The Design of Near-Perfect Spectrum-Selective Mirror Based on Photonic Structures for Passive Cooling of Silicon Solar Cells

Abstract

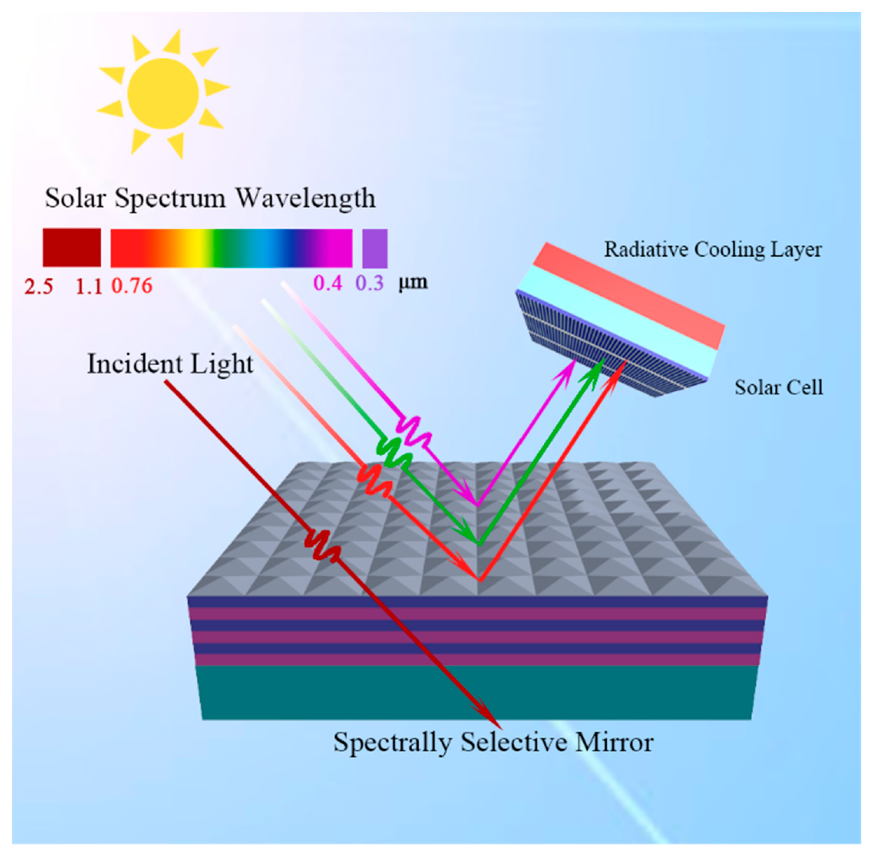

:1. Introduction

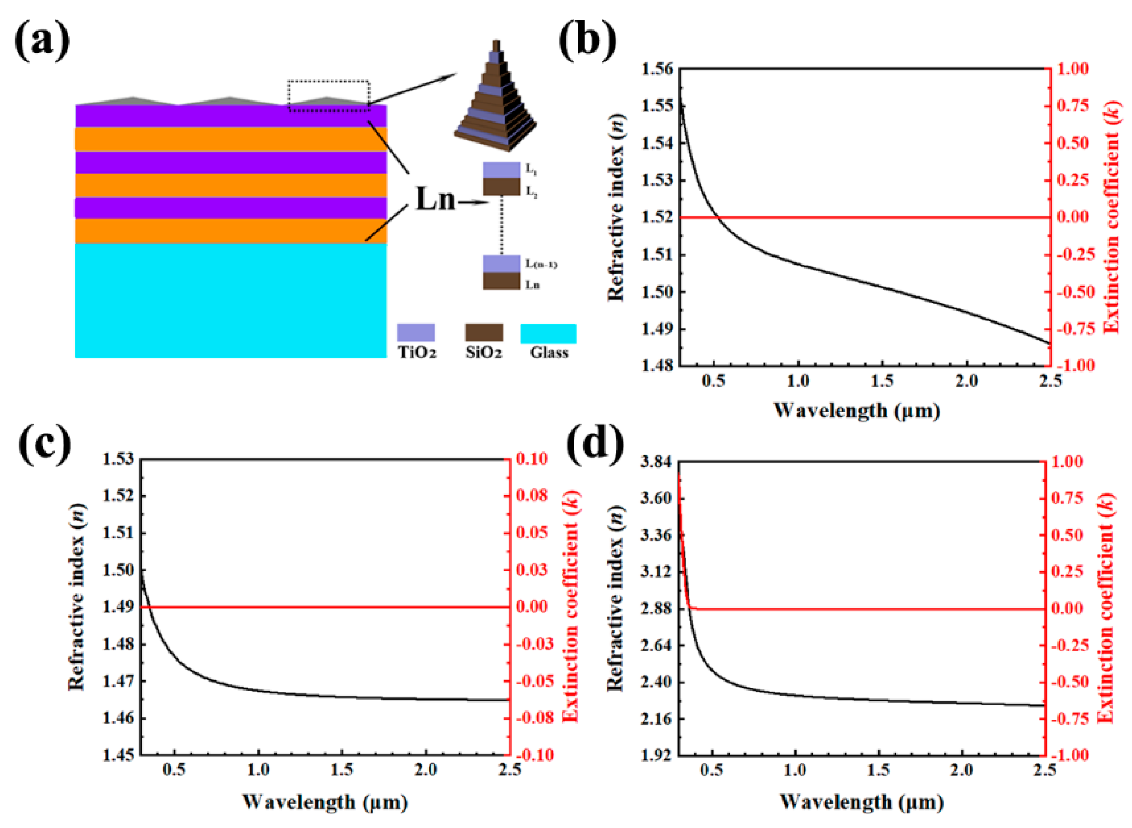

2. Materials and Methods

