High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results

Abstract

:1. Introduction—Nanostructure Formation in Semiconductor Lithography

2. EUV Introduction and Main Technical Challenges

3. Material Absorption at EUV

4. Chemical Directions for Highly Sensitive Resists at EUV

4.1. Chemically Amplified Resists

4.1.1. Polymeric Systems Based on Hydrophilicity Change

4.1.2. Polymeric Systems Based on Acid-Catalyzed Main Chain Scission

4.1.3. Molecular Chemically Amplified Systems

4.2. Non Chemically Amplified Photoresists

4.3. Inorganic Resists

5. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Pease, R.F.; Chou, S.Y. Lithography and Other Patterning Techniques for Future Electronics. Proc. IEEE 2008, 96, 248–270. [Google Scholar] [CrossRef]

- Pimpin, A.; Srituravanich, W. Review on Micro- and Nanolithography Techniques and Their Applications. Eng. J. 2011, 16, 37. [Google Scholar] [CrossRef] [Green Version]

- Seisyan, R.P. Nanolithography in microelectronics: A review. Tech. Phys. 2011, 56, 1061. [Google Scholar] [CrossRef]

- Lawson, R.A.; Robinson, A.P.G. Chapter 1—Overview of materials and processes for lithography. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 1–90. [Google Scholar]

- Jeong, S.-J.; Kim, J.Y.; Kim, B.H.; Moon, H.-S.; Kim, S.O. Directed self-assembly of block copolymers for next generation nanolithography. Mater. Today 2013, 16, 468–476. [Google Scholar] [CrossRef]

- Kim, B.H.; Kim, J.Y.; Kim, S.O. Directed self-assembly of block copolymers for universal nanopatterning. Soft Matter 2013, 9, 2780–2786. [Google Scholar] [CrossRef]

- Stoykovich, M.P.; Nealey, P.F. Block copolymers and conventional lithography. Mater. Today 2006, 9, 20–29. [Google Scholar] [CrossRef]

- Yang, G.-W.; Wu, G.-P.; Chen, X.; Xiong, S.; Arges, C.G.; Ji, S.; Nealey, P.F.; Lu, X.-B.; Darensbourg, D.J.; Xu, Z.-K. Directed Self-Assembly of Polystyrene-b-poly(propylene carbonate) on Chemical Patterns via Thermal Annealing for Next Generation Lithography. Nano Lett. 2017, 17, 1233–1239. [Google Scholar] [CrossRef]

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Okazaki, S. High resolution optical lithography or high throughput electron beam lithography: The technical struggle from the micro to the nano-fabrication evolution. Microelectron. Eng. 2015, 133, 23–35. [Google Scholar] [CrossRef]

- Tseng, A.A.; Kuan, C.; Chen, C.D.; Ma, K.J. Electron beam lithography in nanoscale fabrication: Recent development. IEEE Trans. Electron. Packag. Manuf. 2003, 26, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Vieu, C.; Carcenac, F.; Pépin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron beam lithography: Resolution limits and applications. Appl. Surf. Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Öktem, B.; Pavlov, I.; Ilday, S.; Kalaycıoğlu, H.; Rybak, A.; Yavaş, S.; Erdoğan, M.; Ilday, F.Ö. Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses. Nat. Photonics 2013, 7, 897–901. [Google Scholar] [CrossRef]

- Walsh, M.E.; Zhang, F.; Menon, R.; Smith, H.I. 6—Maskless photolithography. In Nanolithography; Feldman, M., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 179–193. [Google Scholar] [CrossRef]

- Douglas, J.R.; Jin, C. A review of nanoimprint lithography for high-volume semiconductor device manufacturing. Adv. Opt. Technol. 2017, 6, 229–241. [Google Scholar] [CrossRef]

- Jan van, S.; Helmut, S. Next-generation lithography—An outlook on EUV projection and nanoimprint. Adv. Opt. Technol. 2017, 6, 159–162. [Google Scholar] [CrossRef] [Green Version]

- Danilo De, S.; Yannick, V.; Geert, V. Photoresists in extreme ultraviolet lithography (EUVL). Adv. Opt. Technol. 2017, 6, 163–172. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Pal, S.; Wang, S.; Ober, C.K.; Giannelis, E.P. Extreme ultraviolet resist materials for sub-7 nm patterning. Chem. Soc. Rev. 2017, 46, 4855–4866. [Google Scholar] [CrossRef]

- Luo, C.; Xu, C.; Lv, L.; Li, H.; Huang, X.; Liu, W. Review of recent advances in inorganic photoresists. RSC Adv. 2020, 10, 8385–8395. [Google Scholar] [CrossRef]

- Wu, B.; Kumar, A. Extreme ultraviolet lithography: A review. J. Vac. Sci. Technol. B 2007, 25, 1743–1761. [Google Scholar] [CrossRef]

- Buitrago, E.; Kulmala, T.S.; Fallica, R.; Ekinci, Y. Chapter 4—EUV lithography process challenges. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 135–176. [Google Scholar]

- Solak, H.H.; He, D.; Li, W.; Singh-Gasson, S.; Cerrina, F.; Sohn, B.H.; Yang, X.M.; Nealey, P. Exposure of 38 nm period grating patterns with extreme ultraviolet interferometric lithography. Appl. Phys. Lett. 1999, 75, 2328–2330. [Google Scholar] [CrossRef] [Green Version]

- Bhattarai, S.; Neureuther, A.R.; Naulleau, P.P. Study of shot noise in photoresists for extreme ultraviolet lithography through comparative analysis of line edge roughness in electron beam and extreme ultraviolet lithography. J. Vac. Sci. Technol. B 2017, 35, 061602. [Google Scholar] [CrossRef]

