Numerical Simulation of Dynamic Degradation and Fatigue Damage of Degradable Zinc Alloy Stents

Abstract

:1. Introduction

2. Materials and Methods

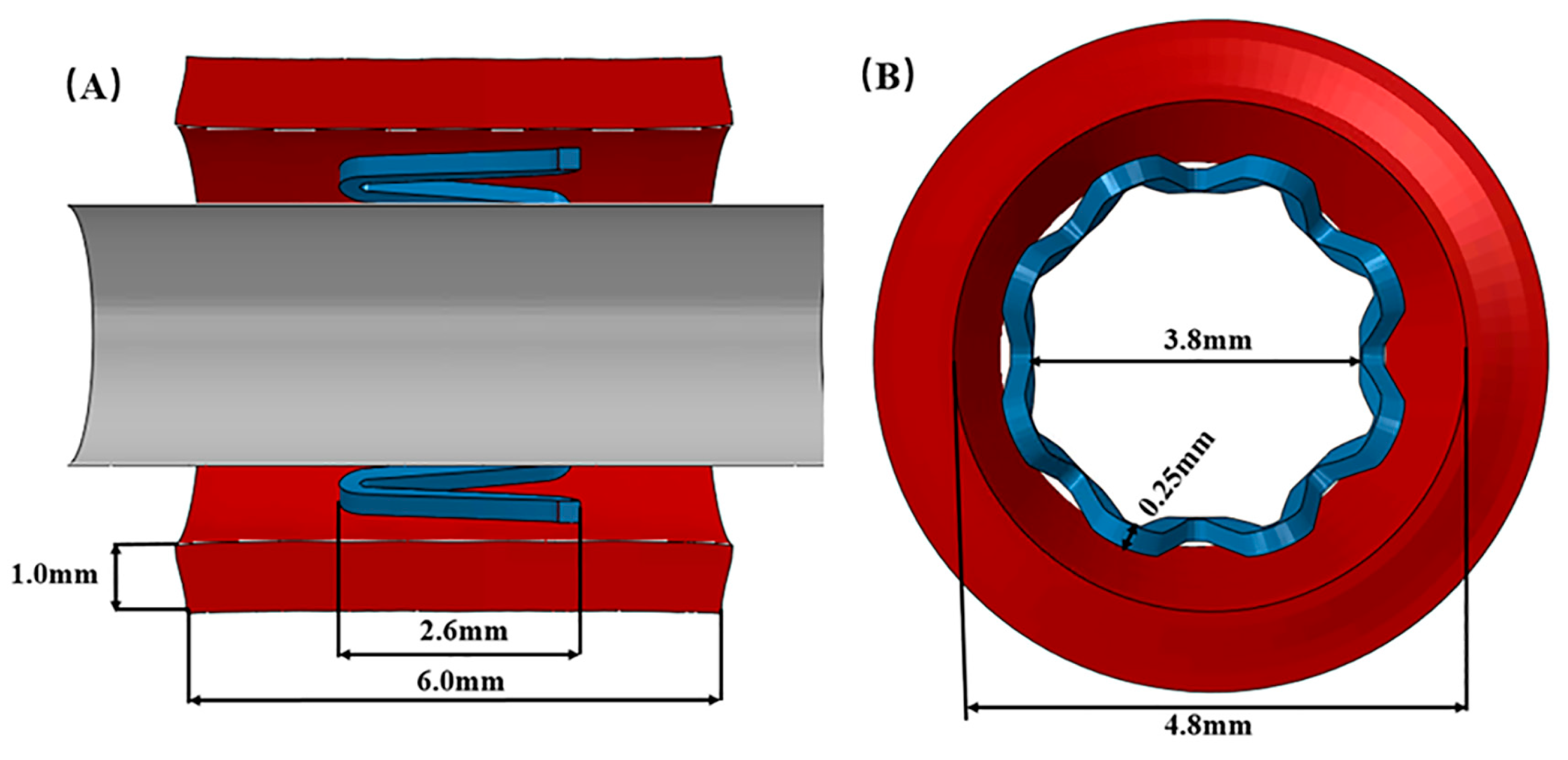

2.1. Model Construction and Setting of Material Properties

2.2. Stent Expansion-Recoil and Pulsatile Compression Loading

2.3. Corrosion Fatigue Algorithm Model

2.4. Grouping of Corrosion Fatigue Model

3. Results

3.1. Stress Analysis of the Stent

3.2. Contour of the Damage Field of the Stent

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Katritsis, D.G.; Meier, B. Percutaneous coronary intervention for stable coronary artery disease. J. Am. Coll. Cardiol. 2008, 52, 889–893. [Google Scholar] [CrossRef]

