Comparative Study of Zirconium Nitride Multilayer Coatings: Crystallinity, In Vitro Oxidation Behaviour and Tribological Properties Deposited via Sputtering and Arc Deposition

Abstract

1. Introduction

2. Materials and Methods

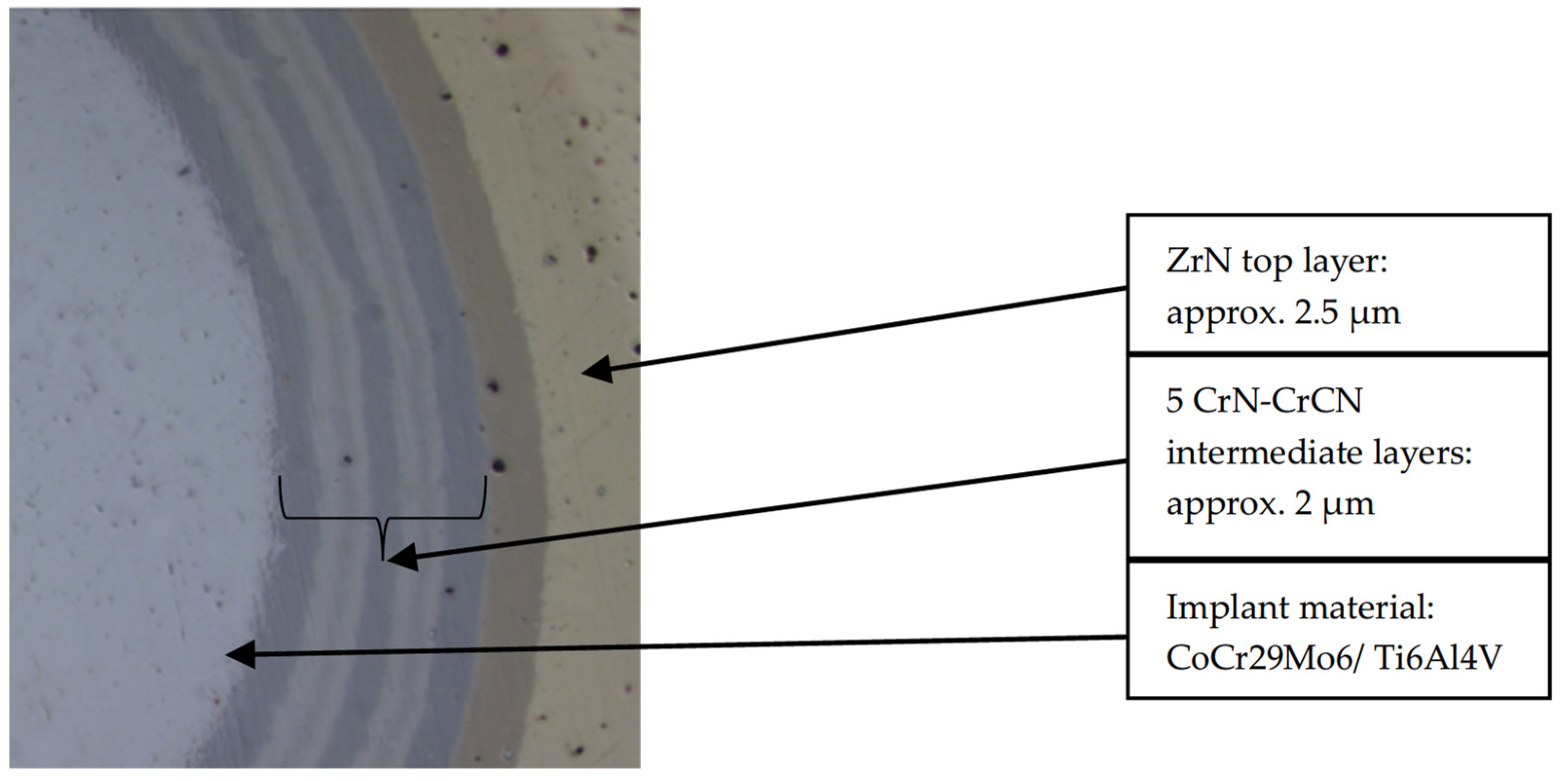

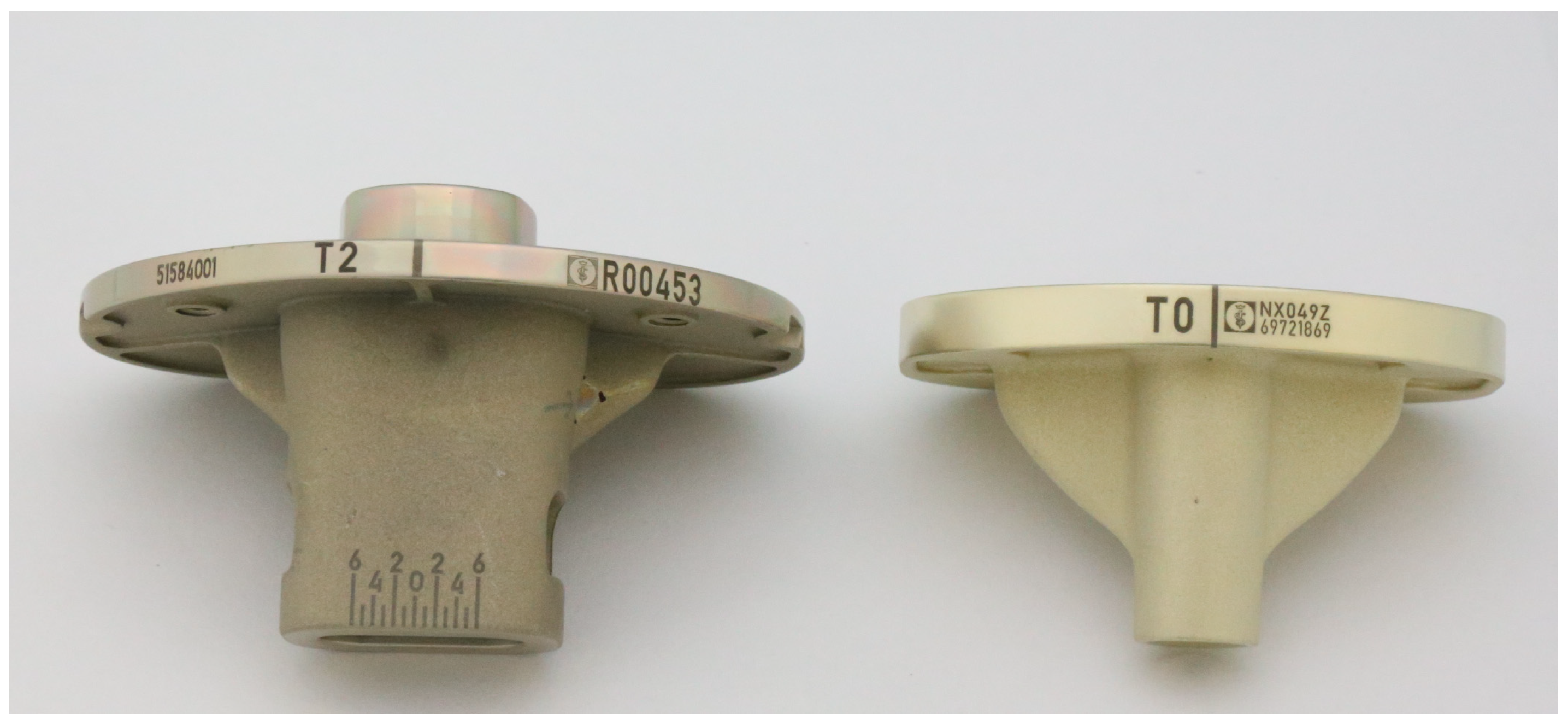

2.1. Sample Preparation

2.2. Oxidation and Characterization

2.3. Coating Characterization

2.4. Tribological Test

3. Results and Discussion

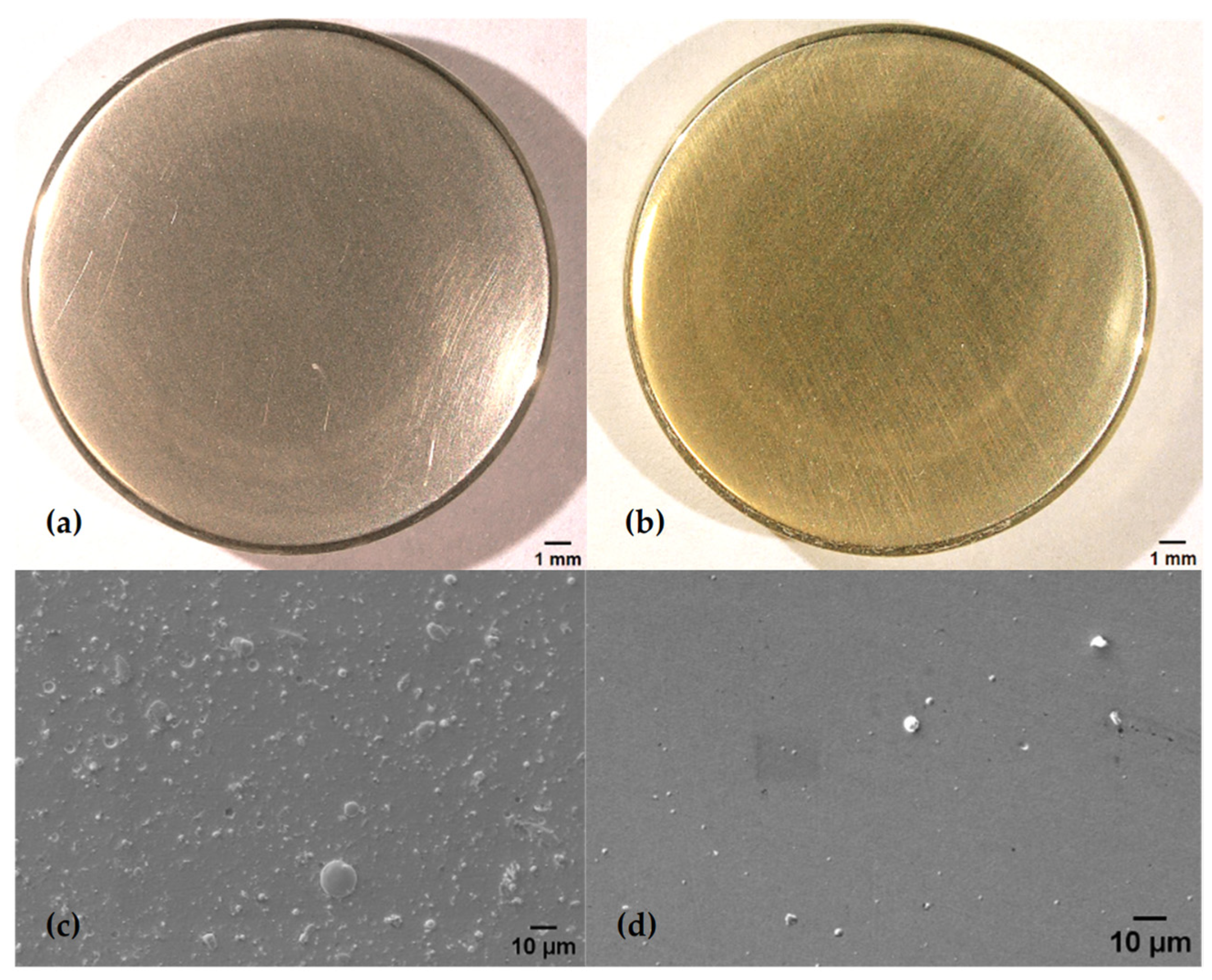

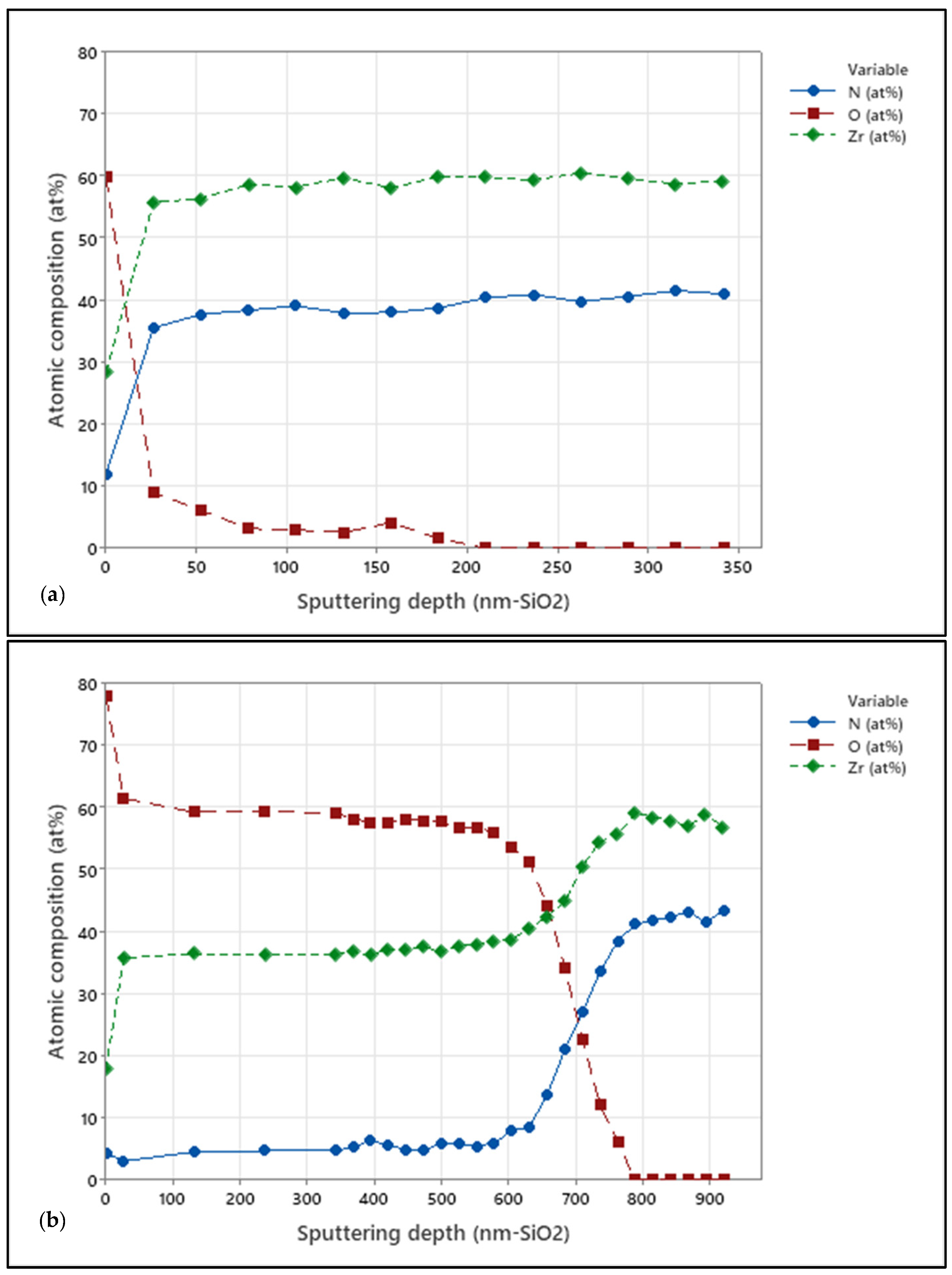

3.1. Oxidation and Surface Characterisation on CoCrMo Substrate Material

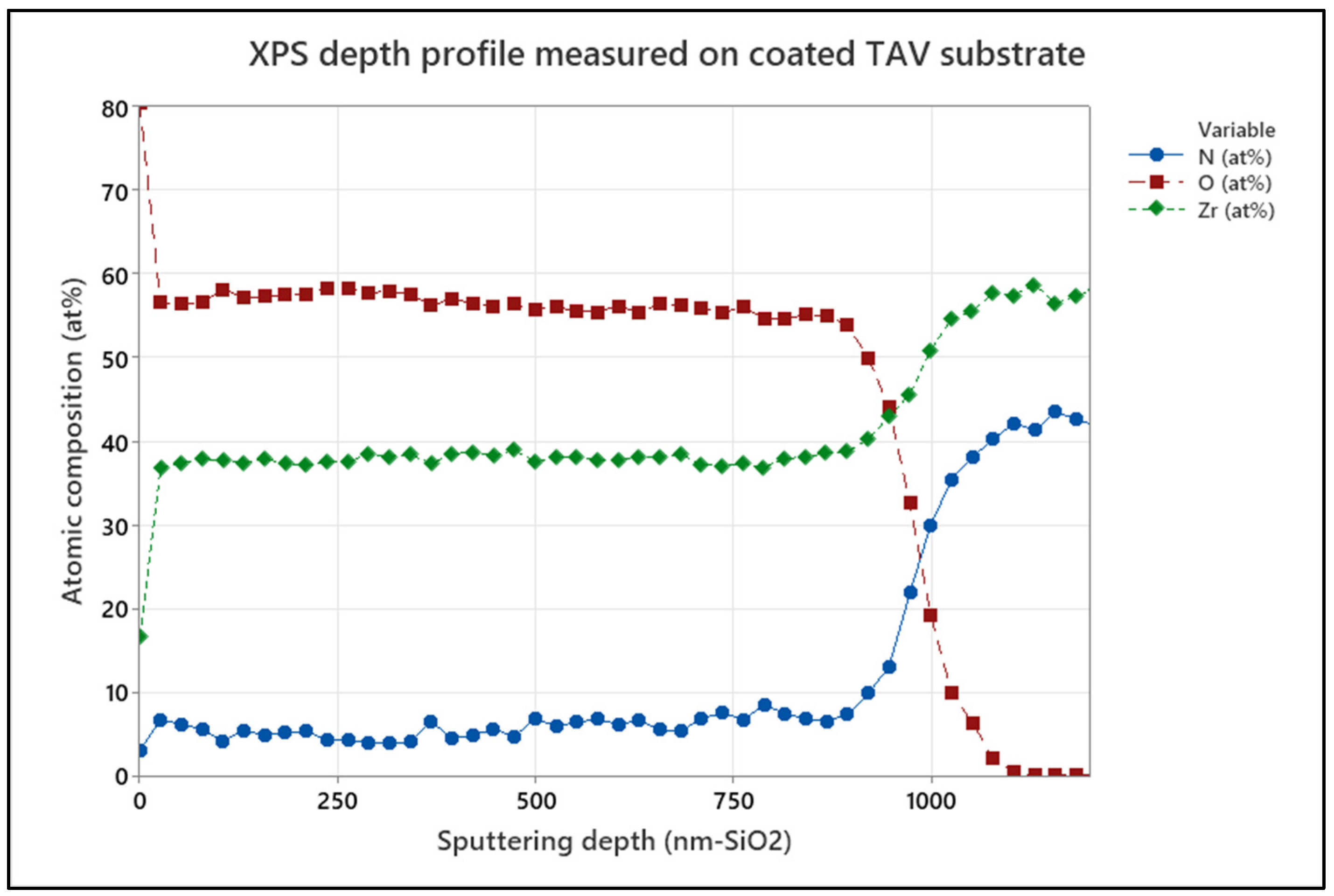

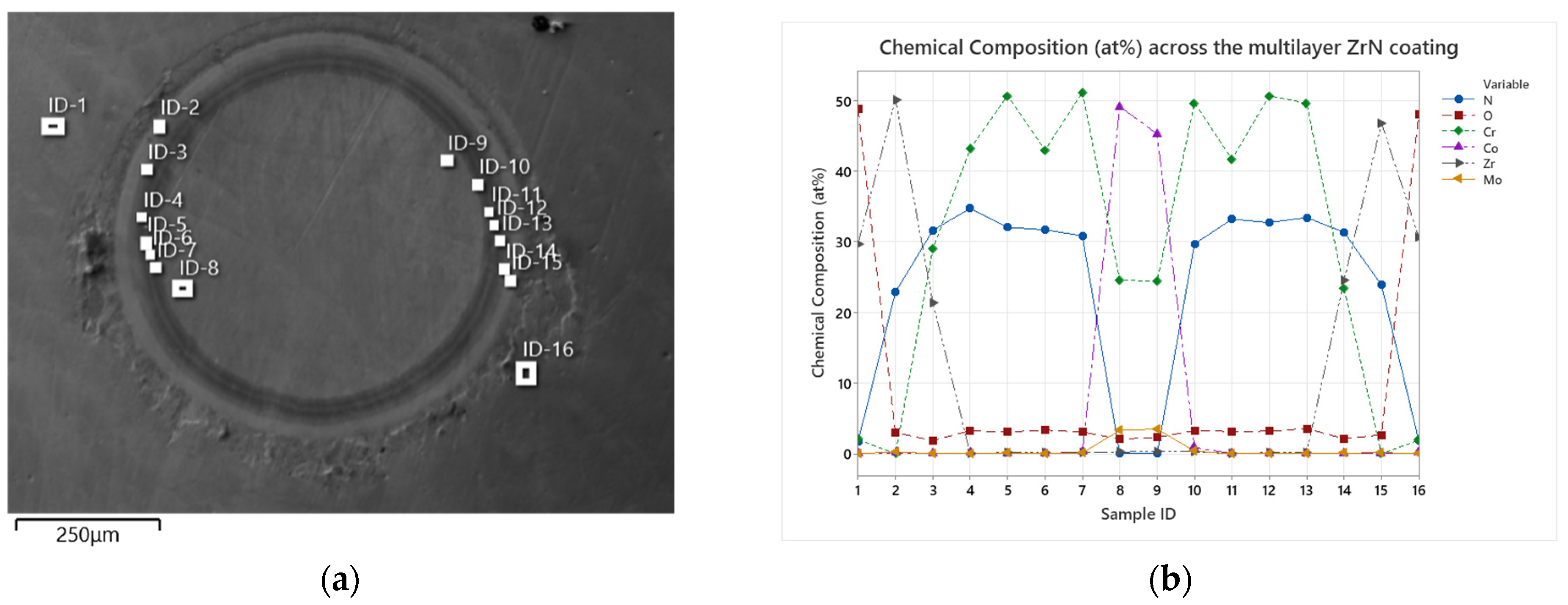

