Valorization of Brewery Wastes for the Synthesis of Silver Nanocomposites Containing Orthophosphate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Nanoparticles

2.3. Instruments and Analysis Methods

2.4. Bacterial Susceptibility Tests

3. Results

3.1. Brewery Wastes Analyses

3.2. Characterization of Nanocomposites

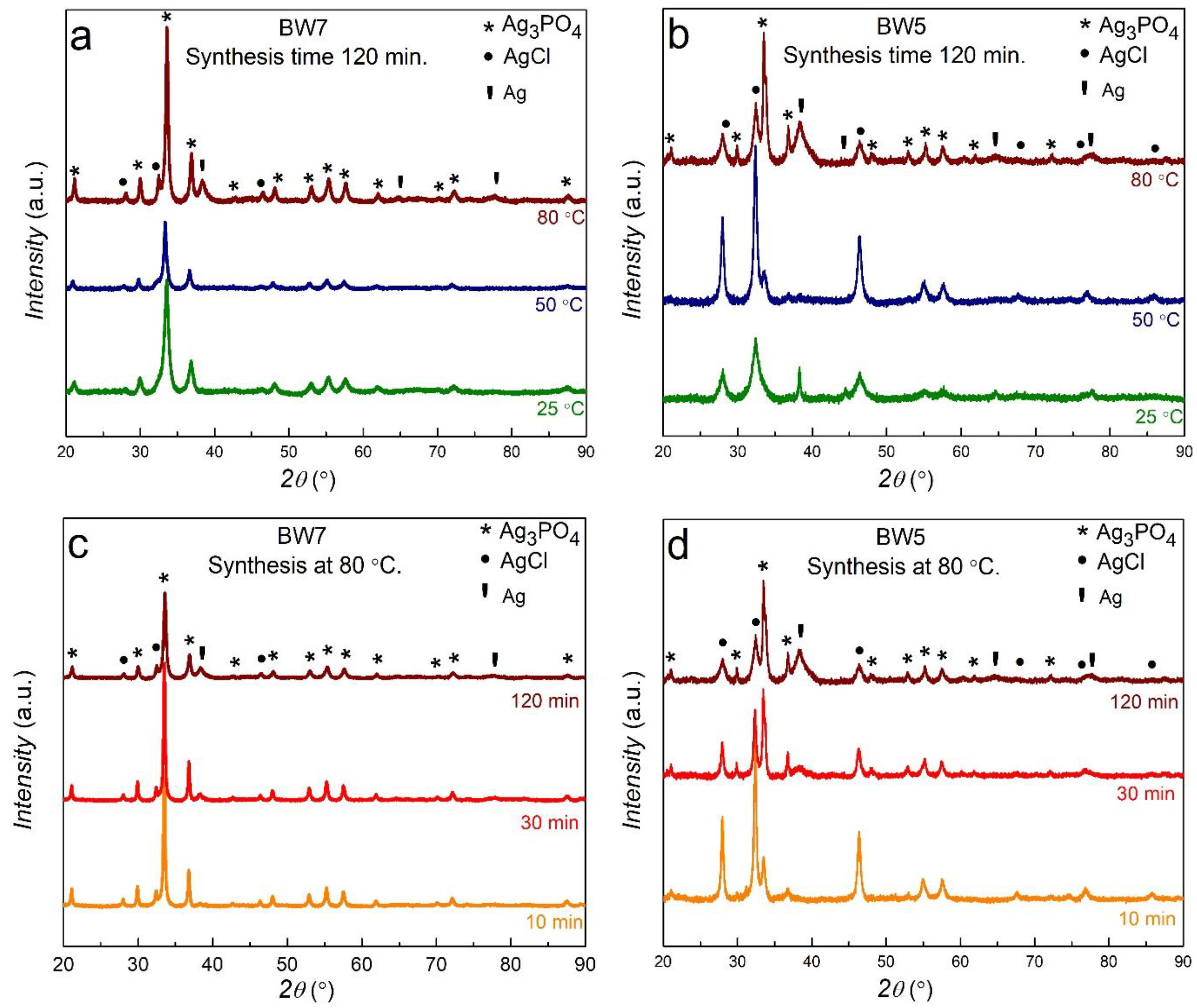

3.2.1. Crystallography and Phase Analysis

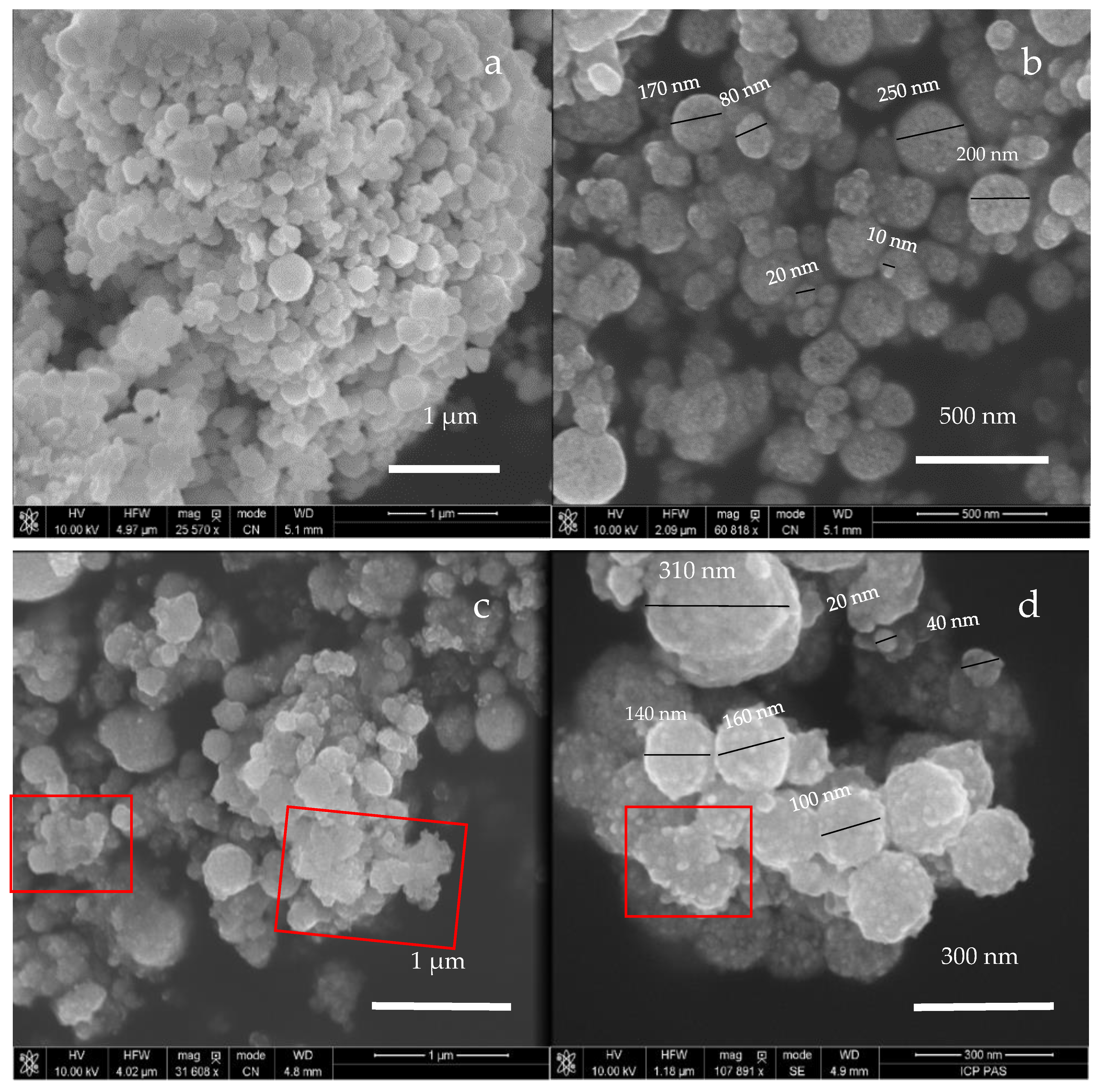

3.2.2. Elemental and Morphological Analysis

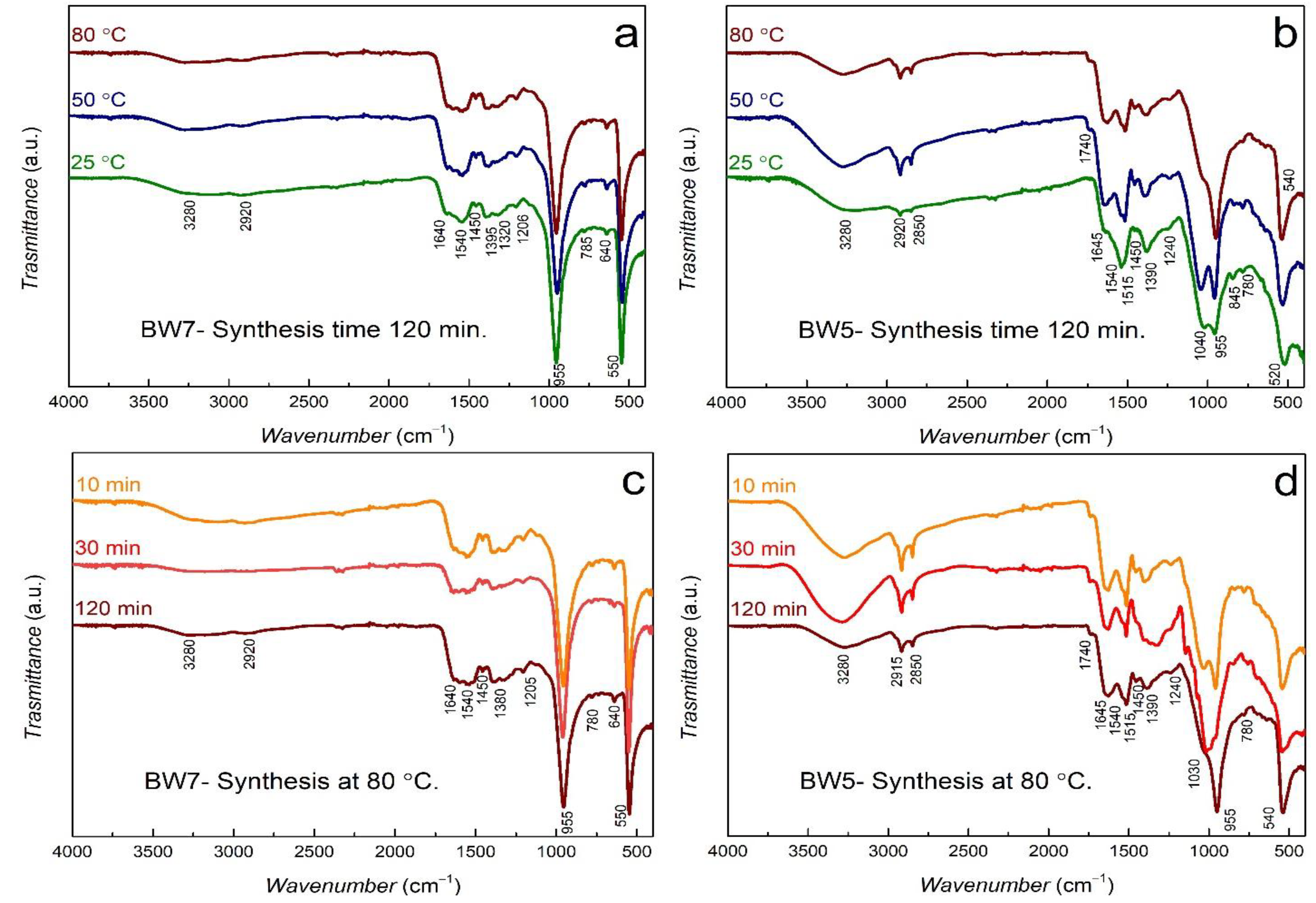

3.2.3. Chemical Analysis

3.2.4. Bacterial Susceptibility Testing

4. Discussion

5. Conclusions

- Nanocomposites of mainly Ag3PO4 and minor amounts of AgCl and Agmet were obtained using BW7. BW5, disparately, converted the silver salt to mainly AgCl with minor amounts of Ag3PO4 and Agmet. The reduction of Ag+ ions is promoted only at higher temperatures.

- Nanocomposites with different ratios of Ag3PO4, AgCl, and Agmet can be obtained by varying the synthesis temperature and time. The highest Ag3PO4 content (90 wt.%) was obtained using BW7 in room temperature synthesis for 120 min.

- The organic surface capping was rich in functional groups observed in the brewery wastes. The thickness of the organic layer was ~15–40 Å. BW7 nanocomposites contain a thinner capping than BW5 nanocomposites.

