Ceramic Composite Materials Obtained by Electron-Beam Physical Vapor Deposition Used as Thermal Barriers in the Aerospace Industry

Abstract

:1. Introduction

2. Thermal Barrier Coating

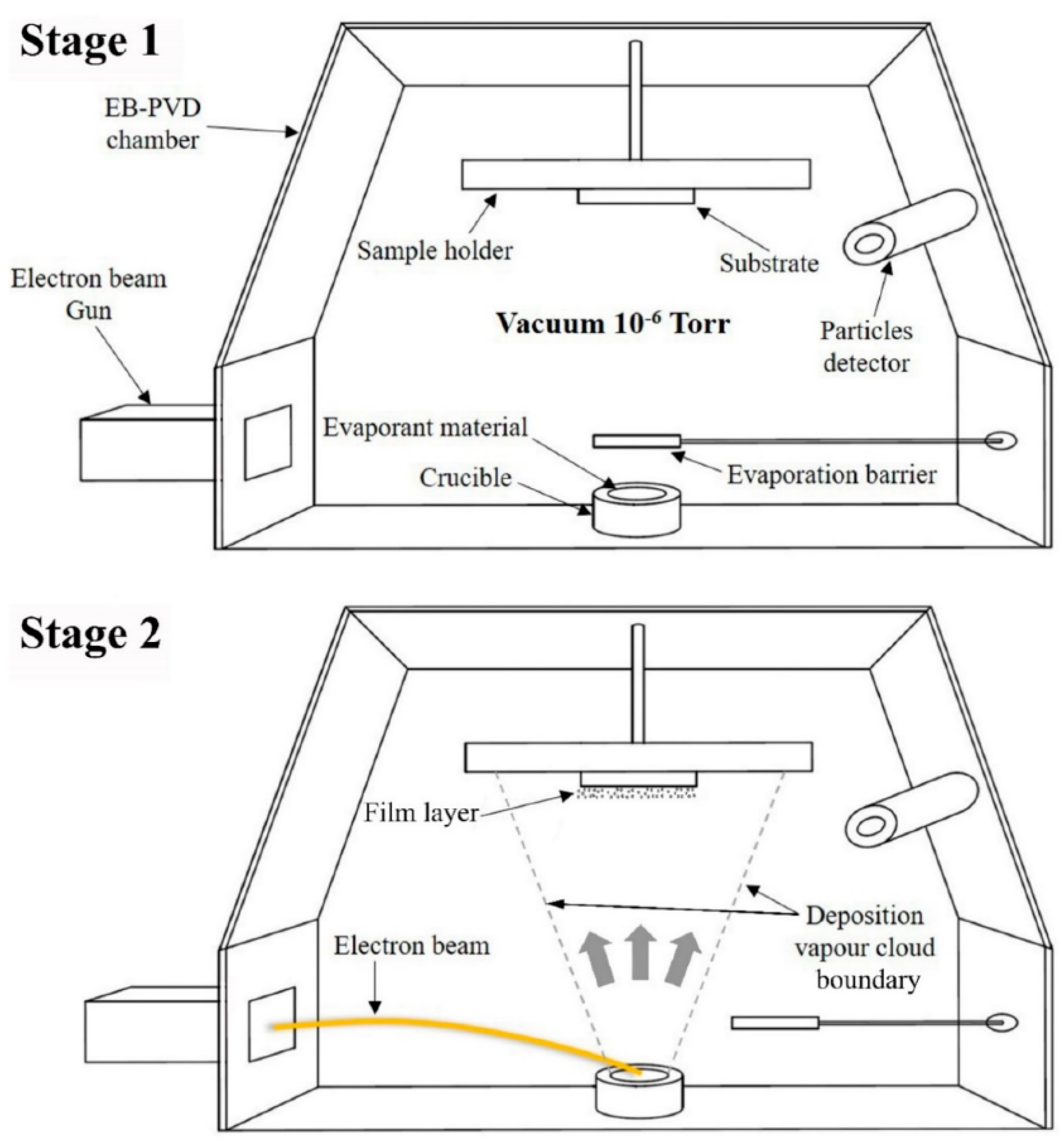

3. Electron Beam Physical Vapour Deposition (EB-PVD) Technology

4. Ultra-High Temperature Ceramics

5. Ceramic Matrix Composites

5.1. Carbon–Carbon Composites

5.2. Hafnium Carbide (HfC) Composites

5.3. Carbon/Silicon Carbide (C/SiC) Composites

5.4. Zirconium Carbide/Silicon Carbide (ZrC/SiC) Composites

5.5. Zirconium Diboride/Silicon Carbide (ZrB2/SiC) Composites

5.6. Aluminum Oxide/Zirconium Dioxide (Al2O3/ZrO2) Composites and Zirconium Dioxide/Silicon Dioxide (ZrO2/SiO2) Aerogels

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rana, S.; Fangueiro, R. Advanced Composite Materials for Aerospace Engineering: Processing, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Misra, A. Composite Materials for Aerospace Propulsion Related to Air and Space Transportation. In Lightweight Composite Structures in Transport; Elsevier: Amsterdam, The Netherlands, 2016; pp. 305–327. [Google Scholar]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Zhang, W.-H.; Xia, L. Topology optimization in aircraft and aerospace structures design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef] [Green Version]

- Rana, S.; Fangueiro, R. Advanced Composites in Aerospace Engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–15. [Google Scholar]

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing Processes for Composite Materials and Components for Aerospace Applications. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 53–75. [Google Scholar]

- Toozandehjani, M.; Kamarudin, N.; Dashtizadeh, Z.; Lim, E.Y.; Gomes, A.; Gomes, C. Conventional and advanced composites in aerospace industry: Technologies revisited. Am. J. Aerosp. Eng. 2018, 5, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Park, S.-J.; Seo, M.-K. (Eds.) Chapter 7—Types of Composites. In Interface Science and Technology; Elsevier: Amsterdam, The Netherlands, 2011; Volume 18, pp. 501–629. [Google Scholar]

