Recent Progress on Vanadium Dioxide Nanostructures and Devices: Fabrication, Properties, Applications and Perspectives

Abstract

:1. Introduction

2. Overview of VO2 Polymorphs

3. Methods for the Growth of VO2 Nanostructures

3.1. Hydrothermal Method

3.1.1. The Growth of VO2 Nanoparticles (NPs)

3.1.2. The Growth of VO2 Nanowires/Nanorods (NWs/NRs)

3.1.3. The Growth of VO2 Nanosheets (NSs)

3.1.4. The Growth of VO2 Nanorings

3.1.5. The Growth of Other Structures

3.2. Chemical Vapor Deposition (CVD)

3.2.1. The Growth of VO2 Thin Films

3.2.2. The Growth of VO2 Nanowires (NWs)

3.3. PLD

3.3.1. The Growth of VO2 Thin Films

3.3.2. The Growth of VO2 Low-Dimensional Structures (LDSs)

3.4. Sol–Gel Method

3.5. Other Methods

3.5.1. Magnetron Sputtering

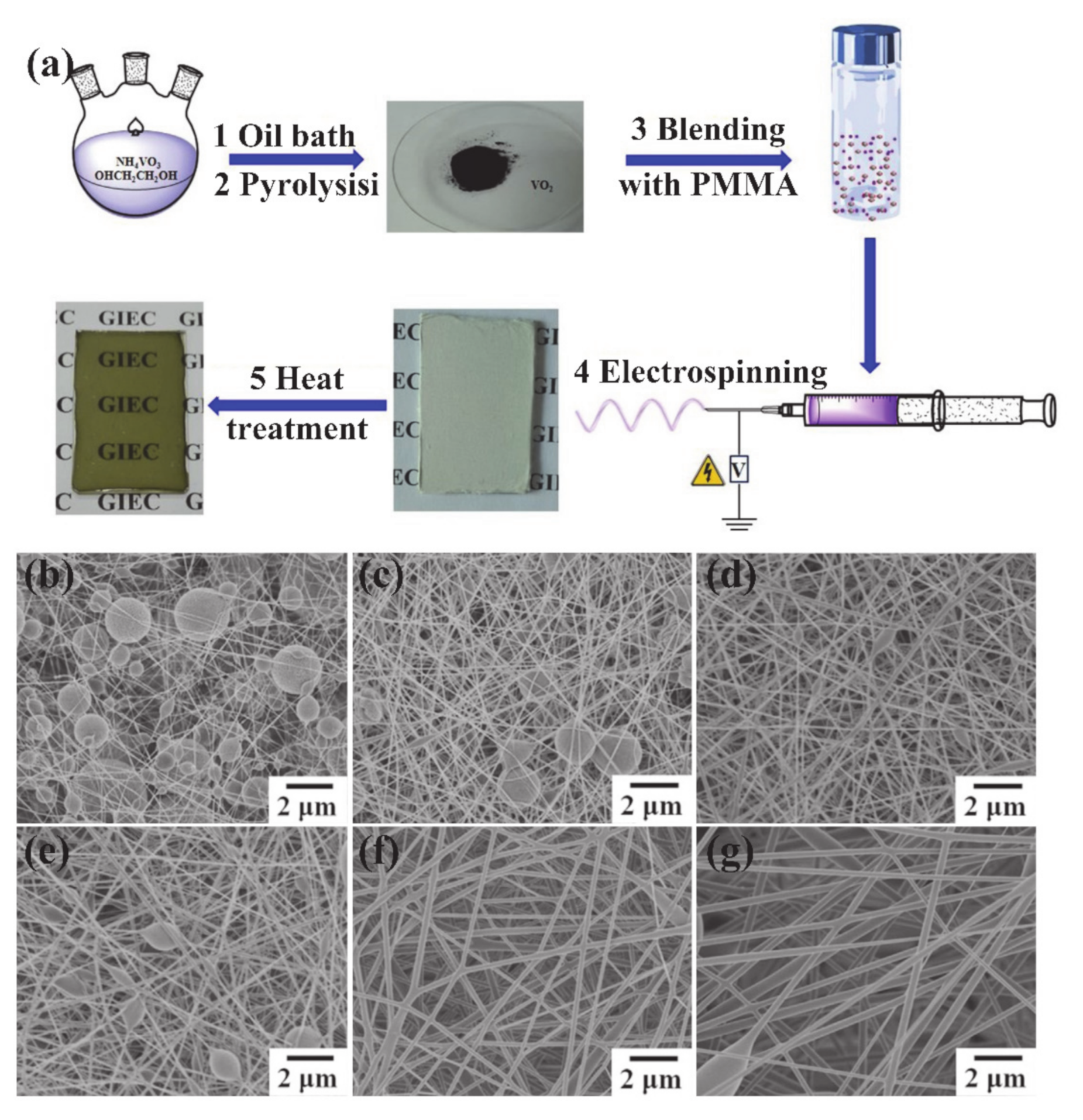

3.5.2. Electrospinning

3.5.3. Molecular Beam Epitaxy (MBE)

3.6. Summary

4. Properties and Related Applications of VO2

4.1. Electrical Devices

4.1.1. Electronic Switch

4.1.2. Field-Effect Transistor (FET)

4.1.3. Memory Device

4.2. Optical Devices

4.2.1. Smart Window

4.2.2. Photodetector

4.3. Multi-Responsive Devices

4.3.1. Strain Sensor

4.3.2. Gas Sensor

4.3.3. Thermal and Laser Sensors

4.4. Other Devices

4.5. Summary

5. Summary and Outlook

- (1)

- Regarding the fabrication aspect, it is still a challenge to precisely control the sizes and alignments of VO2 products. The size of NWs can directly affect the MIT behavior of VO2; thus, it is important to accurately control the size of NWs. For the hydrothermal method, it is also a tough task to fabricate ultra-small size (<20 nm) VO2 nanostructures. As we mentioned earlier, the decomposition rate of the precursor (rd) and the growth rate of the grain (rg) are two important factors determining the particle size of VO2. Therefore, in the hydrothermal method, VO2 nanostructures with ideal size can be synthesized by controlling rd and rg. Besides, due to the polymorphs of VO2 and the complicated growth process, it is still a challenge to synthesize the VO2 (M) in one step via hydrothermal method. Therefore, the one-step synthesis of VO2 (M) needs to be further explored, and the choice of surfactant or catalyst and the precise control of the synthesis process can be considered in the process of hydrothermal synthesis. For the CVD method, it is a challenge to control the orderly alignment of VO2 NWs. As we mentioned before, one of the strategies to control the growth orientation of VO2 NW is to form a template by modifying the surface structures of the substrate or depositing a patterned seed layer. Meanwhile, catalysts also may be necessary to promote the growth of aligned VO2 NWs. On the other hand, for the PLD, magnetron sputtering and MBE, proper substrate and deposition conditions are key factors for the fabrication of VO2 thin films of high-quality. Besides, surface pre-treatment always is needed to improve the surface status of the substrate and thereby decrease the defects in as-grown thin films.

- (2)

- For the application aspect, almost all the application prospects are based on the phase transition characteristic of VO2. Therefore, controlling the MIT temperature of VO2 is very important in the device applications. However, the phase transition temperature of VO2 is about 68 °C, which is still too high for applications in electronic devices. In particular, for the VO2-based switch devices, smart windows, laser power meters, thermally activated actuators, etc., the relatively high Tc results in high energy consumption and damage to the device. At present, the conventional approach to control the Tc is doping, and the Tc can be reduced to near room temperature. However, the corresponding slow transition rate and large hysteresis window during the MIT will limit the high-speed responses of VO2-based devices. Therefore, to find an efficient way to tune Tc without affecting the transition rate and hysteresis window of MIT is very necessary to improve the performances of VO2-based devices. On the other hand, due to the intrinsic properties of VO2, e.g., the low resistance of insulating phase in doped VO2, the low visible light transmittance of VO2 smart windows, etc., there is a big gap to realize the practical applications of VO2-based devices. Therefore, in order to improve the performance of VO2-based devices, a good strategy is to combine VO2 with other functional materials (ferroelectric multifunctional layer, etc.) to form composite structures.