- Increasing the synthesis temperature led to the incorporation of higher amounts of the minor components in the nanocomposite structures.

- The nanocomposites differ in their inhibition and bactericidal activity depending on their composition and surface organic overlayer. BW7 nanocomposites exhibited a better antibacterial activity.

6. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fillaudeau, L.; Blanpain-Avet, P.; Daufin, G. Water, wastewater and waste management in brewing industries. J. Cleaner Prod. 2006, 14, 463–471. [Google Scholar] [CrossRef]

- Thiel, P.G.; Du Toit, P.J. The chemical composition of a brewery waste. J. Inst. Brew. 1965, 71, 6. [Google Scholar] [CrossRef]

- Moshtagh, B.; Hawboldt, K.; Zhang, B. Optimization of biosurfactant production by Bacillus Subtilis N3-1P using the brewery waste as the carbon source. Environ. Technol. 2019, 40, 3371–3380. [Google Scholar] [CrossRef]

- Stefanello, F.S.; Dos Santos, C.O.; Bochi, V.C.; Fruet, A.P.B.; Soquetta, M.B.; Dorr, A.C.; Nornberg, J.L. Analysis of polyphenols in brewer’s spent grain and its comparison with corn silage and cereal brans commonly used for animal nutrition. Food Chem. 2018, 239, 385–401. [Google Scholar] [CrossRef] [PubMed]

