Effects of Process Parameters on Structure and Properties of Melt-Blown Poly(Lactic Acid) Nonwovens for Skin Regeneration

Abstract

:1. Introduction

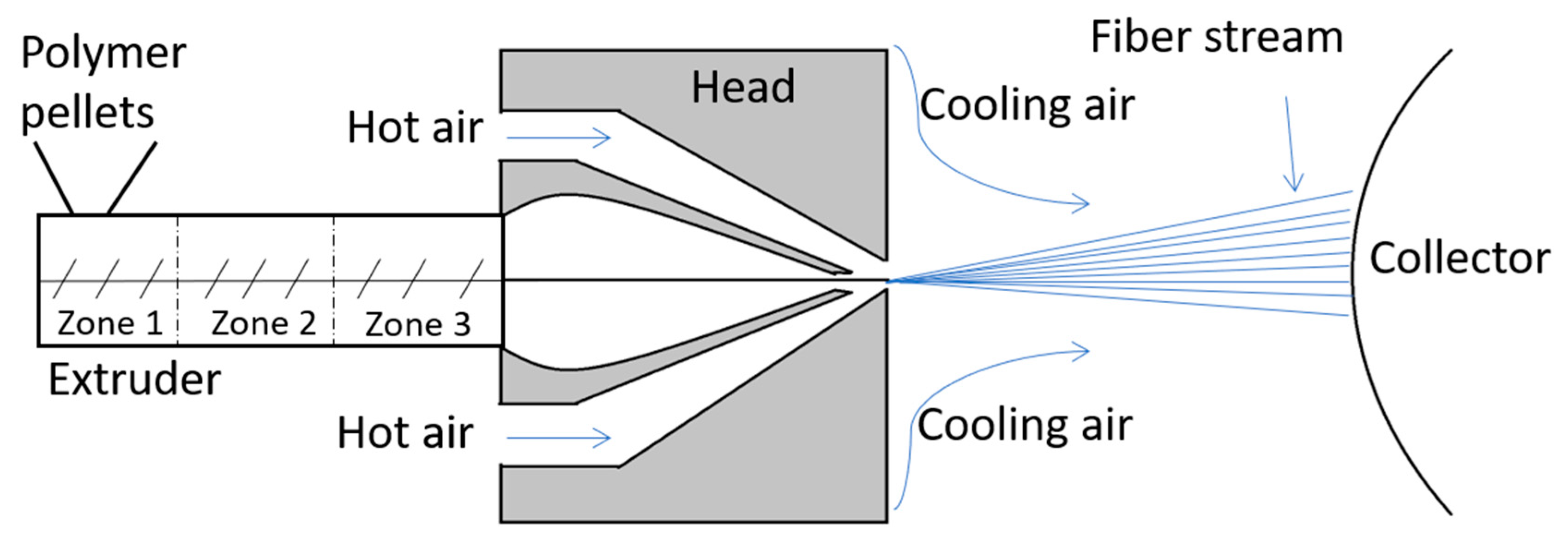

