Exploring the Interfacial Phase and π–π Stacking in Aligned Carbon Nanotube/Polyimide Nanocomposites

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Fabrication of the Aligned Carbon Nanotube/Polymide Composites

2.2. Characterizations

3. Results and Discussions

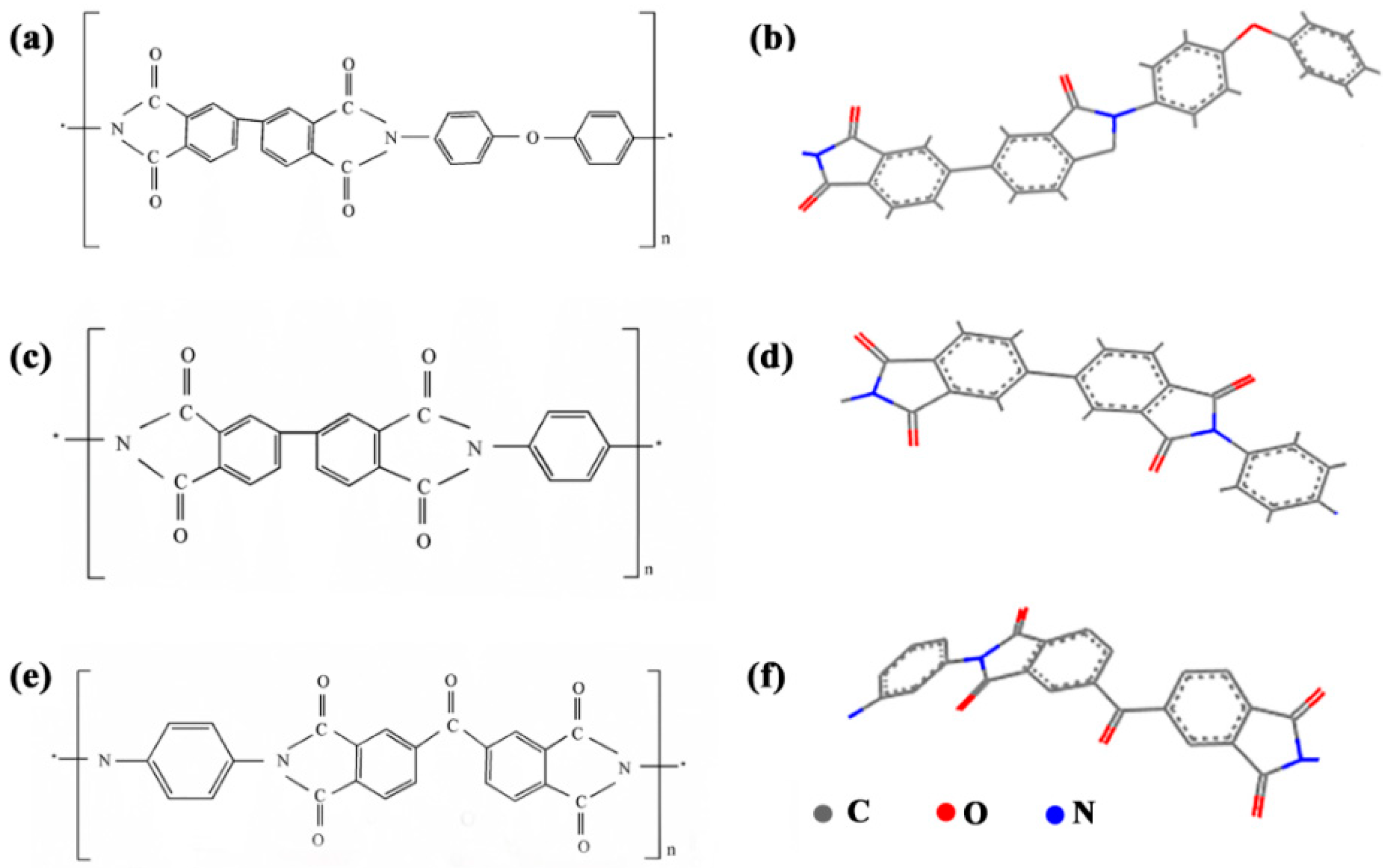

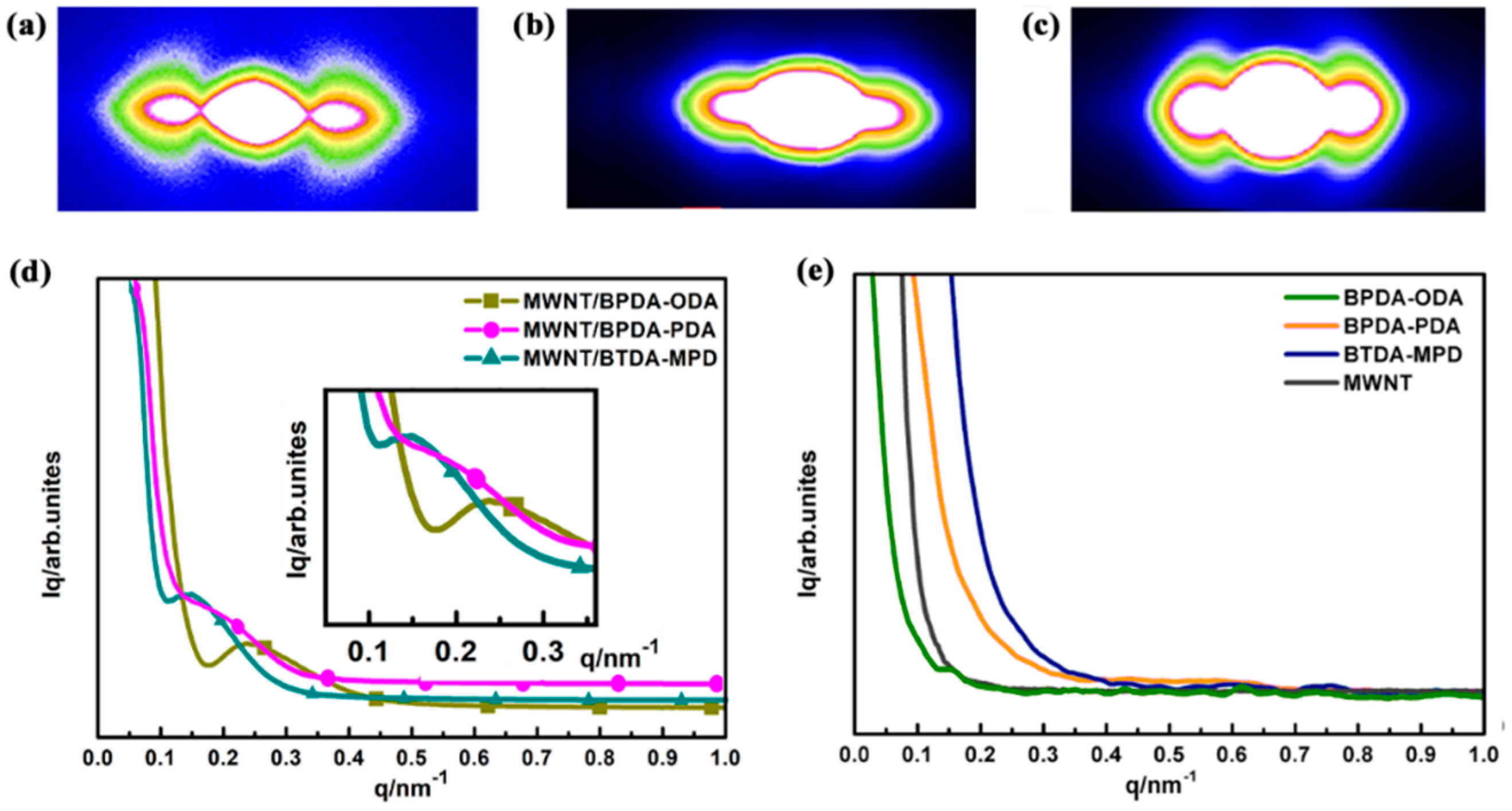

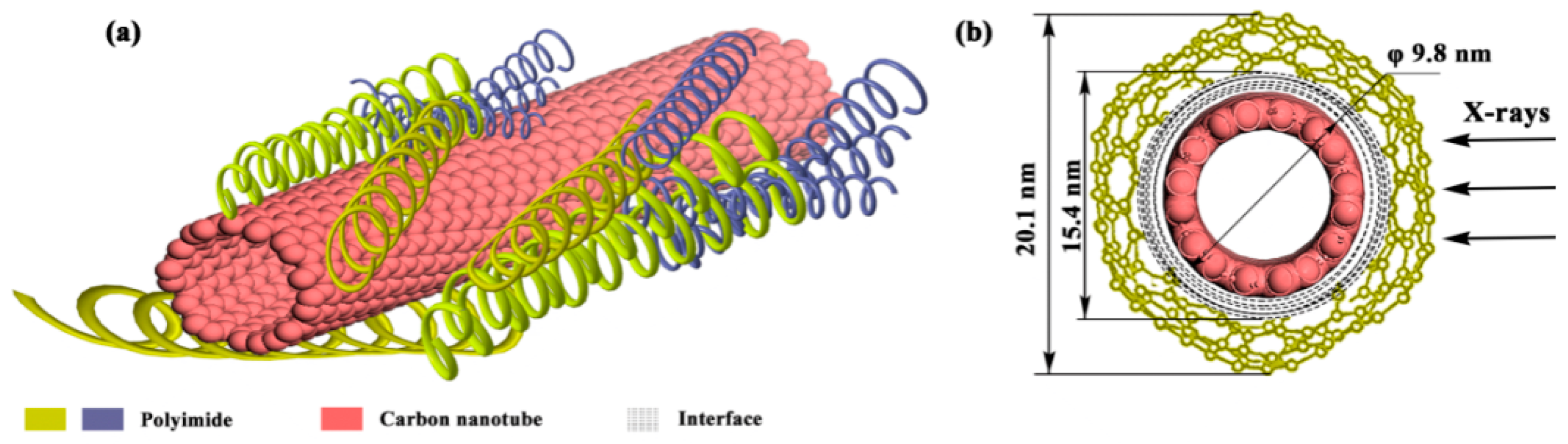

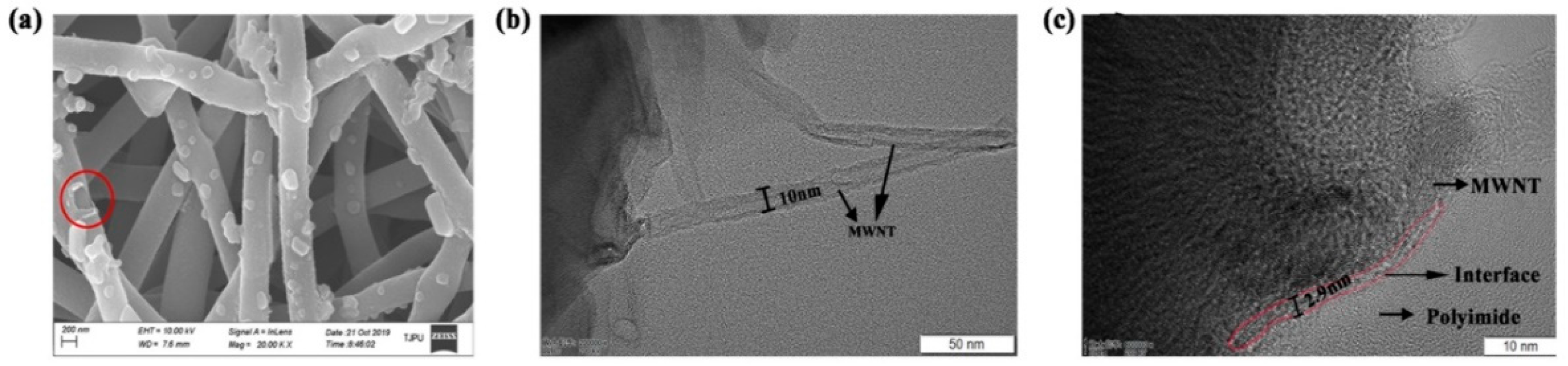

3.1. Interface Characteristics of MWNT/PI Nanocomposite

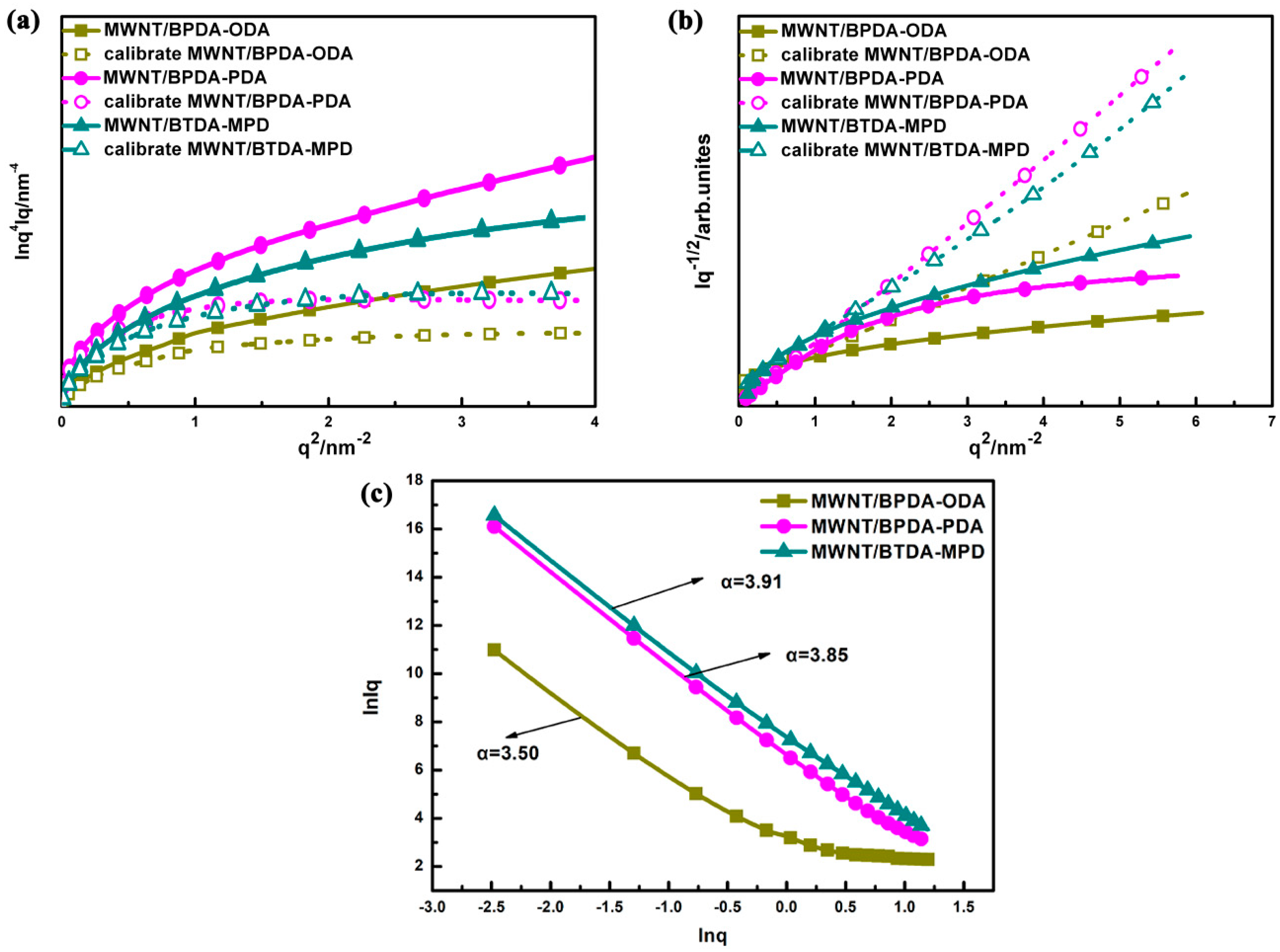

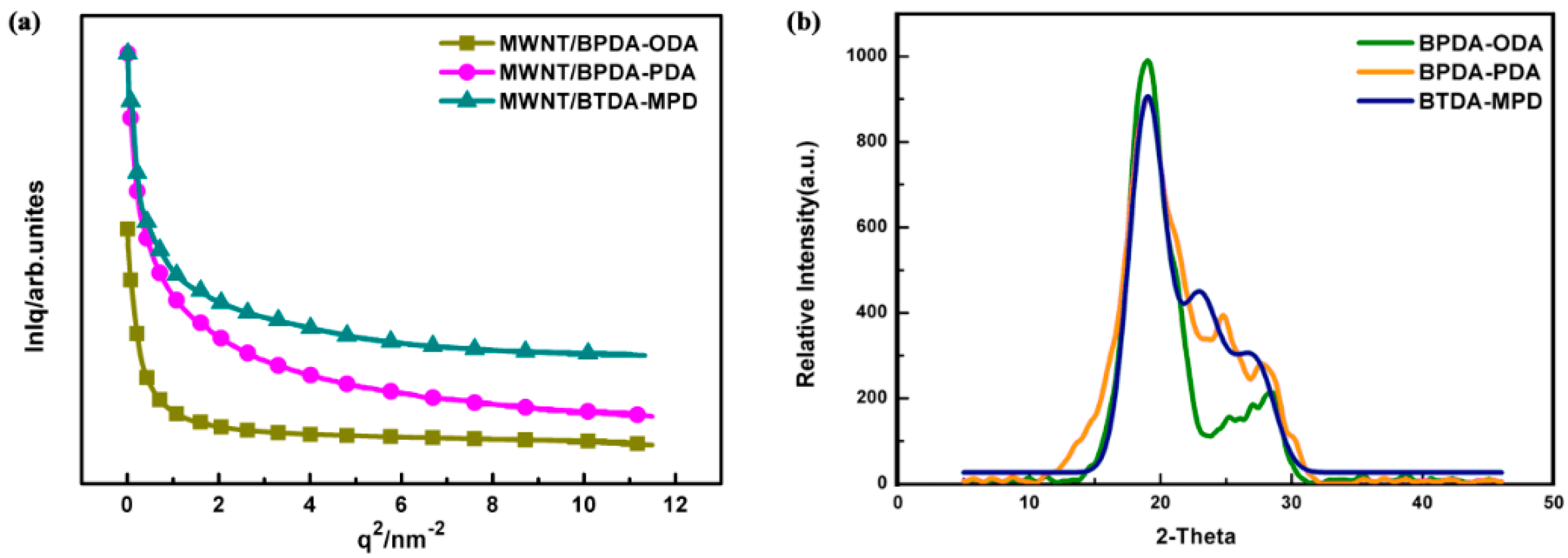

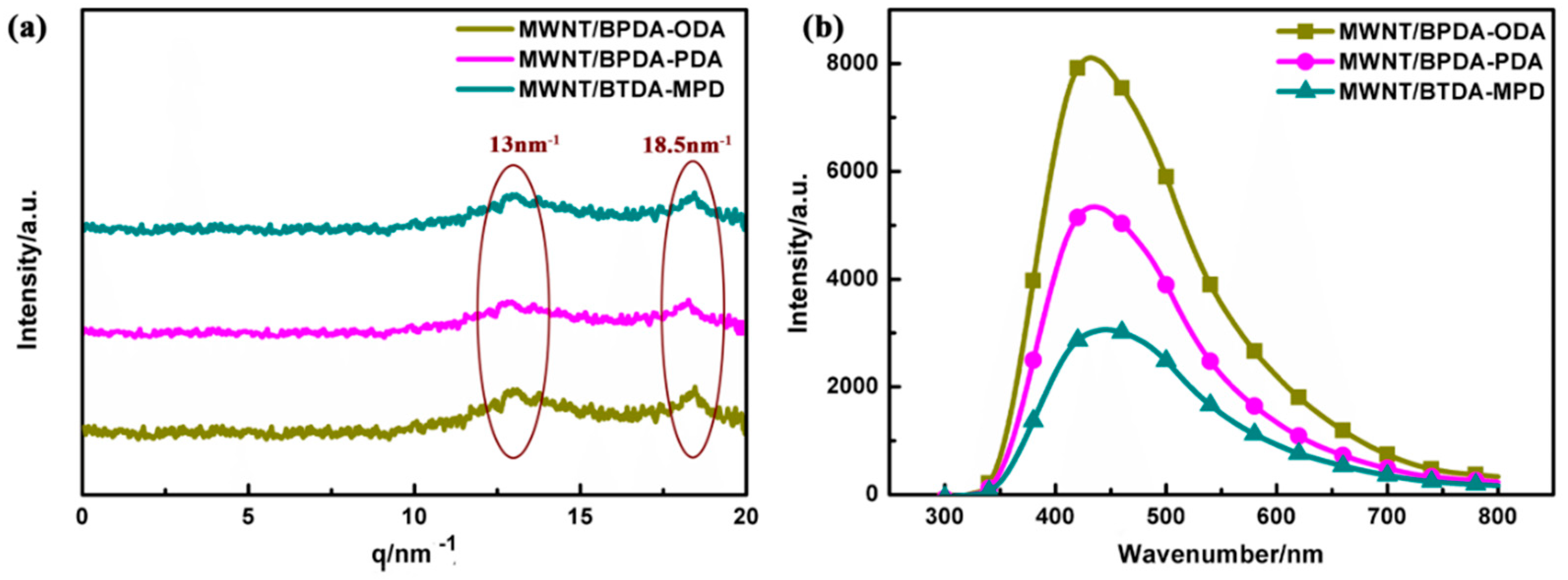

3.2. Phase Dimension Analysis of MWNT/PI Nanocomposites

3.3. π–π Stacking Effect in MWNT/PI Nanocomposite Interface