- Barbosa-Pereira, L.; Pocheville, A.; Angulo, I.; Paseiro-Losada, P.; Cruz, J.M. Fractionation and purification of bioactive compounds obtained from a brewery waste stream. Biomed. Res. Int. 2013, 2013, 408491. [Google Scholar] [CrossRef] [Green Version]

- Brewing Beer: The Brewing Process. Available online: https://www.braeuamberg.at/en/brewing-process/ (accessed on 1 June 2020).

- Fărcaş, A.C.; Socaci, S.A.; Mudura, E.; Dulf, F.V.; Vodnar, D.C.; Tofană, M.; Salanță, L.C. Exploitation of Brewing Industry Wastes to Produce Functional Ingredients. In Brewing Technology; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- Corbo, M.R.; Bevilacqua, A.; Petruzzi, L.; Casanova, F.P.; Sinigaglia, M. Functional Beverages: The Emerging Side of Functional Foods. Compre. Rev. Food Sci. Food Saf. 2014, 13, 1192–1206. [Google Scholar] [CrossRef]

- Handbook of Brewing; Priest, F.G.; Stewart, G.G. (Eds.) Taylor & Francis Group CRC press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Hellborg, L.; Piskur, J. Yeast Diversity in the Brewing Industry. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: London, UK, 2008. [Google Scholar]