- Zhou, C.; Feng, X.Y.; Shi, Z.Z.; Song, C.X.; Cui, X.S.; Zhang, J.W.; Li, T.; Toft, E.S.; Ge, J.B.; Wang, L.N. Research on elastic recoil and restoration of vessel pulsatility of Zn-Cu biodegradable coronary stents. Biomed. Eng.-Biomed. Tech. 2020, 65, 219–227. [Google Scholar] [CrossRef]

- Wang, C.; Yu, Z.T.; Cui, Y.J.; Zhang, Y.F.; Yu, S.; Qu, G.Q.; Gong, H.B. Processing of a Novel Zn Alloy Micro-Tube for Biodegradable Vascular Stent Application. J. Mater. Sci. Technol. 2016, 32, 925–929. [Google Scholar] [CrossRef]

- Niu, J.L.; Tang, Z.B.; Huang, H.; Pei, J.; Zhang, H.; Yuan, G.Y.; Ding, W.J. Research on a Zn-Cu alloy as a biodegradable material for potential vascular stents application. Mater. Sci. Eng. C-Mater. Biol. Appl. 2016, 69, 407–413. [Google Scholar] [CrossRef] [PubMed]

- Cockerill, I.; Su, Y.C.; Sinha, S.; Qin, Y.-X.; Zheng, Y.F.; Young, M.L.; Zhu, D.H. Porous zinc scaffolds for bone tissue engineering applications: A novel additive manufacturing and casting approach. Mater. Sci. Eng. C-Mater. Biol. Appl. 2020, 110, 110738. [Google Scholar] [CrossRef] [PubMed]

- Shojaei, S.; Shahgholi, M.; Ksrimipour, A. The effects of atomic percentage and size of Zinc nanoparticles, and atomic porosity on thermal and mechanical properties of reinforced calcium phosphate cement by molecular dynamics simulation. J. Mech. Behav. Biomed. Mater. 2023, 141, 105785. [Google Scholar] [CrossRef]

- Zhuang, Y.; Liu, Q.C.; Jia, G.Z.; Li, H.L.; Yuan, G.Y.; Yu, H.B. A Biomimetic Zinc Alloy Scaffold Coated with Brushite for Enhanced Cranial Bone Regeneration. ACS Biomater. Sci. Eng. 2021, 7, 893–903. [Google Scholar] [CrossRef] [PubMed]

- He, Y.H.; Tao, H.R.; Zhang, Y.; Jiang, Y.; Zhang, S.X.; Zhao, C.L.; Li, J.N.; Zhang, B.L.; Song, Y.; Zhang, X.N. Biocompatibility of bio-Mg-Zn alloy within bone with heart, liver, kidney and spleen. Chin. Sci. Bull. 2009, 54, 484–491. [Google Scholar] [CrossRef]

- Umeda, H.; Gochi, T.; Iwase, M.; Izawa, H.; Shimizu, T.; Ishiki, R.; Inagaki, H.; Toyama, J.; Yokota, M.; Murohara, T. Frequency, predictors and outcome of stent fracture after sirolimus-eluting stent implantation. Int. J. Cardiol. 2009, 133, 321–326. [Google Scholar] [CrossRef]

- Chung, W.-S.; Park, C.-S.; Seung, K.-B.; Kim, P.-J.; Lee, J.-M.; Koo, B.-K.; Jang, Y.-S.; Yang, J.-Y.; Yoon, J.-H.; Kim, D.-I.; et al. The incidence and clinical impact of stent strut fractures developed after drug-eluting stent implantation. Int. J. Cardiol. 2008, 125, 325–331. [Google Scholar] [CrossRef]

- Kuramitsu, S.; Iwabuchi, M.; Yokoi, H.; Domei, T.; Sonoda, S.; Hiromasa, T.; Morinaga, T.; Kobayashi, Y.; Ohe, K.; Goya, K.; et al. Incidence and Clinical Impact of Stent Fracture After the Nobori Biolimus-Eluting Stent Implantation. J. Am. Heart Assoc. 2014, 3, e000703. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, D.D.; Liao, Y.H.; Yao, X.D.; Ruan, Y.H.; Zou, K.; Liao, H.H.; Ding, J.W.; Qin, H.; Yu, Z.Z.; et al. Incidence of coronary drug-eluting stent fracture: A systematic review and meta-analysis. Front. Cardiovasc. Med. 2022, 9, 925912. [Google Scholar] [CrossRef] [PubMed]

- Co, N.E.C.; Burns, J.T. Effects of macro-scale corrosion damage feature on fatigue crack initiation and fatigue behavior. Int. J. Fatigue 2017, 103, 234–247. [Google Scholar] [CrossRef]

