Limitations of Thermal Stability Analysis via In-Situ TEM/Heating Experiments

Abstract

:1. Introduction

2. Materials and Methods

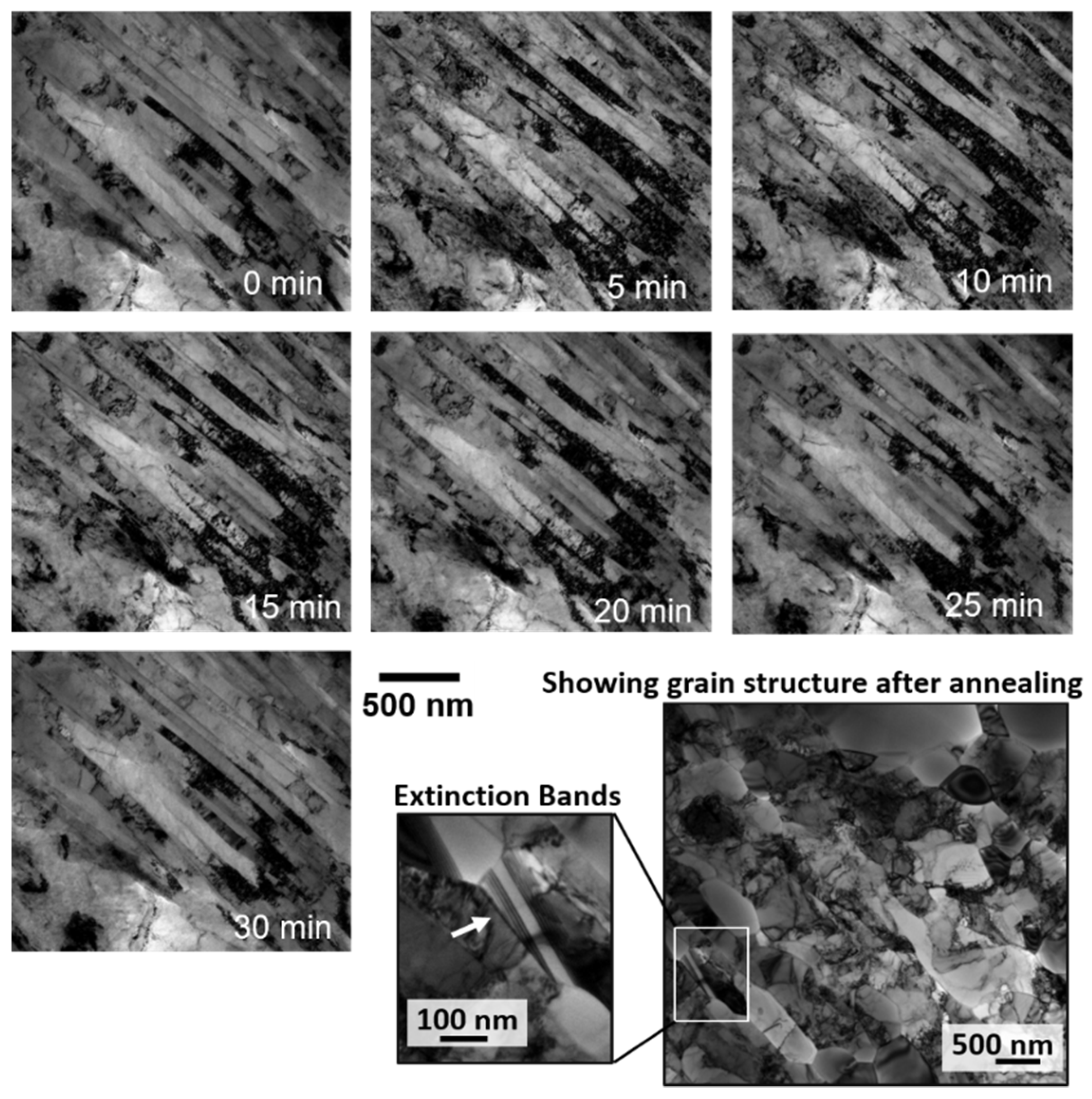

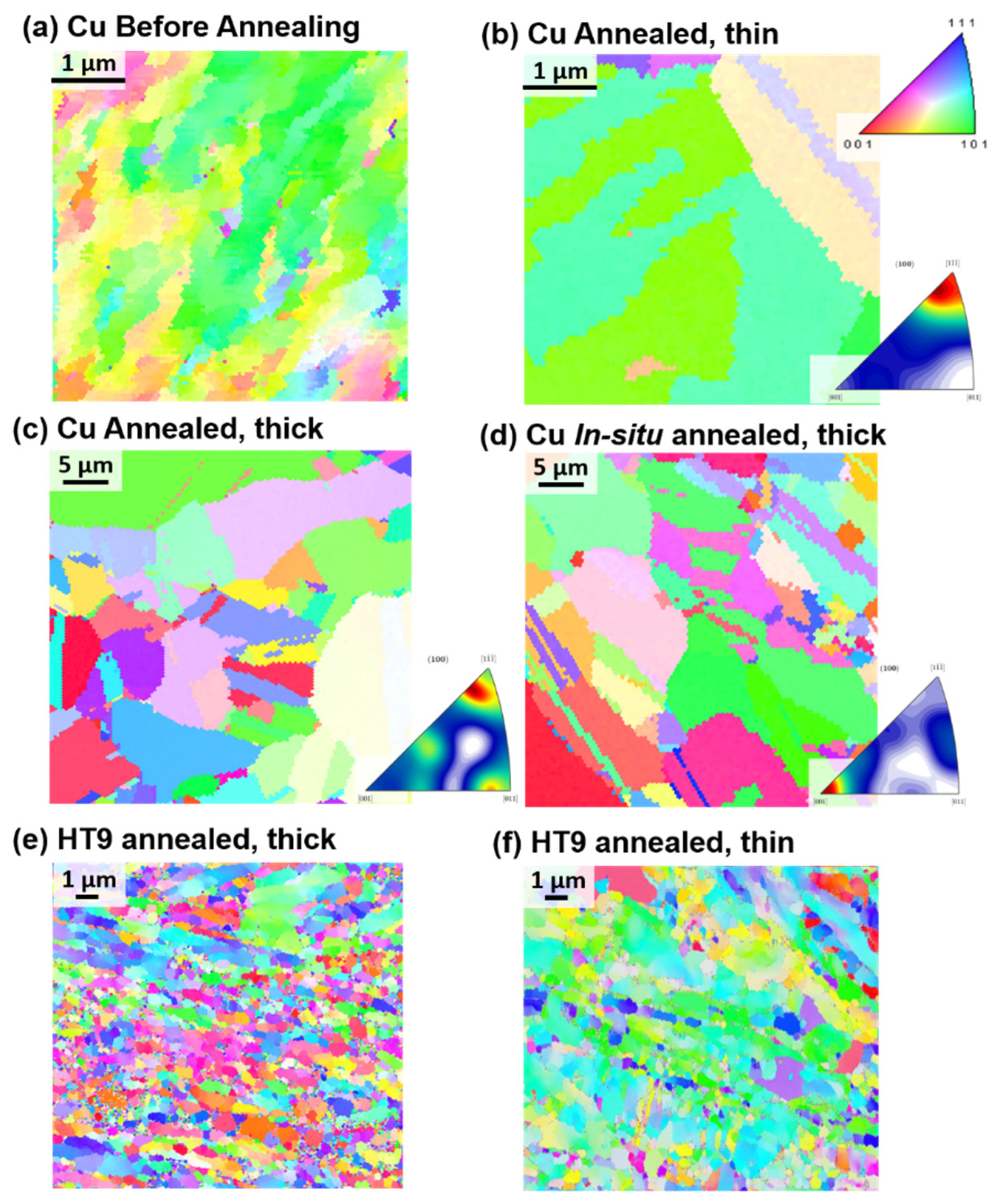

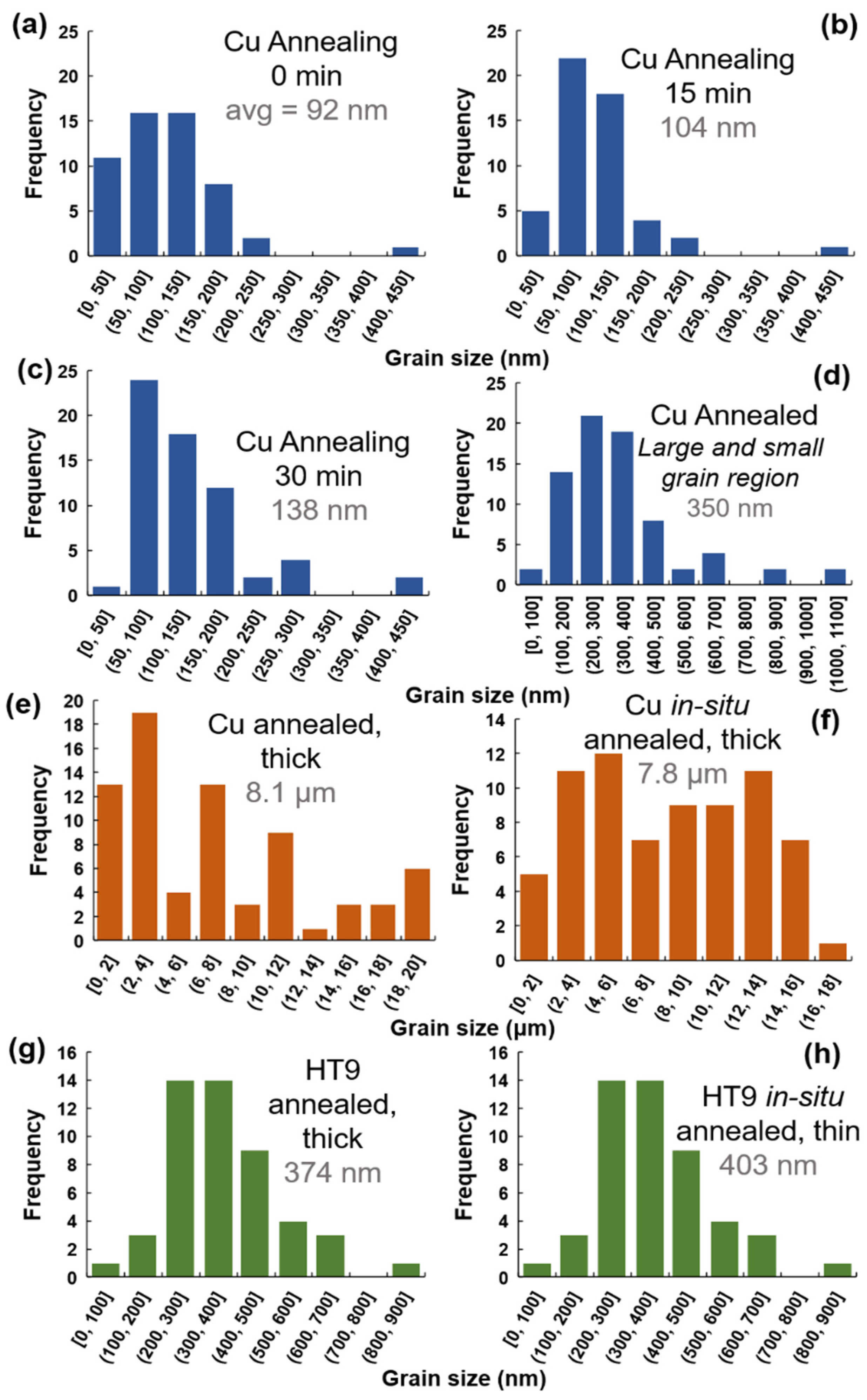

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, N.; Wang, Z.; Aust, K.; Erb, U. Effect of grain size on mechanical properties of nanocrystalline materials. Acta Metall. Mater. 1995, 43, 519–528. [Google Scholar] [CrossRef]

- Fujita, H.; Tabata, T. The effect of grain size and deformation sub-structure on mechanical properties of polycrystalline aluminum. Acta Metall. 1973, 21, 355–365. [Google Scholar] [CrossRef]

- Meyers, M.; Mishra, A.; Benson, D. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Wei, Q.; Jiao, T.; Ramesh, K.; Ma, E.; Kecskes, L.; Magness, L.; Dowding, R.; Kazykhanov, V.; Valiev, R. Mechanical behavior and dynamic failure of high-strength ultrafine grained tungsten under uniaxial compression. Acta Mater. 2006, 54, 77–87. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, H.; Schuster, B.; Ramesh, K.; Valiev, R.; Kecskes, L.; Dowding, R.; Magness, L.; Cho, K. Microstructure and mechanical properties of super-strong nanocrystalline tungsten processed by high-pressure torsion. Acta Mater. 2006, 54, 4079–4089. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar] [CrossRef]

- Tillack, M.; Raffray, A.; Wang, X.; Malang, S.; Abdel-Khalik, S.; Yoda, M.; Youchison, D. Recent US activities on advanced He-cooled W-alloy divertor concepts for fusion power plants. Fusion Eng. Des. 2011, 86, 71–98. [Google Scholar] [CrossRef]