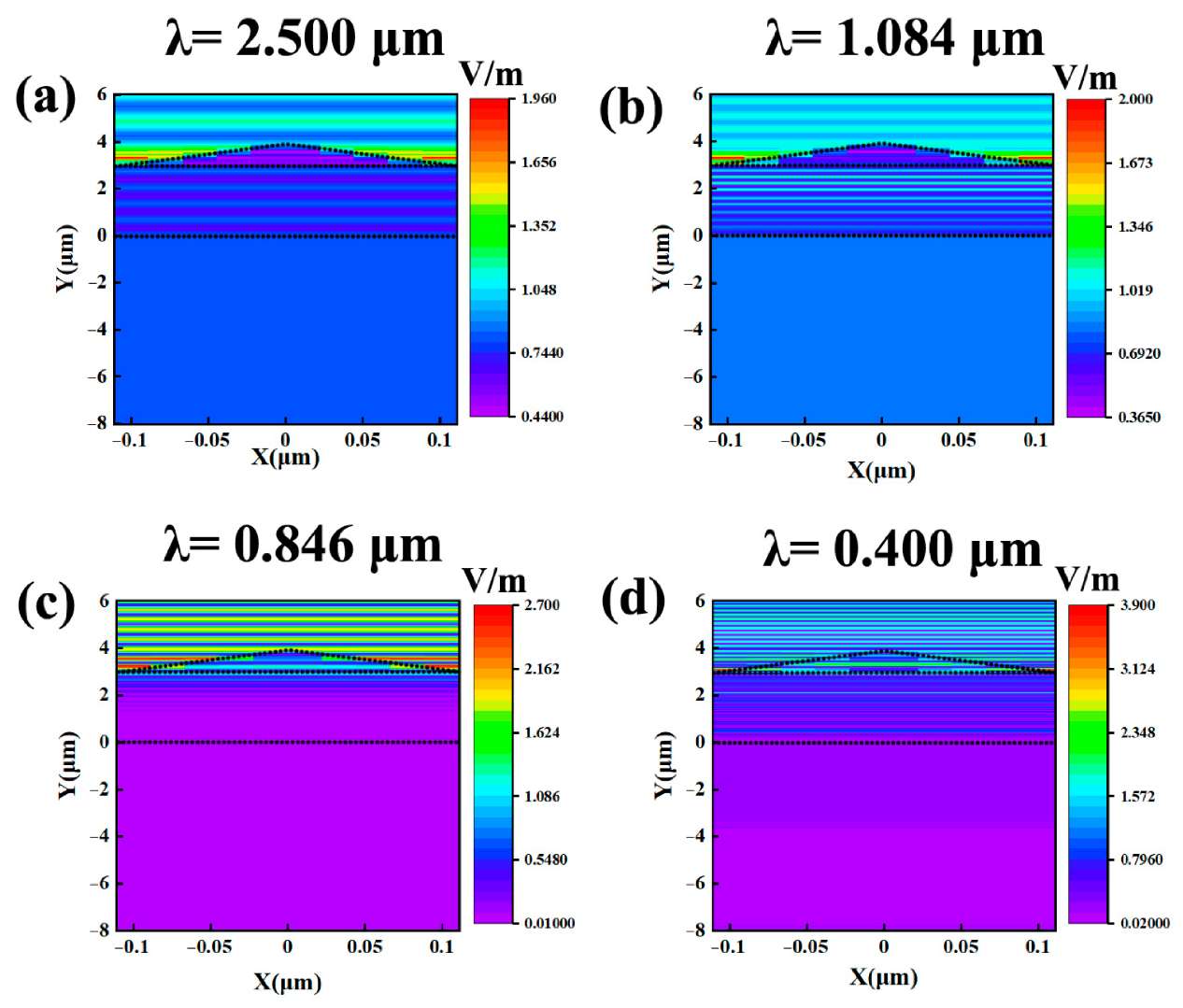

2.1. Electromagnetic Simulation of Spectrum-Selective Mirror

2.2. Thermal Simulation of CSSC

3. Results and Discussion

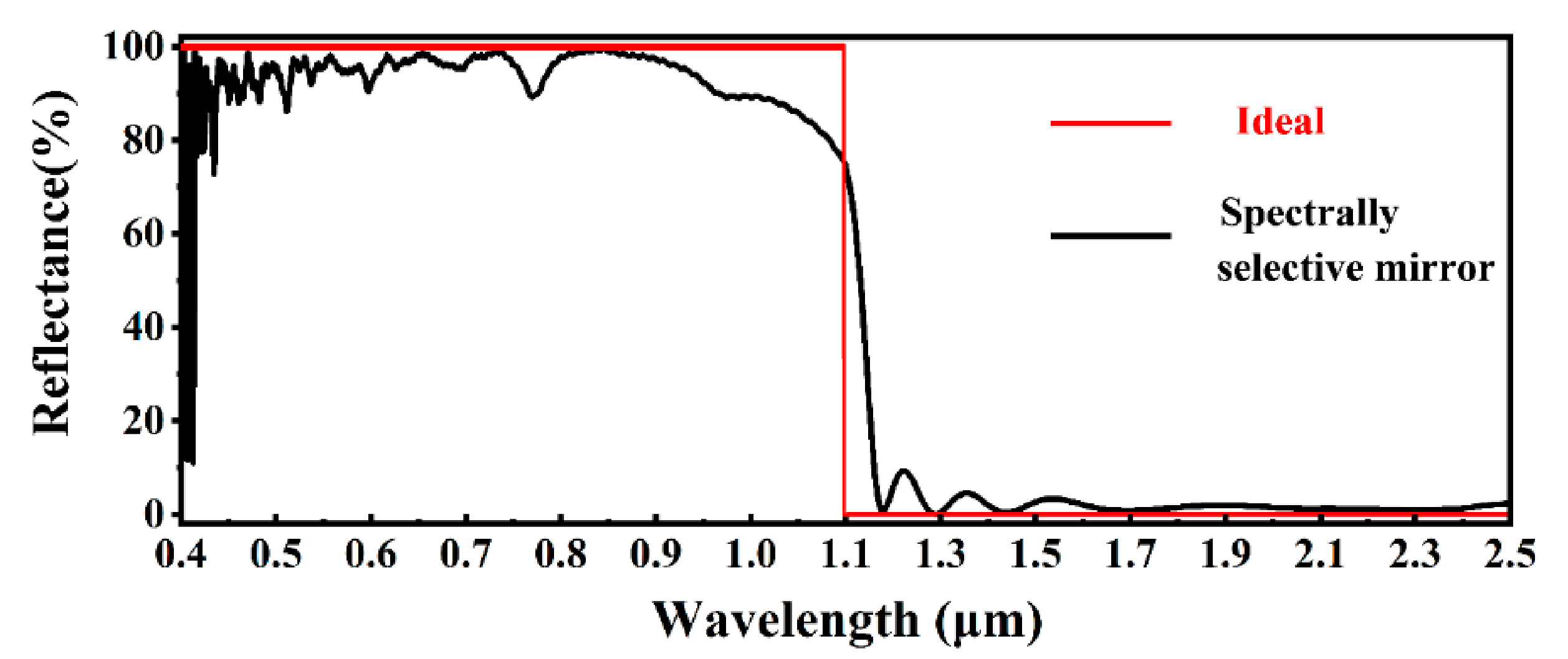

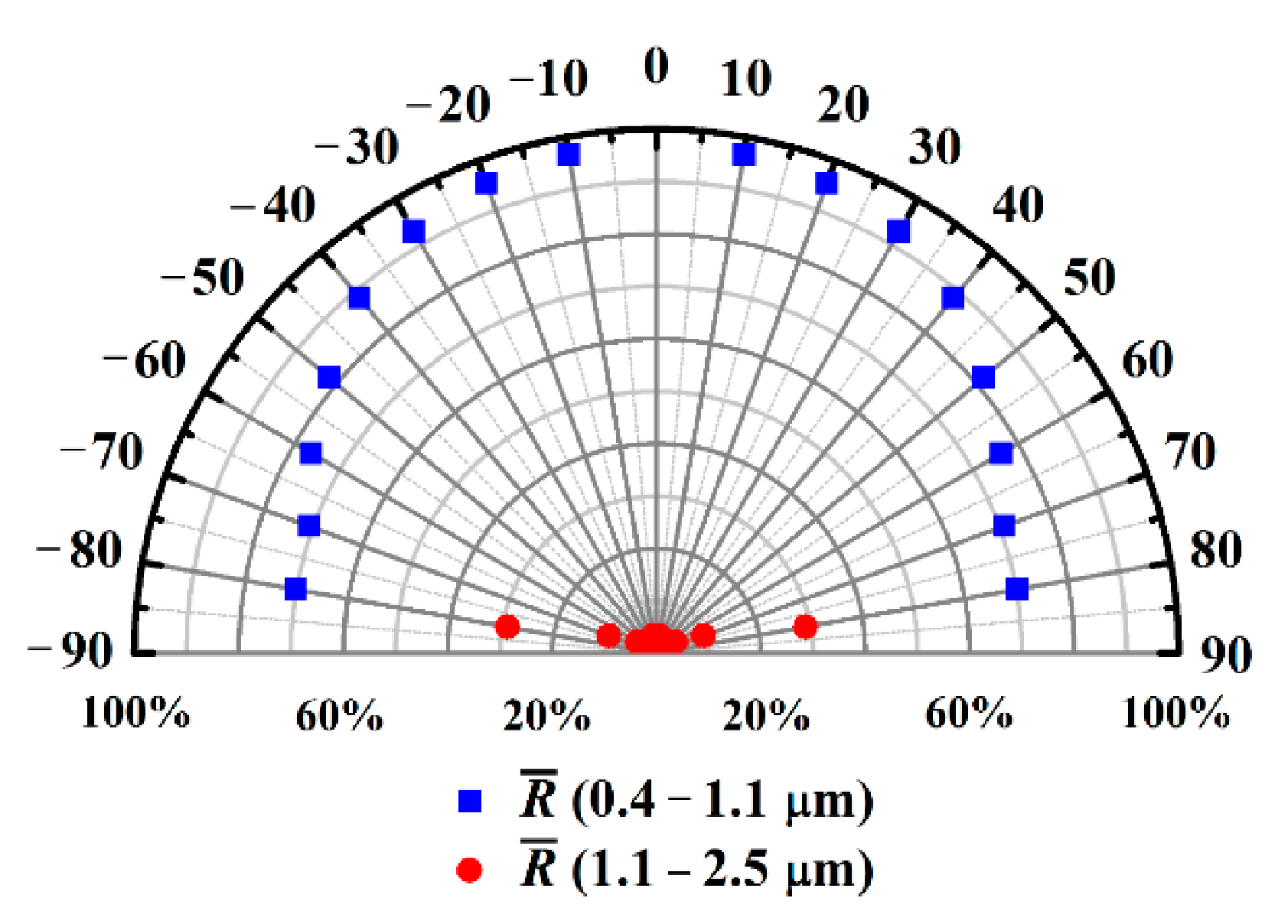

