A Review on Heat Transfer of Nanofluids by Applied Electric Field or Magnetic Field

Abstract

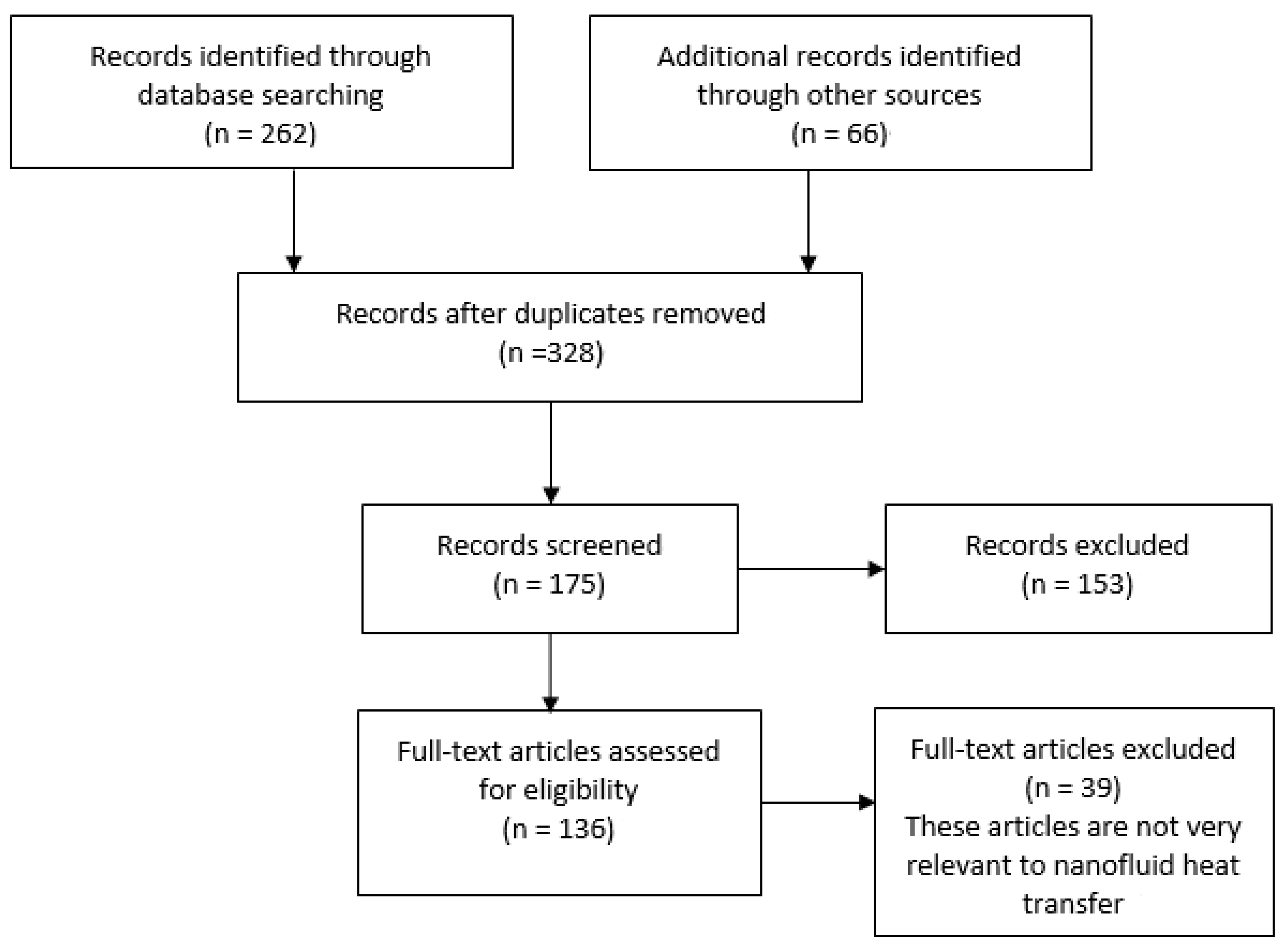

:1. Introduction

2. Effect of Electric Field on Heat Transfer

2.1. The Mechanism of Heat Transfer Enhancement by Electric Field

2.2. Effect of Electric Field on Heat Transfer Enhancement

2.3. Applications

2.4. Summary

3. Effect of Magnetic Field on Heat Transfer

3.1. The Mechanism of Heat Transfer Enhancement by Magnetic Field

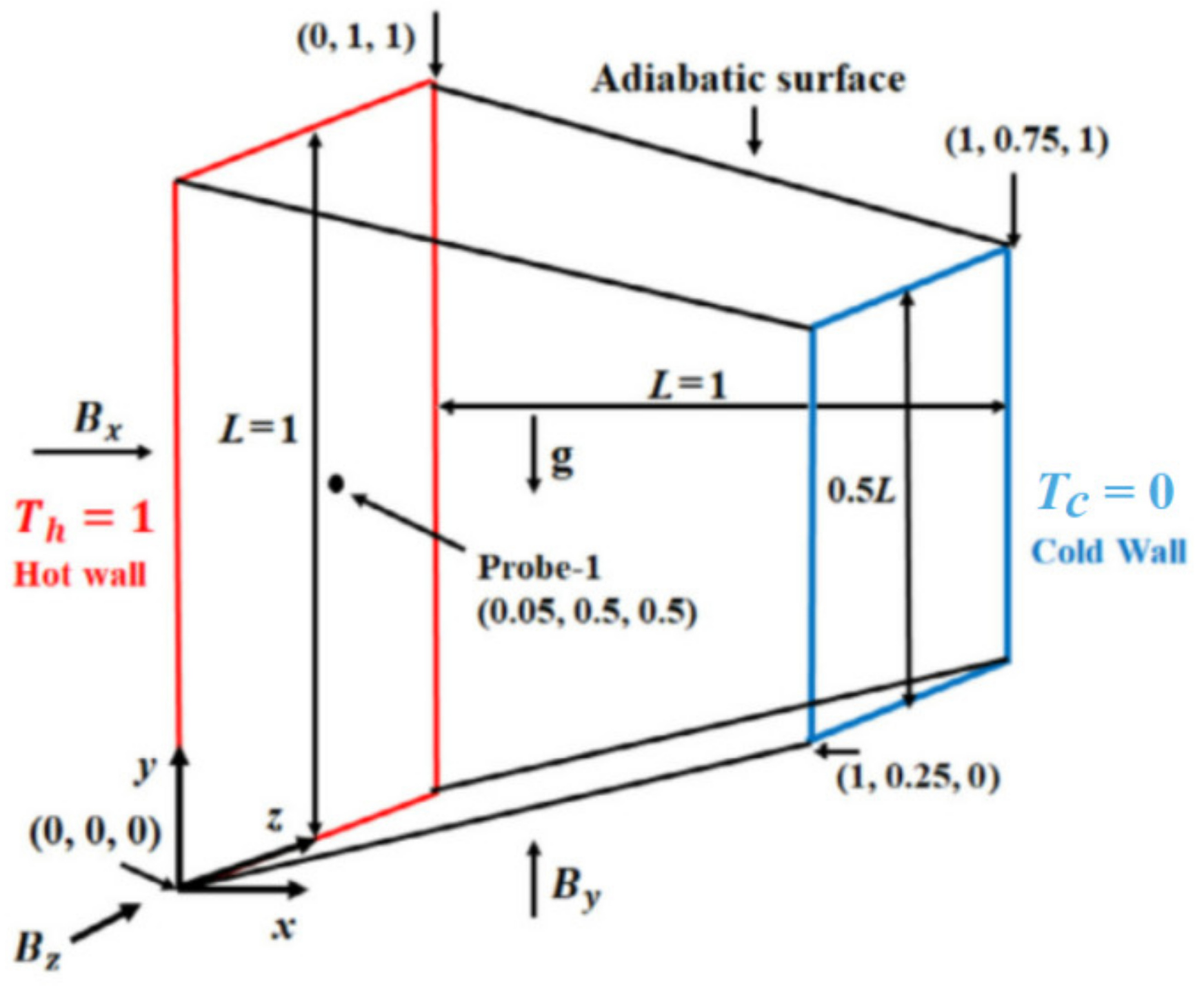

3.2. Effect of Magnetic Field on Heat Transfer Enhancement

3.2.1. Positive Impact

3.2.2. Negative Effect

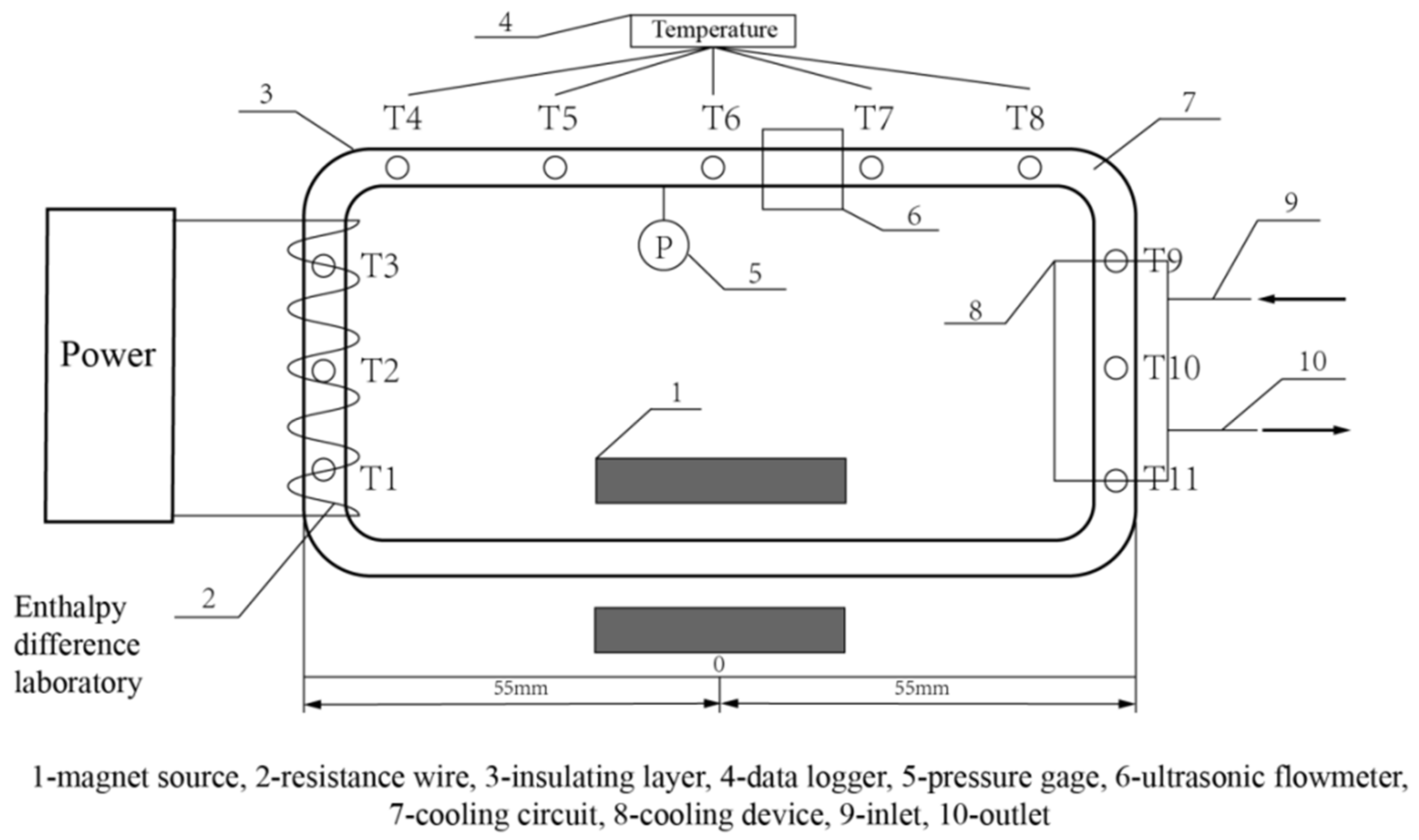

3.3. Application Research

3.4. Summary

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kasaeian, A.; Eshghi, A.T.; Sameti, M. A review on the applications of nanofluids in solar energy systems. Renew. Sustain. Energy Rev. 2015, 43, 584–598. [Google Scholar] [CrossRef]

- Choi, S.U.S. Enhancing thermal conductivity of fluids with nanoparticles. In Proceedings of the 1995 ASME International Mechanical Engineering Congress and Exposition, San Francisco, CA, USA, 12–17 November 1995; pp. 99–105. [Google Scholar]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Yu, W.; Thompson, L.J. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Yousefi, T.; Veysi, F.; Shojaeizadeh, E.; Zinadini, S. An experimental investigation on the effect of Al2O3-H2O nanofluid on the efficiency of flat-plate solar collectors. Renew. Energy 2012, 39, 293–298. [Google Scholar] [CrossRef]