- Tobita, K.; Nishio, S.; Enoeda, M.; Kawashima, H.; Kurita, G.; Tanigawa, H.; Nakamura, H.; Honda, M.; Saito, A.; Sato, S.; et al. Compact DEMO, SlimCS: Design progress and issues. Nucl. Fusion 2009, 49, 075029. [Google Scholar] [CrossRef]

- Davis, J.; Barabash, V.; Makhankov, A.; Plöchl, L.; Slattery, K. Assessment of tungsten for use in the ITER plasma facing components. J. Nucl. Mater. 1998, 258, 308–312. [Google Scholar] [CrossRef]

- El-Atwani, O.; Hinks, J.A.; Greaves, G.; Allain, J.P.; Maloy, S.A. Grain size threshold for enhanced irradiation resistance in nanocrystalline and ultrafine tungsten. Mater. Res. Lett. 2017, 5, 343–349. [Google Scholar] [CrossRef] [Green Version]

- El-Atwani, O.; Li, N.; Li, M.; Devaraj, A.; Baldwin, J.K.S.; Schneider, M.M.; Sobieraj, D.; Wróbel, J.S.; Nguyen-Manh, D.; Maloy, S.A. Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci. Adv. 2019, 5, eaav2002. [Google Scholar] [CrossRef] [Green Version]

- Du, C.; Jin, S.; Fang, Y.; Li, J.; Hu, S.; Yang, T.; Zhang, Y.; Huang, J.; Sha, G.; Wang, Y.; et al. Ultrastrong nanocrystalline steel with exceptional thermal stability and radiation tolerance. Nat. Commun. 2018, 9, 5389. [Google Scholar] [CrossRef]

- Kacher, J.; Hattar, K.; Robertson, I.M. Initial texture effects on the thermal stability and grain growth behavior of nanocrystalline Ni thin films. Mater. Sci. Eng. A 2016, 675, 110–119. [Google Scholar] [CrossRef] [Green Version]

- Clark, B.G.; Hattar, K.; Marshall, M.T.; Chookajorn, T.; Boyce, B.; Schuh, C.A. Thermal Stability Comparison of Nanocrystalline Fe-Based Binary Alloy Pairs. JOM 2016, 68, 1625–1633. [Google Scholar] [CrossRef]

- Anber, E.A.; Lang, A.C.; Lass, E.A.; Suri, P.K.; D’Antuono, D.S.; Diao, H.; Liaw, P.K.; Taheri, M.L. Thermal Stability of High Entropy Alloys during in Situ TEM Heating. Microsc. Microanal. 2018, 24, 1928–1929. [Google Scholar] [CrossRef] [Green Version]

- Efe, M.; El-Atwani, O.; Guo, Y.; Klenosky, D.R. Microstructure refinement of tungsten by surface deformation for irradiation damage resistance. Scr. Mater. 2014, 70, 31–34. [Google Scholar] [CrossRef]

- El Atwani, H.K.O.; Gigax, J.; Harvey, C.; Aytuna, B.; Efe, M.; Maloy, S. Highly Stable, Ductile and Strong Nanocrystalline HT-9 Steels via Large Strain Machining. Nanomaterials 2021, in press. [Google Scholar]

- Barmak, K.; Eggeling, E.; Kinderlehrer, D.; Sharp, R.; Ta’Asan, S.; Rollett, A.; Coffey, K. Grain growth and the puzzle of its stagnation in thin films: The curious tale of a tail and an ear. Prog. Mater. Sci. 2013, 58, 987–1055. [Google Scholar] [CrossRef]

- Kinderlehrer, D.; Livshits, I.; Ta’Asan, S. A Variational Approach to Modeling and Simulation of Grain Growth. SIAM J. Sci. Comput. 2006, 28, 1694–1715. [Google Scholar] [CrossRef]

- Battaile, C.; Holm, E.; Weiland, H.; Adams, B.; Rollett, A. Grain growth in polycrystalline materials. In Proceedings of the Third International Conference on Grain Growth, Warrendale, PA, USA, 14–19 June 1998; p. 119. [Google Scholar]

- Lücke, K.; Stüwe, H. On the theory of impurity controlled grain boundary motion. Acta Metall. 1971, 19, 1087–1099. [Google Scholar] [CrossRef]

- Mullins, W.W. Theory of Thermal Grooving. J. Appl. Phys. 1957, 28, 333–339. [Google Scholar] [CrossRef]

- Mullins, W. The effect of thermal grooving on grain boundary motion. Acta Metall. 1958, 6, 414–427. [Google Scholar] [CrossRef]