- Gopal, K. Product Design for Advanced Composite Materials in Aerospace Engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 413–428. [Google Scholar]

- Falaschetti, M.P.; Rans, C.; Troiani, E. On the application of metal foils for improving the impact damage tolerance of composite materials. Compos. Part B Eng. 2017, 112, 224–234. [Google Scholar]

- Jawaid, M.; Thariq, M. Sustainable Composites for Aerospace Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Jin, X.; Fan, X.; Lu, C.; Wang, T. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. J. Eur. Ceram. Soc. 2018, 38, 1–28. [Google Scholar] [CrossRef]

- Tang, S.; Hu, C. Design, preparation and properties of carbon fiber reinforced ultra-high temperature ceramic composites for aerospace applications: A review. J. Mater. Sci. Technol. 2017, 33, 117–130. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Yu, S. Ablation behavior and mechanism analysis of C/SiC composites. J. Mater. Res. Technol. 2016, 5, 170–182. [Google Scholar] [CrossRef] [Green Version]

- Marsh, G. Composites in commercial jets. Reinf. Plast. 2015, 59, 190–193. [Google Scholar] [CrossRef]

- Asl, M.S.; Nayebi, B.; Ahmadi, Z.; Zamharir, M.J.; Shokouhimehr, M. Effects of carbon additives on the properties of ZrB2–based composites: A review. Ceram. Int. 2018, 44, 7334–7348. [Google Scholar] [CrossRef]

- Lino Alves, F.J.; Baptista, A.M.; Marques, A.T. 3—Metal and Ceramic Matrix Composites in Aerospace Engineering. In Advanced Composite Materials for Aerospace Engineering; Rana, S., Fangueiro, R., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 59–99. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Doorbar, P.J.; Kyle-Henney, S. 4.19 Development of Continuously-Reinforced Metal Matrix Composites for Aerospace Applications. Compr. Compos. Mater. 2018, 4, 439–463. [Google Scholar]