3.2. Oxidation Penetration of Multilayer Coating

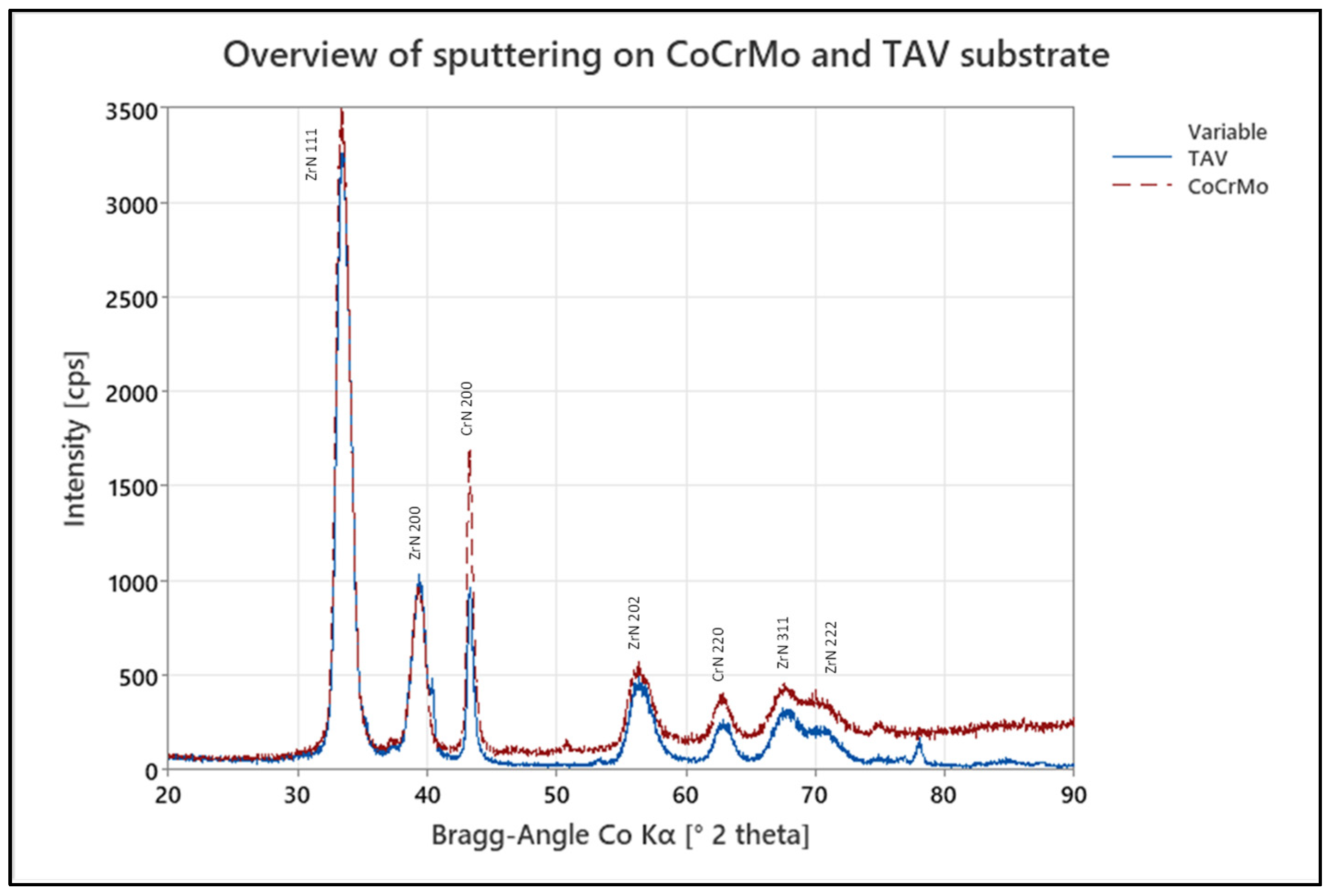

3.3. Effect of Coating Process on Crystalline Structure

3.4. Influence of Substrate Material

3.5. Tribological Results

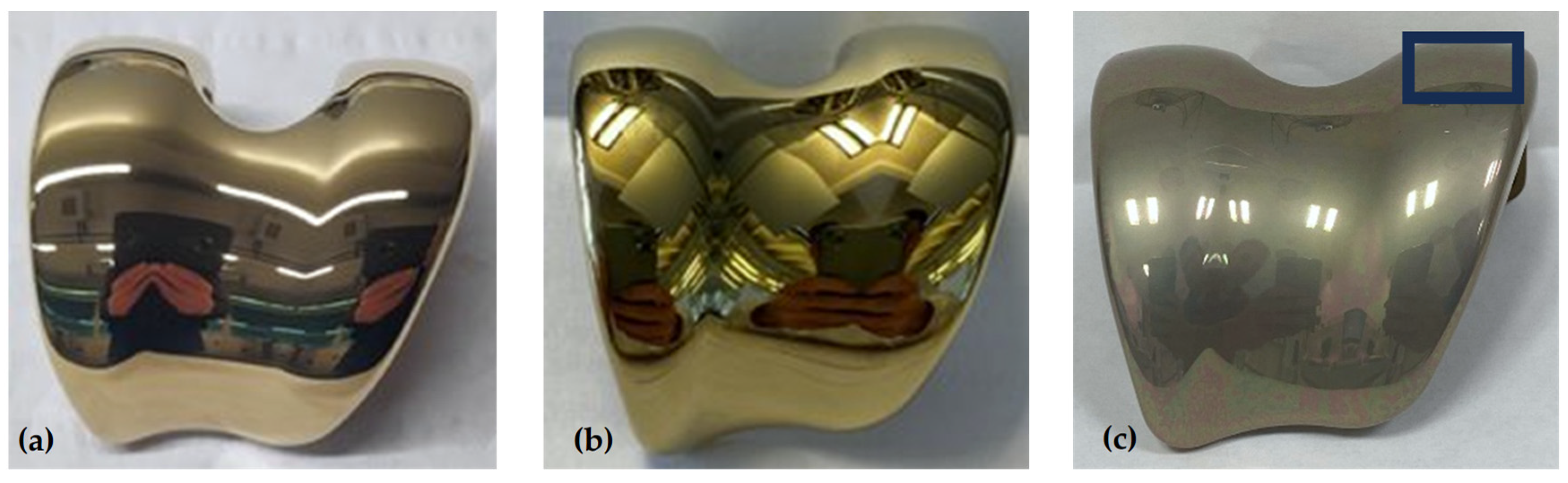

3.6. Basic Application Verification

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Uter, W.; Gefeller, O.; Geier, J.; Schnuch, A. Contact sensitization to cobalt–multifactorial analysis of risk factors based on long-term data of the Information Network of Departments of Dermatology. Contact Dermat. 2014, 71, 326–337. [Google Scholar] [CrossRef] [PubMed]

- Reyna, A.L.P.; Fritz, B.; Schwiesau, J.; Schilling, C.; Summer, B.; Thomas, P.; Grupp, T.M. Metal ion release barrier