- (3)

- In recent years, phase separation and coexistence (i.e., metal–insulator domain structures) of VO2 became a hot topic due to its importance in the deep understanding of the mechanism of phase transition and the controllability of phase transition behavior. More recently, we found that a macroscopic defect, i.e., a void, has significant influence over the metal–insulator domain structures and their evolutionary paths during the phase transition. By analyzing the distribution of stress field near the defect and the evolution paths of domain structures, we suppose that the defect-induced local stress should play an important role. Defect-induced local stress concentration leads to the pinning of the phases and high agreement in the evolutionary paths of domain structures during the phase transition. Moreover, the shape, position and number of macroscopic defects, which are determinants of the distribution of the stress fields in the VO2 nanostructures, could be precisely controlled by employing a focused ion beam (FIB) and nanoindentation. This results in the MIT temperature, hysteresis loop, conductivity and domain structure of VO2 nanostructures also being precisely controlled. This provides a novel strategy to precisely control the phase transition temperature and behaviors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morin, F.J. Oxides which show a metal-to-insulator transition at the neel temperature. Phys. Rev. Lett. 1959, 3, 1. [Google Scholar] [CrossRef]

- Gonçalves, A.R.J.; Marques, A.C.; Pinto, J.V.; Nunes, D.; Marie, A.; Goncalves, R.; Pereira, L.; Martins, R.; Fortunato, E. Smart optically active VO2 nanostructured layers applied in roof-type ceramic tiles for energy dfficiency. Sol. Energy Mater. Sol. C 2016, 150, 1–9. [Google Scholar] [CrossRef]

- Yang, Z.; Ko, C.; Ramanathan, S. Oxide electronics utilizing ultrafast metal-insulator transitions. Ann. Rev. Mater. Res. 2011, 41, 337–367. [Google Scholar] [CrossRef]

- Sasaki, T.; Ueda, H.; Kanki, T.; Tanaka, H. Electrochemical gating-induced reversible and drastic resistance switching in VO2 nanowires. Sci. Rep. 2015, 5, 17080. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abbas, K.; Hwang, J.; Bae, G.; Choi, H.; Kang, D.J. Control of multilevel resistance in vanadium dioxide by electric field using hybrid dielectrics. ACS Appl. Mater. Interfaces 2017, 9, 13571–13576. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.A.N.; Graf, T.; Schladt, T.D.; Samant, M.G.; Parkin, S.S.P. Suppression of metal-insulator transition in VO2 by electric field–induced oxygen vacancy formation. Science 2013, 339, 1402–1405. [Google Scholar] [CrossRef]

- Chae, B.-G.; Kim, H.-T.; Youn, D.-H.; Kang, K.-Y. Abrupt metal-insulator transition observed in VO2 thin films induced by a switchig voltage pulse. Physica B 2005, 369, 76–80. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Evans, P.G.; Haglund, R.F., Jr.; Valentine, J.G. Dynamically reconfigurable metadevice employing nanostructured phase-change materials. Nano Lett. 2017, 17, 4881–4885. [Google Scholar] [CrossRef]

- Kim, H.; Kim, Y.; Kim, K.S.; Jeong, H.Y.; Jang, A.-R.; Han, S.H.; Yoon, D.H.; Suh, K.S.; Shin, H.S.; Kim, T.Y.; et al. Flexible thermochromic window based on hybridized VO2/graphene. ACS Nano 2013, 7, 5769–5776. [Google Scholar] [CrossRef]

- Bae, S.H.; Lee, S.; Koo, H.; Lin, L.; Jo, B.H.; Park, C.; Wang, Z.L. The memristive properties of a single VO2 nanowire with switching controlled by self-heating. Adv. Mater. 2013, 25, 5098–5103. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Z.; Ren, H.; Chen, Y.; Yan, W.; Wang, C.; Li, B.; Jiang, J.; Zou, C. Gate-controlled VO2 phase transition for high-performance smart windows. Sci. Adv. 2019, 5, eaav6815. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, J.; Ertekin, E.; Srinivasan, V.; Fan, W.; Huang, S.; Zheng, H.; Yim, J.W.; Khanal, D.R.; Ogletree, D.F.; Grossman, J.C.; et al. Strain engineering and one-dimensional organization of metal-insulator domains in single-crystal vanadium dioxide beams. Nat. Nanotechnol. 2009, 4, 732–737. [Google Scholar] [CrossRef] [PubMed]

- Strelcov, E.; Lilach, Y.; Kolmakov, A. Gas sensor based on metal-insulator transition in VO2 nanowire thermistor. Nano Lett. 2009, 9, 2322–2326. [Google Scholar] [CrossRef]

- Strelcov, E.; Tselev, A.; Ivanov, I.; Budai, J.D.; Zhang, J.; Tischler, J.Z.; Kravchenko, I.; Kalinin, S.V.; Kolmakov, A. Doping-based stabilization of the M2 phase in free-standing VO2 nanostructures at room temperature. Nano Lett. 2012, 12, 6198–6205. [Google Scholar] [CrossRef] [PubMed]

- Ji, C.; Wu, Z.; Wu, X.; Wang, J.; Liu, X.; Gou, J.; Zhou, H.; Yao, W.; Jiang, Y. Terahertz transmittance and metal-insulator phase transition properties of M2 phase VO2 films induced by Cr doping. Appl. Surf. Sci. 2018, 455, 622–628. [Google Scholar] [CrossRef]

- Xiong, W.M.; Shao, J.; Zhang, Y.Q.; Chen, Y.; Zhang, X.Y.; Chen, W.J.; Zheng, Y. Morphology-controlled epitaxial vanadium dioxide low-dimensional structures: The delicate effects on the phase transition behaviors. Phys. Chem. Chem. Phys. 2018, 20, 14339–14347. [Google Scholar] [CrossRef]

- Sharma, Y.; Balachandran, J.; Sohn, C.; Krogel, J.T.; Ganesh, P.; Collins, L.; Ievlev, A.V.; Li, Q.; Gao, X.; Balke, N.; et al. Nanoscale control of oxygen defects and metal-insulator transition in epitaxial vanadium dioxides. ACS Nano 2018, 12, 7159–7166. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H. Distinguishing the photothermal and photoinjection effects in vanadium dioxide nanowires. Nano Lett. 2015, 15, 7037–7042. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, H.; Ding, W.; Zhang, B.; Lu, Y.; Ke, X.; Liu, W.; Chen, F.; Sui, M. Nanoscale engineering in VO2 nanowires via direct electron writing process. Nano Lett. 2017, 17, 851–855. [Google Scholar] [CrossRef]

- Wang, C.Q.; Shao, J.; Liu, X.L.; Chen, Y.; Xiong, W.M.; Zhang, X.Y.; Zheng, Y. Phase transition characteristics in the conductivity of VO2(A) nanowires: Size and surface effects. Phys. Chem. Chem. Phys. 2016, 18, 10262. [Google Scholar] [CrossRef]

- Li, W.; Ji, S.; Li, Y.; Huang, A.; Luo, H.; Jin, P. Synthesis of VO2 nanoparticles by a hydrothermal-assisted homogeneous precipitation approach for thermochromic applications. RSC Adv. 2014, 4, 13026–13033. [Google Scholar] [CrossRef]

- Cao, C.; Gao, Y.; Luo, H. Pure single-crystal rutile vanadium dioxide powders: Synthesis, mechanism and phase-transformation property. J. Phys. Chem. C 2008, 112, 18810–18814. [Google Scholar] [CrossRef]

- Yin, H.; Luo, M.; Yu, K.; Gao, Y.; Huang, R.; Zhang, Z.; Zeng, M.; Cao, C.; Zhu, Z. Fabrication and temperature-dependent field-emission properties of bundlelike VO2 nanostructures. ACS Appl. Mater. Interfaces 2011, 3, 2057–2062. [Google Scholar] [CrossRef] [PubMed]

- Popuri, S.R.; Miclau, M.; Artemenko, A.; Labrugere, C.; Villesuzanne, A.; Pollet, M. Rapid hydrothermal synthesis of VO2 (B) and its conversion to thermochromic VO2 (M1). Inorg. Chem. 2013, 52, 4780–4785. [Google Scholar] [CrossRef]

- Liu, L.; Cao, F.; Yao, T.; Xu, Y.; Zhou, M.; Qu, B.; Pan, B.; Wu, C.; Wei, S.; Xie, Y. New-phase VO2 micro/nanostructures: Investigation of phase transformation and magnetic property. New J. Chem. 2012, 36, 619–625. [Google Scholar] [CrossRef]

- Wu, C.; Hu, Z.; Wang, W.; Zhang, M.; Yang, J.; Xie, Y. Synthetic paramontroseite VO2 with good aqueous lithium-ion battery performance. Chem. Commun. 2008, 33, 3891–3893. [Google Scholar] [CrossRef]

- Oka, Y.; Sato, S.; Yao, T.; Yamamoto, N. Crystal structures and transition mechanism of VO2 (A). J. Solid State Chem. 1998, 141, 594–598. [Google Scholar] [CrossRef]

- Hagrman, D.; Zubieta, J.; Warren, C.J.; Meyer, L.M.; Treacy, M.M.J.; Haushalter, R.C. A new polymorph of VO2 prepared by soft chemical methods. J. Solid State Chem. 1998, 138, 178–182. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Shao, J.; Xiong, W.; Ma, W.; Zheng, Y. Structural transition and temperature-driven conductivity switching of single crystalline VO2 (A) nanowires. RSC Adv. 2014, 4, 64021–64026. [Google Scholar] [CrossRef]

- Park, J.-S.; Jo, J.H.; Aniskevich, Y.; Bakavets, A.; Ragoisha, G.; Streltsov, E.; Kim, J.; Myung, S.-T. Open-Structured Vanadium Dioxide as an Intercalation Host for Zn Ions: Investigation by first-principles calculation and experiments. Chem. Mater. 2018, 30, 6777–6787. [Google Scholar] [CrossRef]