- Naulleau, P. Chapter 5—EUV lithography patterning challenges. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 177–192. [Google Scholar]

- Banine, V.; Moors, R. Plasma sources for EUV lithography exposure tools. J. Phys. D Appl. Phys. 2004, 37, 3207–3212. [Google Scholar] [CrossRef]

- Banine, V.; Benschop, J.; Leenders, M.; Moors, R. Relationship between an EUV source and the performance of an EUV lithographic system. In Emerging Lithographic Technologies IV; SPIE: Bellingham, WA, USA, 2000; Volume 3997, pp. 126–135. [Google Scholar]

- Photonic Frontiers: EUV Lithography: EUV Lithography Has Yet to Find Its Way into the Fab. Available online: https://www.laserfocusworld.com/lasers-sources/article/16557008/photonic-frontiers-euv-lithography-euv-lithography-has-yet-to-find-its-way-into-the-fab (accessed on 2 August 2020).

- Wood Ii, O.R. EUVL: Challenges to Manufacturing Insertion. J. Photopolym. Sci. Technol. 2017, 30, 599–604. [Google Scholar] [CrossRef] [Green Version]

- Kostko, O.; Xu, B.; Ahmed, M.; Slaughter, D.S.; Ogletree, D.F.; Closser, K.D.; Prendergast, D.G.; Naulleau, P.; Olynick, D.L.; Ashby, P.D.; et al. Fundamental understanding of chemical processes in extreme ultraviolet resist materials. J. Chem. Phys. 2018, 149, 154305. [Google Scholar] [CrossRef]

- Ogletree, D.F. Chapter 2—Molecular excitation and relaxation of extreme ultraviolet lithography photoresists. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 91–113. [Google Scholar]

- Henke, B.L.; Gullikson, E.M.; Davis, J.C. X-Ray Interactions: Photoabsorption, Scattering, Transmission, and Reflection at E = 50–30,000 eV, Z = 1–92. At. Data Nucl. Data Tables 1993, 54, 181–342. [Google Scholar] [CrossRef] [Green Version]

- Irie, S.; Endo, M.; Sasago, M.; Kandaka, N.; Kondo, H.; Murakami, K. Study of Transmittance of Polymers and Influence of Photoacid Generator on Resist Transmittance at Extreme Ultraviolet Wavelength. Jpn. J. Appl. Phys. 2002, 41, 5864–5867. [Google Scholar] [CrossRef]

- Yeh, J.J.; Lindau, I. Atomic subshell photoionization cross sections and asymmetry parameters: 1 ≤ Z ≤ 103. At. Data Nucl. Data Tables 1985, 32, 1–155. [Google Scholar] [CrossRef]

- He, D.; Solak, H.; Li, W.; Cerrina, F. Extreme ultraviolet and x-ray resist: Comparison study. J. Vac. Sci. Technol. B 1999, 17, 3379–3383. [Google Scholar] [CrossRef]

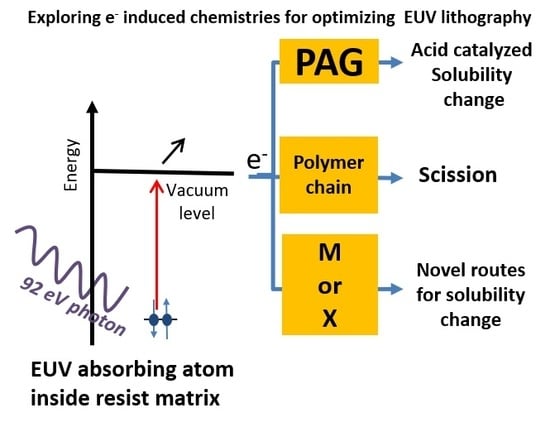

- Kozawa, T.; Tagawa, S. Radiation Chemistry in Chemically Amplified Resists. Jpn. J. Appl. Phys. 2010, 49, 030001. [Google Scholar] [CrossRef]

- Narasimhan, A.; Wisehart, L.; Grzeskowiak, S.; Ocola, L.E.; Denbeaux, G.; Brainard, R.L. What We Don’t Know About EUV Exposure Mechanisms. J. Photopolym. Sci. Technol. 2017, 30, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Torok, J.; Re, R.D.; Herbol, H.; Das, S.; Bocharova, I.; Paolucci, A.; Ocola, L.E.; Ventrice, C., Jr.; Lifshin, E.; Denbeaux, G.; et al. Secondary Electrons in EUV Lithography. J. Photopolym. Sci. Technol. 2013, 26, 625–634. [Google Scholar] [CrossRef] [Green Version]

- Böhler, E.; Warneke, J.; Swiderek, P. Control of chemical reactions and synthesis by low-energy electrons. Chem. Soc. Rev. 2013, 42, 9219–9231. [Google Scholar] [CrossRef]

- van Dorp, W.F. Chapter 3—Theory: Electron-induced chemistry. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 115–133. [Google Scholar]