- Paul, A.; Jayaseelan, D.D.; Venugopal, S.; Zapata-Solvas, E.; Binner, J.; Vaidhyanathan, B.; Heaton, A.; Brown, P.M.; Lee, W. UHTC Composites for Hypersonic Applications; The American Ceramic Society Bulletin: Westerville, OH, USA, 2012. [Google Scholar]

- Neuman, E.W.; Hilmas, G.E.; Fahrenholtz, W.G. Ultra-high temperature mechanical properties of a zirconium diboride–zirconium carbide ceramic. J. Am. Ceram. Soc. 2016, 99, 597–603. [Google Scholar] [CrossRef]

- Krishnarao, R.; Alam, M.Z.; Das, D. In-situ formation of SiC, ZrB2-SiC and ZrB2-SiC-B4C-YAG coatings for high temperature oxidation protection of C/C composites. Corros. Sci. 2018, 141, 72–80. [Google Scholar] [CrossRef]

- Binner, J.; Porter, M.; Baker, B.; Zou, J.; Venkatachalam, V.; Diaz, V.R.; D’Angio, A.; Ramanujam, P.; Zhang, T.; Murthy, T. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs—A review. Int. Mater. Rev. 2019. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P. Loadings in Thermal Barrier Coatings of Jet Engine Turbine Blades: An Experimental Research and Numerical Modeling; Springer: New York, NY, USA, 2016. [Google Scholar]

- Sahith, M.S.; Giridhara, G.; Kumar, R.S. Development and analysis of thermal barrier coatings on gas turbine blades—A Review. Mater. Today Proc. 2018, 5, 2746–2751. [Google Scholar] [CrossRef]

- Northam, M.; Rossmann, L.; Sarley, B.; Harder, B.; Park, J.-S.; Kenesei, P.; Almer, J.; Viswanathan, V.; Raghavan, S. Comparison of Electron-Beam Physical Vapor Deposition and Plasma-Spray Physical Vapor Deposition Thermal Barrier Coating Properties Using Synchrotron X-ray Diffraction. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Karaoglanli, A.C.; Doleker, K.M.; Ozgurluk, Y. State of the Art Thermal Barrier Coating (TBC) Materials and TBC Failure Mechanisms. In Properties and Characterization of Modern Materials; Springer: New York, NY, USA, 2017; pp. 441–452. [Google Scholar]

- Xu, H.; Guo, H. Thermal Barrier Coatings; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Schmitt, M.P. Advanced Thermal Barrier Coating Materials and Design Architectures for Improved Durability. Ph.D. Dissertation, The Pennsylvania State University, University Park, PA, USA, 2016. [Google Scholar]

- Ghosh, S. Thermal barrier ceramic coatings—A review. Adv. Ceram. Process. 2015, 111–138. [Google Scholar]

- Kumar, V.; Balasubramanian, K. Progress update on failure mechanisms of advanced thermal barrier coatings: A review. Prog. Org. Coat. 2016, 90, 54–82. [Google Scholar] [CrossRef]

- Nandi, A.; Ghosh, S. Advanced Multi-layered Thermal Barrier Coatings—An Overview. J. Mater. Sci. Res. Rev. 2019, 30, 1–17. [Google Scholar]

- Kumar, V.; Kandasubramanian, B. Processing and design methodologies for advanced and novel thermal barrier coatings for engineering applications. Particuology 2016, 27, 1–28. [Google Scholar] [CrossRef]

- Zhang, B.; Song, W.; Wei, L.; Xiu, Y.; Xu, H.; Dingwell, D.B.; Guo, H. Novel thermal barrier coatings repel and resist molten silicate deposits. Scr. Mater. 2019, 163, 71–76. [Google Scholar] [CrossRef]