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Ma, Z.; Chai, L.; Xu, L.; Zhu, Z.; Hu, Y.; Qian, J.; Huang, S. Mof derived n-doped carbon coated cop particle/carbon nanotube composite for efficient oxygen evolution reaction. Carbon 2019, 141, 643–651. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Wang, Y.; Brown, K.A. Design of elastomer-cnt film photoactuators for nanolithography. Polymers 2019, 11, 314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, Q.; Pei, X.; Wu, L.; Li, T.-T.; Lou, C.-W.; Lin, J.-H. High-performance thermoplastic hybrid composite reinforced with bucky paper for electromagnetic interference shielding. Polym. Compos. 2018, 40, 3065–3074. [Google Scholar] [CrossRef]

- He, Z.; Zhou, G.; Byun, J.-H.; Lee, S.K.; Um, M.-K.; Park, B.; Kim, T.; Lee, S.B.; Li, J.; Zuoli, H. Highly stretchable multi-walled carbon nanotube/thermoplastic polyurethane composite fibers for ultrasensitive, wearable strain sensors. Nanoscale 2019, 11, 5884–5890. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Weng, M.; Zhou, Z.; Zhou, Y.; Zhang, L.; Li, J.; Huang, Z.; Zhang, W.; Liu, C.; Fan, S. Large-deformation curling actuators based on carbon nanotube composite: Advanced-structure design and biomimetic application. ACS Nano 2015, 9, 12189–12196. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Yuan, J.; Mehedi, H.-a.; Gheeraert, E.; Sylvestre, A. Carbon nanotube forest based electrostatic capacitor with excellent dielectric performances. Carbon 2017, 116, 648–654. [Google Scholar] [CrossRef]