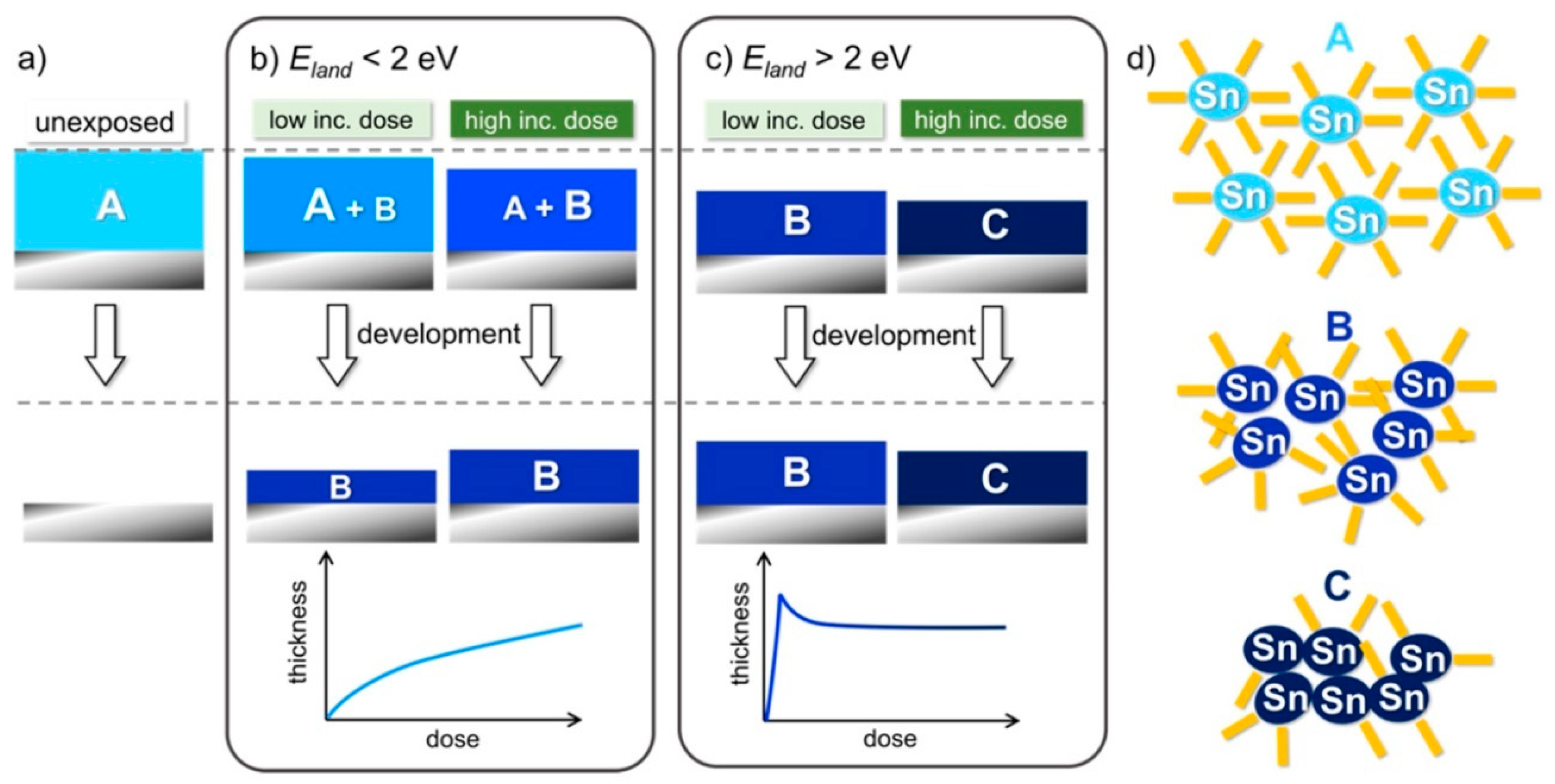

- Bespalov, I.; Zhang, Y.; Haitjema, J.; Tromp, R.M.; van der Molen, S.J.; Brouwer, A.M.; Jobst, J.; Castellanos, S. Key Role of Very Low Energy Electrons in Tin-Based Molecular Resists for Extreme Ultraviolet Nanolithography. ACS Appl. Mater. Interfaces 2020, 12, 9881–9889. [Google Scholar] [CrossRef] [Green Version]

- Pollentier, I.; Vesters, Y.; Petersen, J.; Vanelderen, P.; Rathore, A.; de Simone, D.; Vandenberghe, G. Unraveling the role of photons and electrons upon their chemical interaction with photoresist during EUV exposure. In Advances in Patterning Materials and Processes XXXV; SPIE: Bellingham, WA, USA, 2018; Volume 10586, p. 105860C. [Google Scholar]

- Pollentier, I.; Petersen, J.; De Bisschop, P.; De Simone, D.; Vandenberghe, G. Unraveling the EUV photoresist reactions: Which, how much, and how do they relate to printing performance. In Extreme Ultraviolet (EUV) Lithography X; SPIE: Bellingham, WA, USA, 2019; Volume 10957, p. 109570I. [Google Scholar]

- Torti, E.; Protti, S.; Bollanti, S.; Flora, F.; Torre, A.; Brusatin, G.; Gerardino, A.; Businaro, L.; Fagnoni, M.; Della Giustina, G.; et al. Aryl Sulfonates as Initiators for Extreme Ultraviolet Lithography: Applications in Epoxy-Based Hybrid Materials. ChemPhotoChem 2018, 2, 425–432. [Google Scholar] [CrossRef]

- Yamamoto, H.; Kozawa, T.; Nakano, A.; Okamoto, K.; Tagawa, S.; Ando, T.; Sato, M.; Komano, H. Dependence of acid generation efficiency on the protection ratio of hydroxyl groups in chemically amplified electron beam, x-ray and EUV resists. J. Vac. Sci. Technol. B 2004, 22, 3522–3524. [Google Scholar] [CrossRef]

- Fedynyshyn, T.; Goodman, R.; Roberts, J. Polymer matrix effects on acid generation. In Advances in Resist Materials and Processing Technology XXV; SPIE: Bellingham, WA, USA, 2008; Volume 6923, p. 692319. [Google Scholar]

- Tamaoki, H.; Tarutani, S.; Tsubaki, H.; Takahashi, T.; Inoue, N.; Tsuchihashi, T.; Takizawa, H.; Takahashi, H. Characterizing polymer bound PAG-type EUV resist. In Advances in Resist Materials and Processing Technology XXVIII; SPIE: Bellingham, WA, USA, 2011; Volume 7972, p. 79720A. [Google Scholar]

