Effect of Nano-Reinforcement Topologies on the Viscoelastic Performance of Carbon Nanotube/Carbon Fiber Hybrid Composites

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Synthesis of Hybrid Reinforcements

2.2. Composites Fabrication

2.3. Mechanical Testing

2.4. Morphology Characterization

3. Results and Discussion

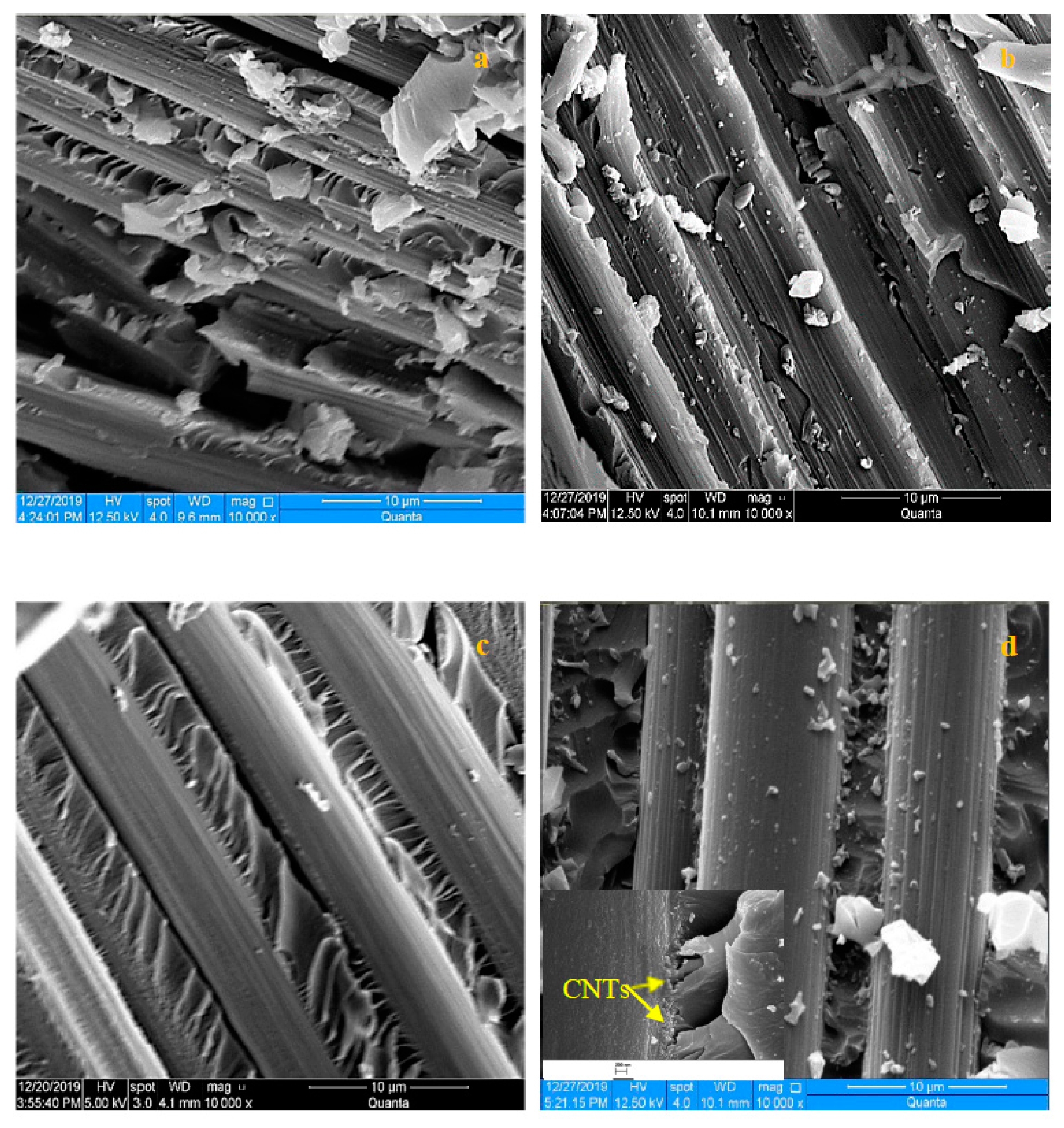