- Bernard, B.; Quet, A.; Bianchi, L.; Joulia, A.; Malié, A.; Schick, V.; Rémy, B. Thermal insulation properties of YSZ coatings: Suspension plasma spraying (SPS) versus electron beam physical vapor deposition (EB-PVD) and atmospheric plasma spraying (APS). Surf. Coat. Technol. 2017, 318, 122–128. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Doleker, K.M.; Demirel, B.; Turk, A.; Varol, R. Effect of shot peening on the oxidation behavior of thermal barrier coatings. Appl. Surf. Sci. 2015, 354, 314–322. [Google Scholar] [CrossRef]

- Bose, S. High Temperature Coatings; Elsevier: Oxford, UK, 2017. [Google Scholar]

- Fan, W.; Bai, Y. Review of suspension and solution precursor plasma sprayed thermal barrier coatings. Ceram. Int. 2016, 42, 14299–14312. [Google Scholar] [CrossRef]

- Soboyejo, W.O.; Obayemi, J.; Annan, E.; Ampaw, E.; Daniels, L.; Rahbar, N. Review of High Temperature Ceramics for Aerospace Applications. Adv. Mater. Res. 2016, 1132, 385. [Google Scholar] [CrossRef]

- Bose, S. (Ed.) Chapter 7—Thermal Barrier Coatings (TBCs). In High Temperature Coatings, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 199–299. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E. Review Nano and macro-structured component fabrication by electron beam-physical vapor deposition (EB-PVD). J. Mater. Sci. 2005, 40, 1–26. [Google Scholar] [CrossRef]

- Ali, N.; Teixeira, J.A.; Addali, A.; Saeed, M.; Al-Zubi, F.; Sedaghat, A.; Bahzad, H. Deposition of Stainless Steel Thin Films: An Electron Beam Physical Vapour Deposition Approach. Materials 2019, 12, 571. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.-J.; Ni, D.-W.; Zou, J.; Liu, H.-T.; Wu, W.-W.; Liu, J.-X.; Suzuki, T.S.; Sakka, Y. Inherent anisotropy in transition metal diborides and microstructure/property tailoring in ultra-high temperature ceramics—A review. J. Eur. Ceram. Soc. 2018, 38, 371–389. [Google Scholar] [CrossRef]

- Savino, R.; Criscuolo, L.; Di Martino, G.D.; Mungiguerra, S. Aero-thermo-chemical characterization of ultra-high-temperature ceramics for aerospace applications. J. Eur. Ceram. Soc. 2018, 38, 2937–2953. [Google Scholar] [CrossRef] [Green Version]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and Additive Manufacturing with Metal Matrix Composites: A Perspective. Procedia Manuf. 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Huang, Z.; Wu, L. Ultrahigh-Temperature Ceramics (UHTCs) Systems. In Phase Equilibria Diagrams of High Temperature Non-Oxide Ceramics; Springer: New York, NY, USA, 2018; pp. 103–162. [Google Scholar]

- Ghasali, E.; Yazdani-Rad, R.; Asadian, K.; Ebadzadeh, T. Production of Al-SiC-TiC hybrid composites using pure and 1056 aluminum powders prepared through microwave and conventional heating methods. J. Alloys Compd. 2017, 690, 512–518. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. A review on properties, behaviour and processing methods for Al-nano Al2O3 composites. Procedia Mater. Sci. 2014, 6, 567–589. [Google Scholar] [CrossRef] [Green Version]

- Balani, K.; Harimkar, S.P.; Keshri, A.; Chen, Y.; Dahotre, N.B.; Agarwal, A. Multiscale wear of plasma-sprayed carbon-nanotube-reinforced aluminum oxide nanocomposite coating. Acta Mater. 2008, 56, 5984–5994. [Google Scholar] [CrossRef]