- Frost, H. Microstructural evolution in thin films. Mater. Charact. 1994, 32, 257–273. [Google Scholar] [CrossRef]

- Burke, J.E.; Turnbull, D. Recrystallization and grain growth. Prog. Met. Phys. 1952, 3, 220–292. [Google Scholar] [CrossRef]

- Thompson, C.V. Grain growth in thin films. Annu. Rev. Mater. Res. 1990, 20, 245–268. [Google Scholar] [CrossRef]

- Chen, W.; Xu, J.; Liu, D.; Bao, J.; Sabbaghianrad, S.; Shan, D.; Guo, B.; Langdon, T.G. Microstructural Evolution and Microhardness Variations in Pure Titanium Processed by High-Pressure Torsion. Adv. Eng. Mater. 2020, 22, 1901462. [Google Scholar] [CrossRef]

- Lian, J.; Valiev, R.Z.; Baudelet, B. On the enhanced grain growth in ultrafine grained metals. Acta Metall. Mater. 1995, 43, 4165–4170. [Google Scholar] [CrossRef]

- Valiev, R. Paradoxes of Severe Plastic Deformation. Adv. Eng. Mater. 2003, 5, 296–300. [Google Scholar] [CrossRef]

- Srolovitz, D.J.; Grest, G.S.; Anderson, M.P. Computer simulation of grain growth—V. Abnormal grain growth. Acta Metall. 1985, 33, 2233–2247. [Google Scholar] [CrossRef]

- Glushko, O.; Dehm, G. Initiation and stagnation of room temperature grain coarsening in cyclically strained gold films. Acta Mater. 2019, 169, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Sonnweber-Ribic, P.; Gruber, P.A.; Dehm, G.; Strunk, H.P.; Arzt, E. Kinetics and driving forces of abnormal grain growth in thin Cu films. Acta Mater. 2012, 60, 2397–2406. [Google Scholar] [CrossRef]

- Ellis, E.; Chmielus, M.; Lin, M.-T.; Joress, H.; Visser, K.; Woll, A.; Vinci, R.; Brown, W.L.; Baker, S.P. Driving forces for texture transformation in thin Ag films. Acta Mater. 2016, 105, 495–504. [Google Scholar] [CrossRef] [Green Version]

- Nes, E.; Ryum, N.; Hunderi, O.J.A.M. On the Zener drag. Acta Metall. 1985, 33, 11–22. [Google Scholar] [CrossRef]

- El-Atwani, O.; Nathaniel, J.E.; Leff, A.C.; Hattar, K.; Taheri, M.L. Direct Observation of Sink-Dependent Defect Evolution in Nanocrystalline Iron under Irradiation. Sci. Rep. 2017, 7, 1836. [Google Scholar] [CrossRef] [Green Version]

- Darling, K.; VanLeeuwen, B.; Semones, J.; Koch, C.; Scattergood, R.; Kecskes, L.; Mathaudhu, S. Stabilized nanocrystalline iron-based alloys: Guiding efforts in alloy selection. Mater. Sci. Eng. A 2011, 528, 4365–4371. [Google Scholar] [CrossRef]

- Malow, T.; Koch, C.J.A.M. Grain growth in nanocrystalline iron prepared by mechanical attrition. Acta Mater. 1997, 45, 2177–2186. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Atwani, O.; Kim, H.; Harvey, C.; Efe, M.; Maloy, S.A. Limitations of Thermal Stability Analysis via In-Situ TEM/Heating Experiments. Nanomaterials 2021, 11, 2541. https://doi.org/10.3390/nano11102541

El-Atwani O, Kim H, Harvey C, Efe M, Maloy SA. Limitations of Thermal Stability Analysis via In-Situ TEM/Heating Experiments. Nanomaterials. 2021; 11(10):2541. https://doi.org/10.3390/nano11102541

Chicago/Turabian StyleEl-Atwani, Osman, Hyosim Kim, Cayla Harvey, Mert Efe, and Stuart A. Maloy. 2021. "Limitations of Thermal Stability Analysis via In-Situ TEM/Heating Experiments" Nanomaterials 11, no. 10: 2541. https://doi.org/10.3390/nano11102541

APA StyleEl-Atwani, O., Kim, H., Harvey, C., Efe, M., & Maloy, S. A. (2021). Limitations of Thermal Stability Analysis via In-Situ TEM/Heating Experiments. Nanomaterials, 11(10), 2541. https://doi.org/10.3390/nano11102541