3.1. CNTs Growth Analysis

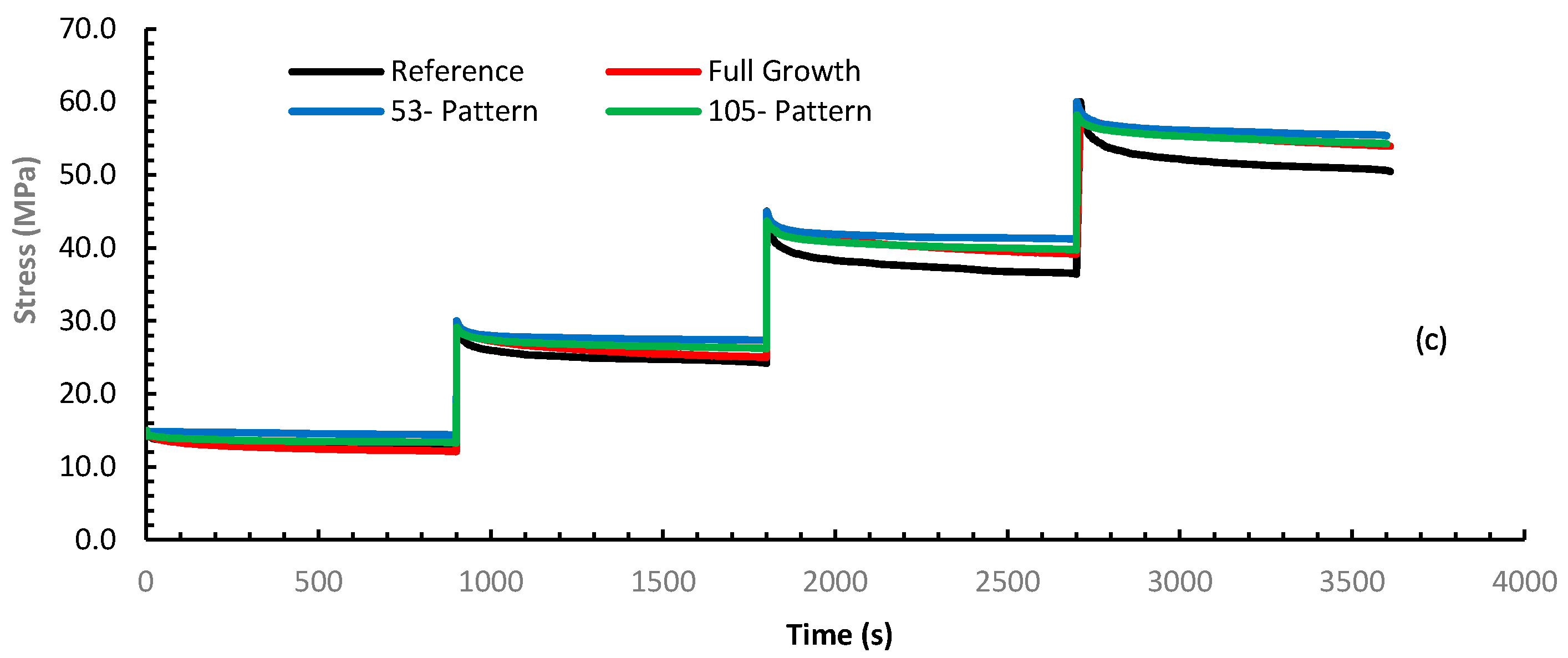

3.2. Tensile Test Results

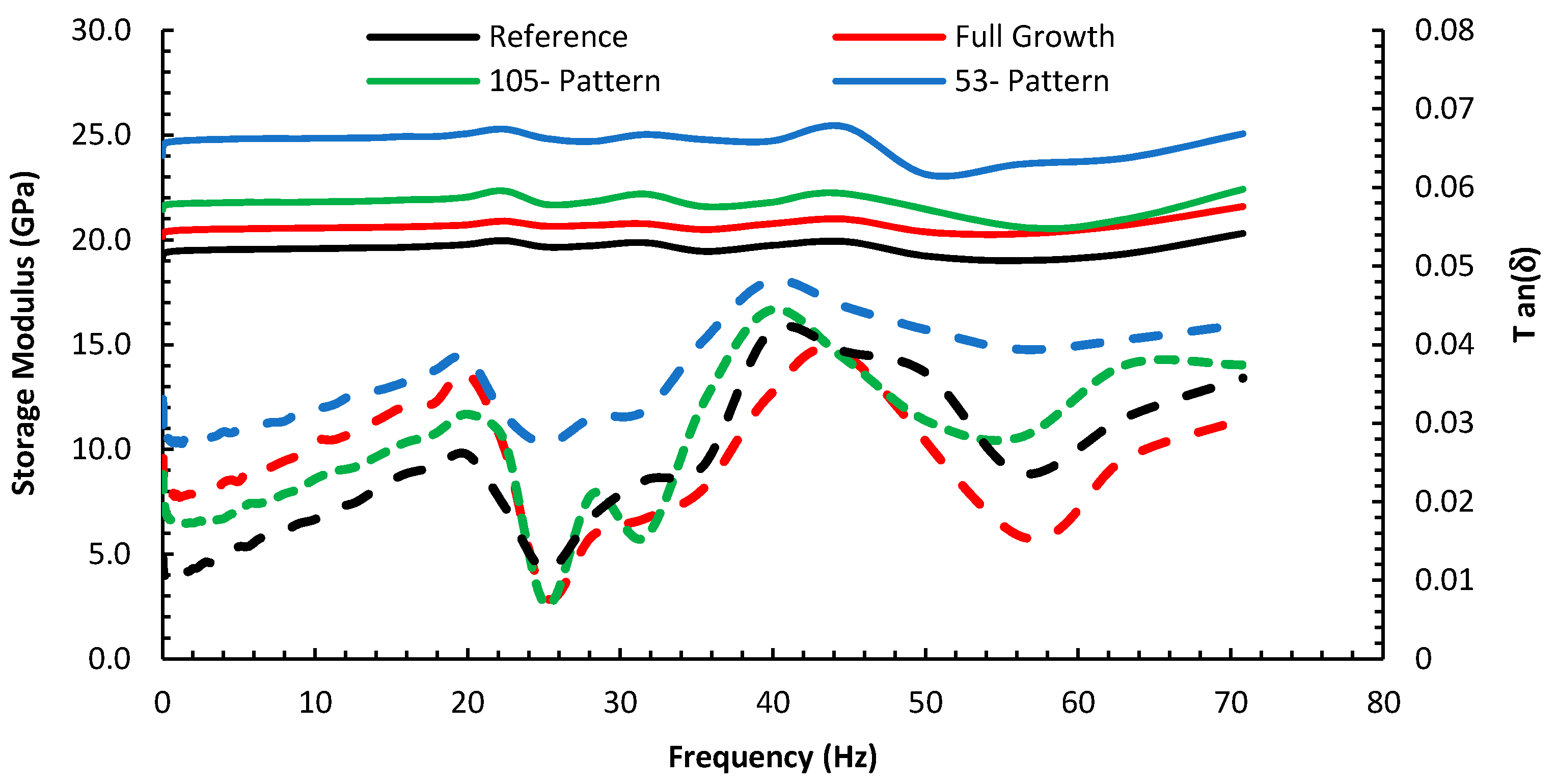

3.3. DMTA Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hyer, M.W. Stress Analysis of Fiber Reinforced Composite Materials; DEStech Publications: Lancaster, PA, USA, 2009. [Google Scholar]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Hatakeyama, T.; Quinn, F.X. Thermal Analysis Fundamentals and Applications to Polymer Science; John Wiley & Sons Ltd.: New York, NY, USA, 1999. [Google Scholar]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Wetton, R.E.; Marsh, R.D.; Van-de-Velde, J.G. Theory and application of dynamic mechanical thermal analysis. Thermochim. Acta 1991, 175, 1–11. [Google Scholar] [CrossRef]