2. Materials and Methods

3. Results

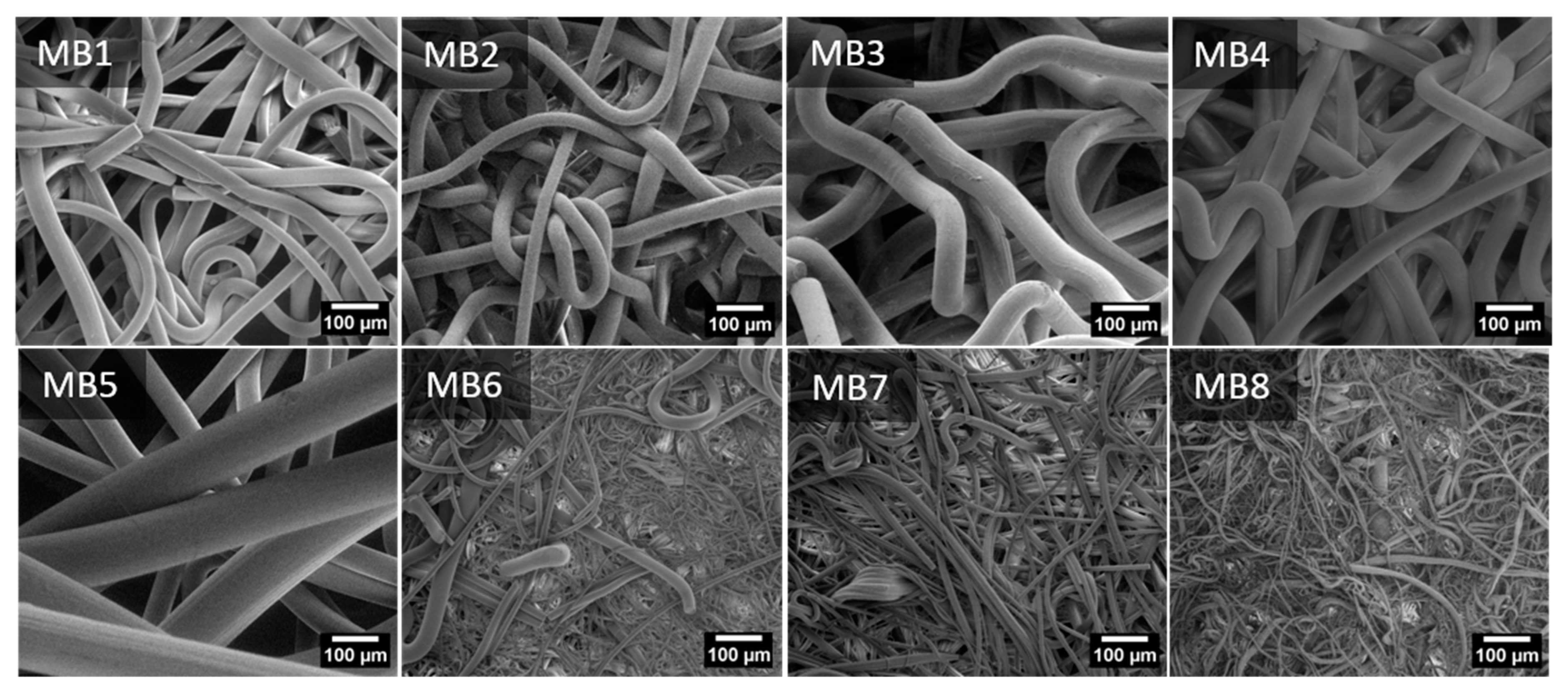

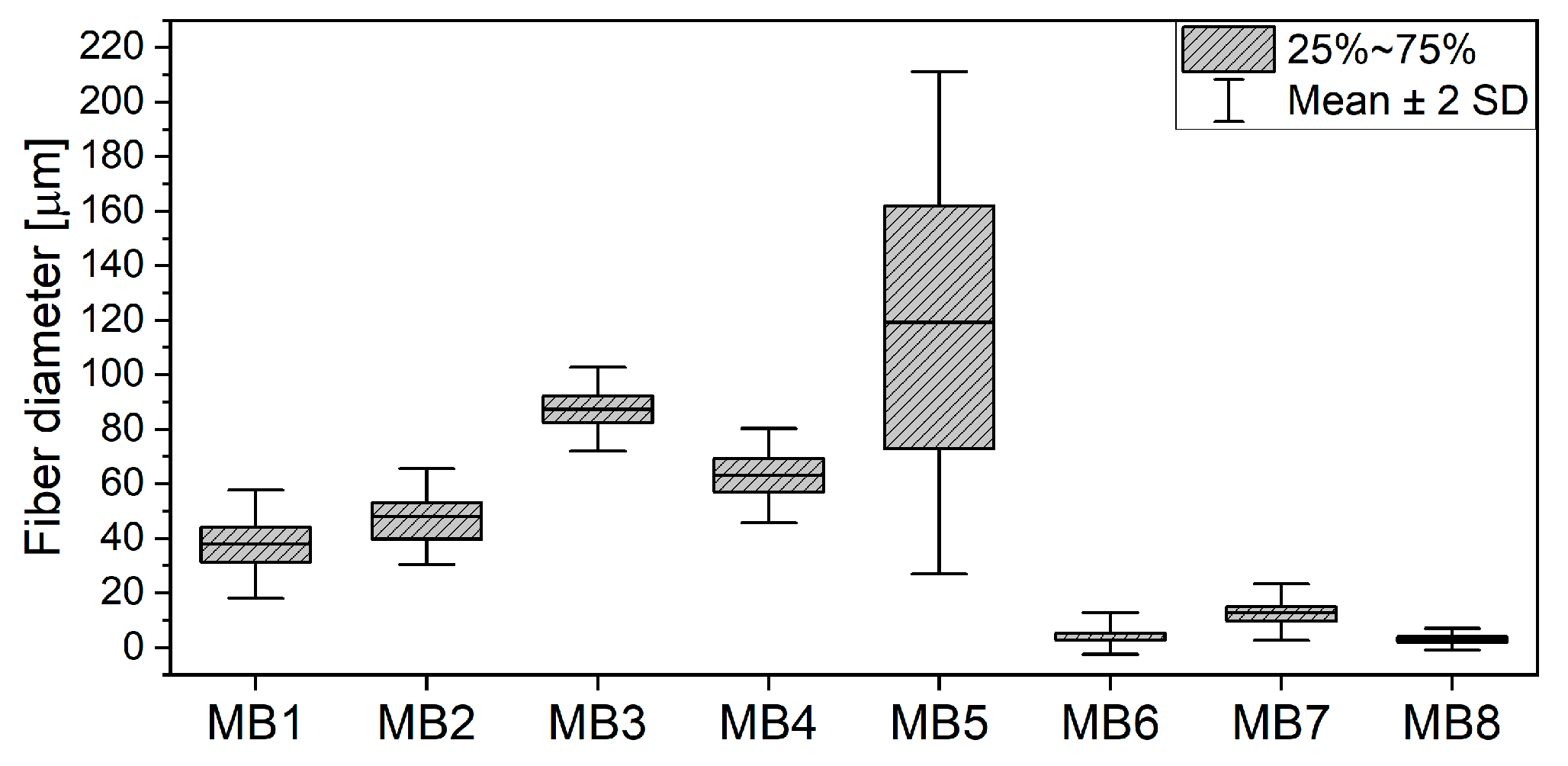

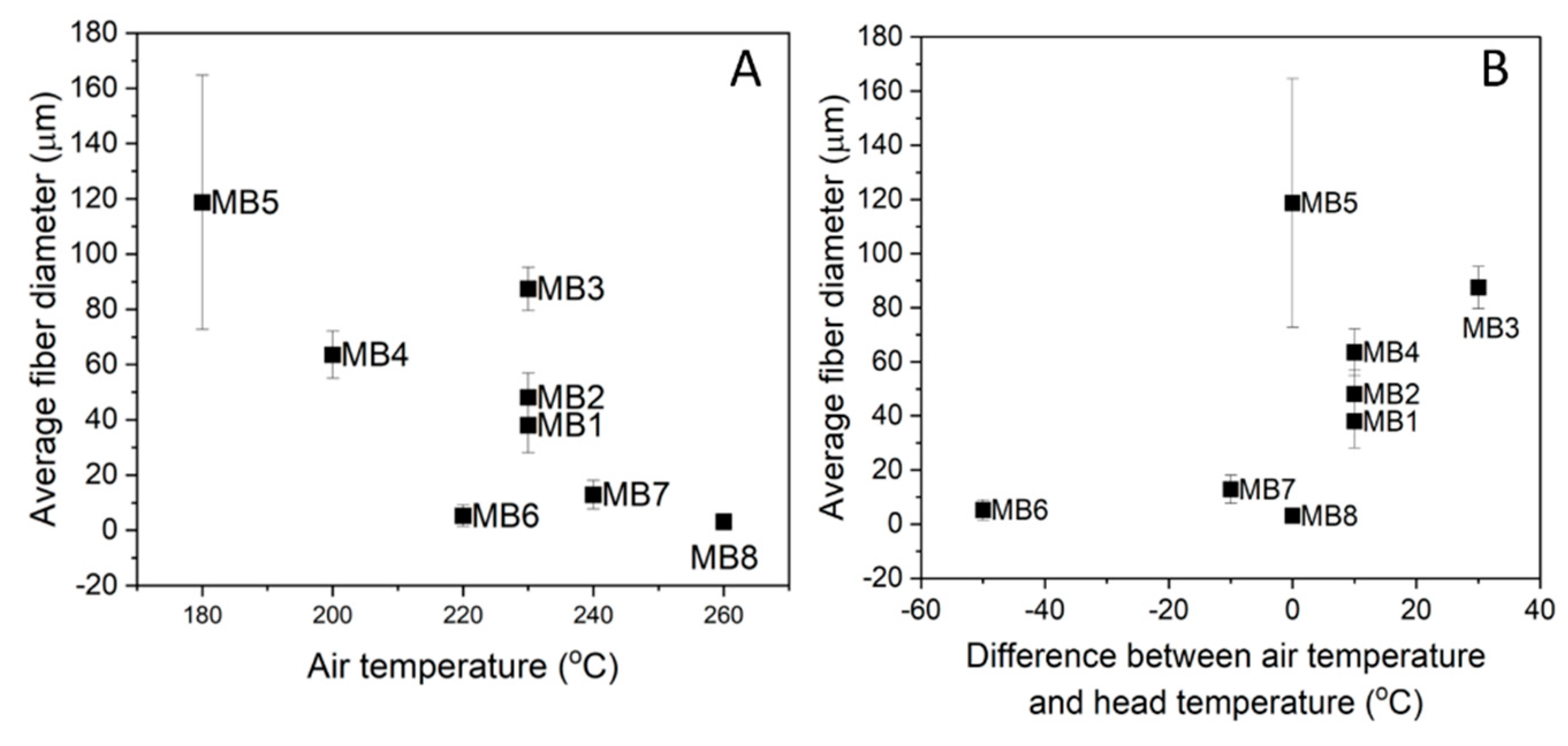