- Tarutani, S.; Tsubaki, H.; Takizawa, H.; Goto, T. EUV Resist Materials for 16 nm and below Half Pitch Applications. J. Photopolym. Sci. Technol. 2012, 25, 597–602. [Google Scholar] [CrossRef] [Green Version]

- Tsubaki, H.; Tarutani, S.; Inoue, N.; Takizawa, H.; Goto, T. EUV Resist Materials Design for 15 nm Half Pitch and Below. J. Photopolym. Sci. Technol. 2013, 26, 649–657. [Google Scholar] [CrossRef] [Green Version]

- Iwashita, J.; Hirayama, T.; Matsuzawa, K.; Utsumi, Y.; Ohmori, K. Out-of-band insensitive polymer-bound PAG for EUV resist. In Extreme Ultraviolet (EUV) Lithography III; SPIE: Bellingham, WA, USA, 2012; Volume 8322, p. 83220Y. [Google Scholar]

- Jain, V.; Coley, S.; Lee, J.J.; Christianson, M.; Arriola, D.; LaBeaume, P.; Danis, M.; Ortiz, N.; Kang, S.-J.; Wagner, M.; et al. Impact of polymerization process on OOB on lithographic performance of a EUV resist. In Extreme Ultraviolet (EUV) Lithography II; SPIE: Bellingham, WA, USA, 2011; Volume 7969, p. 796912. [Google Scholar]

- Park, C.-M.; Kim, I.; Kim, S.-H.; Kim, D.-W.; Hwang, M.-S.; Kang, S.-N.; Park, C.; Kim, H.-W.; Yeo, J.-H.; Kim, S.-S. Prospects of DUV OoB suppression techniques in EUV lithography. In Extreme Ultraviolet (EUV) Lithography V; SPIE: Bellingham, WA, USA, 2014; Volume 9048, p. 90480S. [Google Scholar]

- Roberts, J.; Bristol, R.; Younkin, T.; Fedynyshyn, T.; Astolfi, D.; Cabral, A. Sensitivity of EUV resists to out-of-band radiation. In Advances in Resist Materials and Processing Technology XXVI; SPIE: Bellingham, WA, USA, 2009; Volume 7273, p. 72731W. [Google Scholar]

- Liu, J.; Qiao, Y.; Wang, L. Novel polymeric sulfonium photoacid generator and its application for chemically amplified photoresists. In Advances in Patterning Materials and Processes XXXI; SPIE: Bellingham, WA, USA, 2014; Volume 9051, p. 905124. [Google Scholar]

- Narasimhan, A.; Grzeskowiak, S.; Srivats, B.; Herbol, H.; Wisehart, L.; Kelly, C.; Earley, W.; Ocola, L.; Neisser, M.; Denbeaux, G.; et al. Studying secondary electron behavior in EUV resists using experimentation and modeling. In Extreme Ultraviolet (EUV) Lithography VI; SPIE: Bellingham, WA, USA, 2015; Volume 9422, p. 942208. [Google Scholar]

- Fujiwara, K. Novel EUV resist development for sub-14 nm half pitch. In Proceedings of the 2017 China Semiconductor Technology International Conference (CSTIC), Shangai, China, 12–13 March 2017; pp. 1–2. [Google Scholar]

- Kimoto, T.; Naruoka, T.; Nakagawa, H.; Fujisawa, T.; Shiratani, M.; Nagai, T.; Ayothi, R.; Hishiro, Y.; Hori, M.; Hoshiko, K.; et al. Novel EUV Resist Development for Sub-14nm Half Pitch. J. Photopolym. Sci. Technol. 2015, 28, 519–523. [Google Scholar] [CrossRef] [Green Version]

- Krysak, M.; Leeson, M.; Han, E.; Blackwell, J.; Harlson, S. Extending resolution limits of EUV resist materials. In Extreme Ultraviolet (EUV) Lithography VI; SPIE: Bellingham, WA, USA, 2015; Volume 9422, p. 942205. [Google Scholar]

- Thackeray, J.; Cameron, J.; Jain, V.; LaBeaume, P.; Coley, S.; Ongayi, O.; Wagner, M.; Rachford, A.; Biafore, J. Progress in resolution, sensitivity, and critical dimensional uniformity of EUV chemically amplified resists. In Advances in Resist Materials and Processing Technology XXX; SPIE: Bellingham, WA, USA, 2013; Volume 8682, p. 868213. [Google Scholar]

- Thackeray, J.W.; Nassar, R.A.; Brainard, R.L.; Goldfarb, D.L.; Wallow, T.; Wei, Y.; Mackey, J.; Naulleau, P.P.; Pierson, B.; Solak, H.H. Chemically amplified resists resolving 25 nm 1:1 line: Space features with EUV lithography. In Emerging Lithographic Technologies XI; SPIE: Bellingham, WA, USA, 2007; Volume 6517, p. 651719. [Google Scholar]

- Fujii, T.; Matsumaru, S.; Yamada, T.; Komuro, Y.; Kawana, D.; Ohmori, K. Patterning performance of chemically amplified resist in EUV lithography. In Extreme Ultraviolet (EUV) Lithography VII; SPIE: Bellingham, WA, USA, 2016; Volume 9776, p. 97760Y. [Google Scholar]

- Yamamoto, H.; Vesters, Y.; Jiang, J.; Simone, D.D.; Vandenberghe, G.; Kozawa, T. Role of Metal Sensitizers for Sensitivity Improvement in EUV Chemically Amplified Resist. J. Photopolym. Sci. Technol. 2018, 31, 747–751. [Google Scholar] [CrossRef] [Green Version]