- Goertzen, W.K.; Kessler, M.R. Dynamic mechanical analysis of carbon/epoxy composites for structural pipeline repair. Compos. Part B 2007, 38, 1–9. [Google Scholar] [CrossRef]

- Paiva, J.M.; Costa, M.L.; Rezende, M.C. Evaluation of thermal stability and glass transition temperature of different aeronautical polymeric composites. Polym. Plast. Technol. Eng. 2006, 45, 157–164. [Google Scholar] [CrossRef]

- Obaid, N.; Kortschot, M.T.; Sain, M. Predicting the stress relaxation behavior of glass-fiber reinforced polypropylene composite. Compos. Sci. Technol. 2018, 161, 85–91. [Google Scholar] [CrossRef]

- Hashin, Z. Composite materials with viscoelastic interphase: Creep and relaxation. Mech. Mater. 1991, 11, 135–148. [Google Scholar] [CrossRef]

- Al-Haik, M.S.; Garmestani, H.; Savran, A. Explicit and implicit viscoplastic models for polymeric composite. Int. J. Plast. 2004, 20, 1875–1907. [Google Scholar] [CrossRef]

- Gates, T.S. Experimental characterization nonlinear rate dependent behavior in advanced polymer matrix composites. Exp. Mech. 1992, 32, 68–73. [Google Scholar] [CrossRef]

- Gates, T.S.; Sun, C.T. Elastic/viscoplastic consitutive model for fiber reinforced thermoplastic composites. AIAA 1991, 29, 457–463. [Google Scholar] [CrossRef]

- Al-Haik, M.; Vaghar, M.R.; Garmestani, H.; Shahawy, M. Viscoplastic analysis of structural polymer composites using stress relaxation and creep data. Compos. Part B Eng. 2001, 32, 165–170. [Google Scholar] [CrossRef]

- Guo, C.; Zheng, Z.; Zhu, Q.; Wang, X. Preparation and characterization of polyurethane/ZnO nanoparticle composites. Polym. Plast. Technol. Eng. 2007, 46, 1161–1166. [Google Scholar] [CrossRef]

- Abdel-Magid, B.; Lopez-Anido, R.; Smith, G.; Trofka, S. Flexure creep properties of E-glass reinforced polymers. Compos. Struct. 2003, 62, 247–253. [Google Scholar] [CrossRef]

- Goertzen, W.K.; Kessler, M.R. Creep behavior of carbon fiber/epoxy matrix composites. Mater. Sci. Eng. A 2006, 421, 217–225. [Google Scholar] [CrossRef]

- Brinson, H.F.; Brinson, L.C. Polymer Engineering Science and Viscoelasticity: An Introduction; Springer: New York, NY, USA, 2008. [Google Scholar]

- Alipour Skandani, A.; Masghouni, N.; Case, S.W.; Leo, D.J.; Al-Haik, M. Enhanced vibration damping of carbon fibers-ZnO nanorods hybrid composites. Appl. Phys. Lett. 2012, 101, 073111. [Google Scholar] [CrossRef]

- Munkhbayar, B.; Nine, M.J.; Jeoun, J.; Bat-Erdene, M.; Chung, H.; Jeong, H. Influence of dry and wet ball milling on dispersion characteristics of the multi-walled carbon nanotubes in aqueous solution with and without surfactant. Powder Technol. 2013, 234, 132–140. [Google Scholar] [CrossRef]

- Forró, L.; Gaal, R.; Grimaldi, C.; Mionić, M.; Ribič, P.R.; Smajda, R.; Magrez, A. Tuning the length dispersion of multi-walled carbon nanotubes by ball milling. AIP Adv. 2013, 3, 092117. [Google Scholar] [CrossRef]