- Das, S.K.; Putra, N.; Thiesen, P.; Roetzel, W. Temperature dependence of thermal conductivity enhancement for nanofluids. J. Heat Transf. Trans. ASME 2003, 125, 567–574. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z. The numerical investigation of nanofluid based cylinder battery thermal management using lattice Boltzmann method. Int. J. Heat Mass Transf. 2015, 91, 374–384. [Google Scholar] [CrossRef]

- Wu, F.; Rao, Z. The lattice Boltzmann investigation of natural convection for nanofluid based battery thermal management. Appl. Therm. Eng. 2017, 115, 659–669. [Google Scholar] [CrossRef]

- Jafari, S.M.; Jabari, S.S.; Dehnad, D.; Shahidi, S.A. Effects of thermal processing by nanofluids on vitamin C, total phenolics and total soluble solids of tomato juice. J. Food Sci. Technol. Mysore 2017, 54, 679–686. [Google Scholar] [CrossRef] [Green Version]

- Kah, M.; Tufenkji, N.; White, J.C. Nano-enabled strategies to enhance crop nutrition and protection. Nat. Nanotechnol. 2019, 14, 532–540. [Google Scholar] [CrossRef]

- Wang, R.J.; Wang, W.; Wang, J.W.; Zhu, Z.F. Analysis and optimization of trapezoidal grooved microchannel heat sink using nanofluids in a micro solar cell. Entropy 2018, 20, 17. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.J.; Yuan, W.J.; Wang, J.W.; Zhu, Z.F. Parametric investigation on a micro-array heat sink with staggered trapezoidal bumps. Micromachines 2019, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.J.; Wang, J.W.; Yuan, W.J. Analysis and optimization of a microchannel heat sink with v-ribs using nanofluids for micro solar cells. Micromachines 2019, 10, 21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mekheimer, K.S.; Hasona, W.M.; Abo-Elkhair, R.E.; Zaher, A.Z. Peristaltic blood flow with gold nanoparticles as a third grade nanofluid in catheter: Application of cancer therapy. Phys. Lett. A 2018, 382, 85–93. [Google Scholar] [CrossRef]

- Guo, P.; Huang, J.; Moses, M.A. Cancer nanomedicines in an evolving oncology landscape. Trends Pharmacol. Sci. 2020, 41, 730–742. [Google Scholar] [CrossRef] [PubMed]

- Benos, L.; Spyrou, L.A.; Sarris, I.E. Development of a new theoretical model for blood-CNTs effective thermal conductivity pertaining to hyperthermia therapy of glioblastoma multiform. Comput. Methods Programs Biomed. 2019, 172, 79–85. [Google Scholar] [CrossRef]

- Karvelas, E.; Liosis, C.; Benos, L.; Karakasidis, T.; Sarris, I. Micromixing efficiency of particles in heavy metal removal processes under various inlet conditions. Water 2019, 11, 1135. [Google Scholar] [CrossRef] [Green Version]

- Sharshir, S.W.; Peng, G.; Wu, L.; Yang, N.; Essa, F.A.; Elsheikh, A.H.; Mohamed, S.I.T.; Kabeel, A.E. Enhancing the solar still performance using nanofluids and glass cover cooling: Experimental study. Appl. Therm. Eng. 2017, 113, 684–693. [Google Scholar] [CrossRef]

- Li, X.; Zou, C.; Qi, A. Experimental study on the thermo-physical properties of car engine coolant (water/ethylene glycol mixture type) based SiC nanofluids. Int. Commun. Heat Mass Transf. 2016, 77, 159–164. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Arya, A.; Hormozi, F.; Nikkhah, V. On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: A comparative study. Appl. Therm. Eng. 2017, 112, 1373–1381. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Mujumdar, A.S. Heat transfer characteristics of nanofluids: A review. Int. J. Therm. Sci. 2007, 46, 1–19. [Google Scholar] [CrossRef]

- Mohammad, R.; Kandasamy, R. Nanoparticle shapes on electric and magnetic force in water, ethylene glycol and engine oil based Cu, Al2O3 and SWCNTs. J. Mol. Liq. 2017, 237, 54–64. [Google Scholar] [CrossRef]

- Bilal, M. Micropolar flow of EMHD nanofluid with nonlinear thermal radiation and slip effects. Alex. Eng. J. 2020, 59, 965–976. [Google Scholar] [CrossRef]

- Asha, S.K.; Sunitha, G. Thermal radiation and Hall effects on peristaltic blood flow with double diffusion in the presence of nanoparticles. Case Stud. Therm. Eng. 2020, 17. [Google Scholar] [CrossRef]

- Daniel, Y.S.; Aziz, Z.A.; Ismail, Z.; Salah, F. Thermal radiation on unsteady electrical MHD flow of nanofluid over stretching sheet with chemical reaction. J. King Saud Univ. Sci. 2019, 31, 804–812. [Google Scholar] [CrossRef]

- Zeeshan, A.; Shehzad, N.; Ellahi, R.; Alamri, S.Z. Convective poiseuille flow of Al2O3-EG nanofluid in a porous wavy channel with thermal radiation. Neural Comput. Appl. 2018, 30, 3371–3382. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Li, Z.; Shamlooei, M. Nanofluid MHD natural convection through a porous complex shaped cavity considering thermal radiation. Phys. Lett. A 2018, 382, 1615–1632. [Google Scholar] [CrossRef]

- Li, Z.; Sheikholeslami, M.; Chamkha, A.J.; Raizah, Z.A.; Saleem, S. Control volume finite element method for nanofluid MHD natural convective flow inside a sinusoidal annulus under the impact of thermal radiation. Comput. Methods Appl. Mech. Eng. 2018, 338, 618–633. [Google Scholar] [CrossRef]

- Heris, S.Z.; Mohammadpur, F.; Mahian, O.; Sahin, A.Z. Experimental study of two phase closed thermosyphon using CUO/Water nanofluid in the presence of electric field. Exp. Heat Transf. 2015, 28, 328–343. [Google Scholar] [CrossRef]

- Chand, R. Electro-thermal convection in a Brinkman porous medium saturated by nanofluid. Ain Shams Eng. J. 2017, 8, 633–641. [Google Scholar] [CrossRef]

- Wu, Z.; Yin, S. Experimental study on convection heat transfer characteristics of magnetic nano-refrigerant. In Research on Mechanical Engineering, Civil Engineering and Material Engineering; Xu, B., Li, H.Y., Eds.; Trans Tech Publications: Bäch, Switzerland, 2014; Volume 454, pp. 268–271. [Google Scholar]

- Mallick, B.; Misra, J.C. Peristaltic flow of eyring-powell nanofluid under the action of an electromagnetic field. Eng. Sci. Technol. Int. J. Jestech 2019, 22, 266–281. [Google Scholar] [CrossRef]