3.1. Simulated Reflectance of Spectrum-Selective Mirror

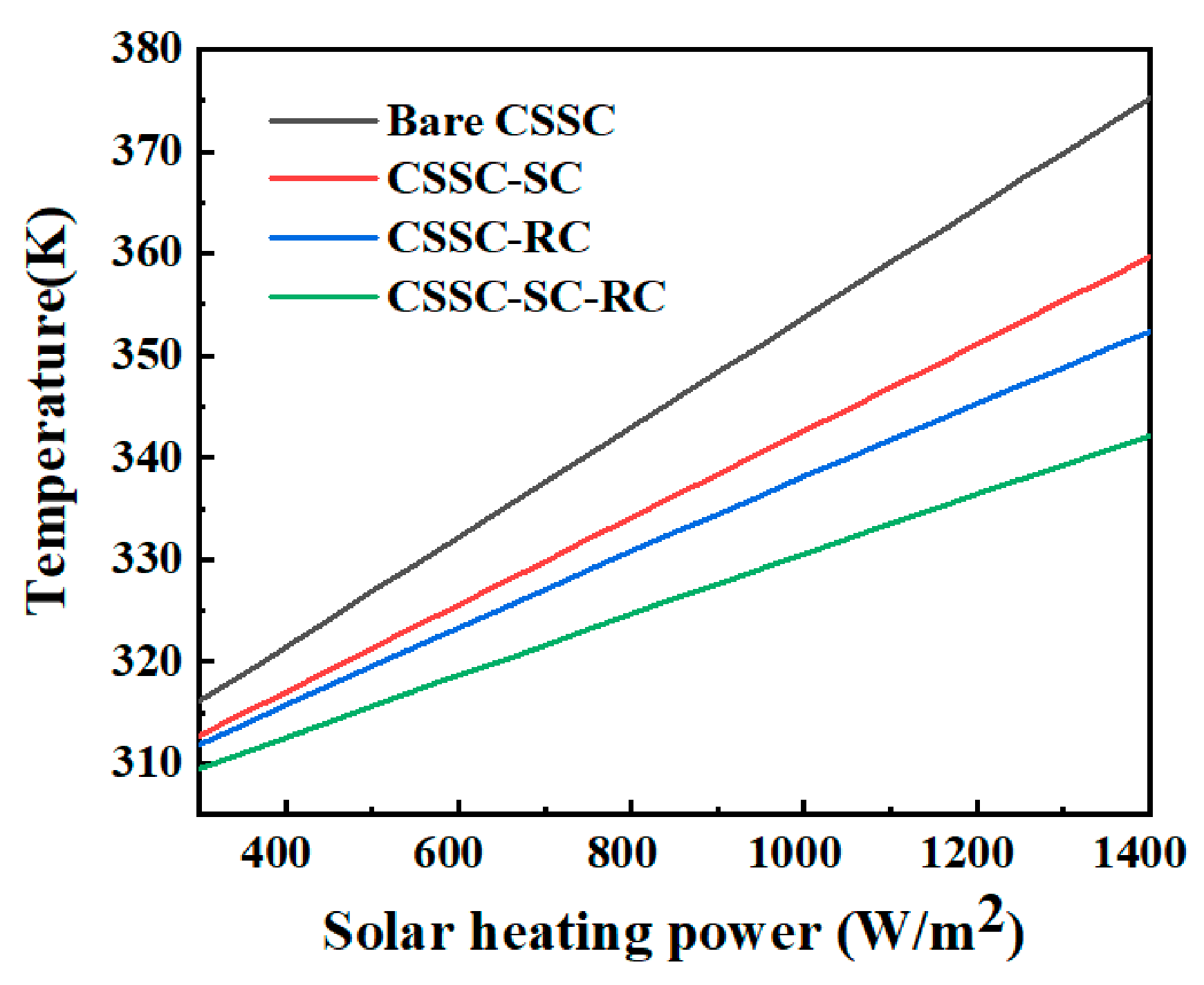

3.2. Simulation of Cooling Effect with Different Solar Heating Powers

3.3. Simulation of Cooling Effect with Different Non-Radiative Heat Exchange Coefficients

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jäger-Waldau, A. Snapshot of photovoltaics—February 2020. Energies 2020, 13, 930. [Google Scholar] [CrossRef] [Green Version]

- Battersby, S. News Feature: The solar cell of the future. Proc. Natl. Acad. Sci. USA 2019, 116, 7–10. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Shi, Y.; Chen, K.; Zhu, L.; Fan, S. A comprehensive photonic approach for solar cell cooling. ACS Photonics 2017, 4, 774–782. [Google Scholar] [CrossRef]