- Fallica, R.; Ekinci, Y. Photoacid generator-polymer interaction on the quantum yield of chemically amplified resists for extreme ultraviolet lithography. J. Mater. Chem. C 2018, 6, 7267–7273. [Google Scholar] [CrossRef]

- Lee, H.; Kim, M.; Moon, J.; Park, S.; Lee, B.; Jeong, C.; Cho, M. Multiscale approach for modeling EUV patterning of chemically amplified resist. In Advances in Patterning Materials and Processes XXXVI; SPIE: Bellingham, WA, USA, 2019; Volume 10960, p. 1096008. [Google Scholar]

- Brainard, R.; Kruger, S.; Higgins, C.; Revuru, S.; Gibbons, S.; Freedman, D.; Yueh, W.; Younkin, T. Kinetics, Chemical Modeling and Lithography of Novel Acid Amplifiers for Use in EUV Photoresists. J. Photopolym. Sci. Technol. 2009, 22, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Sekiguchi, A.; Harada, T.; Watanabe, T. A study on enhancing EUV resist sensitivity. In Extreme Ultraviolet (EUV) Lithography VIII; SPIE: Bellingham, WA, USA, 2017; Volume 10143, p. 1014322. [Google Scholar]

- Jiang, J.; Giordano, G.; Fallica, R.; DeSimone, D.; Vandenberghe, G. Sensitizer for EUV Chemically Amplified Resist: Metal versus Halogen. J. Photopolym. Sci. Technol. 2019, 32, 21–25. [Google Scholar] [CrossRef]

- Nagahara, S.; Dinh, C.Q.; Yoshida, K.; Shiraishi, G.; Kondo, Y.; Yoshihara, K.; Nafus, K.; Petersen, J.; De Simone, D.; Foubert, P.; et al. EUV resist chemical gradient enhancement by UV flood exposure for improvement in EUV resist resolution, process control, roughness, sensitivity, and stochastic defectivity. In Advances in Patterning Materials and Processes XXXVII; SPIE: Bellingham, WA, USA, 2020; Volume 11326, p. 113260A. [Google Scholar]

- Okamoto, K.; Kawai, S.; Kozawa, T. Sensitivity enhancement of chemically amplified EUV resist by adding diphenyl sulfone derivatives. In Advances in Patterning Materials and Processes XXXVII; SPIE: Bellingham, WA, USA, 2020; Volume 11326, p. 113260D. [Google Scholar]

- Cardineau, B.; Garczynski, P.; Earley, W.; Brainard, R.L. Chain-Scission Polyethers for EUV Lithography. J. Photopolym. Sci. Technol. 2013, 26, 665–671. [Google Scholar] [CrossRef] [Green Version]

- Manouras, T.; Kazazis, D.; Koufakis, E.; Ekinci, Y.; Vamvakaki, M.; Argitis, P. Ultra-sensitive EUV resists based on acid-catalyzed polymer backbone breaking. In Extreme Ultraviolet (EUV) Lithography IX; SPIE: Bellingham, WA, USA, 2018; Volume 10583, p. 105831R. [Google Scholar]

- Argitis, P.; Vidali, V.P.; Niakoula, D. Chapter 9—Positive molecular resists. In Frontiers of Nanoscience; Robinson, A., Lawson, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 11, pp. 319–348. [Google Scholar]

- Echigo, M.; Oguro, D. Development of new phenylcalix [4] resorcinarene: Its application to positive-tone molecular resist for EB and EUV lithography. In Advances in Resist Materials and Processing Technology XXVI; SPIE: Bellingham, WA, USA, 2009; Volume 7273, p. 72732Q. [Google Scholar]

- Owada, T.; Yomogita, A.; Kashiwamura, T.; Kusaba, T.; Miyamoto, S.; Takeya, T. Development of novel positive-tone resists for EUVL. In Advances in Resist Materials and Processing Technology XXVI; SPIE: Bellingham, WA, USA, 2009; Volume 7273, p. 72732R. [Google Scholar]

- Kudo, H.; Nina, N.; Sato, T.; Oizumi, H.; Itani, T.; Miura, T.; Watanabe, T.; Kinoshita, H. Extreme Ultraviolet (EUV)-Resist Material Based on Noria (Water Wheel-like Macrocycle) Derivatives with Pendant Alkoxyl and Adamantyl Ester Groups. J. Photopolym. Sci. Technol. 2012, 25, 587–592. [Google Scholar] [CrossRef] [Green Version]

- Kulshreshtha, P.; Maruyama, K.; Kiani, S.; Dhuey, S.; Perera, P.; Blackwell, J.; Olynick, D.; Ashby, P. Sub-20nm lithography negative tone chemically amplified resists using cross-linker additives. In Advances in Resist Materials and Processing Technology XXX; SPIE: Bellingham, WA, USA, 2013; Volume 8682, p. 86820N. [Google Scholar]

- Kulshreshtha, P.K.; Maruyama, K.; Kiani, S.; Blackwell, J.; Olynick, D.L.; Ashby, P.D. Harnessing entropic and enthalpic contributions to create a negative tone chemically amplified molecular resist for high-resolution lithography. Nanotechnology 2014, 25, 315301. [Google Scholar] [CrossRef]

- Green, D.P.; Jain, V.; Bailey, B.; Wagner, M.; Clark, M.; Valeri, D.; Lakso, S. Development of molecular resist derivatives for EUV lithography. In Extreme Ultraviolet (EUV) Lithography IV; SPIE: Bellingham, WA, USA, 2013; Volume 8679, p. 867912. [Google Scholar]

