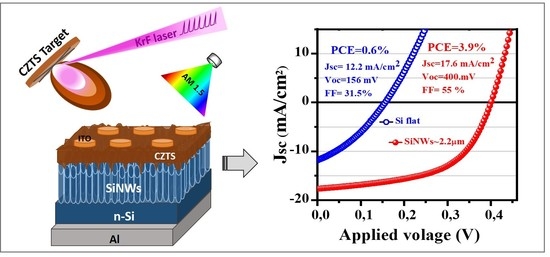

Photoconversion Optimization of Pulsed-Laser-Deposited p-CZTS/n-Si-Nanowires Heterojunction-Based Photovoltaic Devices

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ford, G.M.; Guo, Q.; Agrawal, R.; Hillhouse, H.W. Earth Abundant Element Cu2Zn(Sn1−xGex)S4 Nanocrystals for Tunable Band Gap Solar Cells: 6.8% Efficient Device Fabrication. Chem. Mater. 2011, 23, 2626–2629. [Google Scholar] [CrossRef]

- Kim, I.; Kim, K.; Oh, Y.; Woo, K.; Cao, G.; Jeong, S.; Moon, J. Bandgap-Graded Cu2Zn(Sn1–xGex)S4 Thin-Film Solar Cells Derived from Metal Chalcogenide Complex Ligand Capped Nanocrystals. Chem. Mater. 2014, 26, 3957–3965. [Google Scholar] [CrossRef]

- Jiang, F.; Gunawan, L.; Harada, T.; Kuang, Y.; Minegishi, T.; Domen, K.; Ikeda, S. Pt/In2S3/CdS/Cu2ZnSnS4 Thin Film as an Efficient and Stable Photocathode for Water Reduction under Sunlight Radiation. J. Am. Chem. Soc. 2015, 137, 13691–13697. [Google Scholar] [CrossRef]

- Gour, K.S.; Bhattacharyya, B.; Singh, O.P.; Yadav, A.K.; Husale, S.; Singh, V.N. Nanostructured Cu2ZnSnS4 (CZTS) thin film for self-powered broadband photodetection. J. Alloy. Compd. 2018, 735, 285–290. [Google Scholar] [CrossRef]

- Patel, S.B.; Patel, A.H.; Gohel, J.V. A novel and cost effective CZTS hole transport material applied in perovskite solar cells. CrystEngComm 2018, 20, 7677–7687. [Google Scholar] [CrossRef]

- Zhou, Z.; Deng, Y.; Zhang, P.; Kou, D.; Zhou, W.; Meng, Y.; Yuan, S.; Wu, S. Cu2ZnSnS4 Quantum Dots as Hole Transport Material for Enhanced Charge Extraction and Stability in All-Inorganic CsPbBr3 Perovskite Solar Cells. Sol. RRL 2019, 3, 1800354. [Google Scholar] [CrossRef]

- Kauk-Kuusik, M.; Li, X.; Pilvet, M.; Timmo, K.; Mikli, V.; Kaupmees, R.; Danilson, M.; Grossberg, M. Nano-scale sulfurization of the Cu2ZnSnSe4 crystal surface for photovoltaic applications. J. Mater. Chem. A 2019, 7, 24884–24890. [Google Scholar] [CrossRef]

- Wang, W.; Chen, G.; Cai, H.; Chen, B.; Yao, L.; Yang, M.; Chen, S.; Huang, Z. The effects of SnS2 secondary phases on Cu2ZnSnS4 solar cells: A promising mechanical exfoliation method for its removal. J. Mater. Chem. A 2018, 6, 2995–3004. [Google Scholar] [CrossRef]

- Sun, K.; Yan, C.; Huang, J.; Liu, F.; Li, J.; Sun, H.; Zhang, Y.; Cui, X.; Wang, A.; Fang, Z.; et al. Beyond 10% efficiency Cu2ZnSnS4 solar cells enabled by modifying the heterojunction interface chemistry. J. Mater. Chem. A 2019, 7, 27289–27296. [Google Scholar] [CrossRef]

- Li, W.; Chen, J.; Yan, C.; Liu, F.; Hao, X. Transmission electron microscopy analysis for the process of crystallization of Cu2ZnSnS4 film from sputtered Zn/CuSn precursor. Nanotechnology 2014, 25, 195701. [Google Scholar] [CrossRef]