- Bastos-Arrieta, J.; Florido, A.; Perez-Rafols, C.; Serrano, N.; Fiol, N.; Poch, J.; Villaescusa, I. Green Synthesis of Ag Nanoparticles Using Grape Stalk Waste Extract for the Modification of Screen-Printed Electrodes. Nanomaterials 2018, 8, 946. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, P.R.; Fawcett, D.; Sharma, S.B.; Poinern, G.E.J. Production of High-Value Nanoparticles via Biogenic Processes Using Aquacultural and Horticultural Food Waste. Materials 2017, 10, 852. [Google Scholar] [CrossRef] [Green Version]

- Dubey, S.P.; Lahtinen, M.; Sillanpää, M. Tansy fruit mediated greener synthesis of silver and gold nanoparticles. Process Biochem. 2010, 45, 1065–1071. [Google Scholar] [CrossRef]

- Abboud, Y.; Saffaj, T.; Chagraoui, A.; El Bouari, A.; Brouzi, K.; Tanane, O.; Ihssane, B. Biosynthesis, characterization and antimicrobial activity of copper oxide nanoparticles (CONPs) produced using brown alga extract (Bifurcaria bifurcata). Appl. Nanosci. 2013, 4, 571–576. [Google Scholar] [CrossRef] [Green Version]

- Yantcheva, N.S.; Karashanova, D.B.; Georgieva, B.C.; Vasileva, I.N.; Stoyanova, A.S.; Denev, P.N.; Dinkova, R.H.; Ognyanov, M.H.; Slavov, A.M. Characterization and application of spent brewer’s yeast for silver nanoparticles synthesis. Bulg. Chem. Commun. 2019, 51, 173–177. [Google Scholar]

- Yi, Z.; Ye, J.; Kikugawa, N.; Kako, T.; Ouyang, S.; Stuart-Williams, H.; Yang, H.; Cao, J.; Luo, W.; Li, Z.; et al. An orthophosphate semiconductor with photooxidation properties under visible-light irradiation. Nat. Mater. 2010, 9, 559–564. [Google Scholar] [CrossRef]

- Cui, X.; Tian, L.; Xian, X.; Tang, H.; Yang, X. Solar photocatalytic water oxidation over Ag3PO4/g-C3N4 composite materials mediated by metallic Ag and graphene. Appl. Surf. Sci. 2018, 430, 108–115. [Google Scholar] [CrossRef]

- Gupta, A.; Mumtaz, S.; Li, C.H.; Hussain, I.; Rotello, V.M. Combatting antibiotic-resistant bacteria using nanomaterials. Chem. Soc. Rev. 2019, 48, 415–427. [Google Scholar] [CrossRef] [PubMed]

- Magiorakos, A.-P.; Srinivasan, A.; Carey, R.B.; Carmeli, Y.; Falagas, M.E.; Giske, C.G.; Harbarth, S.; Hindler, J.F.; Kahlmeter, G.; Olsson-Liljequist, B.; et al. Multidrug-resistant, extensively drug-resistant and pandrug-resistant bacteria: An international expert proposal for interim standard definitions for acquired resistance. Clin. Microbiol. Infection 2012, 18, 268–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 1871:2009. Food and feed products—General guidelines for the determination of nitrogen by the Kjeldahl method. Available online: https://www.iso.org/standard/41320.html (accessed on 2 October 2021).

- Grubesic, R.J.; Vukovic, J.; Kremer, D.; Vladimir-Knezevic, S. Spectrophotometric method for polyphenols analysis: Prevalidation and application on Plantago L. species. J. Pharm. Biomed. Anal. 2005, 39, 837–842. [Google Scholar] [CrossRef] [PubMed]

- Hewitt, B.R. Spectrophotometric Determination of Total Carbohydrate. Nature 1958, 182, 246–247. [Google Scholar] [CrossRef]

- Petkova, N.; Vrancheva, R.; Denev, P.; Ivanov, I.; Pavlov, A. HPLC-RID method for determination of inulin and fructooligosaccharides. In Proceedings of the Conference XI National Conference Natural Sciences 2013, “Bishop Konstantin Preslavski”, Varna, Bulgaria, September 2013; pp. 23–28. [Google Scholar]

- Cendejas-Bueno, E.; Rodriguez-Tudela, J.L.; Cuenca-Estrella, M.; Gomez-Lopez, A. Development and validation of a fast HPLC/photodiode array detection method for the measurement of voriconazole in human serum samples. A reference laboratory experience. Enferm. Infecc. Microbiol. Clin. 2013, 31, 23–28. [Google Scholar] [CrossRef]

- Bisutti, I.; Hilke, I.; Raessler, M. Determination of total organic carbon—an overview of current methods. TrAC, Trends Anal. Chem. 2004, 23, 716–726. [Google Scholar] [CrossRef]

- Kover, L.; Varga, D.; Cserny, I.; Toth, J.; Tokesi, K. Some applications of high-energy, high-resolution Auger-electron spectroscopy using Bremsstrahlung radiation. Surf. Interface Anal. 1992, 19, 9–15. [Google Scholar] [CrossRef]

- Georget, D.M.R.; Belton, P.S. Effects of Temperature and Water Content on the Secondary Structure of Wheat Gluten Studied by FTIR Spectroscopy. Biomacromolecules 2006, 7, 469–475. [Google Scholar] [CrossRef]