function and biotribological evaluation of a zirconium nitride multilayer coated knee implant under highly demanding activities wear simulation. J. Biomech. 2018, 79, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Warshaw, E.M.; Belsito, D.V.; Taylor, J.S.; Sasseville, D.; DeKoven, J.G.; Zirwas, M.J.; Fransway, A.F.; Mathias, C.T.; Zug, K.A.; DeLeo, V.A.; et al. North American Contact Dermatitis Group patch test results: 2009 to 2010. Dermat. Contact Atopic Occup. Drug 2013, 24, 50–59. [Google Scholar] [CrossRef] [PubMed]

- Sadoghi, P.; Liebensteiner, M.; Agreiter, M.; Leithner, A.; Böhler, N.; Labek, G. Revision surgery after total joint arthroplasty: A complication-based analysis using worldwide arthroplasty registers. J. Arthroplast. 2013, 28, 1329–1332. [Google Scholar] [CrossRef] [PubMed]

- Boutefnouchet, T.; Vallières, F.; Delisle, J.; Benderdour, M.; Fernandes, J.C. Lymphocyte transformation test reveals low prevalence of true metal hypersensitivity among pre-operative total knee arthroplasty patients. Knee Surg. Sports Traumatol. Arthrosc. Off. J. ESSKA 2022, 30, 4123–4133. [Google Scholar] [CrossRef]

- Kurmis, A.P.; Herman, A.; McIntyre, A.R.; Masri, B.A.; Garbuz, D.S. Pseudotumors and High-Grade Aseptic Lymphocyte-Dominated Vasculitis-Associated Lesions Around Total Knee Replacements Identified at Aseptic Revision Surgery: Findings of a Large-Scale Histologic Review. J. Arthroplast. 2019, 34, 2434–2438. [Google Scholar] [CrossRef] [PubMed]