- Jin, L.; Bower, C.; Zhou, O. Alignment of carbon nanotubes in a polymer matrix by mechanical stretching. Appl. Phys. Lett. 1998, 73, 1197–1199. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-compo sites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Choi, E.S.; Brooks, J.S.; Eaton, D.L.; Al-Haik, M.S.; Hussaini, M.Y.; Garmestani, H.; Li, D.; Dahmen, K. Enhancement of thermal and electrical properties of carbon nanotube polymer composites by magnetic field processing. J. Appl. Phys. 2003, 94, 6034–6039. [Google Scholar] [CrossRef]

- Xia, Z.; Curtin, W.A.; Li, H.; Sheldon, B.W.; Liang, J.; Chang, B.; Xu, M. Direct observation of toughening mechanisms in carbon nanotube ceramic matrix composites. Acta Mater. 2004, 52, 931–944. [Google Scholar] [CrossRef]

- Garcia, E.; Wardle, B.L.; de Villori, R.G.; Wicks, S.; Ishiguro, K.; Yamamoto, N.; Hart, A.J. Aligned carbon nanotube reinforcement of advanced composite ply interfaces. In Proceedings of the 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 16t, Schaumburg, IL, USA, 7–10 April 2008. [Google Scholar]

- Qian, H.; Greenhalgh, E.S.; Shaffer, M.S.; Bismarck, A. Carbon nanotube-based hierarchical composites: A review. J. Mater. Chem. 2010, 20, 4751–4762. [Google Scholar] [CrossRef]

- Garcia, E.J.; Wardle, B.L.; Hart, A.J.; Yamamoto, N. Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown In Situ. Compos. Sci. Technol. 2008, 68, 2034–2041. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Sager, R.; Dai, L.; Baur, J. Hierarchical composites of carbon nanotubes on carbon fiber: Influence of growth condition on fiber tensile properties. Compos. Sci. Technol. 2009, 69, 594–601. [Google Scholar] [CrossRef]

- Boroujeni, A.Y.; Tehrani, M.; Nelson, A.J.; Al-Haik, M. Hybrid carbon nanotube-carbon fiber composites with improved in-plane mechanical properties. Compos. Part B Eng. 2014, 66, 475–483. [Google Scholar] [CrossRef]

- Tehrani, M.; Boroujeni, A.Y.; Luhrs, C.; Phillips, J.; Al-Haik, M.S. Hybrid composites based on carbon fiber/carbon nanofilament reinforcement. Materials 2014, 7, 4182–4195. [Google Scholar] [CrossRef] [PubMed]

- Tehrani, M.; Safdari, M.; Boroujeni, A.Y.; Razavi, Z.; Case, S.W.; Dahmen, K.; Garmestani, H.; Al-Haik, M.S. Hybrid carbon fiber/carbon nanotube composites for structural damping applications. Nanotechnology 2013, 24. [Google Scholar] [CrossRef] [PubMed]

- Boroujeni, A.Y.; Tehrani, M.; Nelson, A.J.; Al-Haik, M. Effect of carbon nanotubes growth topology on the mechanical behavior of hybrid carbon nanotube/carbon fiber polymer composites. Polym. Compos. 2015, 37, 2639–2648. [Google Scholar] [CrossRef]

- Miyagawa, H.; Rich, M.J.; Drzal, L.T. Thermo-physical properties of epoxy nanocomposites reinforced by carbon nanotubes and vapor grown carbon fibers. Thermochim. Acta 2006, 442, 67–73. [Google Scholar] [CrossRef]

- Sharma, R.; Yadav, A.K.; Panwar, V.; Kar, K.K. Viscoelastic properties of coil carbon nanotube-coated carbon fiber-reinforced polymer nanocomposites. J. Reinf. Plast. Compos. 2015, 34, 941–950. [Google Scholar] [CrossRef]