- Hackett, K.; Verhoef, S.; Cutler, R.A.; Shetty, D.K. Phase constitution and mechanical properties of carbides in the Ta–C system. J. Am. Ceram. Soc. 2009, 92, 2404–2407. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Akbari, M.K.; Pakseresht, A.; Ghasali, E.; Naebe, M. Boron carbide reinforced aluminium matrix composite: Physical, mechanical characterization and mathematical modelling. Mater. Sci. Eng. A 2016, 658, 135–149. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.H.; Alizadeh, M.; Shirvanimoghaddam, K.; Ebadzadeh, T. Vanadium carbide reinforced aluminum matrix composite prepared by conventional, microwave and spark plasma sintering. J. Alloys Compd. 2016, 688, 527–533. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Ebadzadeh, T.; hossein Pakseresht, A.; Rahbari, A. Investigation on microstructural and mechanical properties of B4C–aluminum matrix composites prepared by microwave sintering. J. Mater. Res. Technol. 2015, 4, 411–415. [Google Scholar] [CrossRef] [Green Version]

- Ghasali, E.; Pakseresht, A.; Rahbari, A.; Eslami-Shahed, H.; Alizadeh, M.; Ebadzadeh, T. Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al–SiC–TiC composites. J. Alloys Compd. 2016, 666, 366–371. [Google Scholar] [CrossRef]

- Ghasali, E.; Shirvanimoghaddam, K.; Pakseresht, A.H.; Alizadeh, M.; Ebadzadeh, T. Evaluation of microstructure and mechanical properties of Al-TaC composites prepared by spark plasma sintering process. J. Alloys Compd. 2017, 705, 283–289. [Google Scholar] [CrossRef]

- Fahrenholtz, W.G.; Hilmas, G.E. Ultra-high temperature ceramics: Materials for extreme environments. Scr. Mater. 2017, 129, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Ancona, E.; Kezerashvili, R.Y. Temperature restrictions for materials used in aerospace industry for the near-Sun orbits. Acta Astronaut. 2017, 140, 565–569. [Google Scholar] [CrossRef] [Green Version]

- Scarponi, C. Carbon–Carbon Composites in Aerospace Engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 385–412. [Google Scholar]

- Zhu, L.; Li, N.; Childs, P. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Hendler, M.; Extra, S.; Lockan, M.; Bestle, D.; Flassig, P. Compressor Design in the Context of Holistic Aero Engine Design. In Proceedings of the 18th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Atlanta, GA, USA, 25–29 June 2018; p. 3334. [Google Scholar]

- Jahan, A.; Edwards, K.L.; Bahraminasab, M. Multi-Criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Zhang, Y.; Wang, H.; Li, T.; Fu, Y.; Ren, J. Ultra-high temperature ceramic coating for carbon/carbon composites against ablation above 2000 K. Ceram. Int. 2018, 44, 3056–3063. [Google Scholar] [CrossRef]

- Albano, M.; Delfini, A.; Pastore, R.; Micheli, D.; Marchetti, M. A new technology for production of high thickness carbon/carbon composites for launchers application. Acta Astronaut. 2016, 128, 277–285. [Google Scholar] [CrossRef]

- Prasad, N.E.; Wanhill, R.J. Aerospace Materials and Material Technologies; Springer: New York, NY, USA, 2017; Volume 3. [Google Scholar]

- Kumar, S.; Shekar, K.C.; Jana, B.; Manocha, L.; Prasad, N.E. C/C and C/SiC Composites for Aerospace Applications. In Aerospace Materials and Material Technologies; Springer: New York, NY, USA, 2017; pp. 343–369. [Google Scholar]

- Wang, J.; Yang, G.; Zhang, F.; Xiong, Y.; Xiong, Q. The preparation and mechanical properties of carbon/carbon (C/C) composite and carbon fiber reinforced silicon carbide (Cf/SiC) composite joint by partial transient liquid phase (PTLP) diffusion bonding process. Vacuum 2018, 158, 113–116. [Google Scholar] [CrossRef]

- Patra, N.; Al Nasiri, N.; Jayaseelan, D.D.; Lee, W.E. Thermal properties of Cf/HfC and Cf/HfC-SiC composites prepared by precursor infiltration and pyrolysis. J. Eur. Ceram. Soc. 2018, 38, 2297–2303. [Google Scholar] [CrossRef]