- Pouget, J.P.; Launois, H.; D’Haenens, J.P.; Merenda, P.; Rice, T.M. Electron localization induced by uniaxial stress in pure VO2. Phys. Rev. Lett. 1975, 35, 873–875. [Google Scholar] [CrossRef]

- Oka, Y.; Yao, T.; Yamamoto, N. Structural phase transition of VO2 (B) to VO2 (A). J. Mater. Chem. 1991, 1, 815–818. [Google Scholar] [CrossRef]

- Horrocks, G.A.; Singh, S.; Likely, M.F.; Sambandamurthy, G.; Banerjee, S. Scalable hydrothermal synthesis of free-standing VO2 nanowires in the M1 phase. ACS Appl. Mater. Interfaces 2014, 6, 15726–15732. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.I.; Joo, H.J.; Ahn, D.; Lee, H.H.; Porter, A.E.; Kim, K.; Kang, D.J.; Welland, M.E. Surface-stress-induced mott transition and nature of associated spatial phase transition in single crystalline VO2 nanowires. Nano Lett. 2009, 9, 3392–3397. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Lai, J.; Dai, J.; Ma, K.; Wang, H.; Yi, X. Characterization of nanostructured VO2 thin films grown by magnetron controlled sputtering deposition and post annealing method. Opt. Express 2009, 17, 26. [Google Scholar] [CrossRef] [PubMed]

- Kosuge, K. The phase diagram and phase transition of the V2O3-V2O5 system. J. Phys. Chem. Solids 1967, 28, 1613–1621. [Google Scholar] [CrossRef]

- Cesca, T.; Scian, C.; Petronijevic, E.; Leahu, G.; Voti, R.L.; Cesario, G.; Macaluso, R.; Mosca, M.; Sibilia, C.; Mattei, G. Correlation between in situ structural and optical characterization of the semiconductor-to-metal phase transition of VO2 thin films on sapphire. Nanoscale 2020, 12, 851–863. [Google Scholar] [CrossRef] [Green Version]

- Clarke, H.; Caraway, B.D.; Sellers, D.G.; Braham, E.J.; Banerjee, S.; Arróyave, R.; Shamberger, P.J. Nucleation-controlled hysteresis in unstrained hydrothermal VO2 particles. Phys. Rev. Mater. 2018, 2, 103402. [Google Scholar] [CrossRef]

- Lin, T.; Wang, L.; Wang, X.; Zhang, Y.; Yu, Y. Influence of lattice distortion on phase transition properties of polycrystalline VO2 thin film. Appl. Surf. Sci. 2016, 379, 179–185. [Google Scholar] [CrossRef]

- Nakano, M.; Okuyama, D.; Shibuya, K.; Mizumaki, M.; Ohsumi, H.; Yoshida, M.; Takata, M.; Kawasaki, M.; Tokura, Y.; Arima, T.; et al. Distinct substrate effect on the reversibility of the metal-insulator transitions in electrolyte-gated VO2 thin films. Adv. Electron. Mater. 2015, 1, 1500093. [Google Scholar] [CrossRef]

- Dou, S.; Wang, Y.; Zhang, X.; Tian, Y.; Hou, X.; Wang, J.; Li, X.; Zhao, J.; Li, Y. Facile preparation of double-sided VO2 (M) films with micro-structure and enhanced thermochromic performances. Sol. Energy Mater. Sol. C 2017, 160, 164–173. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Cao, Z.; Zhan, Y.; Cheng, H.; Xu, G. Transparent optically vanadium dioxide thermochromic smart film fabricated via electrospinning technique. Appl. Surf. Sci. 2017, 425, 233–240. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, L.; Xia, F.; Webster, N.A.S.; Song, J.; Liu, B.; Luo, H.; Gao, Y. Controllable synthesis of VO2 (D) and their conversion to VO2 (M) nanostructures with thermochromic phase transition properties. Inorg. Chem. Front. 2016, 3, 1035–1042. [Google Scholar] [CrossRef]

- Petukhova, Y.V.; Mosiagin, I.P.; Mezenov, I.A.; Sarnovskiy-Gonzalez, A.D.; Ubyivovk, E.V.; Bobrysheva, N.P.; Levin, O.V.; Osmolowsky, M.G.; Osmolovskaya, O.M. Fabrication of composite nanoparticles based on VO2 with given structure and its optical and electrochemical performance. J. Phys. Chem. Solids 2018, 121, 128–138. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, R.; Li, Y.; Xu, Y.; Su, B. Self-assembled three-dimensional architectures of VO2:Yb3+, Er3+ controlled synthesis and dual-power dependent luminescence properties. New J. Chem. 2018, 42, 15436–15443. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, X.; Fang, C.; Chen, J.; Su, J.; Wang, Z.; Sun, G.; Liu, D. Synthesis, structure and properties of printable W-doped thermochromic VO2 with a low phase transition temperature. Ceram. Int. 2018, 44, 20084–20092. [Google Scholar] [CrossRef]

- Granqvist, C.G. Spectrally selective coatings for energy efficiency and solar applications. Phys. Scr. 1985, 32, 401–407. [Google Scholar] [CrossRef]

- Li, S.Y.; Niklasson, G.A.; Granqvist, C.G. Nanothermochromics: Calculations for VO2 nanoparticles in dielectric hosts show much improved luminous transmittance and solar energy transmittance modulation. J. Appl. Phys. 2010, 108, 063525. [Google Scholar] [CrossRef]

- Li, M.; Wu, X.; Li, L.; Wang, Y.; Li, D.; Pan, J.; Li, S.; Sun, L.; Li, G. Defect-mediated phase transition temperature of VO2 (M) nanoparticles with excellent thermochromic performance and low threshold voltage. J. Mater. Chem. A 2014, 2, 4520–4523. [Google Scholar] [CrossRef]

- Chen, Z.; Gao, Y.; Kang, L.; Cao, C.; Chen, S.; Luo, H. Fine crystalline VO2 nanoparticles: Synthesis, abnormal phase transition temperatures and excellent optical properties of a derived VO2 nanocomposite foil. J. Mater. Chem. A 2014, 2, 2718–2727. [Google Scholar] [CrossRef]

- Pavasupree, S.; Suzuki, Y.; Kitiyanan, A.; Pivsa-Art, S.; Yoshikawa, S. Synthesis and characterization of vanadium oxides nanorods. J. Solid State Chem. 2005, 178, 2152–2158. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, J.; Guo, Y.; Xia, F.; Cui, Y.; Liu, B.; Gao, Y. VO2 (A) nanorods: One-pot synthesis, formation mechanism and thermal transformation to VO2 (M). Ceram. Int. 2018, 44, 19301–19306. [Google Scholar] [CrossRef]

- Li, M.; Kong, F.; Li, L.; Zhang, Y.; Chen, L.; Yan, W.; Li, G. Synthesis, field-emission and electric properties of metastable phase VO2 (A) ultra-long nanobelts. Dalton Trans. 2011, 40, 10961–10965. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Zhang, X.; Dai, J.; Yang, J.; Wu, Z.; Wei, S.; Xie, Y. Direct hydrothermal synthesis of monoclinic VO2 (M) single-domain nanorods on large scale displaying magnetocaloric effect. J. Mater. Chem. 2011, 21, 4509–4517. [Google Scholar] [CrossRef]

- Simo, A.; Sibanyoni, J.; Fuku, X.; Numan, N.; Omorogbe, S.; Maaza, M. Shape control VO2 nanorods prepared by soft chemistry and electrochemical method. Appl. Surf. Sci. 2018, 446, 145–150. [Google Scholar] [CrossRef]

- Wang, H.; Li, W.; Fei, H.; Guo, L.; Feng, J.; Ci, L.; Xiong, S. Facile hydrothermal growth of VO2 nanowire, nanorod and nanosheet arrays as binder free cathode materials for sodium batteries. RSC Adv. 2016, 6, 14314–14320. [Google Scholar] [CrossRef]

- Wu, C.; Dai, J.; Zhang, X.; Yang, J.; Xie, Y. Synthetic haggite V4O6(OH)4 nanobelts: Oxyhydroxide as a new catalog of smart electrical switch materials. J. Am. Chem. Soc. 2009, 131, 7218–7219. [Google Scholar] [CrossRef]

- Li, R.; Ji, S.; Li, Y.; Gao, Y.; Luo, H.; Jin, P. Synthesis and characterization of plate-like VO2(M)@SiO2 nanoparticles and their application to smart window. Mater. Lett. 2013, 110, 241–244. [Google Scholar] [CrossRef]

- Uchaker, E.; Gu, M.; Zhou, N.; Li, Y.; Wang, C.; Cao, G. Enhanced intercalation dynamics and stability of engineered micro/nano-structured electrode materials: Vanadium oxide mesocrystals. Small 2013, 9, 3880–3886. [Google Scholar] [CrossRef]

- Li, G.C.K.; Zhang, C.; Zhang, Q.; Peng, H.; Chen, K. Synthesis of urchin-like VO2 nanostructures composed of radially aligned nanobelts and their disassembly. Inorg. Chem. 2009, 48, 1168–1172. [Google Scholar] [CrossRef]