- Wenelska, K.; Michalkiewicz, B.; Chen, X.; Mijowska, E. Pd nanoparticles with tunable diameter deposited on carbon nanotubes with enhanced hydrogen storage capacity. Energy 2014, 75, 549–554. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef] [Green Version]

- Odegard, G.M.; Pipes, R.B.; Hubert, P. Comparison of two models of swcn polymer composites. Compos. Sci. Technol. 2004, 64, 1011–1020. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Song, W.; Xu, D. Interfacial characteristics of carbon nanotube-polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 149–169. [Google Scholar] [CrossRef]

- Wang, C.; Wang, T.; Wang, Q. Controllable porous fluorinated polyimide thin films for ultralow dielectric constant interlayer dielectric applications. J. Macromol. Sci. Pure Appl. Chem. 2017, 54, 311–315. [Google Scholar] [CrossRef]

- Kim, K.; Nam, K.-H.; Lee, J.; Kim, H.-J.; Goh, M.; Ku, B.-C.; You, N.-H. Effect of defect-healing in graphene nanosheets on the mechanical properties of polyimide nanocomposites. Carbon 2017, 122, 614–621. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, C.; Li, N.; Yin, J.; Zhao, X.; Li, J.; Zhao, H.; Zhu, C.; Chen, M.; Su, B. The effects of mcnts on electro-spinning carbonization microstructure of polyimide composite film and resistive switching behavior. Surf. Coat. Technol. 2019, 359, 438–444. [Google Scholar] [CrossRef]

- Ning, W.; Wang, Z.; Liu, P.; Zhou, D.; Yang, S.; Wang, J.; Li, Q.; Fan, S.; Jiang, K. Multifunctional super-aligned carbon nanotube/polyimide composite film heaters and actuators. Carbon 2018, 139, 1136–1143. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, X.; Zhu, Y.; Hui, D.; Qiu, Y. Mechanical, electrical and thermal properties of aligned carbon nanotube/polyimide composites. Compos. Part B Eng. 2014, 56, 408–412. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, L. Property enhancement of aligned carbon nanotube/polyimide composite by strategic prestraining. J. Reinf. Plast. Compos. 2016, 35, 287–294. [Google Scholar] [CrossRef]

- Jiang, Q.; Tallury, S.S.; Qiu, Y.; Pasquinelli, M.A. Molecular dynamics simulations of the effect of the volume fraction on unidirectional polyimide–carbon nanotube nanocomposites. Carbon 2014, 67, 440–448. [Google Scholar] [CrossRef]