- Patra, N.; Al Nasiri, N.; Jayaseelan, D.D.; Lee, W.E. Low-temperature solution synthesis of nanosized hafnium carbide using pectin. Ceram. Int. 2016, 42, 1959–1963. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.-L.; Xiong, X.; Li, G.-D.; Liu, H.-F.; Chen, Z.-K.; Sun, W.; Zhao, X.-J. Ablation behavior of HfC protective coatings for carbon/carbon composites in an oxyacetylene combustion flame. Corros. Sci. 2012, 65, 549–555. [Google Scholar] [CrossRef]

- Wang, Y.-L.; Xiong, X.; Li, G.-D.; Liu, H.-F.; Chen, Z.-K.; Sun, W.; Zhao, X.-J. Preparation and ablation properties of Hf (Ta) C co-deposition coating for carbon/carbon composites. Corros. Sci. 2013, 66, 177–182. [Google Scholar] [CrossRef]

- Li, C.; Li, K.; Li, H.; Ouyang, H.; Zhang, Y.; Guo, L. Mechanical and thermophysical properties of carbon/carbon composites with hafnium carbide. Ceram. Int. 2013, 39, 6769–6776. [Google Scholar] [CrossRef]

- Xue, L.; Su, Z.-A.; Yang, X.; Huang, D.; Yin, T.; Liu, C.; Huang, Q. Microstructure and ablation behavior of C/C–HfC composites prepared by precursor infiltration and pyrolysis. Corros. Sci. 2015, 94, 165–170. [Google Scholar] [CrossRef]

- Vinci, A.; Zoli, L.; Sciti, D.; Watts, J.; Hilmas, G.E.; Fahrenholtz, W.G. Influence of fibre content on the strength of carbon fibre reinforced HfC/SiC composites up to 2100 °C. J. Eur. Ceram. Soc. 2019, 39, 3594–3603. [Google Scholar] [CrossRef]

- Zhu, W.; Fu, H.; Xu, Z.; Liu, R.; Jiang, P.; Shao, X.; Shi, Y.; Yan, C. Fabrication and characterization of carbon fiber reinforced SiC ceramic matrix composites based on 3D printing technology. J. Eur. Ceram. Soc. 2018, 38, 4604–4613. [Google Scholar] [CrossRef]

- Hu, C.; Hong, W.; Xu, X.; Tang, S.; Du, S.; Cheng, H.-M. Sandwich-structured C/C-SiC composites fabricated by electromagnetic-coupling chemical vapor infiltration. Sci. Rep. 2017, 7, 13120. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.; Tang, S.; Pang, S.; Cheng, H.-M. Long-term oxidation behaviors of C/SiC composites with a SiC/UHTC/SiC three-layer coating in a wide temperature range. Corros. Sci. 2019, 147, 1–8. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804. [Google Scholar] [CrossRef]

- Wang, L.; Si, L.; Zhu, Y.; Qian, Y. Solid-state reaction synthesis of ZrC from zirconium oxide at low temperature. Int. J. Refract. Met. Hard Mater. 2013, 38, 134–136. [Google Scholar] [CrossRef]

- Cheng, Y.; Hu, P.; Zhou, S.; Zhang, X.; Han, W. Using macroporous graphene networks to toughen ZrC–SiC ceramic. J. Eur. Ceram. Soc. 2018, 38, 3752–3758. [Google Scholar] [CrossRef]

- Wang, X.F.; Liu, J.C.; Hou, F.; Hu, J.D.; Sun, X.; Zhou, Y.C. Synthesis of ZrC–SiC powders from hybrid liquid precursors with improved oxidation resistance. J. Am. Ceram. Soc. 2015, 98, 197–204. [Google Scholar] [CrossRef]

- Vinci, A.; Zoli, L.; Landi, E.; Sciti, D. Oxidation behaviour of a continuous carbon fibre reinforced ZrB2–SiC composite. Corros. Sci. 2017, 123, 129–138. [Google Scholar] [CrossRef]