- Zhang, S.L.Y.; Wu, C.; Zheng, F.; Xie, Y. Novel flowerlike metastable vanadium dioxide (B) micronanostructures: Facile synthesis and application in aqueous lithium Ion batteries. J. Phys. Chem. C 2009, 113, 15058–15067. [Google Scholar] [CrossRef]

- Shen, G.C.D. Self-coiling of Ag2V4O11 nanobelts into perfect nanorings and microloops. J. Am. Chem. Soc. 2006, 128, 11762–11763. [Google Scholar] [CrossRef]

- Wu, C.; Zhu, H.; Dai, J.; Yan, W.; Yang, J.; Tian, Y.; Wei, S.; Xie, Y. Room-temperature ferromagnetic silver vanadium oxide (Ag1.2V3O8): A magnetic semiconductor nanoring structure. Adv. Funct. Mater. 2010, 20, 3666–3672. [Google Scholar] [CrossRef]

- Li, M.; Kong, F.; Zhang, Y.; Li, G. Hydrothermal synthesis of VO2 (B) nanorings with inorganic V2O5 sol. CrystEngComm 2011, 13, 2204–2207. [Google Scholar] [CrossRef]

- Mai, L.; Wei, Q.; An, Q.; Tian, X.; Zhao, Y.; Xu, X.; Xu, L.; Chang, L.; Zhang, Q. Nanoscroll buffered hybrid nanostructural VO2 (B) cathodes for high-rate and long-life lithium storage. Adv. Mater. 2013, 25, 2969–2973. [Google Scholar] [CrossRef] [PubMed]

- Man, P.; Zhang, Q.; Sun, J.; Guo, J.; Wang, X.; Zhou, Z.; He, B.; Li, Q.; Xie, L.; Zhao, J.; et al. Hierarchically structured VO2@PPy core-shell nanowire arrays grown on carbon nanotube fibers as advanced cathodes for high-performance wearable asymmetric supercapacitors. Carbon 2018, 139, 21–28. [Google Scholar] [CrossRef]

- Pan, A.; Wu, H.B.; Yu, L.; Lou, X.W.D. Template-free synthesis of VO2 hollow microspheres with various interiors and their conversion into V2O5 for lithium-ion batteries. Angew. Chem. 2013, 125, 2282–2286. [Google Scholar] [CrossRef]

- Lou, X.W.; Archer, L.A.; Yang, Z. Hollow micro-/nanostructures: Synthesis and applications. Adv. Mater. 2008, 20, 3987–4019. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, S.Z.; Chen, J.S.; Lou, X.W.; Xing, X.; Lu, G.Q. Yolk/shell nanoparticles: New platforms for nanoreactors, drug delivery and lithium-ion batteries. Chem. Commun. 2011, 47, 12578–12591. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, L. Hollow micro/nanomaterials with multilevel interior structures. Adv. Mater. 2009, 21, 3621–3638. [Google Scholar] [CrossRef]

- Matsusaki, M.; Ajiro, H.; Kida, T.; Serizawa, T.; Akashi, M. Layer-by-layer assembly through weak interactions and their biomedical applications. Adv. Mater. 2012, 24, 454–474. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Wang, X.; Wang, H.; Dong, Y.; Ma, Y.; Yao, J. Multi-shelled titania hollow spheres fabricated by a hard template strategy: Enhanced photocatalytic activity. Chem. Commun. 2010, 46, 4312–4314. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Lu, G.Q.; Wang, L. Shell-in-shell TiO2 hollow spheres synthesized by one-pot hydrothermal method for dye-sensitized solar cell application. Energy Environ. Sci. 2011, 4, 3565–3572. [Google Scholar] [CrossRef]

- Lai, X.; Li, J.; Korgel, B.A.; Dong, Z.; Li, Z.; Su, F.; Du, J.; Wang, D. General synthesis and gas-sensing properties of multiple-shell metal oxide hollow microspheres. Angew. Chem. Int. Ed. Engl. 2011, 50, 2738–2741. [Google Scholar] [CrossRef]

- Yakovkina, L.V.; Mutilin, S.V.; Prinz, V.Y.; Smirnova, T.P.; Shayapov, V.R.; Korol’kov, I.V.; Maksimovsky, E.A.; Volchok, N.D. MOCVD growth and characterization of vanadium dioxide films. J. Mater. Sci. 2017, 52, 4061–4069. [Google Scholar] [CrossRef]

- Guo, B.; Wan, D.; Wang, J.; Zhu, S.; Luo, H.; Gao, Y. Mo-Al co-doped VO2 (B) thin films: CVD synthesis, thermal sensitive properties, synchrotron radiation photoelectron and absorption spectroscopy study. J. Alloys Compod. 2018, 745, 247–255. [Google Scholar] [CrossRef]

- Guition, B.S.; Gu, Q.; Prieto, A.L.; Gudiksen, M.S.; Park, H. Single-crystalline vanadium dioxide nanowires with rectangular cross sections. J. Am. Chem. Soc. 2005, 127, 498–499. [Google Scholar] [CrossRef]

- Strelcov, E.; Davydov, A.V.; Lanke, U.; Watts, C.; Kolmakov, A. In situ monitoring of the growth, intermediate phase transformations and templating of single crystal VO2 nanowires and nanoplatelets. ACS Nano 2011, 5, 3373–3384. [Google Scholar] [CrossRef]

- Wu, J.M.; Liou, L.B. Room temperature photo-induced phase transitions of VO2 nanodevices. J. Mater. Chem. 2011, 21, 5499–5504. [Google Scholar] [CrossRef]

- Lee, S.; Hippalgaonkar, K.; Yang, F.; Hong, J.; Ko, C.; Suh, J.; Liu, K.; Wang, K.; Urban, J.J.; Zhang, X.; et al. Anomalously low electronic thermal conductivity in metallic vanadium dioxide. Science 2017, 355, 371–374. [Google Scholar] [CrossRef] [Green Version]

- Maeng, J.; Kim, T.-W.; Jo, G.; Lee, T. Fabrication, structural and electrical characterization of VO2 nanowires. Mater. Res. Bull. 2008, 43, 1649–1656. [Google Scholar] [CrossRef]

- 8Cheng, C.; Guo, H.; Amini, A.; Liu, K.; Fu, D.; Zou, J.; Song, H. Self-assembly and horizontal orientation growth of VO2 nanowires. Sci. Rep. 2014, 4, 5456. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Liu, K.; Xiang, B.; Suh, J.; Wu, J. Ultra-long, free-standing, single-crystalline vanadium dioxide micro/nanowires grown by simple thermal evaporation. Appl. Phys. Lett. 2012, 100, 103111. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Li, W.; Liu, J.; Hu, M. Room temperature NO2 sensing performance of free-standing mesh-structure vanadium dioxide nanorods by a chemical vapour deposition method. J. Alloys Compd. 2016, 687, 845–854. [Google Scholar] [CrossRef]

- Mutilin, S.V.; Prinz, V.Y.; Seleznev, V.A.; Yakovkina, L.V. Growth of ordered arrays of vertical free-standing VO2 nanowires on nanoimprinted Si. Appl. Phys. Lett. 2018, 113, 043101. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X.; Chen, Z.; Cai, Z.; Zhou, H.; Lu, T.-M.; Shi, J. Defect-engineered epitaxial VO2±δ in strain engineering of heterogeneous soft crystals. Sci. Adv. 2018, 4, eaar3679. [Google Scholar] [CrossRef] [Green Version]

- Christen, H.M.; Eres, G. Recent advances in pulsed-laser deposition of complex-oxides. J. Phys. Condens. Mater. 2008, 20, 264005. [Google Scholar] [CrossRef] [Green Version]

- Martens, K.; Aetukuri, N.; Jeong, J.; Samant, M.G.; Parkin, S.S.P. Improved metal-insulator-transition characteristics of ultrathin VO2 epitaxial films by optimized surface preparation of rutile TiO2 substrates. Appl. Phys. Lett. 2014, 104, 081918. [Google Scholar] [CrossRef]

- Narayan, J.; Bhosle, V.M. Phase transition and critical issues in structure-property correlations of vanadium oxide. J. Appl. Phys. 2006, 100, 103524. [Google Scholar] [CrossRef]

- Nag, J.; Payzant, E.A.; More, K.L.; Haglund, R.F. Enhanced performance of room-temperature-grown epitaxial thin films of vanadium dioxide. Appl. Phys. Lett. 2011, 98, 251916. [Google Scholar] [CrossRef]

- Lin, T.; Zhang, Y.; Zheng, D. The ultrathin VO2 (M) film with ultrahigh visible transmittance synthesized on the quartz glass substrate by HiPIMS. Vacuum 2018, 156, 449–455. [Google Scholar] [CrossRef]

- 9Lafane, S.; Abdelli-Messaci, S.; Kechouane, M.; Malek, S.; Guedouar, B.; Lappalainen, J.; Nemraoui, O.; Kerdja, T. Direct growth of VO2 nanoplatelets on glass and silicon by pulsed laser deposition through substrate temperature control. Thin Solid Films 2017, 632, 119–127. [Google Scholar] [CrossRef]

