Design of a Naturally Dyed and Waterproof Biotechnological Leather from Reconstituted Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microorganisms and Means of Maintenance

2.2. BC Culture Conditions, Purification, and Yield

2.3. Water Retention Capacity (WRC)

2.4. Natural Dye Extraction

2.5. Preparation of BC Films for Dyeing

2.6. Dyeing and Natural Dye Fixation Procedure

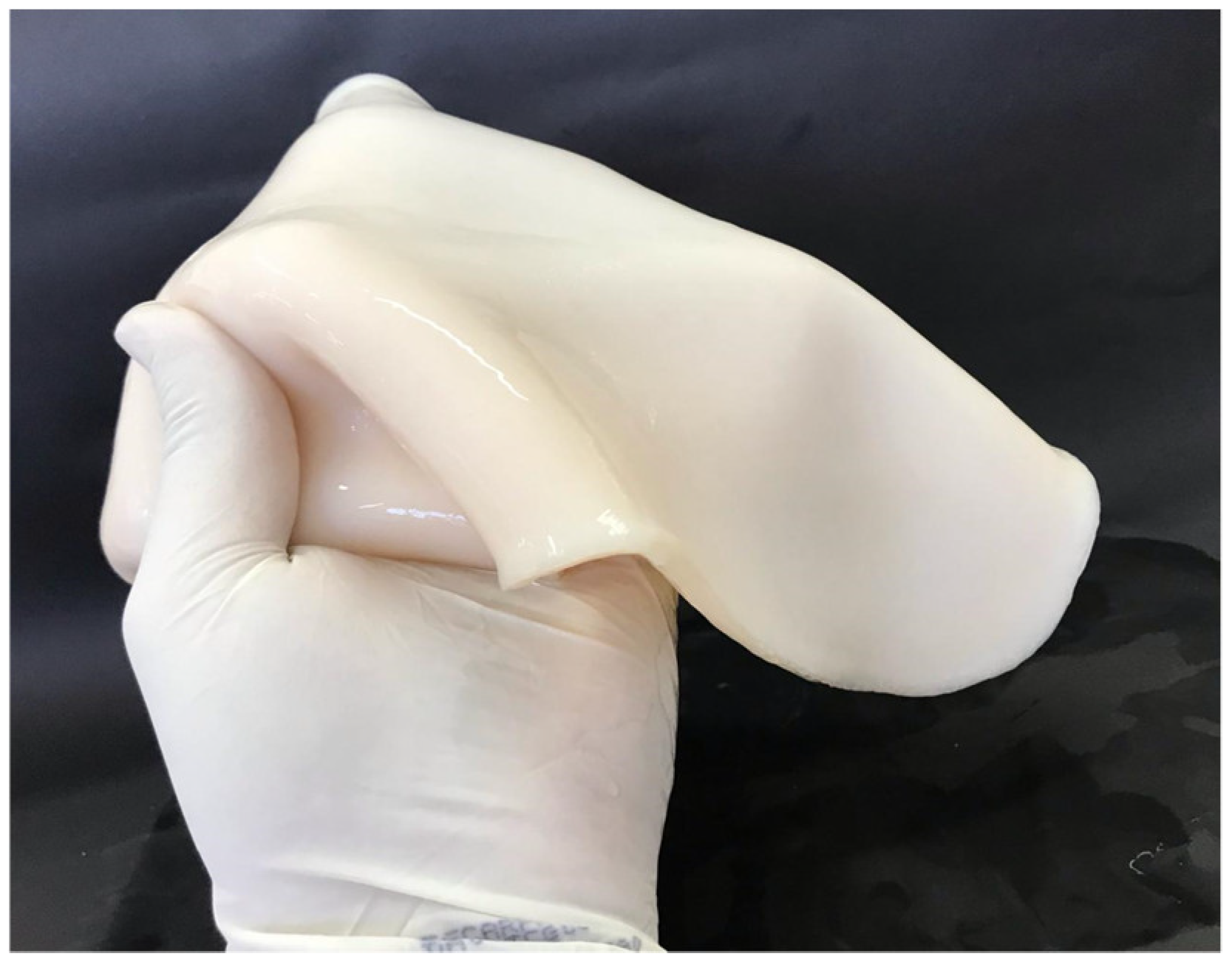

2.7. Shredding, Reconstitution, and Drying

2.8. Waterproofing with Essential Oil and Wax

2.9. Characterisation of Biotechnological Vegan Leathers

2.9.1. Determination of Water Contact Angle and Sorption Index

2.9.2. Swelling Ratio