- Farhat, I.A.; Orset, S.; Moreau, P.; Blanshard, J.M.V. FTIR Study of Hydration Phenomena in Protein–Sugar Systems. J. Colloid Interface Sci. 1998, 207, 200–208. [Google Scholar] [CrossRef]

- Zhbankov, R.G.; Firsov, S.P.; Buslov, D.K.; Nikonenko, N.A.; Marchewka, M.K.; Ratajczak, H. Structural physico-chemistry of cellulose macromolecules. Vibrational spectra and structure of cellulose. J. Mol. Struct. 2002, 614, 117–125. [Google Scholar] [CrossRef]

- Duarte, I.F.; Barros, A.; Almeida, C.; Spraul, M.; Gil, A.M. Multivariate Analysis of NMR and FTIR Data as a Potential Tool for the Quality Control of Beer. J. Agric. Food Chem. 2004, 52, 1031–1038. [Google Scholar] [CrossRef]

- Edelmann, A.; Lendl, B. Toward the Optical Tongue: Flow-Through Sensing of Tannin−Protein Interactions Based on FTIR Spectroscopy. J. Am. Chem. Soc. 2002, 124, 14741–14747. [Google Scholar] [CrossRef]

- Talari, A.C.S.; Martinez, M.A.G.; Movasaghi, Z.; Rehman, S.; Rehman, I.U. Advances in Fourier transform infrared (FTIR) spectroscopy of biological tissues. Appl. Spectrosc. Rev. 2016, 52, 456–506. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, W.; Via, B.K.; Fasina, O.; Han, G. Prediction of mixed hardwood lignin and carbohydrate content using ATR-FTIR and FT-NIR. Carbohydr. Polym. 2015, 121, 336–341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hubbard, C.R. RIR—measurement and use in quantitative XRD. Powder Diff. 1988, 3, 74–77. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Niu, X.; Wang, J.; Wu, J. Facile synthesis of Ag3PO4 with the assistance of N,N-dimethylformamid and urea for high performance photocatalysis. Cat. Commun. 2016, 77, 55–59. [Google Scholar] [CrossRef]

- Padmanabhan, S.K.; Pal, S.; Licciulli, A. Diatomite/silver phosphate composite for efficient degradation of organic dyes under solar radiation. Bull. Mater. Sci. 2020, 43, s12034-020. [Google Scholar] [CrossRef]

- Saud, P.S.; Pant, B.; Twari, A.P.; Ghouri, Z.K.; Park, M.; Kim, H.Y. Effective photocatalytic efficacy of hydrothermally synthesized silver phosphate decorated titanium dioxide nanocomposite fibers. J. Colloid Interface Sci. 2016, 465, 225–232. [Google Scholar] [CrossRef]

- Background analysis of XPS/AES QUASES Simple Backgrounds; 2.2; Tougaard Inc.: Odense, Denmark, 1999–2001.

- Mohai, M. XPS MultiQuant: Multimodel XPS quantification software. Surf. Interface Anal. 2004, 36, 828–832. [Google Scholar] [CrossRef]

- Multimodel of X-ray photoelectron spectroscopy quantification program for 32-bit Windows. In XPSMuliQuant; ver. 7; Mohai, M.: Budapest, Hungary, 1999–2001.

- Scofield, J.H. Hartree-Slater subshell photoionization cross-sections at 1254 and 1487 eV. J. Electron. Spectrosc. Relat. Phenom. 1976, 8, 129–137. [Google Scholar] [CrossRef]

- NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database Number 20, National Institute of Standards and Technology, Gaithersburg MD, 20899. 2000. (accessed on 1 May 2021). [CrossRef]

- XPS Peak Fitting Program for WIN95/98 XPSPEAK; 4.1; Department of Chemistry, The Chinese University of Hong Kong: Shatin, Hong Kong, 2000.

- Sulaeman, U.; Hermawan, D.; Andreas, R.; Abdullah, A.Z.; Yin, S. Native defects in silver orthophosphate and their effects on photocatalytic activity under visible light irradiation. Appl. Surf. Sci. 2018, 428, 1029–1035. [Google Scholar] [CrossRef]

- Sulaeman, U.; Suhendar, S.; Diastuti, H.; Riapanitra, A.; Yin, S. Design of Ag3PO4 for highly enhanced photocatalyst using hydroxyapatite as a source of phosphate ion. Solid State Sci. 2018, 86, 1–5. [Google Scholar] [CrossRef]

- Kaushik, V.K. XPS core level spectra and Auger parameters for some silver compounds. J. Electron. Spectrosc. Relat. Phenom. 1991, 56, 273–277. [Google Scholar] [CrossRef]

- Kibis, L.S.; Stadnichenko, A.I.; Pajetnov, E.M.; Koscheev, S.V.; Zaykovskii, V.I.; Boronin, A.I. The investigation of oxidized silver nanoparticles prepared by thermal evaporation and radio-frequency sputtering of metallic silver under oxygen. Appl. Surf. Sci. 2010, 257, 404–413. [Google Scholar] [CrossRef]

- Rocha, T.C.; Oestereich, A.; Demidov, D.V.; Havecker, M.; Zafeiratos, S.; Weinberg, G.; Bukhtiyarov, V.I.; Knop-Gericke, A.; Schlogl, R. The silver-oxygen system in catalysis: New insights by near ambient pressure X-ray photoelectron spectroscopy. Phys. Chem. Chem. Phys. 2012, 14, 4554–4564. [Google Scholar] [CrossRef] [Green Version]