- Bhardwaj, D.; Goswami, A.; Umarji, A.M. Synthesis of phase pure vanadium dioxide (VO2) thin film by reactive pulsed laser deposition. J. Appl. Phys 2018, 124, 135301. [Google Scholar] [CrossRef]

- Guo, Y.X.; Liu, Y.F.; Zou, C.W.; Qi, Z.M.; Wang, Y.Y.; Xu, Y.Q.; Wang, X.L.; Zhang, F.; Zhou, R. Oxygen pressure induced structure, morphology and phase-transition for VO2/c-sapphire films by PLD. Appl. Phys. A 2014, 115, 1245–1250. [Google Scholar] [CrossRef]

- Kim, D.H.; Kwok, H.S. Pulsed laser deposition of VO2 thin films. Appl. Phys. Lett. 1994, 65, 3188–3190. [Google Scholar] [CrossRef]

- Fan, L.L.; Wu, Y.F.; Si, C.; Zou, C.W.; Qi, Z.M.; Li, L.B.; Pan, G.Q.; Wu, Z.Y. Oxygen pressure dependent VO2 crystal film preparation and the interfacial epitaxial growth study. Thin Solid Films 2012, 520, 6124–6129. [Google Scholar] [CrossRef]

- Wu, Z.P.; Yamamoto, S.; Miyashita, A.; Zhang, Z.J.; Narumin, K.; Naramoto, H. Single-crystalline epitaxy and twinned structure of vanadium dioxide thin film on (0001) sapphire. J. Phys. Condens. Matter 1998, 10, 765–771. [Google Scholar] [CrossRef]

- Schwartz, R.W. Chemical solution deposition of perovskite thin films. Chem. Mater. 1997, 9, 2325–2340. [Google Scholar] [CrossRef]

- Yuan, N.; Li, J.; Lin, C. Valence reduction process from sol-gel V2O5 to VO2 thin films. Appl. Surf. Sci. 2002, 191, 176–180. [Google Scholar]

- Spck, K.R.; Hu, H.S.-W.; Sherwin, M.E.; Potember, R.S. Vanadium dioxide films grown from vanadium tetraisopropoxide by the sol-gel process. Thin Solid Films 1988, 165, 317–322. [Google Scholar] [CrossRef]

- Partlow, D.P.; Gurkovich, S.R.; Radford, K.C.; Denes, L.J. Switchable vanadium oxide films by a sol-gel process. J. Appl. Phys 1991, 70, 443–452. [Google Scholar] [CrossRef]

- Chae, B.-G.; Kim, H.-T.; Yun, S.-J.; Kim, B.-J.; Lee, Y.-W.; Youn, D.-H.; Kang, K.-Y. Highly oriented VO2 thin films prepared by sol-gel deposition. Electrochem. Solid State 2006, 9, C12. [Google Scholar] [CrossRef]

- Dou, S.; Zhang, W.; Wang, Y.; Wang, Y.; Zhang, X.; Zhang, L.; Wang, L.; Zhao, J.; Li, Y. The influence of temperature on preparing tungsten doped vanadium dioxide films by sol-gel method. Mater. Res. Express 2019, 6, 016408. [Google Scholar] [CrossRef]

- Wu, Y.F.; Fan, L.L.; Chen, S.M.; Chen, S.; Zou, C.W.; Wu, Z.Y. Spectroscopic analysis of phase constitution of high quality VO2 thin film prepared by facile sol-gel method. AIP Adv. 2013, 3, 042132. [Google Scholar] [CrossRef]

- Chae, B.-G.; Kim, H.-T.; Yun, S.-J.; Kim, B.-J.; Lee, Y.-W.; Kang, K.-Y. Comparative analysis of VO2 thin films prepared on sapphire and SiO2/Si substrates by the sol–gel process. Jpn. J. Appl. Phys. 2007, 46, 738–743. [Google Scholar] [CrossRef]

- Ji, S.; Zhang, F.; Jin, P. Preparation of high performance pure single phase VO2 nanopowder by hydrothermally reducing the V2O5 gel. Sol. Energy Mater. Sol. C 2011, 95, 3520–3526. [Google Scholar] [CrossRef]

- Paik, T.; Hong, S.-H.; Gaulding, E.A.; Caglayan, H.; Gordon, T.R.; Engheta, N.; Kagan, C.R.; Murray, C.B. Solution-processed phase-change VO2 metamaterials from colloidal vanadium oxide (VOx) nanocrystals. ACS Nano 2014, 8, 797–806. [Google Scholar] [CrossRef]

- Salamtati, M.; Kamyabjou, G.; Mohamadi, M.; Taghizade, K.; Kowsari, E. Preparation of TiO2@W-VO2 thermochromic thin film for the application of energy efficient smart windows and energy modeling studies of the produced glass. Const. Build. Mater. 2019, 218, 477–482. [Google Scholar] [CrossRef]

- Cavanna, E.; Segaud, J.P.; Livage, J. Optical switching of Au-doped VO2 sol-gel films. Mater. Res. Bull. 1999, 34, 167–177. [Google Scholar] [CrossRef]

- Dang, Y.; Wang, D.; Zhang, X.; Ren, L.; Li, B.; Liu, J. Structure and thermochromic properties of Mo-doped VO2 thin films deposited by sol–gel method. Inorg. Nano Met. Chem. 2019, 49, 120–125. [Google Scholar] [CrossRef]

- Ke, Y.; Wen, X.; Zhao, D.; Che, R.; Xiong, Q.; Long, Y. Controllable fabrication of two-dimensional patterned VO2 nanoparticle, nanodome, and nanonet arrays with tunable temperature-dependent localized surface plasmon resonance. ACS Nano 2017, 11, 7542–7551. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Gao, M.; Lu, C.; Zhang, Z.; Chan, C.H.; Zhuge, L.; Dai, J.; Yang, H.; Chen, C.; Park, B.H.; et al. Enhanced Metal−Insulator Transition Performance in Scalable Vanadium Dioxide Thin Films Prepared Using a Moisture-Assisted Chemical Solution Approach. ACS Appl. Mater. Interfaces 2018, 10, 8341–8348. [Google Scholar] [CrossRef] [PubMed]

- Son, J.-H.; Wei, J.; Cobden, D.; Cao, G.; Xia, Y. Hydrothermal Synthesis of Monoclinic VO2 Micro- and Nanocrystals in One Step and Their Use in Fabricating Inverse Opals. Chem. Mater. 2010, 22, 3043–3050. [Google Scholar] [CrossRef]

- Zhu, M.; Qi, H.; Li, C.; Wang, B.; Wang, H.; Guan, T.; Zhang, D. VO2 thin films with low phase transition temperature grown on ZnO/glass by applying substrate DC bias at low temperature of 250 °C. Appl. Surf. Sci. 2018, 453, 23–30. [Google Scholar] [CrossRef]

- Taha, M.; Walia, S.; Ahmed, T.; Headland, D.; Withayachumnankul, W.; Sriram, S.; Bhaskaran, M. Insulator-metal transition in substrate-independent VO2 thin film for phase-change devices. Sci. Rep. 2017, 7, 17899. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.L.; Chen, S.; Wu, Y.F.; Chen, F.H.; Chu, W.S.; Chen, X.; Zou, C.W.; Wu, Z.Y. Growth and phase transition characteristics of pure M-phase VO2 epitaxial film prepared by oxide molecular beam epitaxy. Appl. Phys. Lett. 2013, 103, 131914. [Google Scholar] [CrossRef]

- Paik, H.; Moyer, J.A.; Spila, T.; Tashman, J.W.; Mundy, J.A.; Freeman, E.; Shukal, N.; Lapano, J.M.; Engel-Herbert, R.; Zander, W.; et al. Transport properties of ultra-thin VO2 films on (001) TiO2 grown by reactive molecular-beam epitaxy. Appl. Phys. Lett. 2015, 107, 163101. [Google Scholar] [CrossRef] [Green Version]

- Kar, A.; Shukla, N.; Freeman, E.; Paik, H.; Liu, H.; Engel-Herbert, R.; Bhardwaja, S.S.N.; Schlom, D.G.; Datta, S. Intrinsic electronic switching time in ultrathin epitaxial vanadium dioxide thin film. Appl. Phys. Lett. 2013, 102, 072106. [Google Scholar] [CrossRef] [Green Version]

- McLeod, P.S.; Hartsough, L.D. High-rate sputtering of aluminum for metallization of integrated circuits. J. Vac. Sci. Technol. 1977, 14, 263–265. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Yu, S.; Wang, S.; Lu, M.; Zuo, L. A metal-insulator transition study of VO2 thin films grown on sapphire substrates. J. Appl. Phys. 2017, 122, 235102. [Google Scholar] [CrossRef]

- Jian, J.; Zhang, W.; Jacob, C.; Chen, A.; Wang, H.; Huang, J.; Wang, H. Roles of grain boundaries on the semiconductor to metal phase transition of VO2 thin films. Appl. Phys. Lett. 2015, 107, 102105. [Google Scholar] [CrossRef]