- Sengupta, P.; Manna, I. Advanced High-Temperature Structural Materials for Aerospace and Power Sectors: A Critical Review. Trans. Indian Inst. Met. 2019, 72, 2043–2059. [Google Scholar] [CrossRef]

- Cui, Y.-H.; Hu, Z.-C.; Ma, Y.-D.; Yang, Y.; Zhao, C.-C.; Ran, Y.-T.; Gao, P.-Y.; Wang, L.; Dong, Y.-C.; Yan, D.-R. Porous nanostructured ZrO2 coatings prepared by plasma spraying. Surf. Coat. Technol. 2019, 363, 112–119. [Google Scholar] [CrossRef]

- Yan, S.; Wu, D.; Niu, F.; Huang, Y.; Liu, N.; Ma, G. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceram. Int. 2018, 44, 1120–1126. [Google Scholar] [CrossRef]

- Fu, L.-S.; Wang, Z.; Fu, X.-S.; Chen, G.-Q.; Zhou, W.-L. Microstructure and mechanical properties of Y2O3-doped melt-grown Al2O3-ZrO2 eutectic ceramic. Mater. Sci. Eng. A 2017, 703, 372–379. [Google Scholar] [CrossRef]

- Chen, Y.-D.; Yang, Y.; Chu, Z.-H.; Chen, X.-G.; Wang, L.; Liu, Z.; Dong, Y.-C.; Yan, D.-R.; Zhang, J.-X.; Kang, Z.-L. Microstructure and properties of Al2O3-ZrO2 composite coatings prepared by air plasma spraying. Appl. Surf. Sci. 2018, 431, 93–100. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, R.; Fang, D. An ultralight silica-modified ZrO2–SiO2 aerogel composite with ultra-low thermal conductivity and enhanced mechanical strength. Scr. Mater. 2018, 143, 113–116. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, R.; Wang, B. Novel self-reinforcing ZrO2–SiO2 aerogels with high mechanical strength and ultralow thermal conductivity. Ceram. Int. 2018, 44, 15440–15445. [Google Scholar] [CrossRef]

- Liu, B.; Gao, M. Highly Mixed ZrO2/SiO2 Hybrid Aerogel Deriving from Freely Tangled Weakly Branched Primary Clusters Enables Improved Thermal Stability and Excellent Thermal Insulating Performance. ACS Appl. Nano Mater. 2019. [Google Scholar] [CrossRef]

- He, J.; Zhao, H.; Li, X.; Su, D.; Ji, H.; Yu, H.; Hu, Z. Large-scale and ultra-low thermal conductivity of ZrO2 fibrofelt/ZrO2-SiO2 aerogels composites for thermal insulation. Ceram. Int. 2018, 44, 8742–8748. [Google Scholar] [CrossRef]

- Castle, E.; Csanádi, T.; Grasso, S.; Dusza, J.; Reece, M. Processing and properties of high-entropy ultra-high temperature carbides. Sci. Rep. 2018, 8, 8609. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Zhao, H.C.; Feng, C. High-temperature protective coatings for C/SiC composites. J. Asian Ceram. Soc. 2014, 2, 305–309. [Google Scholar] [CrossRef] [Green Version]

- Moema, J.S.; Papo, M.J.; Stumpf, W.E.; Slabbert, D. The role of retained austenite on performance of grinding media. Wear 2010, 4, 5. [Google Scholar]

- Auciello, O.; Birrell, J.; Carlisle, J.A.; Gerbi, J.E.; Xiao, X.; Peng, B.; Espinosa, H.D. Materials science and fabrication processes for a new MEMS technology based on ultrananocrystalline diamond thin films. J. Phys. Condens. Matter 2004, 16, R539. [Google Scholar] [CrossRef]

- Gale, T.; Totemeir, W.C. Smithells Metals Reference Book; Butterworth-Heinemann: Boston, MA, USA, 2004. [Google Scholar]