- Rau, C.; Zimmermann-Stenzel, M.; Parsch, D. Total knee arthroplasty-GPs’ views in Germany: A questionnaire-based study. Orthopäde 2008, 37, 374–380. [Google Scholar] [CrossRef] [PubMed]

- Thomas, P.; Summer, B.; Thyssen, J.P. Hypersensitivity Reactions to Orthopedic Implants. In Contact Dermatitis; Johansen, J.D., Mahler, V., Lepoittevin, J.-P., Frosch, P.J., Eds.; Springer: Cham, Switzerland, 2019; pp. 1–9. [Google Scholar]

- Kretzer, J.P.; Reinders, J.; Sonntag, R.; Hagmann, S.; Streit, M.; Jeager, S.; Moradi, B. Wear in total knee arthroplasty—Just a question of polyethylene? Metal ion release in total knee arthroplasty. Int. Orthop. 2014, 38, 335–340. [Google Scholar] [CrossRef]

- Forte, G.; Petrucci, F.; Bocca, B. Metal Allergens of Growing Significance: Epidemiology, Immunotoxicology, Strategies for Testing and Prevention; Bentham Science Publishers: Potomac, MD, USA, 2008. [Google Scholar]

- Mitchelson, A.J.; Wilson, C.J.; Mihalko, W.M.; Grupp, T.M.; Manning, B.T.; Dennis, D.A.; Goodman, S.B.; Tzeng, T.H.; Vasdev, S.; Saleh, K.J. Biomaterial hypersensitivity: Is it real? Supportive evidence and approach considerations for metal allergic patients following total knee arthroplasty. BioMed Res. Int. 2015, 2015, 137287. [Google Scholar] [CrossRef]

- Ching, H.A.; Choudhury, D.; Nine, J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 14402. [Google Scholar] [CrossRef]