- Kim, H.Y.; Viswanathamurthi, P.; Bhattarai, N.; Lee, D.R. Vanadium oxide nanofibers by electrospinning. Rev. Adv. Mater. Sic. 2003, 5, 216–219. [Google Scholar]

- Deng, H.; Li, X.; Ding, B.; Du, Y.; Li, G.; Yang, J.; Hu, X. Fabrication of polymer/layered silicate intercalated nanofibrous mats and their bacterial inhibition activity. Carbohydr. Polym. 2011, 83, 973–978. [Google Scholar] [CrossRef]

- Crunteanu, A.; Givernaud, J.; Leroy, J.; Mardivirin, D.; Champeaux, C.; Orlianges, J.-C.; Catherinot, A.; Blondy, P. Voltage- and current-activated metal-insulator transition in VO2-based electrical switches: A lifetime operation analysis. Sci. Technol. Adv. Mater. 2010, 11, 065002. [Google Scholar] [CrossRef] [PubMed]

- Stefanovich, G.; Pergament, A.; Stefanovich, D. Electrical switching and Mott transition in VO2. J. Phys. Condens. Matter 2000, 12, 8837–8845. [Google Scholar] [CrossRef]

- Boriskov, P.P.; Velichko, A.A.; Pergament, A.L.; Stefanovich, G.B.; Stefanovich, D.G. The effect of electric field on metal-insulator phase transition in vanadium dioxide. Tech. Phys. Lett. 2002, 28, 406–408. [Google Scholar] [CrossRef]

- Ko, C.; Ramanathan, S. Observation of electric field-assisted phase transition in thin film vanadium oxide in a metal-oxide-semiconductor device geometry. Appl. Phys. Lett. 2008, 93, 252101. [Google Scholar] [CrossRef]

- Li, Y.-C.; Zhang, H.-M.; Zhang, Y.-M.; Hu, H.-Y.; Wang, B.; Lou, Y.-L.; Zhou, C.-Y. Two-dimensional threshold voltage model of a nanoscale silicon-on-insulator tunneling field-effect transistor. Chin. Phys. B 2013, 22, 038501. [Google Scholar] [CrossRef]

- Newns, D.M.; Misewich, J.A.; Tsuei, C.C.; Gupta, A.; Scott, B.A.; Schrott, A. Mott transition field effect transistor. Appl. Phys. Lett. 1998, 73, 780–782. [Google Scholar] [CrossRef]

- Zhou, C.; Newns, D.M.; Misewich, J.A.; Pattnaik, P.C. A field effect transistor based on the Mott transition in a molecular layer. Appl. Phys. Lett. 1997, 70, 598–600. [Google Scholar] [CrossRef] [Green Version]

- Hormoz, S.; Ramanathan, S. Limits on vanadium oxide Mott metal–insulator transition field-effect transistors. Solid-State Electron. 2010, 54, 654–659. [Google Scholar] [CrossRef]

- Wei, T.; Kanki, T.; Fujiwara, K.; Chikanari, M.; Tanaka, H. Electric field-induced transport modulation in VO2 FETs with high-k oxide-organic parylene-C hybrid gate dielectric. Appl. Phys. Lett. 2016, 108, 053503. [Google Scholar] [CrossRef]

- Belyaev, M.A.; Putrolaynen, V.V.; Velichko, A.A.; Stefanovich, G.B.; Pergament, A.L. Field-effect modulation of resistance in VO2 thin film at lower temperature. Jpn. J. Appl. Phys 2014, 53, 111102. [Google Scholar] [CrossRef]

- Yajima, T.; Nishimura, T.; Toriumi, A. Positive-bias gate-controlled metal–insulator transition in ultrathin VO2 channels with TiO2 gate dielectrics. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ruzmetov, D.; Gopalakrishnan, G.; Ko, C.; Narayanamurti, V.; Ramanathan, S. Three-terminal field effect devices utilizing thin film vanadium oxide as the channel layer. J. Appl. Phys. 2010, 107, 114516. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Fu, D.; Cao, J.; Suh, J.; Wang, K.X.; Cheng, C.; Ogletree, D.F.; Guo, H.; Sengupta, S.; Khan, A.; et al. Dense electron system from gate-controlled surface metal-insulator transition. Nano Lett. 2012, 12, 6272–6277. [Google Scholar] [CrossRef]

- Shibuya, K.; Sawa, A. Modulation of Metal-Insulator Transition in VO2 by Electrolyte Gating-Induced Protonation. Adv. Electron. Mater. 2016, 2, 1500131. [Google Scholar] [CrossRef]

- Kim, H.-T.; Chae, B.-G.; Youn, D.-H.; Maeng, S.-L.; Kim, G.; Kang, K.-Y.; Lim, Y.-S. Mechanism and observation of Mott transition in VO2-based two- and three-terminal devices. New J. Phys. 2004, 6, 52. [Google Scholar] [CrossRef] [Green Version]

- Sengupta, S.; Wang, K.; Liu, K.; Bhat, A.K.; Dhara, S.; Wu, J.; Deshmukh, M.M. Field-effect modulation of conductance in VO2 nanobeam transistors with HfO2 as the gate dielectric. Appl. Phys. Lett. 2011, 99, 062114. [Google Scholar] [CrossRef] [Green Version]

- Nakano, M.; Shibuya, K.; Okuyama, D.; Hatano, T.; Ono, S.; Kawasaki, M.; Iwasa, Y.; Tokura, Y. Collective bulk carrier delocalization driven by electrostatic surface charge accumulation. Nature 2012, 487, 459–462. [Google Scholar] [CrossRef]

- Zhou, Y.; Park, J.; Shi, J.; Chhowalla, M.; Park, H.; Weitz, D.A.; Ramanathan, S. Control of emergent properties at a correlated oxide interface with graphene. Nano Lett. 2015, 15, 1627–1634. [Google Scholar] [CrossRef] [PubMed]

- Jo, M.L.H.J.; Oh, C.; Yoon, H.; Jo, J.Y.; Son, J. Gate-induced massive and reversible phase transition of VO2 channels using solid-state proton electrolytes. Adv. Funct. Mater. 2018, 28, 1802003. [Google Scholar] [CrossRef]

- Zhi, B.; Gao, G.; Xu, H.; Chen, F.; Tan, X.; Chen, P.; Wang, L.; Wu, W. Electric-field-modulated nonvolatile resistance switching in VO2/PMN-PT(111) heterostructures. ACS Appl. Mater. Interfaces 2014, 6, 4603–4608. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Kong, W.; Liu, L.; Li, C.; Fang, L.; Feng, Y.P.; Tang, R.; Su, X.; Chen, J. Piezoelectric control of resistance switching in VO2/Pb(Zr0.52Ti0.48)O3 heterostructure. Appl. Phys. Lett. 2019, 114, 061603. [Google Scholar] [CrossRef]

- Hong, B.; Yang, Y.; Hu, K.; Yang, M.; Luo, Z.; Li, X.; Cao, C. Dynamic strain control of the metal–insulator transition and non-volatile resistance switching in (010) VO2/(111)Pb(Mg1/3Nb2/3)0.7Ti0.3O3 epitaxial heterostructures. Mater. Lett. 2017, 196, 108–111. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, W.; Chen, W.; Luo, X.; Zhang, X.; Zheng, Y. Nonvolatile ferroelectric field effect transistor based on vanadium dioxide nanowire with large on- and off- field resistance switching. Phys. Chem. Chem. Phys. 2020, 22, 4685–4691. [Google Scholar] [CrossRef] [PubMed]

- Driscoll, T.; Kim, H.-T.; Chae, B.-G.; Ventra, M.D.; Basov, D.N. Phase-transition driven memristive system. Appl. Phys. Lett. 2009, 95, 043503. [Google Scholar] [CrossRef] [Green Version]

- Coy, H.; Cabrera, R.; Sepúlveda, N.; Fernández, F.E. Optoelectronic and all-optical multiple memory states in vanadium dioxide. J. Appl. Phys. 2010, 108, 113115. [Google Scholar] [CrossRef] [Green Version]

- Driscoll, T.; Kim, H.-T.; Chae, B.-G.; Kim, B.-J.; Lee, Y.-W.; Jokerst, N.M.; Palit, S.; Smith, D.R.; Ventra, M.D.; Basov, D.N. Memory metamaterials. Science 2009, 325, 1518–1521. [Google Scholar] [CrossRef] [Green Version]

- Pellegrino, L.; Manca, N.; Kanki, T.; Tanaka, H.; Biasotti, M.; Bellingeri, E.; Siri, A.S.; Marre, D. Multistate memory devices based on free-standing VO2/TiO2 microstructures driven by Joule self-heating. Adv. Mater. 2012, 24, 2929–2934. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.; Zhang, X.; Gupta, A.; LeClair, P. Avalanche breakdown in microscale VO2 structures. J. Appl. Phys. 2011, 110, 084516. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Tao, H.; Chen, G.; Pan, R.; Wan, M.; Xiong, D.; Zhao, X. Porous W-doped VO2 films with simultaneously enhanced visible transparency and thermochromic properties. J. Sol-Gel Sci. Technol. 2016, 77, 85–93. [Google Scholar] [CrossRef]