- Frommhold, A.; McClelland, A.; Roth, J.; Fallica, R.; Ekinci, Y.; Robinson, A.P. Optimization and sensitivity enhancement of high-resolution molecular resist for EUV lithography. In Extreme Ultraviolet (EUV) Lithography VII; SPIE: Bellingham, WA, USA, 2016; Volume 9776, p. 977614. [Google Scholar]

- Frommhold, A.; Yang, D.; McClelland, A.; Roth, J.; Xue, X.; Rosamund, M.C.; Linfield, E.H.; Robinson, A.P.G. Novel Molecular Resist for EUV and Electron Beam Lithography. J. Photopolym. Sci. Technol. 2015, 28, 537–540. [Google Scholar] [CrossRef] [Green Version]

- O’Callaghan, G.; Popescu, C.; McClelland, A.; Kazazis, D.; Roth, J.; Theis, W.; Ekinci, Y.; Robinson, A.P. Multi-trigger resist: Novel synthesis improvements for high resolution EUV lithography. In Advances in Patterning Materials and Processes XXXVI; SPIE: Bellingham, WA, USA, 2019; Volume 10960, p. 109600C. [Google Scholar]

- Popescu, C.; Frommhold, A.; McClelland, A.; Roth, J.; Ekinci, Y.; Robinson, A.P. Sensitivity enhancement of the high-resolution xMT multi-trigger resist for EUV lithography. In Extreme Ultraviolet (EUV) Lithography VIII; SPIE: Bellingham, WA, USA, 2017; Volume 10143, p. 101430V. [Google Scholar]

- Popescu, C.; Kazazis, D.; McClelland, A.; Dawson, G.; Roth, J.; Theis, W.; Ekinci, Y.; Robinson, A.P. High-resolution EUV lithography using a multi-trigger resist. In Extreme Ultraviolet (EUV) Lithography IX; SPIE: Bellingham, WA, USA, 2018; Volume 10583, p. 105831L. [Google Scholar]

- Popescu, C.; Vesters, Y.; McClelland, A.; De Simone, D.; Dawson, G.; Roth, J.; Theis, W.; Vandenberghe, G.; Robinson, A.P.G. Multi Trigger Resist for EUV Lithography. J. Photopolym. Sci. Technol. 2018, 31, 227–232. [Google Scholar] [CrossRef] [Green Version]

- Popescu, C.; O’Callaghan, G.; McClelland, A.; Roth, J.; Lada, T.; Robinson, A.P. Performance enhancements with high opacity multi-trigger resist. In Advances in Patterning Materials and Processes XXXVII; SPIE: Bellingham, WA, USA, 2020; Volume 11326, p. 1132611. [Google Scholar]

- Kudo, H.; Hayashi, R.; Mitani, K.; Yokozawa, T.; Kasuga, N.C.; Nishikubo, T. Molecular waterwheel (Noria) from a simple condensation of resorcinol and an alkanedial. Angew. Chem. Int. Ed. 2006, 45, 7948–7952. [Google Scholar] [CrossRef]

- Moreau, W.M. Semiconductor Lithography, Principles, Particles and Materials; Plenum Press: New York, NY, USA, 1988. [Google Scholar]

- Pasparakis, G.; Manouras, T.; Argitis, P.; Vamvakaki, M. Photodegradable Polymers for Biotechnological Applications. Macromol. Rapid Commun. 2012, 33, 183–198. [Google Scholar] [CrossRef]

- Tiwale, N.; Subramanian, A.; Kisslinger, K.; Lu, M.; Kim, J.; Stein, A.; Nam, C.-Y. Advancing next generation nanolithography with infiltration synthesis of hybrid nanocomposite resists. J. Mater. Chem. C 2019, 7, 8803–8812. [Google Scholar] [CrossRef]

- Fallica, R.; Kirchner, R.; Ekinci, Y.; Mailly, D. Comparative study of resists and lithographic tools using the Lumped Parameter Model. J. Vac. Sci. Technol. B 2016, 34, 06K702. [Google Scholar] [CrossRef]

- Hosaka, Y.; Oyama, T.G.; Oshima, A.; Enomoto, S.; Washio, M.; Tagawa, S. Pulse Radiolysis Study on a Highly Sensitive Chlorinated Resist ZEP520A. J. Photopolym. Sci. Technol. 2013, 26, 745–750. [Google Scholar] [CrossRef] [Green Version]

- Oyama, T.G.; Enomoto, K.; Hosaka, Y.; Oshima, A.; Washio, M.; Tagawa, S. Electron-Beam-Induced Decomposition Mechanisms of High-Sensitivity Chlorinated Resist ZEP520A. Appl. Phys. Express 2012, 5, 036501. [Google Scholar] [CrossRef]

- Fallica, R.; Kazazis, D.; Kirchner, R.; Voigt, A.; Mochi, I.; Schift, H.; Ekinci, Y. Lithographic performance of ZEP520A and mr-PosEBR resists exposed by electron beam and extreme ultraviolet lithography. J. Vac. Sci. Technol. B 2017, 35, 061603. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.K.; Pal, S.P.; Reddy, P.G.; Kumar, P.; Ghosh, S.; Gonsalves, K.E. Design and development of low activation energy based nonchemically amplified resists (n-CARs) for next generation EUV lithography. Microelectron. Eng. 2016, 164, 115–122. [Google Scholar] [CrossRef]

- Oyama, T.G.; Oshima, A.; Tagawa, S. Estimation of resist sensitivity for extreme ultraviolet lithography using an electron beam. AIP Adv. 2016, 6, 085210. [Google Scholar] [CrossRef] [Green Version]