2.9.3. Scanning Electron Microscopy (SEM)

2.9.4. Thermogravimetric Analysis (TGA)

2.9.5. Flexibility

2.9.6. Mechanical Test

3. Results and Discussion

3.1. BC Yield and Water Retention Capacity

3.2. BC Dyeing, Dye Fixation, and Waterproofing with Essential Oil and Wax

3.3. Water Contact Angle, Swelling Ratio, and Sorption Index

3.4. Scanning Electron Microscopy

3.5. Thermogravimetric Analysis (TGA)

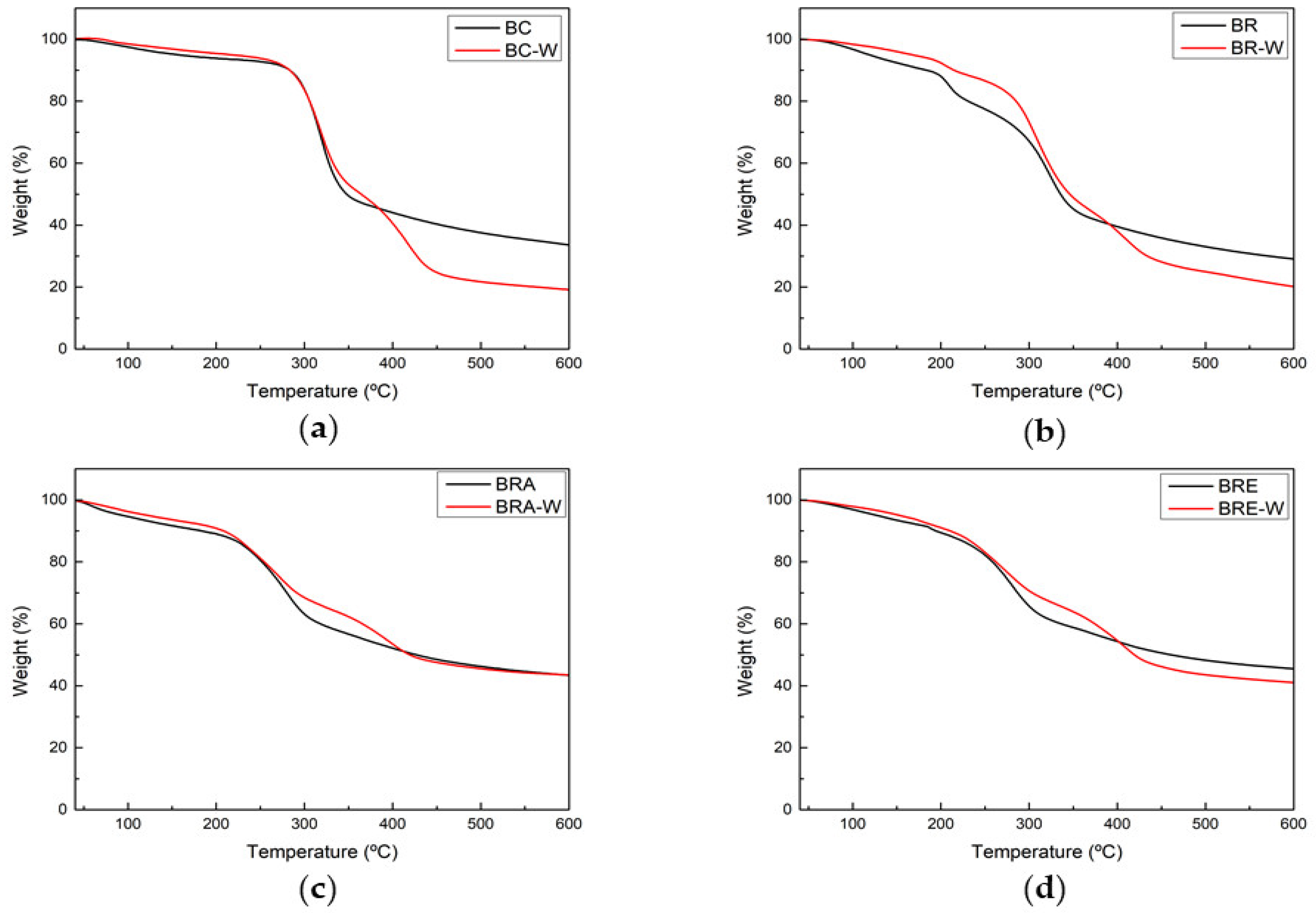

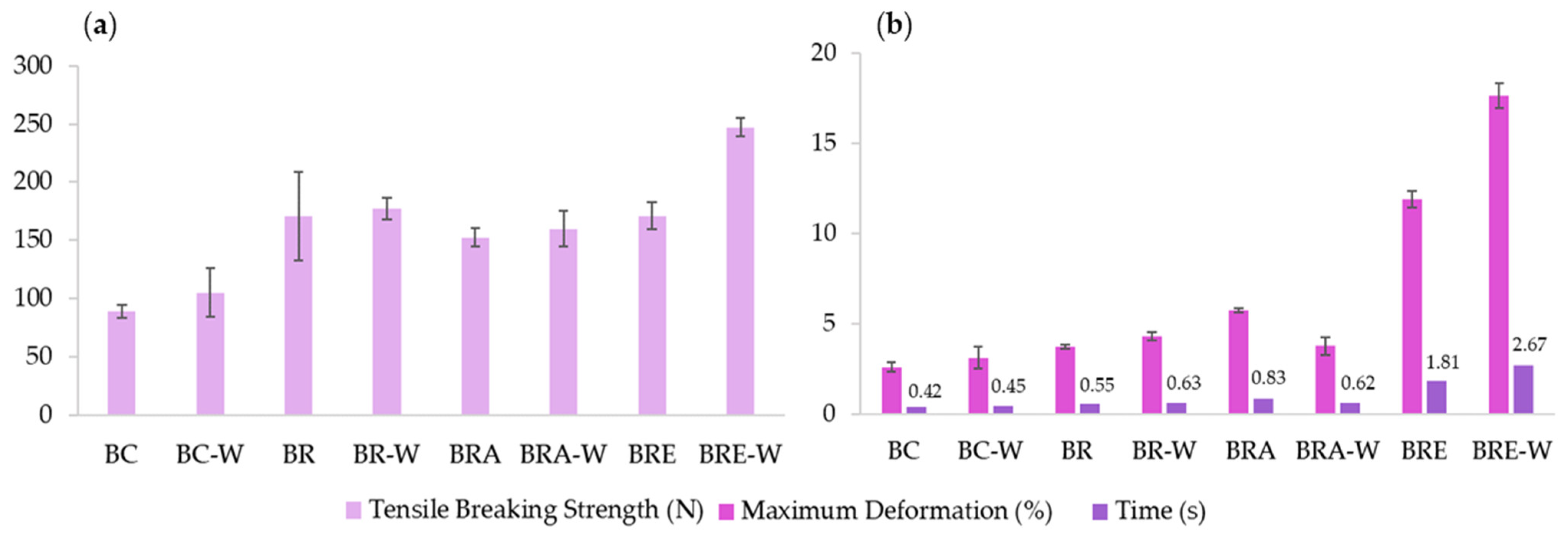

3.6. Flexibility and Mechanical Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Islam, S. Sustainable raw materials. Sustain. Technol. Fash. Text. 2020, 15, 343–357. [Google Scholar] [CrossRef]

- Galdino, C.J.S.; Maia, A.D.M.; Meira, H.M.; Souza, T.C.; Amorim, J.D.P.; Almeida, F.C.G.; Costa, A.F.S.; Sarubbo, L.A. Use of a bacterial cellulose filter for the removal of oil from wastewater. Process Biochem. 2020, 91, 288–296. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Kiruba, T. Bacterial cellulose-A potential material for sustainable eco-friendly fashion products. J. Nat. Fibers 2020, 1, 1–13. [Google Scholar] [CrossRef]

- Fernandes, M.; Souto, A.P.; Dourado, F.; Gama, M. Application of Bacterial Cellulose in the Textile and Shoe Industry: Development of biocomposites. Polysaccharides 2021, 2, 566–581. [Google Scholar] [CrossRef]