- Mikhlin, Y.L.; Vishnyakova, E.A.; Romanchenko, A.S.; Saikova, S.V.; Likhatski, M.N.; Larichev, Y.V.; Tuzikov, F.V.; Zaikovskii, V.I.; Zharkov, S.M. Oxidation of Ag nanoparticles in aqueous media: Effect of particle size and capping. Appl. Surf. Sci. 2014, 297, 75–83. [Google Scholar] [CrossRef]

- Lesiak, B.; Kövér, L.; Tóth, J.; Zemek, J.; Jiricek, P.; Kromka, A.; Rangam, N. C sp2/sp3 hybridisations in carbon nanomaterials—XPS and (X)AES study. Appl. Surf. Sci. 2018, 452, 223–231. [Google Scholar] [CrossRef]

- Vorobyev, S.; Vishnyakova, E.; Likhatski, M.; Romanchenko, A.; Nemtsev, I.; Mikhlin, Y. Reactivity and Chemical Sintering of Carey Lea Silver Nanoparticles. Nanomaterials 2019, 9, 1525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- QUASES-Tougaard Background Analysis of XPS/AES Part1-QUASES-Analyze; 5.0; Tougaard Inc.: Odense, Denmark, 1994–2003.

- Tanuma, S.; Powell, C.J.; Penn, D.R. Calculations of electron inelastic mean free paths. V. Data for 14 organic compounds over the 50–2000 eV range. Surf. Interface Anal. 1993, 21, 165–176. [Google Scholar] [CrossRef]

- Kubasheva, Z.; Sprynskyy, M.; Railean-Plugaru, V.; Pomastowski, P.; Ospanova, A.; Buszewski, B. Synthesis and Antibacterial Activity of (AgCl, Ag)NPs/Diatomite Hybrid Composite. Materials 2020, 13, 3409. [Google Scholar] [CrossRef] [PubMed]

- Iravani, S. Green synthesis of metal nanoparticles using plants. Green Chem. 2011, 13, 2638. [Google Scholar] [CrossRef]

- El-Seedi, H.R.; El-Shabasy, R.M.; Khalifa, S.A.M.; Saeed, A.; Shah, A.; Shah, R.; Iftikhar, F.J.; Abdel-Daim, M.M.; Omri, A.; Hajrahand, N.H.; et al. Metal nanoparticles fabricated by green chemistry using natural extracts: Biosynthesis, mechanisms, and applications. RSC Adv. 2019, 9, 24539–24559. [Google Scholar] [CrossRef] [Green Version]

- Meshram, S.M.; Bonde, S.R.; Gupta, I.R.; Gade, A.K.; Rai, M.K. Green synthesis of silver nanoparticles using white sugar. IET Nanobiotechnol. 2013, 7, 28–32. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, A.D.; Gopal, K. Biosynthesis of silver and gold nanoparticles using Chenopodium album leaf extract. Colloids Surf. A 2010, 369, 27–33. [Google Scholar] [CrossRef]

- Lin, Z.; Wu, J.; Xue, R.; Yang, Y. Spectroscopic characterization of Au3+ biosorption by waste biomass of Saccharomyces cerevisiae. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2005, 61, 761–765. [Google Scholar] [CrossRef]

- Deshmukh, S.P.; Patil, S.M.; Mullani, S.B.; Delekar, S.D. Silver nanoparticles as an effective disinfectant: A review. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 97, 954–965. [Google Scholar] [CrossRef]

- Mikhailova, E.O. Silver Nanoparticles: Mechanism of Action and Probable Bio-Application. J. Funct. Biomater. 2020, 11, 84. [Google Scholar] [CrossRef]

- CRC Handbook of Chemistry and Physics, 99th ed.; Rumble, J. (Ed.) CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