- Shen, Z.Q.; Zhao, M.; Zhou, X.C.; Yang, H.T.; Liu, J.N.; Guo, H.; Zheng, Y.F.; Yang, J.-A. A numerical corrosion-fatigue model for biodegradable Mg alloy stents. Acta Biomater. 2019, 97, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Gastaldi, D.; Sassi, V.; Petrini, L.; Vedani, M.; Trasatti, S.; Migliavacca, F. Continuum damage model for bioresorbable magnesium alloy devices—Application to coronary stents. J. Mech. Behav. Biomed. Mater. 2011, 4, 352–365. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.N.; Zhou, W.R.; Zheng, Y.F.; Cheng, Y.; Wei, S.C.; Zhong, S.P.; Xi, T.F.; Chen, L.J. Corrosion fatigue behaviors of two biomedical Mg alloys-AZ91D and WE43-In simulated body fluid. Acta Biomater. 2010, 6, 4605–4613. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Yu, Y.; Hu, X. Fatigue behavior of modified ZK60 magnesium alloy after pre-corrosion under stress-controlled loading. Eng. Fract. Mech. 2022, 260, 108187. [Google Scholar] [CrossRef]

- Raman, R.K.S.; Jafari, S.; Harandi, S.E. Corrosion fatigue fracture of magnesium alloys in bioimplant applications: A review. Eng. Fract. Mech. 2015, 137, 97–108. [Google Scholar] [CrossRef]

- Savaşkan, T.; Aydin, M. Fatigue behaviour of monotectoid-based Zn–Al–Cu alloys in 3.5% NaCl and 1% HCl solutions. Mater. Charact. 2004, 52, 269–278. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Bobbert, F.S.L.; Lietaert, K.; Dong, J.-H.; Leeflang, M.A.; Zhou, J.; Zadpoor, A.A. Corrosion fatigue behavior of additively manufactured biodegradable porous zinc. Acta Biomater. 2020, 106, 439–449. [Google Scholar] [CrossRef]

- Auricchio, F.; Constantinescu, A.; Conti, M.; Scalet, G. Fatigue of Metallic Stents: From Clinical Evidence to Computational Analysis. Ann. Biomed. Eng. 2016, 44, 287–301. [Google Scholar] [CrossRef] [PubMed]

- Dai, T.T.; Ren, L.; Jia, Z.G.; Li, Y.-T.; Li, Y. Crack extension identification based on distributed fiber sensing measurement and optimized support vector regression. Ocean Eng. 2022, 245, 110515. [Google Scholar] [CrossRef]

- Banno, Y.; Kinoshita, K.; Barsoum, Z. Life extension analysis considering crack opening-closing behavior in HFMI-treated welds. Weld World 2023. [CrossRef]

- Salimpour, M.R.; Darvanjooghi, M.H.K.; Abdollahi, A.; Karimipour, A.; Goodarzi, M. Providing a model for Csf according to pool boiling convection heat transfer of water/ferrous oxide nanofluid using sensitivity analysis. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 2867–2881. [Google Scholar] [CrossRef]

- Dai, X.H.; Chen, H.J.; Bagherzadeh, S.A.; Shayan, M.; Akbari, M. Statistical estimation the thermal conductivity of MWCNTs-SiO2/Water-EG nanofluid using the ridge regression method. Physica A 2020, 537, 122782. [Google Scholar]

- Ou, Z.-C.; Ju, Y.-B.; Li, J.-Y.; Duan, Z.-P.; Huang, F.-L. Ubiquitiformal Crack Extension in Quasi-Brittle Materials. Acta Mech. Solida Sin. 2020, 33, 674–691. [Google Scholar] [CrossRef]

- Cui, X.Y.; Peng, K.; Liu, S.C.; Ren, Q.S.; Li, G.Y.; Gu, Z.Y.; Qiao, A.K. A Computational Modelling of the Mechanical Performance of a Bioabsorbable Stent Undergoing Cyclic Loading. Procedia Struct. Integr. 2019, 15, 67–74. [Google Scholar] [CrossRef]

- Martin, D.; Boyle, F. Finite element analysis of balloon-expandable coronary stent deployment: Influence of angioplasty balloon configuration. Int. J. Numer. Meth. Biomed. 2013, 29, 1161–1175. [Google Scholar] [CrossRef]

- Dordoni, E.; Meoli, A.; Wu, W.; Dubini, G.; Migliavacca, F.; Pennati, G.; Petrini, L. Fatigue behaviour of Nitinol peripheral stents: The role of plaque shape studied with computational structural analyses. Med. Eng. Phys. 2014, 36, 842–849. [Google Scholar] [CrossRef]