- Herbster, M.; Döring, J.; Nohava, J.; Lohmann, C.H.; Halle, T.; Bertrand, J. Retrieval study of commercially available knee implant coatings TiN, TiNbN and ZrN on TiAl6V4 and CoCr28Mo6. J. Mech. Behav. Biomed. Mater. 2020, 112, 104034. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, D.; Hernández-Bravo, R.; Ruden, A.; Espinosa-Arbelaez, D.; González-Carmona, J.; Mujica, V. Mechanical, tribological and electrochemical behavior of Zr-based ceramic thin films for dental implants. Ceram. Int. 2023, 49, 2102–2114. [Google Scholar] [CrossRef]

- Raimondi, M.T.; Pietrabissa, R. The in-vivo wear performance of prosthetic femoral heads with titanium nitride coating. Biomaterials 2000, 21, 907–913. [Google Scholar] [CrossRef] [PubMed]

- Thomas, P.; Weik, T.; Roider, G.; Summer, B.; Thomsen, M. Influence of Surface Coating on Metal Ion Release: Evaluation in Patients With Metal Allergy. Orthopedics 2016, 39 (Suppl. S3), S24–S30. [Google Scholar] [CrossRef] [PubMed]

- Lützner, J.; Beyer, F.; Lützner, C.; Tille, E.; Postler, A.E. A Novel Multilayer-Coating for Total Knee Arthroplasty Implants is Safe—10-Year Results From a Randomized-Controlled Trial. J. Arthroplast. 2023, 38, 90–95.e1. [Google Scholar] [CrossRef] [PubMed]

- Thomas, P.; Hisgen, P.; Kiefer, H.; Schmerwitz, U.; Ottersbach, A.; Albrecht, D.; Summer, B.; Schinkel, C. Blood cytokine pattern and clinical outcome in knee arthroplasty patients: Comparative analysis 5 years after standard versus “hypoallergenic” surface coated prosthesis implantation. Acta Orthop. 2018, 89, 646–651. [Google Scholar] [CrossRef] [PubMed]

- Döring, J.; Crackau, M.; Nestler, C.; Welzel, F.; Bertrand, J.; Lohmann, C.H. Characteristics of different cathodic arc deposition coatings on CoCrMo for biomedical applications. J. Mech. Behav. Biomed. Mater. 2019, 97, 212–221. [Google Scholar] [CrossRef] [PubMed]

- Reyna, A.L.P.; Lützner, J.; Altermann, B.; Grupp, T.M. Analysis of the In Vivo Oxidation and Integrity of a Zirconium Nitride Multilayer Coated Knee Implant and Possible Effect of Oxidation on the Implant-Cement-Bone Interface Fixation Strength. Int. Case Rep. J. 2023, 3, 1–16. [Google Scholar]

- Purandare, Y.; Ehiasarian, A.; Santana, A.; Hovsepian, P. ZrN coatings deposited by high power impulse magnetron sputtering and cathodic arc techniques. J. Vac. Sci. Technol. A Vac. Surf. Film. 2014, 32, 31507. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.P.; Purandare, Y.P.; Braun, R.; Ross, I.M. Effect of High Ion Irradiation on the Structure, Properties and High Temperature Tribology of Nanoscale CrAlYN/CrN Multilayer Coating Deposited by HIPIMS-HIPIMS Technique. Plasma Process. Polym. 2009, 6 (Suppl. S1), S118–S123. [Google Scholar] [CrossRef]

- Wu, D.; Bhalekar, R.M.; Marsh, J.S.; Langton, D.J.; Stewart, A.J. Periarticular metal hypersensitivity complications of hip bearings containing cobalt-chromium. EFORT Open Rev. 2022, 7, 758–771. [Google Scholar] [CrossRef] [PubMed]

- Gaillard-Campbell, D.M.; Gross, T.P. Hypersensitivity to metals in metal-on-metal hip arthroplasty: A prospective study of one hundred and thirty five lymphocyte transformation tests. Int. Orthop. 2024, 48, 693–698. [Google Scholar] [CrossRef] [PubMed]

- ISO 5832-12:2019; Implants for Surgery—Metallic Materials—Part 12: Wrought Cobalt-Chromium-Molybdenum Alloy. ISO: Geneva, Switzerland, 2019.

- ISO 5832-3:2021; Implants for Surgery—Metallic Materials—Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy. ISO: Geneva, Switzerland, 2021.

- Thomsen, M.; Rozak, M.; Thomas, P. Pain in a chromium-allergic patient with total knee arthroplasty: Disappearance of symptoms after revision with a special surface-coated TKA—A case report. Acta Orthop. 2011, 82, 386–388. [Google Scholar] [CrossRef] [PubMed]

- Bormann, T.; Kraenzler, S.; Jaeger, S.; Kluess, D.; Mittelmeier, W.; Renkawitz, T.; Kretzer, J.P. Stability of ceramic coatings on retrieved knee prostheses. J. Mech. Behav. Biomed. Mater. 2023, 144, 105997. [Google Scholar] [CrossRef] [PubMed]

- Purandare, Y.P.; Ehiasarian, A.P.; Hovsepian, P.E. Structure and properties of ZrN coatings deposited by high power impulse magnetron sputtering technology. J. Vac. Sci. Technol. A Vac. Surf. Film. 2011, 29, 11004. [Google Scholar] [CrossRef]

- B10 Committee. Specification for Zirconium and Zirconium Alloy Strip, Sheet, and Plate; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- B08 Committee. Practice for Preparation of Titanium and Titanium Alloys for Electroplating; ASTM International: West Conshohocken, PA, USA, 2024. [Google Scholar]