- Jiang, Q.; Tallury, S.S.; Qiu, Y.; Pasquinelli, M.A. Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation. Nanotechnol. Rev. 2020, 9, 136–145. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Wang, J.; Fan, C.; Chen, Z.; Liu, P.; Zhu, D.; Xu, Z.; Pang, L.; Li, T. Synthesis of carbon self-repairing porous g-c 3 n 4 nanosheets/nico 2 s 4 nanoparticles hybrid composite as high-performance electrode materials for supercapacitors. Electrochim. Acta 2017, 253, 68–77. [Google Scholar] [CrossRef]

- Rana, M.K.; Chandra, A. Wetting behavior of nonpolar nanotubes in simple dipolar liquids for varying nanotube diameter and solute-solvent interactions. J. Chem. Phys. 2015, 142, 034704. [Google Scholar] [CrossRef]

- Zhou, K.; Zhou, X.; Xu, X.; Musumeci, C.; Inganäs, O. Π–π stacking distance and phase separation controlled efficiency in stable all-polymer solar cells. Polymers 2019, 11, 1665. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, M.; Koutsos, V.; Zaiser, M. Interactions between polymers and carbon nanotubes:? A molecular dynamics study. J. Phys. Chem. B 2005, 109, 10009–10014. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.Q.; Hennequin, B.; Sacher, E. Xps demonstration of π−π interaction between benzyl mercaptan and multiwalled carbon nanotubes and their use in the adhesion of pt nanoparticles. Chem. Mater. 2006, 18, 5033–5038. [Google Scholar] [CrossRef]

- Wu, K.; Li, Y.; Huang, R.; Chai, S.; Chen, F.; Fu, Q. Constructing conductive multi-walled carbon nanotubes network inside hexagonal boron nitride network in polymer composites for significantly improved dielectric property and thermal conductivity. Compos. Sci. Technol. 2017, 151, 193–201. [Google Scholar] [CrossRef]

- Chun, K.Y.; Oh, Y.; Rho, J.; Ahn, J.H.; Kim, Y.J.; Choi, H.R.; Baik, S. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat. Nanotechnol. 2010, 5, 853–857. [Google Scholar] [CrossRef]

- Chen, J.; Cui, X.; Zhu, Y.; Jiang, W.; Sui, K. Design of superior conductive polymer composite with precisely controlling carbon nanotubes at the interface of a co-continuous polymer blend via a balance of pi-pi interactions and dipole-dipole interactions. Carbon Int. J. Spons. By Am. Carbon Soc. 2017, 114, 441–448. [Google Scholar] [CrossRef]

- Tanaka, H.; Hiratsuka, T.; Nishiyama, N.; Mori, K.; Miyahara, M.T. Capillary condensation in mesoporous silica with surface roughness. Adsorpt.-J. Int. Adsorpt. Soc. 2013, 19, 631–641. [Google Scholar] [CrossRef]

- Reinhold, B.; Geue, T.; Huber, P.; Sant, T.; Pietsch, U.; Sztucki, M. In situ and ex situ saxs investigation of colloidal sedimentation onto laterally patterned support. Langmuir 2009, 25, 814–819. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Li, L.; Yu, X.; Han, H.; Guo, X. Distribution of magnetic nanoparticles in spherical polyelectrolyte brushes as observed by small-angle x-ray scattering. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1681–1688. [Google Scholar] [CrossRef]

- Yu, X.-J.; Wang, W.-H.; Li, L.; Guo, X.-H.; Zhou, Z.-M.; Wang, F.-C. Analysis of spherical polyelectrolyte brushes by small angle X-ray scattering. Chin. J. Polym. Sci. 2014, 32, 778–785. [Google Scholar] [CrossRef]

- Liu, Y.H.; Wang, G.; Wang, R.J.; Pan, M.X.; Wang, W.H. Super plastic bulk metallic glasses at room temperature. Science 2007, 315, 1385–1388. [Google Scholar] [CrossRef] [PubMed]

- Debye, P.; Anderson, H., Jr.; Brumberger, H. Scattering by an inhomogeneous solid. Ii. The correlation function and its application. J. Appl. Phys. 1957, 28, 679–683. [Google Scholar] [CrossRef]

- Dubey, K.A.; Mondal, R.K.; Kumar, J.; Melo, J.S.; Bhardwaj, Y.K. Enhanced electromechanics of morphology-immobilized co-continuous polymer blend/carbon nanotube high-range piezoresistive sensor. Chem. Eng. J. 2020, 389, 124112. [Google Scholar] [CrossRef]