- Foncrose, V.; Persello, J.; Puech, P.; Chane-Ching, J.Y.; Lagarde, D.; Balocchi, A.; Marie, X. Chemical insights into the formation of Cu2ZnSnS4 films from all-aqueous dispersions for low-cost solar cells. Nanotechnology 2017, 28, 445709. [Google Scholar] [CrossRef] [PubMed]

- Momose, N.; Htay, M.T.; Mikoshiba, N.; Hashimoto, Y.; Ito, K. Effects of Na2S treatment and post-annealing on Sn-rich Cu2ZnSnS4-based thin film solar cells. Jpn. J. Appl. Phys. 2020, 59, SCCD03. [Google Scholar] [CrossRef]

- Xu, J.; Yang, Y.; Cao, Z.; Xie, Z. Preparations of Cu2ZnSnS4 thin films and Cu2ZnSnS4/Si heterojunctions on silicon substrates by sputtering. Optik 2016, 127, 1567–1571. [Google Scholar] [CrossRef]

- Shin, B.; Zhu, Y.; Gershon, T.; Bojarczuk, N.A.; Guha, S. Epitaxial growth of kesterite Cu2ZnSnS4 on a Si(001) substrate by thermal co-evaporation. Thin Solid Films 2014, 556, 9–12. [Google Scholar] [CrossRef]

- Sheng, X.; Wang, L.; Tian, Y.; Luo, Y.; Chang, L.; Yang, D. Low-cost fabrication of Cu2ZnSnS4 thin films for solar cell absorber layers. J. Mater. Sci. Mater. Electron. 2013, 24, 548–552. [Google Scholar] [CrossRef]

- Yeh, M.Y.; Lei, P.H.; Lin, S.H.; Yang, C. Da Copper-Zinc-Tin-Sulfur thin film using spin-coating technology. Materials 2016, 9, 526. [Google Scholar] [CrossRef]

- Song, N.; Young, M.; Liu, F.; Erslev, P.; Wilson, S.; Harvey, S.P.; Teeter, G.; Huang, Y.; Hao, X.; Green, M.A. Epitaxial Cu2ZnSnS4 thin film on Si (111) 4° substrate. Appl. Phys. Lett. 2015, 106, 252102. [Google Scholar] [CrossRef]

- Song, N.; Green, M.A.; Huang, J.; Hu, Y.; Hao, X. Study of sputtered Cu2ZnSnS4 thin films on Si. Appl. Surf. Sci. 2018, 459, 700–706. [Google Scholar] [CrossRef]

- Hajijafarassar, A.; Martinho, F.; Stulen, F.; Grini, S.; López-Mariño, S.; Espíndola-Rodríguez, M.; Döbeli, M.; Canulescu, S.; Stamate, E.; Gansukh, M.; et al. Monolithic thin-film chalcogenide–silicon tandem solar cells enabled by a diffusion barrier. Sol. Energy Mater. Sol. Cells 2020, 207, 110334. [Google Scholar] [CrossRef]

- Ka, I.; Le Borgne, V.; Ma, D.; El Khakani, M.A. Pulsed Laser Ablation based Direct Synthesis of Single-Wall Carbon Nanotube/PbS Quantum Dot Nanohybrids Exhibiting Strong, Spectrally Wide and Fast Photoresponse. Adv. Mater. 2012, 24, 6289–6294. [Google Scholar] [CrossRef]

- Ka, I.; Le Borgne, V.; Fujisawa, K.; Hayashi, T.; Kim, Y.A.; Endo, M.; Ma, D.; El Khakani, M.A. Multiple exciton generation induced enhancement of the photoresponse of pulsed-laser-ablation synthesized single-wall-carbon-nanotube/PbS-quantum-dots nanohybrids. Sci. Rep. 2016, 6, 20083. [Google Scholar] [CrossRef]

- Ojeda, G.-P.A.; Döbeli, M.; Lippert, T. Influence of Plume Properties on Thin Film Composition in Pulsed Laser Deposition. Adv. Mater. Interfaces 2018, 5, 1701062. [Google Scholar] [CrossRef]

- Brassard, D.; El Khakani, M.A. Pulsed-laser deposition of high- k titanium silicate thin films. J. Appl. Phys. 2005, 98, 054912. [Google Scholar] [CrossRef]

- Ka, I.; Ma, D.; El Khakani, M.A. Tailoring the photoluminescence of PbS-nanoparticles layers deposited by means of the pulsed laser ablation technique. J. Nanopartic. Res. 2011, 13, 2269–2274. [Google Scholar] [CrossRef]