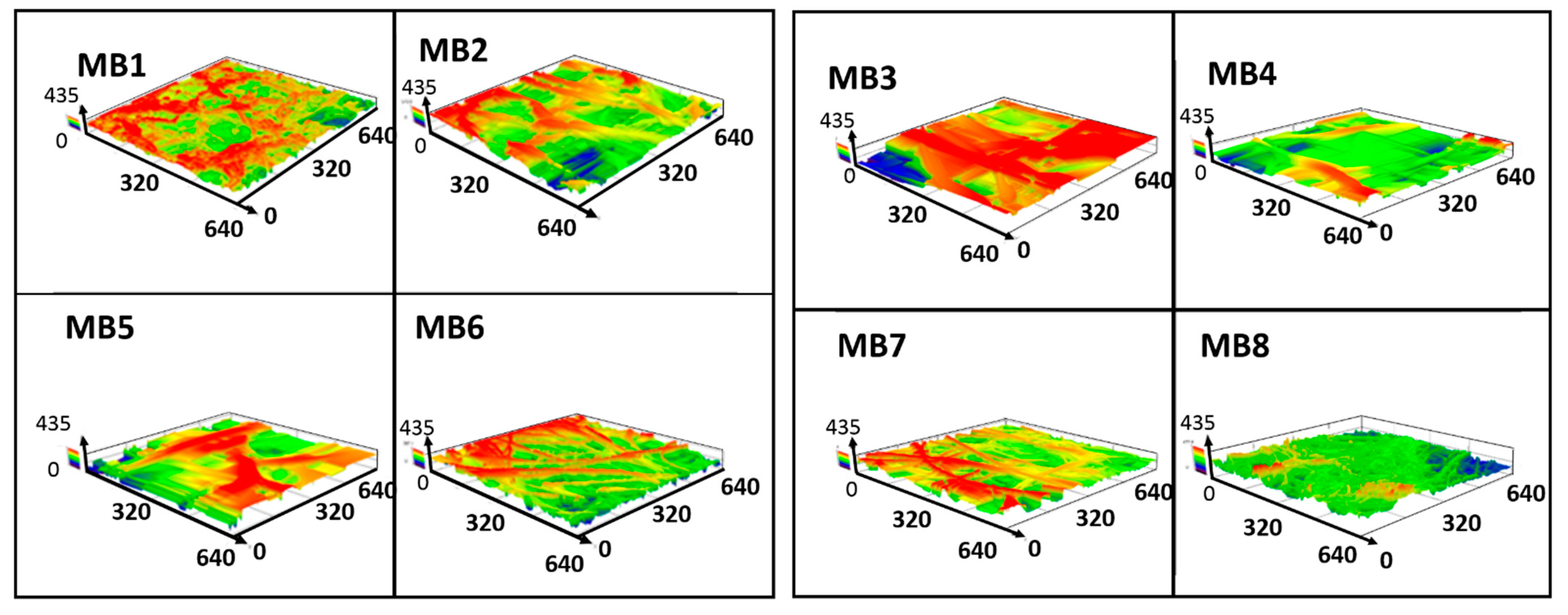

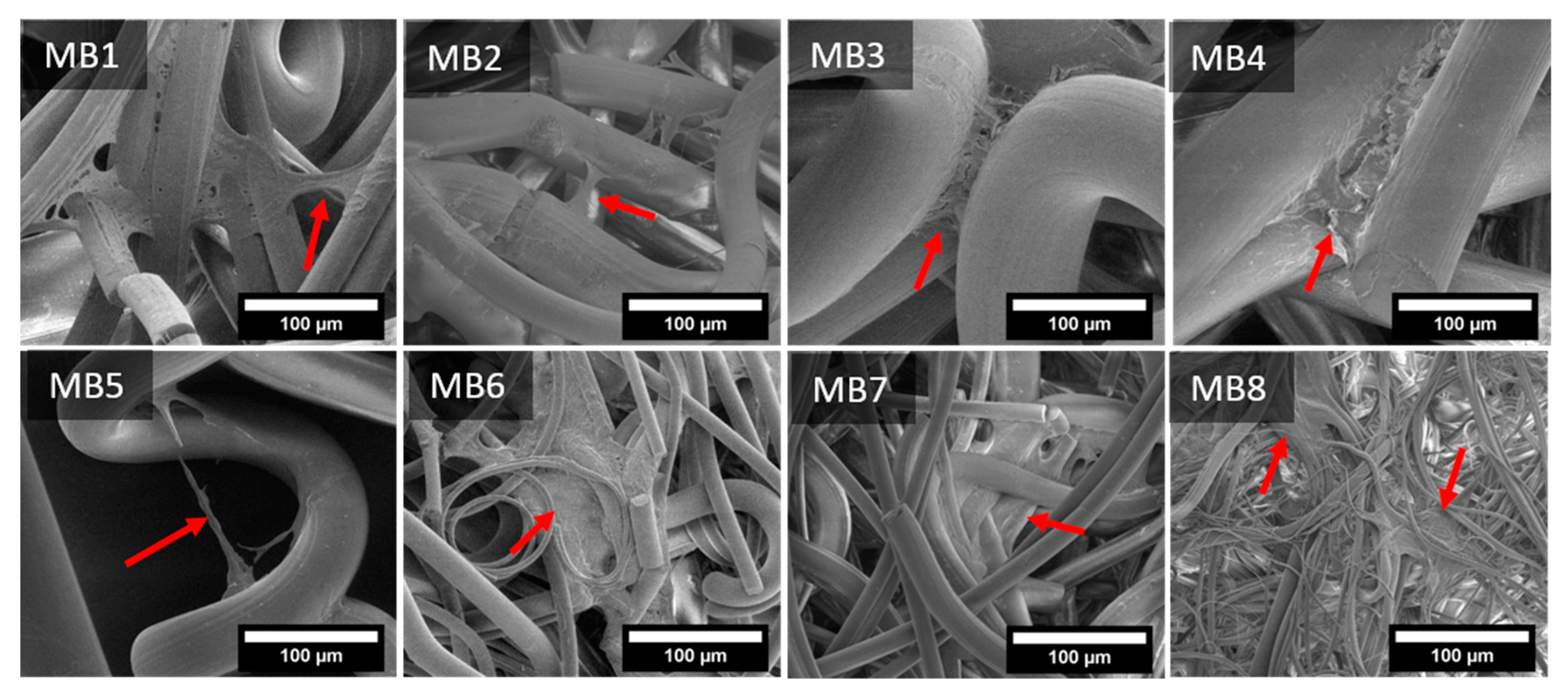

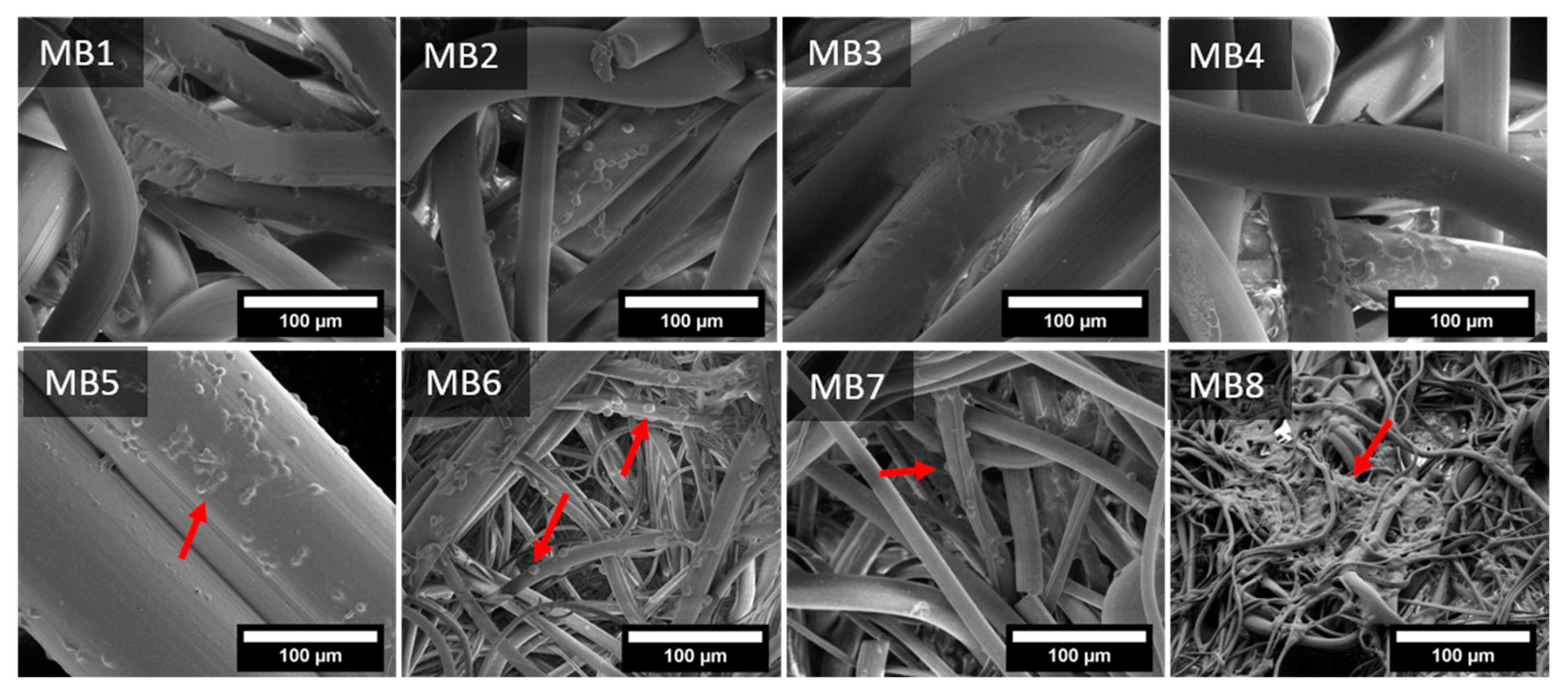

3.1. Nonwoven Scaffold Morphology

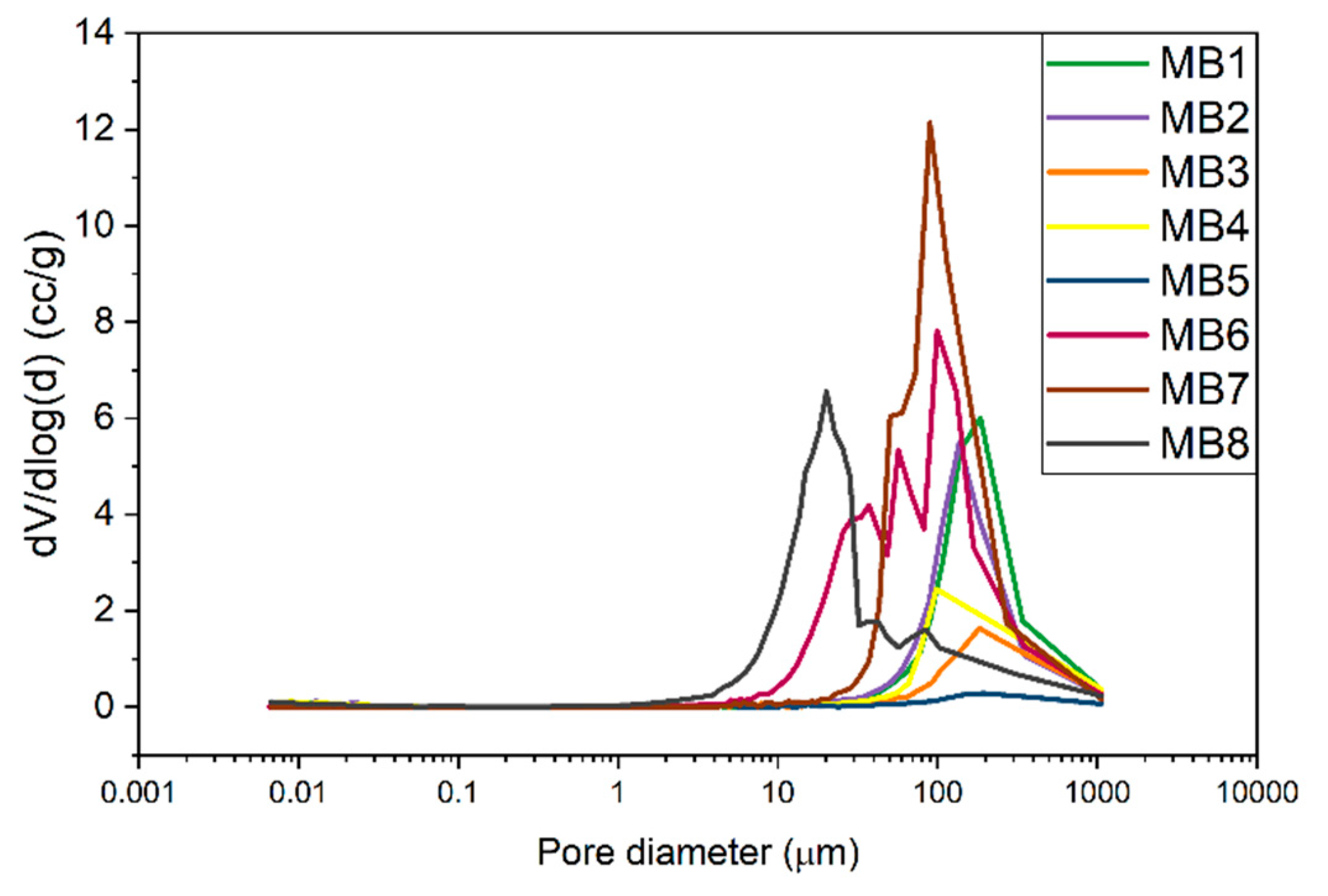