- Rathore, A.; Pollentier, I.; Singh, H.; Fallica, R.; De Simone, D.; De Gendt, S. Effect of molecular weight on the EUV-printability of main chain scission type polymers. J. Mater. Chem. C 2020, 8, 5958–5966. [Google Scholar] [CrossRef]

- Trikeriotis, M.; Bae, W.J.; Schwartz, E.; Krysak, M.; Lafferty, N.; Xie, P.; Smith, B.; Zimmerman, P.; Ober, C.; Giannelis, E. Development of an inorganic photoresist for DUV, EUV, and electron beam imaging. In Advances in Resist Materials and Processing Technology XXVII; SPIE: Bellingham, WA, USA, 2010; Volume 7639, p. 76390E. [Google Scholar]

- Trikeriotis, M.; Krysak, M.; Chung, Y.S.; Ouyang, C.; Cardineau, B.; Brainard, R.; Ober, C.; Giannelis, E.; Cho, K. A new inorganic EUV resist with high-etch resistance. In Extreme Ultraviolet (EUV) Lithography III; SPIE: Bellingham, WA, USA, 2012; Volume 8322, p. 83220U. [Google Scholar]

- Kosma, V.; Kasahara, K.; Xu, H.; Odent, J.; Ober, C.; Giannelis, E. Elucidating the patterning mechanism of zirconium-based hybrid photoresists. J. Micro Nanolithogr. MEMS MOEMS 2017, 16, 041007. [Google Scholar] [CrossRef]

- Cardineau, B.; Del Re, R.; Marnell, M.; Al-Mashat, H.; Vockenhuber, M.; Ekinci, Y.; Sarma, C.; Freedman, D.A.; Brainard, R.L. Photolithographic properties of tin-oxo clusters using extreme ultraviolet light (13.5 nm). Microelectron. Eng. 2014, 127, 44–50. [Google Scholar] [CrossRef]

- Passarelli, J.; Murphy, M.; Del Re, R.; Sortland, M.; Hotalen, J.; Dousharm, L.; Fallica, R.; Ekinci, Y.; Neisser, M.; Freedman, D.; et al. Organometallic carboxylate resists for extreme ultraviolet with high sensitivity. J. Micro Nanolithogr. MEMS MOEMS 2015, 14, 043503. [Google Scholar] [CrossRef]

- Sortland, M.; Del Re, R.; Passarelli, J.; Hotalen, J.; Vockenhuber, M.; Ekinci, Y.; Neisser, M.; Freedman, D.; Brainard, R. Positive-tone EUV resists: Complexes of platinum and palladium. In Extreme Ultraviolet (EUV) Lithography VI; SPIE: Bellingham, WA, USA, 2015; Volume 9422. [Google Scholar]

- Fujimori, T.; Tsuchihashi, T.; Minegishi, S.; Kamizono, T.; Itani, T. Novel ultra-high sensitive ‘metal resist’ for EUV lithography. In Extreme Ultraviolet (EUV) Lithography VII; SPIE: Bellingham, WA, USA, 2016; Volume 9776, p. 977605. [Google Scholar]

- Li, L.; Chakrabarty, S.; Spyrou, K.; Ober, C.K.; Giannelis, E.P. Studying the Mechanism of Hybrid Nanoparticle Photoresists: Effect of Particle Size on Photopatterning. Chem. Mater. 2015, 27, 5027–5031. [Google Scholar] [CrossRef]

- Grenville, A.; Anderson, J.; Clark, B.; De Schepper, P.; Edson, J.; Greer, M.; Jiang, K.; Kocsis, M.; Meyers, S.; Stowers, J.; et al. Integrated fab process for metal oxide EUV photoresist. In Advances in Patterning Materials and Processes XXXII; SPIE: Bellingham, WA, USA, 2015; Volume 9425, p. 94250S. [Google Scholar]

- Hinsberg, W.; Meyers, S. A numeric model for the imaging mechanism of metal oxide EUV resists. In Advances in Patterning Materials and Processes XXXIV; SPIE: Bellingham, WA, USA, 2017; Volume 10146, p. 1014604. [Google Scholar]

- Xu, H.; Sakai, K.; Kasahara, K.; Kosma, V.; Yang, K.; Herbol, H.C.; Odent, J.; Clancy, P.; Giannelis, E.P.; Ober, C.K. Metal-Organic Framework-Inspired Metal-Containing Clusters for High-Resolution Patterning. Chem. Mater. 2018, 30, 4124–4133. [Google Scholar] [CrossRef]

- Zhang, Y.; Haitjema, J.; Baljozovic, M.; Vockenhuber, M.; Kazazis, D.; Jung, T.A.; Ekinci, Y.; Brouwer, A.M. Dual-tone Application of a Tin-Oxo Cage Photoresist Under E-beam and EUV Exposure. J. Photopolym. Sci. Technol. 2018, 31, 249–255. [Google Scholar] [CrossRef] [Green Version]

- Sitterly, J.; Murphy, M.; Grzeskowiak, S.; Denbeaux, G.; Brainard, R. Molecular organometallic resists for EUV (MORE): Reactivity as a function of metal center (Bi, Sb, Te and Sn). In Advances in Patterning Materials and Processes XXXV; SPIE: Bellingham, WA, USA, 2018; Volume 10586, p. 105861P. [Google Scholar]

- Rantala, J.; Gädda, T.; Laukkanen, M.; Dang, L.N.; Karaste, K.; Kazizis, D.; Ekinci, Y. New resist and underlayer approaches toward EUV lithography. In Proceedings of the International Conference on Extreme Ultraviolet Lithography, Monterey, CA, USA, 17–20 September 2018; SPIE: Bellingham, WA, USA, 2018; Volume 10809, p. 108090X. [Google Scholar]