- Schierjott, R.A.; Giurea, A.; Neuhaus, H.-J.; Schwiesau, J.; Pfaff, A.M.; Utzschneider, S.; Tozzi, G.; Grupp, T.M. Analysis of Carbon Fiber Reinforced PEEK Hinge Mechanism Articulation Components in a Rotating Hinge Knee Design: A Comparison of In Vitro and Retrieval Findings. BioMed Res. Int. 2016, 2016, 7032830. [Google Scholar] [CrossRef]

- Sproul, W.D. Very high rate reactive sputtering of TiN, ZrN and HfN. Thin Solid Film. 1983, 107, 141–147. [Google Scholar] [CrossRef]

- Johnson, P.C.; Randhawa, H. Zirconium nitride films prepared by cathodic arc plasma deposition process. Surf. Coat. Technol. 1987, 33, 53–62. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; Wen, J.G.; Petrov, I. Interface microstructure engineering by high power impulse magnetron sputtering for the enhancement of adhesion. J. Appl. Phys. 2007, 101, 54301. [Google Scholar] [CrossRef]

- Harrison, R.W.; Lee, W.E. Mechanism and Kinetics of Oxidation of ZrN Ceramics. J. Am. Ceram. Soc. 2015, 98, 2205–2213. [Google Scholar] [CrossRef]

- Kateb, M.; Hajihoseini, H.; Gudmundsson, J.T.; Ingvarsson, S. Role of ionization fraction on the surface roughness, density, and interface mixing of the films deposited by thermal evaporation, dc magnetron sputtering, and HiPIMS: An atomistic simulation. J. Vac. Sci. Technol. A Vac. Surf. Film. 2019, 37, 31306. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. Crystal Structures—Volume 1; Interscience Publishers: New York, NY, USA, 1963. [Google Scholar]

- Pelleg, J.; Zevin, L.Z.; Lungo, S.; Croitoru, N. Reactive-sputter-deposited TiN films on glass substrates. Thin Solid Film. 1991, 197, 117–128. [Google Scholar] [CrossRef]

- Dobosz, D.; Golaszewska, K.; Zytkiewicz, Z.R.; Kaminska, E.; Piotrowska, A.; Piotrowski, T.T.; Barcz, A.; Jakiela, R. Properties of ZrN films as substrate masks in liquid phase epitaxial lateral overgrowth of compound semiconductors. Cryst. Res. Technol. 2005, 40, 492–497. [Google Scholar] [CrossRef]

| N [at.%] | O [at.%] | Zr [at.%] | Total [at.%] | |

|---|---|---|---|---|

| Arc (0 days) | 44.8 ± 0.6 | 3.8 ± 0.8 | 51.4 ± 0.8 | 100.00 |

| Pulsed Sputtering (0 days) | 46.2 ± 0.5 | 2.7 ± 0.3 | 51.1 ± 0.4 | 100.00 |

| Arc (10 days) | 10.7 ± 0.5 | 53.0 ± 1.1 | 36.3 ± 0.9 | 100.00 |

| Pulsed Sputtering (10 days) | 8.7 ± 0.9 | 59.5 ± 1.1 | 31.8 ± 1.0 | 100.00 |

| Average Surface Roughness, Ra [µm] | Rockwell C Adhesion [ISO Class] | N/Zr Ratio by EDX | ZrN Coating Thickness [µm] | Grain Size by XRD [nm] | Coating Wear Rate against ZrOx [mm3/N/m] | Appearance | |

|---|---|---|---|---|---|---|---|

| Arc coating as deposited | 0.08 ± 0.005 | 1 | 0.87 | 1.6 | 200–250 | 3.7 × 10−6 ± 0.5 × 10−6 | Bright gold (14k) |

| Sputtered coating as deposited | 0.03 ± 0.005 | 1 | 0.90 | 1.4 | 120–200 | 1.5 × 10−6 ± 0.2 × 10−6 | Gold (22k) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dohm, J.C.; Schmidt, S.; Puente Reyna, A.L.; Richter, B.; Santana, A.; Grupp, T.M. Comparative Study of Zirconium Nitride Multilayer Coatings: Crystallinity, In Vitro Oxidation Behaviour and Tribological Properties Deposited via Sputtering and Arc Deposition. J. Funct. Biomater. 2024, 15, 223. https://doi.org/10.3390/jfb15080223

Dohm JC, Schmidt S, Puente Reyna AL, Richter B, Santana A, Grupp TM. Comparative Study of Zirconium Nitride Multilayer Coatings: Crystallinity, In Vitro Oxidation Behaviour and Tribological Properties Deposited via Sputtering and Arc Deposition. Journal of Functional Biomaterials. 2024; 15(8):223. https://doi.org/10.3390/jfb15080223

Chicago/Turabian StyleDohm, Julius C., Susann Schmidt, Ana Laura Puente Reyna, Berna Richter, Antonio Santana, and Thomas M. Grupp. 2024. "Comparative Study of Zirconium Nitride Multilayer Coatings: Crystallinity, In Vitro Oxidation Behaviour and Tribological Properties Deposited via Sputtering and Arc Deposition" Journal of Functional Biomaterials 15, no. 8: 223. https://doi.org/10.3390/jfb15080223

APA StyleDohm, J. C., Schmidt, S., Puente Reyna, A. L., Richter, B., Santana, A., & Grupp, T. M. (2024). Comparative Study of Zirconium Nitride Multilayer Coatings: Crystallinity, In Vitro Oxidation Behaviour and Tribological Properties Deposited via Sputtering and Arc Deposition. Journal of Functional Biomaterials, 15(8), 223. https://doi.org/10.3390/jfb15080223