- Du, J.; Li, L.; Zhuo, Q.; Wang, R.; Zhu, Z. Investigation on inertial sorter coupled with magnetophoretic effect for nonmagnetic microparticles. Micromachines 2020, 11, 566. [Google Scholar] [CrossRef]

- Asadzadeh, F.; Esfahany, M.N.; Etesami, N. Natural convective heat transfer of Fe3O4/ethylene glycol nanofluid in electric field. Int. J. Therm. Sci. 2012, 62, 114–119. [Google Scholar] [CrossRef]

- Jones, T.B. Electrohydrodynamically enhanced heat transfer in liquids-A review. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1978; Volume 14, pp. 107–148. [Google Scholar]

- Allen, P.H.G.; Karayiannis, T.G. Electrohydrodynamic enhancement of heat transfer and fluid flow. Heat Recovery Syst. CHP 1995, 15, 389–423. [Google Scholar] [CrossRef]

- Laohalertdecha, S.; Naphon, P.; Wongwises, S. A review of electrohydrodynamic enhancement of heat transfer. Renew. Sustain. Energy Rev. 2007, 11, 858–876. [Google Scholar] [CrossRef]

- Keblinski, P.; Phillpot, S.R.; Choi, S.U.S.; Eastman, J.A. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int. J. Heat Mass Transf. 2002, 45, 855–863. [Google Scholar] [CrossRef]

- Eastman, J.A.; Phillpot, S.R.; Choi, S.U.S.; Keblinski, P. Thermal transport in nanofluids. Annu. Rev. Mater. Res. 2004, 34, 219–246. [Google Scholar] [CrossRef]

- Machrafi, H.; Lebon, G. Effective thermal conductivity of spherical particulate nanocomposites: Comparison with theoretical models, monte carlo simulations and experiments. Int. J. Nanosci. 2014, 13, 1450022. [Google Scholar] [CrossRef] [Green Version]

- Xuan, Y.M.; Li, Q.; Hu, W. Aggregation structure and thermal conductivity of nanofluids. AICHE J. 2003, 49, 1038–1043. [Google Scholar] [CrossRef]

- Chen, Y.; He, D. Dynamic calculation and thermal enhancement mechanism analysis of nanofluid under electric field. Int. Commun. Heat Mass Transf. 2020, 113. [Google Scholar] [CrossRef]

- Evans, W.; Fish, J.; Keblinski, P. Role of Brownian motion hydrodynamics on nanofluid thermal conductivity. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef] [Green Version]

- Ramos-Alvarado, B.; Kumar, S.; Peterson, G.P. Solid–liquid thermal transport and its relationship with wettability and the interfacial liquid structure. J. Phys. Chem. Lett. 2016, 7, 3497–3501. [Google Scholar] [CrossRef]

- Wang, R.J.; Qian, S.; Zhang, Z.Q. Investigation of the aggregation morphology of nanoparticle on the thermal conductivity of nanofluid by molecular dynamics simulations. Int. J. Heat Mass Transf. 2018, 127, 1138–1146. [Google Scholar] [CrossRef]

- Iacobazzi, F.; Milanese, M.; Colangelo, G.; Lomascolo, M.; de Risi, A. An explanation of the Al2O3 nanofluid thermal conductivity based on the phonon theory of liquid. Energy 2016, 116, 786–794. [Google Scholar] [CrossRef]

- Wang, R.J.; Pan, G.S.; Qian, S.; Li, L.; Zhu, Z.F. Influence of nanoparticles on the evaporation behavior of nanofluid droplets: A D-h law and underlying mechanism. Langmuir 2020, 36, 919–930. [Google Scholar] [CrossRef] [PubMed]

- Evans, W.; Prasher, R.; Fish, J.; Meakin, P.; Phelan, P.; Keblinski, P. Effect of aggregation and interfacial thermal resistance on thermal conductivity of nanocomposites and colloidal nanofluids. Int. J. Heat Mass Transf. 2008, 51, 1431–1438. [Google Scholar] [CrossRef]

- Zhang, Z.-Q.; Qian, S.; Wang, R.-J.; Zhu, Z.F. Effect of aggregation morphology of nanoparticles on thermal conductivity of nanofluid. Acta Phys. Sin. 2019, 68, 161–170. [Google Scholar] [CrossRef]

- Nagvenkar, A.P.; Perelshtein, I.; Gedanken, A. Doping effect on the thermal conductivity of metal oxide nanofluids: Insight and mechanistic investigation. J. Phys. Chem. C 2017, 121, 26551–26557. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective transport in nanofluids. J. Heat Transf. Trans. ASME 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Wang, R.J.; Sun, S.S.; Wang, W.; Zhu, Z.F. Investigation on the thermophoretic sorting for submicroparticles in a sorter with expansion-contraction microchannel. Int. J. Heat Mass Transf. 2019, 133, 912–919. [Google Scholar] [CrossRef]

- Wang, R.; Du, J.; Guo, W.; Zhu, Z. Investigation on the thermophoresis-coupled inertial sorting of submicrometer particles in a microchannel. Nanoscale Microscale Thermophys. Eng. 2016, 20, 51–65. [Google Scholar] [CrossRef]

- Tzou, D.Y. Macro- to Microscale Heat Transfer: The Lagging Behavior, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Kang, Z.; Zhu, P.; Gui, D.; Wang, L. A method for predicting thermal waves in dual-phase-lag heat conduction. Int. J. Heat Mass Transf. 2017, 115, 250–257. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Q.; Kang, Z.; Pan, W.; Zhang, D.; Wang, L. Non-Fourier heat conduction in oil-in-water emulsions. Int. J. Heat Mass Transf. 2019, 135, 323–330. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Rahmani, R.; Rahnejat, H.; Garner, C.P. Thermal conductivity and molecular heat transport of nanofluids. RSC Adv. 2019, 9, 2516–2524. [Google Scholar] [CrossRef] [Green Version]

- Cosgrove, T. Colloid Science: Principles, Methods and Applications; Blackwell Publishing: Oxford, UK, 2005. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.-W.; Kim, B.G. A new parameter to control heat transport in nanofluids: Surface charge state of the particle in suspension. J. Phys. Chem. B 2006, 110, 4323–4328. [Google Scholar] [CrossRef] [PubMed]

- Lee, D. Thermophysical properties of interfacial layer in nanofluids. Langmuir 2007, 23, 6011–6018. [Google Scholar] [CrossRef]

- Jung, J.-Y.; Kang, Y.T. Effect of surface charge state on the thermal conductivity of nanofluids. Heat Mass Transf. Waerme Stoffuebertragung 2012, 48, 713–718. [Google Scholar] [CrossRef]