| Analysis | Subtype | Units | Brewery Wastes | |

|---|---|---|---|---|

| BW7 | BW5 | |||

| Total nitrogen | mg L−1 | 7454.5 | 975.8 | |

| Total polyphenols | 181.2 | 92.65 | ||

| Total sulfates | 193.03 | 119.65 | ||

| Total carbohydrates | 4500 | 156700 | ||

| Fermentable sugars | Total | 1600 | 115,800 | |

| Fructose | 700 | 2100 | ||

| Glucose | 300 | 12,500 | ||

| Maltose + sucrose | 500 | 76,500 | ||

| Maltotriose | 100 | 24,700 | ||

| Elemental content | K | mg L−1 | 2710 ± 460 | 657 ± 111 |

| P | 97 ± 3.9 | 525 ± 20 | ||

| Cl | <4 | 365 ± 1.0 | ||

| Mg | 228.3 ± 38.8 | 125.9 ± 21.4 | ||

| Ca | 55.0 ± 8.3 | 69.3 ± 10.4 | ||

| Na | 64.0 ± 6.4 | 58.0 ± 5.8 | ||

| Mn | 1.64 ± 0.13 | 0.73 ± 0.06 | ||

| Fe | 0.8 ± 0.11 | 0.3 ± 0.04 | ||

| Zn | 2.6 ± 0.36 | 0.43 ± 0.06 | ||

| Cu | 0.32 ± 0.03 | 0.08 ± 0.01 | ||

| Al | 0.01 ± 0.01 | 0.01 ± 0.01 | ||

| Ni | <0.05 | <0.05 | ||

| Total organic carbon | % | 7.24 | 7.78 | |

| Synthesis temp., °C | Synthesis Time, min. | PXRD Analysis | ||||||

|---|---|---|---|---|---|---|---|---|

| Ag Phase Content (wt.%) | Nanocrystallites Size (nm) | |||||||

| Ag3PO4 | AgCl | Agmet | Ag3PO4 | AgCl | Agmet | |||

| BW7Ag1 | 25 | 120 | 90.0 | 10.0 | - | 9.9 ± 2.3 | 5.5 ± 3.6 | - |

| BW7Ag2 | 50 | 88.7 | 11.3 | - | 15.5 ± 4.2 | 7.5 | - | |

| BW7Ag3 | 80 | 77.1 | 11.8 | 11.1 | 16.2 ± 3.3 | 16.5 ± 5.9 | 7.3 | |

| BW7Ag4 | 80 | 30 | 79.2 | 12.0 | 8.8 | 25.3 ± 4.0 | 26.2 ± 5.2 | 12.2 |

| BW7Ag5 | 80 | 10 | 86.6 | 10.8 | 2.6 | 22.7 ± 3.8 | 21.0 ± 8.3 | 15.1 |

| BW5Ag1 | 25 | 120 | 5.9 | 91.5 | 2.6 | 4.8 | 4.0 ± 0.5 | 18.1 |

| BW5Ag2 | 50 | 13.8 | 85.7 | 0.5 | 5.6 | 8.1 ± 0.8 | 14.0 | |

| BW5Ag3 | 80 | 30.0 | 41.5 | 28.5 | 12.1 ± 6.2 | 6.7 ± 0.4 | 3.2 | |

| BW5Ag4 | 80 | 30 | 28.5 | 46.0 | 25.6 | 15.9 ± 6.2 | 10.2 ± 1.7 | 1.4 |

| BW5Ag5 | 80 | 10 | 13.1 | 86.9 | - | 11.8 ± 0.7 | 11.9 ± 1.0 | - |

| Sample | Synthesis temp., °C | Synthesis Time, min. | XRF Analysis | |||

|---|---|---|---|---|---|---|

| Elemental Composition (wt.%) | ||||||

| Ag | P | Cl | S | |||

| BW7Ag1 | 25 | 120 | 93.5 | 4.8 | 1.0 | 0.8 |

| BW7Ag2 | 50 | 93.7 | 4.3 | 1.1 | 0.8 | |

| BW7Ag3 | 80 | 94.4 | 3.9 | 1.0 | 0.8 | |

| BW7Ag4 | 80 | 30 | 94.4 | 4.0 | 1.0 | 0.6 |

| BW7Ag5 | 80 | 10 | 93.8 | 4.2 | 1.2 | 0.8 |

| BW5Ag1 | 25 | 120 | 86.5 | 5.3 | 7.7 | 0.5 |

| BW5Ag2 | 50 | 88.4 | 2.9 | 8.1 | 0.6 | |

| BW5Ag3 | 80 | 92.2 | 3.0 | 4.4 | 0.5 | |

| BW5Ag4 | 80 | 30 | 91.6 | 2.9 | 5.0 | 0.6 |

| BW5Ag5 | 80 | 10 | 87.6 | 2.9 | 8.8 | 0.6 |

| Sample | Synthesis temp., °C | Synthesis Time, min. | XPS Analysis | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Surface Elemental Composition (wt.%) | |||||||||

| C | O | Ag | N | P | S | Cl | |||

| BW7Ag1 | 25 | 120 | 24.0 | 14.0 | 50.7 | 5.0 | 3.0 | 1.3 | 2.0 |

| BW7Ag2 | 50 | 24.6 | 14.7 | 50.5 | 4.4 | 2.5 | 1.4 | 1.9 | |

| BW7Ag3 | 80 | 19.5 | 12.5 | 59.3 | 3.3 | 3.4 | 1.4 | 0.6 | |

| BW7Ag4 | 80 | 30 | 19.6 | 11.6 | 61.5 | 3.3 | 2.5 | 1.1 | 0.4 |

| BW7Ag5 | 80 | 10 | 20.6 | 12.7 | 57.4 | 3.9 | 3.6 | 1.2 | 0.6 |

| BW5Ag1 | 25 | 120 | 25.7 | 15.6 | 46.8 | 2.6 | 4.1 | 1.3 | 3.9 |

| BW5Ag2 | 50 | 33.3 | 12.9 | 43.2 | 2.8 | 3.6 | 1.0 | 3.2 | |

| BW5Ag3 | 80 | 26.9 | 11.2 | 48.8 | 2.3 | 3.5 | 4.2 | 3.1 | |

| BW5Ag4 | 80 | 30 | 60.2 | 19.1 | 18.0 | 1.2 | 0.9 | - | 0.6 |

| BW5Ag5 | 80 | 10 | 41.2 | 14.2 | 36.2 | 2.6 | 2.3 | 0.7 | 2.8 |

| Sample | Synthesis temp., °C | Synthesis Time, min. | Ag Chemical State (wt.%)—Ag 3d5/2–3/2 | |||