- Vanalakar, S.A.; Agawane, G.L.; Shin, S.W.; Suryawanshi, M.P.; Gurav, K.V.; Jeon, K.S.; Patil, P.S.; Jeong, C.W.; Kim, J.Y.; Kim, J.H. A review on pulsed laser deposited CZTS thin films for solar cell applications. J. Alloy. Compd. 2015, 619, 109–121. [Google Scholar] [CrossRef]

- Moriya, K.; Tanaka, K.; Uchiki, H. Fabrication of Cu2ZnSnS4 thin-film solar cell prepared by pulsed laser deposition. Jpn. J. Appl. Phys. 2007, 46, 5780–5781. [Google Scholar] [CrossRef]

- Moholkar, A.V.; Shinde, S.S.; Babar, A.R.; Sim, K.U.; Lee, H.K.; Rajpure, K.Y.; Patil, P.S.; Bhosale, C.H.; Kim, J.H. Synthesis and characterization of Cu2ZnSnS4 thin films grown by PLD: Solar cells. J. Alloys Compd. 2011, 509, 7439–7446. [Google Scholar] [CrossRef]

- Moholkar, A.V.; Shinde, S.S.; Agawane, G.L.; Jo, S.H.; Rajpure, K.Y.; Patil, P.S.; Bhosale, C.H.; Kim, J.H. Studies of compositional dependent CZTS thin film solar cells by pulsed laser deposition technique: An attempt to improve the efficiency. J. Alloys Compd. 2012, 544, 145–151. [Google Scholar] [CrossRef]

- Cazzaniga, A.; Crovetto, A.; Yan, C.; Sun, K.; Hao, X.; Ramis Estelrich, J.; Canulescu, S.; Stamate, E.; Pryds, N.; Hansen, O.; et al. Ultra-thin Cu2ZnSnS4 solar cell by pulsed laser deposition. Sol. Energy Mater. Sol. Cells 2017, 166, 91–99. [Google Scholar] [CrossRef]

- Pandiyan, R.; Oulad Elhmaidi, Z.; Sekkat, Z.; Abd-lefdil, M.; El Khakani, M.A. Reconstructing the energy band electronic structure of pulsed laser deposited CZTS thin films intended for solar cell absorber applications. Appl. Surf. Sci. 2017, 396, 1562–1570. [Google Scholar] [CrossRef]

- Elhmaidi, Z.O.; Pandiyan, R.; Abd-Lefdil, M.; El Khakani, M.A. Pulsed Laser Deposition of CZTS Thin Films, Their Thermal Annealing and Integration Into n-Si/CZTS Photovoltaic Devices. In Proceedings of the International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016. [Google Scholar]

- Elhmaidi, Z.O.; Pandiyan, R.; Abd-Lefdil, M.; Saucedo, E.; El Khakani, M.A. In-situ tuning of the zinc content of pulsed-laser-deposited CZTS films and its effect on the photoconversion efficiency of p-CZTS/n-Si heterojunction photovoltaic devices. Appl. Surf. Sci 2020, 507, 145003. [Google Scholar] [CrossRef]

- Fan, G.; Zhu, H.; Wang, K.; Wei, J.; Li, X.; Shu, Q.; Guo, N.; Wu, D. Graphene/Silicon Nanowire Schottky Junction for Enhanced Light Harvesting. ACS Appl. Mater. Interfaces 2011, 3, 721–725. [Google Scholar] [CrossRef] [PubMed]

- Convertino, A.; Cuscunà, M.; Martelli, F. Optical reflectivity from highly disordered Si nanowire films. Nanotechnology 2010, 21, 355701. [Google Scholar] [CrossRef]

- Garnett, E.C.; Yang, P. Silicon Nanowire Radial p−n Junction Solar Cells. J. Am. Chem. Soc. 2008, 130, 9224–9225. [Google Scholar] [CrossRef]

- Scherrer, P. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen. Math. Phys. Kl. 1918, 1918, 98–100. [Google Scholar]

- Guc, M.; Levcenko, S.; Bodnar, I.V.; Izquierdo-Roca, V.; Fontane, X.; Volkova, L.V.; Arushanov, E.; Pérez-Rodríguez, A. Polarized Raman scattering study of kesterite type Cu2ZnSnS4 single crystals. Sci. Rep 2016, 6, 19414. [Google Scholar] [CrossRef] [PubMed]