- Zhang, J.; He, H.; Xie, Y.; Pan, B. Theoretical study on the tungsten-induced reduction of transition temperature and the degradation of optical properties for VO2. J. Chem. Phys. 2013, 138, 114705. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Xiao, X.; Lu, Y.; Cao, Z.; Qi, S.; Huan, C.; Ye, C.; Cheng, H.; Shi, J.; Xu, X.; et al. The growth mechanism of VO2 multilayer thin films with high thermochromic performance prepared by RTA in air. Surf. Interfaces 2017, 9, 173–181. [Google Scholar] [CrossRef]

- Liu, M.; Su, B.; Kaneti, Y.V.; Chen, Z.; Tang, Y.; Yuan, Y.; Gao, Y.; Jiang, L.; Jiang, X.; Yu, A. Dual-phase transformation: Spontaneous self-template surface-patterning strategy for ultra-transparent VO2 solar modulating coatings. ACS Nano 2017, 11, 407–415. [Google Scholar] [CrossRef]

- Liu, M.; Su, B.; Tang, Y.; Jiang, X.; Yu, A. Recent advances in nanostructured vanadium oxides and composites for energy conversion. Adv. Energy Mater. 2017, 7, 1700885. [Google Scholar] [CrossRef] [Green Version]

- Zhu, B.; Tao, H.; Zhao, X. Effect of buffer layer on thermochromic performances of VO2 films fabricated by magnetron sputtering. Infrared Phys. Techn. 2016, 75, 22–25. [Google Scholar] [CrossRef] [Green Version]

- Chu, X.; Tao, H.; Liu, Y.; Ni, J.; Bao, J.; Zhao, X. VO2/AZO double-layer films with thermochromism and low-emissivity for smart window applications. J. Non Cryst. Solids 2014, 383, 121–125. [Google Scholar] [CrossRef]

- Yoon, H.; Choi, M.; Lim, T.W.; Kwon, H.; Ihm, K.; Kim, J.K.; Choi, S.Y.; Son, J. Reversible phase modulation and hydrogen storage in multivalent VO2 epitaxial thin films. Nat. Mater. 2016, 15, 1113–1119. [Google Scholar] [CrossRef]

- Mazurenko, D.A.; Kerst, R.; Dijkhuis, J.I.; Akimov, A.V.; Golubev, V.G.; Kaplyanskii, A.A.; Kurdyukov, D.A.; Pevtsov, A.B. Subpicosecond shifting of the photonic band gap in a three-dimensional photonic crystal. Appl. Phys. Lett. 2005, 86, 041114. [Google Scholar] [CrossRef] [Green Version]

- Markov, P.; Marvel, R.E.; Conley, H.J.; Miller, K.J.; Haglund, R.F., Jr.; Weiss, S.M. Optically monitored electrical switching in VO2. ACS Photonics 2015, 2, 1175–1182. [Google Scholar] [CrossRef]

- Wu, J.M.; Chang, W.E. Ultrahigh responsivity and external quantum efficiency of an ultraviolet-light photodetector based on a single VO2 microwire. ACS Appl. Mater. Interfaces 2014, 6, 14286–14292. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Wang, Z.; Ding, Z.; Zhang, Z.; Zhang, J. Facile synthesize VO2 (M1) nanorods for a low-cost infrared photodetector application. Sol. Energy Mater. Sol. C 2018, 176, 142–149. [Google Scholar] [CrossRef]

- Joushaghani, A.; Jeong, J.; Paradis, S.; Alain, D.; Stewart Aitchison, J.; Poon, J.K. Wavelength-size hybrid Si-VO2 waveguide electroabsorption optical switches and photodetectors. Opt. Express 2015, 23, 3657–3668. [Google Scholar] [CrossRef]

- Nakano, M.; Shibuya, K.; Ogawa, N.; Hatano, T.; Kawasaki, M.; Iwasa, Y.; Tokura, Y. Infrared-sensitive electrochromic device based on VO2. Appl. Phys. Lett. 2013, 103, 153503. [Google Scholar] [CrossRef]

- Lysenko, S.; Rua, A.J.; Vikhnin, V.; Jimenez, J.; Fernandez, F.; Liu, H. Light-induced ultrafast phase transitions in VO2 thin film. Appl. Surf. Sci. 2006, 252, 5512–5515. [Google Scholar] [CrossRef]

- Xia, F.; Mueller, T.; Lin, Y.M.; Valdes-Garcia, A.; Avouris, P. Ultrafast graphene photodetector. Nat. Nanotechnol. 2009, 4, 839–843. [Google Scholar] [CrossRef] [Green Version]

- Yin, Z.; Li, H.; Li, H.; Jiang, L.; Shi, Y.; Sun, Y.; Lu, G.; Zhang, Q.; Chen, X.; Zhang, H. Single-layer MoS2 phototransistors. ACS Nano 2012, 6, 74–80. [Google Scholar] [CrossRef] [Green Version]

- Hu, P.; Wang, L.; Yoon, M.; Zhang, J.; Feng, W.; Wang, X.; Wen, Z.; Idrobo, J.C.; Miyamoto, Y.; Geohegan, D.B.; et al. Highly responsive ultrathin GaS nanosheet photodetectors on rigid and flexible substrates. Nano Lett. 2013, 13, 1649–1654. [Google Scholar] [CrossRef]

- Li, M.; Ji, S.; Pan, J.; Wu, H.; Zhong, L.; Wang, Q.; Li, F.; Li, G. Infrared response of self-heating VO2 nanoparticles film based on Ag nanowires heater. J. Mater. Chem. A 2014, 2, 20470–20473. [Google Scholar] [CrossRef]

- Ladd, L.A.; Paul, W. Optical and transoprt properties of high quality crystals of V2O4 near the metallic transition temperature. Solid State Commun. 1968, 7, 425–428. [Google Scholar] [CrossRef]

- Muraoka, Y.; Hiroi, Z. Metal-insulator transition of VO2 thin films grown on TiO2 (001) and (110) substrates. Appl. Phys. Lett. 2002, 80, 583–585. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Chen, K.; Oh, Y.; Wang, K.; Dejoie, C.; Syed Asif, S.A.; Warren, O.L.; Shan, Z.W.; Wu, J.; Minor, A.M. Mechanics and dynamics of the strain-induced M1-M2 structural phase transition in individual VO2 nanowires. Nano Lett. 2011, 11, 3207–3213. [Google Scholar] [CrossRef]

- Hu, B.; Ding, Y.; Chen, W.; Kulkarni, D.; Shen, Y.; Tsukruk, V.V.; Wang, Z.L. External-strain induced insulating phase transition in VO2 nanobeam and its application as flexible strain sensor. Adv. Mater. 2010, 22, 5134–5139. [Google Scholar] [CrossRef]

- Lee, S.; Cheng, C.; Guo, H.; Hippalgaonkar, K.; Wang, K.; Suh, J.; Liu, K.; Wu, J. Axially Engineered metal-insulator phase transition by graded doping VO2 nanowires. J Am. Chem. Soc. 2013, 135, 4850–4855. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, S.; Ke, F.; Ko, C.; Lee, S.; Liu, K.; Chen, B.; Ager, J.W.; Jeanloz, R.; Eyert, V.; et al. Pressure-temperature phase diagram of vanadium dioxide. Nano Lett. 2017, 17, 2512–2516. [Google Scholar] [CrossRef] [Green Version]

- Yin, H.; Yu, K.; Zhang, Z.; Zeng, M.; Lou, L.; Zhu, Z. Humidity sensing properties of flower-like VO2 (B) and VO2 (M) nanostructures. Electroanalysis 2011, 23, 1752–1758. [Google Scholar] [CrossRef]

- Byon, J.W.; Kim, M.-B.; Kim, M.H.; Kim, S.Y.; Lee, S.H.; Lee, B.C.; Baik, J.M. Electrothermally induced highly responsive and highly selective vanadium oxide hydrogen sensor based on metal–insulator transition. J. Phys. Chem. C 2011, 116, 226–230. [Google Scholar] [CrossRef]

- Simo, A.; Mwakikunga, B.; Sone, B.T.; Julies, B.; Madjoe, R.; Maaza, M. VO2 nanostructures based chemiresistors for low power energy consumption hydrogen sensing. Int. J. Hydrogen Energy 2014, 39, 8147–8157. [Google Scholar] [CrossRef]

- Shi, R.; Wang, J.; Cai, X.; Zhang, L.; Chen, P.; Liu, S.; Zhang, L.; Ouyang, W.; Wang, N.; Cheng, C. Axial modulation of metal-insulator phase transition of VO2 nanowires by graded doping engineering for optically readable thermometers. J. Phys. Chem. C 2017, 121, 24877–24885. [Google Scholar] [CrossRef]