- Wei, R.; Gao, W. Viscoelastic behavior of carbon nanotube-enriched epoxy matrix hybrid composites reinforced with unidirectional graphite fibers. Mech. Adv. Mater. Struct. 2019, 1–16. [Google Scholar] [CrossRef]

- Luhrs, C.C.; Garcia, D.; Tehrani, M.; Al-Haik, M.; Taha, M.R.; Phillips, J. Generation of carbon nanofilaments on carbon fibers at 550 C. Carbon 2009, 47, 3071–3078. [Google Scholar] [CrossRef]

- ASTM. Standard guide for preparation of flat composite panels with processing guidelines for specimen preparation. In D30.04; ASTM International: West Conshohocken, PA, USA, 2015; Volume ASTM D5687. [Google Scholar]

- Skandani, A.A.; Boroujeni, A.Y.; Kalhor, R.; Case, S.W.; Al-Haik, M. Viscoelastic behavior of epoxy/carbon fiber/Zno nano-rods hybrid composite. Polym. Compos. 2014, 36, 1967–1972. [Google Scholar] [CrossRef]

- Almeida, J.H.; Ornaghi, H.L.; Lorandi, N.; Marinucci, G.; Amico, S. On creep, recovery, and stress relaxation of carbon fiber-reinforced epoxy filament wound composites. Polym. Eng. Sci. 2018, 58, 1837–1842. [Google Scholar] [CrossRef]

- Kaku, K.H.; Arai, M.; Fukuoka, T.; Matsuda, T. Evaluation of thermo-viscoelastic property of CFRP laminate based on a homogenization theory. Acta Mech. 2010, 214, 111–121. [Google Scholar] [CrossRef]

- Kawai, M.; Kazama, T.; Masuko, Y.; Tsuda, H.; Takahashi, J.; Kemmochi, K. Relaxation behavior of unidirectional carbon/epoxy composites at elevated temperature and analysis using viscoplasticity model. JSME Int. J. Ser. A 2004, 47, 8–16. [Google Scholar] [CrossRef][Green Version]

- Monticeli, F.M.; Ornaghi, H.L.; Neves, R.M.; Cioffi, M.O.H. Creep/recovery and stress-relaxation tests applied in a standardized carbon fiber/epoxy composite: Design of experiment approach. J. Strain Anal. Eng. Des. 2020, 55, 109–117. [Google Scholar] [CrossRef]

- Saha, N.; Banerjee, A.N. Stress-relaxation behavior of unidirectional polyethylene-carbon fibers: PMMA hybrid composite laminates. J. Appl. Polym. Sci. 1998, 67, 1925–1929. [Google Scholar] [CrossRef]

- Skandani, A.A.; Al-Haik, M. Viscoplastic characterization and modeling of hybrid carbon fiber/carbon nanotubes reinforced composites. Compos. Part B Eng. 2016, 99, 63–74. [Google Scholar] [CrossRef]

- Chartoff, R.P.; Menczel, J.D.; Dillman, S.H. Dynamic mechanical analysis. In Thermal Analysis of Polymers: Fundamentals and Applications; Menczel, J.D., Prime, R.B., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Khan, A.S.; Pamies, O.L. Time and temperature dependent response and relaxation of a soft polymer. Int. J. Plast. 2002, 18, 1359–1372. [Google Scholar] [CrossRef]

- Tobolsky, A.V. Properties and Structures of Polymers; Wiley: New York, NY, USA, 1960. [Google Scholar]

- Suhr, J.; Koratkar, N.A.; Keblinski, P.; Ajayan, P. Viscoelasticity in carbon nanotube composites. Nat. Mater. 2005, 4, 134–137. [Google Scholar] [CrossRef]

- Koratkar, N.A.; Suhr, J.; Joshi, A.; Kane, R.S.; Schadler, L.S.; Ajayan, P.M.; Bartolucci, S. Characterizing energy dissipation in single-walled carbon nanotube polycarbonate composites. Appl. Phys. Lett. 2005, 87, 063102. [Google Scholar] [CrossRef]