- Gädda, T.; Luong, N.D.; Laukkanen, M.; Karaste, K.; Kähkönen, O.; Kauppi, E.; Kazazis, D.; Ekinci, Y.; Rantala, J. Advanced EUV negative tone resist and underlayer approaches exhibiting sub-20 nm half-pitch resolution. In Advances in Patterning Materials and Processes XXXVI; SPIE: Bellingham, WA, USA, 2019; Volume 10960, p. 109600B. [Google Scholar]

- Thakur, N.; Tseng, L.-T.; Vockenhuber, M.; Ekinci, Y.; Castellanos, S. Stability studies on a sensitive EUV photoresist based on zinc metal oxoclusters. J. Micro Nanolithogr. MEMS MOEMS 2019, 18, 043504. [Google Scholar] [CrossRef] [Green Version]

- Mattson, E.C.; Cabrera, Y.; Rupich, S.M.; Wang, Y.X.; Oyekan, K.A.; Mustard, T.J.; Halls, M.D.; Bechtel, H.A.; Martin, M.C.; Chabal, Y.J. Chemical Modification Mechanisms in Hybrid Hafnium Oxo-methacrylate Nanocluster Photoresists for Extreme Ultraviolet Patterning. Chem. Mater. 2018, 30, 6192–6206. [Google Scholar] [CrossRef]

- Wu, L.; Baljozovic, M.; Portale, G.; Kazazis, D.; Vockenhuber, M.; Jung, T.; Ekinci, Y.; Castellanos Ortega, S. Mechanistic insights in Zr- and Hf-based molecular hybrid EUV photoresists. J. Micro Nanolithogr. MEMS MOEMS 2019, 18, 013504. [Google Scholar] [CrossRef]

- Haitjema, J.; Zhang, Y.; Ottosson, N.; Brouwer, A.M. Photoreactions of Tin Oxo Cages, Model EUV Photoresists. J. Photopolym. Sci. Technol. 2017, 30, 99–102. [Google Scholar] [CrossRef] [Green Version]

| Design Principle | Materials | Resolution | Sensitivity (Dose to Size) | Pattern Quality (LER-LWR) |

|---|---|---|---|---|

| CAR [45] | Polymeric | 30 nm | <20 mJ/cm2 | - |

| CAR [46] | Polymer bound PAG | 24 nm | 14 mJ/cm2 | 5.3 nm |

| CAR [47] | Polymer bound PAG-increased Hydrophobicity | 16 nm | 24 mJ/cm2 | 3 nm |

| CAR [48] | Polymeric | 15 nm | 25–30 mJ/cm2 | 6 nm |

| CAR [56] | Polymeric with different PAGs | 13 nm | 35.5 mJ/cm2 | |

| CAR [59] | Polymeric | 20 nm | 31 mJ/cm2 | - |

| CAR [60] | Polymeric | 14 nm | 43 mJ/cm2 | 5.8 nm |

| CAR [64] | Polymeric with Acid Amplifier (AA) | 60 nm | 1.9 mJ/cm2 | 7.9 nm |

| CAR-Multi-triggered resist [80,81,82,83] | Molecular | 12.7 nm | 53 mJ/cm2 | 4.2 nm |

| CAR [69] | Polymeric-main chain scission | 20 nm | 4 mJ/cm2 | - |

| CAR [72] | Molecular | 45 nm | 10.3 mJ/cm2 | - |

| CAR [73] | Molecular | 45 nm | 9.5 mJ/cm2 | 6.2 nm |

| CAR [74] | Molecular | 26 nm | 14.5 mJ/cm2 | - |

| CAR [76] | Molecular | 20 nm | 40.5 mJ/cm2 | 3.2 nm |

| CAR [77] | Molecular | 28 nm | 22 mJ/cm2 | 3.7 nm |

| CAR [78,79] | Molecular | 14 nm | 36.1 mJ/cm2 | 3.26 nm |

| Non-CAR [93] | Polymeric | 22 nm | 78 mJ/cm2 | <6 nm |

| Non-CAR [94] | Polymeric | 20 nm | 26.6 mJ/cm2 | - |

| Non-CAR [95] | polymeric | 50 nm | 52 mJ/cm2 | 4.1 nm |

| Inorganic [97,98] | Nanoparticles | 26 nm | 4.2 mJ/cm2 | - |

| Inorganic [101] | Clusters | 18 nm | 350 mJ/cm2 | - |

| Organometallic [102] | Molecular | 35 nm | 5.6 mJ/cm2 | - |

| Organometallic [103] | Complexes | 30 nm | 90 mJ/cm2 | 5.5 nm |

| Metal [104] | - | 17 nm | 7 mJ/cm2 | 5.6 nm |

| Metal oxide [105] | - | 13 nm | 35 mJ/cm2 | - |

| Metal-organic [107] | Clusters | 13 nm | 35 mJ/cm2 | - |

| Metal [108] | Complexes | 50 nm | 53.5 mJ/cm2 | - |

| Organohydrogen silsesquioxane [110] | Molecule | 22 nm | 65.4 mJ/cm2 | 1.4 nm |

| Metal oxide [112] | Clusters | 25 nm | 37 mJ/cm2 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manouras, T.; Argitis, P. High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results. Nanomaterials 2020, 10, 1593. https://doi.org/10.3390/nano10081593

Manouras T, Argitis P. High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results. Nanomaterials. 2020; 10(8):1593. https://doi.org/10.3390/nano10081593

Chicago/Turabian StyleManouras, Theodore, and Panagiotis Argitis. 2020. "High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results" Nanomaterials 10, no. 8: 1593. https://doi.org/10.3390/nano10081593

APA StyleManouras, T., & Argitis, P. (2020). High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results. Nanomaterials, 10(8), 1593. https://doi.org/10.3390/nano10081593