- Balko, J.; Csanádi, T.; Sedlák, R.; Vojtko, M.; KovalĿíková, A.; Koval, K.; Wyzga, P.; Naughton-Duszová, A. Nanoindentation and tribology of VC, NbC and ZrC refractory carbides. J. Eur. Ceram. Soc. 2017, 37, 4371–4377. [Google Scholar] [CrossRef]

- Sonber, J.; Murthy, T.; Sairam, K.; Chakravartty, J. Effect of NdB6 addition on densification and properties of ZrB2. Ceram. Silikáty 2016, 60, 41–47. [Google Scholar] [CrossRef]

- Mitra, R.; Upender, S.; Mallik, M.; Chakraborty, S.; Ray, K.K. Mechanical, Thermal and Oxidation Behaviour of Zirconium Diboride Based Ultra-High Temperature Ceramic Composites. In Proceedings of the 9th ICKEM Key Engineering Materials, Oxford, UK, 31 March–1 April 2019; pp. 55–68. [Google Scholar]

- Vinodkumar, T.; Reddy, B.M. Chapter 3—Catalytic Combustion over Cheaper Metal Oxides in Catalytic Combustion; Nova Science Publisher: Hauppauge, NY, USA, 2011; pp. 105–140. [Google Scholar]

- Alsebaie, A.M. Characterisation of Alumina-Zirconia Composites Produced by Micron-Sized Powders. Master’s Thesis, Dublin City University, Dublin, Ireland, 2006. [Google Scholar]

- El-Mahallawi, I.S.; Shash, A.Y.; Amer, A.E. Nanoreinforced cast Al-Si alloys with Al2O3, TiO2 and ZrO2 nanoparticles. Metals 2015, 5, 802–821. [Google Scholar] [CrossRef] [Green Version]

| Material | Melting Temperature (°C) | Hardness (GPa) | Young’s Modulus (GPa) |

|---|---|---|---|

| TaC | 3427 [92] | 20.6 ± 1.2 [92] | 579 ± 20 [92] |

| HfC | 3890 [93] | 31.5 ± 1.3 [92] | 552 ± 15 [92] |

| SiC | 2730 [93] | 25.5 [94] | 450 [95] |

| ZrC | 3530 [96] | 31.3 ± 1.4 [97] | 507 ± 16 [97] |

| ZrB2 | 3245 [98] | 21 [99] | 490 [99] |

| ZrO2 | 2699 [100] | 11.77 [101] | 171 [102] |

| Al2O3 | 2071 [100] | 21.58 [101] | 380 [102] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasile, B.S.; Birca, A.C.; Surdu, V.A.; Neacsu, I.A.; Nicoară, A.I. Ceramic Composite Materials Obtained by Electron-Beam Physical Vapor Deposition Used as Thermal Barriers in the Aerospace Industry. Nanomaterials 2020, 10, 370. https://doi.org/10.3390/nano10020370

Vasile BS, Birca AC, Surdu VA, Neacsu IA, Nicoară AI. Ceramic Composite Materials Obtained by Electron-Beam Physical Vapor Deposition Used as Thermal Barriers in the Aerospace Industry. Nanomaterials. 2020; 10(2):370. https://doi.org/10.3390/nano10020370

Chicago/Turabian StyleVasile, Bogdan Stefan, Alexandra Catalina Birca, Vasile Adrian Surdu, Ionela Andreea Neacsu, and Adrian Ionut Nicoară. 2020. "Ceramic Composite Materials Obtained by Electron-Beam Physical Vapor Deposition Used as Thermal Barriers in the Aerospace Industry" Nanomaterials 10, no. 2: 370. https://doi.org/10.3390/nano10020370

APA StyleVasile, B. S., Birca, A. C., Surdu, V. A., Neacsu, I. A., & Nicoară, A. I. (2020). Ceramic Composite Materials Obtained by Electron-Beam Physical Vapor Deposition Used as Thermal Barriers in the Aerospace Industry. Nanomaterials, 10(2), 370. https://doi.org/10.3390/nano10020370