- Tabasum, S.; Mahmood, K.; Parveen, B.; Hussain, M. A novel water borne green textile polyurethane dispersions finishes from cotton (Gossypium arboreum) seed oil based polyol used in modification of cellulosic fabrics. Carbohydr. Polym. Technol. Appl. 2021, 2, 100170. [Google Scholar] [CrossRef]

- Costa, A.F.S.; Amorim, J.D.P.; Almeida, F.C.G.; Lima, I.D.; de Paiva, S.C.; Rocha, M.A.V.; Vinhas, G.M.; Sarubbo, L.A. Dyeing of bacterial cellulose films using plant-based natural dyes. Int. J. Biol. Macromol. 2019, 121, 580–587. [Google Scholar] [CrossRef]

- Albuquerque, R.M.B.; Meira, H.M.; Silva, I.D.; Silva, C.J.G.; Almeida, F.C.G.; Amorim, J.D.P.; Vinhas, G.M.; Costa, A.F.S.; Sarubbo, L.A. Production of a bacterial cellulose/poly(3-hydroxybutyrate) blend activated with clove essential oil for food packaging. Polym. Polym. Compos. 2020, 29, 259–270. [Google Scholar] [CrossRef]

- Amorim, J.D.P.; Nascimento, H.A.; Silva Junior, C.J.G.; Medeiros, A.D.M.; Silva, I.D.L.; Costa, A.F.S.; Vinhas, G.M.; Sarubbo, L.A. Obtainment of bacterial cellulose with added propolis extract for cosmetic applications. Polym. Eng. Sci. 2021, 62, 565–575. [Google Scholar] [CrossRef]

- Qasim, U.; Osman, A.I.; Al-Muhtaseb, A.H.; Farrell, C.; Al-Abri, M.; Ali, M.; Vo, D.-V.N.; Jamil, F.; Rooney, D.W. Renewable cellulosic nanocomposites for food packaging to avoid fossil fuel plastic pollution: A review. Environ. Chem. Lett. 2020, 19, 613–641. [Google Scholar] [CrossRef]

- Medeiros, A.D.M.; Silva Junior, C.J.G.; Amorim, J.D.P.; Nascimento, H.A.; Converti, A.; Costa, A.F.S.; Sarubbo, L.A. Biocellulose for Treatment of Wastewaters Generated by Energy Consuming Industries: A review. Energies 2021, 14, 5066. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Amorim, J.D.P.; Souza, K.C.; Duarte, C.R.; Duarte, I.S.; Ribeiro, F.A.S.; Silva, G.S.; Farias, P.M.A.; Stingl, A.; Costa, A.F.S.; Vinhas, G.M. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering: A review. Environ. Chem Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Gelin, K.; Bodin, A.; Gatenholm, P.; Mihranyan, A.; Edwards, K.; Strømme, M. Characterization of water in bacterial cellulose using dielectric spectroscopy and electron microscopy. Polymer 2007, 48, 7623–7631. [Google Scholar] [CrossRef]

- Ng, F.M.C.; Wang, P.W. Natural Self-grown Fashion from Bacterial Cellulose: A paradigm shift design approach in fashion creation. Des. J. 2016, 19, 837–855. [Google Scholar] [CrossRef]

- Ng, M.C.F.; Wang, W. A Study of the Receptivity to Bacterial Cellulosic Pellicle for Fashion. Res. J. Text. Appar. 2015, 19, 65–69. [Google Scholar] [CrossRef]

- Galdino, C.J.S.; Medeiros, A.D.M.; Amorim, J.D.P.; Nascimento, H.A.; Henrique, M.A.; Costa, A.F.S.; Sarubbo, L.A. The Future of Sustainable Fashion: Bacterial cellulose biotextile naturally dyed. Chem. Eng. Trans. 2021, 86, 1333–1338. [Google Scholar] [CrossRef]

- Domskiene, J.; Sederaviciute, F.; Simonaityte, J. Kombucha bacterial cellulose for sustainable fashion. Int. J. Cloth. Sci. 2019, 31, 644–652. [Google Scholar] [CrossRef]

- Villarreal-Soto, S.A.; Beaufort, S.; Bouajila, J.; Souchard, J.-P.; Taillandier, P. Understanding Kombucha Tea Fermentation: A review. J. Food Sci. 2018, 83, 580–588. [Google Scholar] [CrossRef]