- Melo, J.D.D.; Radford, D.W. Time and temperature dependence of the viscoelastic properties of CFRP by dynamic mechanical analysis. Compos. Struct. 2005, 70, 240–253. [Google Scholar] [CrossRef]

| Configuration | Frequency (Hz) | Tg from Storage Modulus (°C) | % Change | Tg from Tan (δ) (°C) | % Change |

|---|---|---|---|---|---|

| Reference | 0.1 | 71 | 0 | 73 | 0 |

| 1 | 74 | 0 | 79 | 0 | |

| 5 | 75 | 0 | 82 | 0 | |

| 10 | 76 | 0 | 85 | 0 | |

| Full Growth | 0.1 | 66 | −7.0 | 77 | 5.47 |

| 1 | 72 | −2.7 | 84 | 6.33 | |

| 5 | 74 | −1.3 | 85 | 3.65 | |

| 10 | 76 | 0 | 87 | 2.35 | |

| 105-micron Pattern | 0.1 | 72 | 1.4 | 73 | 0 |

| 1 | 73 | 1.35 | 84 | 6.33 | |

| 5 | 81 | 8.0 | 85 | 3.66 | |

| 10 | 84 | 10.5 | 88 | 3.53 | |

| 53-micron Pattern | 0.1 | 72 | 1.4 | 75 | 2.73 |

| 1 | 75 | 1.35 | 83 | 1.21 | |

| 5 | 82 | 9.33 | 88 | 7.31 | |

| 10 | 86 | 13.15 | 92 | 8.23 |

| Initial Stress (MPa) | 22 °C | 50 °C | 75 °C | |

|---|---|---|---|---|

| Reference | 15 | 14.2 | 14.0 | 13.7 |

| 30 | 17.3 | 21.2 | 19.7 | |

| 45 | 19.3 | 20.2 | 19.1 | |

| 60 | 18.4 | 16.7 | 16.7 | |

| Full Growth | 15 | 12.0 | 17.3 | 19.3 |

| 30 | 10.1 | 14.3 | 16.3 | |

| 45 | 7.6 | 11.1 | 12.9 | |

| 60 | 5.5 | 8.6 | 10.2 | |

| 105 Pattern | 15 | 11.5 | 11.5 | 11.1 |

| 30 | 10.0 | 11.6 | 12.7 | |

| 45 | 8.1 | 10.5 | 11.6 | |

| 60 | 5.0 | 7.7 | 9.7 | |

| 53 Pattern | 15 | 5.3 | 8.2 | 4.0 |

| 30 | 3.0 | 8.6 | 3.1 | |

| 45 | 2.6 | 6.1 | 8.4 | |

| 60 | 1.6 | 4.5 | 7.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayyagari, S.; Al-Haik, M.; Ren, Y.; Nepal, D. Effect of Nano-Reinforcement Topologies on the Viscoelastic Performance of Carbon Nanotube/Carbon Fiber Hybrid Composites. Nanomaterials 2020, 10, 1213. https://doi.org/10.3390/nano10061213

Ayyagari S, Al-Haik M, Ren Y, Nepal D. Effect of Nano-Reinforcement Topologies on the Viscoelastic Performance of Carbon Nanotube/Carbon Fiber Hybrid Composites. Nanomaterials. 2020; 10(6):1213. https://doi.org/10.3390/nano10061213

Chicago/Turabian StyleAyyagari, Suma, Marwan Al-Haik, Yixin Ren, and Dhriti Nepal. 2020. "Effect of Nano-Reinforcement Topologies on the Viscoelastic Performance of Carbon Nanotube/Carbon Fiber Hybrid Composites" Nanomaterials 10, no. 6: 1213. https://doi.org/10.3390/nano10061213

APA StyleAyyagari, S., Al-Haik, M., Ren, Y., & Nepal, D. (2020). Effect of Nano-Reinforcement Topologies on the Viscoelastic Performance of Carbon Nanotube/Carbon Fiber Hybrid Composites. Nanomaterials, 10(6), 1213. https://doi.org/10.3390/nano10061213