- Svergun, D.I.; Shtykova, E.V.; Kozin, M.B.; Volkov, V.V.; Konarev, P.V.; Dembo, A.T.; Shtykova, E.V.; Bronshtein, L.M.; Chernyshov, D.M.; Platonova, O.A.; et al. Small-angle x-ray scattering study of the structure of self-organized polymer matrices and formation of imbedded metal nanoparticles. Crystallogr. Rep. 2001, 46, 586–595. [Google Scholar] [CrossRef]

- Burghardt, W.; Caputo, F.; Kasiraman, K.; Bates, F.; Lodge, T. Small-Angle Neutron, X-ray and Light Scattering Studies of a Polymer Bicontinuous Microemulsion under Shear; Argonne National Laboratory (ANL): Argonne, IL, USA, 2005. [Google Scholar]

- Chu, B.; Hsiao, B.S. Small-angle x-ray scattering of polymers. Chem. Rev. 2001, 101, 1727–1762. [Google Scholar] [CrossRef] [PubMed]

- Sakuragi, M.; Takeda, Y.; Shimada, N.; Sakurai, K. Entrapment of immature amyloid protofilaments in the hydrophobic domain of schizophyllan. Polym. Bull. 2008, 61, 107–117. [Google Scholar] [CrossRef]

- Yuguchi, Y.; Urakawa, H.; Kajiwara, K. Structural characteristics of carrageenan gels: Various types of counter ions. Food Hydrocoll. 2003, 17, 481–485. [Google Scholar] [CrossRef]

- Kim, F.S.; Ren, G.; Jenekhe, S.A. One-dimensional nanostructures of π-conjugated molecular systems: Assembly, properties, and applications from photovoltaics, sensors, and nanophotonics to nanoelectronics. Chem. Mater. 2011, 23, 682–732. [Google Scholar] [CrossRef]

- Wakita, J.; Jin, S.; Shin, T.J.; Ree, M.; Ando, S. Analysis of molecular aggregation structures of fully aromatic and semialiphatic polyimide films with synchrotron grazing incidence wide-angle X-ray scattering. Macromolecules 2010, 43, 1930–1941. [Google Scholar] [CrossRef]

- Siqing, S.; Wu, H.; Yamaguchi, H.; Shinohara, T.; Sakata, O.; Takahara, A. Grazing-incidence wide-angle X-ray diffraction study on molecular aggregation state of imprinted polyimide film before and after hard baking. Polym. Bull. 2013, 70, 105–115. [Google Scholar] [CrossRef]

- Ahn, J.; Park, S.; Ji, H.L.; Jung, S.H.; Moon, S.J.; Jung, J.H. Fluorescent hydrogels formed by ch-π and π-π interactions as the main driving forces: An approach toward understanding the relationship between fluorescence and structure. Chem. Commun. 2013, 49, 2109–2111. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.Y.; Chen, L.; Zhong, H.Y.; Yang, R.; Liu, X.F.; Wang, Y.Z. Effect of different dimensional carbon nanoparticles on the shape memory behavior of thermotropic liquid crystalline polymer. Compos. Sci. Technol. 2016, 138, 8–14. [Google Scholar]

| Sample | L/nm | dc/nm | dt/nm | da/nm |

|---|---|---|---|---|

| MWNT/BPDA-ODA | 22.7 | 9.8 | 5.6 | 7.3 |

| MWNT/BPDA-PDA | 21.2 | 9.7 | 5.2 | 6.3 |

| MWNT/BTDA-MPD | 22.1 | 10.4 | 5.0 | 6.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Zhang, Q.; Wu, X.; Wu, L.; Lin, J.-H. Exploring the Interfacial Phase and π–π Stacking in Aligned Carbon Nanotube/Polyimide Nanocomposites. Nanomaterials 2020, 10, 1158. https://doi.org/10.3390/nano10061158

Jiang Q, Zhang Q, Wu X, Wu L, Lin J-H. Exploring the Interfacial Phase and π–π Stacking in Aligned Carbon Nanotube/Polyimide Nanocomposites. Nanomaterials. 2020; 10(6):1158. https://doi.org/10.3390/nano10061158

Chicago/Turabian StyleJiang, Qian, Qian Zhang, Xianyan Wu, Liwei Wu, and Jia-Horng Lin. 2020. "Exploring the Interfacial Phase and π–π Stacking in Aligned Carbon Nanotube/Polyimide Nanocomposites" Nanomaterials 10, no. 6: 1158. https://doi.org/10.3390/nano10061158