3.2. Porosity and Pore Size Distrubution

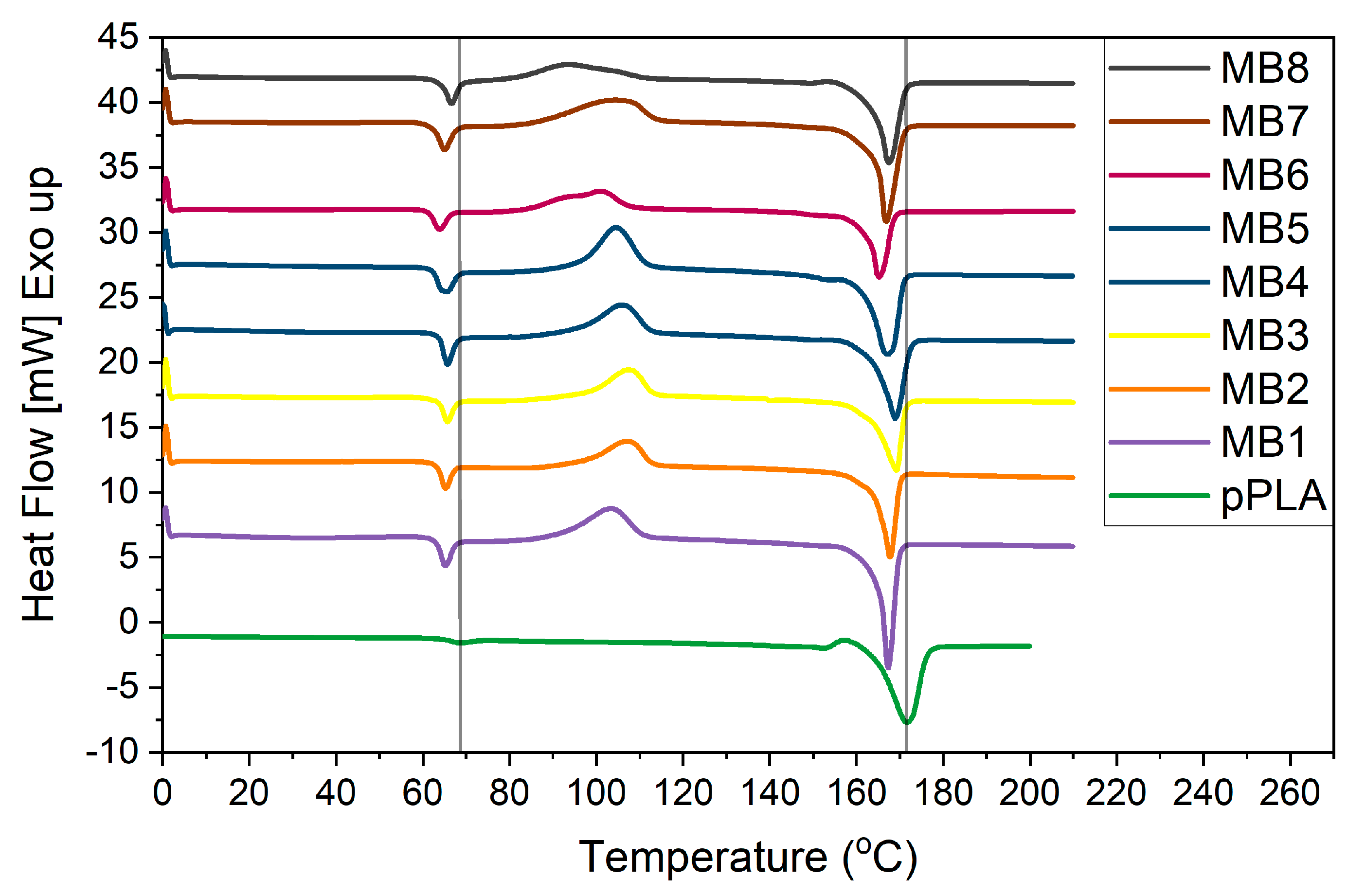

3.3. Thermal Analysis

3.4. Cellular Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamble, P.; Sadarani, B.; Majumdar, A.; Bhullar, S. Nanofiber Based Drug Delivery Systems for Skin: A Promising Therapeutic Approach. J. Drug Deliv. Sci. Technol. 2017, 41, 124–133. [Google Scholar] [CrossRef]