- Milanese, M.; Iacobazzi, F.; Colangelo, G.; de Risi, A. An investigation of layering phenomenon at the liquidsolid interface in Cu and CuO based nanofluids. Int. J. Heat Mass Transf. 2016, 103, 564–571. [Google Scholar] [CrossRef]

- Ha, J.; Jeon, H.; Choi, T.-Y.; Kim, D. Enhancement of thermal conductivity of titanium dioxide nanoparticle suspensions by femtosecond laser irradiation. Int. J. Heat Mass Transf. 2019, 133, 662–668. [Google Scholar] [CrossRef]

- Zhao, Q.; Xu, H.; Tao, L. Flow and heat transfer of nanofluid through a horizontal microchannel with magnetic field and interfacial electrokinetic effects. Eur. J. Mech. B Fluids 2020, 80, 72–79. [Google Scholar] [CrossRef]

- Cui, W.; Shen, Z.; Yang, J.; Wu, S. Molecular dynamics simulation on the microstructure of absorption layer at the liquid–solid interface in nanofluids. Int. Commun. Heat Mass Transf. 2016, 71, 75–85. [Google Scholar] [CrossRef]

- Mitiche, I.; Lamrous, O.; Makhlouf, S.; Marchetti, F.; Laidani, N. Effect of the interface layer vibration modes in enhancing thermal conductivity of nanofluids. Phys. Rev. E 2019, 100. [Google Scholar] [CrossRef]

- Ruijin, W.; Jianzhong, L.; Zhihua, L. Analysis of electro-osmotic flow characteristics at joint of capillaries with step change in ζ -potential and dimension. Biomed. Microdevices 2005, 7, 131–135. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Jian, Y.; Xie, Z.; Li, F. Heat transfer characteristics of magnetohydrodynamic electroosmotic flow in a rectangular microchannel. Eur. J. Mech. B Fluids 2019, 74, 180–190. [Google Scholar] [CrossRef]

- Bao, Y.-Y.; Huang, J.-H.; Chen, Y.-J.; Liu, Z.-H. Natural convection heat transfer of nanofluid in a cavity under an inhomogeneous electric field. Int. J. Heat Mass Transf. 2019, 131, 341–345. [Google Scholar] [CrossRef]

- Hasegawa, S.; Kondo, K.; Oshinoya, Y. Experimental verification of heat transport by acoustic wave. Appl. Therm. Eng. 2015, 78, 551–555. [Google Scholar] [CrossRef]

- Liu, J.-M.; Liu, Z.-H.; Chen, Y.-J. Experiment and calculation of the thermal conductivity of nanofluid under electric field. Int. J. Heat Mass Transf. 2017, 107, 6–12. [Google Scholar] [CrossRef]

- Rubio-Hernandez, F.J.; Gomez-Merino, A.I.; Ruiz-Reina, E. Electroviscous effect in dilute suspensions of alumina. J. Colloid Interface Sci. 2000, 222, 103–106. [Google Scholar] [CrossRef] [Green Version]

- Kang, Z.; Wang, L. Effect of thermal-electric cross coupling on heat transport in nanofluids. Energies 2017, 10, 123. [Google Scholar] [CrossRef] [Green Version]

- Liang, Z.; Tsai, H.-L. Thermal conductivity of interfacial layers in nanofluids. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2011, 83. [Google Scholar] [CrossRef] [Green Version]

- Vadasz, J.J.; Govender, S. Thermal wave effects on heat transfer enhancement in nanofluids suspensions. Int. J. Therm. Sci. 2010, 49, 235–242. [Google Scholar] [CrossRef]

- Saravani, M.S.; Kalteh, M. Heat transfer investigation of combined electroosmotic/pressure driven nanofluid flow in a microchannel: Effect of heterogeneous surface potential and slip boundary condition. Eur. J. Mech. B-Fluids 2020, 80, 13–25. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Soleimani, S.; Ganji, D.D. Effect of electric field on hydrothermal behavior of nanofluid in a complex geometry. J. Mol. Liq. 2016, 213, 153–161. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ellahi, R. Electrohydrodynamic nanofluid hydrothermal treatment in an enclosure with sinusoidal upper wall. Appl. Sci. Basel 2015, 5, 294–306. [Google Scholar] [CrossRef] [Green Version]

- Sheikholeslami, M.; Bhatti, M.M. Active method for nanofluid heat transfer enhancement by means of EHD. Int. J. Heat Mass Transf. 2017, 109, 115–122. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ganji, D.D. Impact of electric field on nanofluid forced convection heat transfer with considering variable properties. J. Mol. Liq. 2017, 229, 566–573. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Hayat, T.; Alsaedi, A.; Abelman, S. Numerical analysis of EHD nanofluid force convective heat transfer considering electric field dependent viscosity. Int. J. Heat Mass Transf. 2017, 108, 2558–2565. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Rokni, H.B. Influence of EFD viscosity on nanofluid forced convection in a cavity with sinusoidal wall. J. Mol. Liq. 2017, 232, 390–395. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Vajravelu, K. Forced convection heat transfer in Fe3O4-ethylene glycol nanofluid under the influence of Coulomb force. J. Mol. Liq. 2017, 233, 203–210. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Chamkha, A.J. Electrohydrodynamic free convection heat transfer of a nanofluid in a semi-annulus enclosure with a sinusoidal wall. Numer. Heat Transf. Part. Appl. 2016, 69, 781–793. [Google Scholar] [CrossRef]

- Sheikholeslami, M. Influence of Coulomb forces on Fe3O4-H2O nanofluid thermal improvement. Int. J. Hydrog. Energy 2017, 42, 821–829. [Google Scholar] [CrossRef]

- Sheikholeslami, M. Investigation of Coulomb force effects on ethylene glycol based nanofluid laminar flow in a porous enclosure. Appl. Math. Mech. Engl. Ed. 2018, 39, 1341–1352. [Google Scholar] [CrossRef]