- Zhang, H.B.; Du, T.M.; Chen, S.L.; Liu, Y.; Yang, Y.J.; Hou, Q.W.; Qiao, A.K. Finite Element Analysis of the Non-Uniform Degradation of Biodegradable Vascular Stents. J. Funct. Biomater. 2022, 13, 152. [Google Scholar] [CrossRef]

- da Costa-Mattos, H.S.; Bastos, I.N.; Gomes, J.A.C.P. A simple model for slow strain rate and constant load corrosion tests of austenitic stainless steel in acid aqueous solution containing sodium chloride. Corros. Sci. 2008, 50, 2858–2866. [Google Scholar] [CrossRef]

- Winzer, N.; Atrens, A.; Song, G.L.; Ghali, E.; Dietzel, W.; Kainer, K.U.; Hort, N.; Blawert, C. A Critical Review of the Stress Corrosion Cracking (SCC) of Magnesium Alloys. Adv. Eng. Mater. 2005, 7, 659–693. [Google Scholar] [CrossRef]

- Grogan, J.A.; O’Brien, B.J.; Leen, S.B.; McHugh, P.E. A corrosion model for bioabsorbable metallic stents. Acta Biomater. 2011, 7, 3523–3533. [Google Scholar] [CrossRef] [PubMed]

- Li, H.F.; Wei, J.L.; Li, S.H.; Liu, Y.Q.; Gu, X.H.; Liu, Z.C.; Yang, S.P. Fatigue life prediction of high-speed train bearings based on the generalized linear cumulative damage theory. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 2112–2120. [Google Scholar] [CrossRef]

- Aydın, M.; Savaskan, T. Fatigue properties of zinc–aluminium alloys in 3.5% NaCl and 1% HCl solutions. Int. J. Fatigue 2004, 26, 103–110. [Google Scholar] [CrossRef]

- Seo, J.; Kwon, S.; Jun, H.; Lee, D. Fatigue crack growth behavior of surface crack in rails. Procedia Eng. 2010, 2, 865–872. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konecná, R.; Pirondi, A. Fatigue crack paths in coarse-grained magnesium. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 237–244. [Google Scholar] [CrossRef]

- Jovicic, G.R.; Vukicevic, A.M.; Filipovic, N.D. Computational Assessment of Stent Durability Using Fatigue to Fracture Approach. J. Med. Devices 2014, 8, 041002. [Google Scholar] [CrossRef]

- Delavar, H.; Mostahsan, A.J.; Ibrahim, H. Corrosion and corrosion-fatigue behavior of magnesium metal matrix composites for bio-implant applications: A review. J. Magnes. Alloys 2023, 11, 1125–1161. [Google Scholar] [CrossRef]

- Bay, R.M.; Schrock, D.J.; Akman, A.M.; Bland, L.G.; Thodla, R.; Locke, J.S. The effect of sensitization and fatigue loading frequency on corrosion fatigue of AA5083-H131. Int. J. Fatigue 2019, 124, 1–9. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lo, I.H. Effects of potential and loading frequency on corrosion fatigue behavior of 2205 duplex stainless steel. Corrosion 2008, 64, 155–163. [Google Scholar] [CrossRef]

| Density | Young’s Modulus | Poisson’s Ratio | Yield Strength | Ultimate Strength |

|---|---|---|---|---|

| 8.5 g/cm3 | 74,500 MPa | 0.3 | 220 MPa | 325 MPa |

| −1.84 | 1.12 | 0.73 | 21.71 | 22 | 21.2 | 4.11 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Zhang, H.; Chen, S.; Du, T.; Zhang, Y.; Qiao, A. Numerical Simulation of Dynamic Degradation and Fatigue Damage of Degradable Zinc Alloy Stents. J. Funct. Biomater. 2023, 14, 547. https://doi.org/10.3390/jfb14110547

Qi J, Zhang H, Chen S, Du T, Zhang Y, Qiao A. Numerical Simulation of Dynamic Degradation and Fatigue Damage of Degradable Zinc Alloy Stents. Journal of Functional Biomaterials. 2023; 14(11):547. https://doi.org/10.3390/jfb14110547

Chicago/Turabian StyleQi, Jing, Hanbing Zhang, Shiliang Chen, Tianming Du, Yanping Zhang, and Aike Qiao. 2023. "Numerical Simulation of Dynamic Degradation and Fatigue Damage of Degradable Zinc Alloy Stents" Journal of Functional Biomaterials 14, no. 11: 547. https://doi.org/10.3390/jfb14110547