- Mai, D.-L.; Park, H.-J.; Choi, I.-H. Growth of Cu2ZnSnS4 crystals by the directional freezing method with an induction heater. J. Cryst. Growth 2014, 402, 104–108. [Google Scholar] [CrossRef]

- Giraldo, S.; Jehl, Z.; Placidi, M.; Izquierdo-Roca, V.; Pérez-Rodríguez, A.; Saucedo, E. Progress and perspectives of thin film kesterite photovoltaic technology: A critical review. Adv. Mater. 2019, 31, 1806692. [Google Scholar] [CrossRef]

- He, L.; Jiang, C.; Wang, H.; Lai, D. Rusli Si Nanowires Organic Semiconductor Hybrid Heterojunction Solar Cells Toward 10% Efficiency. ACS Appl. Mater. Interfaces 2012, 4, 1704–1708. [Google Scholar] [CrossRef]

- Peng, K.; Xu, Y.; Wu, Y.; Yan, Y.; Lee, S.-T.; Zhu, J. Aligned Single-Crystalline Si Nanowire Arrays for Photovoltaic Applications. Small 2005, 1, 1062–1067. [Google Scholar] [CrossRef]

- Striemer, C.C.; Fauchet, P.M. Dynamic etching of silicon for broadband antireflection applications. Appl. Phys. Lett. 2002, 81, 2980–2982. [Google Scholar] [CrossRef]

- Shiu, S.C.; Lin, S.B.; Hung, S.C.; Lin, C.F. Influence of pre-surface treatment on the morphology of silicon nanowires fabricated by metal-assisted etching. Appl. Surf. Sci. 2011, 257, 1829–1834. [Google Scholar] [CrossRef]

- Syafiq, U.; Ataollahi, N.; DiMaggio, R.; Scardi, P. Solution-based synthesis and characterization of Cu2ZnSnS4 thin films. Molecules 2019, 24, 3454. [Google Scholar] [CrossRef] [PubMed]

- Akaltun, Y.; Yildirim, M.A.; Ateş, A.; Yildirim, M. The relationship between refractive index-energy gap and the film thickness effect on the characteristic parameters of CdSe thin films. Opt. Commun. 2011, 284, 2307–2311. [Google Scholar] [CrossRef]

- Dhakal, T.P.; Peng, C.; Reid Tobias, R.; Dasharathy, R.; Westgate, C.R. Characterization of a CZTS thin film solar cell grown by sputtering method. Sol. Energy 2014, 100, 23–30. [Google Scholar] [CrossRef]

- Shin, B.; Gunawan, O.; Zhu, Y.; Bojarczuk, N.A.; Chey, S.J.; Guha, S. Thin film solar cell with 8.4% power conversion efficiency using an earth-abundant Cu2ZnSnS4 absorber. Prog. Photovolt. Res. Appl. 2013, 21, 72–76. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oulad Elhmaidi, Z.; Abd-Lefdil, M.; El Khakani, M.A. Photoconversion Optimization of Pulsed-Laser-Deposited p-CZTS/n-Si-Nanowires Heterojunction-Based Photovoltaic Devices. Nanomaterials 2020, 10, 1393. https://doi.org/10.3390/nano10071393

Oulad Elhmaidi Z, Abd-Lefdil M, El Khakani MA. Photoconversion Optimization of Pulsed-Laser-Deposited p-CZTS/n-Si-Nanowires Heterojunction-Based Photovoltaic Devices. Nanomaterials. 2020; 10(7):1393. https://doi.org/10.3390/nano10071393

Chicago/Turabian StyleOulad Elhmaidi, Zakaria, Mohammed Abd-Lefdil, and My Ali El Khakani. 2020. "Photoconversion Optimization of Pulsed-Laser-Deposited p-CZTS/n-Si-Nanowires Heterojunction-Based Photovoltaic Devices" Nanomaterials 10, no. 7: 1393. https://doi.org/10.3390/nano10071393

APA StyleOulad Elhmaidi, Z., Abd-Lefdil, M., & El Khakani, M. A. (2020). Photoconversion Optimization of Pulsed-Laser-Deposited p-CZTS/n-Si-Nanowires Heterojunction-Based Photovoltaic Devices. Nanomaterials, 10(7), 1393. https://doi.org/10.3390/nano10071393