- Sheikholeslami, M. Numerical investigation of nanofluid free convection under the influence of electric field in a porous enclosure. J. Mol. Liq. 2018, 249, 1212–1221. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shamlooei, M.; Moradi, R. Fe3O4-Ethylene glycol nanofluid forced convection inside a porous enclosure in existence of Coulomb force. J. Mol. Liq. 2018, 249, 429–437. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ganji, D.D. Influence of electric field on Fe3O4- water nanofluid radiative and convective heat transfer in a permeable enclosure. J. Mol. Liq. 2018, 250, 404–412. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Rokni, H.B. Numerical simulation for impact of Coulomb force on nanofluid heat transfer in a porous enclosure in presence of thermal radiation. Int. J. Heat Mass Transf. 2018, 118, 823–831. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Seyednezhad, M. Simulation of nanofluid flow and natural convection in a porous media under the influence of electric field using CVFEM. Int. J. Heat Mass Transf. 2018, 120, 772–781. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shehzad, S.A.; Kumar, R. Natural convection of Fe3O4-ethylene glycol nanofluid under the impact of electric field in a porous enclosure. Commun. Theor. Phys. 2018, 69, 667–675. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Sheremet, M.A.; Shafee, A.; Li, Z. CVFEM approach for EHD flow of nanofluid through porous medium within a wavy chamber under the impacts of radiation and moving walls. J. Therm. Anal. Calorim. 2019, 138, 573–581. [Google Scholar] [CrossRef]

- Safarnia, H.; Sheikholeslami, M.; Ganji, D.D. Electrohydrodynamic nanofluid flow and forced convective heat transfer in a channel. Eur. Phys. J. Plus 2016, 131, i2016-i16096. [Google Scholar] [CrossRef]

- Saleem, S.; Shafee, A.; Nawaz, M.; Dara, R.N.; Tlili, I.; Bonyah, E. Heat transfer in a permeable cavity filled with a ferrofluid under electric force and radiation effects. AIP Adv. 2019, 9. [Google Scholar] [CrossRef]

- Truong Khang, N.; Soomro, F.A.; Ali, J.A.; Ul Haq, R.; Sheikholeslami, M.; Shafee, A. Heat transfer of ethylene glycol-Fe3O4 nanofluid enclosed by curved porous cavity including electric field. Phys. A Stat. Mech. Appl. 2020, 550. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, G.; Wang, B. Flow structure and heat transfer of electro-thermo-convection in a dielectric liquid layer. Phys. Fluids 2019, 31. [Google Scholar] [CrossRef]

- Daniel, Y.S.; Aziz, Z.A.; Ismail, Z.; Salah, F. Impact of thermal radiation on electrical MHD flow of nanofluid over nonlinear stretching sheet with variable thickness. Alex. Eng. J. 2018, 57, 2187–2197. [Google Scholar] [CrossRef]

- Zhao, D.; Hedayat, M.; Barzinjy, A.A.; Dara, R.N.; Shafee, A.; Tlili, I. Numerical investigation of Fe3O4 nanoparticles transportation due to electric field in a porous cavity with lid walls. J. Mol. Liq. 2019, 293. [Google Scholar] [CrossRef]

- Tang, G.; Shafee, A.; Nguyen Dang, N.; Tlili, I. Coulomb forces impacts on nanomaterial transportation within porous tank with lid walls. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Kunti, G.; Bhattacharya, A.; Chakraborty, S. A scaling analysis for electrohydrodynamic convection with variable thermophysical and electrical properties. Int. J. Heat Mass Transf. 2017, 109, 215–222. [Google Scholar] [CrossRef]

- Wang, P.-Y.; Liu, J.-M.; Liu, Z.-H.; Chen, Y.-J. Experiment and simulation of natural convection heat transfer of transformer oil under electric field. Int. J. Heat Mass Transf. 2017, 115, 441–452. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Choi, S.U.S. Thermal Conductivity of Nanoparticle-Fluid Mixture. J. Thermophys. Heat Transf. 1999, 13, 474–480. [Google Scholar] [CrossRef]

- Kestin, J.; Wakeham, W.A. A contribution to the theory of the transient hot-wire technique for thermal conductivity measurements. Phys. A Stat. Mech. Appl. 1978, 92, 102–116. [Google Scholar] [CrossRef]

- Dhar, P.; Maganti, L.S.; Raman, H.A.; Rajput, C. Amplifying thermal conduction calibre of dielectric nanocolloids employing induced electrophoresis. Exp. Therm. Fluid Sci. 2019, 106, 138–147. [Google Scholar] [CrossRef]

- Fragelli, R.L.; de Angelo Sanchez, L.E.; Ingraci Neto, R.R.; Scalon, V.L. Refrigeration capacity of silver nanofluids under electrohydrodynamic effect oriented to heat removal in machining process. Exp. Therm. Fluid Sci. 2018, 96, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; An, W.; Gao, N. Light-induced latent heat reduction of silver nanofluids: A molecular dynamics simulation. Int. J. Heat Mass Transf. 2020, 162, 120343. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Shah, Z.; Tassaddiq, A.; Shafee, A.; Khan, I. Application of electric field for augmentation of ferrofluid heat transfer in an enclosure including double moving walls. IEEE Access 2019, 7, 21048–21056. [Google Scholar] [CrossRef]

- Wang, Z. Mechanism of natural convection heat transfer of magnetic fluid enhanced by magnetic field. J. Chem. Ind. Eng. (China) 2005, 56, 235–238. [Google Scholar] [CrossRef]

- Shakiba, A.; Vahedi, K. Numerical analysis of magnetic field effects on hydro-thermal behavior of a magnetic nanofluid in a double pipe heat exchanger. J. Magn. Magn. Mater. 2016, 402, 131–142. [Google Scholar] [CrossRef]

- Mustafa, M.; Hina, S.; Hayat, T.; Ahmad, B. Influence of induced magnetic field on the peristaltic flow of nanofluid. Meccanica 2014, 49, 521–534. [Google Scholar] [CrossRef]

- Shafee, A.; Shahraki, M.S.; Taleghani, A.H.; Nam, N.D.; Tlili, I. Analysis of nanomaterial flow among two circular tubes in the presence of magnetic force. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Sheikholeslami, M. TiO2-water nanofluid in a porous channel under the effects of an inclined magnetic field and variable thermal conductivity. Appl. Math. Mech. Engl. Ed. 2018, 39, 1201–1216. [Google Scholar] [CrossRef]

- Singh, R.J.; Chandy, A.J. Numerical investigations of the development and suppression of the natural convection flow and heat transfer in the presence of electromagnetic force. Int. J. Heat Mass Transf. 2020, 157. [Google Scholar] [CrossRef]

- Yousefi, E.; Nazif, H.R.; Khaboshan, H.N.; Azarinia, A. Non-uniform magnetic field effect on forced convection heat transfer of flattened tubes using two-phase mixture model. Heat Transf. Eng. 2020. [Google Scholar] [CrossRef]

- Larimi, M.M.; Ghanaat, A.; Ramiar, A.; Ranjbar, A.A. Forced convection heat transfer in a channel under the influence of various non-uniform transverse magnetic field arrangements. Int. J. Mech. Sci. 2016, 118, 101–112. [Google Scholar] [CrossRef]