- Marin, E.; Rojas, J. Preparation and characterization of crosslinked poly (vinyl) alcohol films with waterproof properties. Int. J. Pharm. Pharm. Sci. 2015, 7, 242–248. [Google Scholar]

- Kamiński, K.; Jarosz, M.; Grudzień, J.; Pawlik, J.; Zastawnik, F.; Pandyra, P.; Kołodziejczyk, A.M. Hydrogel bacterial cellulose: A path to improved materials for new eco-friendly textiles. Cellulose 2020, 27, 5353–5365. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Zhang, B.; Zhao, J.; Chen, H. Improved process for the production of cellulose sulfate using sulfuric acid/ethanol solution. Carbohydr. Polym. 2013, 95, 332–337. [Google Scholar] [CrossRef] [PubMed]

- Rethwisch, D.G.J.; William, D.C. Ciência e Engenharia de Materiais: Uma Introdução, 9th ed.; LTC: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Salari, M.; Khiabani, S.M.; Mokarram, R.R.; Ghanbarzadeh, B.; Kafil, S.H. Preparation and characterization of cellulose nanocrystals from bacterial cellulose produced in sugar beet molasses and cheese whey media. Int. J. Biol. Macromol. 2019, 122, 280–288. [Google Scholar] [CrossRef] [PubMed]

- Ul-Islam, M.; Ullah, M.W.; Khan, S.; Park, J.K. Production of bacterial cellulose from alternative cheap and waste resources: A step for cost reduction with positive environmental aspects. Korean J. Chem. Eng. 2020, 37, 925–937. [Google Scholar] [CrossRef]

- Costa, A.F.S.; Almeida, F.C.G.; Vinhas, G.M.; Sarubbo, L.A. Production of bacterial cellulose by Gluconacetobacter hansenii using corn steep liquor as nutrient sources. Front. Microbiol. 2017, 8, 2017. [Google Scholar] [CrossRef]

- Nascimento, H.A.; Amorim, J.D.P.; Silva, C.J.G.J.; Medeiros, A.D.M.; Costa, A.F.S.; Napoleão, D.C.; Vinhas, G.M.; Sarubbo, L.A. Influence of gamma irradiation on the properties of bacterial cellulose produced with concord grape and red cabbage extracts. Curr. Res. Biotechnol. 2022, 4, 119–128. [Google Scholar] [CrossRef]

- Verma, M.; Gahlot, N.; Singh, S.S.J.; Rose, N.M. UV protection and antibacterial treatment of cellulosic fibre (cotton) using chitosan and onion skin dye. Carbohydr. Polym. 2021, 257, 117612. [Google Scholar] [CrossRef]

- Maulik, R.S.; Chakraborty, L.; Pandit, P. Evaluation of Cellulosic and Protein Fibers for Coloring and Functional Finishing Properties Using Simultaneous Method with Eucalyptus Bark Extract as a Natural Dye. Fibers Polym. 2021, 22, 711–719. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, Q.; Zhang, Y.; Hou, X.; Zhang, Y. Obtaining colored patterns on polyamide fabric with laser pretreatment and pomegranate peel dyeing. Text. Res. J. 2022, 1, 405175221076038. [Google Scholar] [CrossRef]

- Chan, C.K.; Shin, J.; Jiang, S.X.K. Development of Tailor-Shaped Bacterial Cellulose Textile Cultivation Techniques for Zero-Waste Design. Cloth. Text. Res. J. 2017, 36, 33–44. [Google Scholar] [CrossRef]

- Classen, E. Comfort testing of textiles. Adv. Charact. Test. Text. 2018, 3, 59–69. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Wahid, F.; Zhao, X.; Qin, X.; Bai, H.; Xie, Y.-Y.; Zhong, C.; Jia, S. Sustainable, superhydrophobic membranes based on bacterial cellulose for gravity-driven oil/water separation. Carbohydr. Polym. 2021, 253, 117220. [Google Scholar] [CrossRef]

- Bashari, A.; Amir, H.S.K.; Salamatipour, N. Bioinspired and green water repellent finishing of textiles using carnauba wax and layer-by-layer technique. J. Text. Inst. 2019, 111, 1148–1158. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Aarthi, T.; Shree, C.A.A.; Haridharani, P.; Shruthi, V.; Vaishnikka, R.L. Development and Characterization of Self -assembled Bacterial Cellulose Nonwoven Film. J. Nat. Fibers 2019, 18, 1857–1870. [Google Scholar] [CrossRef]