- Sun, X.; Silverman, T.J.; Zhou, Z.; Khan, M.R.; Bermel, P.; Alam, M.A. Optics-based approach to thermal management of photovoltaics: Selective-spectral and radiative cooling. IEEE J. Photovolt. 2017, 7, 566–574. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.; Wang, K.X.; Anoma, M.A.; Fan, S. Radiative cooling of solar cells. Optica 2014, 1, 32–38. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.P.; Fan, S. Radiative cooling of solar absorbers using a visibly transparent photonic crystal thermal blackbody. Proc. Natl. Acad. Sci. USA 2015, 112, 12282–12287. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Hu, M.; Ao, X.; Xuan, Q.; Pei, G. Comprehensive photonic approach for diurnal photovoltaic and nocturnal radiative cooling. Sol. Energy Mater. Sol. Cells 2018, 178, 266–272. [Google Scholar] [CrossRef]

- Sato, D.; Yamada, N. Review of photovoltaic module cooling methods and performance evaluation of the radiative cooling method. Renew. Sustain. Energy Rev. 2019, 104, 151–166. [Google Scholar]

- Gao, M.; Han, X.; Chen, F.; Zhou, W.; Liu, P.; Shan, Y.; Chen, Y.; Li, J.; Zhang, R.; Wang, S.; et al. Approach to fabricating high-performance cooler with near-ideal emissive spectrum for above-ambient air temperature radiative cooling. Sol. Energy Mater. Sol. Cells 2019, 200, 110013. [Google Scholar] [CrossRef]

- Li, Q.; Li, T.; Pan, C.; Zhou, Z.; Sun, W. Design and calculation of cooling system to eliminate non-uniform heat transfer on concentration PV system (CPV). Adv. Mater. Res. 2013, 608–609, 143–150. [Google Scholar] [CrossRef]

- Akbarzadeh, A.; Wadowski, T. Heat pipe-based cooling systems for photovoltaic cells under concentrated solar radiation. Appl. Therm. Eng. 1996, 16, 81–87. [Google Scholar] [CrossRef]

- Odeh, S.; Behnia, M. Improving photovoltaic module efficiency using water cooling. Heat Transf. Eng. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- Krauter, S. Increased electrical yield via water flow over the front of photovoltaic panels. Sol. Energy Mater. Sol. Cells 2004, 82, 131–137. [Google Scholar] [CrossRef]

- Du, B.; Hu, E.; Kolhe, M. Performance analysis of water cooled concentrated photovoltaic (CPV) system. Renew. Sustain. Energ. Rev. 2012, 16, 6732–6736. [Google Scholar] [CrossRef]

- Bahaidarah, H.; Subhan, A.; Gandhidasan, P.; Rehman, S. Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 2013, 59, 445–453. [Google Scholar] [CrossRef]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Brinkworth, B.J.; Cross, B.M.; Marshall, R.H.; Yang, H. Thermal regulation of egulation of photovoltaic cladding. Sol. Energy 1997, 61, 169–178. [Google Scholar] [CrossRef]

- Valeh-e-Sheyda, P.; Rahimi, M.; Parsamoghadam, A.; Masahi, M.M. Using a wind-driven ventilator to enhance a photovoltaic cell power generation. Energy Build. 2014, 73, 115–119. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Improving thermodynamic performance parameters of silicon photovoltaic cells via air cooling. Int. J. Ambient Energy 2013, 35, 193–199. [Google Scholar] [CrossRef]

- Royne, A.; Dey, C.J. Design of a jet impingement cooling device for densely packed PV cells under high concentration. Sol. Energy 2007, 81, 1014–1024. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Evaluation of phase change materials for thermal regulation enhancement of building integrated photovoltaics. Sol. Energy 2010, 84, 1601–1612. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.J. The effect of using two PCMs on the thermal regulation performance of BIPV systems. Sol. Energy Mater. Sol. Cells 2011, 95, 957–963. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Phase change materials for limiting temperature rise in building integrated photovoltaics. Sol. Energy 2006, 80, 1121–1130. [Google Scholar] [CrossRef]

- Maiti, S.; Banerjee, S.; Vyas, K.; Patel, P.; Ghosh, P.K. Self regulation of photovoltaic module temperature in V-trough using a metal–wax composite phase change matrix. Sol. Energy 2011, 85, 1805–1816. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Xuan, Q.; Pei, G. Spectrally selective approaches for passive cooling of solar cells: A review. Appl. Energy 2020, 262, 114548. [Google Scholar] [CrossRef]