- Moghadam, H.K.; Baghbani, S.S.; Babazadeh, H. Study of thermal performance of a ferrofluid with multivariable dependence viscosity within a wavy duct with external magnetic force. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Fadaei, F.; Shahrokhi, M.; Dehkordi, A.M.; Abbasi, Z. Forced-convection heat transfer of ferrofluids in a circular duct partially filled with porous medium in the presence of magnetic field. J. Magn. Magn. Mater. 2019, 475, 304–315. [Google Scholar] [CrossRef]

- Yousofvand, R.; Derakhshan, S.; Ghasemi, K.; Siavashi, M. MHD transverse mixed convection and entropy generation study of electromagnetic pump including a nanofluid using 3D LBM simulation. Int. J. Mech. Sci. 2017, 133, 73–90. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Gorji-Bandpay, M.; Domiri Ganji, D. Magnetic field effects on natural convection around a horizontal circular cylinder inside a square enclosure filled with nanofluid. Int. Commun. Heat Mass Transf. 2012, 39, 978–986. [Google Scholar] [CrossRef]

- Mehmood, R.; Tabassum, R. Transverse transport of Fe3O4-H2O with viscosity variation under pure internal heating. Indian J. Phys. 2018, 92, 1271–1280. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Vajravelu, K. Lattice Boltzmann method for nanofluid flow in a porous cavity with heat sources and magnetic field. Chin. J. Phys. 2018, 56, 1578–1587. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Oztop, H.F.; Abu-Hamdeh, N.; Li, Z. Nanoparticle transportation of CuO-H2O nanofluid in a porous semi annulus due to Lorentz forces. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 294–308. [Google Scholar] [CrossRef]

- Alnaqi, A.A.; Aghakhani, S.; Pordanjani, A.H.; Bakhtiari, R.; Asadi, A.; Minh-Duc, T. Effects of magnetic field on the convective heat transfer rate and entropy generation of a nanofluid in an inclined square cavity equipped with a conductor fin: Considering the radiation effect. Int. J. Heat Mass Transf. 2019, 133, 256–267. [Google Scholar] [CrossRef]

- Li, Z.; Shafee, A.; Kandasamy, R.; Ramzan, M.; Al-Mdallal, Q.M. Nanoparticle transportation through a permeable duct with Joule heating influence. Microsyst. Technol. Micro-Nanosyst. -Inf. Storage Process. Syst. 2019, 25, 3571–3580. [Google Scholar] [CrossRef]

- Wang, W.; Li, B.-W.; Hu, Z.-M. Influence of optical parameters on magnetohydrodynamic natural convection in a horizontal cylindrical annulus. J. Heat Transf. Trans. ASME 2019, 141. [Google Scholar] [CrossRef]

- Afrand, M.; Pordanjani, A.H.; Aghakhani, S.; Oztop, H.F.; Abu-Hamdeh, N. Free convection and entropy generation of a nanofluid in a tilted triangular cavity exposed to a magnetic field with sinusoidal wall temperature distribution considering radiation effects. Int. Commun. Heat Mass Transf. 2020, 112. [Google Scholar] [CrossRef]

- Karagiannakis, N.P.; Bourantas, G.C.; Skouras, E.D.; Loukopoulos, V.C.; Miller, K.; Burganos, V.N. Modeling the natural convection flow in a square porous enclosure filled with a micropolar nanofluid under magnetohydrodynamic conditions. Appl. Sci. Basel 2020, 10, 1633. [Google Scholar] [CrossRef] [Green Version]

- Benos, L.T.; Karvelas, E.G.; Sarris, I.E. A theoretical model for the magnetohydrodynamic natural convection of a CNT-water nanofluid incorporating a renovated Hamilton-Crosser model. Int. J. Heat Mass Transf. 2019, 135, 548–560. [Google Scholar] [CrossRef]

- Tran Dinh, M.; Nguyen Dang, N.; Abdulrahman, G.K.; Khan, M.H.; Tlili, I.; Shafee, A.; Shamlooei, M.; Trung, N.-T. Investigation of hybrid nanofluid migration within a porous closed domain. Phys. Stat. Mech. Appl. 2020, 551. [Google Scholar] [CrossRef]

- Astanina, M.S.; Riahi, M.K.; Abu-Nada, E.; Sheremet, M.A. Magnetohydrodynamic in partially heated square cavity with variable properties: Discrepancy in experimental and theoretical conductivity correlations. Int. J. Heat Mass Transf. 2018, 116, 532–548. [Google Scholar] [CrossRef]

- Tassone, A.; Nobili, M.; Caruso, G. Numerical study of the MHD flow around a bounded heating cylinder: Heat transfer and pressure drops. Int. Commun. Heat Mass Transf. 2018, 91, 165–175. [Google Scholar] [CrossRef]

- Ghadiri, M.; Sardarabadi, M.; Pasandideh-fard, M.; Moghadam, A.J. Experimental investigation of a PVT system performance using nano ferrofluids. Energy Convers. Manag. 2015, 103, 468–476. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, D.; Wang, J.; Chen, L.; Sunden, B. Experimental investigation on heat transfer characteristics of various nanofluids in an indoor electric heater. Renew. Energy 2020, 147, 1011–1018. [Google Scholar] [CrossRef]

- Salehi, H.; Heris, S.Z.; Noie, S.H. Experimental study of a two-phase closed thermosyphon with nanofluid and magnetic field effect. J. Enhanc. Heat Transf. 2011, 18, 261–269. [Google Scholar] [CrossRef]

- Salehi, H.; Zeinali Heris, S.; Noie, S.H. Water-silver nanofluid application in a TPCT under an external magnetic field. Heat Transf. Asian Res. 2012, 41, 289–301. [Google Scholar] [CrossRef]