- Rahmati, M.; Mills, D.K.; Urbanska, A.M.; Saeb, M.R.; Venugopal, J.R.; Ramakrishna, S.; Mozafari, M. Electrospinning for Tissue Engineering Applications. Prog. Mater. Sci. 2020, 100721. [Google Scholar] [CrossRef]

- Stodolak-Zych, E.; Dzierzkowska, E.; Matwally, S.; Mikołajczyk, M.; Gajek, M.; Rapacz-Kmita, A. Multifunctional Porous Membranes with Antibacterial Properties. Int. J. Polym. Mater. Polym. Biomater. 2019, 68, 19–26. [Google Scholar] [CrossRef]

- Gazzola, W.H.; Benson, R.S.; Carver, W. Meltblown Polylactic Acid Nanowebs as a Tissue Engineering Scaffold. Ann. Plast. Surg. 2019, 83, 716–721. [Google Scholar] [CrossRef]

- Ameer, J.M.; PR, A.K.; Kasoju, N. Strategies to Tune Electrospun Scaffold Porosity for Effective Cell Response in Tissue Engineering. J. Funct. Biomater. 2019, 10, 30. [Google Scholar] [CrossRef] [Green Version]

- Dutton, K. Overview and Analysis of the Meltblown Process and Parameters. Available online: /paper/Overview-and-Analysis-of-the-Meltblown-Process-and-Dutton/7ca8fb5442bd680d1ced649283086bafc215b306 (accessed on 17 November 2020).

- Jenkins, T.L.; Meehan, S.; Pourdeyhimi, B.; Little, D. Meltblown Polymer Fabrics as Candidate Scaffolds for Rotator Cuff Tendon Tissue Engineering. Tissue Eng. Part A 2017, 23, 958–967. [Google Scholar] [CrossRef]

- Yu, B.; Sun, H.; Cao, Y.; Han, J.; Kong, J.; Wang, P.; Zhu, F. Effects of Poly(ϵ-Caprolactone) on Structure and Properties of Poly(Lactic Acid)/Poly(ϵ-Caprolactone) Meltblown Nonwoven. Null 2014, 53, 1788–1793. [Google Scholar] [CrossRef]

- Rungiah, S.; Ruamsuk, R.; Vroman, P.; Takarada, W.; Appert-Collin, J.-C.; Kikutani, T. Structural Characterization of Polypropylene/Poly(Lactic Acid) Bicomponent Meltblown. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Gopanna, A.; Rajan, K.P.; Thomas, S.P.; Chavali, M. Chapter 6 Polyethylene and Polypropylene Matrix Composites for Biomedical Applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Masutani, K.; Kimura, Y. Chapter 1 PLA Synthesis. From the Monomer to the Polymer. Add. Appl. 2014, 1–36. [Google Scholar] [CrossRef]

- Lasprilla, A.; Martinez, G.; Lunelli, B.; Jaimes Figueroa, J.E.; Jardini, A.; Filho, R. Synthesis and Characterization of Poly (Lactic Acid) for Use in Biomedical Field. Chem. Eng. Trans. 2011, 24, 985. [Google Scholar] [CrossRef]

- Kohli, N.; Sharma, V.; Brown, S.J.; García-Gareta, E. 5—Synthetic polymers for skin biomaterials. In Biomaterials for Skin Repair and Regeneration; García-Gareta, E., Ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 125–149. ISBN 978-0-08-102546-8. [Google Scholar]

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-Lactic Acid Synthesis for Application in Biomedical Devices—A Review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Santoro, M.; Shah, S.R.; Walker, J.L.; Mikos, A.G. Poly(Lactic Acid) Nanofibrous Scaffolds for Tissue Engineering. Adv. Drug Deliv. Rev. 2016, 107, 206–212. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing Technologies for Poly(Lactic Acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Wang, J.; Li, C. Preparation and Characterization of PLLA/NHA Nonwoven Mats via Laser Melt Electrospinning. Mater. Lett. 2012, 73, 103–106. [Google Scholar] [CrossRef]

- Price, A.; Naik, G.; Harding, K. 2—Skin repair technology. In Biomaterials for Skin Repair and Regeneration; García-Gareta, E., Ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 27–57. ISBN 978-0-08-102546-8. [Google Scholar]

- Stodolak-Zych, E.; Jeleń, P.; Dzierzkowska, E.; Krok-Borkowicz, M.; Zych, Ł.; Boguń, M.; Rapacz-Kmita, A.; Kolesińska, B. Modification of Chitosan Fibers with Short Peptides as a Model of Synthetic Extracellular Matrix. J. Mol. Struct. 2020, 1211, 128061. [Google Scholar] [CrossRef]

- Growney Kalaf, E.A.; Hixon, K.R.; Kadakia, P.U.; Dunn, A.J.; Sell, S.A. 9—Electrospun biomaterials for dermal regeneration. In Electrospun Materials for Tissue Engineering and Biomedical Applications; Uyar, T., Kny, E., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 179–231. ISBN 978-0-08-101022-8. [Google Scholar]

- Erben, J.; Jencova, V.; Chvojka, J.; Blazkova, L.; Strnadova, K.; Modrak, M.; Kostakova, E.K. The Combination of Meltblown Technology and Electrospinning—The Influence of the Ratio of Micro and Nanofibers on Cell Viability. Mater. Lett. 2016, 173, 153–157. [Google Scholar] [CrossRef]

- Rampichová, M.; Chvojka, J.; Jenčová, V.; Kubíková, T.; Tonar, Z.; Erben, J.; Buzgo, M.; Daňková, J.; Litvinec, A.; Vocetková, K.; et al. The Combination of Nanofibrous and Microfibrous Materials for Enhancement of Cell Infiltration and in Vivo Bone Tissue Formation. Biomed. Mater. 2018, 13, 025004. [Google Scholar] [CrossRef] [PubMed]

- Dzierzkowska, E.; ŚcisŁowska-Czarnecka, A.; Matwally, S.; Romaniszyn, D.; ChadziŃska, M.; Stodolak-Zych, E. Porous Poly(Lactic Acid) Based Fibres as Drug Carriers in Active Dressings. Acta Bioeng. Biomech. 2020, 22, 185–197. [Google Scholar] [CrossRef]

- Sun, T.; Norton, D.; McKean, R.J.; Haycock, J.W.; Ryan, A.J.; MacNeil, S. Development of a 3D Cell Culture System for Investigating Cell Interactions with Electrospun Fibers. Biotechnol. Bioeng. 2007, 97, 1318–1328. [Google Scholar] [CrossRef]