|---|---|---|---|---|---|---|

| AgO-polymer | Ag2O, AgO, AgOH | Ag3PO4 | AgCl | |||

| BE (eV) 364.09 ± 0.11 (BW7) 363.8 ± 0.3 (BW5) | BE (eV) 367.30 | BE (eV) 367.8 | BE (eV) 368.1 | |||

| BW7Ag1 | 25 | 120 | 3.35 | 0.25 | 42.75 | 4.35 |

| BW7Ag2 | 50 | 4.21 | - | 40.72 | 5.57 | |

| BW7Ag3 | 80 | 5.81 | 0.49 | 45.52 | 7.48 | |

| BW7Ag4 | 80 | 30 | 5.98 | 0.7 | 49.35 | 5.47 |

| BW7Ag5 | 80 | 10 | 5.57 | - | 47.51 | 4.32 |

| BW5Ag1 | 25 | 120 | 3.82 | 2.32 | 2.74 | 37.92 |

| BW5Ag2 | 50 | 3.52 | 2.51 | 0.71 | 36.47 | |

| BW5Ag3 | 80 | 3.72 | 7.01 | 14.73 | 23.34 | |

| BW5Ag4 | 80 | 30 | 0.88 | 0.57 | 3.0 | 13.56 |

| BW5Ag5 | 80 | 10 | 3.09 | - | 4.36 | 28.76 |

| Sample | Synthesis temp., °C | Synthesis Time, min. | C Chemical State (wt.%)—C 1s | XPS QUASES-Tougaard BL Model Overlayer Thickness (Å) | |||

|---|---|---|---|---|---|---|---|

| C sp2 | C sp3 | C–OH | C=O | ||||

| BE (eV) 284.4 ± 0.1 | BE (eV) 285.3 ± 0.1 | BE (eV) 286.5 ± 0.1 | BE (eV) 287.5 ± 0.1 | ||||

| BW7Ag1 | 25 | 120 | 9.78 | 8.96 | 0.55 | 4.71 | 20.7 |

| BW7Ag2 | 50 | 14.2 | 3.92 | 3.76 | 2.72 | 24.2 | |

| BW7Ag3 | 80 | 11.37 | 4.64 | 3.49 | - | 18.0 | |

| BW7Ag4 | 80 | 30 | 12.46 | 4.11 | 3.03 | - | 17.5 |

| BW7Ag5 | 80 | 10 | 13.0 | 3.88 | 3.52 | - | 17.5 |

| BW5Ag1 | 25 | 120 | 10.36 | 9.57 | 2.03 | 3.74 | 23.0 |

| BW5Ag2 | 50 | 24.38 | 2.87 | 2.87 | 3.18 | 24.5 | |

| BW5Ag3 | 80 | 17.60 | 4.04 | 2.13 | 3.13 | 23.9 | |

| BW5Ag4 | 80 | 30 | 41.75 | 7.52 | 7.52 | 3.41 | 37.0 |

| BW5Ag5 | 80 | 10 | 31.12 | 3.93 | 2.86 | 3.29 | 32.5 |

| Sample | Synthesis temp., °C | Synthesis Time, min. | MIC (μg mL−1) |

|---|---|---|---|

| Escherichia coli | |||

| BW7Ag1 | 25 | 120 | 9.375 |

| BW7Ag3 | 80 | 9.375 | |

| BW5Ag1 | 25 | 12.5 | |

| BW5Ag3 | 80 | 15.625 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudagar, A.J.; Rangam, N.V.; Ruszczak, A.; Borowicz, P.; Tóth, J.; Kövér, L.; Michałowska, D.; Roszko, M.Ł.; Noworyta, K.R.; Lesiak, B. Valorization of Brewery Wastes for the Synthesis of Silver Nanocomposites Containing Orthophosphate. Nanomaterials 2021, 11, 2659. https://doi.org/10.3390/nano11102659

Sudagar AJ, Rangam NV, Ruszczak A, Borowicz P, Tóth J, Kövér L, Michałowska D, Roszko MŁ, Noworyta KR, Lesiak B. Valorization of Brewery Wastes for the Synthesis of Silver Nanocomposites Containing Orthophosphate. Nanomaterials. 2021; 11(10):2659. https://doi.org/10.3390/nano11102659

Chicago/Turabian StyleSudagar, Alcina Johnson, Neha Venkatesh Rangam, Artur Ruszczak, Paweł Borowicz, József Tóth, László Kövér, Dorota Michałowska, Marek Ł. Roszko, Krzysztof R. Noworyta, and Beata Lesiak. 2021. "Valorization of Brewery Wastes for the Synthesis of Silver Nanocomposites Containing Orthophosphate" Nanomaterials 11, no. 10: 2659. https://doi.org/10.3390/nano11102659

APA StyleSudagar, A. J., Rangam, N. V., Ruszczak, A., Borowicz, P., Tóth, J., Kövér, L., Michałowska, D., Roszko, M. Ł., Noworyta, K. R., & Lesiak, B. (2021). Valorization of Brewery Wastes for the Synthesis of Silver Nanocomposites Containing Orthophosphate. Nanomaterials, 11(10), 2659. https://doi.org/10.3390/nano11102659