- Ma, Y.; Mohebbi, R.; Rashidi, M.M.; Yang, Z.; Sheremet, M. Nanoliquid thermal convection in I-shaped multiple-pipe heat exchanger under magnetic field influence. Phys. A: Stat. Mech. Appl. 2020, 550. [Google Scholar] [CrossRef]

| Author | Nanofluid | Factors | Research Methods | Main Conclusion |

|---|---|---|---|---|

| Bao et al. [68] | Al2O3-oil nanofluid | gravity | experimental study | The natural convection caused by gravity can counteract the electric convection generated by the electric field, thus weaken the enhancement effect of the electric field. |

| Saravani et al. [75] | Al2O3-H2O nanofluid | pressure | numerical simulation | The pressure is negatively correlated with the heat transfer of nanofluids, while the electric field is positively correlated. |

| Sheikholeslami et al. [76,77,78,79,80,81,82] | Fe3O4-ethylene glycol nanofluid | Reynolds number and nanoparticle volume fraction and supplied voltage | numerical simulation | Thermal conductivity increases with an increase of Reynolds number and supplied voltage. The heat transfer performance of the electric field is better at a low Reynolds number. |

| Sheikholeslami et al. [83] | Fe3O4-ethylene glycol nanofluid | Rayleigh number, nanoparticle volume fraction and the supplied voltage | numerical simulation | Thermal conductivity increases with the increase of Rayleigh number and supplied voltage. The heat transfer performance of the electric field is better at a low Reynolds number. |

| Sheikholeslami et al. [84] | Fe3O4-H2O nanofluid | Reynolds number, nanoparticle volume fraction and supplied voltage | numerical simulation | Thermal conductivity increases with the increase of Reynolds number and supplied voltage. |

| Sheikholeslami et al. [85,86,87] | Fe3O4-ethylene glycol nanofluid | radiation parameter, supplied voltage, volume fraction of nanofluid, Darcy number and Reynolds number | numerical simulation | The distortion of isotherm increases because of the rise of Darcy number, radiation parameters and Coulomb force. Thermal conductivity increases with the increase of Reynolds number and supplied voltage. |

| Sheikholeslami et al. [88] | Fe3O4-H2O nanofluid | radiation parameter, supplied voltage, volume fraction of nanofluid, Darcy number and Reynolds number | numerical simulation | The temperature gradient is positively correlated with Darcy number, radiation parameters and Coulomb force. The maximum temperature gradient is obtained when the nanoparticles are platelet shape. |

| Sheikholeslami et al. [89,90] | Fe3O4-ethylene glycol nanofluid | radiation parameter, supplied voltage, volume fraction of nanofluid, Darcy number and Reynolds number | numerical simulation | The heat transfer rate is the highest when the shape of nanoparticles is platelet shape. Darcy number, radiation parameter and Coulomb forces can enhance the convective heat transfer. |

| Sheikholeslami et al. [91] | Fe3O4-ethylene glycol nanofluid | radiation parameter, supplied voltage, volume fraction of nanofluid, Darcy number and Rayleigh number | numerical simulation | The distortion of isotherm increases because of the rise of Darcy number, radiation parameters and Coulomb force. Nusselt number increases with the argument of Darcy number, radiation parameters and Coulomb force. |

| Sheikholeslami et al. [92] | Fe3O4–C2H6O2 nanofluid | supplied voltage, permeability, radiation parameters, nanoparticles’ shape and concentration. | numerical simulation | Nusselt number increases with the argument of supplied voltage, permeability, radiation parameters and concentration of nanoparticles. |

| Safarnia et al. [93] | Fe3O4-H2O nanofluid | Reynolds number and supplied voltage | numerical simulation | Nusselt number increases with the argument of Reynolds number and supplied voltage. The heat transfer performance of the electric field is better at a low Reynolds number. |

| Saleem et al. [94] | Fe3O4-ethylene glycol nanofluid | supplied voltage, Darcy number, shape factor, Radiation parameter and volume fraction | numerical simulation | The distortion of isotherm increases because of the rise of Darcy number, radiation parameters and Coulomb force. |

| Truong Khang et al. [95] | Fe3O4-ethylene glycol nanofluid | supplied voltage, radiation parameter, nanoparticles shape factor and permeability | numerical simulation | The convection enhancement with the increase of Darcy number and supplied voltage. The heat transfer performance is positively correlated with electric field and radiation. |

| Lu et al. [96] | dielectric liquid | Rayleigh number, buoyancy force and mobility parameters | numerical simulation | The electric field can enhance the heat transfer more effectively for the fluid with a larger Prandtl number at a lower Rayleigh number and lower mobility parameters. |

| Asadzadeh et al. [33] | Fe3O4-ethylene glycol nanofluid | Rayleigh number and nanoparticle volume fraction | experimental study | The enhancement effect of the electric field increases with the rise of supply voltage and decreases with the increase of the Rayleigh number. The applied electric field can weaken the negative effect of particle deposition. |

| Author | Application Direction | Research Methods | Effect |

|---|---|---|---|

| Dhar et al. [104] | Coolant | experimental study | An electric field can control the thermal conductivity transiently. |

| Fragelli et al. [105] | Tool cutting fluids | experimental study | An electric field can weaken the negative effect of the deposition of nanoparticles. |

| Heris et al. [28] | Two-phase closed thermosyphon (TPCT) | experimental study | An electric field can increase the thermal efficiency. |

| Zhao et al. [106] | Latent heat of vaporization (LHV) | numerical simulation | An electric field can reduce the LHV of nanofluid. |

| Author | Application Direction | Research Methods | Effect |

|---|---|---|---|

| Ghadiri et al. [132] | PVT | Experimental study | Increasing heat transfer efficiency by an alternating magnetic field. |

| Chen et al. [133] | Electric heater | Experimental study | Increasing heat transfer efficiency by an optimal magnetic field strength. |

| Salehi et al. [134] | TPCT | Experimental study | The magnetic field can increase the Nusselt number. |

| Salehi et al. [135] | TPCT | Experimental study | TPCT performed better at the magnetic field strength. |

| Shakiba et al. [109] | Double pipe heat exchanger | Numerical simulation | Improving the magnetic fluid flow and enhancing the cooling performance |

| Zhao et al. [63] | Microfluidic devices | Numerical simulation | The heat transfer and flow of nanofluid can be controlled by the magnetic and EDL. |

| Ma et al. [136] | Heat exchanger | Numerical simulation | Decreasing heat transfer efficiency |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Zhang, Z.; Wang, R.; Zhu, Z. A Review on Heat Transfer of Nanofluids by Applied Electric Field or Magnetic Field. Nanomaterials 2020, 10, 2386. https://doi.org/10.3390/nano10122386

Wang G, Zhang Z, Wang R, Zhu Z. A Review on Heat Transfer of Nanofluids by Applied Electric Field or Magnetic Field. Nanomaterials. 2020; 10(12):2386. https://doi.org/10.3390/nano10122386

Chicago/Turabian StyleWang, Guannan, Zhen Zhang, Ruijin Wang, and Zefei Zhu. 2020. "A Review on Heat Transfer of Nanofluids by Applied Electric Field or Magnetic Field" Nanomaterials 10, no. 12: 2386. https://doi.org/10.3390/nano10122386

APA StyleWang, G., Zhang, Z., Wang, R., & Zhu, Z. (2020). A Review on Heat Transfer of Nanofluids by Applied Electric Field or Magnetic Field. Nanomaterials, 10(12), 2386. https://doi.org/10.3390/nano10122386