- Pedram Rad, Z.; Mokhtari, J.; Abbasi, M. Calendula Officinalis Extract/PCL/Zein/Gum Arabic Nanofibrous Bio-Composite Scaffolds via Suspension, Two-Nozzle and Multilayer Electrospinning for Skin Tissue Engineering. Int. J. Biol. Macromol. 2019, 135, 530–543. [Google Scholar] [CrossRef]

- Ribeiro, C.; Sencadas, V.; Costa, C.M.; Ribelles, J.L.G.; Lanceros-Méndez, S. Tailoring the Morphology and Crystallinity of Poly(L-Lactide Acid) Electrospun Membranes. Sci. Technol. Adv. Mater. 2011, 12, 015001. [Google Scholar] [CrossRef] [PubMed]

- Bresee, R.R.; Qureshi, U.A. Influence of Process Conditions on Melt Blown Web Structure. Part IV—Fiber Diameter. J. Eng. Fibers Fabr. 2006, 1. [Google Scholar] [CrossRef] [Green Version]

- Kun, M.; Chan, C.; Ramakrishna, S.; Kulkarni, A.; Vadodaria, K. 12—Textile-based scaffolds for tissue engineering. In Advanced Textiles for Wound Care, 2nd ed.; Rajendran, S., Ed.; The Textile Institute Book Series; Woodhead Publishing: Sawston, UK, 2019; pp. 329–362. ISBN 978-0-08-102192-7. [Google Scholar]

- Liu, Y.; Cheng, B.; Cheng, G. Development and Filtration Performance of Polylactic Acid Meltblowns. Text. Res. J. Text Res. J. 2009, 79. [Google Scholar] [CrossRef]

- Chang, H.-I.; Wang, Y. Cell Responses to Surface and Architecture of Tissue Engineering Scaffolds. Regen. Med. Tissue Eng. Cells Biomater. 2011. [Google Scholar] [CrossRef] [Green Version]

- Loh, Q.L.; Choong, C. Three-Dimensional Scaffolds for Tissue Engineering Applications: Role of Porosity and Pore Size. Tissue Eng. Part B Rev. 2013, 19, 485–502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hammonds, R.L.; Gazzola, W.H.; Benson, R.S. Physical and Thermal Characterization of Polylactic Acid Meltblown Nonwovens. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Improving Mechanical Performance of Injection Molded PLA by Controlling Crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Xing, Q.; Li, R.; Zhang, X.; Dong, X.; Wang, D.; Zhang, L. Tailoring Crystallization Behavior of Poly (l-Lactide) with a Low Molecular Weight Aliphatic Amide. Colloid Polym. Sci. 2015, 293, 3573–3583. [Google Scholar] [CrossRef]

- Xin, S.; Wang, X. Shear Flow of Molten Polymer in Melt Blowing. Polym. Eng. Sci. 2012, 52, 1325–1331. [Google Scholar] [CrossRef]

- Iannace, S.; Maffezzoli, A.; Leo, G.; Nicolais, L. Influence of Crystal and Amorphous Phase Morphology on Hydrolytic Degradation of PLLA Subjected to Different Processing Conditions. Polymer 2001, 42, 3799–3807. [Google Scholar] [CrossRef]

- Tsuji, H.; Miyauchi, S. Poly(l-Lactide): 7. Enzymatic Hydrolysis of Free and Restricted Amorphous Regions in Poly(l-Lactide) Films with Different Crystallinities and a Fixed Crystalline Thickness. Polymer 2001, 42, 4463–4467. [Google Scholar] [CrossRef]

- Li, L.; Hashaikeh, R.; Arafat, H.A. Development of Eco-Efficient Micro-Porous Membranes via Electrospinning and Annealing of Poly (Lactic Acid). J. Membr. Sci. 2013, 436, 57–67. [Google Scholar] [CrossRef]

- Sarasua, J.R.; López-Rodríguez, N.; Zuza, E.; Petisco, S.; Castro, B.; del Olmo, M.; Palomares, T.; Alonso-Varona, A. Crystallinity Assessment and in Vitro Cytotoxicity of Polylactide Scaffolds for Biomedical Applications. J. Mater. Sci: Mater. Med. 2011, 22, 2513–2523. [Google Scholar] [CrossRef]

- Cui, H.; Sinko, P.J. The Role of Crystallinity on Differential Attachment/Proliferation of Osteoblasts and Fibroblasts on Poly (Caprolactone- Co -Glycolide) Polymeric Surfaces. Front. Mater. Sci. 2012, 6, 47–59. [Google Scholar] [CrossRef]

- Park, A.; Cima, L.G. In Vitro Cell Response to Differences in Poly-l-Lactide Crystallinity. J. Biomed. Mater. Res. 1996, 31, 17–30. [Google Scholar] [CrossRef]

- Stodolak, E.; Rozmus, K.; Dzierzkowska, E.; Zych, Ł.; Rapacz-Kmita, A.; Gargas, M.; Kolaczkowska, E.; Cieniawska, M.; Książek, K.; Ścisłowska-Czarnecka, A. The Membrane with Polylactide and Hyaluronic Fibers for Skin Substitute. Acta Bioeng. Biomech. 2018, 20, 91–99. [Google Scholar]

- Azimi, B.; Thomas, L.; Fusco, A.; Kalaoglu-Altan, O.I.; Basnett, P.; Cinelli, P.; De Clerck, K.; Roy, I.; Donnarumma, G.; Coltelli, M.-B.; et al. Electrosprayed Chitin Nanofibril/Electrospun Polyhydroxyalkanoate Fiber Mesh as Functional Nonwoven for Skin Application. J. Funct. Biomater. 2020, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Saino, E.; Focarete, M.L.; Gualandi, C.; Emanuele, E.; Cornaglia, A.I.; Imbriani, M.; Visai, L. Effect of Electrospun Fiber Diameter and Alignment on Macrophage Activation and Secretion of Proinflammatory Cytokines and Chemokines. Biomacromolecules 2011, 12, 1900–1911. [Google Scholar] [CrossRef] [PubMed]

- Pelipenko, J.; Kocbek, P.; Kristl, J. Nanofiber Diameter as a Critical Parameter Affecting Skin Cell Response. Eur. J. Pharm. Sci. Off. J. Eur. Fed. Pharm. Sci. 2014, 66. [Google Scholar] [CrossRef] [PubMed]

- Spiller, K.L.; Freytes, D.O.; Vunjak-Novakovic, G. Macrophages Modulate Engineered Human Tissues for Enhanced Vascularization and Healing. Ann. Biomed. Eng. 2015, 43, 616–627. [Google Scholar] [CrossRef] [Green Version]