- Gentle, A.R.; Smith, G.B. Is enhanced radiative cooling of solar cell modules worth pursuing? Sol. Energy Mater. Sol. Cells 2016, 150, 39–42. [Google Scholar] [CrossRef]

- Safi, T.S.; Munday, J.N. Improving photovoltaic performance through radiative cooling in both terrestrial and extraterrestrial environments. Opt. Express 2015, 23, A1120–A1128. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.; Jia, M.; Sun, K.; Shi, N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef] [Green Version]

- Zhai, Y.; Ma, Y.N.; David, S.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef] [Green Version]

- Slauch, I.M.; Deceglie, M.G.; Silverman, T.J.; Ferry, V.E. Spectrally Selective Mirrors with Combined Optical and Thermal Benefit for Photovoltaic Module Thermal Management. ACS Photonics 2018, 5, 1528–1538. [Google Scholar] [CrossRef]

- An, Y.; Sheng, C.; Li, X. Radiative cooling of solar cells: Opto-electro-thermal physics and modeling. Nanoscale 2019, 11, 17073–17083. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Chen, Z.; Ai, L.; Zhang, X.; Zhang, J.; Li, J.; Wang, W.; Tan, R.; Dai, N.; Song, W. A universal route to realize radiative cooling and light management in photovoltaic modules. Sol. RRL 2017, 1, 1700084. [Google Scholar] [CrossRef]

- Sun, K.; Riedel, C.A.; Wang, Y.; Urbani, A.; Simeoni, M.; Mengali, S.; Zalkovskij, M.; Bilenberg, B.; de Groot, C.H.; Muskens, O.L. Metasurface optical solar reflectors using AZO transparent conducting oxides for radiative cooling of Spacecraft. ACS Photonics 2018, 5, 495–501. [Google Scholar] [CrossRef] [Green Version]

- El-Khozondar, H.J.; El-Khozondar, R.J.; Shabat, M.M.; Schaadt, D.M. Solar cell with multilayer structure based on nanoparticles composite. Optik 2018, 166, 127–131. [Google Scholar] [CrossRef]

- Nilsson, T.M.J.; Niklasson, G.A. Radiative cooling during the day: Simulations and experiments on pigmented polyethylene cover foils. Sol. Energy Mater Sol. Cells 1995, 37, 93–118. [Google Scholar] [CrossRef]

- Kou, Q.; Klein, S.A.; Beckman, W.A. A method for estimating the long-term performance of direct-coupled PV pumping systems. Sol. Energy 1998, 64, 33–40. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: New York, NY, USA, 2013. [Google Scholar]

- Green, M.A.; Emery, K.; King, D.L.; Hisikawa, Y.; Warta, W. Solar cell efficiency tables (version 27). Prog. Photovolt. 2006, 14, 45–51. [Google Scholar] [CrossRef]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar cell efficiency tables (version 48). Prog. Photovolt. 2016, 24, 905–913. [Google Scholar] [CrossRef] [Green Version]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, M.; Xia, Y.; Li, R.; Zhang, Z.; He, Y.; Zhang, C.; Chen, L.; Qi, L.; Si, Y.; Zhang, Q.; et al. The Design of Near-Perfect Spectrum-Selective Mirror Based on Photonic Structures for Passive Cooling of Silicon Solar Cells. Nanomaterials 2020, 10, 2483. https://doi.org/10.3390/nano10122483

Gao M, Xia Y, Li R, Zhang Z, He Y, Zhang C, Chen L, Qi L, Si Y, Zhang Q, et al. The Design of Near-Perfect Spectrum-Selective Mirror Based on Photonic Structures for Passive Cooling of Silicon Solar Cells. Nanomaterials. 2020; 10(12):2483. https://doi.org/10.3390/nano10122483

Chicago/Turabian StyleGao, Mengyu, Ye Xia, Rong Li, Zhen Zhang, Yutian He, Chi Zhang, Laijun Chen, Lina Qi, Yang Si, Qinghong Zhang, and et al. 2020. "The Design of Near-Perfect Spectrum-Selective Mirror Based on Photonic Structures for Passive Cooling of Silicon Solar Cells" Nanomaterials 10, no. 12: 2483. https://doi.org/10.3390/nano10122483