- Xu, K.; Li, Q.; Xie, L.; Shi, Z.; Su, G.; Harper, D.; Tang, Z.; Zhou, J.; Du, G.; Wang, S. Novel flexible, strong, thermal-stable, and high-barrier switchgrass-based lignin-containing cellulose nanofibrils/chitosan biocomposites for food packaging. Ind. Crop. Prod. 2022, 179, 114661. [Google Scholar] [CrossRef]

- Zhu, P.; Sui, S.; Wang, B.; Sun, K.; Sun, G. A study of pyrolysis and pyrolysis products of flame-retardant cotton fabrics by DSC, TGA, and PY–GC–MS. J Anal. Appl. Pyrol. 2004, 71, 645–655. [Google Scholar] [CrossRef]

- Pan, Y.F.; Xiao, H.N.; Xu, J.X.; Zhao, Y. Cellulose Fibers Modified with Starch-Based Microcapsules for Green Packaging. Adv. Mater. Res. 2013, 781–784, 2734–2737. [Google Scholar] [CrossRef]

- Silveira, M.P.; Silva, H.C.; Pimentel, I.C.; Poitevin, C.G.; Stuart, A.K.C.; Carpiné, D.; Jorge, L.M.M.; Jorge, R.M.M. Development of active cassava starch cellulose nanofiber-based films incorporated with natural antimicrobial tea tree essential oil. J. Appl. Polym. Sci. 2019, 137, 48726. [Google Scholar] [CrossRef]

- Ismar, E.; Bahadir, K.S.; Kalaoglu, F.; Koncar, V. Futuristic Clothes: Electronic Textiles and Wearable Technologies. Glob. Chall. 2020, 4, 1900092. [Google Scholar] [CrossRef] [Green Version]

- Gorgieva, S.; Trček, J. Bacterial Cellulose: Production, Modification and Perspectives in Biomedical Applications. Nanomaterials 2019, 9, 1352. [Google Scholar] [CrossRef] [Green Version]

| BC 14 Days | Yield (g/L) Mean ± Standard Deviation | WRC (%) Mean ± Standard Deviation |

|---|---|---|

| Wet weight | 422.12 ± 15.26 | 97.62 ± 0.39 |

| Dry weight | 10.07 ± 1.97 |

| Sample | Abbreviation |

|---|---|

| Pure bacterial cellulose | BC |

| Waterproofed bacterial cellulose | BC-W |

| Reconstituted bacterial cellulose | BR |

| Water-proofed reconstituted bacterial cellulose | BR-W |

| Reconstituted bacterial cellulose dyed with onion and pomegranate | BRA |

| Water-proofed reconstituted bacterial cellulose dyed with onion and pomegranate | BRA-W |

| Reconstituted bacterial cellulose dyed with eucalyptus | BRE |

| Water-proofed reconstituted bacterial cellulose dyed with eucalyptus | BRE-W |

| Sample | Water Contact Angle (o) | Swelling Ratio (%) | Sorption Index (s) |

|---|---|---|---|

| BC | 43.26 | 57.92 ± 3.12 | 76.32 ± 3.12 |

| BC-W | 67.64 | 3.81± 0.46 | 600 > |

| BR | 38.58 | 33.32 ± 4.32 | 331.22 ± 12.34 |

| BR-W | 80.72 | 16.77 ± 2.33 | 600 > |

| BRA | 40.60 | 34.64 ± 1.47 | 293.32 ± 26.62 |

| BRA-W | 76.32 | 15.85 ± 2.86 | 600 > |

| BRE | 52.22 | 31.78 ± 4.74 | 312.43 ± 17.29 |

| BRE-W | 83.96 | 18.11 ± 1.12 | 600 > |

| Samples | Stage 1 | Stage 2 | Stage 3 | Mass Loss at 600 °C (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tmax | Tonset | Tendset | Tmax | Tonset | Tendset | Tmax | Tonset | Tendset | ||

