]

- Hašek, P. Tables for Thermal Engineering, 11th ed.; VŠB: Ostrava, Czech Republic, 1980. [Google Scholar]

| t | a | b | c | d |

|---|---|---|---|---|

| <800 °C | 0.4727 | 1.67 × 10−4 | −2.654 × 10−7 | 5.0107 × 10−10 |

| ≥800 °C | −0.093 | 2.2962 × 10−3 | −2.1714 × 10−6 | 6.66668 × 10−10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varga, A.; Kizek, J.; Rimár, M.; Fedák, M.; Čorný, I.; Lukáč, L. Modeling of Heat Flux in a Heating Furnace. Computation 2023, 11, 144. https://doi.org/10.3390/computation11070144

Varga A, Kizek J, Rimár M, Fedák M, Čorný I, Lukáč L. Modeling of Heat Flux in a Heating Furnace. Computation. 2023; 11(7):144. https://doi.org/10.3390/computation11070144

Chicago/Turabian StyleVarga, Augustín, Ján Kizek, Miroslav Rimár, Marcel Fedák, Ivan Čorný, and Ladislav Lukáč. 2023. "Modeling of Heat Flux in a Heating Furnace" Computation 11, no. 7: 144. https://doi.org/10.3390/computation11070144

APA StyleVarga, A., Kizek, J., Rimár, M., Fedák, M., Čorný, I., & Lukáč, L. (2023). Modeling of Heat Flux in a Heating Furnace. Computation, 11(7), 144. https://doi.org/10.3390/computation11070144