- Tylek, T.; Blum, C.; Hrynevich, A.; Schlegelmilch, K.; Schilling, T.; Dalton, P.D.; Groll, J. Precisely Defined Fiber Scaffolds with 40 µm Porosity Induce Elongation Driven M2-like Polarization of Human Macrophages. Biofabrication 2020, 12, 025007. [Google Scholar] [CrossRef] [PubMed]

| Processing Parameter | MB1 | MB2 | MB3 | MB4 | MB5 | MB6 | MB7 | MB8 |

|---|---|---|---|---|---|---|---|---|

| Extruder zone 1 (°C) | 195 | 195 | 190 | 180 | 170 | 195 | 195 | 195 |

| Extruder zone 2 (°C) | 230 | 230 | 195 | 190 | 175 | 200 | 230 | 245 |

| Extruder zone 3 (°C) | 235 | 235 | 210 | 190 | 180 | 205 | 245 | 260 |

| Head temperature (°C) | 220 | 220 | 200 | 190 | 180 | 270 | 250 | 260 |

| Air temperature (°C) | 230 | 230 | 230 | 200 | 180 | 220 | 240 | 260 |

| Air flow (m3/h) | 7–8 | 7–8 | 7–8 | 7–8 | 7–8 | 7–8 | 7–8 | 7–8 |

| Melt flow rate (g/min) | 5 | 5 | 8 | 5 | 5 | 5 | 5 | 5 |

| Hole diameter (mm) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Die to collector distance DCD (cm) | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| Roughness | MB1 | MB2 | MB3 | MB4 | MB5 | MB6 | MB7 | MB8 |

|---|---|---|---|---|---|---|---|---|

| Ra (µm) | 70.32 ± 12.38 | 91.41 ± 17.92 | 158.01 ± 27.90 | 118.44 ± 31.10 | 101.69 ± 20.39 | 54.24 ± 11.23 | 47.95 ± 12.53 | 48.89 ± 7.29 |

| Material | Weight (g) | Thickness (cm) | Basic Weight (g/m2) | Apparent Density of Scaffold (g/cm3) | Total Porosity (%) |

|---|---|---|---|---|---|

| MB1 | 2.23 × 10−2 | 4.09× 10−2 | 129.7 | 6.79 × 10−2 | 94.52 |

| MB2 | 7.04 × 10−2 | 1.24 × 10−1 | 335.6 | 7.07 × 10−2 | 94.30 |

| MB3 | 3.85 × 10−2 | 6.32 × 10−2 | 195.5 | 7.58 × 10−2 | 93.89 |

| MB4 | 3.84 × 10−2 | 6.68 × 10−2 | 195.1 | 7.15 × 10−2 | 94.23 |

| MB5 | 2.08 × 10−2 | 4.08 × 10−2 | 242.3 | 6.34 × 10−2 | 94.88 |

| MB6 | 2.32 × 10−2 | 1.79 × 10−1 | 130.9 | 1.61 × 10−2 | 98.70 |

| MB7 | 3.53 × 10−2 | 2.36 × 10−1 | 162.0 | 1.86 × 10−2 | 98.50 |

| MB8 | 2.90 × 10−2 | 2.00 × 10−1 | 146.5 | 1.80 × 10−2 | 98.55 |

| Material | Tg (°C) | Tc (°C) | Hc (J/gPLA) | Tm (°C) | Hm (J/gPLA) | Xc (%) | Cp (J/gK) |

|---|---|---|---|---|---|---|---|

| MB1 | 62.81 | 91.54 | 32.54 | 164.75 | 44.89 | 48.27 | 0.46 |

| MB2 | 63.16 | 96.84 | 29.85 | 164.10 | 44.52 | 47.87 | 0.59 |

| MB3 | 63.52 | 97.61 | 32.35 | 162.90 | 40.12 | 43.01 | 0.41 |

| MB4 | 63.58 | 95.89 | 26.61 | 163.61 | 40.20 | 43.23 | 0.44 |

| MB5 | 62.12 | 96.59 | 28.52 | 161.77 | 44.94 | 47.31 | 0.40 |

| MB6 | 61.21 | 83.58 | 28.29 | 162.14 | 39.21 | 42.16 | 0.36 |

| MB7 | 62.15 | 86.81 | 33.08 | 164.07 | 48.58 | 52.24 | 0.43 |

| MB8 | 63.97 | 81.07 | 27.30 | 163.44 | 47.94 | 51.55 | 0.58 |

| pPLA | 64.28 | - | - | 164.25 | 44.13 | 47.45 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzierzkowska, E.; Scisłowska-Czarnecka, A.; Kudzin, M.; Boguń, M.; Szatkowski, P.; Gajek, M.; Kornaus, K.; Chadzinska, M.; Stodolak-Zych, E. Effects of Process Parameters on Structure and Properties of Melt-Blown Poly(Lactic Acid) Nonwovens for Skin Regeneration. J. Funct. Biomater. 2021, 12, 16. https://doi.org/10.3390/jfb12010016

Dzierzkowska E, Scisłowska-Czarnecka A, Kudzin M, Boguń M, Szatkowski P, Gajek M, Kornaus K, Chadzinska M, Stodolak-Zych E. Effects of Process Parameters on Structure and Properties of Melt-Blown Poly(Lactic Acid) Nonwovens for Skin Regeneration. Journal of Functional Biomaterials. 2021; 12(1):16. https://doi.org/10.3390/jfb12010016

Chicago/Turabian StyleDzierzkowska, Ewa, Anna Scisłowska-Czarnecka, Marcin Kudzin, Maciej Boguń, Piotr Szatkowski, Marcin Gajek, Kamil Kornaus, Magdalena Chadzinska, and Ewa Stodolak-Zych. 2021. "Effects of Process Parameters on Structure and Properties of Melt-Blown Poly(Lactic Acid) Nonwovens for Skin Regeneration" Journal of Functional Biomaterials 12, no. 1: 16. https://doi.org/10.3390/jfb12010016

APA StyleDzierzkowska, E., Scisłowska-Czarnecka, A., Kudzin, M., Boguń, M., Szatkowski, P., Gajek, M., Kornaus, K., Chadzinska, M., & Stodolak-Zych, E. (2021). Effects of Process Parameters on Structure and Properties of Melt-Blown Poly(Lactic Acid) Nonwovens for Skin Regeneration. Journal of Functional Biomaterials, 12(1), 16. https://doi.org/10.3390/jfb12010016