| BC | 301.31 | 94.72 | 320.84 | 339.04 | 322.04 | 416.30 | - | - | - | 33.78 |

| BC-W | 289.62 | 91.22 | 323.01 | 341.21 | 325.78 | 381.59 | 447.53 | 390.87 | 517.92 | 20.55 |

| BR | 283.23 | 80.05 | 326.14 | 349.77 | 328.91 | 423.90 | - | -- | -- | 29.24 |

| BR-W | 269.13 | 87.59 | 327.71 | 342.66 | 327.71 | 384.00 | 440.65 | 390.98 | 503.81 | 20.30 |

| BRA | 236.59 | 83.30 | 275.16 | 312.25 | 275.64 | 420.52 | - | - | -- | 42.87 |

| BRA-W | 224.05 | 87.08 | 298.42 | 369.34 | 298.90 | 404.37 | 429.19 | 405.21 | 504.65 | 43.00 |

| BRE | 245.51 | 84.35 | 271.90 | 309.27 | 272.26 | 424.96 | - | - | - | 45.42 |

| BRE-W | 216.25 | 85.22 | 293.00 | 372.07 | 300.47 | 406.47 | 437.52 | 406.68 | 495.32 | 40.31 |

| Sample | Tensile Strength (N) | Maximum Deformation (%) | Time (s) |

|---|---|---|---|

| BC | 89.04 ± 11.04 | 2.61 ± 0.51 | 0.41 ± 0.05 |

| BC-W | 105.11 ± 42.02 | 3.12 ± 1.19 | 0.45 ± 0.15 |

| BR | 171.01 ± 76.11 | 3.73 ± 0.23 | 0.55 ± 0.04 |

| BR-W | 177.33 ± 18.55 | 4.27 ± 0.46 | 0.63 ± 0.04 |

| BRA | 152.53 ± 15.52 | 5.73 ± 0.23 | 0.83 ± 0.04 |

| BRA-W | 160.02 ± 30.85 | 3.77 ± 0.96 | 0.62 ± 0.11 |

| BRE | 171.07 ± 23.51 | 11.87 ± 0.93 | 1.81 ± 0.14 |

| BRE-W | 247.21 ± 16.52 | 17.63 ± 1.38 | 2.67 ± 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva Junior, C.J.G.; de Amorim, J.D.P.; de Medeiros, A.D.M.; de Holanda Cavalcanti, A.K.L.; do Nascimento, H.A.; Henrique, M.A.; do Nascimento Maranhão, L.J.C.; Vinhas, G.M.; de Oliveira Souto Silva, K.K.; de Santana Costa, A.F.; et al. Design of a Naturally Dyed and Waterproof Biotechnological Leather from Reconstituted Cellulose. J. Funct. Biomater. 2022, 13, 49. https://doi.org/10.3390/jfb13020049

da Silva Junior CJG, de Amorim JDP, de Medeiros ADM, de Holanda Cavalcanti AKL, do Nascimento HA, Henrique MA, do Nascimento Maranhão LJC, Vinhas GM, de Oliveira Souto Silva KK, de Santana Costa AF, et al. Design of a Naturally Dyed and Waterproof Biotechnological Leather from Reconstituted Cellulose. Journal of Functional Biomaterials. 2022; 13(2):49. https://doi.org/10.3390/jfb13020049

Chicago/Turabian Styleda Silva Junior, Claudio José Galdino, Julia Didier Pedrosa de Amorim, Alexandre D’Lamare Maia de Medeiros, Anantcha Karla Lafaiete de Holanda Cavalcanti, Helenise Almeida do Nascimento, Mariana Alves Henrique, Leonardo José Costa do Nascimento Maranhão, Glória Maria Vinhas, Késia Karina de Oliveira Souto Silva, Andréa Fernanda de Santana Costa, and et al. 2022. "Design of a Naturally Dyed and Waterproof Biotechnological Leather from Reconstituted Cellulose" Journal of Functional Biomaterials 13, no. 2: 49. https://doi.org/10.3390/jfb13020049

APA Styleda Silva Junior, C. J. G., de Amorim, J. D. P., de Medeiros, A. D. M., de Holanda Cavalcanti, A. K. L., do Nascimento, H. A., Henrique, M. A., do Nascimento Maranhão, L. J. C., Vinhas, G. M., de Oliveira Souto Silva, K. K., de Santana Costa, A. F., & Sarubbo, L. A. (2022). Design of a Naturally Dyed and Waterproof Biotechnological Leather from Reconstituted Cellulose. Journal of Functional Biomaterials, 13(2), 49. https://doi.org/10.3390/jfb13020049