- Cheng, C.; Fu, D.; Liu, K.; Guo, H.; Xu, S.; Ryu, S.-G.; Ho, O.; Zhou, J.; Fan, W.; Bao, W.; et al. Directly metering light absorption and heat transfer in single nanowires using metal-insulator transition in VO2. Adv. Opt. Mater. 2015, 3, 336–341. [Google Scholar] [CrossRef]

- Cheng, C.; Fan, W.; Cao, J.; Ryu, S.G.; Ji, J.; Grigoropoulos, C.P.; Wu, J. Heat transfer across the interface between nanoscale solids and gas. ACS Nano 2011, 5, 10102–10107. [Google Scholar] [CrossRef] [PubMed]

- Xie, R.; Bui, C.T.; Varghese, B.; Zhang, Q.; Sow, C.H.; Li, B.; Thong, T.L. An electrically tuned solid-state thermal memory based on metal insulator transition of single-crystalline VO2 nanbeams. Adv. Funct. Mater. 2011, 21, 1602–1607. [Google Scholar] [CrossRef]

- Kats, M.A.; Blanchard, R.; Zhang, S.; Genevet, P.; Ko, C.; Ramanathan, S.; Capasso, F. Vanadium dioxide as a natural disordered metamaterial: Perfect thermal emission and large broadband negative differential thermal emittance. Phys. Rev. X 2013, 3, 041004. [Google Scholar] [CrossRef] [Green Version]

- Xiao, L.; Ma, H.; Liu, J.; Zhao, W.; Jia, Y.; Zhao, Q.; Liu, K.; Wu, Y.; Wei, Y.; Fan, S.; et al. Fast adaptive thermal camouflage based on flexible VO2/graphene/CNT thin films. Nano Lett. 2015, 15, 8365–8370. [Google Scholar] [CrossRef]

- Rúa, A.; Fernández, F.E.; Sepúlveda, N. Bending inVO2-coated microcantilevers suitable for thermally activated actuators. J. Appl. Phys 2010, 107, 074506. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Cheng, C.; Cheng, Z.; Wang, K.; Ramesh, R.; Wu, J. Giant-amplitude, high-work density microactuators with phase transition activated nanolayer bimorphs. Nano Lett. 2012, 12, 6302–6308. [Google Scholar] [CrossRef]

- Liu, K.; Cheng, C.; Suh, J.; Tang-Kong, R.; Fu, D.; Lee, S.; Zhou, J.; Chua, L.O.; Wu, J. Powerful, multifunctional torsional micromuscles activated by phase transition. Adv. Mater. 2014, 26, 1746–1750. [Google Scholar] [CrossRef]

- Ma, H.; Hou, J.; Wang, X.; Zhang, J.; Yuan, Z.; Xiao, L.; Wei, Y.; Fan, S.; Jiang, K.; Liu, K. Flexible, all-inorganic actuators based on vanadium dioxide and carbon nanotube bimorphs. Nano Lett. 2017, 17, 421–428. [Google Scholar] [CrossRef]

- Tian, Z.; Xu, B.; Hsu, B.; Stan, L.; Yang, Z.; Mei, Y. Reconfigurable vanadium dioxide nanomembranes and microtubes with controllable phase transition temperatures. Nano Lett. 2018, 18, 3017–3023. [Google Scholar] [CrossRef] [PubMed]

- Liao, F.; Zhu, Z.; Yan, Z.; Yao, G.; Huang, Z.; Gao, M.; Pan, T.; Zhang, Y.; Li, Q.; Feng, X. Ultrafast response flexible breath sensor based on vanadium dioxide. J. Breath Res. 2017, 11, 036002. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Hua, Q.; Yu, R.; Zhang, Y.; Pan, C. Flexible, stretchable and wearable multifunctional sensor array as artificial electronic skin for static and dynamic strain mapping. Adv. Electron. Mater. 2015, 1, 1500142. [Google Scholar] [CrossRef]

- Li, G.; Zhou, Q.; Du, J.; Guo, E.; He, M.; Wang, C.; Yang, G.; Jin, K. Gating-induced reversible HxVO2 phase transformations for neuromorphic computing. Nano Energy 2020, 67, 104268. [Google Scholar]

| Polymorphs | Space Group | Unit Cell Parameters | Common Reaction Conditions | Comment | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| a | b | c | αβγ | ||||||

| VO2 (M) | VO2 (M1) | P 21/c | 5.715 | 4.554 | 5.385 | β = 122.6° | V source: V2O5, VH4VO3 Reductant: H2C2O4, N2H4 Surfacant: polyvinylpyrrolidone (PVP), polyethylene glycol (PEG) Temperature: ~150–260 °C Time: a few hours to a few days | Most of the research and applications are based on the MIT of VO2 (M). | [21] |

| VO2 (M2) | C 2/m | 9.067 | 5.797 | 4.526 | β = 91.88° | ||||

| VO2 (R) | P 42/mnm | 4.554 | 4.554 | 2.85 | α = β = γ = 90° | The high-temperature rutile phase of VO2. | [22] | ||

| VO2 (A) | P 42/nmc | 8.434 | 8.434 | 7.678 | α = β = γ = 90° | Another phase with MIT Behaviour with Tc = 435 K | [27,29] | ||

| VO2 (B) | C 2/m | 12.03 | 3.693 | 6.42 | β = 106.6° | It has layer structure, which suitable for electrode materials and thermal sensitive materials of batteries. | [24,30] | ||

| VO2 (C) | I 4/mmm | 3.7211 | 15.421 | N/A | N/A | The structure of VO2 (C) consists of VO5 square pyramids, each of which shares its four base edges with four adjacent VO5 square pyramids. | [28] | ||

| VO2 (D) | P 2/c | 4.597 | 5.684 | 4.913 | β = 89.39° | VO2 (D) exhibits magnetic properties, and it can be transformed to VO2 (M) at 300 °C. | [25] | ||

| VO2 (P) | Pbnm | 4.890 | 9.390 | 2.930 | β = 90° | VO2 (P) was synthesized by simple chemical reaction by Wu et al. and it can be transformed to VO2 (M) by rapid annealing. | [26] | ||

| Method | Structure | Phase | Advantages | Disadvantages | References |

|---|---|---|---|---|---|

| Hydrothermal method | NPs, NWs, NRs, NSs, nanorings, microsheres | VO2 (A), VO2 (B), VO2 (C), VO2 (D), VO2 (P), VO2 (M) | 1. High crystallinity of products 2. Simple process 3. High yield 4. Various structures can be prepared. | 1. Narrow reaction temperature 2. High pressure | [33,49,50,54,58,64,67] |

| CVD | Thin film, NWs, microplates | VO2 (M), VO2 (B) | 1. Simple equipment 2. High flexibility | 1. Low deposition rate 2. Difficult to control the size of NWs | [75,76,81,82] |

| PLD | Thin film, NDs, NWs, NBs, NRs, nanoplatelets | VO2 (M) | 1. Simple process 2. Low temperature 3. High deposition rate 4. In situ growth | 1. Low yield 2. Small film area 3. Easy to from particle | [16,88] |

| Sol–gel method | Thin film, nanopowders, ND array | VO2 (M) | 1. Material composition can be strictly controlled 2. Easy to dope 3. Simple equipment | 1. Low film-forming quality 2. Long reaction time | [104,106,107] |

| Magnetron sputtering | Thin film | VO2 (M) | 1. High film formation rate 2. Good crystallinity 3. Low substrate temperature | 1. Poor consistency between film composition and target material 2. Poor process stability | [114,115] |

| Electrospinning | Nanofibers | VO2 (M) | 1. Controllable diameter of nanowires 2. Simple equipment and low cost | 1. Low fiber strength 2. Low yield 3. The products are greatly affected by ambient temperature and humidity. 4. Difficulty in separating fibers | [42] |

| MBE | Thin film | VO2 (M) | 1. Clean growth environment 2. Low growth temperature 3. Good crystal integrity 4. Easy to dope | 1. Expensive equipment and high maintenance costs 2. High vacuum requirements | [116,117,118] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Xiong, W.; Chen, W.; Zheng, Y. Recent Progress on Vanadium Dioxide Nanostructures and Devices: Fabrication, Properties, Applications and Perspectives. Nanomaterials 2021, 11, 338. https://doi.org/10.3390/nano11020338

Zhang Y, Xiong W, Chen W, Zheng Y. Recent Progress on Vanadium Dioxide Nanostructures and Devices: Fabrication, Properties, Applications and Perspectives. Nanomaterials. 2021; 11(2):338. https://doi.org/10.3390/nano11020338

Chicago/Turabian StyleZhang, Yanqing, Weiming Xiong, Weijin Chen, and Yue Zheng. 2021. "Recent Progress on Vanadium Dioxide Nanostructures and Devices: Fabrication, Properties, Applications and Perspectives" Nanomaterials 11, no. 2: 338. https://doi.org/10.3390/nano11020338

APA StyleZhang, Y., Xiong, W., Chen, W., & Zheng, Y. (2021). Recent Progress on Vanadium Dioxide Nanostructures and Devices: Fabrication, Properties, Applications and Perspectives. Nanomaterials, 11(2), 338. https://doi.org/10.3390/nano11020338